Radiation and Radical Grafting Compatibilization of Polymers for Improved Bituminous Binders—A Review

Abstract

:1. Introduction

2. Electromagnetic and Electron Beam Radiation

3. Radiation Treatment and Grafting for Tailored Bitumen Modifiers

Radiation-Induced Grafting (RIG)

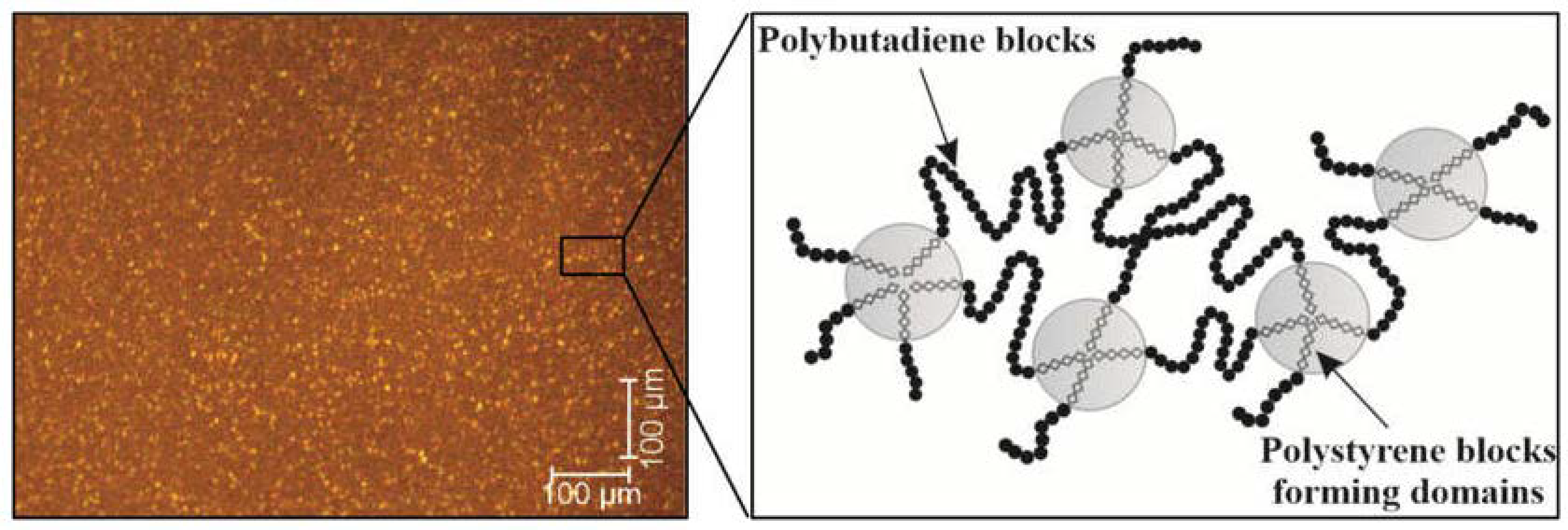

4. Poly(styrene-butadiene-styrene) (SBS) and Its Modification

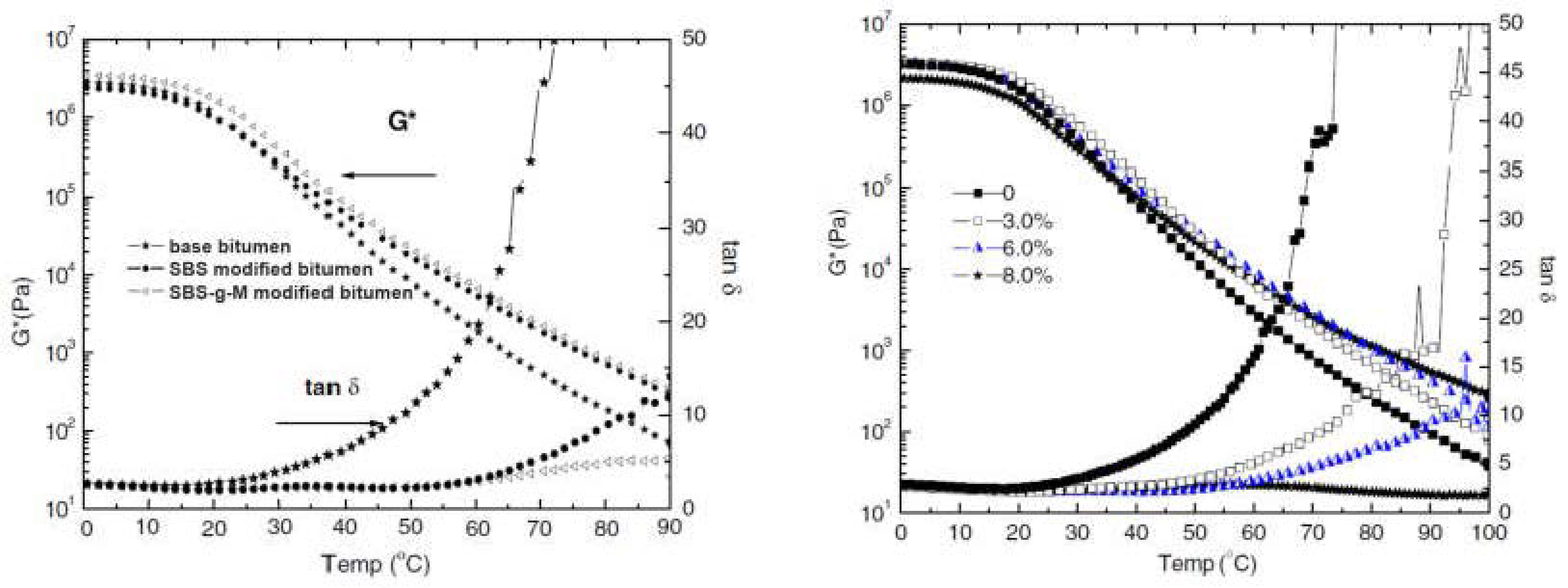

4.1. Radiation-Induced Grafting of SBS

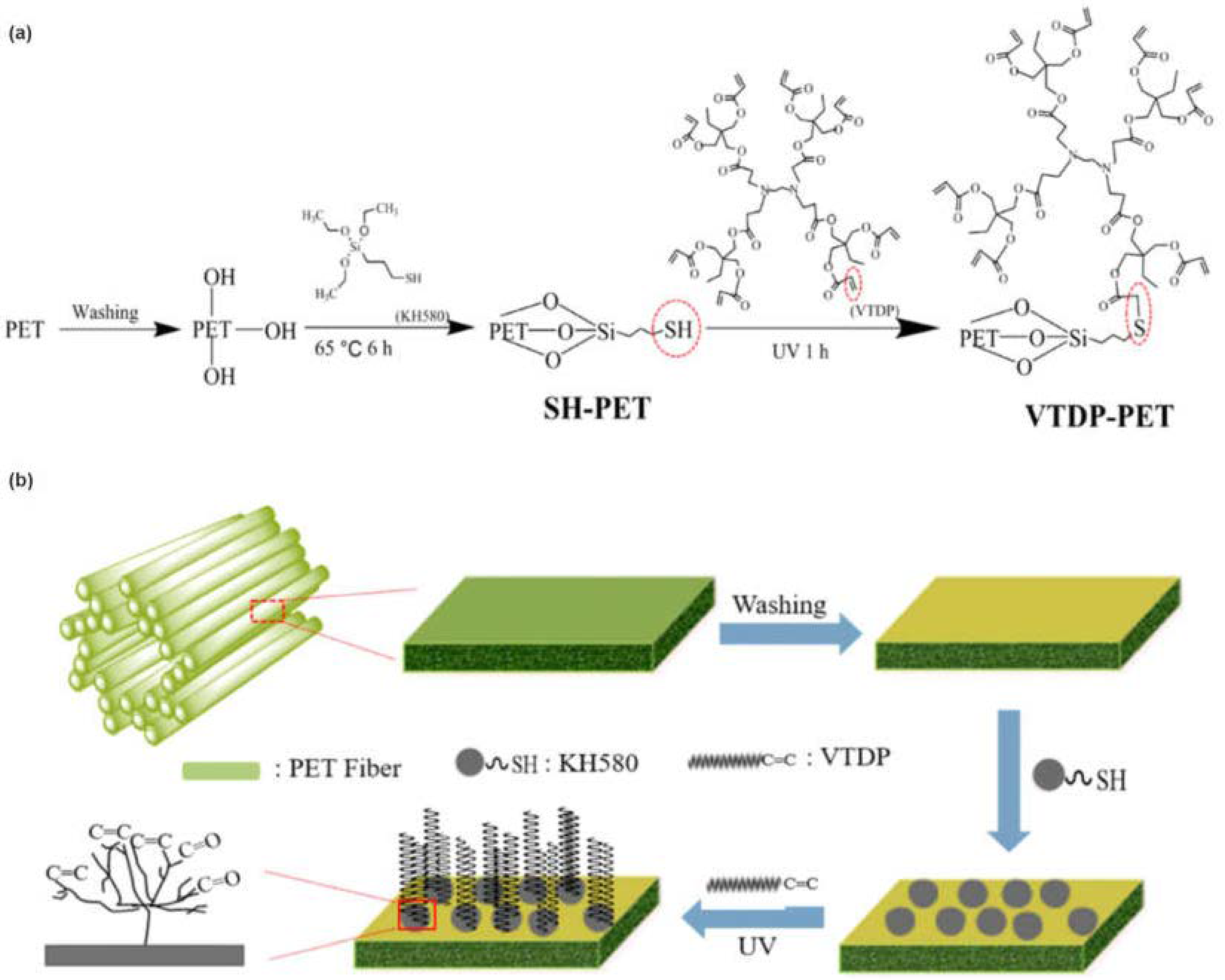

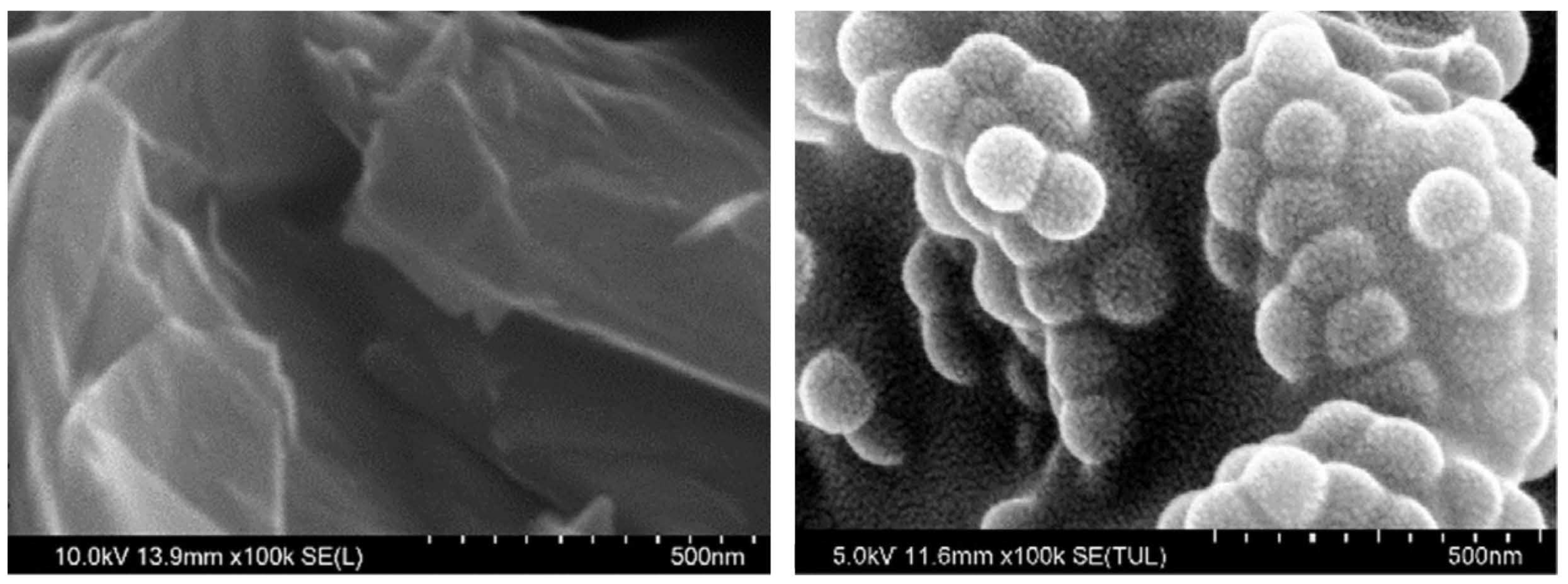

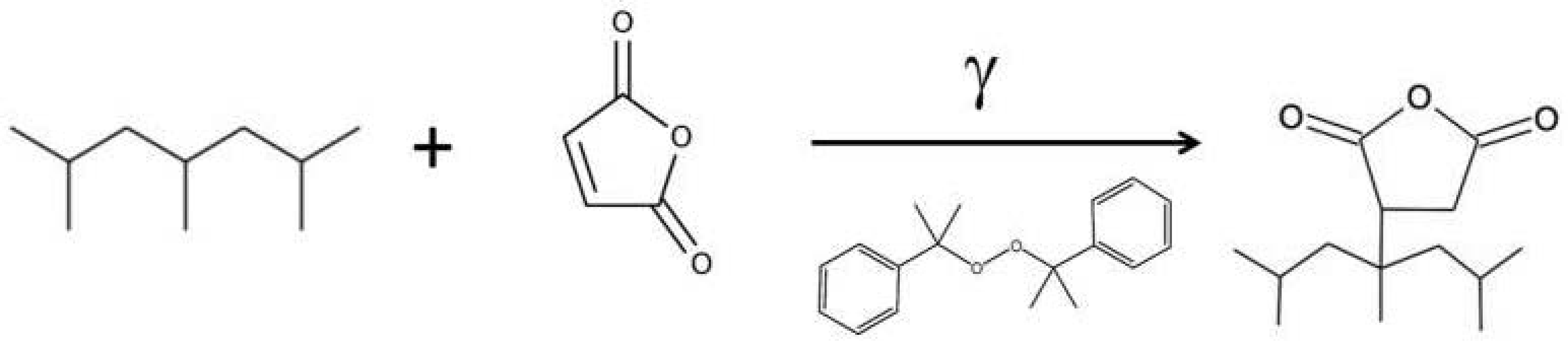

4.2. Chemical Grafting of SBS

5. Radiation Treatment and Grafting Strategies for Reclaimed Polymers

5.1. Waste Polypropylene (PP)

5.2. Waste Polyethylene (PE)

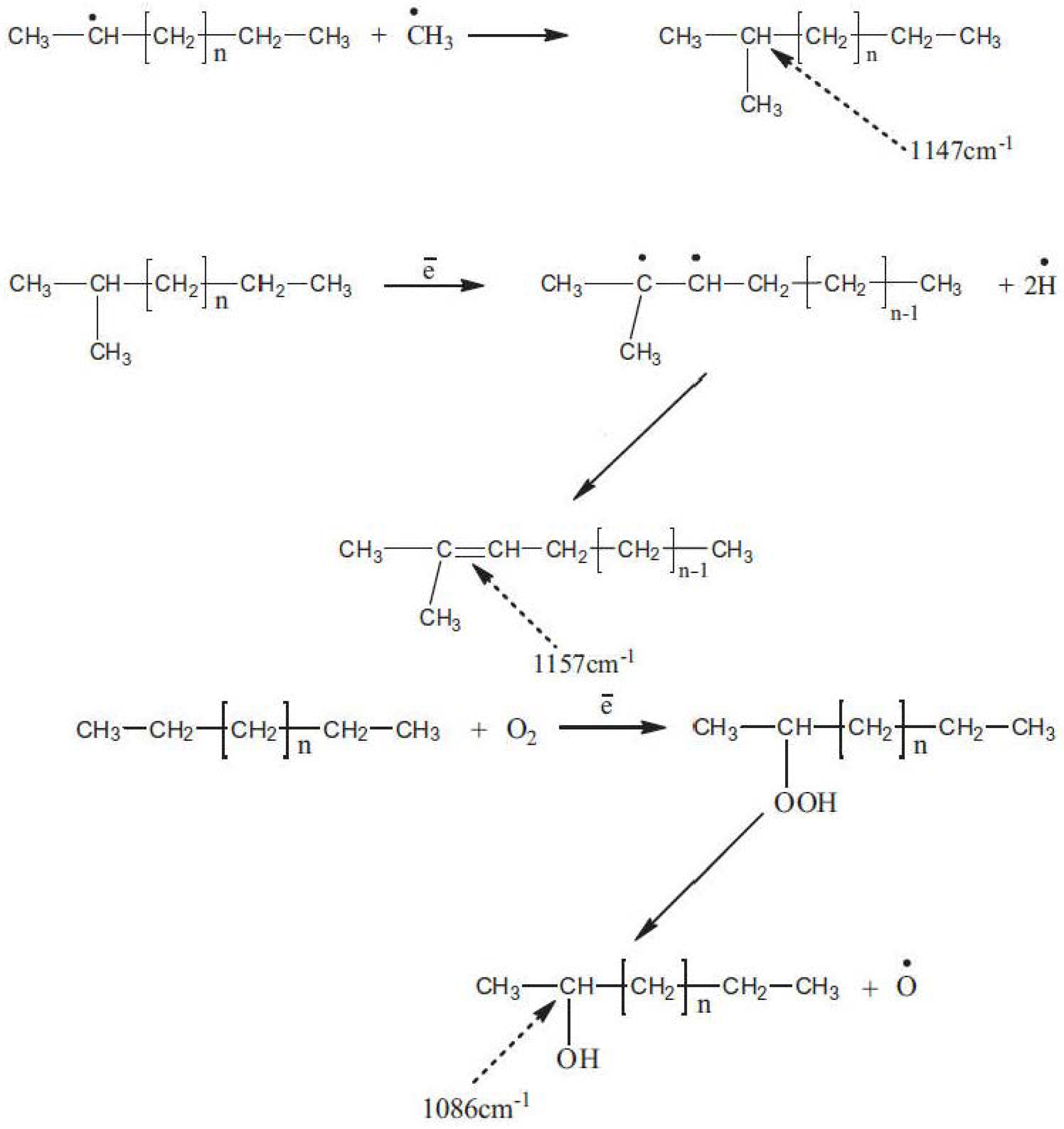

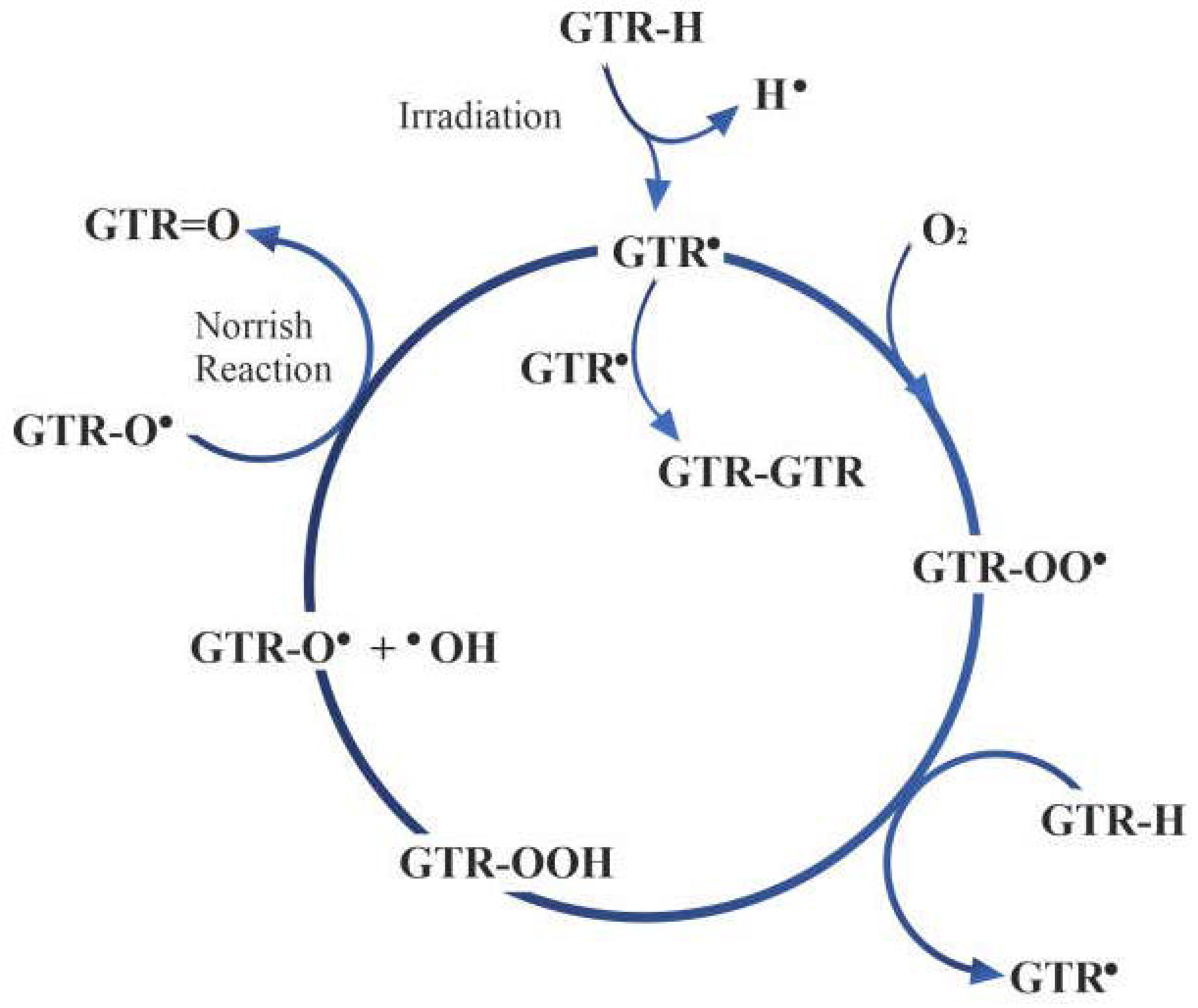

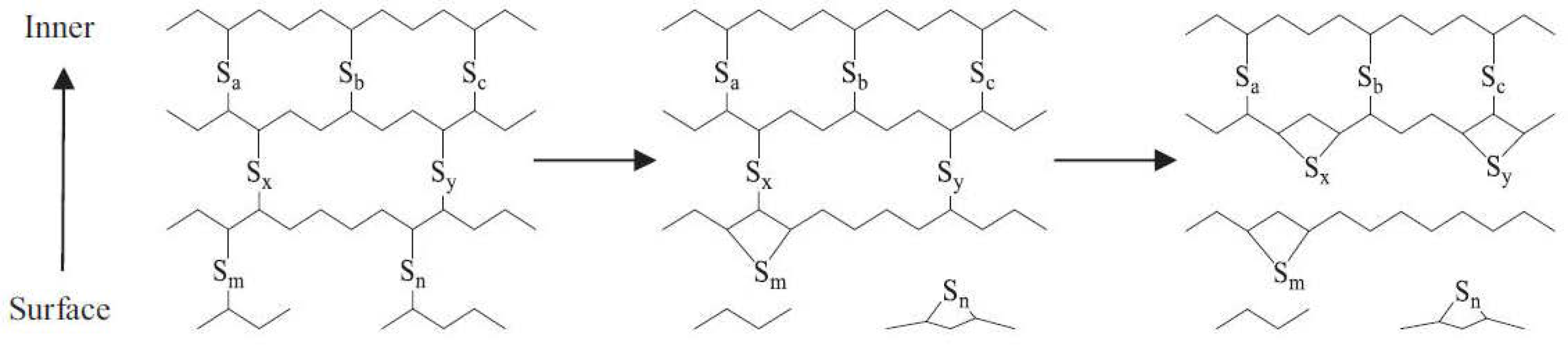

5.3. Waste Rubber

5.4. Synthetic Rubbers

6. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AA | acrylic acid |

| APS | ammonium persulfate |

| CNTs | carbon nanotubes |

| CR | crumb rubber |

| d–GTR | devulcanized ground tire rubber |

| DBM | dibutyl maleate |

| DCP | dicumyl peroxide |

| DSR | dynamic shear rheometer test |

| DWR | devulcanized waste rubber |

| EBI | electron beam irradiation |

| e-LDPER | electron beam-irradiated recycled high-density polyethylene |

| EPDM | ethylene propylene diene monomer |

| EVA | ethylene vinyl acetate |

| FPP | Hydroxyl-functionalized isotactic polypropylene |

| GF | glass fiber |

| GMA | glycidyl methacrylate |

| GNPs | graphite nanoplatelets |

| gOs-SH | thiolated graphene oxide nanoplatelets |

| GTR | ground tire rubber |

| HDPE | high-density polyethylene |

| HDPERe | recycled high-density polyethylene |

| HMA | hot mix asphalt |

| i-HDPER | ion-irradiated recycled high-density polyethylene |

| LAS | linear amplitude sweep test |

| LDPE | low-density polyethylene |

| LTP | low-temperature plasma |

| MA | maleic acid |

| MAH | maleic anhydride |

| M-CR | microwave-activated crumb rubber |

| MSCR | multiple stress creep recovery tests |

| NR | natural rubber |

| ODA | octadecyl-amine |

| ODA-WRP | waste rubber powder with octadecyl-amine |

| PB | polybutadiene |

| PE-g-MA | radically grafted polyethylene with maleic anhydride |

| PET | polyethylene terephthalate |

| PG | performance grade |

| PI | phase inversion |

| PMB | polymer modified bitumen |

| PP | polypropylene |

| PPR-γ-MA | radically grafted waste polypropylene with maleic anhydride |

| PS | polystyrene |

| PS-GNPs | polystyrene-grafted graphene nanoplatelets |

| PVC | polyvinyl chloride |

| RIG | radiation-induced grafting |

| RRP | reclaimed rubber powder |

| RTFOT | rolling thin film oven test |

| SAR | surface-activated crumb rubber |

| SBS | poly(styrene-butadiene-styrene) |

| SBS-g-M | poly(styrene-butadiene-styrene) modified by 60Co γ-rays radiation |

| TEPA | tetraethylenepentamine |

| TPEs | thermoplastic elastomers |

| TPO | tire pyrolysis oil |

| VTDP | vinyl-terminated dendritic polyester |

| VTDP-PET | hyperbranch-structure of vinyl-terminated dendritic polyester and polyester fiber |

| WRP | waste rubber powder |

References

- Górski, W. Przetwory Naftowe i Płyny Eksploatacyjne; Leksykon, Instytut Technologii Nafty: Kraków, Poland, 2016; ISBN 978-83-65649-19-5. [Google Scholar]

- Hunter, R.N.; Self, A.; Read, J. The Shell Bitumen Handbook, 6th ed.; ICE Publishing: Leeds, UK, 2015. [Google Scholar]

- Gaweł, I.; Kalabińska, M.; Piłat, J. Asfalty Drogowe; Wyd. 2. zm.; Wydawnictwa Komunikacji i Łączności: Warszawa, Poland, 2014; ISBN 978-83-206-1945-4. [Google Scholar]

- Kennedy, T.W.; Huber, G.; Harrigan, E.; Cominsky, R.; Hughes, C.; Quintus, H.; Moulthrop, J. Superior Performing Asphalt Pavements—Superpave: The Product of the SHRP Asphalt Research Program; National Research Council: Washington, DC, USA, 1994. [Google Scholar]

- Chen, J.; Dan, H.; Ding, Y.; Gao, Y.; Guo, M.; Guo, S.; Han, B.; Hong, B.; Hou, Y.; Hu, C.; et al. New Innovations in Pavement Materials and Engineering: A Review on Pavement Engineering Research 2021. J. Traffic Transp. Eng. Engl. Ed. 2021, 8, 815–999. [Google Scholar] [CrossRef]

- Cavalli, M.C.; Chen, D.; Chen, Q.; Chen, Y.; Cannone Falchetto, A.; Fang, M.; Gu, H.; Han, Z.; He, Z.; Hu, J.; et al. Review of Advanced Road Materials, Structures, Equipment, and Detection Technologies. J. Road Eng. 2023, 3, 370–468. [Google Scholar] [CrossRef]

- Bańkowski, W.; Gajewski, M.; Horodecka, R.; Mirski, K.; Targowska-Lech, E.; Jasiński, D. Assessment of the Effect of the Use of Highly-Modified Binder on the Viscoelastic and Functional Properties of Bituminous Mixtures Illustrated with the Example of Asphalt Concrete for the Binder Course. Constr. Build. Mater. 2021, 296, 123412. [Google Scholar] [CrossRef]

- Cong, P.; Liu, C.; Han, Z.; Zhao, Y. A Comprehensive Review on Polyurethane Modified Asphalt: Mechanism, Characterization and Prospect. J. Road Eng. 2023, 3, 315–335. [Google Scholar] [CrossRef]

- Redelius, P. Solubility Parameters and Bitumen. Fuel 2000, 79, 27–35. [Google Scholar] [CrossRef]

- Nellensteyn, F. Bereiding en Constitutie van Asphalt. Ph.D. Thesis, Delft University, Delft, The Netherlands, 1923. [Google Scholar]

- Petersen, J.; Robertson, R.; Branthaver, J.; Harnsberger, P.; Duvall, J.; Kim, S.; Anderson, D.; Christiansen, D.; Bahia, H. Binder Characterization and Evaluation: Volume 1; Rep No SHRP–367; Strategic Highway Research Program National Research Council: Washington, DC, USA, 1994. [Google Scholar]

- Pfeiffer, J.P.; Saal, R. Asphaltic Bitumen as Colloid System. J. Phys. Chem. 1940, 44, 139–149. [Google Scholar] [CrossRef]

- Yen, T.F.; Erdman, J.G.; Pollack, S.S. Investigation of the Structure of Petroleum Asphaltenes by X-ray Diffraction. Anal. Chem. 1961, 33, 1587–1594. [Google Scholar] [CrossRef]

- Zhang, Y.; Siskin, M.; Gray, M.R.; Walters, C.C.; Rodgers, R.P. Mechanisms of Asphaltene Aggregation: Puzzles and a New Hypothesis. Energy Fuels 2020, 34, 9094–9107. [Google Scholar] [CrossRef]

- Błażejowski, K.; Styk, S. Technologia Warstw Asfaltowych; Nawierzchnie Drogowe: Poradnik; Wydawnictwa Komunikacji i Łączności: Warszawa, Poland, 2004; ISBN 978-83-206-1540-1. [Google Scholar]

- Trzaska, E. Dodatki i modyfikatory do asfaltów drogowych. Nafta-Gaz 2015, 71, 195–199. [Google Scholar]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer Modification of Bitumen: Advances and Challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Yadykova, A.Y.; Ilyin, S.O. Nanocellulose-Stabilized Bitumen Emulsions as a Base for Preparation of Nanocomposite Asphalt Binders. Carbohydr. Polym. 2023, 313, 120896. [Google Scholar] [CrossRef]

- Dias, A.; Silva, H.; Palha, C.; Oliveira, J. Low-Temperature Performance of Polymer-Modified Binders in Stone Mastic Asphalts. Infrastructures 2021, 6, 58. [Google Scholar] [CrossRef]

- Becker, Y.; Mendez, M.P.; Rodriguez, Y. Polymer Modified Asphalt. Vis. Tecnol. 2001, 9, 39–50. [Google Scholar]

- Brasileiro, L.; Moreno-Navarro, F.; Tauste-Martínez, R.; Matos, J.; Rubio-Gámez, M. Reclaimed Polymers as Asphalt Binder Modifiers for More Sustainable Roads: A Review. Sustainability 2019, 11, 646. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Ma, Y.; Zhou, H.; Jiang, X.; Polaczyk, P.; Xiao, R.; Zhang, M.; Huang, B. The Utilization of Waste Plastics in Asphalt Pavements: A Review. Clean. Mater. 2021, 2, 100031. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Boom, Y.J.; Giustozzi, F. Sustainable Polymers from Recycled Waste Plastics and Their Virgin Counterparts as Bitumen Modifiers: A Comprehensive Review. Polymers 2021, 13, 3242. [Google Scholar] [CrossRef]

- Mahida, S.; Shah, Y.U.; Sharma, S.; Mehta, P. A Review on Polymers Additives in Flexible Pavement. J. Mater. Sci. 2023, 58, 6106–6123. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U.; Ekblad, J. Phase Separation of SBS Polymer Modified Bitumens. J. Mater. Civ. Eng. 1999, 11, 51–57. [Google Scholar] [CrossRef]

- Fu, H.; Xie, L.; Dou, D.; Li, L.; Yu, M.; Yao, S. Storage Stability and Compatibility of Asphalt Binder Modified by SBS Graft Copolymer. Constr. Build. Mater. 2007, 21, 1528–1533. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Günay, T.; Grigoryeva, O.; Starostenko, O. Irradiated Recycled High Density Polyethylene Usage as a Modifier for Bitumen. J. Mater. Civ. Eng. 2017, 29, 04016233. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, H.; Chen, Y.; Ji, J.; You, Z.; Zhang, Y. A Review on Compatibility between Crumb Rubber and Asphalt Binder. Constr. Build. Mater. 2021, 297, 123820. [Google Scholar] [CrossRef]

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Oliviero Rossi, C. Bitumen and Bitumen Modification: A Review on Latest Advances. Appl. Sci. 2019, 9, 742. [Google Scholar] [CrossRef]

- Rohayzi, N.F.; Katman, H.Y.B.; Ibrahim, M.R.; Norhisham, S.; Rahman, N.A. Potential Additives in Natural Rubber-Modified Bitumen: A Review. Polymers 2023, 15, 1951. [Google Scholar] [CrossRef]

- Hawesah, H.A.; Sadique, M.; Harris, C.; Nageim, H.A.; Stopp, K.; Pearl, H. Polymer Modified Asphalt Binder—An Approach for Enhancing Temperature Sensitivity for Emergency Pavement Repair. Int. J. Pavement Eng. 2022, 23, 4760–4774. [Google Scholar] [CrossRef]

- Syzdykova, A.; Zhakyp, A.; Tulebekova, A. Features of Using Modified Bitumen in Road Construction. Technobius 2021, 1, 0007. [Google Scholar] [CrossRef]

- Maqbool, M. Interaction of Gamma Rays and X-rays with Matter. In An Introduction to Medical Physics; Maqbool, M., Ed.; Biological and Medical Physics, Biomedical Engineering; Springer International Publishing: Cham, Switzerland, 2017; pp. 43–61. ISBN 978-3-319-61540-0. [Google Scholar]

- Cleland, M.R.; Parks, L.A.; Cheng, S. Applications for Radiation Processing of Materials. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2003, 208, 66–73. [Google Scholar] [CrossRef]

- Diehl, R. Gamma-Ray Production and Absorption Processes. In The Universe in Gamma Rays; Schönfelder, V., Ed.; Astronomy and Astrophysics Library; Springer: Berlin/Heidelberg, Germany, 2001; pp. 9–25. ISBN 978-3-642-08745-5. [Google Scholar]

- Fan, X.; Niemira, B.A. Gamma Ray, Electron Beam, and X-ray Irradiation. In Food Safety Engineering; Demirci, A., Feng, H., Krishnamurthy, K., Eds.; Food Engineering Series; Springer International Publishing: Cham, Switzerland, 2020; pp. 471–492. ISBN 978-3-030-42660-6. [Google Scholar]

- Chmielewski, A.; Haji-Saeid, M.; Ahmed, S. Progress in Radiation Processing of Polymers. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2005, 236, 44–54. [Google Scholar] [CrossRef]

- Ashfaq, A.; Clochard, M.-C.; Coqueret, X.; Dispenza, C.; Driscoll, M.S.; Ulański, P.; Al-Sheikhly, M. Polymerization Reactions and Modifications of Polymers by Ionizing Radiation. Polymers 2020, 12, 2877. [Google Scholar] [CrossRef] [PubMed]

- Walo, M. Chapter 9: Radiation-Induced Grafting. In Applications of Ionizing Radiation in Materials Processing. Volume 1; Institute of Nuclear Chemistry and Technology: Warszawa, Poland, 2017; pp. 193–210. ISBN 978-83-933935-8-9. [Google Scholar]

- Ahmedzade, P.; Fainleib, A.; Günay, T.; Grygoryeva, O. Modification of Bitumen by Electron Beam Irradiated Recycled Low Density Polyethylene. Constr. Build. Mater. 2014, 69, 1–9. [Google Scholar] [CrossRef]

- Günay, T.; Ahmedzade, P.; Hassanpour-Kasanagh, S.; Fainleib, A.M.; Starostenko, O. Effect of Maleic Anhydride Grafted and Gamma-Irradiated Waste Polypropylene on Rheological Properties of Asphalt Binder. Int. J. Pavement Eng. 2022, 23, 4819–4830. [Google Scholar] [CrossRef]

- Yu, G.-X.; Li, Z.-M.; Zhou, X.-L.; Li, C.-L. Crumb Rubber–Modified Asphalt: Microwave Treatment Effects. Pet. Sci. Technol. 2011, 29, 411–417. [Google Scholar] [CrossRef]

- Hirayama, D.; Saron, C. Chemical Modifications in Styrene–Butadiene Rubber after Microwave Devulcanization. Ind. Eng. Chem. Res. 2012, 51, 3975–3980. [Google Scholar] [CrossRef]

- Yao, Z.; Yang, R.; Shi, J.; Zhang, C.; Zhang, Y. Separation Mechanism of Asphalt Rubber and Improvement with Microwave Irradiation. Constr. Build. Mater. 2022, 342, 127862. [Google Scholar] [CrossRef]

- Formela, K.; Hejna, A.; Zedler, L.; Colom, X.; Canavate, J. Microwave Treatment in Waste Rubber Recycling—Recent Advances and Limitations. Express Polym. Lett. 2019, 13, 565–588. [Google Scholar] [CrossRef]

- Vonk, W.C.; Van Gooswilligen, G. Improvement of Paving Grade Bitumens with SBS Polymers. In Proceedings of the Fourth Eurobitume Symposium, Madrid, Spain, 4–6 October 1989; pp. 289–303. [Google Scholar]

- Blazejowski, K.; Wójcik-Wiśniewska, M.; Baranowska, W.; Ostrowski, P. Highly Modified Binders ORBITON HiMA—Application Guide 2019; ORLEN Asfalt Sp. z o.o.: Płock, Poland, 2019. [Google Scholar]

- Dong, F.; Zhao, W.; Zhang, Y.; Wei, J.; Fan, W.; Yu, Y.; Wang, Z. Influence of SBS and Asphalt on SBS Dispersion and the Performance of Modified Asphalt. Constr. Build. Mater. 2014, 62, 1–7. [Google Scholar] [CrossRef]

- Błażejowski, K.; Wójcik-Wiśniewska, M.; Baranowska, W.; Ostrowski, P.; Černý, R.; Jisa, P. Fatigue Performance of Bituminous Binders Tested by Linear Amplitude Sweep Test; Springer: Berlin/Heidelberg, Germany, 2020; pp. 385–394. [Google Scholar]

- Liu, S.; Shan, L.; Qi, C.; Zhang, W.; Li, G.; Wang, B.; Wei, W. Effect of SBS Structure on Viscosity of SBS-Modified Asphalt Based on Molecular Dynamics: Insights from Shearing Phase Morphology, Adsorption and Swelling Mechanisms. J. Mol. Liq. 2024, 393, 123567. [Google Scholar] [CrossRef]

- Xia, T.; Qin, Y.; Xu, J.; Zhou, L.; Chen, W.; Dai, J. Viscoelastic Phase Separation and Crystalline-to-Amorphous Phase Transition in Bitumen/SBS/PE Blends. Polymer 2018, 155, 129–135. [Google Scholar] [CrossRef]

- Laukkanen, O.-V.; Soenen, H.; Winter, H.H.; Seppälä, J. Low-Temperature Rheological and Morphological Characterization of SBS Modified Bitumen. Constr. Build. Mater. 2018, 179, 348–359. [Google Scholar] [CrossRef]

- Zanzotto, L.; Stastna, J.; Vacin, O. Thermomechanical Properties of Several Polymer Modified Asphalts. Appl. Rheol. 2000, 10, 185–191. [Google Scholar] [CrossRef]

- Schaur, A.; Unterberger, S.; Lackner, R. Impact of Molecular Structure of SBS on Thermomechanical Properties of Polymer Modified Bitumen. Eur. Polym. J. 2017, 96, 256–265. [Google Scholar] [CrossRef]

- Pang, J.; Du, S.; Chang, R.; Cui, D. Rheological Properties of SBS-Modified Asphalt in the Presence of Dithiodimorpholine and Tetraethyl Thiuram Disulfide. Polym. Compos. 2016, 37, 943–948. [Google Scholar] [CrossRef]

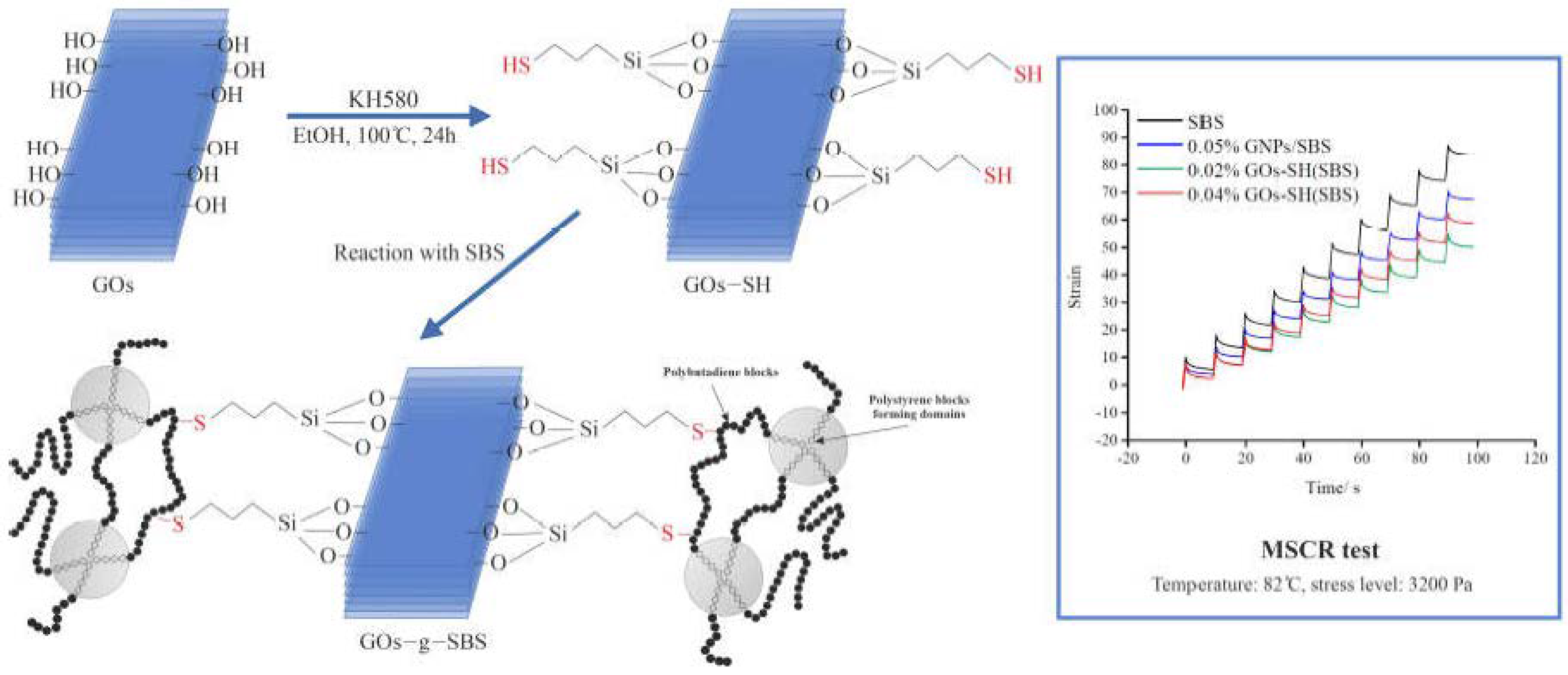

- Li, J.; Han, M.; Muhammad, Y.; Liu, Y.; Su, Z.; Yang, J.; Yang, S.; Duan, S. Preparation and Properties of SBS-g-GOs-Modified Asphalt Based on a Thiol-Ene Click Reaction in a Bituminous Environment. Polymers 2018, 10, 1264. [Google Scholar] [CrossRef]

- Cong, P.; Chen, S.; Chen, H. Preparation and Properties of Bitumen Modified with the Maleic Anhydride Grafted Styrene-butadiene-styrene Triblock Copolymer. Polym. Eng. Sci. 2011, 51, 1273–1279. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, X.; Cao, D.; Zhang, Y.; He, M. Effect of Linear Low Density-Polyethylene Grafted with Maleic Anhydride (LLDPE-g-MAH) on Properties of High Density-Polyethylene/Styrene–Butadiene–Styrene (HDPE/SBS) Modified Asphalt. Constr. Build. Mater. 2013, 47, 192–198. [Google Scholar] [CrossRef]

- Goli, A.; Ziari, H.; Amini, A. Influence of Carbon Nanotubes on Performance Properties and Storage Stability of SBS Modified Asphalt Binders. J. Mater. Civ. Eng. 2017, 29, 04017070. [Google Scholar] [CrossRef]

- Meng, F.; Muhammad, Y.; Ye, Y.; Ji, J.; Tao, H.; Huang, J.; Zhu, Z.; Li, J. Preparation of Hyperbranch-structured Polyester Fiber via Thiol-ene Click Reaction under UV Light Irradiation for Asphalt Binder Modification. J. Appl. Polym. Sci. 2021, 138, 50135. [Google Scholar] [CrossRef]

- Maurano, C.H.F.; Portal, L.L.; Baumhardt Neto, R.; Mauler, R.S. Functionalization of Styrene-Butadiene-Styrene (SBS) Triblock Copolymer with Maleic Anhydride. Polym. Bull. 2001, 46, 491–498. [Google Scholar] [CrossRef]

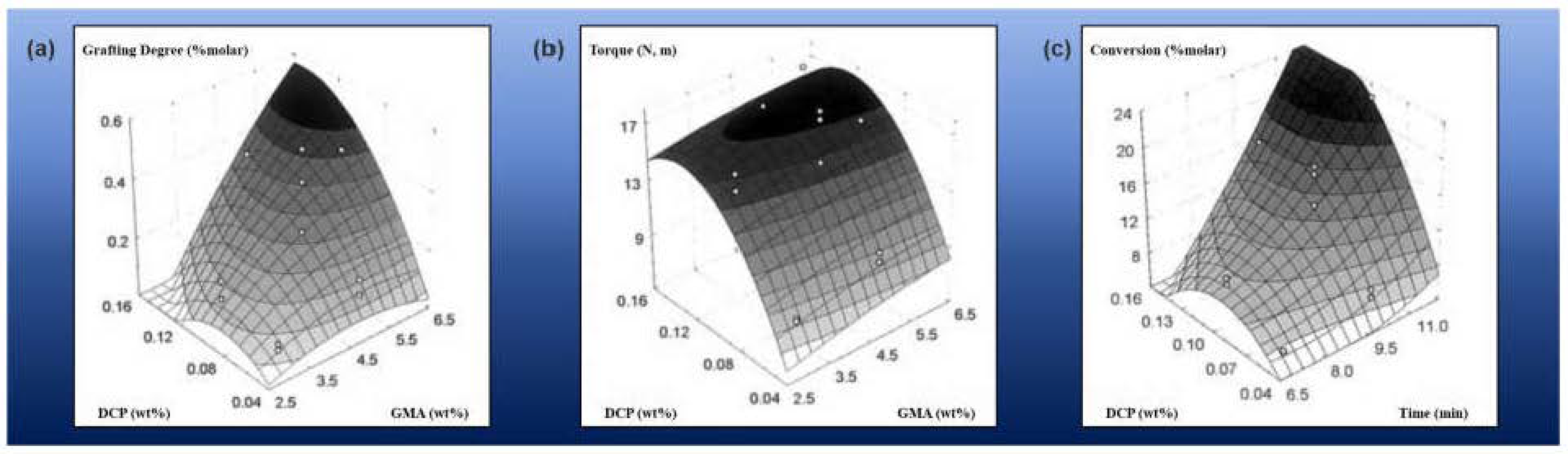

- Cordella, C.D.; Cardozo, N.S.M.; Neto, R.B.; Mauler, R.S. Functionalization of Styrene–Butadiene–Styrene (SBS) Triblock Copolymer with Glycidyl Methacrylate (GMA). J. Appl. Polym. Sci. 2003, 87, 2074–2079. [Google Scholar] [CrossRef]

- Arabani, M.; Faramarzi, M. Characterization of CNTs-Modified HMA’s Mechanical Properties. Constr. Build. Mater. 2015, 83, 207–215. [Google Scholar] [CrossRef]

- Amirkhanian, A.N.; Xiao, F.; Amirkhanian, S.N. Characterization of Unaged Asphalt Binder Modified with Carbon Nano Particles. Int. J. Pavement Res. Technol. 2011, 4, 281. [Google Scholar]

- Chen, M.; Geng, J.; Xia, C.; He, L.; Liu, Z. A Review of Phase Structure of SBS Modified Asphalt: Affecting Factors, Analytical Methods, Phase Models and Improvements. Constr. Build. Mater. 2021, 294, 123610. [Google Scholar] [CrossRef]

- Le, J.-L.; Marasteanu, M.O.; Turos, M. Mechanical and Compaction Properties of Graphite Nanoplatelet-Modified Asphalt Binders and Mixtures. Road Mater. Pavement Des. 2020, 21, 1799–1814. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, K.; Liu, K.; Shi, X. Adhesion Characteristics of Graphene Oxide Modified Asphalt Unveiled by Surface Free Energy and AFM-Scanned Micro-Morphology. Constr. Build. Mater. 2020, 244, 118404. [Google Scholar] [CrossRef]

- Duan, S.; Li, J.; Muhammad, Y.; Su, Z.; Meng, F.; Yang, H.; Yao, X. Synthesis and Evaluation of High-Temperature Properties of Butylated Graphene Oxide Composite Incorporated SBS (C4H9-GO/SBS)-Modified Asphalt. J. Appl. Polym. Sci. 2019, 136, 48231. [Google Scholar] [CrossRef]

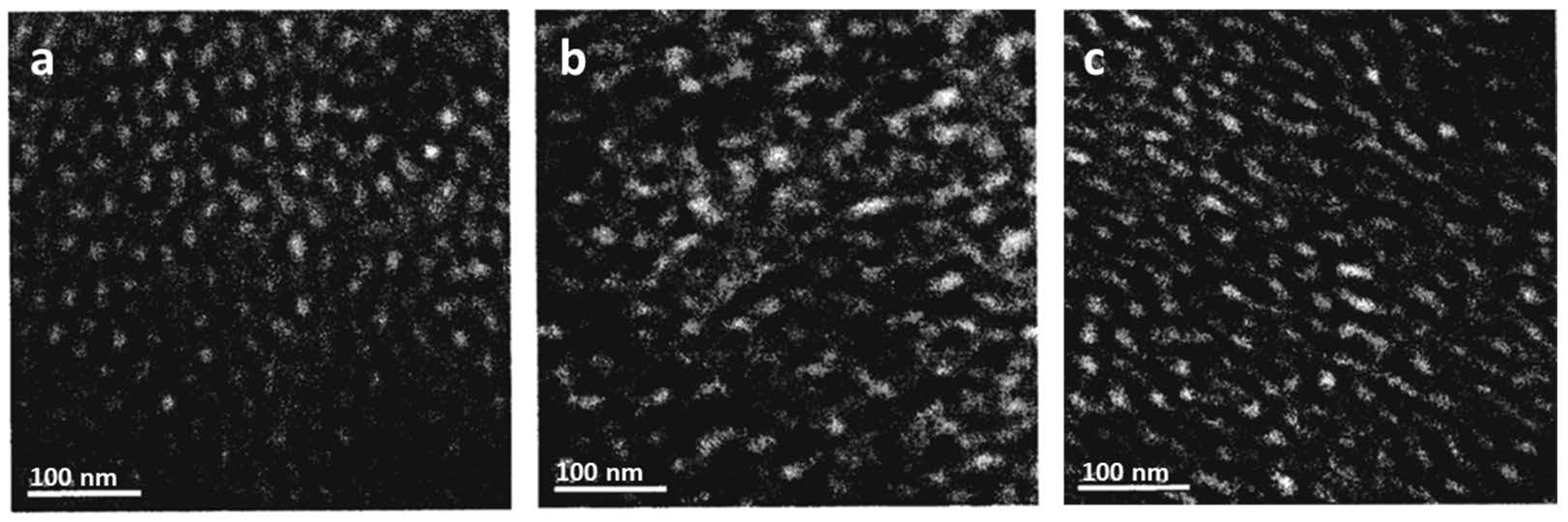

- Han, M.; Li, J.; Muhammad, Y.; Hou, D.; Zhang, F.; Yin, Y.; Duan, S. Effect of Polystyrene Grafted Graphene Nanoplatelets on the Physical and Chemical Properties of Asphalt Binder. Constr. Build. Mater. 2018, 174, 108–119. [Google Scholar] [CrossRef]

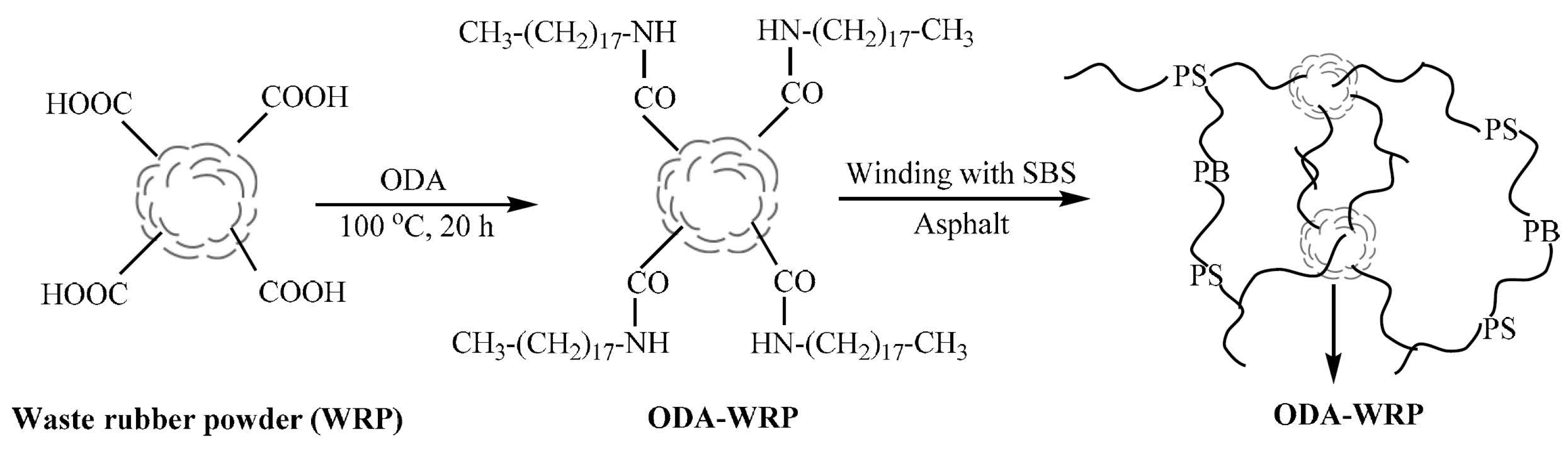

- Han, M.; Zeng, X.; Muhammad, Y.; Li, J.; Yang, J.; Yang, S.; Wei, Y.; Meng, F. Preparation of Octadecyl Amine Grafted over Waste Rubber Powder (ODA-WRP) and Properties of Its Incorporation in SBS-Modified Asphalt. Polymers 2019, 11, 665. [Google Scholar] [CrossRef]

- EN 14023:2010; Bitumen and Bituminous Binders—Specification Framework for Polymer Modified Bitumens. The European Committee for Standardization: Brussels, Belgium, 2010.

- Wang, Q.; Liao, M.; Wang, Y.; Ren, Y. Characterization of End-functionalized Styrene–Butadiene–Styrene Copolymers and Their Application in Modified Asphalt. J. Appl. Polym. Sci. 2007, 103, 8–16. [Google Scholar] [CrossRef]

- Wilhelm, H.M.; Felisberti, M.I. Reactive Compatibilization of Maleated Polypropylene and Maleated Poly(Styrene-b-butadiene-b-styrene) Blends. J. Appl. Polym. Sci. 2002, 86, 366–371. [Google Scholar] [CrossRef]

- Ponomarev, A.V. Radiolysis as a Powerful Tool for Polymer Waste Recycling. High Energy Chem. 2020, 54, 194–204. [Google Scholar] [CrossRef]

- Lu, D.X.; Enfrin, M.; Boom, Y.J.; Giustozzi, F. Future Recyclability of Hot Mix Asphalt Containing Recycled Plastics. Constr. Build. Mater. 2023, 368, 130396. [Google Scholar] [CrossRef]

- Plastics—The Facts 2022 • Plastics Europe; Plastics Europe: Brussels, Belgium, 2022.

- Scheirs, J. Polymer Recycling: Science, Technology and Applications; Wiley Series in Polymer Science; Repr.; Wiley: Chichester, UK, 2001; ISBN 978-0-471-97054-5. [Google Scholar]

- Otuoze, H.; Shuaibu, A. An Experimental Study on the Use of Polypropylene Waste In Bituminous Mix. Niger. J. Technol. 2017, 36, 677–685. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Jamal, M.; Gravina, R.; Giustozzi, F. Recycled Plastic as Bitumen Modifier: The Role of Recycled Linear Low-Density Polyethylene in the Modification of Physical, Chemical and Rheological Properties of Bitumen. J. Clean. Prod. 2020, 266, 121988. [Google Scholar] [CrossRef]

- Akkouri, N.; Baba, K.; Ait Elkassia, A. Valorization of Plastic Waste (PP-LDPE) from Moroccan Industry in Modification of Hybrid Bitumen: Application of the Mixture Design Methodology. Int. J. Pavement Res. Technol. 2023, 16, 760–779. [Google Scholar] [CrossRef]

- Desidery, L.; Lanotte, M. Effect of Waste Polyethylene and Wax-Based Additives on Bitumen Performance. Polymers 2021, 13, 3733. [Google Scholar] [CrossRef]

- Abdy, C.; Zhang, Y.; Wang, J.; Yang, Y.; Artamendi, I.; Allen, B. Pyrolysis of Polyolefin Plastic Waste and Potential Applications in Asphalt Road Construction: A Technical Review. Resour. Conserv. Recycl. 2022, 180, 106213. [Google Scholar] [CrossRef]

- Vargas, C.; El Hanandeh, A. Systematic Literature Review, Meta-Analysis and Artificial Neural Network Modelling of Plastic Waste Addition to Bitumen. J. Clean. Prod. 2021, 280, 124369. [Google Scholar] [CrossRef]

- Kalantar, Z.N.; Karim, M.R.; Mahrez, A. A Review of Using Waste and Virgin Polymer in Pavement. Constr. Build. Mater. 2012, 33, 55–62. [Google Scholar] [CrossRef]

- Masad, E.; Roja, K.L.; Rehman, A.; Abdala, A.A. A Review of Asphalt Modification Using Plastics: A Focus on Polyethylene; Texas A&M University at Qatar: Doha, Qatar, 2020. [Google Scholar] [CrossRef]

- Xu, F.; Zhao, Y.; Li, K. Using Waste Plastics as Asphalt Modifier: A Review. Materials 2021, 15, 110. [Google Scholar] [CrossRef]

- Victory, W. A Review on the Utilization of Waste Material in Asphalt Pavements. Environ. Sci. Pollut. Res. 2022, 29, 27279–27282. [Google Scholar] [CrossRef]

- Wu, S.; Montalvo, L. Repurposing Waste Plastics into Cleaner Asphalt Pavement Materials: A Critical Literature Review. J. Clean. Prod. 2021, 280, 124355. [Google Scholar] [CrossRef]

- Yeh, P.; Nien, Y.; Chen, J.; Chen, W.; Chen, J. Thermal and Rheological Properties of Maleated Polypropylene Modified Asphalt. Polym. Eng. Sci. 2005, 45, 1152–1158. [Google Scholar] [CrossRef]

- Malus, M.; Bojda, J.; Sienkiewicz, M.; Bouyahyi, M.; Yang, L.; Javier Navarro, F.; Soliman, M.; Duchateau, R.; Jasinska-Walc, L. Structurally Well-Defined Functionalized Polyolefins and Graft Copolymers Thereof as Bitumen Modifiers. Constr. Build. Mater. 2023, 390, 131630. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Fainleib, A.; Günay, T.; Grigoryeva, O.; Kultayev, B.; Starostenko, O. Influence of Ion Irradiated Recycled Polyethylene on Physical Properties of Bituminous Binder. Adv. Mater. Res. 2015, 1125, 360–364. [Google Scholar] [CrossRef]

- Bellamy, L. The Infra-Red Spectra of Complex Molecules; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; ISBN 94-011-6017-1. [Google Scholar]

- Smith, M.B.; March, J. March’s Advanced Organic Chemistry: Reactions, Mechanisms, and Structure, 1st ed.; Wiley: Hoboken, NJ, USA, 2006; ISBN 978-0-471-72091-1. [Google Scholar]

- Mengual, A.; Juárez, D.; Balart, R.; Ferrándiz, S. PE-g-MA, PP-g-MA and SEBS-g-MA Compatibilizers Used in Material Blends. Procedia Manuf. 2017, 13, 321–326. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Jamal, M.; Biligiri, K.P.; Giustozzi, F. Effect of Various Compatibilizers on the Storage Stability, Thermochemical and Rheological Properties of Recycled Plastic-Modified Bitumen. Int. J. Pavement Res. Technol. 2023, 1–4. [Google Scholar] [CrossRef]

- Jun, L.; Yuxia, Z.; Yuzhen, Z. The Research of GMA-g-LDPE Modified Qinhuangdao Bitumen. Constr. Build. Mater. 2008, 22, 1067–1073. [Google Scholar] [CrossRef]

- El-Nemr, K.F.; Khalil, A.M.; Fathy, E.S. Thermoplastic Elastomers Based on Waste Rubber and Expanded Polystyrene: Role of Devulcanization and Ionizing Radiation. Int. J. Polym. Anal. Charact. 2018, 23, 58–69. [Google Scholar] [CrossRef]

- Li, J.; Chen, Z.; Xiao, F.; Amirkhanian, S.N. Surface Activation of Scrap Tire Crumb Rubber to Improve Compatibility of Rubberized Asphalt. Resour. Conserv. Recycl. 2021, 169, 105518. [Google Scholar] [CrossRef]

- Mousavi, M.; Hosseinnezhad, S.; Kabir, S.F.; Burnett, D.J.; Fini, E.H. Reaction Pathways for Surface Activated Rubber Particles. Resour. Conserv. Recycl. 2019, 149, 292–300. [Google Scholar] [CrossRef]

- Spadaro, G.; Valenza, A. Influence of the Irradiation Parameters on the Molecular Modifications of an Isotactic Polypropylene Gamma-Irradiated under Vacuum. Polym. Degrad. Stab. 2000, 67, 449–454. [Google Scholar] [CrossRef]

- Phiri, M.M.; Phiri, M.J.; Formela, K.; Wang, S.; Hlangothi, S.P. Grafting and Reactive Extrusion Technologies for Compatibilization of Ground Tyre Rubber Composites: Compounding, Properties, and Applications. J. Clean. Prod. 2022, 369, 133084. [Google Scholar] [CrossRef]

- Tolstov, A.; Grigoryeva, O.; Fainleib, A.; Danilenko, I.; Spanoudaki, A.; Pissis, P.; Grenet, J. Reactive Compatibilization of Polyethylene/Ground Tire Rubber Inhomogeneous Blends via Interactions of Pre-Functionalized Polymers in Interface. Macromol. Symp. 2007, 254, 226–232. [Google Scholar] [CrossRef]

- Rezaei Abadchi, M.; Jalali Arani, A.; Nazockdast, H. Partial Replacement of NR by GTR in Thermoplastic Elastomer Based on LLDPE/NR through Using Reactive Blending: Its Effects on Morphology, Rheological, and Mechanical Properties. J. Appl. Polym. Sci. 2010, 115, 2416–2422. [Google Scholar] [CrossRef]

- Naskar, A.K.; De, S.K.; Bhowmick, A.K. Thermoplastic Elastomeric Composition Based on Maleic Anhydride–Grafted Ground Rubber Tire. J. Appl. Polym. Sci. 2002, 84, 370–378. [Google Scholar] [CrossRef]

- Ramezani Kakroodi, A.; Rodrigue, D. Degradation Behavior of Maleated Polyethylene/Ground Tire Rubber Thermoplastic Elastomers with and without Stabilizers. Polym. Degrad. Stab. 2013, 98, 2184–2192. [Google Scholar] [CrossRef]

- Song, P.; Li, S.; Wang, S. Interfacial Interaction between Degraded Ground Tire Rubber and Polyethylene. Polym. Degrad. Stab. 2017, 143, 85–94. [Google Scholar] [CrossRef]

- Fathy, E.S.; Elnaggar, M.Y.; Raslan, H.A. Thermoplastic Elastomer Based on Waste Polyethylene/Waste Rubber Containing Activated Carbon Black: Impact of Gamma Irradiation. J. Vinyl Addit. Technol. 2019, 25, E166–E173. [Google Scholar] [CrossRef]

- Hassan, M.M.; Aly, R.O.; Abdel Aal, S.E.; El-Masry, A.M.; Fathy, E.S. Mechanochemical Devulcanization and Gamma Irradiation of Devulcanized Waste Rubber/High Density Polyethylene Thermoplastic Elastomer. J. Ind. Eng. Chem. 2013, 19, 1722–1729. [Google Scholar] [CrossRef]

- Kiss, L.; Mészáros, L. Recycling Waste Tire Rubber through an Innovative Water-Medium Ionizing Radiation Treatment: Enhancing Compatibility and Mechanical Performance. Radiat. Phys. Chem. 2024, 216, 111475. [Google Scholar] [CrossRef]

- Mészáros, L.; Bárány, T.; Czvikovszky, T. EB-Promoted Recycling of Waste Tire Rubber with Polyolefins. Radiat. Phys. Chem. 2012, 81, 1357–1360. [Google Scholar] [CrossRef]

- Ramarad, S.; Ratnam, C.T.; Khalid, M.; Chuah, A.L. Improving the Properties of Reclaimed Waste Tire Rubber by Blending with Poly(Ethylene-Co-vinyl Acetate) and Electron Beam Irradiation. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Ramarad, S.; Ratnam, C.T.; Munusamy, Y.; Rahim, N.A.A.; Muniyadi, M. Thermochemical Compatibilization of Reclaimed Tire Rubber/ Poly(Ethylene-Co-Vinyl Acetate) Blend Using Electron Beam Irradiation and Amine-Based Chemical. J. Polym. Res. 2021, 28, 389. [Google Scholar] [CrossRef]

- Ren, M.; Luo, J.; Xu, D.; Guo, Y.; Jing, Z.; Zhang, H.; Feng, P.; Shuai, M. Post-Irradiation Degradation of Radio-Oxidized Natural Rubber Latex Films Induced by 60Co Gamma Rays. Radiat. Phys. Chem. 2023, 206, 110807. [Google Scholar] [CrossRef]

- Ibrahim, I.; Fathy, E.; El-Shafie, M.; Elnaggar, M.Y. Impact of Incorporated Gamma Irradiated Crumb Rubber on the Short-Term Aging Resistance and Rheological Properties of Asphalt Binder. Constr. Build. Mater. 2015, 81, 42–46. [Google Scholar] [CrossRef]

- Hassan, M.M.; Mahmoud, G.A.; El-Nahas, H.H.; Hegazy, E.A. Reinforced Material from Reclaimed Rubber/Natural Rubber, Using Electron Beam and Thermal Treatment. J. Appl. Polym. Sci. 2007, 104, 2569–2578. [Google Scholar] [CrossRef]

- Hassan, M.M.; Aly, R.O.; Aal, S.A.; El-Masry, A.M.; Fathy, E. Styrene Butadiene-Based Blends Containing Waste Rubber Powder: Physico-Mechanical Effects of Mechanochemical Devulcanization and Gamma Irradiation. J. Ind. Eng. Chem. 2013, 19, 1735–1742. [Google Scholar] [CrossRef]

- Hosseinnezhad, S.; Kabir, S.F.; Oldham, D.; Mousavi, M.; Fini, E.H. Surface Functionalization of Rubber Particles to Reduce Phase Separation in Rubberized Asphalt for Sustainable Construction. J. Clean. Prod. 2019, 225, 82–89. [Google Scholar] [CrossRef]

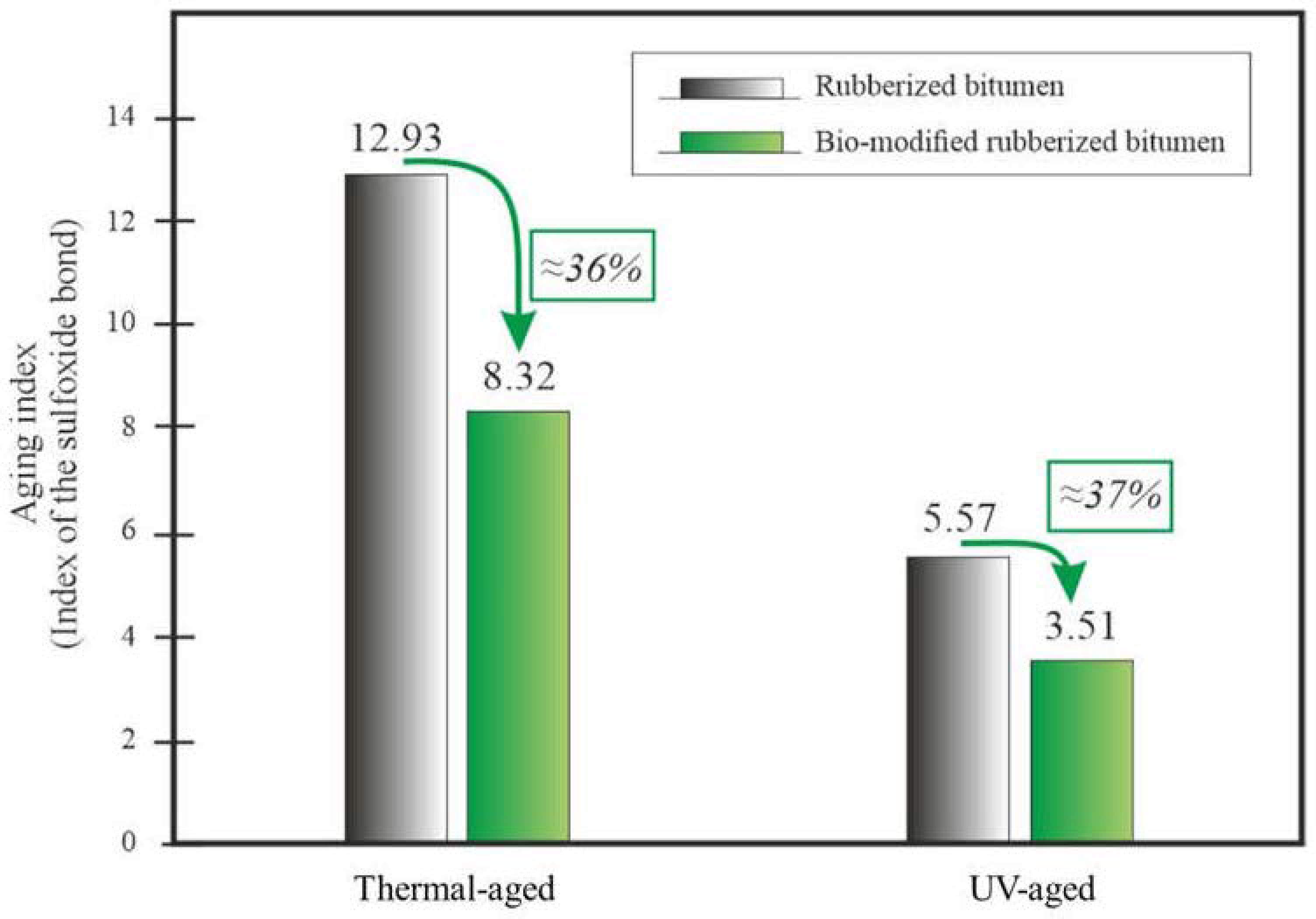

- Lyu, L.; Pei, J.; Hu, D.; Fini, E.H. Durability of Rubberized Asphalt Binders Containing Waste Cooking Oil under Thermal and Ultraviolet Aging. Constr. Build. Mater. 2021, 299, 124282. [Google Scholar] [CrossRef]

- Xie, J.; Yang, Y.; Lv, S.; Zhang, Y.; Zhu, X.; Zheng, C. Investigation on Rheological Properties and Storage Stability of Modified Asphalt Based on the Grafting Activation of Crumb Rubber. Polymers 2019, 11, 1563. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, Y.; Yang, Y.; Ma, Y.; Li, J.; Huang, M. The Effect of Activation Method of Rubber on the Performance of Modified Asphalt Binder. Materials 2020, 13, 3679. [Google Scholar] [CrossRef]

- Jiang, C.; Zhang, Y.; Ma, L.; Zhou, L.; He, H. Tailoring the Properties of Ground Tire Rubber/High-Density Polyethylene Blends by Combining Surface Devulcanization and in-Situ Grafting Technology. Mater. Chem. Phys. 2018, 220, 161–170. [Google Scholar] [CrossRef]

- Kocevski, S.; Yagneswaran, S.; Xiao, F.; Punith, V.; Smith Jr, D.W.; Amirkhanian, S. Surface Modified Ground Rubber Tire by Grafting Acrylic Acid for Paving Applications. Constr. Build. Mater. 2012, 34, 83–90. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Modification of Road Bitumens with Thermoplastic Polymers. Polym. Test. 2000, 20, 77–86. [Google Scholar] [CrossRef]

- Kumar, A.; Choudhary, R.; Kumar, A. Characterisation of Asphalt Binder Modified with Ethylene–Propylene–Diene–Monomer (EPDM) Rubber Waste from Automobile Industry. Road Mater. Pavement Des. 2021, 22, 2044–2068. [Google Scholar] [CrossRef]

- Ito, M. Degradation of Elastomer by Heat and/or Radiation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2007, 265, 227–231. [Google Scholar] [CrossRef]

- Zaharescu, T.; Giurginca, M.; Jipa, S. Radiochemical Oxidation of Ethylene–Propylene Elastomers in the Presence of Some Phenolic Antioxidants. Polym. Degrad. Stab. 1999, 63, 245–251. [Google Scholar] [CrossRef]

- Ghoreishi, A.; Koosha, M.; Nasirizadeh, N. Modification of Bitumen by EPDM Blended with Hybrid Nanoparticles: Physical, Thermal, and Rheological Properties. J. Thermoplast. Compos. Mater. 2020, 33, 343–356. [Google Scholar] [CrossRef]

- Airey, G.D. Rheological Evaluation of Ethylene Vinyl Acetate Polymer Modified Bitumens. Constr. Build. Mater. 2002, 16, 473–487. [Google Scholar] [CrossRef]

- Gonzalez, O.; Munoz, M.; Santamarıa, A.; Garcıa-Morales, M.; Navarro, F.; Partal, P. Rheology and Stability of Bitumen/EVA Blends. Eur. Polym. J. 2004, 40, 2365–2372. [Google Scholar] [CrossRef]

- Ameri, M.; Mansourian, A.; Sheikhmotevali, A.H. Investigating Effects of Ethylene Vinyl Acetate and Gilsonite Modifiers upon Performance of Base Bitumen Using Superpave Tests Methodology. Constr. Build. Mater. 2012, 36, 1001–1007. [Google Scholar] [CrossRef]

- Gad, Y.; Magida, M.; El-Nahas, H. Effect of Ionizing Irradiation on the Thermal Blend of Waste Low Density Polyethylene/Ethylene Vinyl Acetate/Bitumen for Some Industrial Applications. J. Ind. Eng. Chem. 2010, 16, 1019–1024. [Google Scholar] [CrossRef]

- Sonnier, R.; Massardier, V.; Clerc, L.; Lopez-Cuesta, J.M.; Bergeret, A. Reactive Compatibilization of Polymer Blends by Γ-irradiation: Influence of the Order of Processing Steps. J. Appl. Polym. Sci. 2010, 115, 1710–1717. [Google Scholar] [CrossRef]

- Müller, M.T.; Zschech, C.; Gedan-Smolka, M.; Pech, M.; Streicher, R.; Gohs, U. Surface Modification and Edge Layer Post Curing of 3D Sheet Moulding Compounds (SMC). Radiat. Phys. Chem. 2020, 173, 108872. [Google Scholar] [CrossRef]

- Grigoryeva, O.; Starostenko, O.; Fainleib, A.; Martínez-Barrera, G.; Saiter, J.-M.; Youssef, B. Joint Reuse of Post-Consumer Polyolefins and Ground Tire Rubber for Thermoplastic Elastomers Production. Mechanical Performance, Thermal and Radiation Stability. Chem. Chem. Technol. 2012, 6, 59–72. [Google Scholar] [CrossRef]

- Kumar, A.; Choudhary, R. Effect of Microwave Pretreatment on Characteristics of Asphalt Binders Modified with Scrap Non-Tire Automotive Rubber and Waste Derived Pyrolytic Oils after Prolonged Thermal Storage. Constr. Build. Mater. 2024, 419, 135558. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baranowska, W.; Rzepna, M.; Ostrowski, P.; Lewandowska, H. Radiation and Radical Grafting Compatibilization of Polymers for Improved Bituminous Binders—A Review. Materials 2024, 17, 1642. https://doi.org/10.3390/ma17071642

Baranowska W, Rzepna M, Ostrowski P, Lewandowska H. Radiation and Radical Grafting Compatibilization of Polymers for Improved Bituminous Binders—A Review. Materials. 2024; 17(7):1642. https://doi.org/10.3390/ma17071642

Chicago/Turabian StyleBaranowska, Wiktoria, Magdalena Rzepna, Przemysław Ostrowski, and Hanna Lewandowska. 2024. "Radiation and Radical Grafting Compatibilization of Polymers for Improved Bituminous Binders—A Review" Materials 17, no. 7: 1642. https://doi.org/10.3390/ma17071642