Evaluation of Cracking Resistance of SMA-13 Hot Recycling Asphalt Mixtures Reinforced by Basalt Fiber

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Reclaimed Asphalt Pavement (RAP)

2.1.2. Rejuvenating Agent

2.1.3. New Aggregates and New Asphalt

2.1.4. Basalt Fiber

2.1.5. Lignin Fiber

2.2. Mixture Design

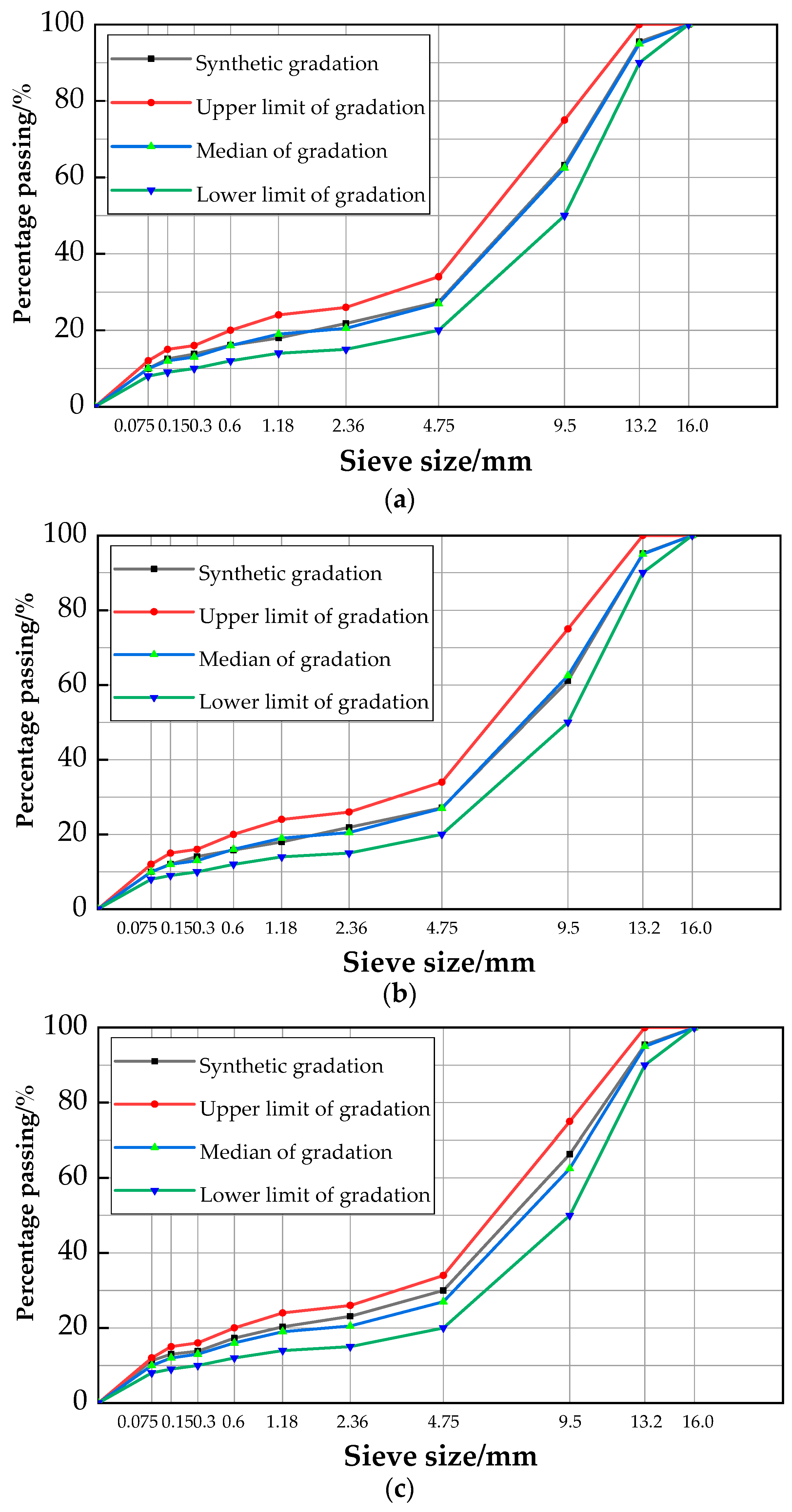

2.2.1. Gradation

2.2.2. Dosage of Rejuvenating Agent

2.2.3. Optimum Oil/Aggregate Ratio

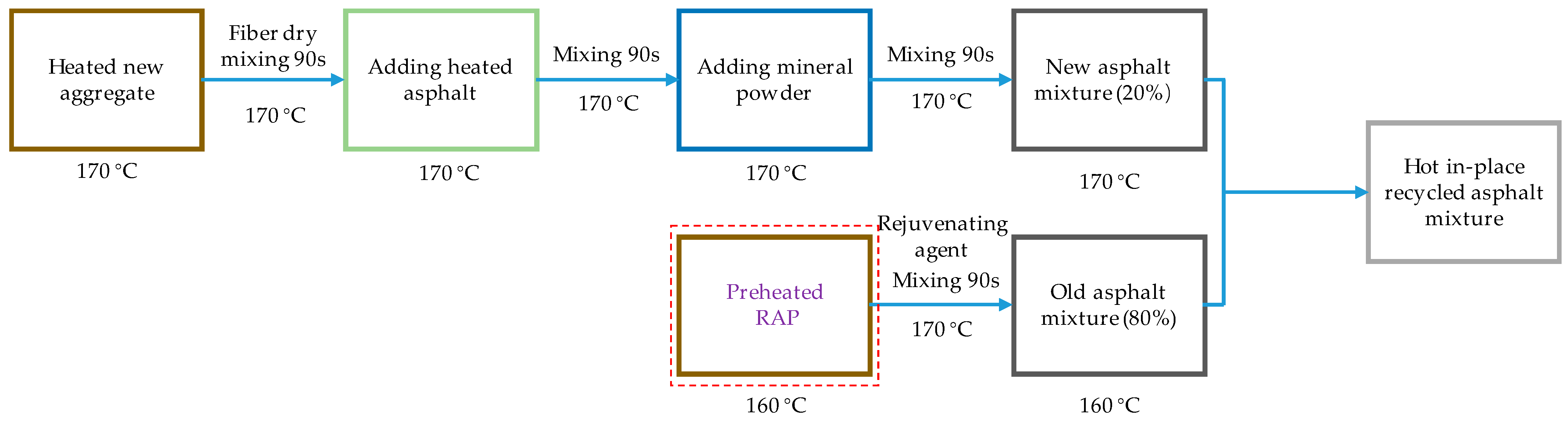

2.2.4. Preparation of Recycled Asphalt Mixture

2.3. Test Method

2.3.1. Trabecular Bending Test

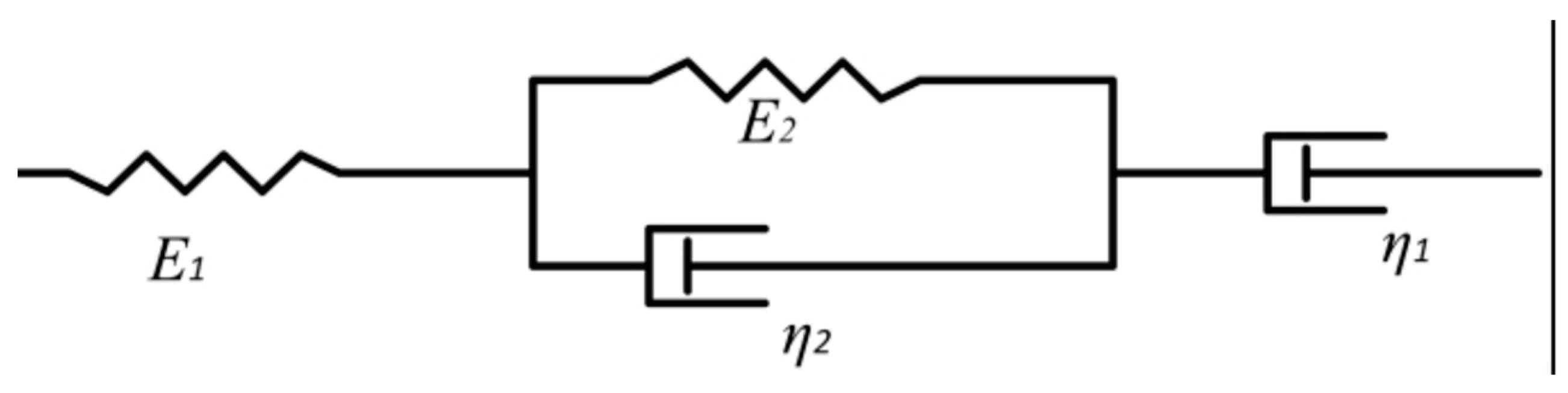

2.3.2. Low-Temperature Creep Test

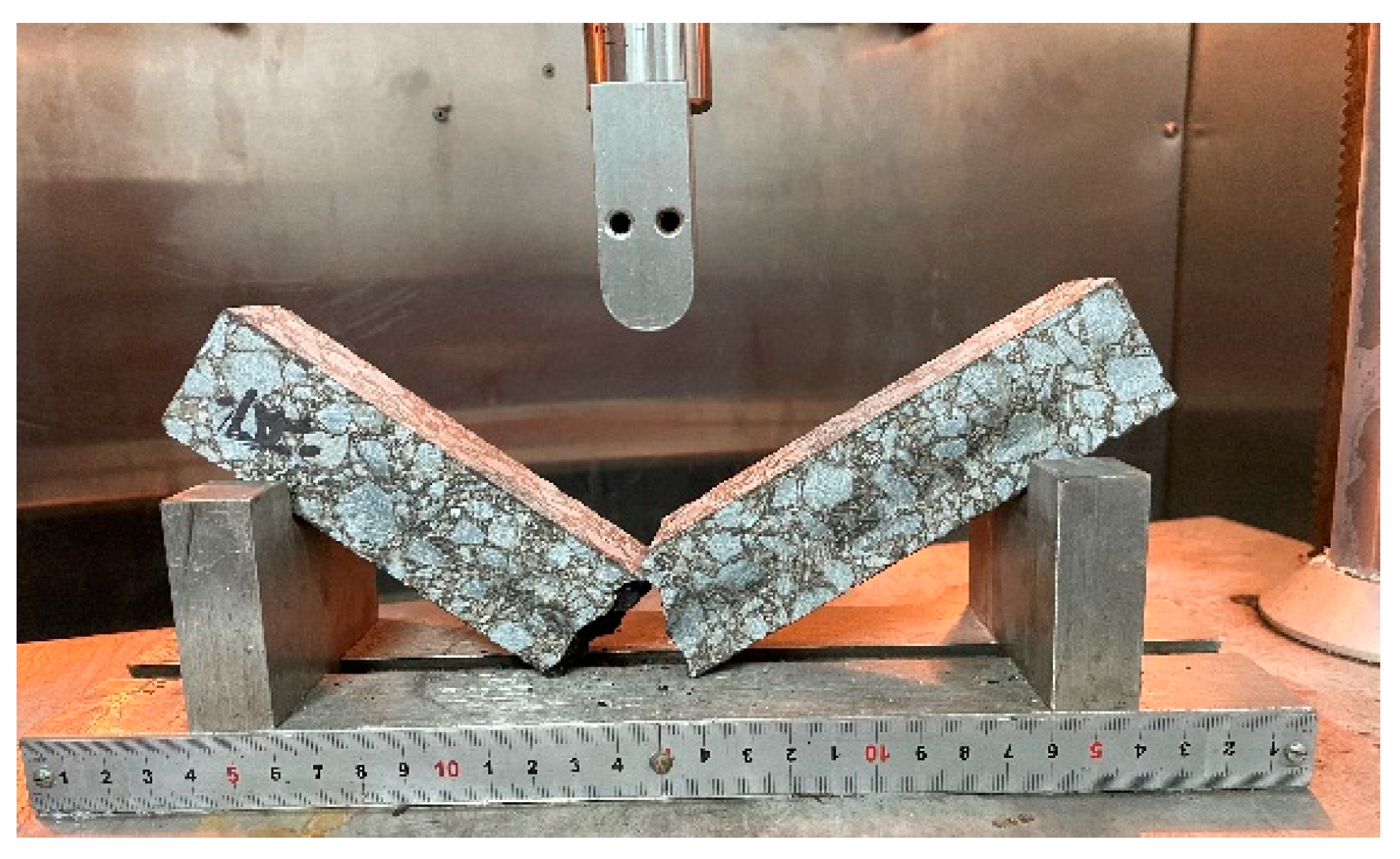

2.3.3. Semi-Circular Bending Test

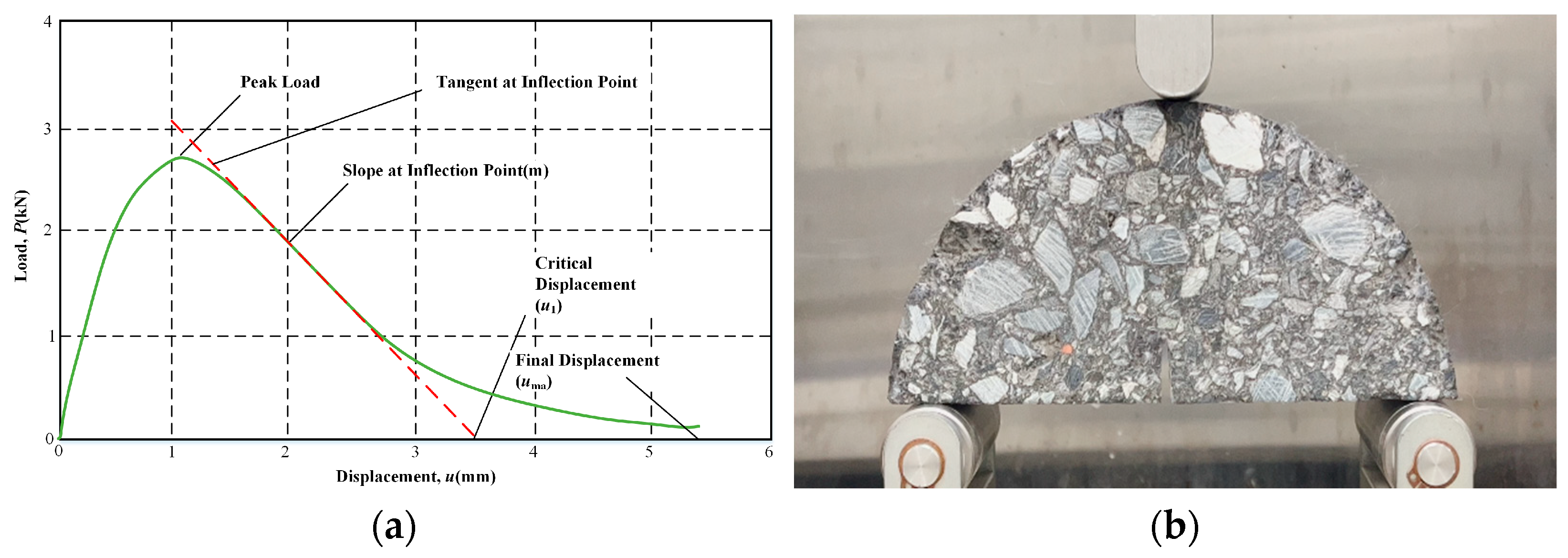

2.3.4. IDEAL Cracking Test

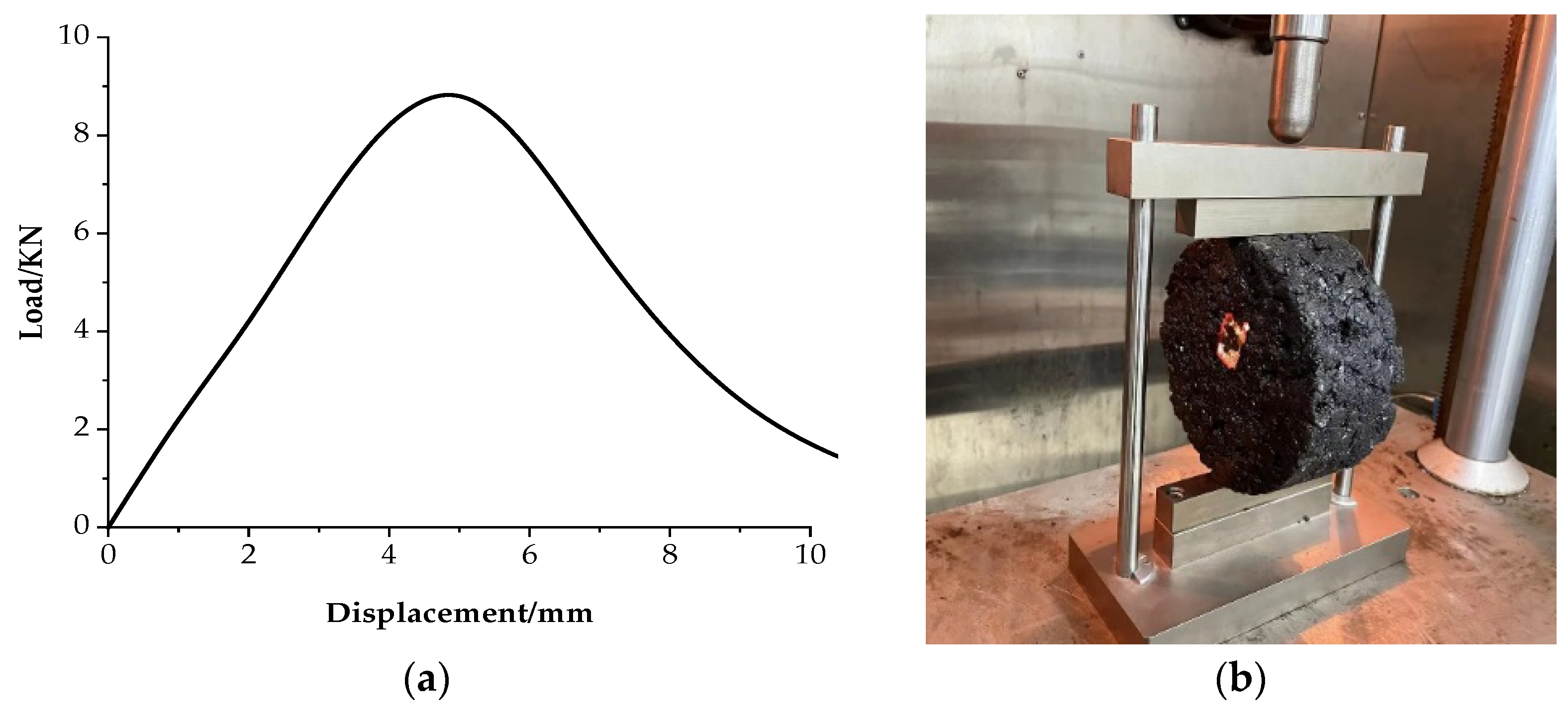

3. Results and Discussion

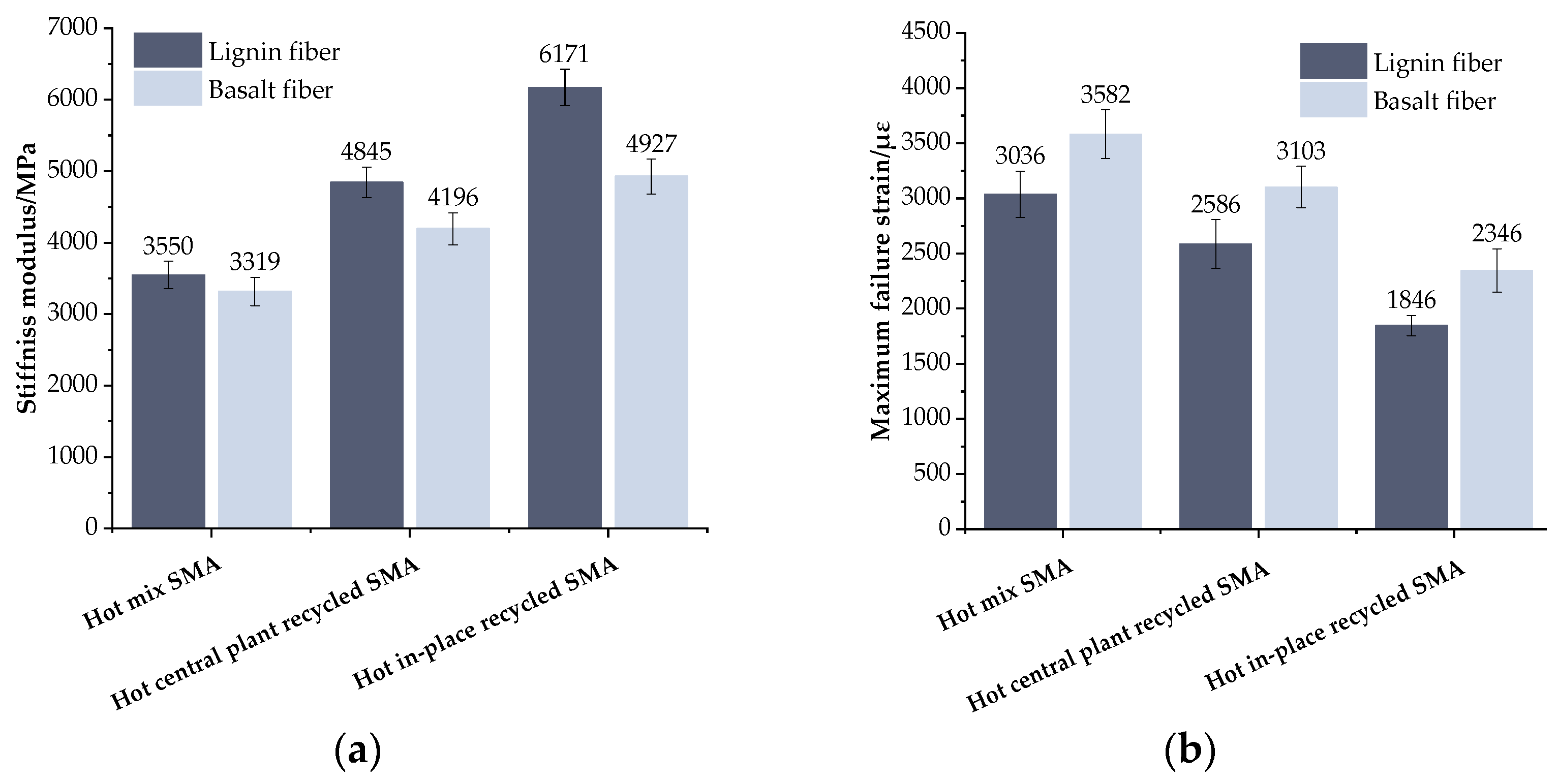

3.1. Results of Trabecular Bending Test

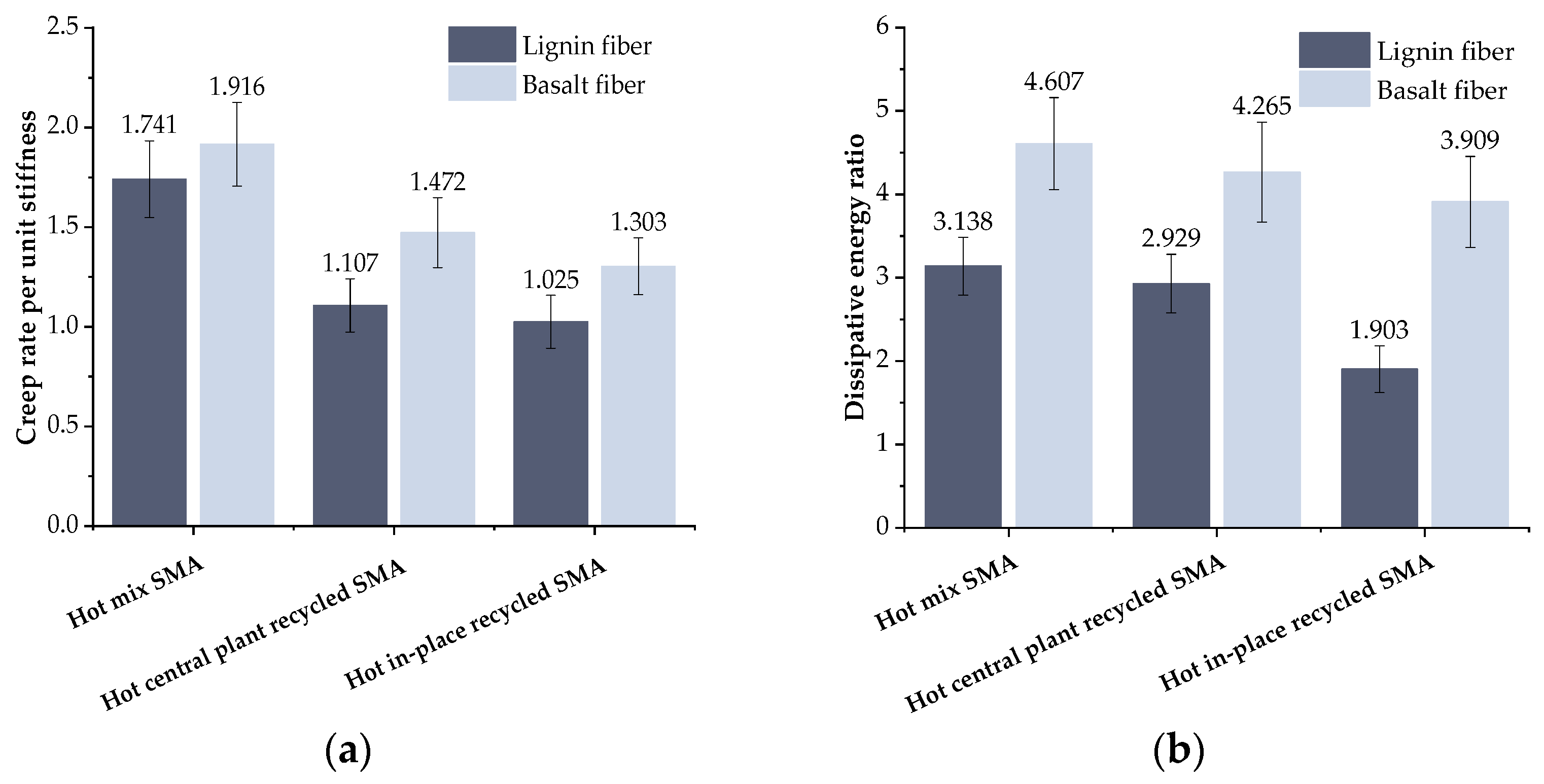

3.2. Results of Low-Temperature Creep Test

3.3. Results of Semi-Circular Bending Test

3.4. Results of IDEAL-CT Cracking Test

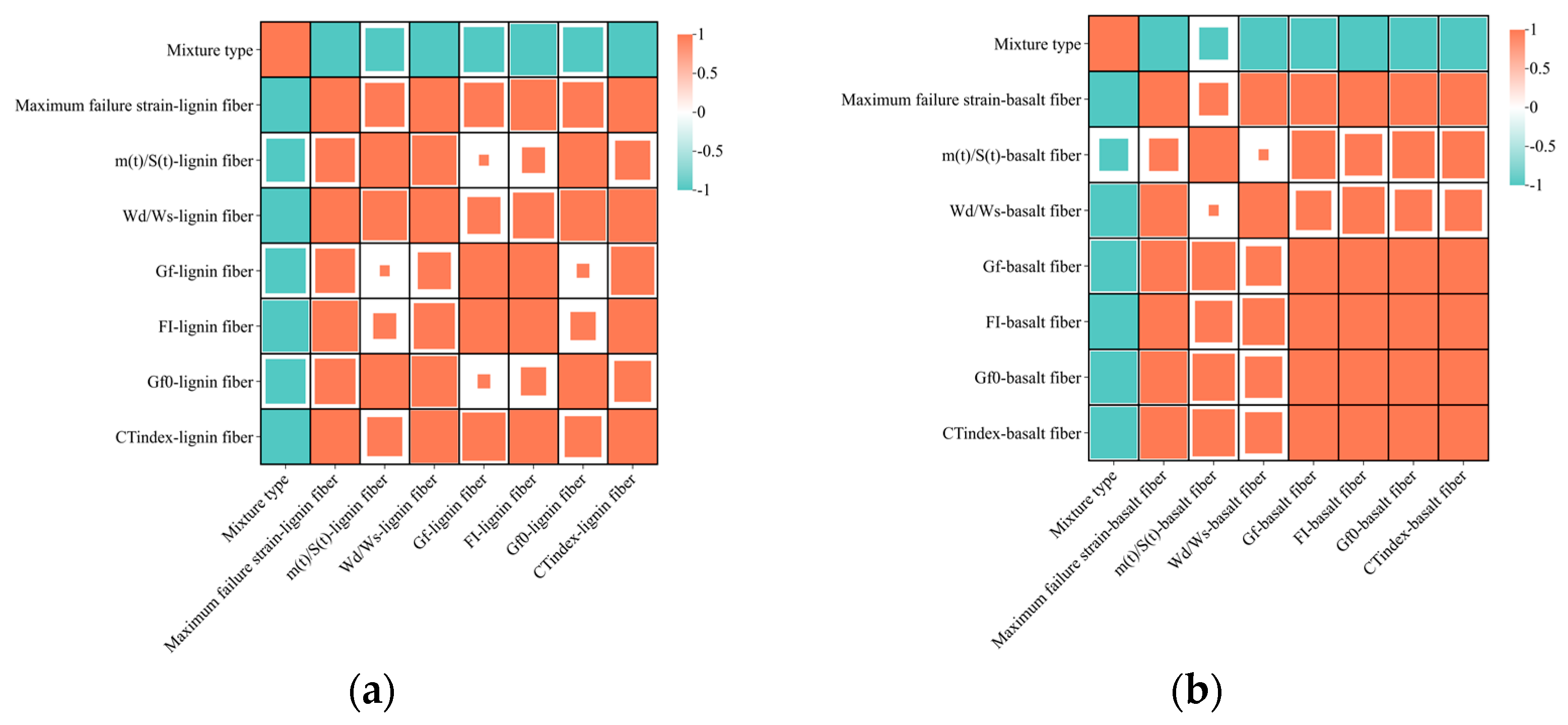

3.5. Correlation Analysis

4. Conclusions

- (1)

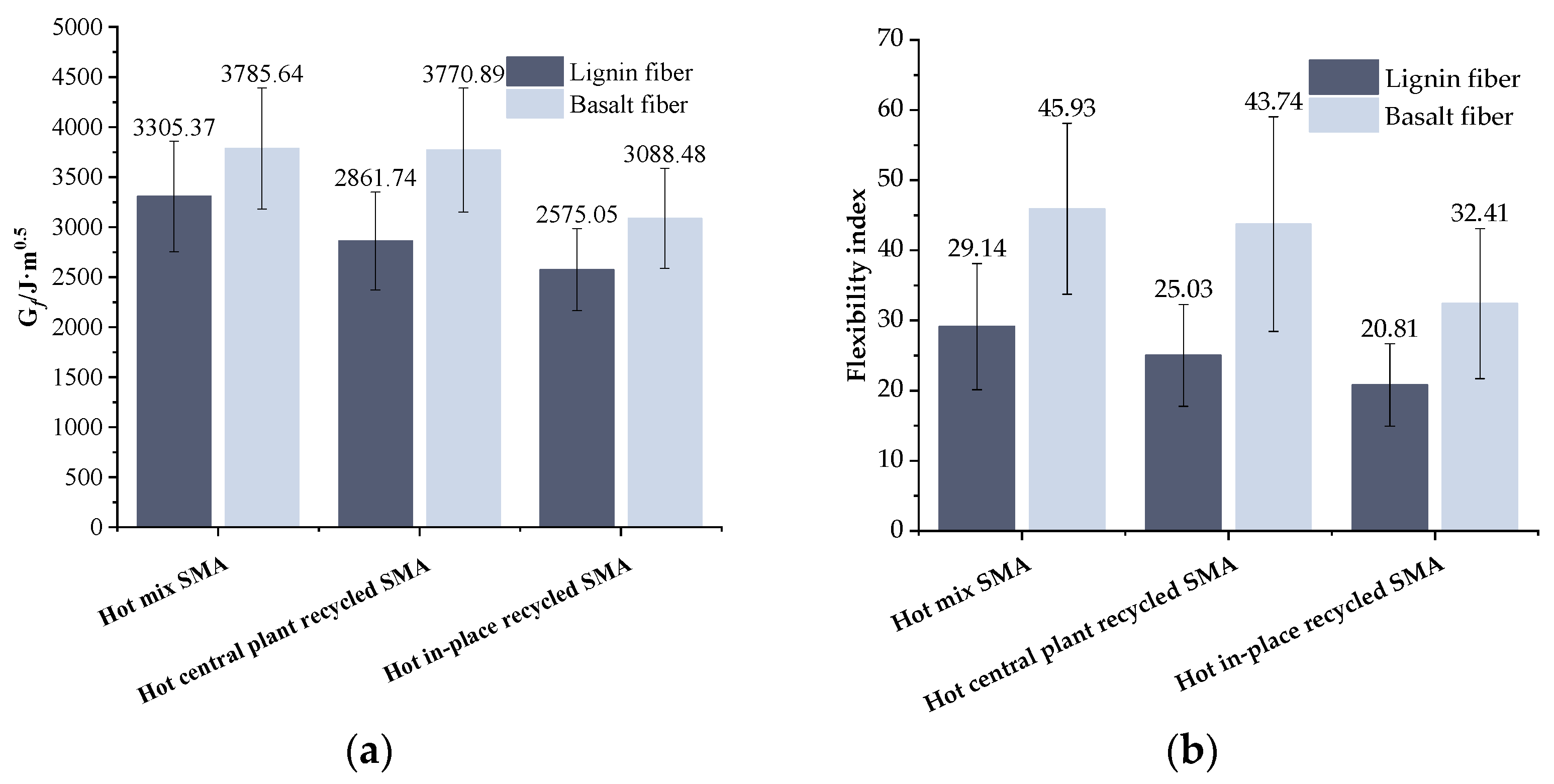

- Compared to the hot mix SMA-13 asphalt mixture, the low and intermediate-temperature cracking resistance of the hot recycled asphalt mixture deteriorated. The amplitude of the hot in-place recycled asphalt mixtures decreased more due to the higher percentage of RAP. In terms of intermediate-temperature cracking resistance, the hot in-place recycled mixture decreased by 22.1% and 28.6% (in terms of Gf and FI, respectively), while the hot central plant recycled mixture decreased by 13.4% and 14.1%. In terms of low-temperature cracking resistance, the hot in-place recycled mixture decreased by 41.1% and 39.4% (in terms of m(t)/S(t) and Wd/Ws, respectively), while the hot central plant recycled mixture decreased by 36.4% and 6.7%.

- (2)

- Basalt fiber improved the low and intermediate-temperature cracking resistance of recycled mixtures compared to lignin fiber. The enhancing amplitude in cracking resistance was greater for the hot in-place recycled mixture. In terms of intermediate-temperature cracking resistance, the hot in-place recycled mixture increased by 19.9% and 55.7% (in terms of Gf and FI, respectively), while the hot central plant recycled mixture increased by 31.8% and 74.8%. In terms of low-temperature cracking resistance, the hot in-place recycled mixture decreased by 27.1% and 105.4% (in terms of m(t)/S(t) and Wd/Ws, respectively), while the hot central plant recycled mixture decreased by 33.0% and 45.6%. It was shown that basalt fibers could improve toughness and enhance energy dissipation.

- (3)

- The results of the above four sets of cracking tests show that basalt fiber could effectively improve the cracking resistance of hot in-place recycled mixtures and hot central plant recycled mixtures, and the test results supplement the research on the application of basalt fiber in asphalt mixtures, which could provide an effective basis for the recycling of pavements.

- (4)

- There were differences in the cracking resistance properties derived from different experimental methods, which may reflect different cracking mechanisms. Based on the correlation analysis, the results indicated that the trabecular bending test was more apt for evaluating the low-temperature cracking resistance of hot recycled asphalt mixtures, whereas the IDEAL-CT test was more suitable for assessing the intermediate-temperature cracking resistance of the mixtures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aravind, K.; Das, A. Pavement design with central plant hot-mix recycled asphalt mixes. Constr. Build. Mater. 2007, 21, 928–936. [Google Scholar] [CrossRef]

- Bowers, B.F.; Powell, R.B. Use of a hot-mix asphalt plant to produce a cold central plant recycled mix: Production method and performance. Transp. Res. Rec. 2021, 2675, 451–459. [Google Scholar] [CrossRef]

- Moon, B.; Bozorgzad, A.; Lee, H.; Kwon, S.; Jeong, K.D.; Cho, N.J. Development of warm in-place recycling technique as an eco-friendly asphalt rehabilitation method. Infrastructure 2021, 6, 101. [Google Scholar] [CrossRef]

- Chiara, R.; Augusto, C.; Massimo, L.; Michael, P. Rheological modeling of asphalt binder and asphalt mortar containing recycled asphalt material. Mater. Struct. 2016, 49, 4167–4183. [Google Scholar]

- Kent, R.; Hansen, A. Asphalt pavement industry survey on recycled materials and warm-mix asphalt usage 2016 (Information Series 138) 7th annual survey. NAPA 2017, 2015. [Google Scholar] [CrossRef]

- Xiang, M.; Jia, W.; Yin, X. Investigation on the Effects of RAP Proportions on the Pavement Performance of Recycled Asphalt Mixtures. Front. Mater. 2022, 8, 841809. [Google Scholar]

- Kocak, S.; Haider, S.W. Performance and cost evaluations of 100% recycled hot asphalt mixtures for pothole patching applications in flexible pavements. Constr. Build. Mater. 2023, 392, 131921. [Google Scholar] [CrossRef]

- Nosetti, A.; Pérez-Madrigal, D.; Pérez-Jiménez, F.; Martínez, A.H. Effect of the recycling process and binder type on bituminous mixtures with 100% reclaimed asphalt pavement. Constr. Build. Mater. 2018, 167, 404–448. [Google Scholar] [CrossRef]

- Mojtaba, M.; Hesham, A.; James, A.; Musse, M.; Gregory, A.; Aidin, M. The effect of aging on the cracking resistance of recycled asphalt. Adv. Civ. Eng. 2017, 2017, 7240462. [Google Scholar]

- Bouraima, M.B.; Zhang, X.H.; Rahman, A.; Qiu, Y.J. A comparative study on asphalt binder and mixture performance of two traffic lanes during hot in-place recycling (HIR) procedure. Constr. Build. Mater. 2019, 223, 33–43. [Google Scholar] [CrossRef]

- Sivilevicius, H.; Braziunas, J.; Prentkovskis, O. Technologies and principles of hot recycling and investigation of preheated reclaimed asphalt pavement batching process in an asphalt mixing plant. Appl. Sci. 2017, 7, 1104. [Google Scholar] [CrossRef]

- Seyed, A.Z.; Fereidoon, M.N.; Mohammad, D.; Mansour, F. Evaluation of rheological and mechanical properties of hot and warm mix asphalt mixtures containing Electric Arc Furnace Slag using gyratory compactor. Constr. Build. Mater. 2023, 378, 131042. [Google Scholar]

- Tran, N.H.; Julian, G.; Taylor, A.J.; Willis, R.; Hunt, D. Effect of geosynthetic material in reclaimed asphalt pavement on performance properties of asphalt mixtures. Transp. Res. Rec. 2012, 2294, 26–33. [Google Scholar] [CrossRef]

- Noto, S.; Mangiafico, S.; Sauzéat, C.; Di Benedetto, H.; Romeo, E.; Tebaldi, G. Diffusion phenomenon between two different bitumens from mechanical analysis. J. Mater. Civil. Eng. 2022, 34, 04021476. [Google Scholar] [CrossRef]

- Nahar, S.N.; Mohajeri, M.; Schmets, A.J.M.; Scarpas, A.; Ven, M.F.C.; Schitter, G. First observation of blending-zone morphology at interface of reclaimed asphalt binder and virgin bitumen. Transport Res. Rec. 2013, 2370, 1–9. [Google Scholar] [CrossRef]

- Mandal, T.; Hanz, A.; Bahia, H. Challenges in using the Disc-Shaped Compact Tension (DCT) test to determine role of asphalt mix design variables in cracking resistance at low temperatures. Int. J. Pavement Eng. 2019, 20, 1275–1284. [Google Scholar] [CrossRef]

- Xiang, S.; Bao, H.; Dragon, V. Evaluation of cracking resistance of recycled asphalt mixture using semi-circular bending test. In Proceedings of the GeoShanghai 2010, Paving Materials and Pavement Analysis, Shanghai, China, 3–5 June 2010; pp. 58–65. [Google Scholar]

- Fu, Z.; Soohyok, I.; Li, S.; Tom, S. Development of an IDEAL cracking test for asphalt mix design and QC/QA. Road Mater. Pavement Des. 2016, 18, 405–427. [Google Scholar]

- Jing, H.; Cong, Y.; Zhang, Y.; Song, L.; Romanovich, M. Mix ratio optimization design method for hot in-place recycled asphalt mixtures. DYNA 2020, 95, 553–560. [Google Scholar] [CrossRef] [PubMed]

- Moon, K.; Falchetto, A.; Marasteanu, M.; Turos, M. Using recycled asphalt materials as an alternative material source in asphalt pavements. KSCE J. Civ. Eng. 2014, 18, 149–159. [Google Scholar] [CrossRef]

- Ming, L.; Li, L.; Wei, H.; Hua, W. Study on the mixing process improvement for hot recycled asphalt mixture. Constr. Build. Mater. 2023, 365, 130068. [Google Scholar]

- Seyedeh, G.H.; Kordani, A.; Mohammad, Z. Effect of recycled additives on pure mode I fracture resistance and moisture susceptibility of hot mix asphalt (HMA): An experimental study using semicircular bending (SCB) and indirect tensile strength (ITS) tests. Theor. Appl. Fract. Mech. 2023, 128, 104168. [Google Scholar]

- Dai, L.; Marie, E.; Yeong, J.; Filippo, G. Future recyclability of hot mix asphalt containing recycled plastics. Constr. Build. Mater. 2023, 368, 130396. [Google Scholar]

- Guo, Q.; Chen, Z.; Liu, P.; Yi, L.; Hu, J.; Gao, Y.; Li, X. Influence of basalt fiber on mode I and II fracture properties of asphalt mixture at medium and low temperatures. Theor. Appl. Fract. Mech. 2021, 112, 102884. [Google Scholar] [CrossRef]

- Pirmohammad, S.; Amani, B.; Shokorlou, Y.M. The effect of basalt fibres on fracture toughness of asphalt mixture. Fatigue Fract. Eng. M 2020, 43, 1446–1460. [Google Scholar] [CrossRef]

- Celauro, C.; Praticò, F.G. Asphalt mixtures modified with basalt fibres for surface courses. Constr. Build. Mater. 2018, 170, 245–253. [Google Scholar] [CrossRef]

- Çetín, A.; Oral, G. Performance evaluation of porous asphalt mixtures modified with basalt fiber. Rev. Constr. 2022, 21, 93–104. [Google Scholar] [CrossRef]

- Ying, H.; Guang, M.; Peng, X.; Qin, T.; Fang, H.; Ai, K.; Zheng, W. Recent advances in basalt fiber reinforced asphalt mixture for pavement applications. Materials 2022, 15, 6826. [Google Scholar] [CrossRef]

- JTG 5142-2019; Technical Specifications for Maintenance of Highway Asphalt Pavement. Ministry of Transport of the People’s Republic of China: Beijing, China, 2019.

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- JTG/T 5521-2019; Technical Specifications for Highway Asphalt Pavement Recycling. Ministry of Transport of the People’s Republic of China: Beijing, China, 2019.

- JTG E42-2005; Test Methods of Aggregatate for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2005.

- GB/T 7690.5; Reinforcements. Test Method for Yarns. Part 5:Determination of Fiber Diameter for Glass Fiber. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2013.

- JT/T 776.1-2010; Basalt Fiber and Product for Highway Engineering—Part 1: Basalt Fiber Chopped Strand. Ministry of Transport of the People’s Republic of China: Beijing, China, 2010.

- GB/T 20310-2006; Textile Glass-Rovings-Manufacture of Test Specimens and Determination of Tensile Strength of Impregnated Rovings. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2006.

- GB/T 1549-2008; Chemical Analysis Methods of Glass, Glass Marble and Vitreous Fiber. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2008.

- AASHTO TP 124-16; Determining the Fracture Potential of Asphalt Mixtures Using Semicircular Bend Geometry (SCB) at Intermediate Temperature. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2016.

- Pei, Z.; Xu, M.; Cao, J.; Feng, D.; Hu, W.; Ren, J.; Jing, R.; Yi, J. Analysis of the microcharacteristics of different kinds of asphalt based on different aging conditions. Mater. Struct. 2022, 55, 250. [Google Scholar] [CrossRef]

- Ke, L.; Peng, X.; Ai, K.; Zheng, W.; Peng, L. Suitability of fiber lengths for hot mix asphalt with different nominal maximum aggregate size: A pilot experimental investigation. Materials 2020, 13, 3685. [Google Scholar] [CrossRef]

- Bo, L.; Yang, Z.; Ai, K.; Ke, L.; Qian, G. Research on fracture behavior of fiber-asphalt mixtures using digital image correlation technology. Materials 2023, 16, 6825. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.W.; Meng, W.J.; Xia, J.; Xiao, P. Influence of basalt fibers on the crack resistance of asphalt mixtures and mechanism analysis. Materials 2022, 15, 744. [Google Scholar] [CrossRef]

- Martin, D.; Zuzana, P.; Michal, J.; Maria, K. Evaluation of the effect of average annual temperatures in Slovakia between 1971 and 2020 on stresses in rigid pavements. Land 2022, 11, 764. [Google Scholar] [CrossRef]

| Property | Old Asphalt | Requirements for SBS Modified Asphalt | Test Method JTG E20 [30] |

|---|---|---|---|

| Penetration (25 °C)/0.1 mm | 39 | 50–80 | T0604 |

| Softening point/°C | 69 | >60 | T0606 |

| Ductility (5 °C)/cm | 7.8 | >30 | T0605 |

| Viscosity (135 °C)/Pa·s | 2.33 | ≤3 | T0613 |

| Sieve Size/mm | 16.0 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

|---|---|---|---|---|---|---|---|---|---|---|

| Upper limit | 100 | 100 | 75 | 34 | 26 | 24 | 20 | 16 | 15 | 12 |

| Lower limit | 100 | 90 | 50 | 20 | 15 | 14 | 12 | 10 | 9 | 8 |

| Median | 100 | 95 | 62.5 | 27 | 20.5 | 19 | 16 | 13 | 12 | 10 |

| RAP | 100.0 | 96.3 | 64.3 | 30.1 | 24.5 | 19.7 | 17.0 | 14.8 | 12.6 | 10.2 |

| Technical Index | RA-102 | Requirements in JTG/T 5521-2019 [31] | Test Method JTG E20 |

|---|---|---|---|

| Viscosity at 60 °C/cP | 4000 | — — | T0619 |

| Flashpoint/°C | 248 | ≥220 | T0633 |

| Saturated fraction content/% | 25.6 | ≤30 | T0618 |

| Aromatic content/% | 53 | ≥30 | T0618 |

| Viscosity ratio (RTFOT pre to post) | 1.34 | ≤3 | T0610 |

| Mass change (%, RTFOT pre to post) | 1.02 | ≤4% | T0603 |

| Index | Results | Test Method |

|---|---|---|

| Diameter/μm | 17 | GB/T 7690.5 [33] |

| Length range/mm | 3–9 mixed length | JT/T 776.1 [34] |

| Fracture strength/MPa | 2430 | GB/T 20310 [35] |

| Elongation at break/% | 3.0 | GB/T 20310 |

| Modulus of elasticity/GPa | 84.5 | GB/T 20310 |

| Heat resistance, retained fracture strength/% | 94.8 | JT/T 776.1 |

| (Fe2O3 + FeO) content/% | 9.68 | GB/T 1549 [36] |

| Acidity factor | 6.1 | GB/T 1549 |

| Index | Requirements | Results |

|---|---|---|

| Ash content/% | 18 ± 5 | 19.3 |

| PH Value | 7.5 ± 1.0 | 7.7 |

| Oil absorption | 5 times the fiber quality | 6.2 |

| Property | Rejuvenating Agent Dosage | New Asphalt | Test Method JTG E20 | ||||

|---|---|---|---|---|---|---|---|

| 0 | 4 | 6 | 8 | 10 | |||

| Penetration (0.1 mm, 25 °C) | 39 | 60 | 68 | 74 | 78 | 71 | T0604 |

| Softening point (°C) | 69 | 65 | 63 | 61 | 56 | 64 | T0606 |

| Ductility (cm, 5 °C) | 7.8 | 22.4 | 28.6 | 31.4 | 34.6 | 48 | T0605 |

| Gradation Type | Fiber Type | Fiber Dosage/‰ | Oil/Aggregate Ratio/% | Air Voids/% | Voids in Mineral Aggregate/% | Voids Filled with Asphalt/% | Marshall Stability/kN |

|---|---|---|---|---|---|---|---|

| Hot mixed SMA-13 | Lignin fiber | 3 | 6.0 | 3.8 | 17.2 | 74.8 | 8.4 |

| Basalt fiber (6 mm) | 3 | 5.8 | 4.3 | 16.8 | 74.4 | 11.5 | |

| Hot central plant recycled SMA-13 | Lignin fiber | 3 | 6.1 | 4.4 | 17.5 | 74.9 | 10.3 |

| Basalt fiber (6 mm) | 3 | 5.9 | 4.1 | 17.1 | 76.0. | 12.1 | |

| Hot in-place recycled SMA-13 | Lignin fiber | 1 | 6.0 | 4.0 | 17.5 | 78.3 | 11.3 |

| Basalt fiber (6 mm) | 3 | 6.0 | 4.1 | 17.5 | 76.9 | 12.5 | |

| Requirements | —— | —— | —— | 3~4.5 | ≥16.5 | 70~85 | ≥6 |

| Gradation Type | Fiber Type | Flyaway Losses/% | Leakage Losses/% |

|---|---|---|---|

| Hot mixed SMA-13 | Lignin fiber | 6.8 | 0.09 |

| Hot mixed SMA-13 | Basalt fiber (6 mm) | 4.5 | 0.08 |

| Hot central plant recycled SMA-13 | Lignin fiber | 7.3 | 0.08 |

| Hot central plant recycled SMA-13 | Basalt fiber (6 mm) | 4.9 | 0.07 |

| Hot in-place recycled SMA-13 | Lignin fiber | 7.9 | 0.09 |

| Hot in-place recycled SMA-13 | Basalt fiber (6 mm) | 5.4 | 0.08 |

| Requirements | —— | ≤15 | ≤0.1 |

| Pearson’s correlation coefficients | Size of Correlation | Interpretation |

| 0.9 to 1.0 (−0.9 to −1.0) | Very high positive (negative) correlation | |

| 0.7 to 0.9 (−0.7 to −0.9) | High positive (negative) correlation | |

| 0.5 to 0.7 (−0.5 to −0.7) | Moderate positive (negative) correlation | |

| 0.3 to 0.5 (−0.3 to −0.5) | Low positive (negative) correlation | |

| 0.0 to 0.3 (−0.0 to −0.3) | Negligible correlation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhang, Y.; Li, B.; Kang, A.; Wang, Y. Evaluation of Cracking Resistance of SMA-13 Hot Recycling Asphalt Mixtures Reinforced by Basalt Fiber. Materials 2024, 17, 1762. https://doi.org/10.3390/ma17081762

Zhang Y, Zhang Y, Li B, Kang A, Wang Y. Evaluation of Cracking Resistance of SMA-13 Hot Recycling Asphalt Mixtures Reinforced by Basalt Fiber. Materials. 2024; 17(8):1762. https://doi.org/10.3390/ma17081762

Chicago/Turabian StyleZhang, Yu, Yao Zhang, Bo Li, Aihong Kang, and Yu Wang. 2024. "Evaluation of Cracking Resistance of SMA-13 Hot Recycling Asphalt Mixtures Reinforced by Basalt Fiber" Materials 17, no. 8: 1762. https://doi.org/10.3390/ma17081762

APA StyleZhang, Y., Zhang, Y., Li, B., Kang, A., & Wang, Y. (2024). Evaluation of Cracking Resistance of SMA-13 Hot Recycling Asphalt Mixtures Reinforced by Basalt Fiber. Materials, 17(8), 1762. https://doi.org/10.3390/ma17081762