Residual Stress Engineering for Wire Drawing of Austenitic Stainless Steel X5CrNi18-10 by Variation in Die Geometries—Effect of Drawing Speed and Process Temperature

Abstract

:1. Introduction

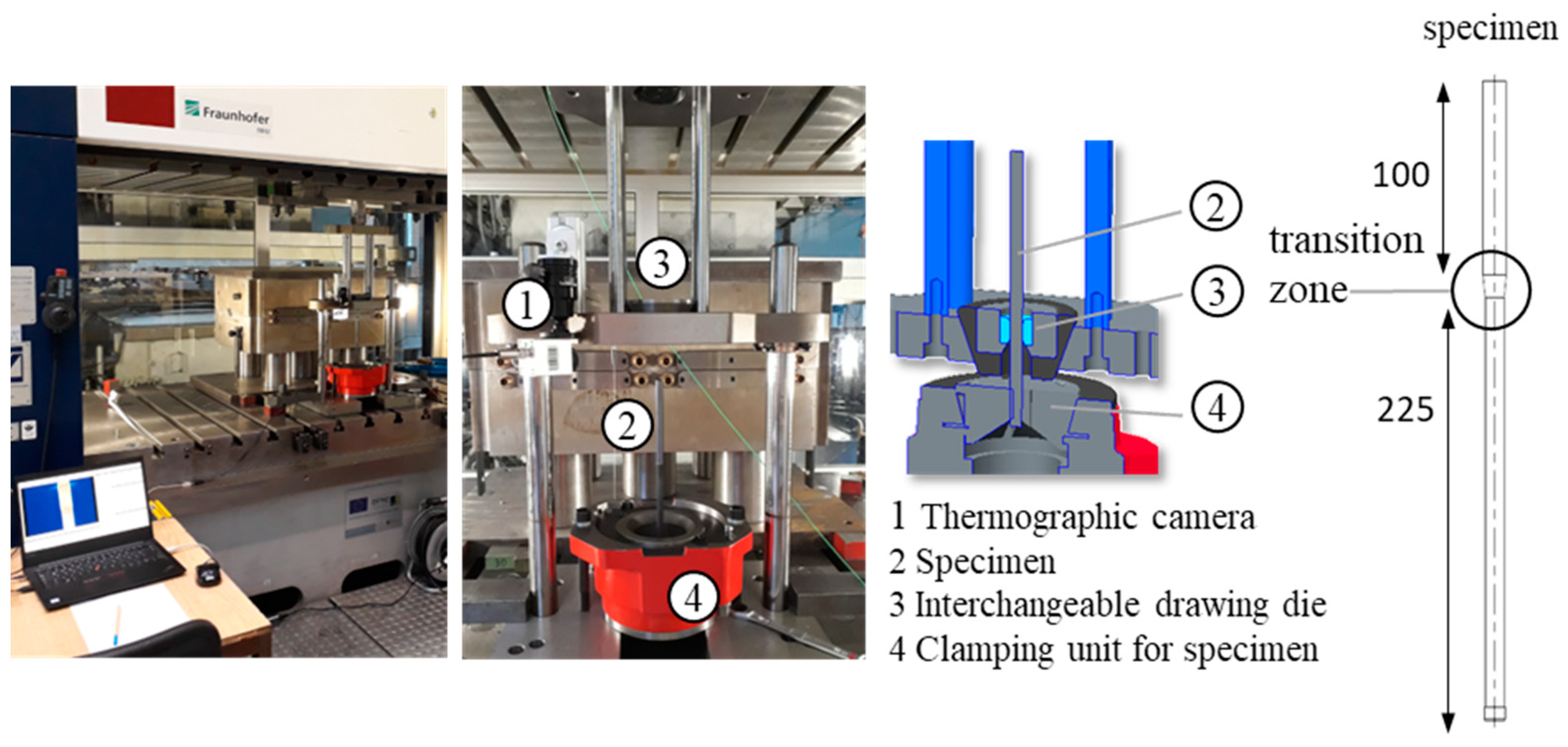

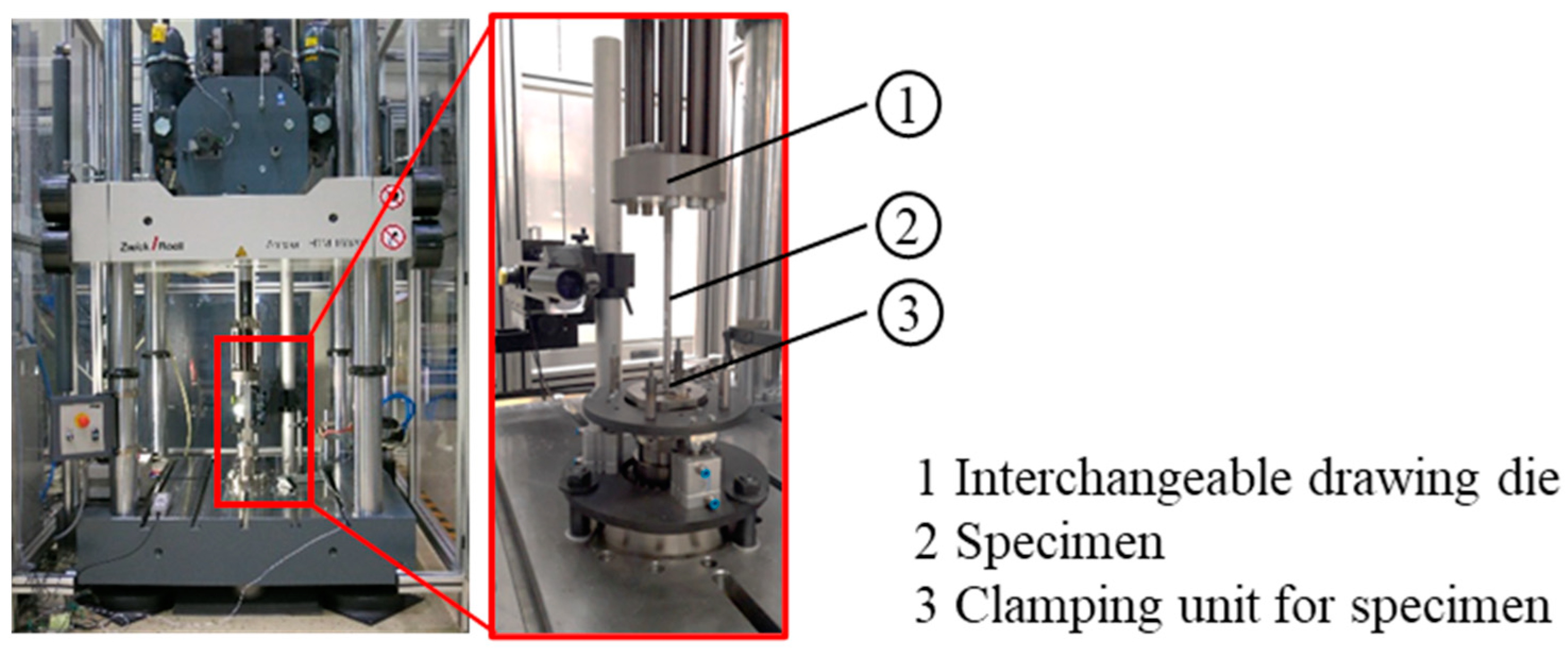

2. Materials and Methods

3. Results and Discussion

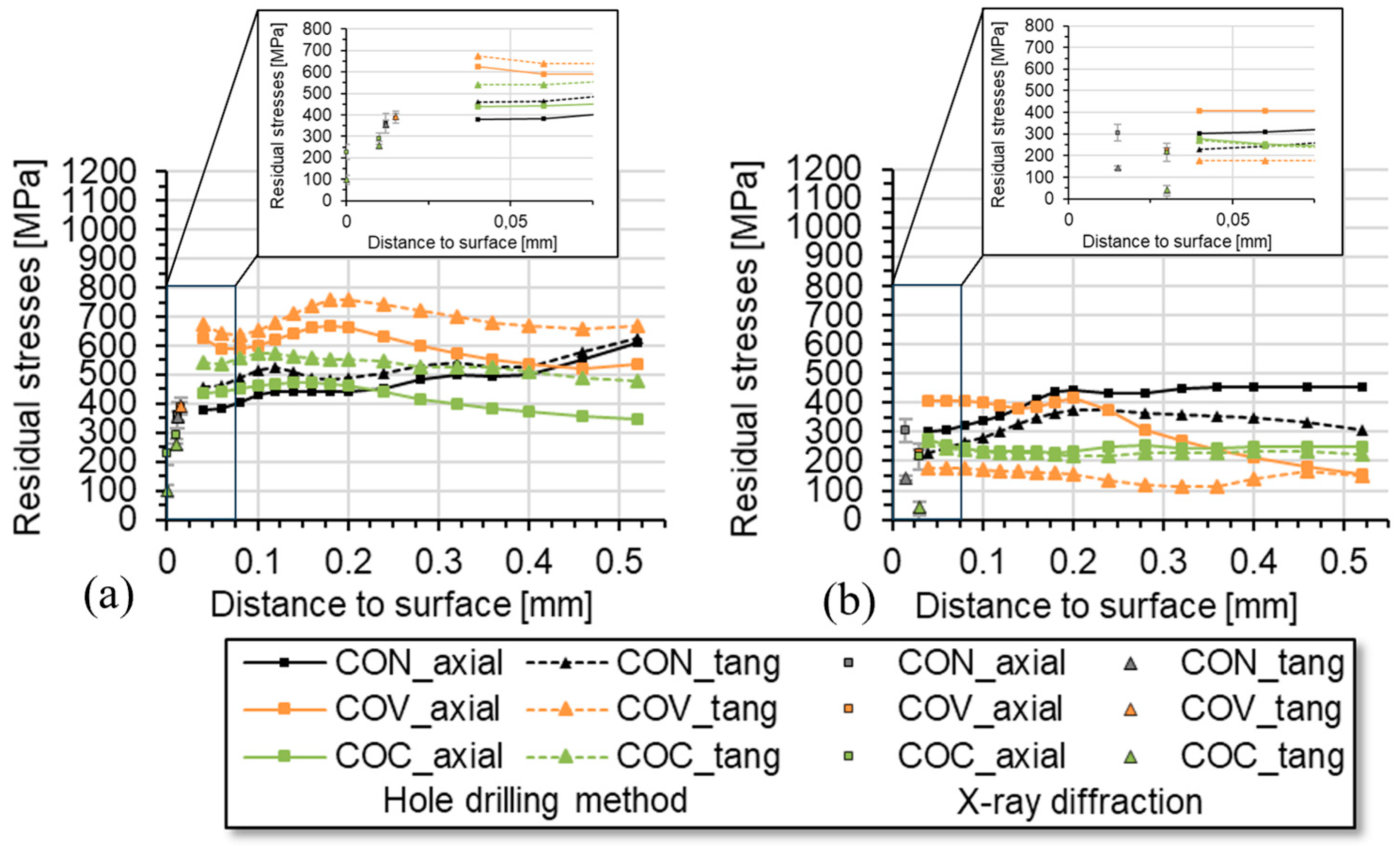

3.1. Drawing Speed of 20 mm/s—Material at Room Temperature and at 180 °C

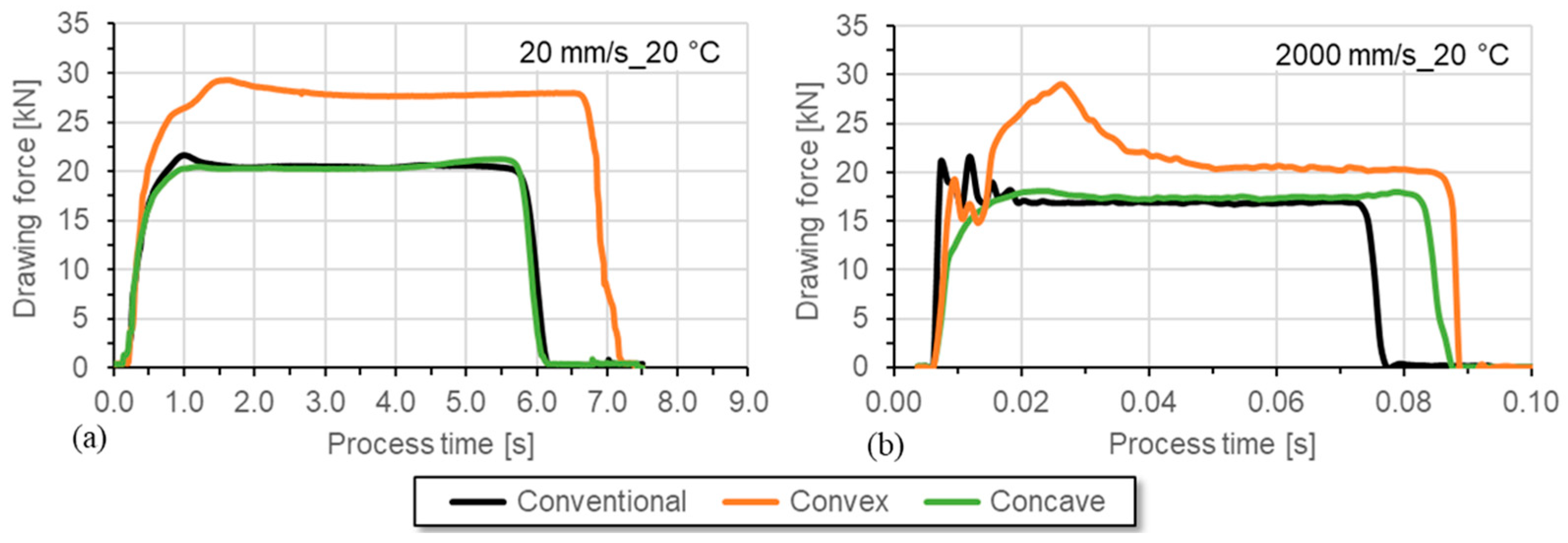

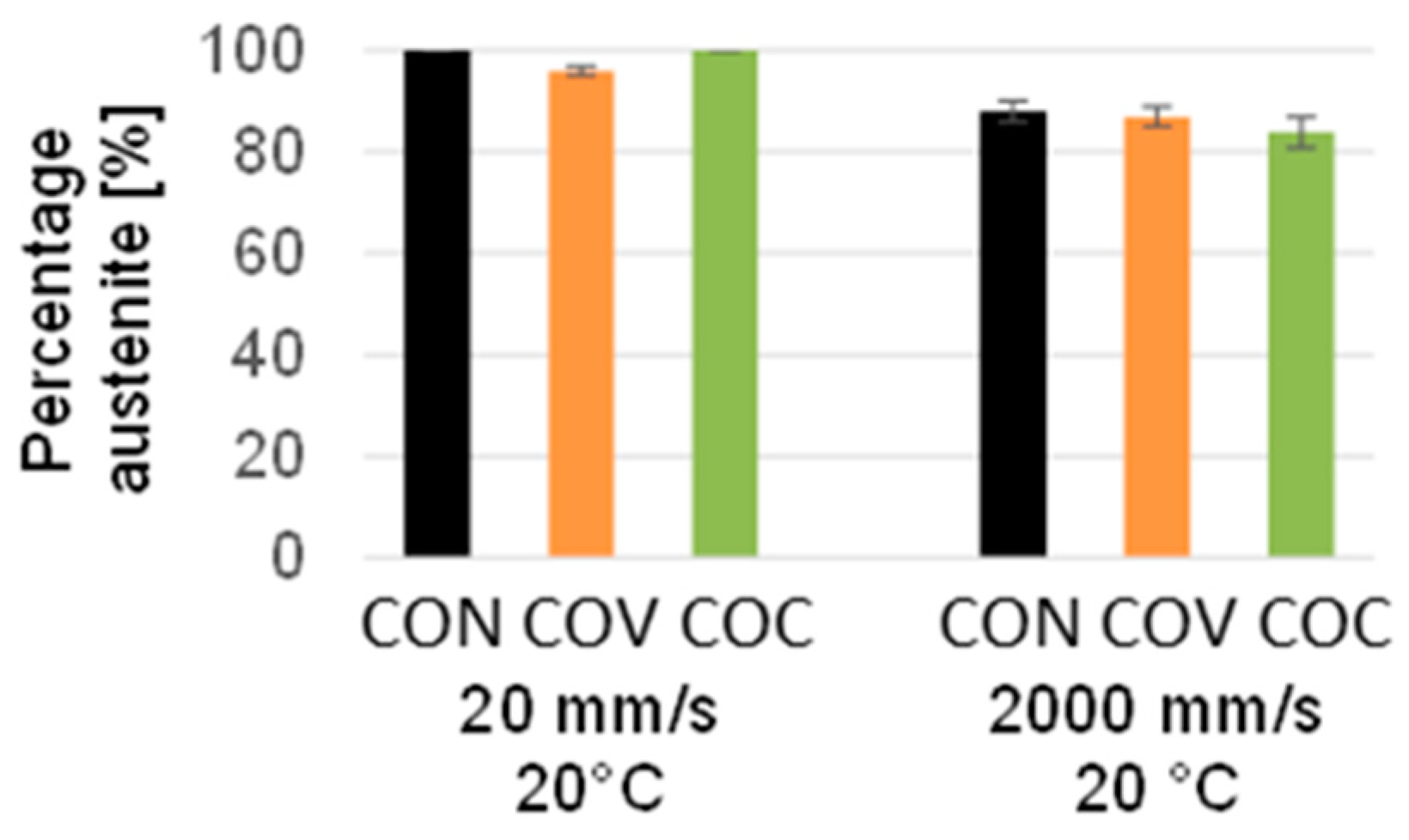

3.2. Drawing Speed at 20 mm/s and 2000 mm/s—Material at Room Temperature

4. Conclusions

- The applied complementary approach using a combination of X-ray stress analysis for residual stress analysis in the bear surface region and incremental hole drilling for a larger depth up to about 1 mm is excellently suited for fast analysis of residual stress depth distribution while taking into account the near-surface effects of deformation-induced martensitic transformations.

- The investigations have further shown that the restriction to the immediate surface is, in any case, insufficient to be able to evaluate the process variants sensibly.

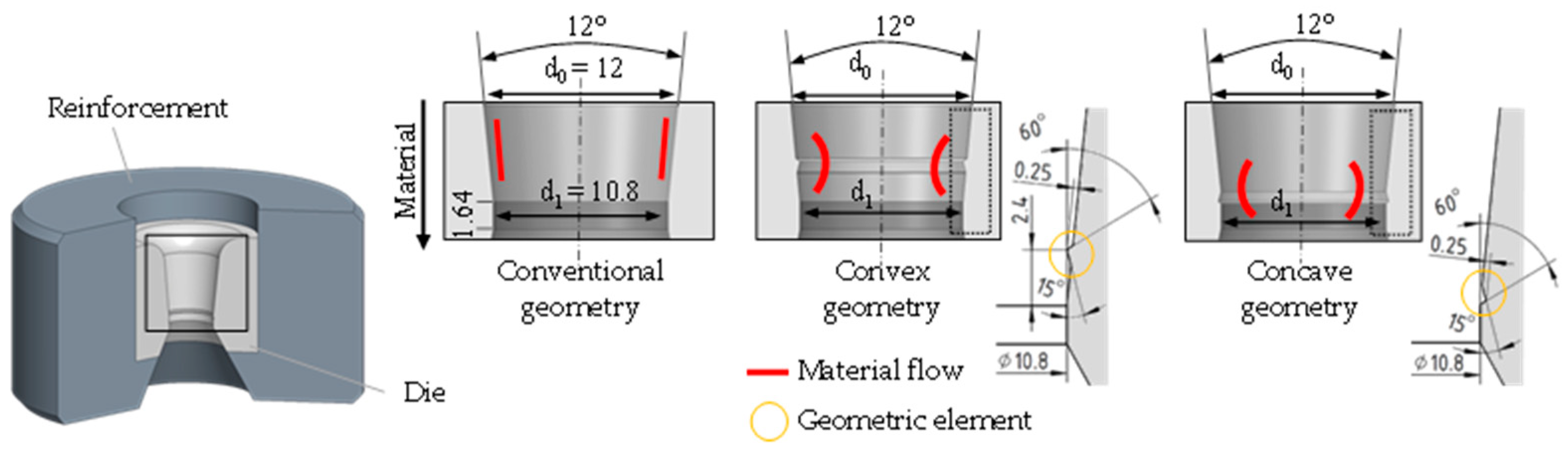

- Clear differences in the residual stress distributions close to the surface occurred between the variants that were drawn using conventional, convex, and concave die geometries. Using convex geometry, a reduction in the tensile residual stresses was experimentally determined compared to the usage of conventional die geometry. This reduction can be explained in connection with the increased plastic strain when using the concave geometry element.

- A higher plastic strain was also reflected in the increase in the drawing force. Residual stresses can thus be achieved with this process approach already by applying individual elements in one drawing stage. Using this research approach, the properties of semi-finished products can be specifically adjusted by in-process modification of the drawing die geometries, which also implies the component properties in further manufacturing processes.

- The experimental investigations have further shown that the residual stresses can be characterized as an essential geometry-related feature for drawn wire samples. The residual stresses could be influenced by the specific application of individual small geometry elements in the drawing die’s forming zone.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, S.; Van Bael, A.; Li, S.; Van Houtte, P.; Mei, F.; Sarban, A. Residual stress determination in cold drawn steel wire by FEM simulation and X-ray diffraction. Mater. Sci. Eng. A 2003, 346, 101–107. [Google Scholar] [CrossRef]

- Schneider, F.; Lang, G. Stahldraht—Herstellung und Anwendung; VEB Deutscher Verlag für Grundstoffindustrie: Leipzig, Germany, 1973. [Google Scholar]

- Llorca, J.; Sánchez-Gálvez, V. Fatique limit and fatigue life prediction in high strength cold drawn eutectoid steel wires. Fatigue Fract. Eng. Mater. Struct. 1989, 12, 31–45. [Google Scholar] [CrossRef]

- Atienza, J.; Ruiz-Hervias, J.; Martinez-Perez, M.; Mompean, F.; Garcia-Hernandez, M.; Elices, M. Residual stresses in cold drawn pearlitic rods. Scr. Mater. 2005, 52, 1223–1228. [Google Scholar] [CrossRef]

- Baumann, M.; Selbmann, R.; Milbrandt, M.; Kräusel, V.; Bergmann, M. Adjusting the Residual Stress State in Wire Drawing Products via In-Process Modification of Tool Geometries. Materials 2021, 14, 2157. [Google Scholar] [CrossRef]

- Tekkaya, A.E. Ermittlung von Eigenspannungen in der Kaltmassivumformung; Berichte aus der Umformtechnik der Universität Stuttgart; Springer: Berlin/Heidelberg, Germany, 1986. [Google Scholar]

- Celentano, D.J.; Palacios, M.; Rojas, E.L.; Cruchaga, M.A.; Artigas, A.A.; Monsalve, A.E. Simulation and experimental validation of multiple-step wire drawing processes. Finite Elem. Anal. Des. 2009, 45, 163–180. [Google Scholar] [CrossRef]

- Överstam, H. The influence of bearing geometry on the residual stress state in cold drawn wire, analysed by the FEM. J. Mater. Process. Technol. 2006, 171, 446–450. [Google Scholar] [CrossRef]

- Atienza, J.M.; Elices, M. Influence of residual stresses in the tensile test of cold drawn wires. Mater. Struct. 2003, 36, 548–552. [Google Scholar] [CrossRef]

- Teja, C.S.N.; Murty, G.; Reddy, P.S. Finite Element Analysis of Wire Drawing Process with different die contours. Int. J. Sci. Eng. Adv. Technol. 2016, 4, 134–143. [Google Scholar]

- Neugebauer, R.; Sterzing, A.; Bergmann, M. Mechanical properties of the AlSi1MgMn aluminium alloy (AA6082) processed by gradation rolling. Mater. Werkst. 2011, 42, 593–598. [Google Scholar] [CrossRef]

- Neugebauer, R.; Sterzing, A.; Selbmann, R.; Zachäus, R.; Bergmann, M. Gradation extrusion—Severe plastic deformation with defined gradient. Mater. Werkst. 2012, 43, 582–588. [Google Scholar] [CrossRef]

- Neugebauer, R.; Bergmann, M. Local severe plastic deformation by modified impact extrusion process. Steel Res. Int. 2012, 14, 471–474. [Google Scholar]

- Frint, P.; Härtel, M.; Selbmann, R.; Dietrich, D.; Bergmann, M.; Landgrebe, D.; Wagner, M.F.-X. Microstructural Evolution during Severe Plastic Deformation by Gradation Extrusion. Metals 2018, 8, 96. [Google Scholar] [CrossRef]

- Tschätsch, H. Praxis der Umformtechnik: Arbeitsverfahren, Maschinen, Werkzeuge; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Baumann, M.; Graf, A.; Selbmann, R.; Brömmelhoff, K.; Kräusel, V.; Landgrebe, D.; Bergmann, M. Influence of a modified drawing process on the resulting residual stress state of cold drawn wire. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 190. [Google Scholar]

- Selbmann, R.; Baumann, M.; Dobecki, M.; Bergmann, M.; Kräusel, V.; Reimers, W. Concept for controlled adjustment of residual stress states in semi-finished products by gradation extrusion. Arch. Appl. Mech. 2021, 91, 3627–3636. [Google Scholar] [CrossRef]

- Baumann, M.; Selbmann, R.; Dobecki, M.; Kräusel, V.; Reimers, W.; Bergmann, M. Gezielte Beeinflussung umformtechnisch induzierter Eigenspannungen beim Drahtziehen. Forsch. Ingenieurwesen 2021, 85, 773–781. [Google Scholar] [CrossRef]

- Gupta, S.; Twardowski, R.; Kucharczyk, P.; Münstermann, S. Experimental and Numerical Investigations of the TRIP Effect in 1.4301 Austenitic Stainless Steel Under Static Loading. Steel Res. Int. 2013, 85, 793–802. [Google Scholar] [CrossRef]

- DIN EN 10088-3:2014-12; Stainless Steels—Part 3: Technical Delivery Conditions for Semi-Finished Products, Bars, Rods, Wire, Sections and Bright Products of Corrosion Resisting Steels for General Purposes. DIN Standards: Berlin, Germany, 2014; German version EN 10088-3: 2014-12.

- Schwarz, T.; Kockelmann, H. Die Bohrlochmethode—Eine für viele Anwendungsbereiche optimales Verfahren zur experimentellen Ermittlung von Eigenspannungen. Messtech. Briefe 1993, 29, 33–38. [Google Scholar]

- Macherauch, E.; Müller, P. Das sin2ψ-Verfahren der röntgenographischen Spannungsermittlung. Ztg. Angew. Phys. 1961, 441, 305–312. [Google Scholar]

- Wolfstieg, U. Die Symmetrisierung unsymmetrischer Interferenzlinien mit Hilfe von Spezialblenden. HTM J. Heat Treat. Mater. 1976, 31, 23–26. [Google Scholar]

- Bechmann, R.; Hearmon, R.F.S. Landolt-Börnstein—Numerical Data and Functional Relationships in Science and Technology, New Series, Group III—Crystal and Solid State Physics: Volume 1—Elastic, Piezoelastic, Piezooptic and Electrooptic Constants of Crystals; Springer: Berlin/Heidelberg, Germany; New York, NY, USA,, 1966. [Google Scholar]

- Salmutter, K.; Stangler, F. Elastizität u. Plastizität eines austenitischen Chrom-Nickel-Stahls. Int. J. Mater. Res. 1960, 51, 544–548. [Google Scholar] [CrossRef]

- Kröner, E. Berechnung der elastischen Konstanten des Vielkristalls aus den Konstanten des Einkristalls. Z. Phys. 1958, 151, 504–518. [Google Scholar] [CrossRef]

- Simon, N.; Erdle, H.; Walzer, S.; Gibmeier, J.; Böhlke, T.; Liewald, M. Phase-specific residual stresses induced by dee drawing of lean duplex steel: Measurement vs. simulation. Prod. Eng. 2019, 13, 227–237. [Google Scholar] [CrossRef]

- Simon, N.; Krause, M.; Heinemann, P.; Erdle, H.; Böhlke, T.; Gibmeier, J. Phase-specific strain hardening and load partitioning of cold rolled duplex stainless steel x2crnin23-4. Crystals 2020, 10, 976. [Google Scholar] [CrossRef]

- Schuster, S.; Gibmeier, J. Incremental Hole Drilling for Residual Stress Analysis of Strongly Textured Material States—A New Calibration Approach. Exp. Mech. 2016, 56, 369–380. [Google Scholar] [CrossRef]

- Moore, M.; Evancs, W. Mathematical Correction for Stress in Removed Layers in X-Ray Diffraction Residual Stress Analysis. SAE Trans. 1958, 66, 340–345. [Google Scholar]

| Element | C | Si | Mn | P | S | Cr | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|

| Content [wt.%] | min | - | - | - | - | - | 17.5 | 8.0 | - |

| max | 0.07 | 1.0 | 2.0 | 0.045 | 0.03 | 19.5 | 10.5 | 0.1 |

| Phase | hkl | s1(hkl)/MPa−1 | ½ s2(hkl)/MPa−1 |

|---|---|---|---|

| Ferrite | {211} | −1.277 × 10−6 | 5.821 × 10−6 |

| Austenite | {220} | −1.457 × 10−6 | 6.157 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Selbmann, R.; Gibmeier, J.; Simon, N.; Kräusel, V.; Bergmann, M. Residual Stress Engineering for Wire Drawing of Austenitic Stainless Steel X5CrNi18-10 by Variation in Die Geometries—Effect of Drawing Speed and Process Temperature. Materials 2024, 17, 1174. https://doi.org/10.3390/ma17051174

Selbmann R, Gibmeier J, Simon N, Kräusel V, Bergmann M. Residual Stress Engineering for Wire Drawing of Austenitic Stainless Steel X5CrNi18-10 by Variation in Die Geometries—Effect of Drawing Speed and Process Temperature. Materials. 2024; 17(5):1174. https://doi.org/10.3390/ma17051174

Chicago/Turabian StyleSelbmann, René, Jens Gibmeier, Nicola Simon, Verena Kräusel, and Markus Bergmann. 2024. "Residual Stress Engineering for Wire Drawing of Austenitic Stainless Steel X5CrNi18-10 by Variation in Die Geometries—Effect of Drawing Speed and Process Temperature" Materials 17, no. 5: 1174. https://doi.org/10.3390/ma17051174

APA StyleSelbmann, R., Gibmeier, J., Simon, N., Kräusel, V., & Bergmann, M. (2024). Residual Stress Engineering for Wire Drawing of Austenitic Stainless Steel X5CrNi18-10 by Variation in Die Geometries—Effect of Drawing Speed and Process Temperature. Materials, 17(5), 1174. https://doi.org/10.3390/ma17051174