Abstract

Additives such as nano-silica and fly ash are widely used in cement and concrete materials to improve the rheology of fresh cement and concrete and the performance of hardened materials and increase the sustainability of the cement and concrete industry by reducing the usage of Portland cement. Therefore, it is important to study the effect of these additives on the rheological behavior of fresh cement. In this paper, we study the pulsating Poiseuille flow of fresh cement in a horizontal pipe by considering two different additives and when they are combined (nano-silica, fly ash, combined nano-silica, and fly ash). To model the fresh cement suspension, we used a modified form of the power-law model to demonstrate the dependency of the cement viscosity on the shear rate and volume fraction of cement and the additive particles. The convection–diffusion equation was used to solve for the volume fraction. After solving the equations in the dimensionless forms, we conducted a parametric study to analyze the effects of nano-silica, fly ash, and combined nano-silica and fly ash additives on the velocity and volume fraction profiles of the cement suspension. According to the parametric study presented here, larger nano-silica content results in lower centerline velocity of the cement suspension and larger non-uniformity of the volume fraction. Compared to nano-silica, fly ash exhibits an opposite effect on the velocity. Larger fly ash content results in higher centerline velocity, while the effect of the fly ash on the volume fraction is not obvious. For cement suspension containing combined nano-silica and fly ash additives, nano-silica plays a dominant role in the flow behavior of the suspension. The findings of the study can help the design and operation of the pulsating flow of fresh cement mortars and concrete in the 3D printing industry.

1. Introduction

There is a strong demand to improve the rheological properties of cement and concrete materials including ultra-high performance concrete, high-strength concrete, self-consolidated concrete, and concrete for 3D printing in the industry. The cement and concrete design with improved rheology is important to enhance constructability and workability, facilitate processing and mixing, and enhance in situ material performance [1]. The addition of nano-additives, such as nano-silica, graphene oxide, nano-TiO2, and cellulose nanofibers (CNFs) can significantly modify and improve the rheological properties of cement-based materials; these additives can also affect the yield stress, the plastic viscosity, the rate of structural buildup at rest, the degree of hydration, mechanical properties, and durability [2,3,4,5,6,7]. Various factors including the nanomaterial type, constituent, degree of dispersion, mixing energy, high-range water reducer, sonication, and water-to-cement ratio (w/c) can affect the rheology of fresh cement and concrete. The combined effects of these various factors would be quite complex. Among different nanoparticles used in cement and concrete materials, nano-silica or nano-SiO2 is the most commonly used nano-additive for performance improvement, mainly due to the pozzolanic reactivity and the pore-filling effect [8]. According to Lavergne, et al. [9], nano-silica particles accelerated the hydration of the cement paste and increased the shear strength and early strength significantly because of the specific surface of the nano-silica. Kim, et al. [10] indicated that the addition of nano-silica and silica fume to the high-volume fly ash cement (HVFC) accelerated the initial hydration reaction of HVPC, resulting in a shorter setting time, and higher compressive strength during the initial and middle stages of hydration. The high viscosity of alkali silicate-activated cements has been a big issue that prevents the wide application of this type of material [11]. Fly ash additives have been widely used in cement, concrete, and asphalt industries to improve rheology and workability by decreasing yield stress and viscosity [12,13,14,15,16,17,18]. Fly ash microspheres (FAMs) with highly spherical particles work as ball bearings in fresh cement suspensions by reducing the internal friction between the additives, mitigating the floc agglomeration, and reducing locked water [11]. Wang, et al. [13] concluded that the addition of fly ash increased the fluidity of graphene oxide-cement paste and improved the rheological properties of the cement paste with fly ash and graphene oxide additives. Fly ash plays an economical and effective role in achieving the intended properties of graphene oxide-cement paste because of its ball effect, size gradation, and less water requirement. Golewski [19] illustrated the combined effect of different additives, including siliceous fly ash, silica fume, and nano-silica, which accelerated the hardening of concrete after 28 days of curing and reduced the microcracks in the interfacial transition zone between the aggregates and the cement paste. García-Taengua, et al. [20] investigated the effect of nano-silica and fly ash on the rheology of fresh cement mortars. The study showed that the viscosity reached its maximum at 2% nano-silica content, and larger fly ash content increased the viscosity when used together with the nano-silica additives. In addition, researchers have used various additives such as viscosity modifying agents, superplasticizers, and organic chemical admixtures [21,22,23,24]. In this paper, we are focusing on nano-additives and fly ashes since they have been widely used in cementitious materials and exhibit effectiveness in improving the rheological properties of fresh cement and concrete.

Computational modeling has been considered a useful tool to simulate the behavior of cement and concrete materials [25,26]. Rheological models can provide some necessary information for the fluid behavior of fresh cement slurries [27]. In general, fresh cement slurries are considered to behave as non-Newtonian fluids [28]. In our previous studies [29,30,31], we reviewed the rheological models for fresh cement by considering various effects on viscosity and yield stress, and conducted parametric studies for steady and pulsating Poiseuille flow of fresh cement modeled as non-Newtonian fluids. The study of the pulsating flow of fresh cement materials provides useful information for the 3D-printed cement and concrete industry by considering the vibration/oscillatory effect. Researchers have conducted experimental investigations and summarized the effect of different additives on the viscosity and yield stress of fresh cementitious suspensions. However, most of the existing models of cement suspensions with additives are obtained from experimental data in one-dimensional form. There is a lack of a comprehensive rheological model with three-dimensional (3D) tensor notation where the non-Newtonian nature of the cement suspensions with additives is considered. In addition, there is no constitutive relation that considers the effect and the significance of shear rate, volume fraction, and additives such as nano-silica, fly ashes, and combined additives on the flow of fresh cement suspensions.

In this paper, we look at the pulsating flow of a cement suspension in a pipe with two additives and when they are combined: (1) nano-silica, (2) fly ash, and (3) nano-silica and fly ash. The fresh cement is modeled as a non-Newtonian fluid. We use a modified form of the power-law model to study the dependency of the cement suspension viscosity on the shear rate and volume fraction of the cement and additive particles. The volume fraction of particles is solved through a convection–diffusion equation. In Section 2, the governing equations of motion are presented, assuming no thermal or chemical effects (isothermal conditions). In Section 3, we briefly discuss the constitutive equations for the viscous stress tensor and the diffusive flux vector. In Section 4, we solve for the dimensionless form of the governing equations and provide numerical solutions in the dimensionless form. A limited parametric study is performed for a limited range of different dimensionless numbers. In Section 5, we present a few concluding remarks.

2. Governing Equations

A fresh cement suspension, in general, behaves like a multiphase fluid composed of different materials such as cement particles, water, additives, etc. To model it mathematically, there are many approaches; for example, the multicomponent (Mixture Theory) approach can be used, where there is a two-way coupling between the two phases (constituents). In this approach, the governing equations are written for each component. Consequently, constitutive equations are needed for the stress tensors, along with the interaction forces (see [32,33]). Alternatively, to simplify things, the cement suspension can be assumed to behave like a non-homogeneous fluid suspension with microstructure because of the presence of the cement particles and other added particles. In this approach, the material parameters, such as viscosity, may depend on the particle concentration, also known as the volume fraction of the particles. This approach has been advocated by Tao et al. [34] and we will use the same approach here. For an isothermal case, the governing equations are the balance equations for mass, linear momentum, angular momentum, and the convection–diffusion for the particle flux [35].

2.1. Conservation of Mass

2.2. Conservation of Linear Momentum

2.3. Conservation of Angular Momentum

The angular momentum equation indicates that the stress tensor is symmetric if there are no couple stresses, namely

2.4. Convection–Diffusion Equation

For the motion of the particles, a convection–diffusion equation is used; the particles move with the velocity of the suspension (see [36,37]).

where is the rate of accumulation of particles, represents particle motion due to the bulk flow, and is the diffusive flux.

In addition to the governing equations above, we also need constitutive relations for and . In the next section, we discuss the constitutive relations of the stress tensor and the flux vector .

3. Constitutive Relations

3.1. Stress Tensor

A cement suspension generally behaves as a complex fluid that has a yield stress, and oftentimes exhibits thixotropy, viscoelasticity, etc. For cement suspensions, the formulation of the stress tensor significantly affects the properties and the workability of fresh and hardened materials. It is usually assumed that the stress tensor has two parts: , with being the yield stress and the viscous stress. Tao et al. [29] gave a comprehensive review of the constitutive relations for fresh cement suspensions. Tao et al. [34], based on the model proposed by Massoudi and Phuoc [38], suggested a general constitutive relation [39,40]. In this paper, a simplified version of this model for the viscous stress is used,

where is the pressure (the mean value of the stress tensor), is the identity tensor, and represents the effective shear viscosity (a function of the volume fraction and the shear rate). The tensor is given as

Bridges and Rajagopal [41] used an effective viscosity relationship:

where is assumed to be given by the Batchelor and Green [42]:

where is the viscosity of the base fluid [43]. Equation (8) follows the traditional power-law model, where the viscosity depends on the shear rate. When m < 0, the suspension behaves as a shear-thinning fluid, and when m > 0, it behaves as a shear-thickening one; and is related to the consistency index. There are other correlations for (see Krieger and Dougherty’s model [44]).

By substituting Equations (8) and (9) into (6), the viscous stress tensor is given:

Equation (10) will be used as the starting point of our modeling. We will modify this equation by incorporating the effects of the nano-silica and the fly ash particles. In this paper, we ignore the thixotropic effect and the yield stress [28,45].

3.1.1. Nano-SiO2 Additive

With the emergence of nanotechnology as a new and promising technology, nanomaterials have been introduced to improve the strength of cementitious materials. Nano-SiO2 (NS) particle is one of the most commonly used nanomaterials in cement. In this paper, we use a viscosity relationship that considers the effect of a hydrophilic NS [46]. The mean diameter of the NS is 12 nm, with a specific surface area of 200 m2/g, density of 2.2 g/cm3, pH of 4.5, with a purity greater than 99.8%. The cement suspension used in the model has the following composition: CaO–65.0%, SiO2–21.2%, Al2O3–5.16%, Fe2O3–3.39%, SO3–2.43%, MgO–1.32%, K2O–0.63%, TiO2–0.78%, and Na2O–0.07%.

Equation (10) is now modified to include the effect of NS particles, obtaining the equation suggested by Ouyang et al. [46]. This viscous stress tensor is shown in Equation (11),

where, is the adsorbed water layer thickness for the nanoparticle, is the diameter of nanoparticles, is the ratio of nano-silica particle volume to the total volume of nano-silica suspension.

3.1.2. Fly Ash Additive

Fly ash (FA) is another commonly used additive in cement; it is primarily used to enhance rheology and the workability of cement. Based on the fly ash study by Sybertz and Reick [18], the viscous stress tensor as given in Equation (10) is modified to include the effect of fly ash additive, as shown in Equation (12). The fly ash we consider in this paper has the following properties: density of Fly Ash I–2320 kg/m3, density of Fly Ash II–2380 kg/m3, surface area from Blaine analysis of Fly Ash I is 309 m2/kg, and surface area from Blaine analysis of Fly Ash II is 332 m2/kg. The cement suspension model now has the following form:

where, is the fly ash content and (n = 1, 2, 3, 4) are the parameters from experimental fitting, where = 2.31 (Fly Ash I) and 4.75 (Fly Ash II), = 20.7 (Fly Ash I) and 19.1 (Fly Ash II), = 7.96 (Fly Ash I) and 1.29 (Fly Ash II), and = 17 (Fly Ash I) and 18.9 (Fly Ash II) [18].

3.1.3. Combined Nano-SiO2 and Fly Ash Additives

Considering that both the nano-SiO2 particles and fly ash particles are added to the cement suspension, the viscous stress tensor for the NSFA-added case is shown in Equation (13),

where the meaning of the parameters is as described previously. We use these three stress tensor equations in our analysis.

3.2. Particle Flux

In our earlier paper, we used a correlation based on the work of Philips et al. [47]. Here, we assume that is given by [41]:

where is the diffusion coefficient or the diffusivity, and is the gradient operator. We also assume that D has two parts: a shear-rate-dependent part and a concentration-dependent part:

For , we have [41]:

where is a constant, and is the trace-norm, where for the one-dimensional flow of a suspension in a pipe. For , based on [48], we use the relation suggested by [42,49], where for a dense suspension:

where is a constant. Substituting Equations (16) and (17) in Equation (14), we have the following:

We use Equation (18) in this paper.

4. Results and Discussion

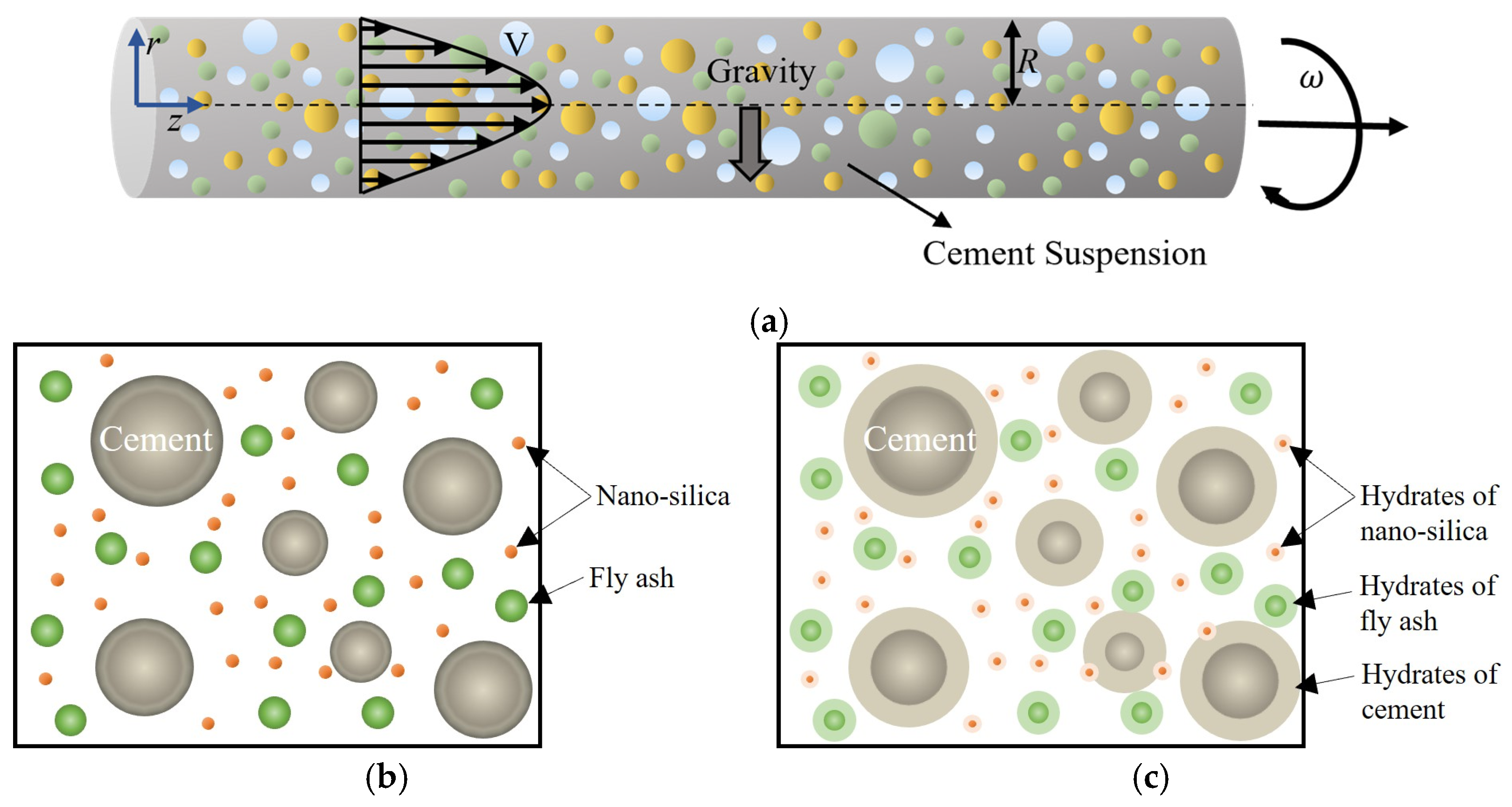

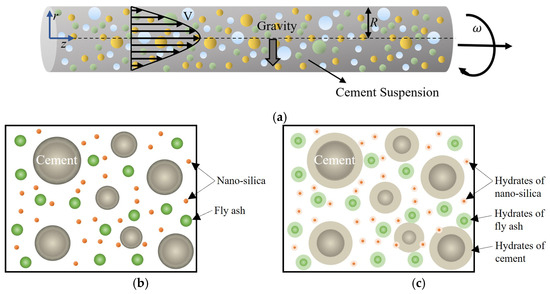

Here, we study the pulsating flow of a cement suspension in a horizontal pipe. Figure 1 shows the schematic of the horizontal pipe flow of cement suspension with nano-silica and fly ash additives.

Figure 1.

(a) Schematic of the horizontal pipe flow of cement suspension; (b) cement suspension with nano-silica and fly ash additives; (c) hydration of cement, nano-silica, and fly ash.

4.1. Problem Statement

We assume that the velocity and the volume fraction fields can be expressed as follows:

Indicating that an unsteady flow is in the z-direction, where the velocity and the volume fraction depend on time and the radius. With the assumptions above, Equation (1) is satisfied.

By substituting the constitutive Equations (11)–(13) into the governing Equation (3), the linear momentum equations are reduced to (using the cylindrical coordinate system)

When NS particles are added to the cement suspension, becomes

When FA particles are added to the cement suspension, becomes

And, when both NS and FA particles are added to the cement suspension, becomes

Equations (20) and (21) show the variation of the pressure in the r- and -directions, respectively. To look at the effects of the pressure, based on previous studies, it is assumed that the axial pressure gradient is expressed as follows [41]:

where and are constants and is the pulsating frequency. By substituting Equation (26) into (22), we have

By substituting Equation (15) into the convection–diffusion Equation (5), we obtain

The above-coupled equations need to be solved numerically. Before solving Equations (27) and (28), we will obtain their dimensionless forms by non-dimensionalizing the equations through:

where R is a reference length (the radius) and V is a reference velocity. The dimensionless forms of Equations (27) and (28) become

where

where is the Reynolds number, the ratio of the forces due to inertia to the viscous effects, is related to the shear rate, P to the pulsation pressure, is related to the gravity term, to the cement suspension diffusivity and the volume fraction, is related to the terms in the pulsating pressure, and represents the ratio of the two densities.

In Equation (30), when NS particles are added to the cement suspension, . And, when FA particles are added to the cement suspension, . When NS and FA particles are added to the cement suspension, .

From the above equations, it is obvious that two boundary conditions are needed for the velocity and two for the volume fraction. Initial conditions also need to be specified for and

4.2. Boundary and Initial Conditions

We impose the no-slip boundary condition and we use the symmetry condition as indicated in Equation (33).

For the volume fraction , an average value is assumed, [34], where

For the initial conditions, based on [41], we apply a uniform value for the velocity at t = 0 and impose a parabolic profile for the volume fraction [41].

According to Equation (35), this initial concentration near the centerline is smaller than the concentration of the particles at the wall. We carried out some tests for a uniform volume fraction profile at t = 0 and we did not notice any noticeable deviation from the suggested equation given in Equation (35).

Also, the flow rate or the flow output is defined as,

4.3. Numerical Results and Discussion

MATLAB (R2022a) pdepe is a function that is used to solve initial-boundary value problems for time-dependent partial differential equations (PDEs) that describe various physical phenomena. This solver is particularly useful for problems with one spatial dimension and time evolution. The above dimensionless partial differential equations are solved using the MATLAB pdepe solver for one spatial variable and time . The step size is the default value used in the solver. In this section, we will present the results for the velocity and volume fraction profiles for a limited range of dimensionless numbers. In this paper, we focus on the effects of (the ratio of nano-silica particle volume to the total volume of nano-silica) and (the fly ash content); by varying these parameters, we look at the effects on the velocity and the volume fraction fields. In this section, a parametric study is performed to investigate the effect of different volume fractions of the additives at different time cycles on the behavior of fresh cement suspension. Table 1 shows the values of the volume fraction of the additives and the dimensionless parameters.

Table 1.

Values of the dimensionless parameters.

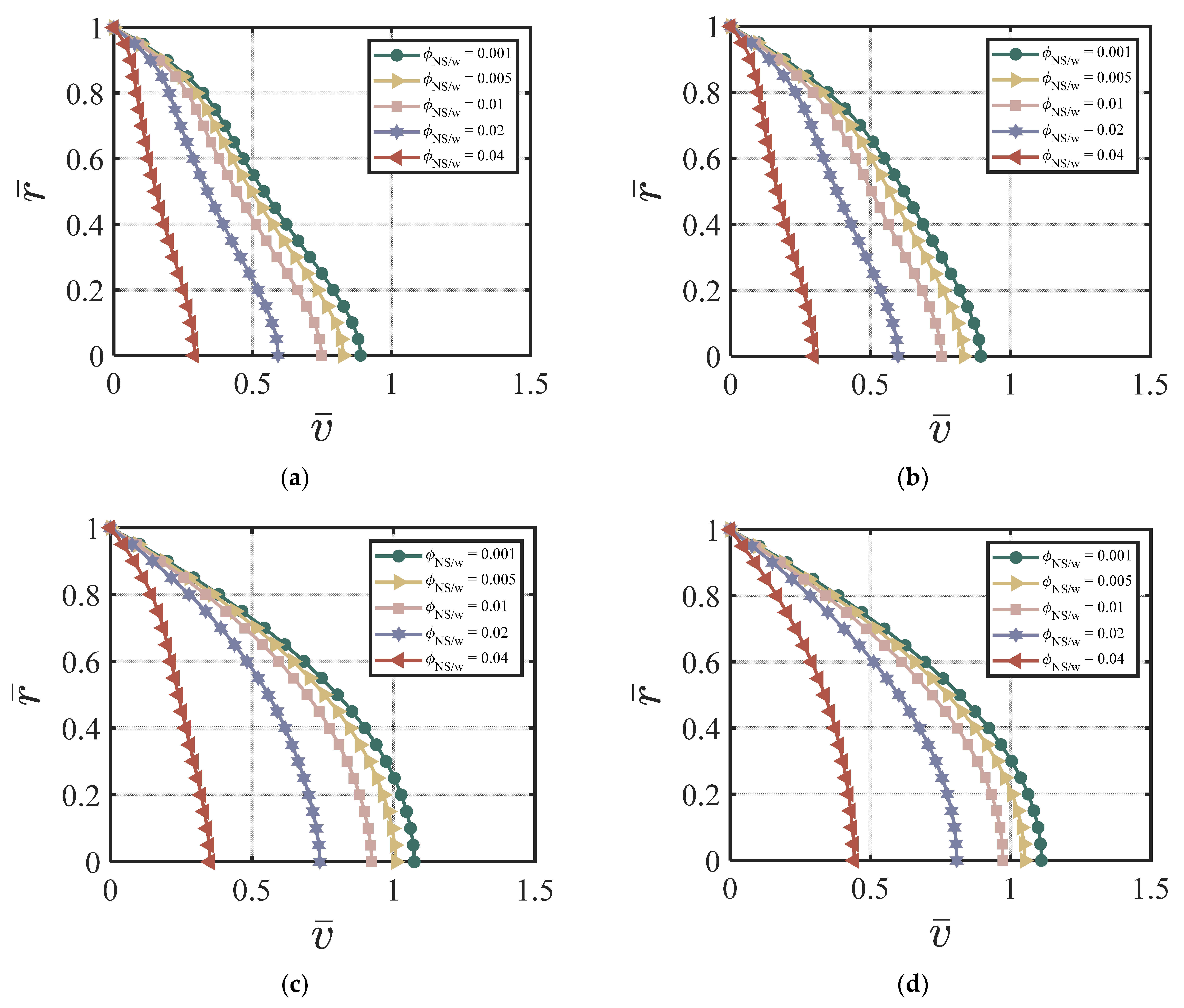

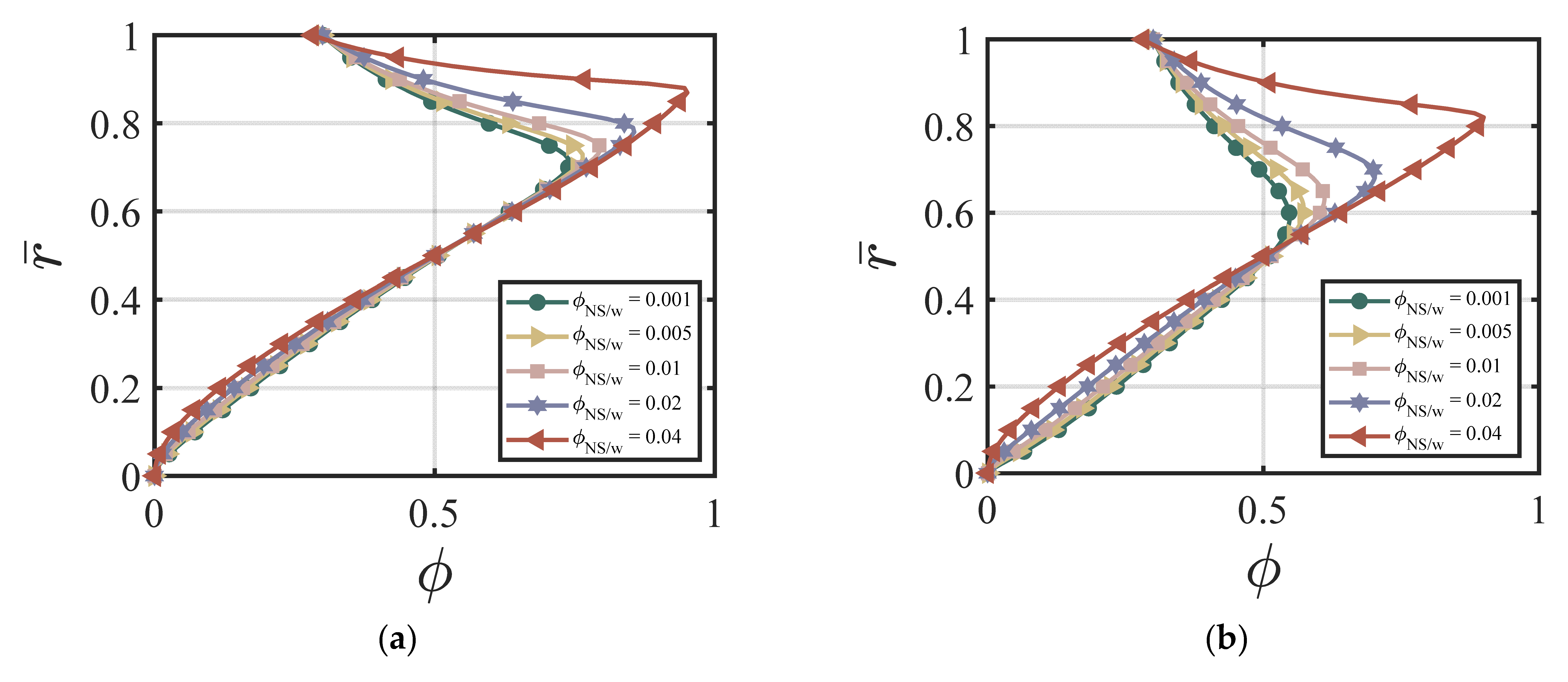

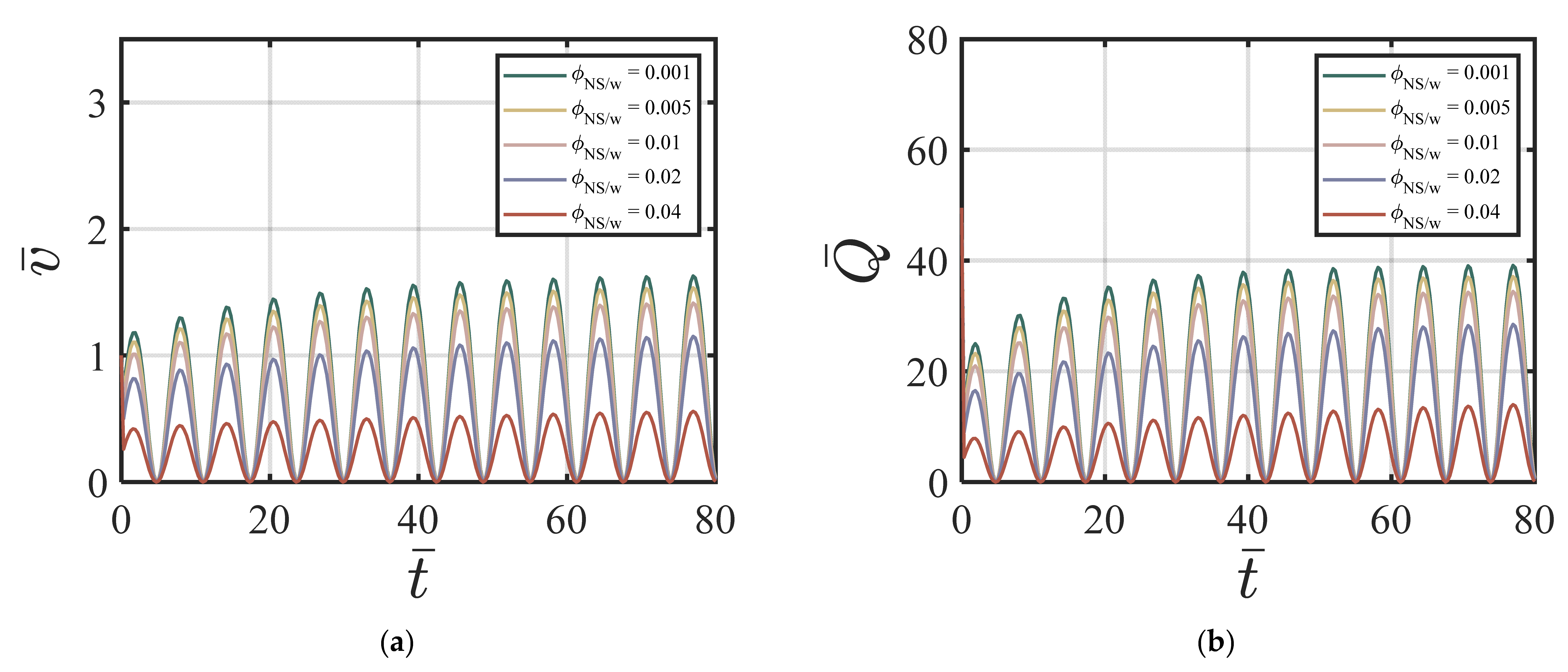

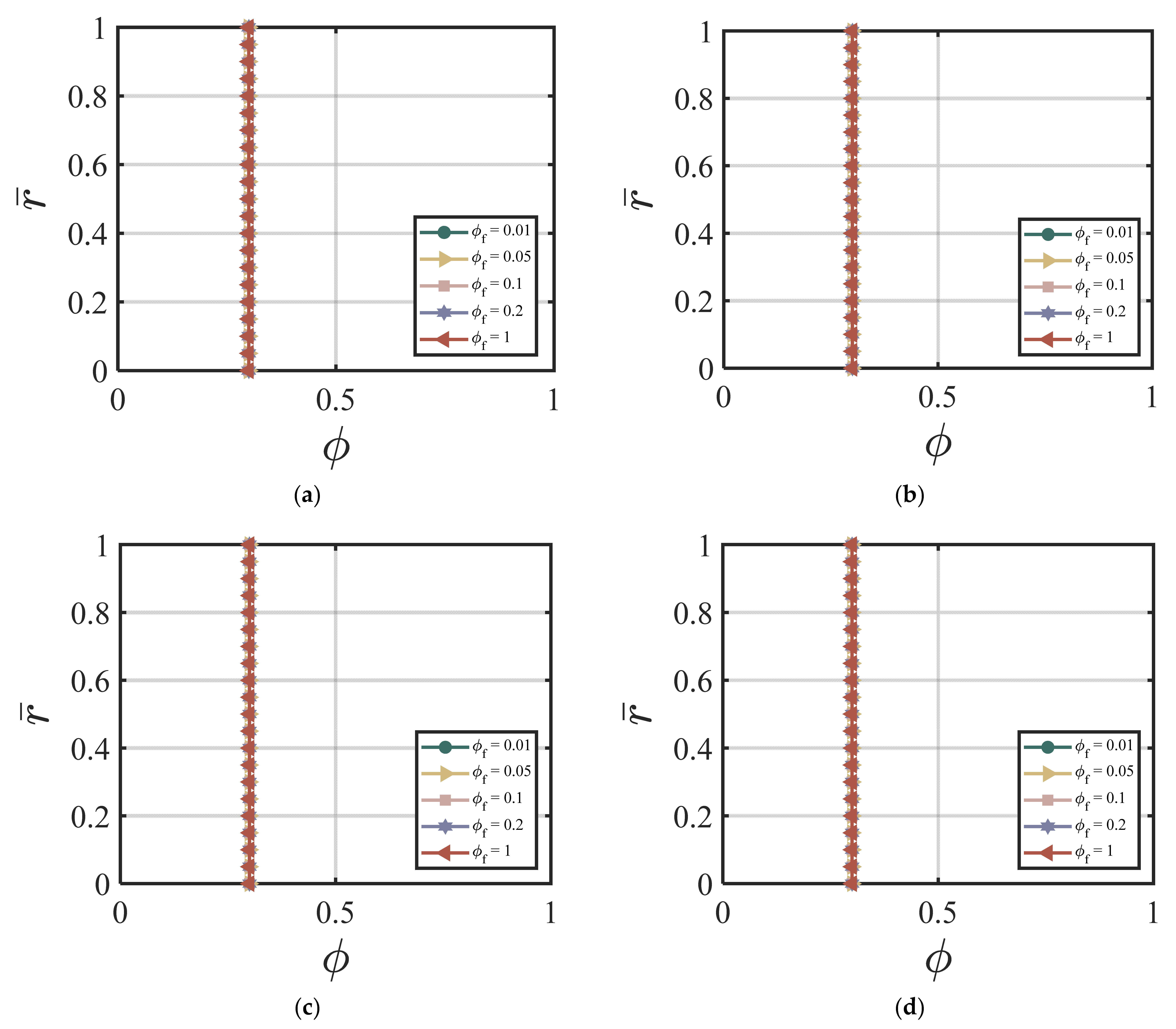

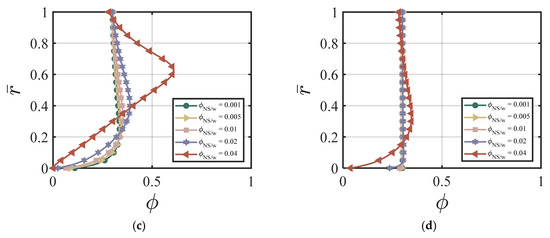

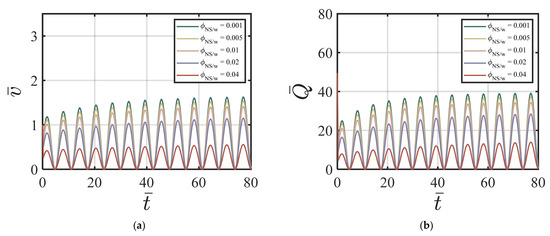

4.3.1. NS-Added Particles to the Cement Suspension

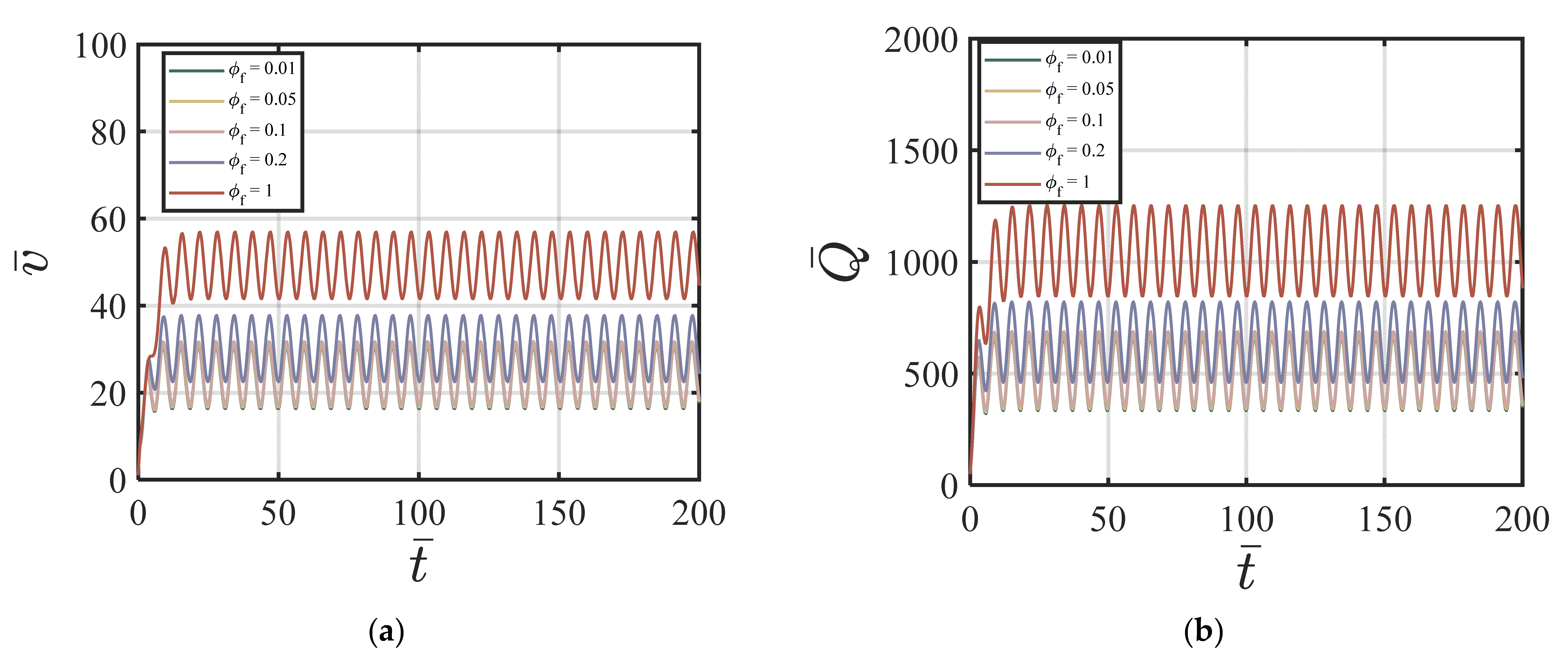

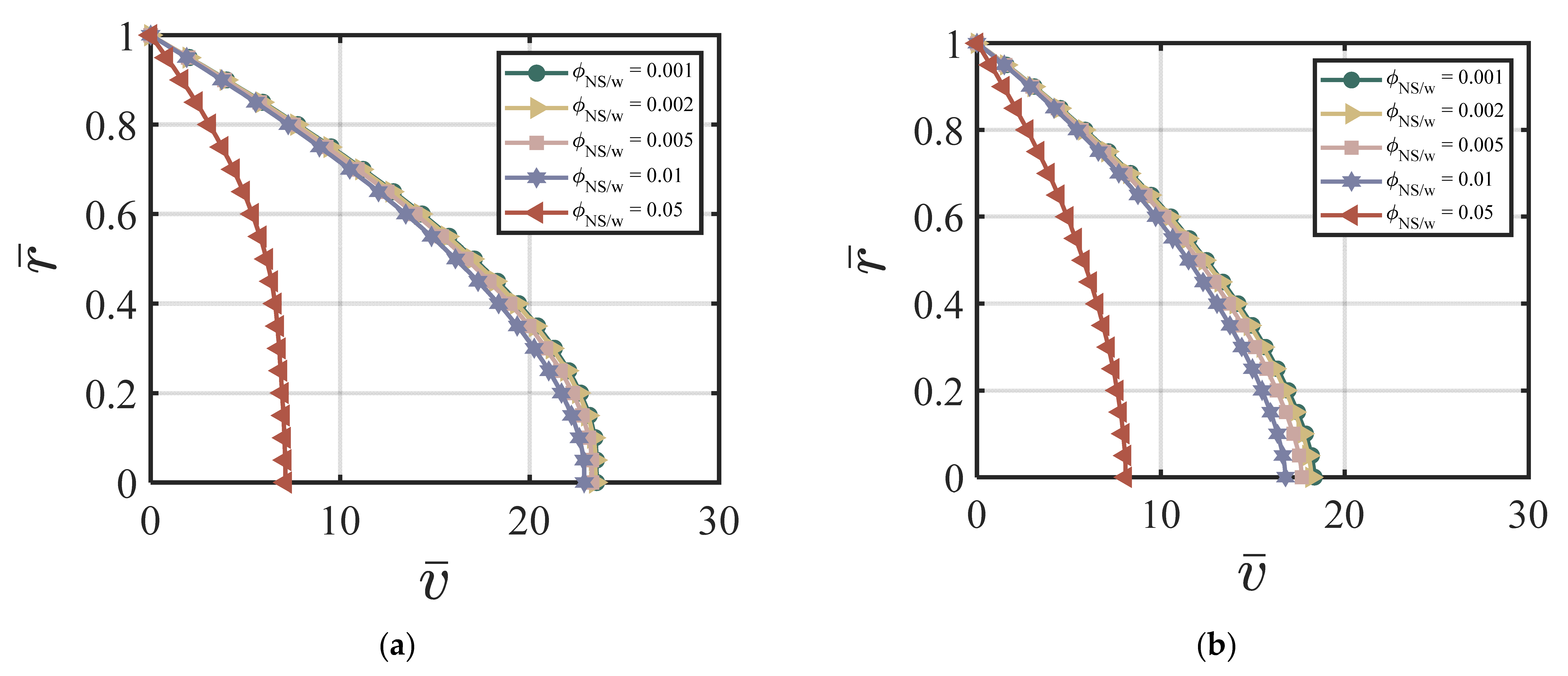

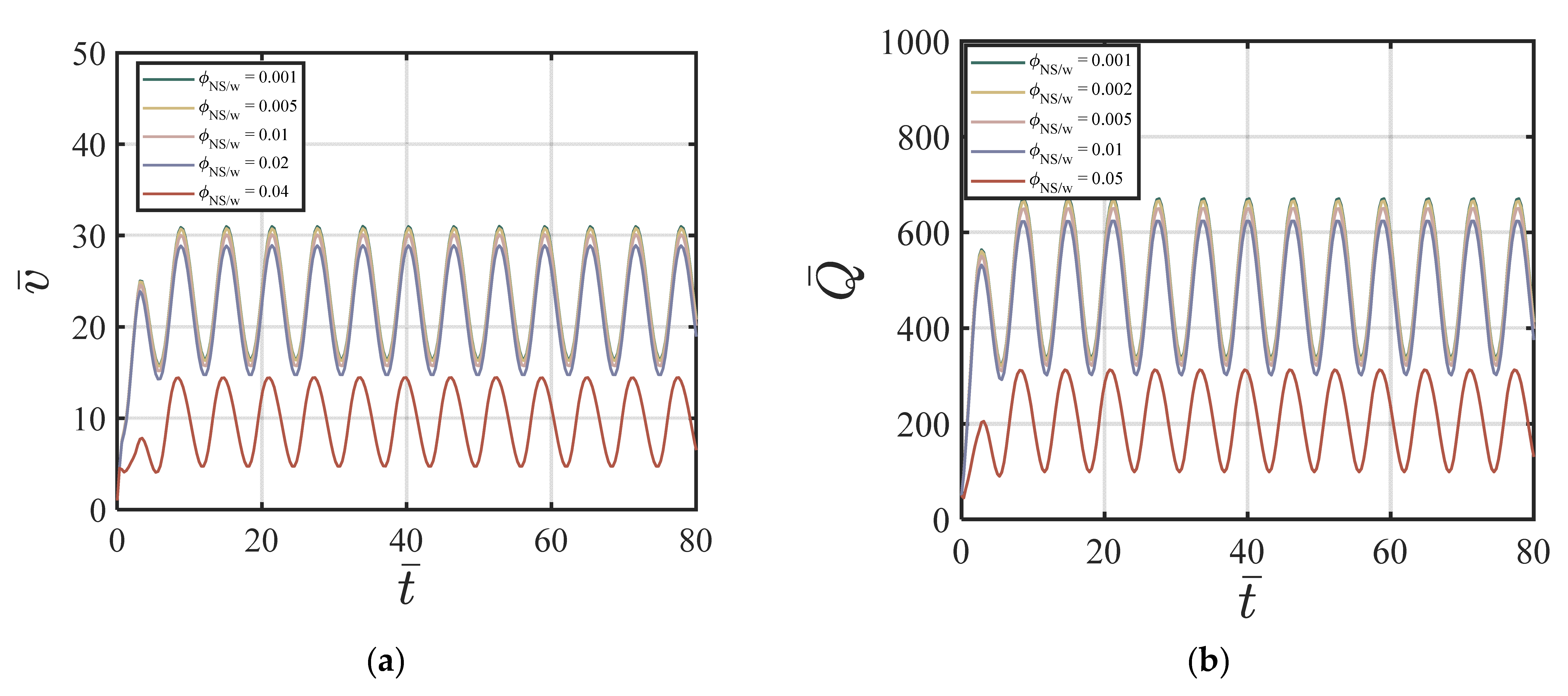

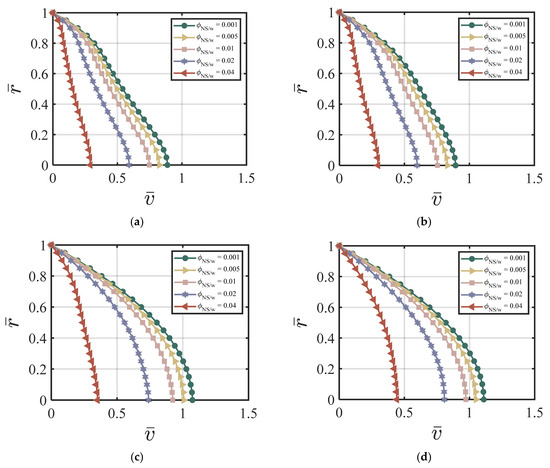

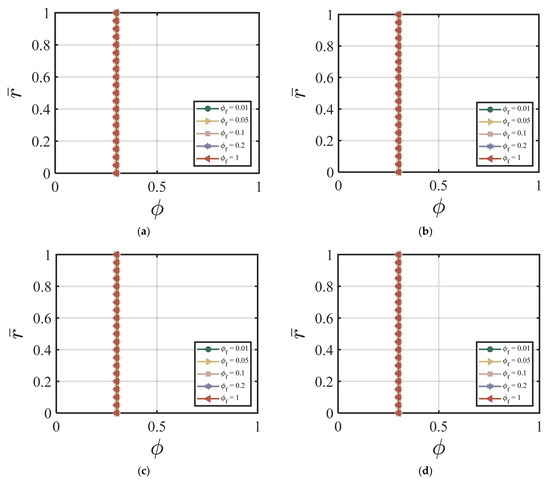

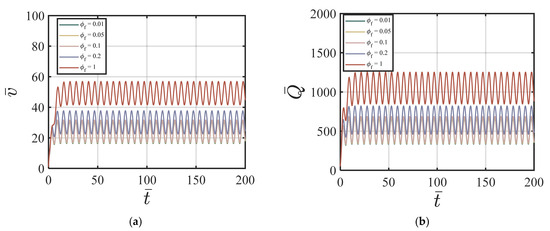

In this section, we demonstrate the effect of nano-silica content on the velocity and the cement volume fraction. As an example, we chose the following dimensionless values for our numerical simulations: , k = 6.5, χ = 3.15, ζ = 1, m = 0.5, Re = 100, P = 10, = 0, κ = 0.001. Figure 2a–d show the effects of different on the velocity at four different time cycles (cycle #2, #10, #50, and #220). According to Figure 2a–d, larger values produce a lower centerline velocity. The velocity profile reaches a steady state and does not change much after 50 time cycles. Figure 3a–d show the effects of different on the cement volume fraction at four different time cycles (cycle #2, #10, #50, and #220). The results show that higher values of results in larger non-uniformity of the volume fraction, especially at the early stages. The volume fraction profiles reach a steady state after 220 time cycles. Figure 4a,b show the effects of on the velocity versus time cycle and the flow rate versus time cycle. The fresh cement suspension with higher nano-silica content reaches the steady state condition faster than those with lower nano-silica content. The results align well with the findings in the literature [9,50,51,52,53] for the effect of nano-silica additives on the early-stage performance of fresh cement suspension. According to Lavergne, et al. [9] and Kim, et al. [10], nano-silica particles accelerated the initial hydration reaction of the cement suspension and increased the shear strength and the early strength significantly because of the specific surface of the nanoparticles, leading to a shorter time of set and a higher compressive early strength.

Figure 2.

Effect of on the velocity at (a) cycle #2; (b) cycle #10; (c) cycle #50; (d) cycle #220 with , k = 6.5, χ = 3.15, ζ = 1, m = 0.5, Re = 100, P = 10, = 0, κ = 0.001.

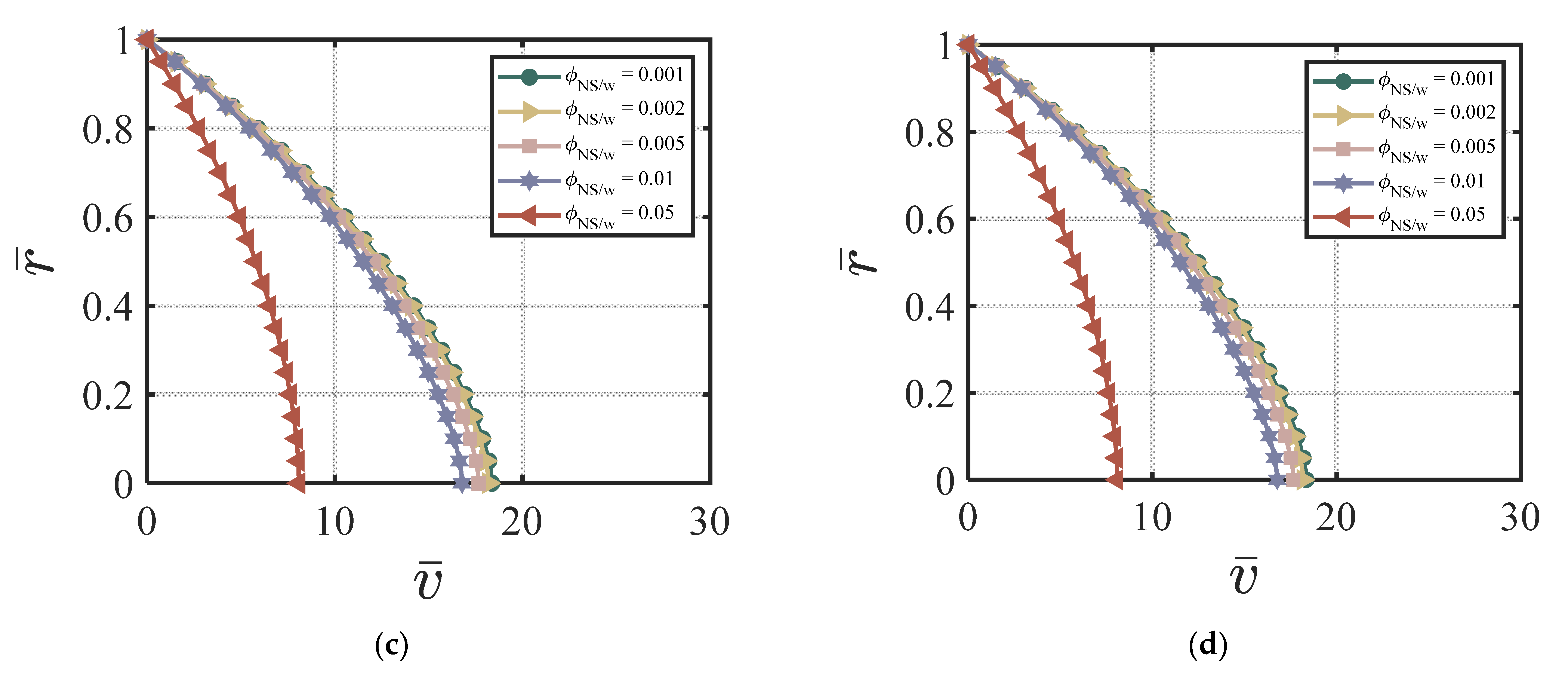

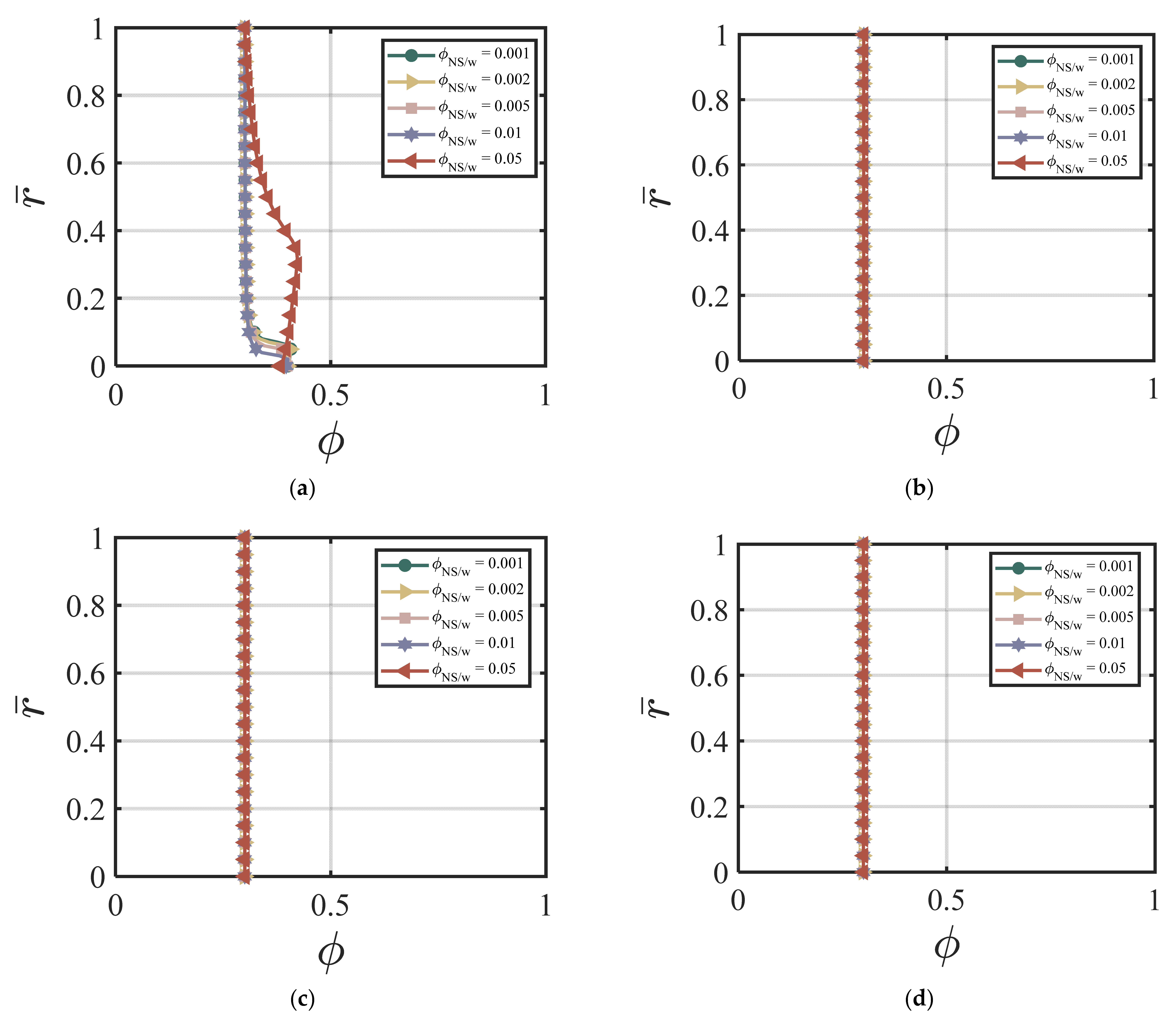

Figure 3.

Effect of on the volume fraction at (a) cycle #2; (b) cycle #10; (c) cycle #50; (d) cycle #220 with , k = 6.5, χ = 3.15, ζ = 1, m = 0.5, Re = 100, P = 10, = 0, κ = 0.001.

Figure 4.

Effect of on (a) vs. t; (b) vs. t with , k = 6.5, χ = 3.15, ζ = 1, m = 0.5, Re = 100, P = 10, = 0, κ = 0.001.

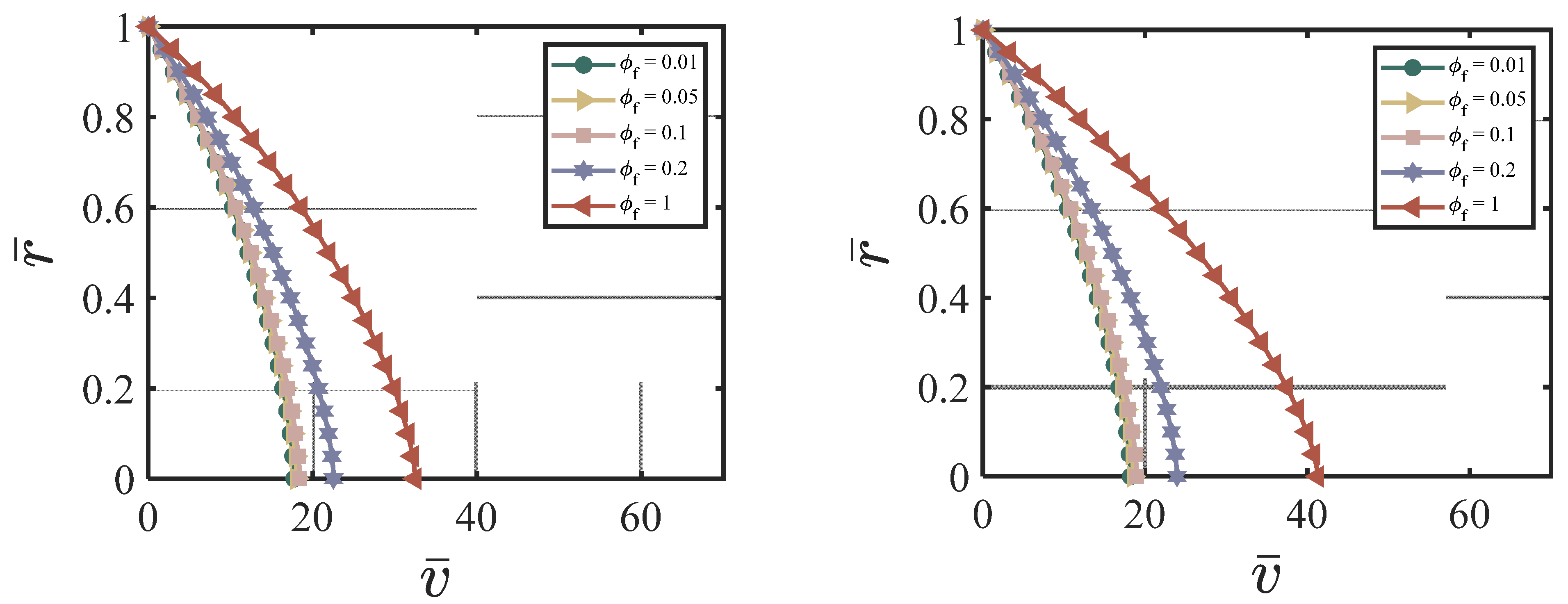

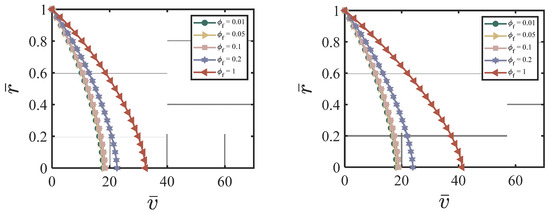

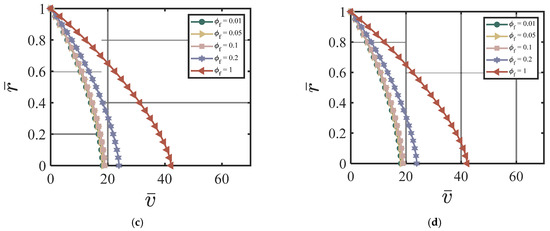

4.3.2. FA-Added Particles to the Cement Suspension

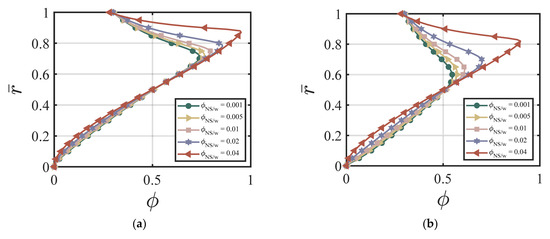

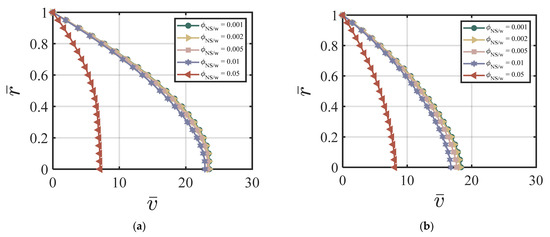

Here, we use the following values for our numerical simulations: , , , , , χ = 3.15, ζ = 1, m = 0.5, Re = 100, P = 10, = 0, κ = 0.001. Figure 5a–d show the effects of different values of on the velocity and the volume fraction at four different time cycles #5, #10, #50, and #200. According to Figure 5a–d, a higher value causes a higher centerline velocity, which exhibits an opposite trend compared to the nano-silica additives in Figure 2a–d. The velocity profile reaches a steady state after 20 time cycles. Figure 6a–d show the effects of different values of on the volume fraction at four different time cycle #5, #10, #50, and #200. The effect of the fly ash particles on the volume fraction is not that obvious. And, the volume fraction field reaches its steady state value very fast (within 5 time cycles). Figure 7a,b show the effects of on the velocity versus time cycle and the flow rate versus time cycle. In contrast to the cement suspension with nano-silica additives, the cement suspension with lower fly ash content reaches the steady state condition faster than those with higher fly ash content. The behavior agrees with the findings by Wang, et al. [50], who indicated that the effect of nano-silica on cement hydration and performance happened in the early stages while high content of fly ash contributed to the strength growth in the later stages. The cement suspension with higher nano-silica content reaches the steady state condition faster than those with lower nano-silica content. In addition, the findings align well with the study by García-Taengua, et al. [20], who indicated that fly ash affected the viscosity only when used together with nano-silica additives, and the fly ash did not affect the dormant period of cement hydration.

Figure 5.

Effect of on the velocity at (a) cycle #5; (b) cycle #10; (c) cycle #50; (d) cycle #200 with , , , , , χ = 3.15, ζ = 1, m = 0.5, Re = 100, P = 10, = 0, κ = 0.001.

Figure 6.

Effect of on the volume fraction at (a) cycle #5; (b) cycle #10; (c) cycle #50; (d) cycle #200 with , , , , , χ = 3.15, ζ = 1, m = 0.5, Re = 100, P = 10, = 0, κ = 0.001.

Figure 7.

Effect of on (a) vs. t; (b) vs. t with , , , , , χ = 3.15, ζ = 1, m = 0.5, Re = 100, P = 10, = 0, κ = 0.001.

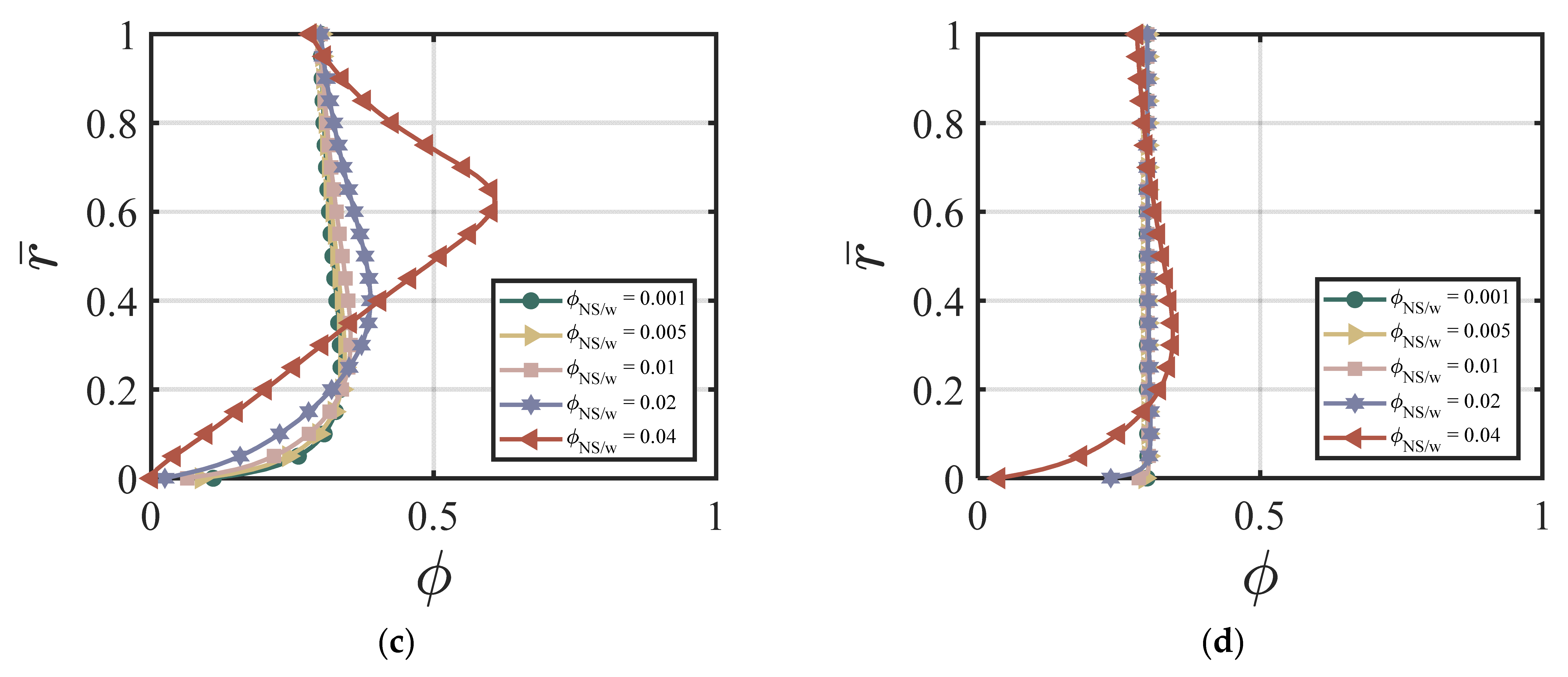

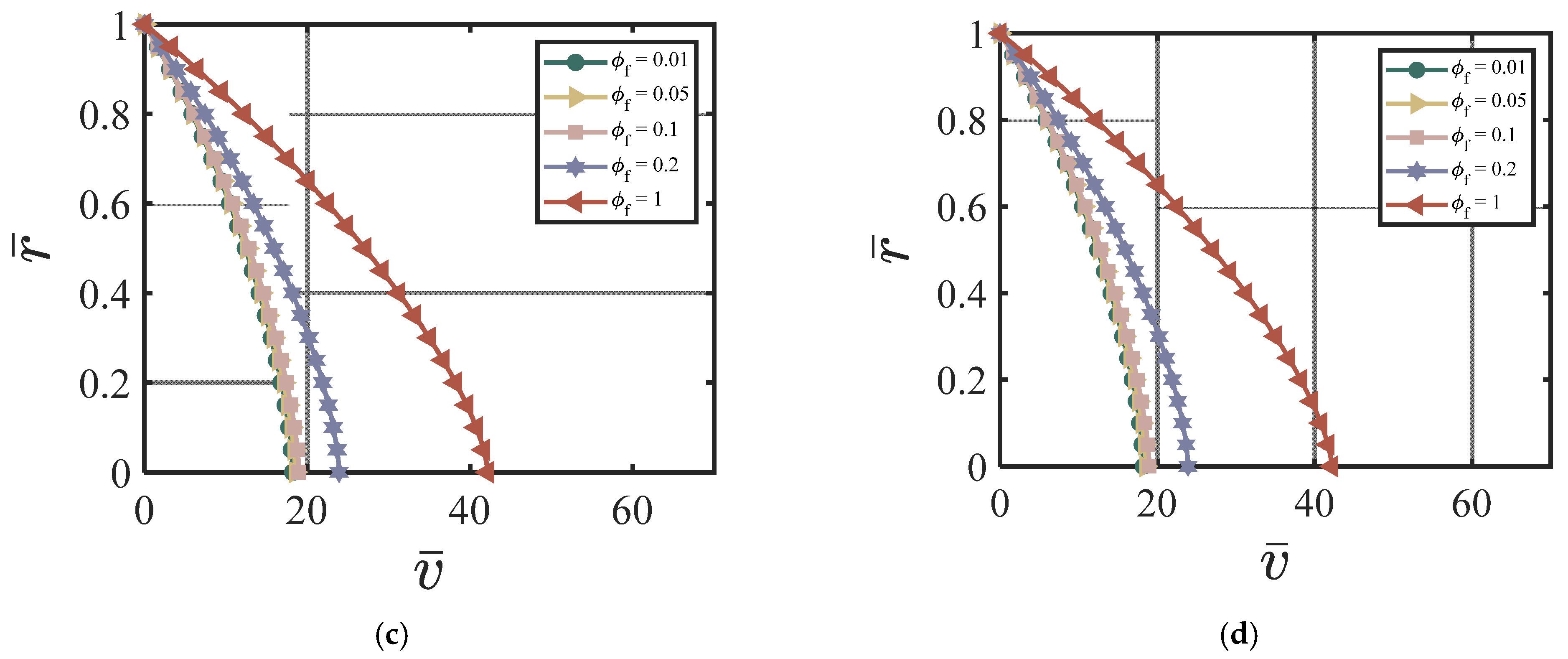

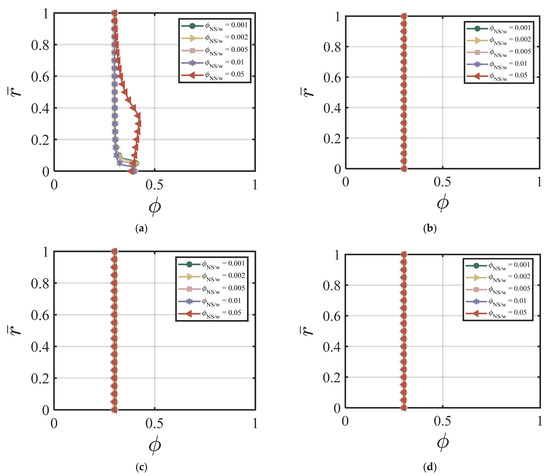

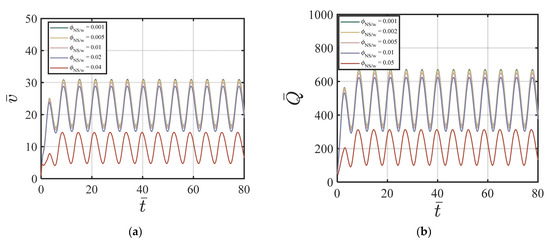

4.3.3. Combined NS and FA-Added Particles to the Cement Suspension

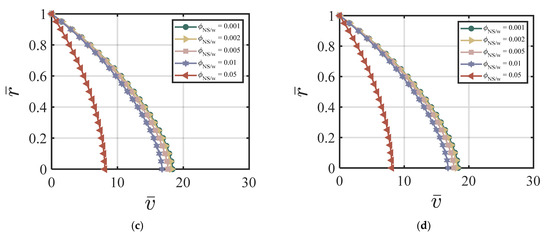

Here, we use the following values for our numerical simulations: , , , , , χ = 3.15, ζ = 1, m = 0.5, Re = 100, P = 10, = 0, κ = 0.001. Figure 8a–d show the effects of on the velocity of the cement suspension with combined nano-silica and fly ash additives at four different time cycles # 2, #10, #50, and #200. From Figure 8a–d, the effect of different values of on velocity is similar to the NS-added cement suspension case. Larger values cause smaller centerline velocity and with the increasing time cycle value, the velocity field does not change much. Figure 9a–d show the effects of on the volume fraction of cement suspension with combined additives at four different time cycles #2, #10, #50, and #200. The volume fraction becomes more uniform in the early time cycle (#10). As shown in Figure 9a–d, after the time cycle 10, the volume fraction profile becomes uniform. Figure 10a,b show the effects of of the cement suspension with combined additives on the velocity and flow rate versus time. According to Figure 8a–d and Figure 10a,b, the dominance of nano-silica is also exhibited with a similar trend in Section 4.3.1. For the case of combined nano-silica and fly ash particles, we find that the nano-silica particles play a dominant effect, where the velocity and the volume fraction fields show similar trends to the case of only nano-silica-added cement suspension. The finding is validated by Wang et al. [50], that nano-silica particles enhance hydration in early stages and provide favorable hydration conditions for fly ash in later stages. García-Taengua, et al. [20] also showed that fly ash did not affect the dormant period of hydration, while the addition of nano-silica shortened the cement hydrate phase. In addition, the synergistic effect of the two additives increases non-evaporative water content and improves pozzolanic activity. Similar findings are found by Kim, et al. [10], indicating the dominant effect of nano-silica added to high-volume fly ash cement composites, resulting in shorter setting time, higher initial and middle stages of hydration rate, and higher compressive strength.

Figure 8.

Effect of of the combined NS FA-added cement suspension on velocity at (a) cycle #2; (b) cycle #10; (c) cycle #50; (d) cycle #200 with , k = 6.5, , , , , χ = 3.15, ζ = 1, m = 0.5, Re = 100, P = 10, = 0, κ = 0.001.

Figure 9.

Effect of of the combined NS FA-added cement suspension on volume fraction at (a) cycle #2; (b) cycle #10; (c) cycle #50; (d) cycle #200 with , k = 6.5, , , , , χ = 3.15, ζ = 1, m = 0.5, Re = 100, P = 10, = 0, κ = 0.001.

Figure 10.

Effect of of the combined NS FA-added cement suspension on (a) vs. t; (b) vs. t with , k = 6.5, , , , , χ = 3.15, ζ = 1, m = 0.5, Re = 100, P = 10, = 0, κ = 0.001.

5. Conclusions

In this paper, we look at the flow of a fresh cement suspension in a pipe where two different additives and when they are combined are added to the cement suspension: (1) nano-silica, (2) fly ash, and (3) nano-silica and fly ash. The main findings of the paper are as follows:

- The cement suspension is modeled as a non-Newtonian fluid, where a modified form of the power-law model is used to study the dependency of the cement suspension viscosity on the shear rate and the volume fraction. The governing equations are made dimensionless, and a limited parametric study is performed for the different dimensionless numbers and parameters.

- For the parametric study, we focused on the effects of (the ratio of NS particle volume to the total volume of nano-silica), (the fly ash content), and the combined two additives; by varying these parameters, we looked at their effects on the velocity and the volume fraction fields.

- Based on the limited numerical simulations, the results indicate that the velocity and the volume fraction profiles are affected by the addition of different additives. For the pulsating flow of a cement suspension with various additives, we can see that larger values of nano-silica particles can cause a smaller centerline velocity and a higher non-uniformity of the volume fraction field. In contrast to nano-silica particles, larger values of fly ash cause a higher centerline velocity. The effect of fly ash content on the volume fraction is not that obvious.

- It can also be seen that the fresh cement suspensions with smaller values of nano-silica reach the steady state conditions faster, while the cement suspension with added fly ash particles reaches the steady state very fast.

- For the case of combined nano-silica and fly ash particles, the nano-silica plays a dominant effect, where the velocity and the volume fraction fields show similar trends to the case of nano-silica-added cement suspension.

These findings can help the design and operation of the pulsating flow of fresh cement mortars and concrete in the 3D printing industry. For future studies, we will do a more systematic parametric study by changing the dimensionless numbers. We will also consider the effect of other factors such as the type of nanoparticles, dispersion of the additives, water-to-cement ratio, particle size and shape, temperature, and the direction of flow on the behavior of fresh cement suspension. In addition, we plan to conduct rheological testing in the laboratory by measuring the viscosity and the yield stress of fresh cement suspensions with various additives under different conditions to check the applicability of the modeling results.

Author Contributions

C.T. performed most of the derivations and all the numerical simulations, and M.M. developed the framework of the paper. Both authors contributed to the writing of the paper. All authors have read and agreed to the published version of the manuscript.

Funding

Funding for this work (performed by C.T.) was provided by the ACI Foundation (ACIF) Program under its Concrete Research Council (CRC) through Grant No. P0068, the National Science Foundation (NSF) I-Corps through Grant No. TI-2243641, and the faculty start-up funding from the School of Construction Management Technology at Purdue University. The findings and opinions expressed in this article are those of the authors only and do not necessarily reflect the views of the sponsors.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| Symbol | Explanation |

| Density | |

| Acceleration due to gravity | |

| Radius of the horizontal pipe | |

| Reference velocity | |

| Particle radius | |

| Adsorbed water layer thickness for the nanoparticle | |

| Radius of nanoparticles | |

| Time | |

| Diffusion coefficient | |

| Cement suspension diffusivity parameter | |

| Diffusion coefficient | |

| Volume fraction-dependent diffusion coefficient | |

| Constant in volume fraction-dependent diffusion coefficient | |

| Local shear rate | |

| Volume fraction of particles | |

| Volume fraction of nano-silica particles | |

| Volume fraction of fly ash | |

| Experimental fitting parameters for different types of fly ash | |

| Capillary pore in cement suspension | |

| Viscosity | |

| Coefficient of viscosity | |

| Effective viscosity | |

| Concentration-dependent viscosity | |

| Additive concentration-dependent viscosity | |

| Experimental (fitting) parameter for viscosity | |

| Maximum particle concentration | |

| Average volume fraction | |

| Pressure | |

| , | Material parameters |

| Reynolds number | |

| Dimensionless numbers | |

| Velocity vector | |

| Body force vector | |

| Particle transport flux | |

| Cauchy stress tensor | |

| Yield stress tensor | |

| Viscous stress tensor | |

| Identity tensor | |

| Gradient of the velocity vector | |

| n-th order Rivlin–Ericksen tensor | |

| Gradient symbol | |

| Divergence operator |

References

- Khayat, K.H.; Meng, W.; Vallurupalli, K.; Teng, L. Rheological properties of ultra-high-performance concrete—An overview. Cem. Concr. Res. 2019, 124, 105828. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Mechanical properties of ultra-high-performance concrete enhanced with graphite nanoplatelets and carbon nanofibers. Compos. Part B Eng. 2016, 107, 113–122. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Effect of graphite nanoplatelets and carbon nanofibers on rheology, hydration, shrinkage, mechanical properties, and microstructure of UHPC. Cem. Concr. Res. 2018, 105, 64–71. [Google Scholar] [CrossRef]

- Wu, Z.; Khayat, K.H.; Shi, C.; Tutikian, B.F.; Chen, Q. Mechanisms underlying the strength enhancement of UHPC modified with nano-SiO2 and nano-CaCO3. Cem. Concr. Compos. 2021, 119, 103992. [Google Scholar] [CrossRef]

- Ghafari, E.; Costa, H.; Júlio, E. Critical review on eco-efficient ultra high performance concrete enhanced with nano-materials. Constr. Build. Mater. 2015, 101, 201–208. [Google Scholar] [CrossRef]

- Praveenkumar, T.R.; Vijayalakshmi, M.M.; Meddah, M.S. Strengths and durability performances of blended cement concrete with TiO2 nanoparticles and rice husk ash. Constr. Build. Mater. 2019, 217, 343–351. [Google Scholar] [CrossRef]

- Long, G.; Li, Y.; Ma, C.; Xie, Y.; Shi, Y. Hydration kinetics of cement incorporating different nanoparticles at elevated temperatures. Thermochim. Acta 2018, 664, 108–117. [Google Scholar] [CrossRef]

- Aggarwal, P.; Singh, R.P.; Aggarwal, Y. Use of nano-silica in cement based materials—A review. Cogent Eng. 2015, 2, 1078018. [Google Scholar] [CrossRef]

- Lavergne, F.; Belhadi, R.; Carriat, J.; Fraj, A.B. Effect of nano-silica particles on the hydration, the rheology and the strength development of a blended cement paste. Cem. Concr. Compos. 2019, 95, 42–55. [Google Scholar] [CrossRef]

- Kim, B.-J.; Lee, G.-W.; Choi, Y.-C. Hydration and mechanical properties of high-volume fly ash concrete with nano-silica and silica fume. Materials 2022, 15, 6599. [Google Scholar] [CrossRef]

- Yang, T.; Zhu, H.; Zhang, Z.; Gao, X.; Zhang, C.; Wu, Q. Effect of fly ash microsphere on the rheology and microstructure of alkali-activated fly ash/slag pastes. Cem. Concr. Res. 2018, 109, 198–207. [Google Scholar] [CrossRef]

- Jiang, D.; Li, X.; Lv, Y.; Zhou, M.; He, C.; Jiang, W.; Liu, Z.; Li, C. Utilization of limestone powder and fly ash in blended cement: Rheology, strength and hydration characteristics. Constr. Build. Mater. 2020, 232, 117228. [Google Scholar] [CrossRef]

- Wang, Q.; Cui, X.; Wang, J.; Li, S.; Lv, C.; Dong, Y. Effect of fly ash on rheological properties of graphene oxide cement paste. Constr. Build. Mater. 2017, 138, 35–44. [Google Scholar] [CrossRef]

- Szostak, B.; Golewski, G.L. Rheology of cement pastes with siliceous fly ash and the CSH nano-admixture. Materials 2021, 14, 3640. [Google Scholar] [CrossRef] [PubMed]

- Sobolev, K.; Vivian, I.F.; Saha, R.; Wasiuddin, N.M.; Saltibus, N.E. The effect of fly ash on the rheological properties of bituminous materials. Fuel 2014, 116, 471–477. [Google Scholar] [CrossRef]

- Laskar, A.I.; Talukdar, S. Rheological behavior of high performance concrete with mineral admixtures and their blending. Constr. Build. Mater. 2008, 22, 2345–2354. [Google Scholar] [CrossRef]

- Provis, J.L.; Duxson, P.; van Deventer, J.S.J. The role of particle technology in developing sustainable construction materials. Adv. Powder Technol. 2010, 21, 2–7. [Google Scholar] [CrossRef]

- Sybertz, F.; Reick, P. Effect of fly as on the rheological properties of cement paste. In Rheology of Fresh Cement and Concrete; Banfill, P.F.G., Ed.; Proceedings of an International Conference, Liverpool, 1991; CRC Press: London, UK; pp. 13–22.

- Golewski, G.L. Concrete composites based on quaternary blended cements with a reduced width of initial microcracks. Appl. Sci. 2023, 13, 7338. [Google Scholar] [CrossRef]

- García-Taengua, E.; Sonebi, M.; Hossain, K.M.A.; Lachemi, M.; Khatib, J. Effects of the addition of nanosilica on the rheology, hydration and development of the compressive strength of cement mortars. Compos. Part B Eng. 2015, 81, 120–129. [Google Scholar] [CrossRef]

- Bessaies-Bey, H.; Khayat, K.H.; Palacios, M.; Schmidt, W.; Roussel, N. Viscosity modifying agents: Key components of advanced cement-based materials with adapted rheology. Cem. Concr. Res. 2022, 152, 106646. [Google Scholar] [CrossRef]

- Papo, A.; Piani, L. Effect of various superplasticizers on the rheological properties of Portland cement pastes. Cem. Concr. Res. 2004, 34, 2097–2101. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, J.; Zhu, J.; Yang, Y.; Zhou, D.; Wang, T.; Shu, X.; Qiao, M. Advances in Organic Rheology-Modifiers (Chemical Admixtures) and Their Effects on the Rheological Properties of Cement-Based Materials. Materials 2022, 15, 8730. [Google Scholar] [CrossRef] [PubMed]

- Souza, M.T.; Ferreira, I.M.; de Moraes, E.G.; Senff, L.; Arcaro, S.; Pessôa, J.R.C.; Ribeiro, M.J.; de Oliveira, A.P.N. Role of chemical admixtures on 3D printed Portland cement: Assessing rheology and buildability. Constr. Build. Mater. 2022, 314, 125666. [Google Scholar] [CrossRef]

- Tao, C.; Watts, B.; Ferraro, C.C.; Masters, F.J. A Multivariate Computational Framework to Characterize and Rate Virtual Portland Cements. Comput.-Aided Civ. Infrastruct. Eng. 2019, 34, 266–278. [Google Scholar] [CrossRef]

- Watts, B.; Tao, C.; Ferraro, C.; Masters, F. Proficiency analysis of VCCTL results for heat of hydration and mortar cube strength. Constr. Build. Mater. 2018, 161, 606–617. [Google Scholar] [CrossRef]

- Skripkiunas, G.; Karpova, E.; Barauskas, I.; Bendoraitiene, J.; Yakovlev, G. Rheological properties of cement pastes with multiwalled carbon nanotubes. Adv. Mater. Sci. Eng. 2018, 2018, 8963542. [Google Scholar] [CrossRef]

- Wallevik, J.E. Thixotropic investigation on cement paste: Experimental and numerical approach. J. Non-Newton. Fluid Mech. 2005, 132, 86–99. [Google Scholar] [CrossRef]

- Tao, C.; Kutchko, B.G.; Rosenbaum, E.; Massoudi, M. A Review of Rheological Modeling of Cement Slurry in Oil Well Applications. Energies 2020, 13, 570. [Google Scholar] [CrossRef]

- Tao, C.; Rosenbaum, E.; Kutchko, B.; Massoudi, M. Pulsating Poiseuille flow of a cement slurry. Int. J. Non-Linear Mech. 2021, 133, 103717. [Google Scholar] [CrossRef]

- Tao, C.; Rosenbaum, E.; Kutchko, B.G.; Massoudi, M. A Brief Review of Gas Migration in Oilwell Cement Slurries. Energies 2021, 14, 2369. [Google Scholar] [CrossRef]

- Rajagopal, K.R.; Tao, L. Mechanics of Mixtures; World Scientific: Singapore, 1995; Volume 35, ISBN 9810215851. [Google Scholar]

- Massoudi, M. A Mixture Theory formulation for hydraulic or pneumatic transport of solid particles. Int. J. Eng. Sci. 2010, 48, 1440–1461. [Google Scholar] [CrossRef]

- Tao, C.; Kutchko, G.B.; Rosenbaum, E.; Wu, W.-T.; Massoudi, M. Steady Flow of a Cement Slurry. Energies 2019, 12, 2604. [Google Scholar] [CrossRef]

- Slattery, J.C. Advanced Transport Phenomena; Cambridge University Press: Cambridge, UK, 1999; ISBN 1316583902. [Google Scholar]

- Probstein, R.F. Physicochemical Hydrodynamics: An Introduction; John Wiley & Sons: Hoboken, NJ, USA, 2005; ISBN 0471725129. [Google Scholar]

- Li, Y.; Wu, W.-T.; Liu, X.; Massoudi, M. The effects of particle concentration and various fluxes on the flow of a fluid-solid suspension. Appl. Math. Comput. 2019, 358, 151–160. [Google Scholar] [CrossRef]

- Massoudi, M.; Tran, P.X. The Couette–Poiseuille flow of a suspension modeled as a modified third-grade fluid. Arch. Appl. Mech. 2016, 86, 921–932. [Google Scholar] [CrossRef]

- Truesdell, C.; Noll, W. The Non-linear Field Theories of Mechanics; Springer-Verlag: Berlin/Heidelberg, Germany, 1992. [Google Scholar]

- Rivlin, R.; Ericksen, J. Stress-Deformation Relations for Isotropic Materials. J. Ration. Mech. Anal. 1955, 4, 323–425. [Google Scholar] [CrossRef]

- Bridges, C.; Rajagopal, K.R. Pulsatile flow of a chemically-reacting nonlinear fluid. Comput. Math. Appl. 2006, 52, 1131–1144. [Google Scholar] [CrossRef]

- Batchelor, G.K.; Green, J.T. The determination of the bulk stress in a suspension of spherical particles to order c2. J. Fluid Mech. 1972, 56, 401–427. [Google Scholar] [CrossRef]

- Asaga, K.; Roy, D.M. Rheological properties of cement mixes: IV. Effects of superplasticizers on viscosity and yield stress. Cem. Concr. Res. 1980, 10, 287–295. [Google Scholar] [CrossRef]

- Krieger, I.M.; Dougherty, T.J. A mechanism for non-Newtonian flow in suspensions of rigid spheres. Trans. Soc. Rheol. 1959, 3, 137–152. [Google Scholar] [CrossRef]

- Barnes, H.A. Thixotropy—A review. J. Non-Newton. Fluid Mech. 1997, 70, 1–33. [Google Scholar] [CrossRef]

- Ouyang, J.; Han, B.; Chen, G.; Zhao, L.; Ou, J. A viscosity prediction model for cement paste with nano-SiO2 particles. Constr. Build. Mater. 2018, 185, 293–301. [Google Scholar] [CrossRef]

- Phillips, R.J.; Armstrong, R.C.; Brown, R.A.; Graham, A.L.; Abbott, J.R. A constitutive equation for concentrated suspensions that accounts for shear-induced particle migration. Phys. Fluids A Fluid Dyn. 1992, 4, 30–40. [Google Scholar] [CrossRef]

- Carnahan, N.F.; Starling, K.E. Equation of state for nonattracting rigid spheres. J. Chem. Phys. 1969, 51, 635–636. [Google Scholar] [CrossRef]

- Russel, W.B.; Russel, W.B.; Saville, D.A.; Schowalter, W.R. Colloidal Dispersions; Cambridge University Press: Cambridge, UK, 1991; ISBN 0521426006. [Google Scholar]

- Wang, J.; Liu, M.; Wang, Y.; Zhou, Z.; Xu, D.; Du, P.; Cheng, X. Synergistic effects of nano-silica and fly ash on properties of cement-based composites. Constr. Build. Mater. 2020, 262, 120737. [Google Scholar] [CrossRef]

- Li, H.; Zhang, L.; Ding, S.; Shu, X.; Wang, X.; Han, B. Effects and mechanisms of incorporated nanoparticles on the rheological performance of cement pastes. J. Build. Eng. 2023, 73, 106694. [Google Scholar] [CrossRef]

- Zhang, C.; Kong, X.; Yin, J.; Fu, X. Rheology of fresh cement pastes containing polymer nanoparticles. Cem. Concr. Res. 2021, 144, 106419. [Google Scholar] [CrossRef]

- Garcia-Rios, M.; Luquot, L.; Soler, J.M.; Cama, J. Influence of the flow rate on dissolution and precipitation features during percolation of CO2-rich sulfate solutions through fractured limestone samples. Chem. Geol. 2015, 414, 95–108. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).