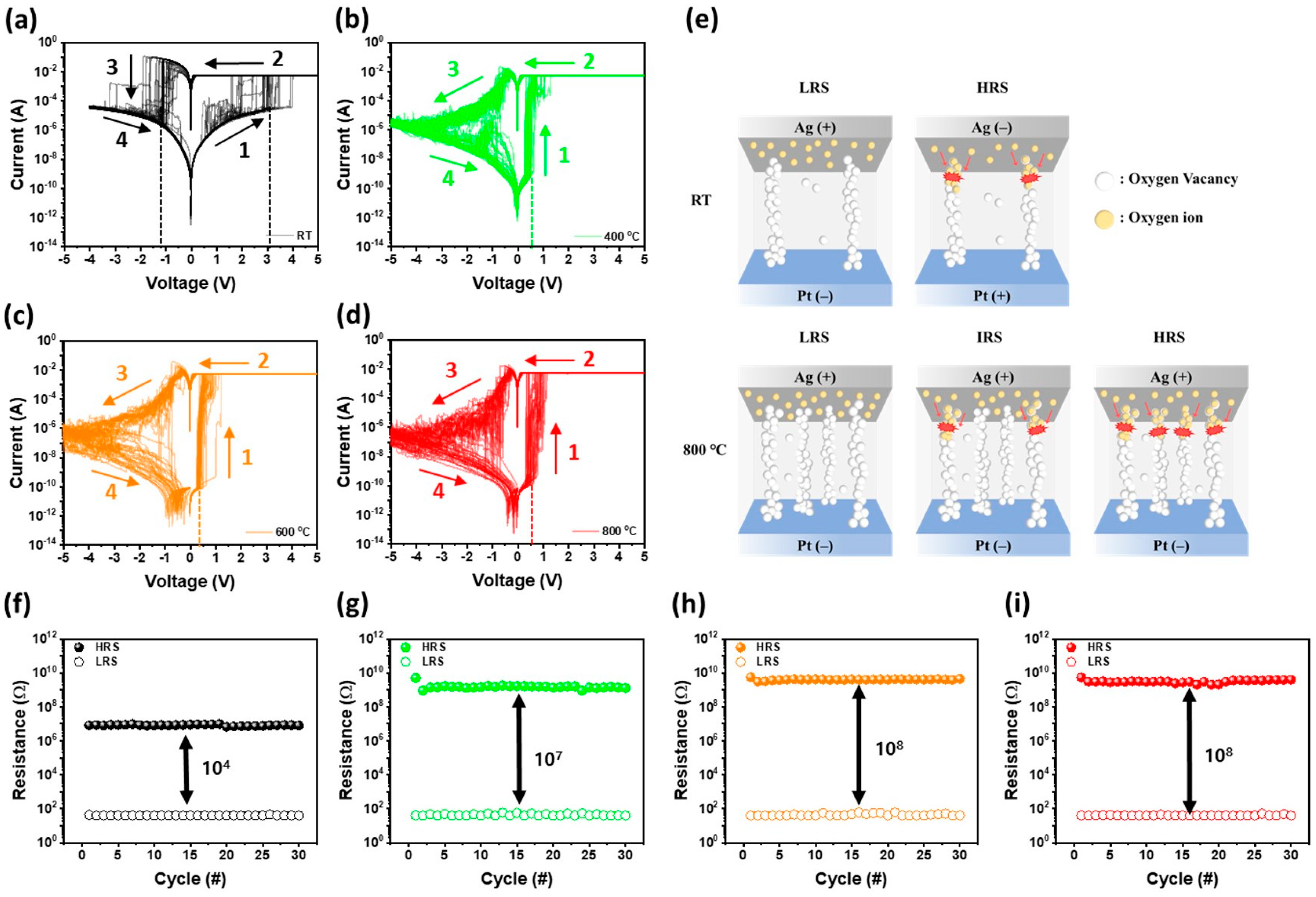

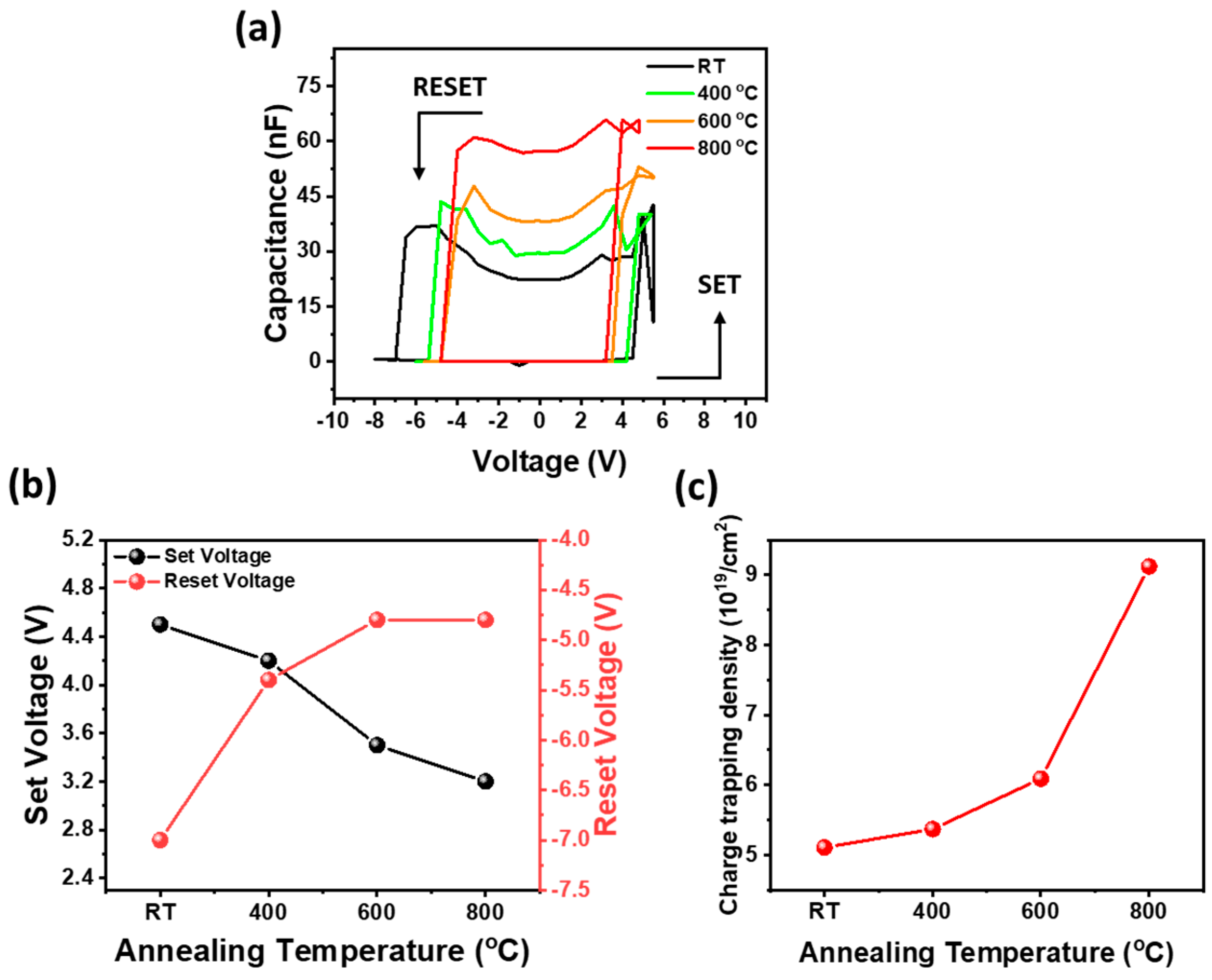

Improvements in Resistive and Capacitive Switching Behaviors in Ga2O3 Memristors via High-Temperature Annealing Process

Abstract

1. Introduction

2. Materials and Methods

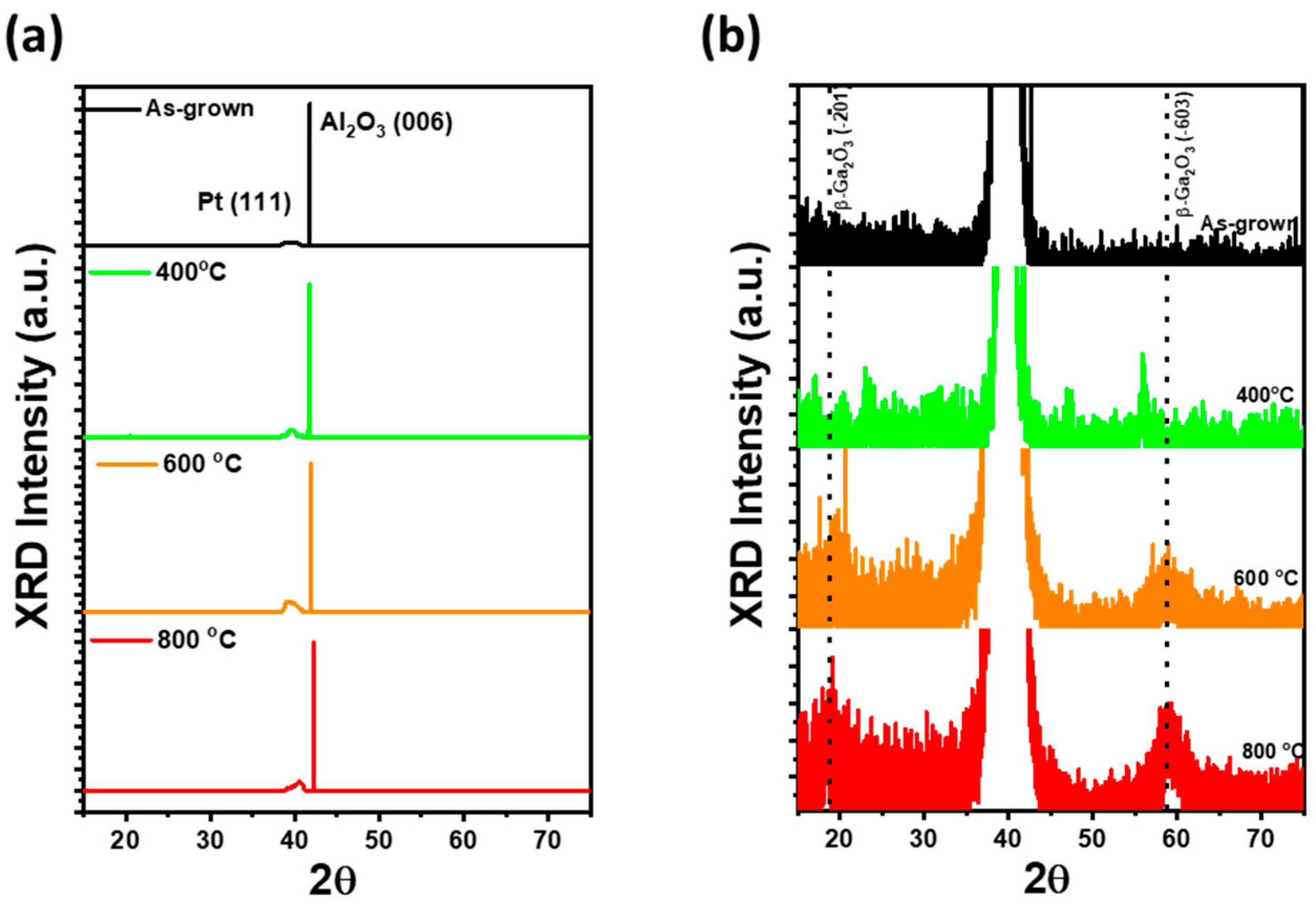

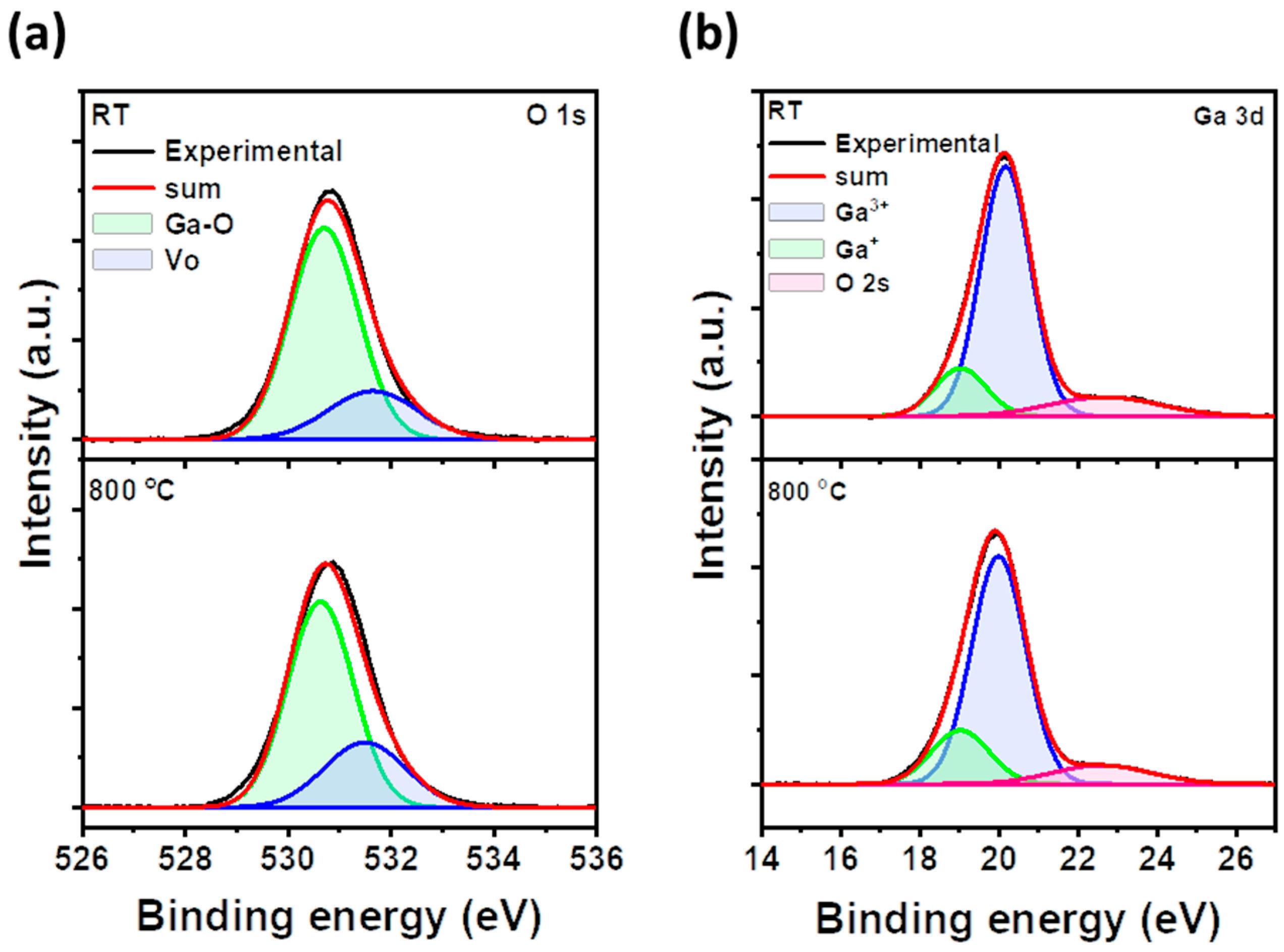

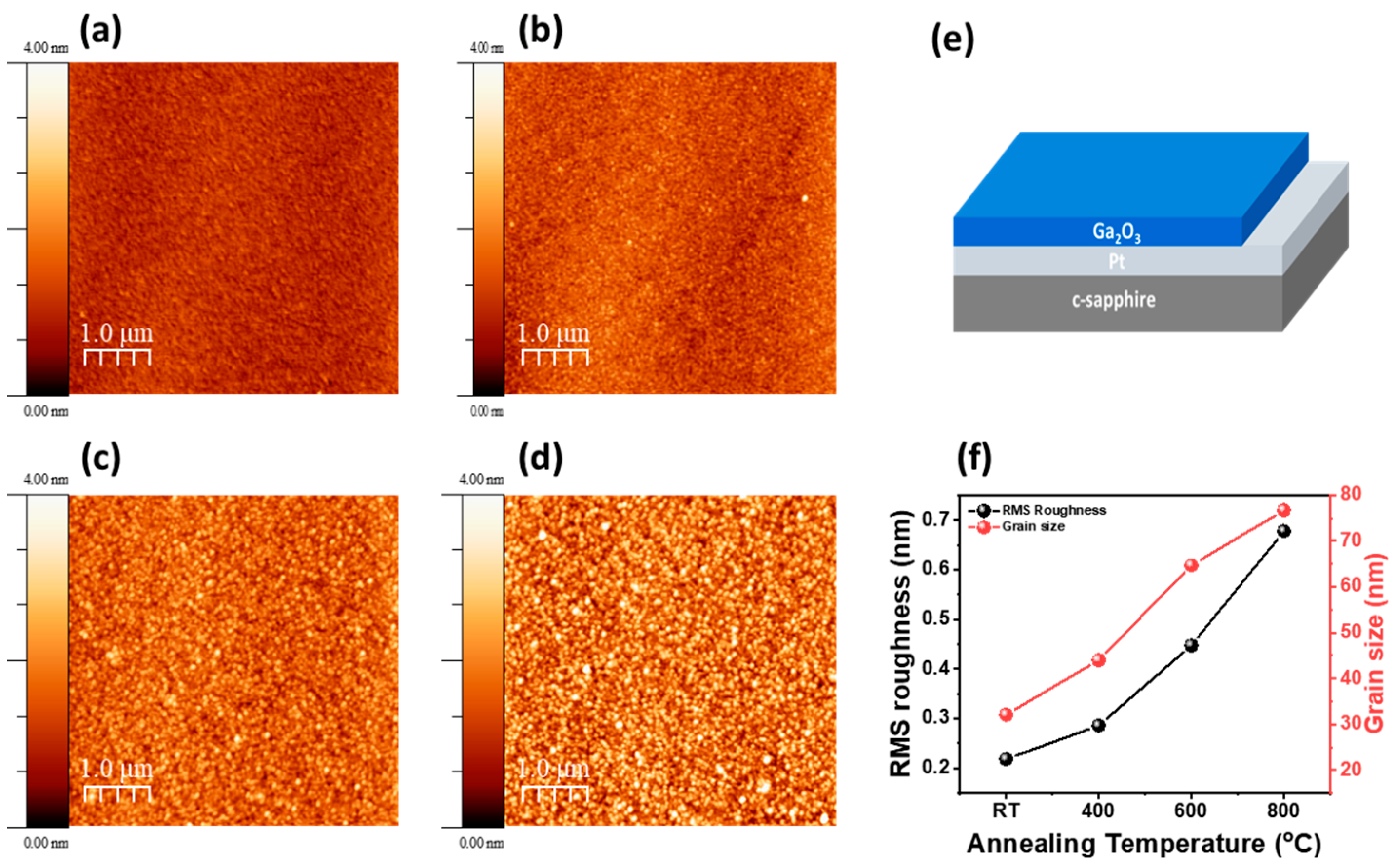

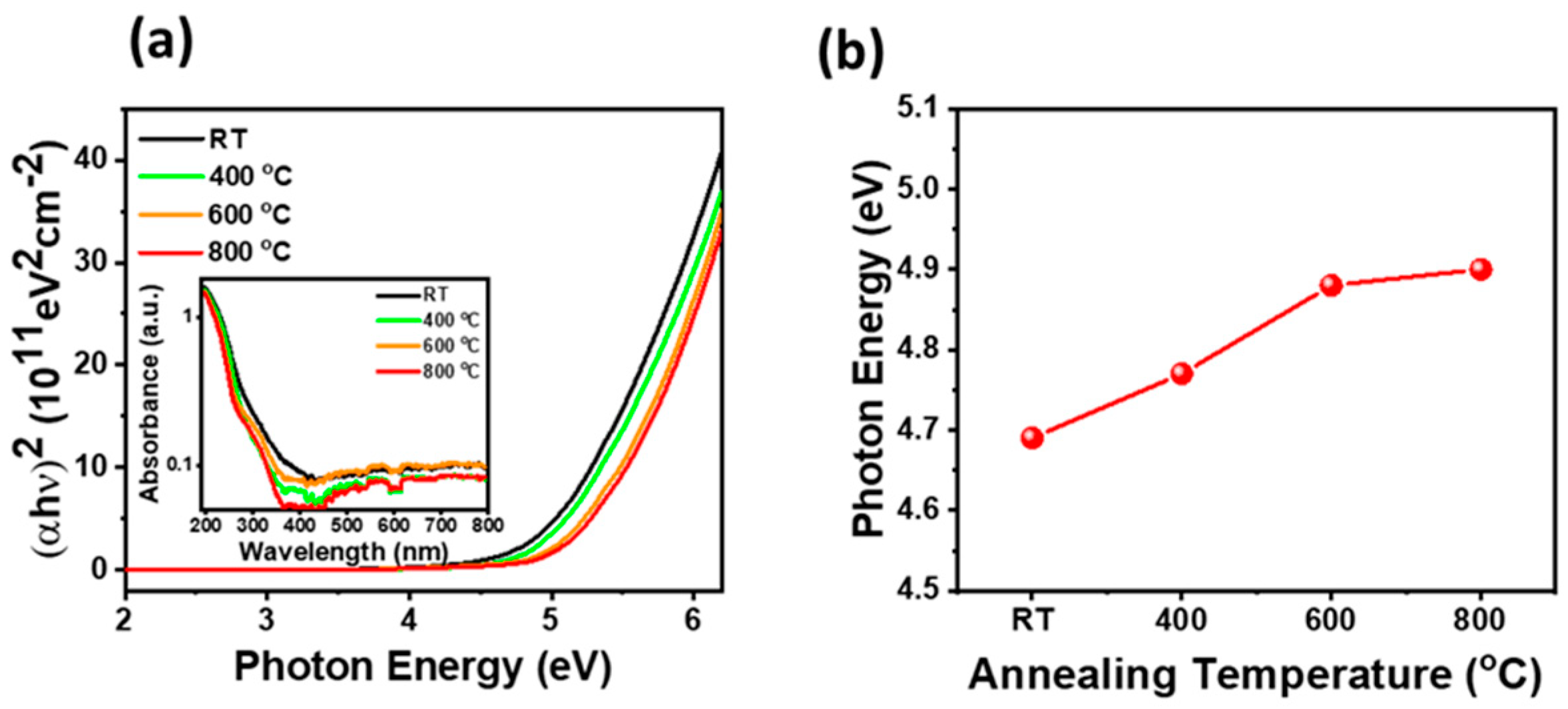

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ohira, S.; Arai, N.; Oshima, T.; Fujita, S. Atomically controlled surfaces with step and terrace of β-Ga2O3 single crystal substrates for thin film growth. Appl. Surf. Sci. 2008, 254, 7838–7842. [Google Scholar] [CrossRef]

- Liu, Z.; Tang, W. A review of Ga2O3 deep-ultraviolet metal–semiconductor Schottky photodiodes. J. Phys. D Appl. Phys. 2023, 56, 093002. [Google Scholar] [CrossRef]

- Nishant, S.J.; Amirkianoosh, K. Gallium Oxide Nanostructures: A Review of Synthesis, Properties and Applications. Nanomaterials 2022, 12, 2061. [Google Scholar] [CrossRef] [PubMed]

- Passlack, M.; Schubert, E.F.; Hobson, W.S.; Hong, M.; Moriya, N.; Chu, S.N.G.; Konstadinidis, K.; Mannaerts, J.P.; Schnoes, M.L.; Zydzik, G.J. Ga2O3 films for electronic and optoelectronic applications. Appl. Phys. Lett. 1995, 77, 686–693. [Google Scholar] [CrossRef]

- Shiu, K.H.; Chiang, T.H.; Chang, P.; Tung, L.T.; Hon, M.; Kwo, J.; Tsai, W. 1 nm equivalent oxide thickness in Ga2O3 (Gd2O3)/In0.2Ga0.8As metal-oxide-semiconductor capacitors. Appl. Phys. Lett. 2008, 92, 172904. [Google Scholar] [CrossRef]

- Suzuki, R.; Nakagomi, S.; Kokubun, Y.; Arai, N.; Ohira, S. Enhancement of responsivity in solar-blind β-Ga2O3 photodiodes with a Au Schottky contact fabricated on single crystal substrates by annealing. Appl. Phys. Lett. 2009, 94, 222102. [Google Scholar] [CrossRef]

- Ogita, M.; Higo, K.; Nakanishi, Y.; Hatanaka, Y. Ga2O3 thin film for oxygen sensor at high temperature. Appl. Surf. Sci. 2001, 175, 721–725. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, H.J.; Kim, H.J.; Choi, J.Y.; Oh, J.H.; Choi, D.C.; Byu, J.; Ahn, S.E.; Lee, S.N. Oxide semiconductor memristor-based optoelectronic synaptic devices with quaternary memory storage. Adv. Electron. Mater. 2024, 2306863. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Midya, R.; Xia, Q.; Yang, J.J. Review of memristor devices in neuromorphic computing: Materials sciences and device challenges. J. Phys. D Appl. Phys. 2018, 51, 503002. [Google Scholar] [CrossRef]

- Di Ventra, M.; Pershin, Y.V.; Chua, L.O. Circuit Elements With Memory: Memristors, Memcapacitors, and Meminductors. Proc. IEEE 2009, 97, 1717–1724. [Google Scholar] [CrossRef]

- Binet, L.; Gourier, D. Optical evidence of intrinsic quantum wells in the transparent conducting oxide β-Ga2O3. Appl. Phys. Lett. 2000, 77, 1138–1140. [Google Scholar] [CrossRef]

- Guo, D.Y.; Wu, Z.P.; An, Y.H.; Li, P.G.; Wang, P.C.; Chu, X.L.; Guo, X.C.; Zhi, Y.S.; Lei, M.; Li, L.H.; et al. Unipolar resistive switching behavior of amorphous gallium oxide thin films for nonvolatile memory applications. Appl. Phys. Lett. 2015, 106, 042105. [Google Scholar] [CrossRef]

- Cui, H.; Mohamed, H.F.; Xia, C.; Sai, Q.; Zhou, W.; Qi, H.; Zhao, J.; Si, J.; Ji, X. Tuning electrical conductivity of β-Ga2O3 single crystals by Ta doping. J. Alloys Compd. 2019, 788, 925–928. [Google Scholar] [CrossRef]

- Alema, F.; Zhang, Y.; Osinsky, A.; Orishchin, N.; Valente, N.; Mauze, A.; Speck, J.S. Low 114 cm−3 free carrier concentration in epitaxial β- Ga2O3 grown by MOCVD. APL Mater. 2020, 8, 021110. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, J.; Qi, D.C.; Chen, L.; Zhang, K.H.L. Recent progress on the electronic structure, defect, and doping properties of Ga2O3. APL Mater. 2020, 8, 020906. [Google Scholar] [CrossRef]

- Liu, Z.; Zhi, Y.; Li, S.; Liu, Y.; Tang, X.; Yan, Z.; Li, P.; Li, X.; Guo, D.; Wu, Z.; et al. Comparison of optoelectrical characteristics between Schottky and Ohmic contacts to β- Ga2O3 thin film. J. Phys. D Appl. Phys. 2020, 53, 085105. [Google Scholar] [CrossRef]

- Shi, T.; Wang, R.; Wu, Z.; Sun, Y.; An, J.; Liu, Q. A Review of Resistive Switching Devices: Performance Improvement, Characterization, and Applications. Small Struct. 2021, 2, 20200109. [Google Scholar] [CrossRef]

- Shen, W.; Dittmann, R.; Breuer, U.; Waser, R. Improved endurance behavior of resistive switching in (Ba, Sr)TiO3 thin films with W top electrode. Appl. Phys. Lett. 2008, 93, 222102. [Google Scholar] [CrossRef]

- Xiong, T.; Li, W.; Yu, P.; Mao, L. Fluidic memristor: Bringing chemistry to neuromorphic devices. Innovation 2023, 4, 100435. [Google Scholar] [CrossRef]

- Choi, B.H.; Im, H.B.; Song, J.S.; Yoon, K.H. Optical and electrical properties of Ga2O3-doped ZnO films prepared by r.f. sputtering. Thin Solid Films 1990, 193, 712–720. [Google Scholar] [CrossRef]

- Saikumar, A.K.; Nehate, S.D.; Sundaram, K.B. Review—RF Sputtered Films of Ga2O3. ECS J. Solid State Sci. Technol. 2019, 8, Q3064. [Google Scholar] [CrossRef]

- Sun, A.; Zhang, Y.; Wu, Z.; Qin, Z.; Ji, H.; Liu, X.; Luo, J.; Hu, W. Sputtering pressure dependence of microstructure and magnetoresistance properties of non-uniform Co–ZnO nanocomposite film. J. Magn. Magn. Mater. 2024, 594, 171886. [Google Scholar] [CrossRef]

- Ievtushenko, A.I.; Karpyna, V.A.; Lazorenko, V.I.; Lashkarev, G.V.; Khranovskyy, V.D.; Baturin, V.A.; Karpenko, O.Y.; Lunika, M.M.; Avramenko, K.A.; Strelchuk, V.V.; et al. High quality ZnO films deposited by radio-frequency magnetron sputtering using layer by layer growth method. Thin Solid Films 2012, 518, 4529–4532. [Google Scholar] [CrossRef]

- Oh, J.H.; Kim, J.H.; Kim, H.J.; Kim, Y.H.; Kim, K.K.; Lee, S.N. Enhanced long-term memory properties of ZnO nanoparticle-based optical synaptic devices for neuromorphic computing. Adv. Intell. Syst. 2023, 5, 2300350. [Google Scholar] [CrossRef]

- Zhang, X.; Jiang, D.; Zhao, M.; Zhang, H.; Li, M.; Xing, M.; Han, J. The effect of annealing temperature on Ga2O3 film properties, Alexey E. Romanov. J. Phys. Conf. Ser. 2021, 1965, 012066. [Google Scholar] [CrossRef]

- Suman, S.; Mukurala, N.; Mohapatra, L.; Kushwaha, A.K. Single step wet-chemical deposition of cesium doped β- Ga2O3 nanostructured films for memristor application. Mem. Mater. Dev. Circuits Syst. 2022, 2, 100015. [Google Scholar]

- Fang, Z.; Yu, H.Y.; Liu, W.J.; Wang, Z.R.; Tran, X.A.; Gao, B.; Kang, J.F. Temperature Instability of Resistive Switching on HfOx-Based RRAM Devices. IEEE Electron Device Lett. 2010, 31, 476–478. [Google Scholar] [CrossRef]

- Walczyk, C.; Walczyk, D.; Schroeder, T.; Bertaud, T.; Sowinska, M.; Lukosi, M.; Fraschke, M.; Wolansky, D.; Tillack, B.; Miranda, E.; et al. Impact of Temperature on the Resistive Switching Behavior of Embedded HfO2-Based RRAM Devices. IEEE Trans. Electron Dev. 2011, 58, 3124–3131. [Google Scholar] [CrossRef]

- Ziyang, L.; Yaoshen, Z.; Zhigang, Y. Low-power soft transistors triggering revolutionary electronics. Innovation 2024, 5, 100616. [Google Scholar]

- Gu, T. Role of oxygen vacancies in TiO2-based resistive switches. J. Appl. Phys. 2013, 113, 033707. [Google Scholar] [CrossRef]

- Lin, Y.S.; Zeng, F.; Tang, S.G.; Liu, H.Y.; Chen, C.; Gao, S.; Wang, Y.G.; Pan, F. Resistive switching mechanisms relating to oxygen vacancies migration in both interfaces in Ti/HfOx/Pt memory devices. J. Appl. Phys. 2013, 113, 064510. [Google Scholar] [CrossRef]

- Ishibashi, K.; Aida, R.; Takahara, M.; Kudo, J.; Tsunoda, I.; Takakura, K.; Nakashima, T.; Shibuya, M.; Murakami, K. Investigation of the crystalline quality of a gallium oxide thick film grown by RF magnetron sputtering. Phys. Status Solidi 2013, 11, 1588. [Google Scholar] [CrossRef]

- Takahara, M.; Funasaki, S.; Kudou, J.; Tsunoda, I.; Takakura, K.; Ohyama, H.; Nakashima, T.; Shibuya, M.; Murakami, K.; Simoen, E.; et al. Improvement of the Crystalline Quality of β- Ga2O3 Films by High-Temperature Annealing. Mater. Sci. Forum 2012, 725, 273–276. [Google Scholar] [CrossRef]

- Sreemany, M. Effect of substrate temperature and annealing temperature on the structural, electrical and microstructural properties of thin Pt films by rf magnetron sputtering. Appl. Surf. Sci. 2006, 253, 2739–2746. [Google Scholar] [CrossRef]

- Saha, R.; Bhowmick, S.; Mishra, M.; Sengupta, A.; Chattopadhyay, S.; Chakrabarti, S. Impact of deposition temperature on crystalline quality, oxygen vacancy, defect modulations and hetero-interfacial properties of RF sputtered deposited Ga2O3 thin films on Si substrate. J. Phys. D Appl. Phys. 2022, 55, 505101. [Google Scholar] [CrossRef]

- Huang, C.Y.; Horng, R.H.; Wuu, D.S.; Tu, L.W.; Kao, H.S. Thermal annealing effect on material characterizations of β- Ga2O3 epilayer grown by metal organic chemical vapor deposition. Appl. Phys. Lett. 2013, 102, 011119. [Google Scholar] [CrossRef]

- Liu, H.; Xu, C.; Pan, X.; Ye, Z. The Photoluminescence Properties of β- Ga2O3 Thin Films. J. Electron. Mater. 2020, 49, 4544–4549. [Google Scholar] [CrossRef]

- Wang, H.; Tang, C.; Yang, W.; Zhao, J.; Liu, L.; Mu, J.; Zhang, Y.; Zeng, C. Recrystallization behavior, oxygen vacancy and photoluminescence performance of sputter-deposited Ga2O3 films via high-vacuum in situ annealing. Ceram. Int. 2022, 48, 3481–3488. [Google Scholar] [CrossRef]

- Mei, M.Y.; Yong, C.H.; Feng, Y.K.; Min, L.; Liang, C.Q.; Jing, L.; Tian, Z.G. High-Pressure and High-Temperature Behaviour of Gallium Oxide. Chin. Phys. Lett. 2008, 25, 1603. [Google Scholar]

- Matsuzaki, K.; Hiramatsu, H.; Nomura, K.; Yanagi, H.; Kamiya, T.; Hirano, M.; Hosono, H. Growth, structure and carrier transport properties of Ga2O3 epitaxial film examined for transparent field-effect transistor. Thin Solid Films 2006, 496, 37–41. [Google Scholar] [CrossRef]

- Mi, W.; Luan, C.; Li, Z.; Zhao, C.; Feng, X.; Ma, J. Ultraviolet–green photoluminescence of β-Ga2O films deposited on MgAl6O10 (1 0 0) substrate. Opt. Mater. 2013, 35, 2624–2628. [Google Scholar] [CrossRef]

- Zhang, T.; Lin, J.; Zhang, X.; Huang, Y.; Xu, X.; Xue, Y.; Zou, J.; Tang, C. Single-crystalline spherical β- Ga2O3 particles: Synthesis, N-doping and photoluminescence properties. J. Lumin. 2013, 140, 30–37. [Google Scholar] [CrossRef]

- Onuma, T.; Fujioka, S.; Yamaguchi, T.; Higashiwaki, M.; Sasaki, K.; Masui, T.; Honda, T. Correlation between blue luminescence intensity and resistivity in β- Ga2O3 single crystals. Appl. Phys. Lett. 2013, 103, 041910. [Google Scholar] [CrossRef]

- Dong, L.; Jia, R.; Xin, B.; Zhang, Y. Effects of post-annealing temperature and oxygen concentration during sputtering on the structural and optical properties of β- Ga2O3 films. J. Vac. Sci. Technol. A 2016, 34, 060602. [Google Scholar] [CrossRef]

- Singh, A.K.; Gupta, M.; Sathe, V.; Katharria, Y.S. Effect of annealing temperature on β- Ga2O3 thin films deposited by RF sputtering method. Superlattices Microstruct. 2021, 156, 106976. [Google Scholar] [CrossRef]

- Cui, D.; Du, Y.; Lin, Z.; Kang, M.; Wang, Y.; Zhang, J.; Hao, Y.; Chang, J. Coexistence of Bipolar and Unipolar Resistive Switching Behavior in Amorphous Ga2O3 Based Resistive Random Access Memory Device. IEEE Electron Device Lett. 2023, 44, 237–240. [Google Scholar] [CrossRef]

- Zhang, F.; Li, H.; Cui, Y.T.; Li, G.L.; Guo, Q. Evolution of optical properties and band structure from amorphous to crystalline Ga2O3 films. AIP Adv. 2018, 8, 045112. [Google Scholar] [CrossRef]

- Dong, L.; Jia, R.; Xin, B.; Peng, B.; Zhang, Y. Effects of oxygen vacancies on the structural and optical properties of β-Ga2O3. Sci. Rep. 2017, 7, 40160. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.J.; Chang, T.C.; Yang, J.B.; Chen, S.C.; Yang, P.C.; Chen, Y.T.; Tseng, H.C.; Sze, S.M.; Chu, A.K.; Tsai, M.J. Influence of Oxygen Concentration on Resistance Switching Characteristics of Gallium Oxide. IEEE Electron Device Lett. 2012, 33, 1387–1389. [Google Scholar] [CrossRef]

- Li, W.; Wan, J.; Tu, Z.; Li, H.; Wu, H.; Liu, C. Optimizing endurance performance of Ga2O3 random resistive access memories by altering oxygen vacancy content. Ceram. Int. 2022, 48, 3185–3191. [Google Scholar] [CrossRef]

- Zhong, C.W.; Tzeng, W.H.; Liu, K.C.; Lin, H.C.; Chang, K.M.; Chan, Y.C.; Kuo, C.C.; Chen, P.S.; Lee, H.Y.; Chen, F.; et al. Effect of ITO electrode with different oxygen contents on the electrical characteristics of HfOx RRAM devices. Surf. Coat. Technol. 2013, 231, 563–566. [Google Scholar] [CrossRef]

- Petzold, S.; Piros, E.; Sharath, S.U.; Zintler, A.; Hildebrandt, E.; Molina-Luna, L.; Wenger, C.; Alff, L. Gradual reset and set characteristics in yttrium oxide based resistive random access memory. Semicond. Sci. Technol. 2019, 34, 075008. [Google Scholar] [CrossRef]

- Lee, H.J.; Kim, J.H.; Choi, J.; Kim, Y.S.; Lee, S.N. Correlation between oxygen flow-controlled resistive switching and capacitance behavior in gallium oxide memristors grown via RF sputtering. Heliyon 2023, 9, e23157. [Google Scholar] [CrossRef]

- Maikap, S.; Das, A.; Wang, T.Y.; Tien, T.C.; Chang, L.B. High- κ HfO2 Nanocrystal Memory Capacitors Prepared by Phase Separation of Atomic-Layer-Deposited HfO2/Al2O3 Nanomixtures. J. Electrochem. Soc. 2009, 156, K28–K32. [Google Scholar] [CrossRef]

- Rahaman, S.Z.; Maikap, S.; Tien, T.C.; Lee, H.Y.; Chen, W.S.; Chen, F.T.; Kao, M.J.; Tsai, M.J. Excellent resistive memory characteristics and switching mechanism using a Ti nanolayer at the Cu/TaOx interface. Nanoscale Res. Lett. 2012, 7, 345. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.J.; Kim, J.-H.; Kim, H.-J.; Lee, S.-N. Improvements in Resistive and Capacitive Switching Behaviors in Ga2O3 Memristors via High-Temperature Annealing Process. Materials 2024, 17, 2727. https://doi.org/10.3390/ma17112727

Lee HJ, Kim J-H, Kim H-J, Lee S-N. Improvements in Resistive and Capacitive Switching Behaviors in Ga2O3 Memristors via High-Temperature Annealing Process. Materials. 2024; 17(11):2727. https://doi.org/10.3390/ma17112727

Chicago/Turabian StyleLee, Hye Jin, Jeong-Hyeon Kim, Hee-Jin Kim, and Sung-Nam Lee. 2024. "Improvements in Resistive and Capacitive Switching Behaviors in Ga2O3 Memristors via High-Temperature Annealing Process" Materials 17, no. 11: 2727. https://doi.org/10.3390/ma17112727

APA StyleLee, H. J., Kim, J.-H., Kim, H.-J., & Lee, S.-N. (2024). Improvements in Resistive and Capacitive Switching Behaviors in Ga2O3 Memristors via High-Temperature Annealing Process. Materials, 17(11), 2727. https://doi.org/10.3390/ma17112727