Numerical Investigation of the Damage Effect on the Evolution of Adiabatic Shear Banding and Its Transition to Fracture during High-Speed Blanking of 304 Stainless Steel Sheets

Abstract

1. Introduction

2. Methodology

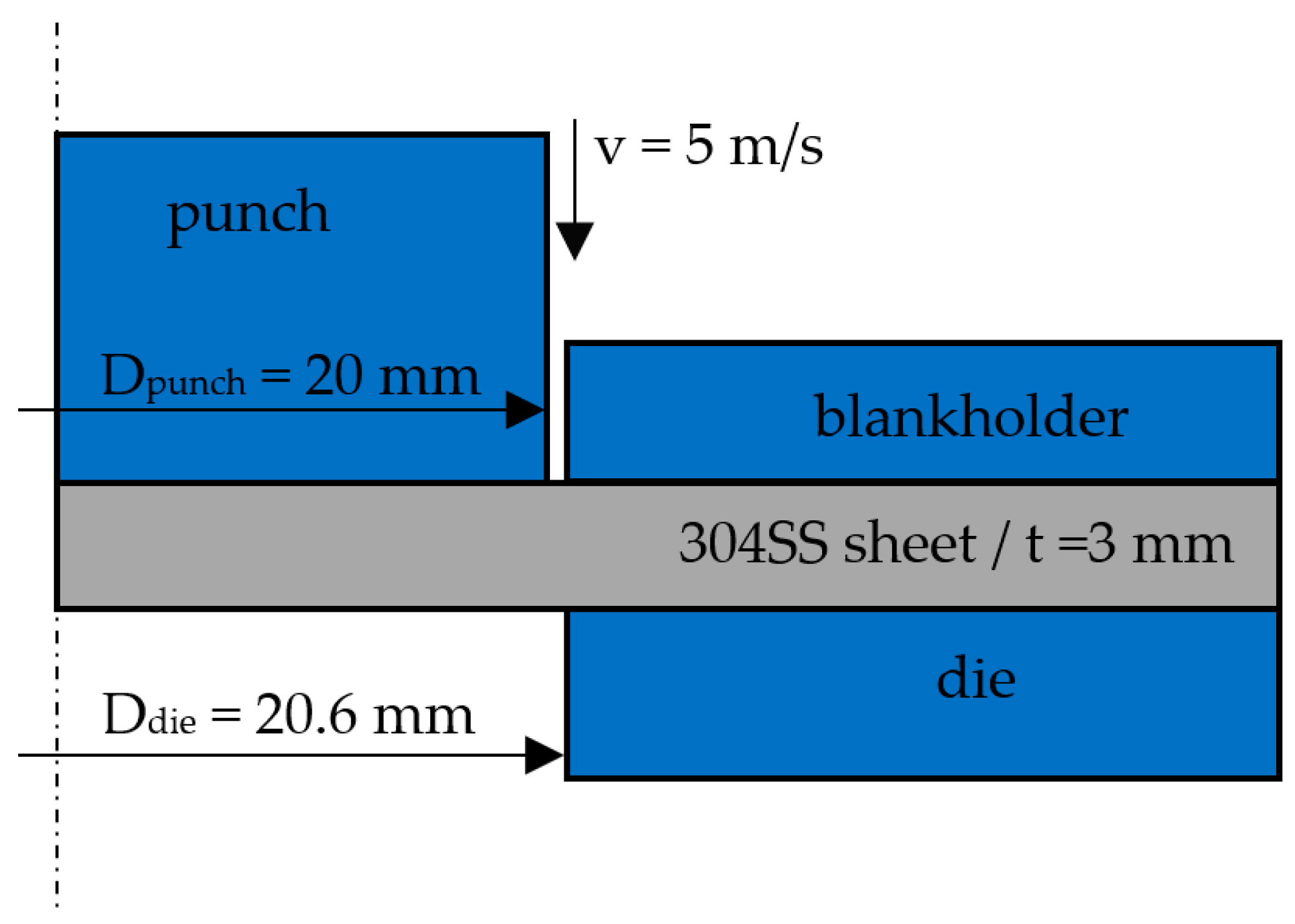

2.1. Examined Configuration

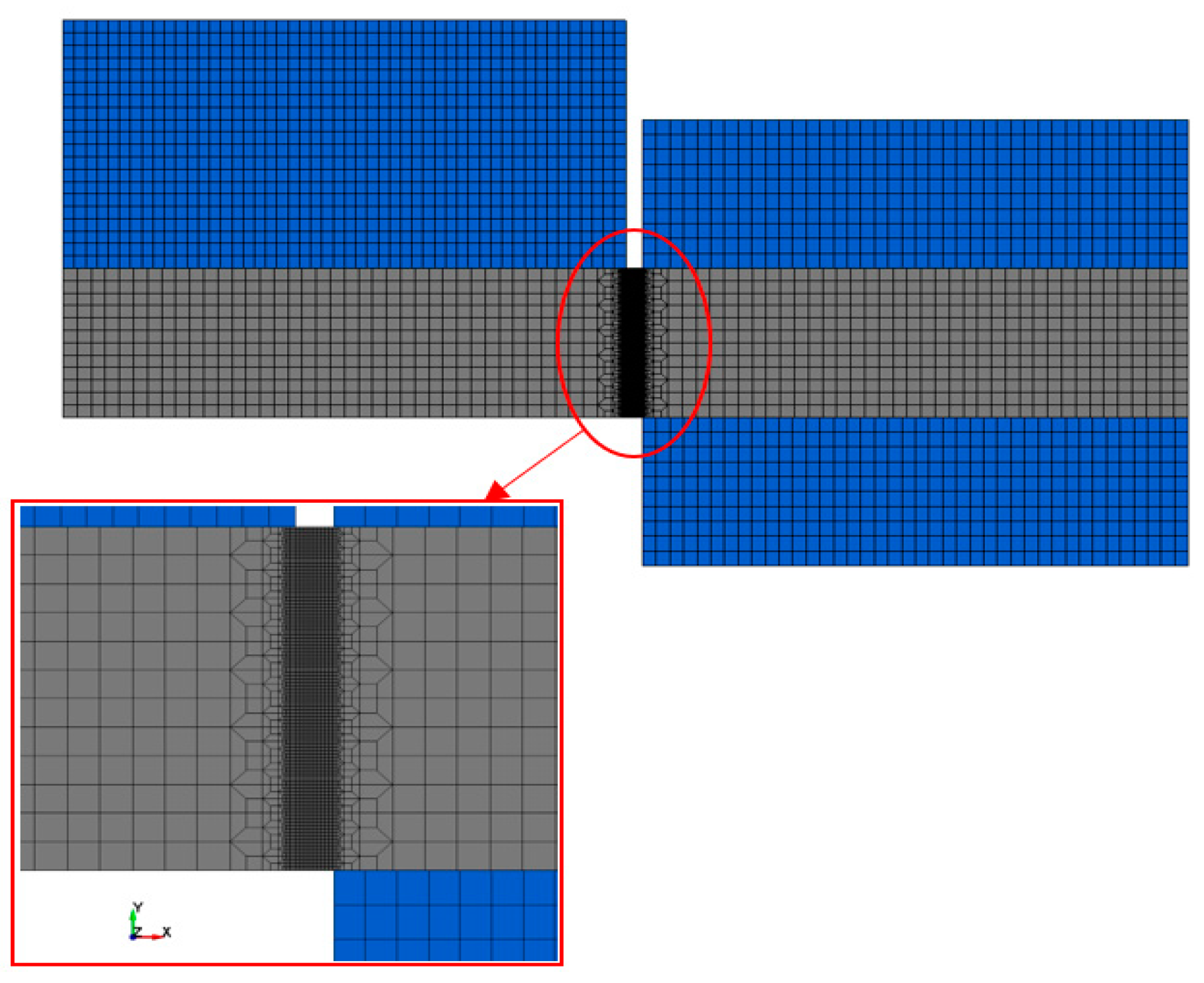

2.2. FE Modeling

2.2.1. FE Discretization

2.2.2. Material and Damage Modeling

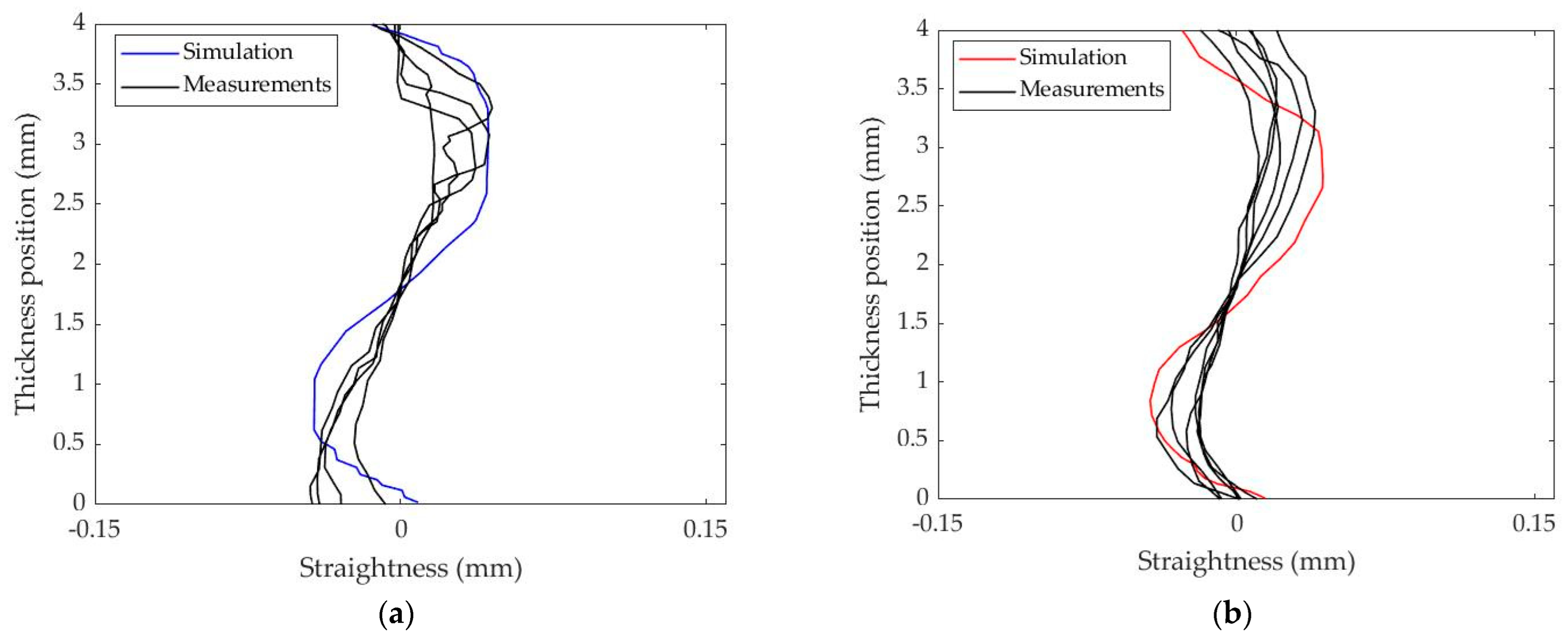

3. Modeling Validation

4. Results

4.1. Simulation Cases

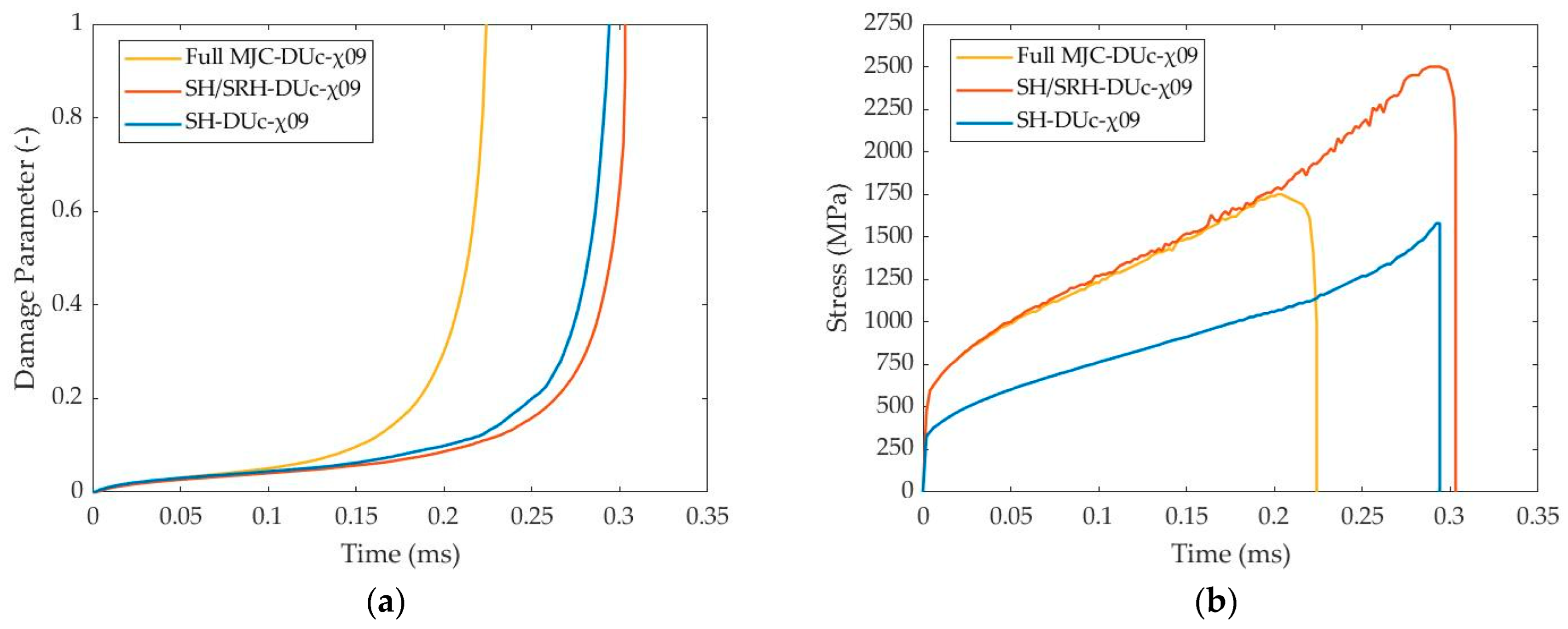

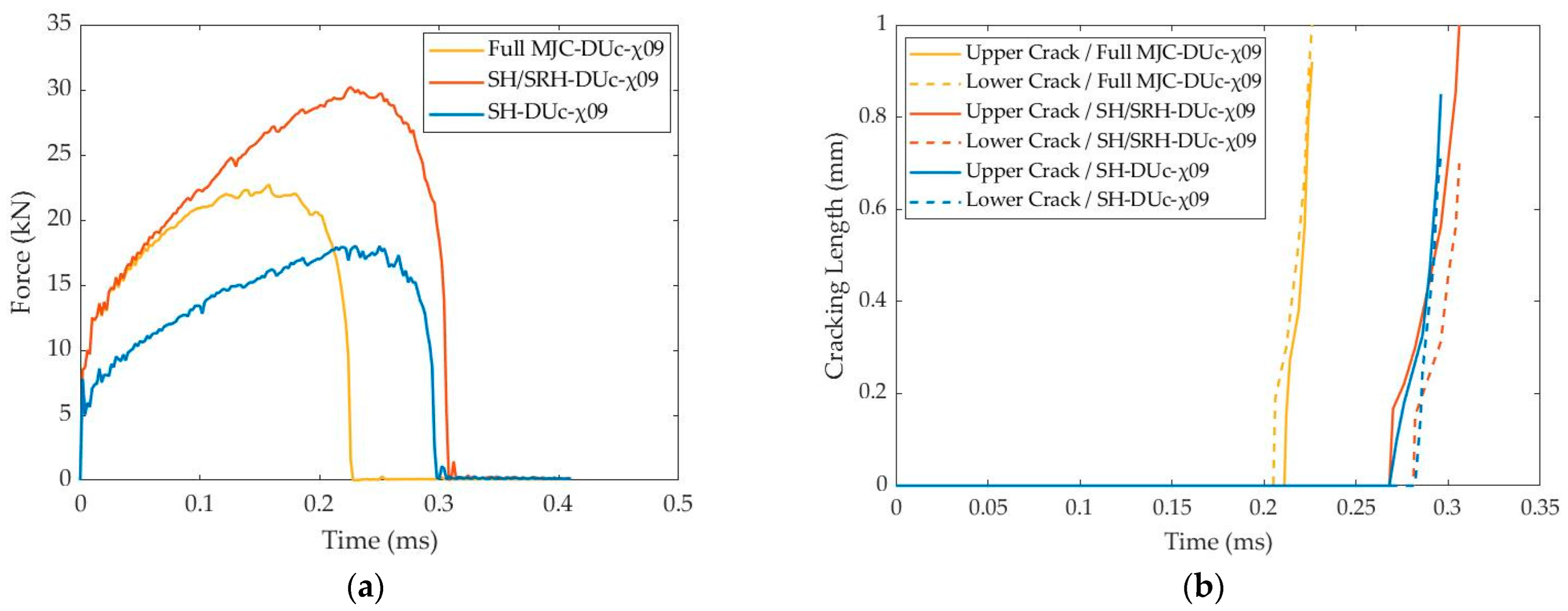

4.2. Strain Rate and Temperature Effect

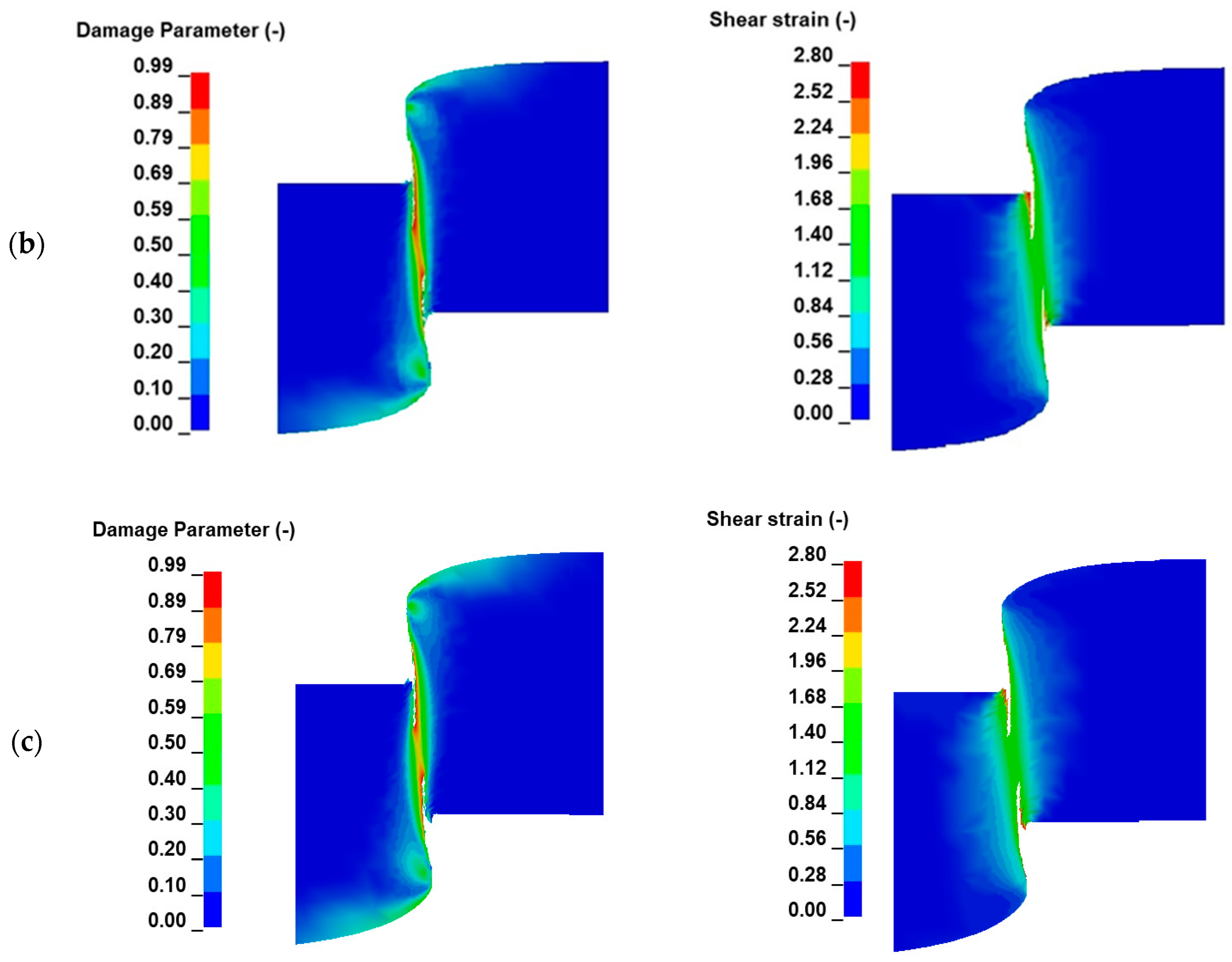

4.3. Damage Coupling Effect

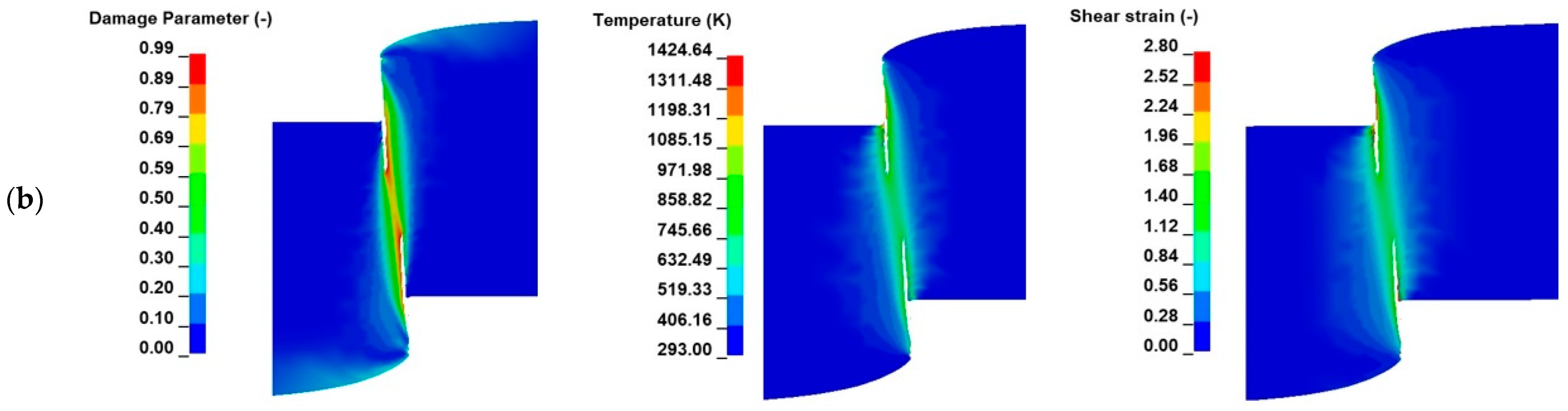

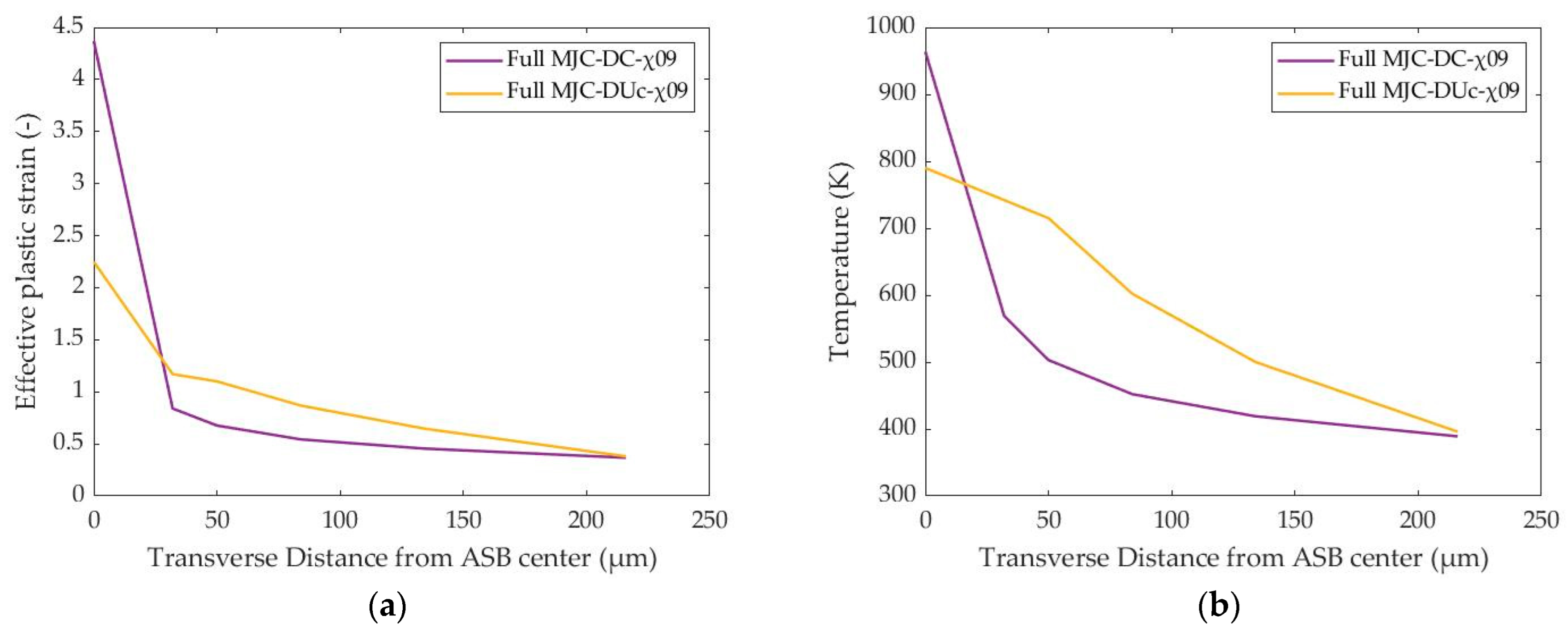

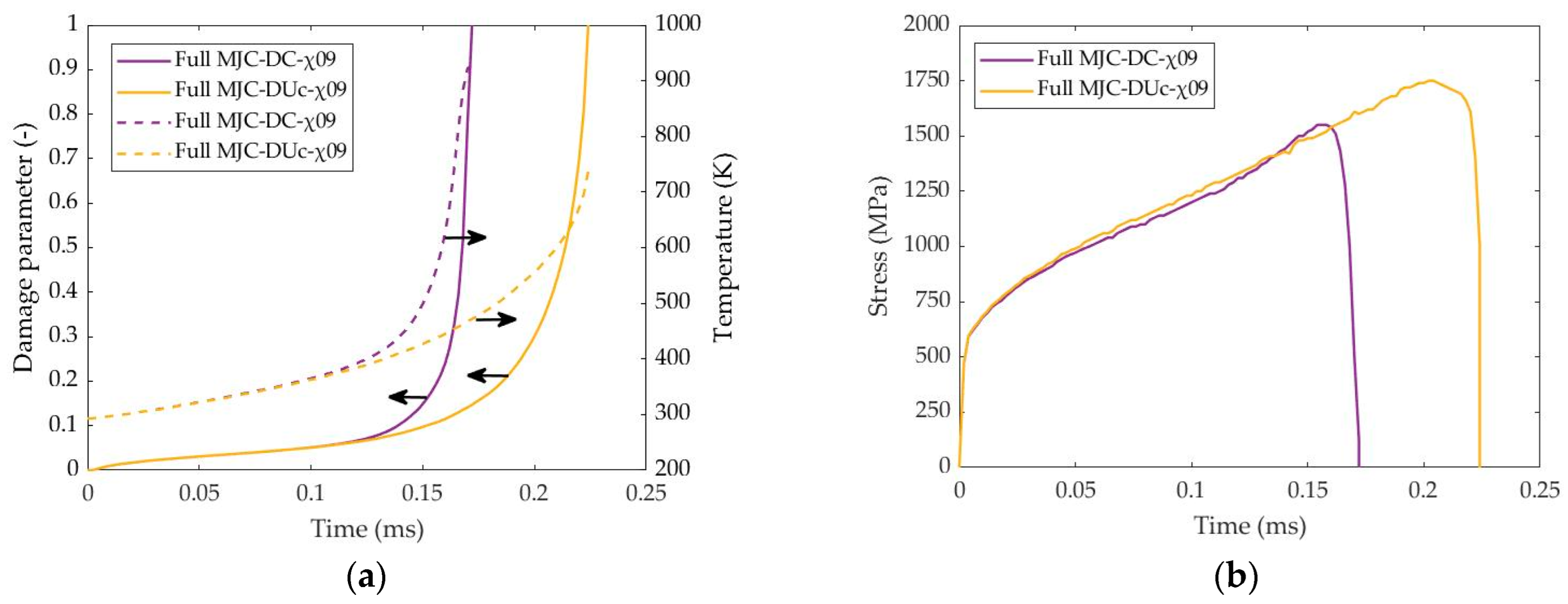

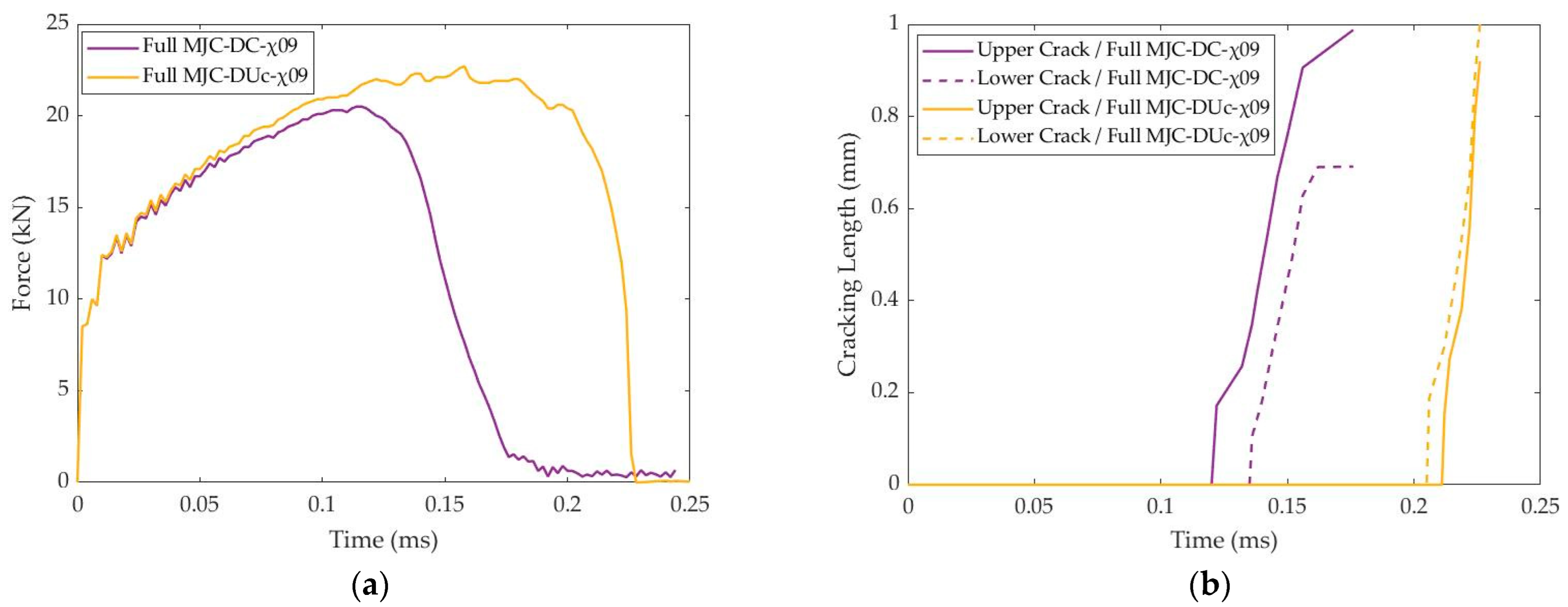

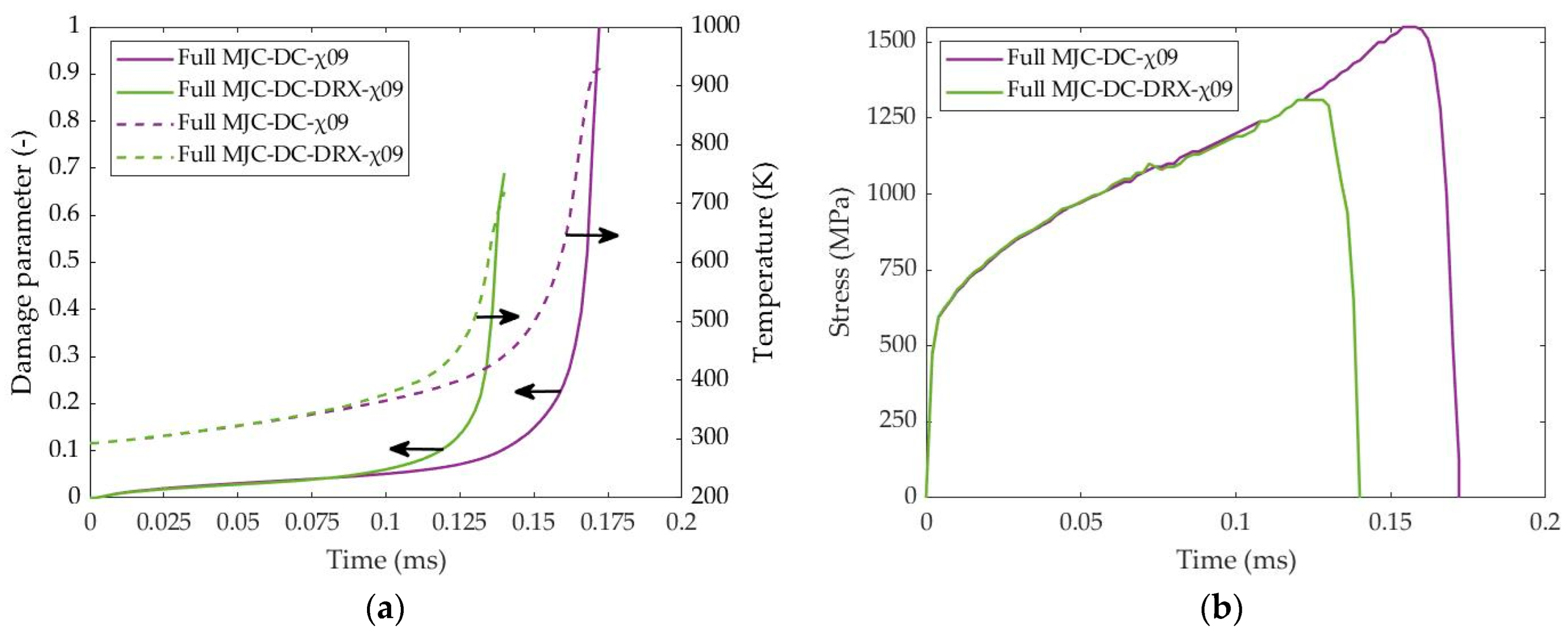

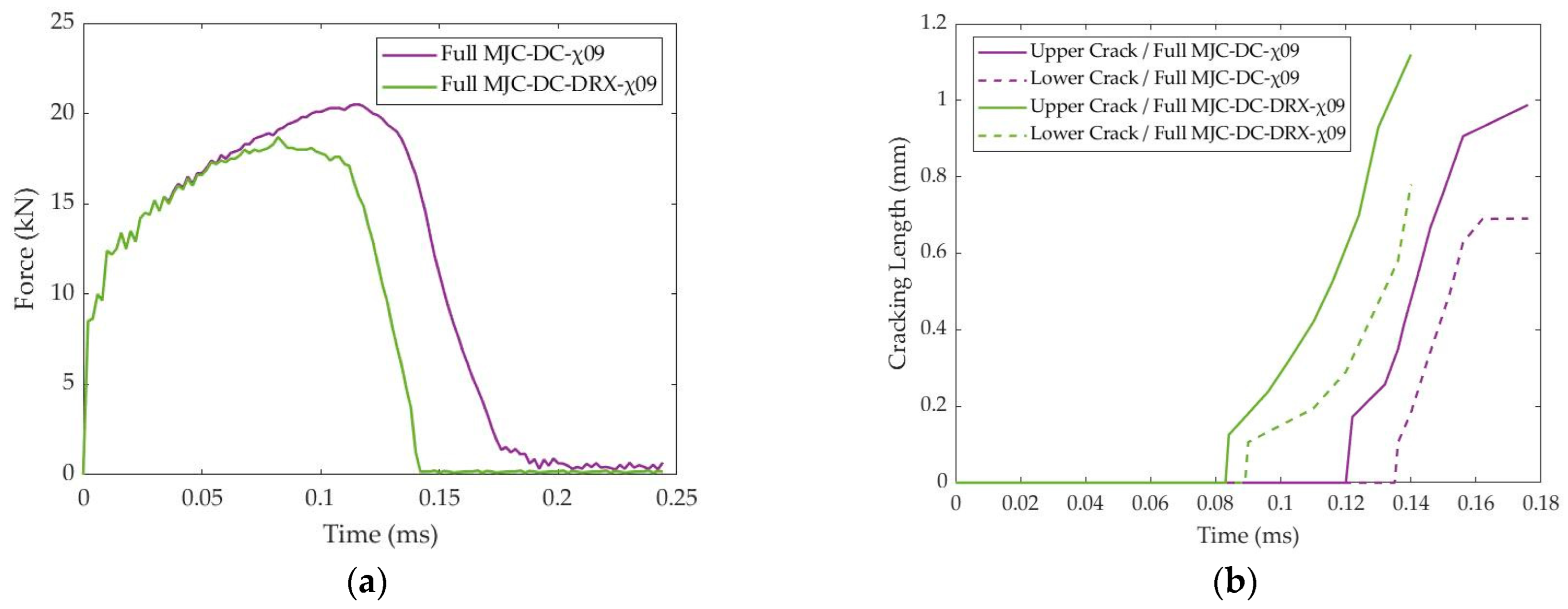

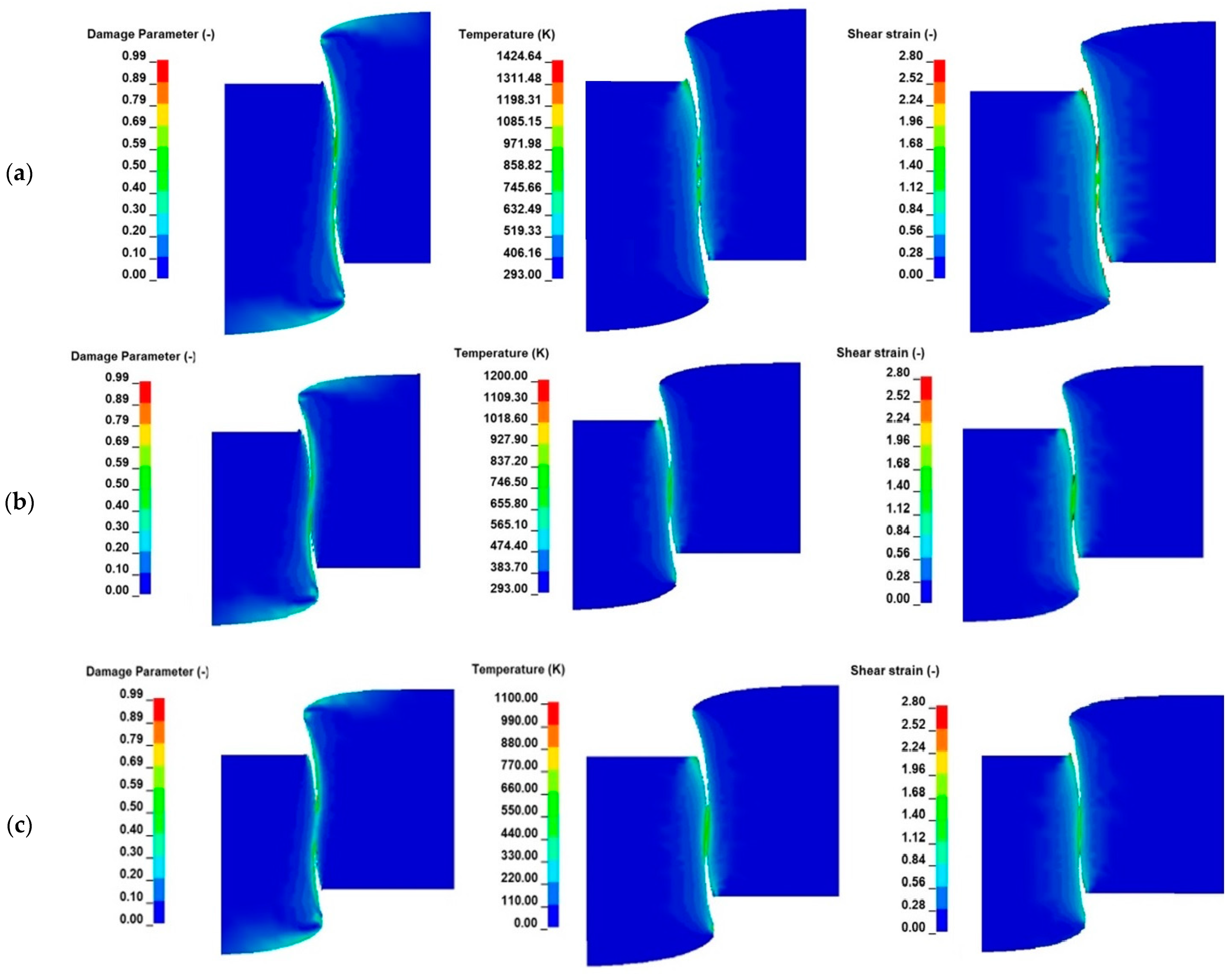

4.4. DRX Effect

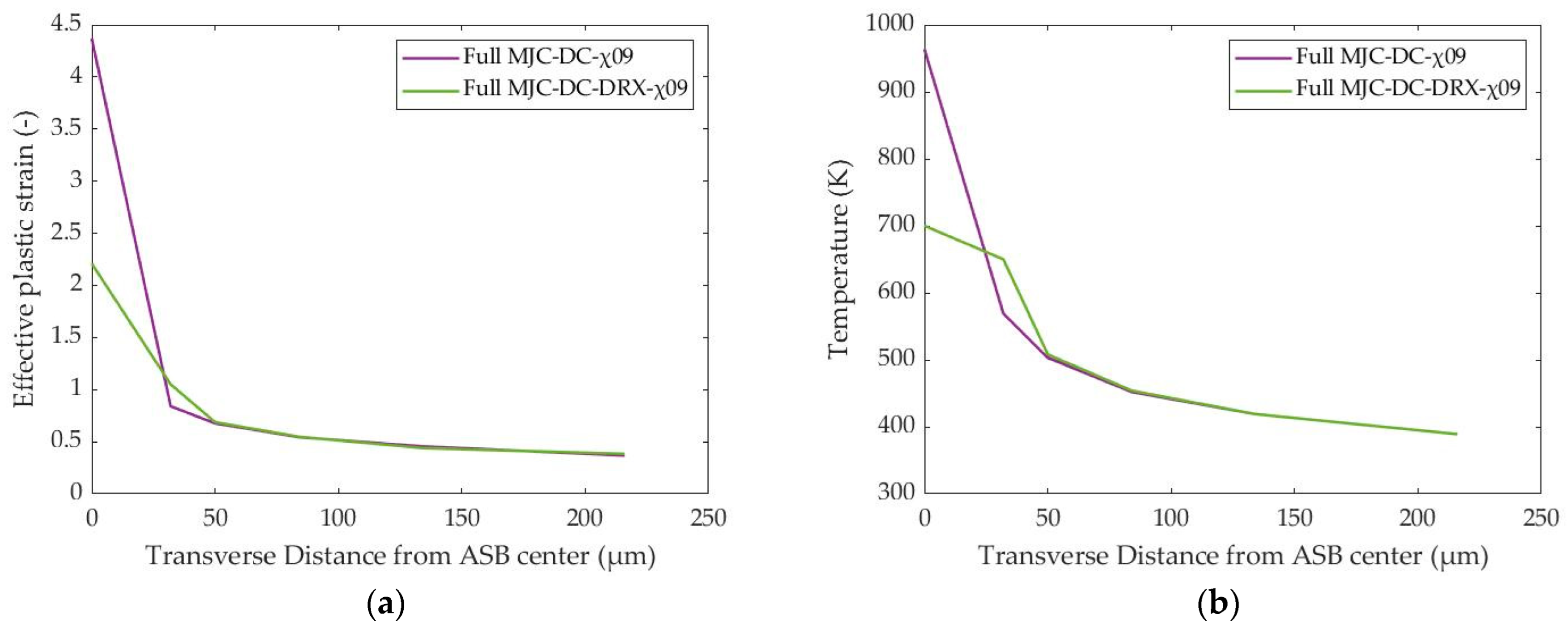

4.5. Taylor–Quinney Parametric Study

5. Discussion

6. Conclusions

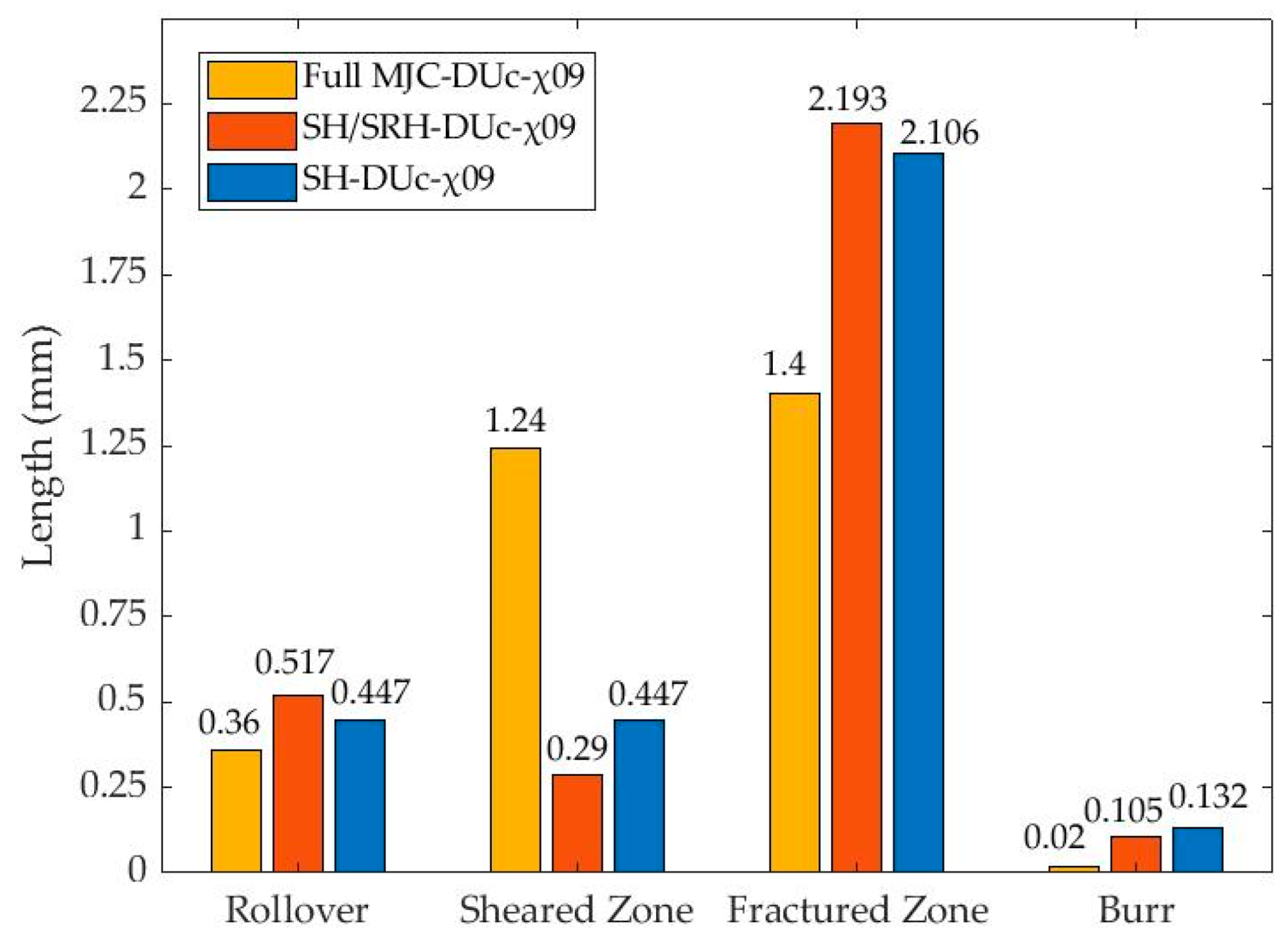

- The consideration of thermal softening showed an earlier fracture initiation via cracking propagation, resulting in an earlier and lower peak force. Also, cracking initiation seems to be mainly determined by thermal softening, which revealed that upper and lower cracks appeared almost simultaneously. On the other hand, when neglecting the temperature effect, the upper crack manifested earlier, while only strain rate does not seem to affect the timing of cracking initiation. On the other hand, the strain rate was found to drive the early deformation stages, during which the temperature increase was weak, thus determining plasticity progress. Finally, the implementation of thermal softening showed a similar extent of sheared and fractured zones in a blanked profile regarding the damage-uncoupled models, while in contrast, the fractured zone was found to be significantly longer compared to other zones when considering only the strain rate hardening.

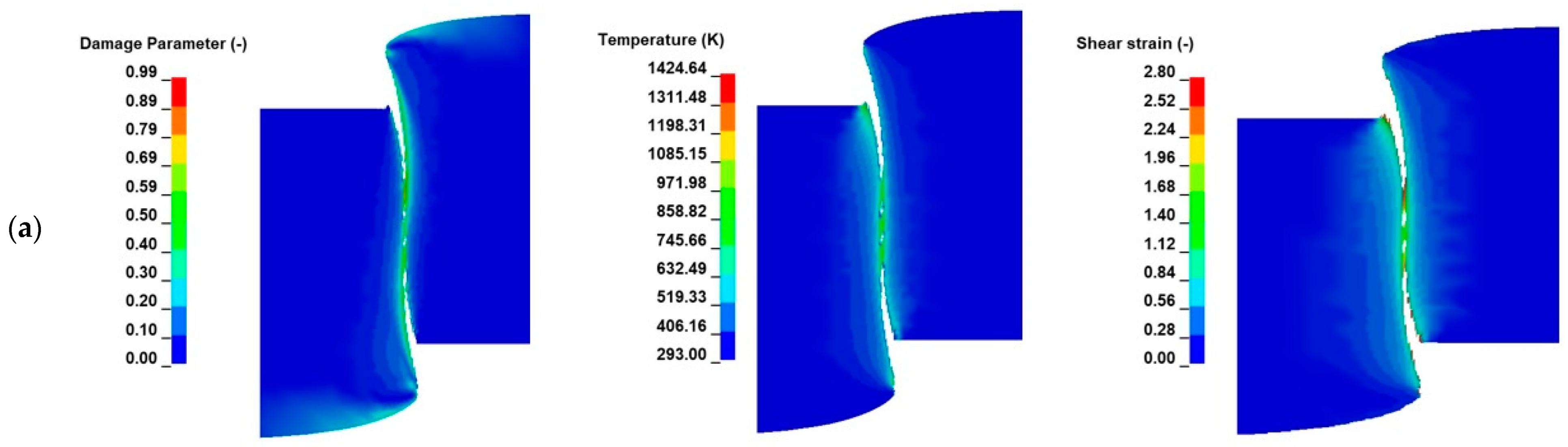

- The consideration of damage coupling resulted in a reduced ASB width and higher maximum strain and temperature inside the ASB core due to additional material softening from the damage extent. For this reason, an 8% lower peak force was also revealed when accounting for both thermal and damage softening, while its occurrence was also captured sooner. In particular, damage coupling showed earlier fracture initiation, which was manifested via earlier cracking initiation around the punch and die corners. Finally, the fracture was completed through the formation of an intermediate micro-crack generated by micro-voiding within the ASB core.

- Thermal softening was found to precede damage softening, indicating that temperature increase is responsible for ASB initiation, while damage evolution drives ASB propagation and its transition to fracture. For this reason, both peak force and stress collapse coincide with the timing of the sharp damage increment. In other words, strain instability seems to be generated from the significant temperature increase, while instead, its unstable evolution is primarily driven by damage softening. Finally, damage coupling revealed an S-shaped fracture profile due to the sigmoid trace of damage evolution, in contrast to the diagonal trace of temperature rise. Instead, the damage-uncoupled models revealed a conventional blanked profile with district zones.

- DRX softening revealed an earlier cracking genesis and premature fracture, resulting in a further 9% peak force reduction. In fact, the fracture was obtained when reaching the DRX temperature and before critical damage in specific points of the ASB core, indicating that failure is driven by both critical temperature and critical damage. However, the maximum temperature inside ASB was found to be lower due to premature element erosion. Therefore, the implementation of multiple damage criteria in parallel seems very important, offering the capability to evaluate the influence of strain failure, damage evolution, and critical temperature on fracture. Finally, DRX softening also led to an S-shaped blanked profile, showing that DRX evolution follows the trace of damage increment.

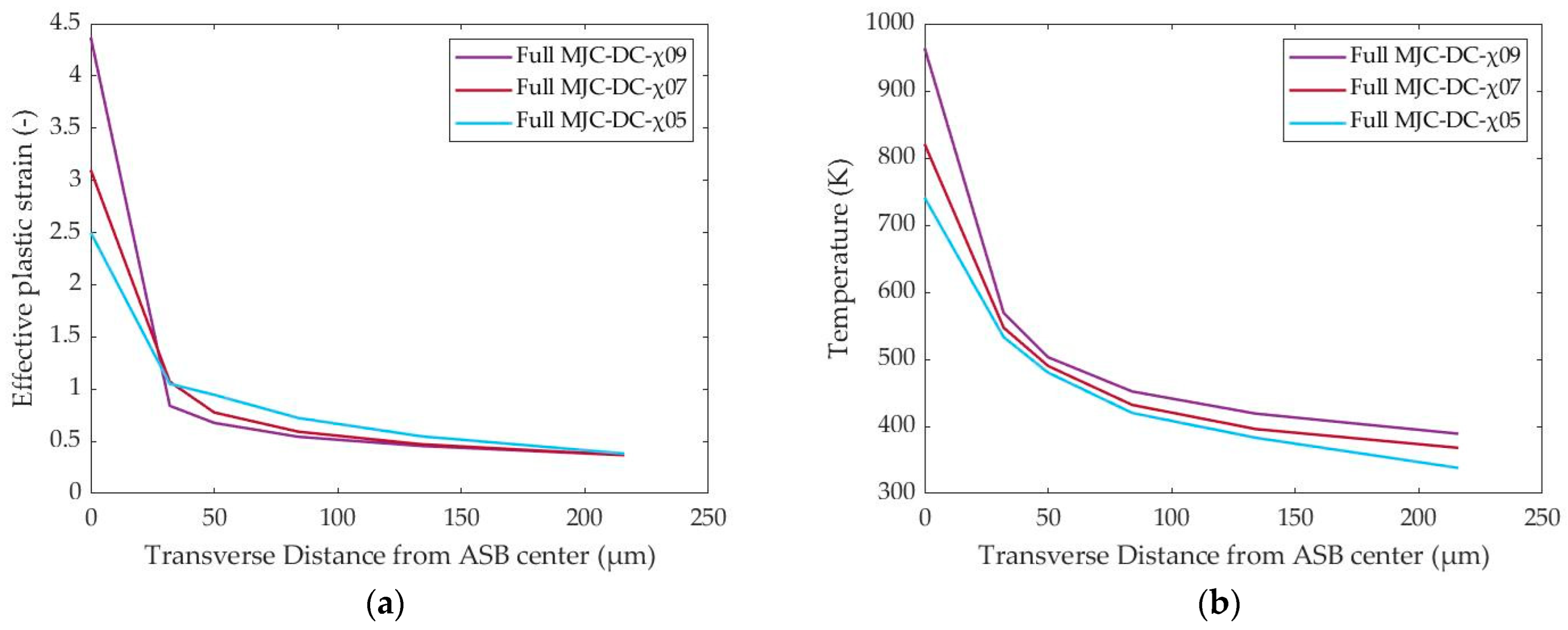

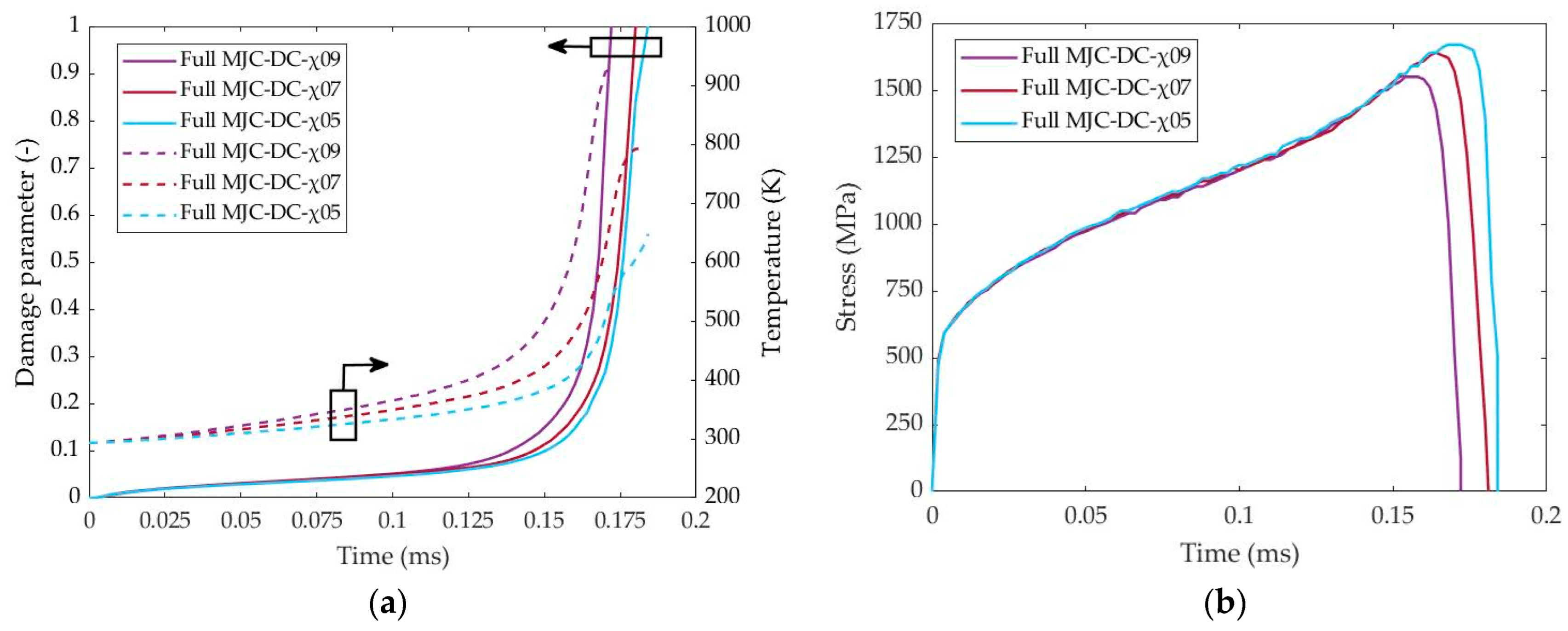

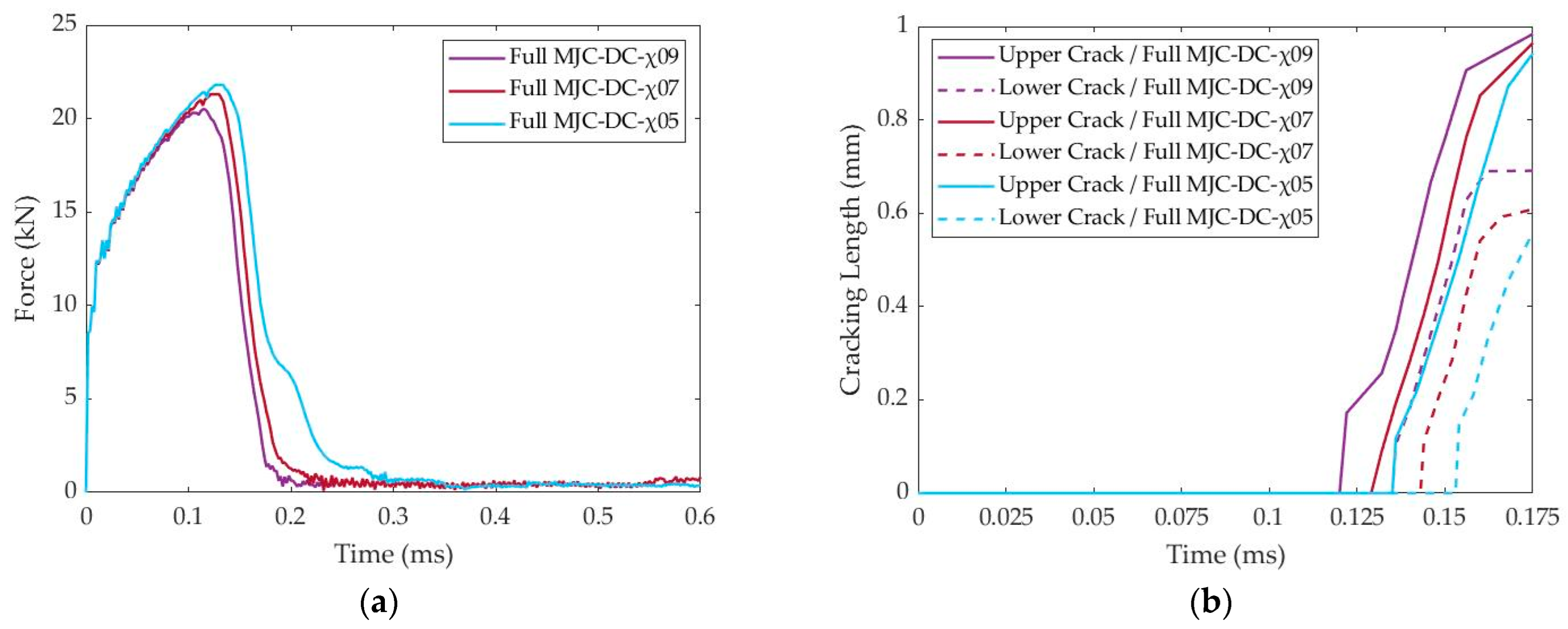

- A higher χ-value resulted in a wider thermal affected zone, providing greater temperature inside ASB. In fact, a χ-value of 0.9 resulted in micro-voiding generation due to local melting within the ASB core, in contrast to lower examined χ-values, which did not provide a high enough temperature to reach the melting point. Also, a higher χ-value reacted to a stronger thermal softening magnitude, which led to earlier ASB formation and damage increment, revealing a lower peak force. Specifically, a reduction rate of 3% in peak force was revealed per 0.2 increase step in χ-value. Moreover, the increase in χ-value results in wider ASB consisting of more intense shear localization, as confirmed by the greater peak strain. Finally, longer upper and lower cracks were observed for a higher χ-value, showing that a greater work-to-heat conversion efficiency promotes cracking propagation.

- The lower examined χ-value of 0.5 revealed a maximum ASB temperature that was marginally greater than the DRX temperature of 720 K. Considering that 0.5 defines the lower bound of χ-value regarding 304SS and that the increase in χ-value results in a higher temperature rise, it is indicated that 304SS promotes the activation of DRX during ASB formation, which is not always guaranteed. Therefore, the implementation of DRX softening during numerical computations seems even more important in order to provide an accurate prediction of the strain instability point and fracture progress.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Karantza, K.D.; Manolakos, D.E. A Review on the Adiabatic Shear Banding Mechanism in Metals and Alloys Considering Microstructural Characteristics, Morphology and Fracture. Metals 2023, 13, 1988. [Google Scholar] [CrossRef]

- Chen, Z.H.; Chan, L.C.; Lee, T.C.; Tang, C.Y. An Investigation on the Formation and Propagation of Shear Band in Fine-Blanking Process. J. Mater. Process. Technol. 2003, 138, 610–614. [Google Scholar] [CrossRef]

- Hu, D.-C.; Chen, M.-H.; Wang, L.; Wang, H.-J. Microstructural Characterization of Blanked Surface of C5191 Phosphor Bronze Sheet under Ultra-High-Speed Blanking. Trans. Nonferrous Met. Soc. China 2021, 31, 692–702. [Google Scholar] [CrossRef]

- Sonkamble, V.; Dhondapure, P.; Narasimhan, K.; Tewari, A. Experimental Investigation of Shear Band and Shear Strain Field Evolution during Blanking of AA6082 Sheet. J. Strain Anal. Eng. Des. 2019, 54, 149–158. [Google Scholar] [CrossRef]

- Fazily, P.; Yu, J.; Lee, C.-W. Characterization of Sheared Edges in Warm Blanking of Magnesium Alloy AZ31B. Materials 2019, 12, 1023. [Google Scholar] [CrossRef]

- Winter, S.; Nestler, M.; Galiev, Ε.; Hartmann, F.J.; Psyk, V.; Kräusel, V.; Dix, M. Adiabatic Blanking: Influence of Clearance, Impact Energy, and Velocity on the Blanked Surface. J. Manuf. Mater. Process. 2021, 5, 35. [Google Scholar] [CrossRef]

- Gotoh, M.; Yamashita, M. A Study of High-Rate Shearing of Commercially Pure Aluminum Sheet. J. Mater. Process. Technol. 2001, 110, 253–264. [Google Scholar] [CrossRef]

- Schmitz, F.; Winter, S.; Clausmeyer, T.; Wagner, M.F.-X.; Tekkaya, A.E. Adiabatic Blanking of Advanced High-Strength Steels. CIRP Ann. 2020, 69, 269–272. [Google Scholar] [CrossRef]

- Gaudillière, C.; Ranc, N.; Larue, A.; Lorong, P. Investigations in High Speed Blanking: Cutting Forces and Microscopic Observations. EPJ Web Conf. 2010, 6, 19003. [Google Scholar] [CrossRef]

- Dodd, B. Shear Instabilities in Blanking and Related Processes. Met. Technol. 1983, 10, 57–60. [Google Scholar] [CrossRef]

- Kolhatkar, A.; Pandey, A. Sheet Metal Shearing Process: An Overview. Trans. Indian Natl. Acad. Eng. 2023, 8, 509–534. [Google Scholar] [CrossRef]

- Subramonian, S.; Altan, T.; Campbell, C.; Ciocirlan, B. Determination of Forces in High Speed Blanking Using FEM and Experiments. J. Mater. Process. Technol. 2013, 213, 2184–2190. [Google Scholar] [CrossRef]

- Bhoir, S.; Dubey, D.; Dongare, M. An Overview of Optimization Techniques Utilized in Sheet Metal Blanking Processes. IJARSCT 2023, 3, 2581–9429. [Google Scholar] [CrossRef]

- Faura, F.; García, A.; Estrems, M. Finite Element Analysis of Optimum Clearance in the Blanking Process. J. Mater. Process. Technol. 1998, 80–81, 121–125. [Google Scholar] [CrossRef]

- Aravind, U.; Chakkingal, U.; Venugopal, P. A Review of Fine Blanking: Influence of Die Design and Process Parameters on Edge Quality. J. Mater. Eng. Perform. 2020, 30, 1–32. [Google Scholar] [CrossRef]

- Sahli, M.; Roizard, X.; Assoul, M.; Colas, G.; Giampiccolo, S.; Barbe, J.P. Finite Element Simulation and Experimental Investigation of the Effect of Clearance on the Forming Quality in the Fine Blanking Process. Microsyst. Technol. 2020, 27, 871–881. [Google Scholar] [CrossRef]

- Quazi, T.Z.; Shaikh, R. An Overview of Clearance Optimization in Sheet Metal Blanking Process. Int. J. Mod. Eng. Res. 2012, 2, 4547–4558. [Google Scholar]

- Barik, J.; Sonkamble, V.; Narasimhan, K. Burr Formation and Shear Strain Field Evolution Studies during Sheet Metal Blanking. IOP Conf. Ser. Mater. Sci. Eng. 2018, 418, 012068. [Google Scholar] [CrossRef]

- Teng, X.; Wierzbicki, T.; Couque, H. On the Transition from Adiabatic Shear Banding to Fracture. Mech. Mater. 2007, 39, 107–125. [Google Scholar] [CrossRef]

- Marouani, H.; Ben Ismail, A.; Hug, E.; Rachik, M. Numerical Investigations on Sheet Metal Blanking with High Speed Deformation. Mater. Des. 2009, 30, 3566–3571. [Google Scholar] [CrossRef]

- Myint, P.W.; Hagihara, S.; Tanaka, T.; Taketomi, S.; Tadano, Y. Application of Finite Element Method to Analyze the Influences of Process Parameters on the Cut Surface in Fine Blanking Processes by Using Clearance-Dependent Critical Fracture Criteria. J. Manuf. Mater. Process. 2018, 2, 26. [Google Scholar] [CrossRef]

- Farzin, M.; Javani, H.R.; Mashayekhi, M.; Hambli, R. Analysis of Blanking Process Using Various Damage Criteria. J. Mater. Process. Technol. 2006, 177, 287–290. [Google Scholar] [CrossRef]

- Yu, S.; Zhao, J. Modeling of Shear Fracture in the Sheet Metal Forming Processes Using FEM Approach. In Engineering Plasticity and Its Applications; Li, J., Li, Z., Feng, X.-T., Lee, W.B., Zhou, H., Eds.; World Scientific: Singapore, 2011; pp. 161–165. [Google Scholar] [CrossRef]

- Hambli, R.; Potiron, A. Finite Element Modeling of Sheet-Metal Blanking Operations with Experimental Verification. J. Mater. Process. Technol. 2000, 102, 257–265. [Google Scholar] [CrossRef]

- Behrens, B.-A.; Peshekhodov, I.; Sidhu, K.B. Numerical Modelling of High Speed Blanking Considering Thermoviscoplastic Effects. In Proceedings of the ICHSF 2008—The 3rd International Conference on High Speed Forming, Eldorado, Dortmund, Germany, 11–12 March 2008; pp. 96–106. [Google Scholar] [CrossRef]

- Krutz, P.; Leonhardt, A.; Graf, A.; Winter, S.; Galiev, E.; Rehm, M.; Kräusel, V.; Dix, M. Design, Numerical and Experimental Testing of a Flexible Test Bench for High-Speed Impact Shear-Cutting with Linear Motors. J. Manuf. Mater. Process. 2023, 7, 173. [Google Scholar] [CrossRef]

- Rittel, D.; Zhang, L.H.; Osovski, S. The dependence of the Taylor-Quinney coefficient on the dynamic loading mode. J. Mech. Phys. Solids 2017, 107, 96–114. [Google Scholar] [CrossRef]

- Azimi, M.B.; Asgari, M.; Salaripoor, H. A New Homo-Polygonal Multi-Cell Structures under Axial and Oblique Impacts; Considering the Effect of Cell Growth in Crashworthiness. Int. J. Crashworthiness 2019, 25, 628–647. [Google Scholar] [CrossRef]

- Medyanik, S.N.; Liu, W.K.; Li, S. On Criteria for Dynamic Adiabatic Shear Band Propagation. J. Mech. Phys. Solids 2007, 55, 1439–1461. [Google Scholar] [CrossRef]

- Espinosa, H.D.; Lee, S.; Moldovan, N. A Novel Fluid Structure Interaction Experiment to Investigate Deformation of Structural Elements Subjected to Impulsive Loading. Exp. Mech. 2006, 46, 805–824. [Google Scholar] [CrossRef]

- Dong, Y.; Ren, Y.; Fan, S.; Wang, Y.; Zhao, S. Investigation of Notch-Induced Precise Splitting of Different Bar Materials under High-Speed Load. Materials 2020, 13, 2461. [Google Scholar] [CrossRef] [PubMed]

- Zener, C.; Hollomon, J.H. Effect of Strain Rate upon Plastic Flow of Steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

| Experimental Method | References | Damage Criterion | References |

|---|---|---|---|

| Optical Microscopy | [2,5,6] | Cockcroft–Latham | [8,14,17,21] |

| Scanning Electron Microscopy | [2,5] | Bao–Wierzbicki | [19] |

| Transmission Electron Microscopy | [3] | Gurson–Tvergaard–Needleman | [20] |

| Electron Backscatter Diffraction | [3] | Oyane | [21] |

| Digital Image Correlation | [4] | Gurson | [22] |

| Goijaerts | [22] | ||

| Brozzo | [23] | ||

| Chaboche–Lemaitre | [24] | ||

| Modified Nodal Release | [25] | ||

| GISSMO | [26] |

| Mechanical and Thermal Properties | Constitutive Relation | Damage Criterion | |||

|---|---|---|---|---|---|

| ρ (kg/m3) | 7900 | A (MPa) | 310 | D1 | 0.53 |

| E (GPa) | 200 | B (MPa) | 1000 | D2 | 0.5 |

| ν (-) | 0.3 | n (-) | 0.65 | D3 | −6.8 |

| Cp (J/kgK) | 440 | C (-) | 0.0515 | D4 | −0.015 |

| a (μm/m °C) | 17.2 | m (-) | 1 | D5 | 0.002 |

| (s−1) | 1 | (s−1) | 1 | Dc | 1 |

| χ (-) | 0.9 | Tm (K) | 1673 | TDRX (K) | 720 |

| Tr (K) | 293 | ||||

| C75S | 20MnB5 | |||

|---|---|---|---|---|

| Experiment | Simulation | Experiment | Simulation | |

| dmax (μm) | 100 | 93 | 85 | 94 |

| Blanked profile shape | S-shape | S-shape | S-shape | S-shape |

| ASB width (μm) | 40 | 44 | 18 | 21 |

| Simulation Case | Description | MJC Damage Criterion | Damage Coupling | DRX Softening | Taylor–Quinney, χ (-) |

|---|---|---|---|---|---|

| I | Full MJC-DC-χ09 | Full 1 | Yes | No | 0.9 |

| II | Full MJC-DUc-χ09 | Full | No | No | 0.9 |

| III | SH-DUc-χ09 | SH | No | No | 0.9 |

| IV | SH/SRH-DUc-χ09 | SH + SRH | No | No | 0.9 |

| V | Full MJC-DC-DRX-χ09 | Full | Yes | Yes | 0.9 |

| VI | Full MJC-DC-χ07 | Full | Yes | No | 0.7 |

| VII | Full MJC-DC-χ05 | Full | Yes | No | 0.5 |

| Study Case | Content | Simulations in Comparison |

|---|---|---|

| 1 | Strain rate/temperature effects | II-III-IV |

| 2 | Damage coupling effect | I-II |

| 3 | DRX effect | I-V |

| 4 | Taylor–Quinney coefficient effect | I-VI-VII |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karantza, K.D.; Papaefthymiou, S.A.; Vaxevanidis, N.M.; Manolakos, D.E. Numerical Investigation of the Damage Effect on the Evolution of Adiabatic Shear Banding and Its Transition to Fracture during High-Speed Blanking of 304 Stainless Steel Sheets. Materials 2024, 17, 1471. https://doi.org/10.3390/ma17071471

Karantza KD, Papaefthymiou SA, Vaxevanidis NM, Manolakos DE. Numerical Investigation of the Damage Effect on the Evolution of Adiabatic Shear Banding and Its Transition to Fracture during High-Speed Blanking of 304 Stainless Steel Sheets. Materials. 2024; 17(7):1471. https://doi.org/10.3390/ma17071471

Chicago/Turabian StyleKarantza, Konstantina D., Spyros A. Papaefthymiou, Nikolaos M. Vaxevanidis, and Dimitrios E. Manolakos. 2024. "Numerical Investigation of the Damage Effect on the Evolution of Adiabatic Shear Banding and Its Transition to Fracture during High-Speed Blanking of 304 Stainless Steel Sheets" Materials 17, no. 7: 1471. https://doi.org/10.3390/ma17071471

APA StyleKarantza, K. D., Papaefthymiou, S. A., Vaxevanidis, N. M., & Manolakos, D. E. (2024). Numerical Investigation of the Damage Effect on the Evolution of Adiabatic Shear Banding and Its Transition to Fracture during High-Speed Blanking of 304 Stainless Steel Sheets. Materials, 17(7), 1471. https://doi.org/10.3390/ma17071471