Degradation Behavior and Lifetime Prediction of Polyurea Anti-Seepage Coating for Concrete Lining in Water Conveyance Tunnels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Field Investigation (In Situ Testing)

2.2. Accelerated Aging Test

2.2.1. Preparation of Specimens

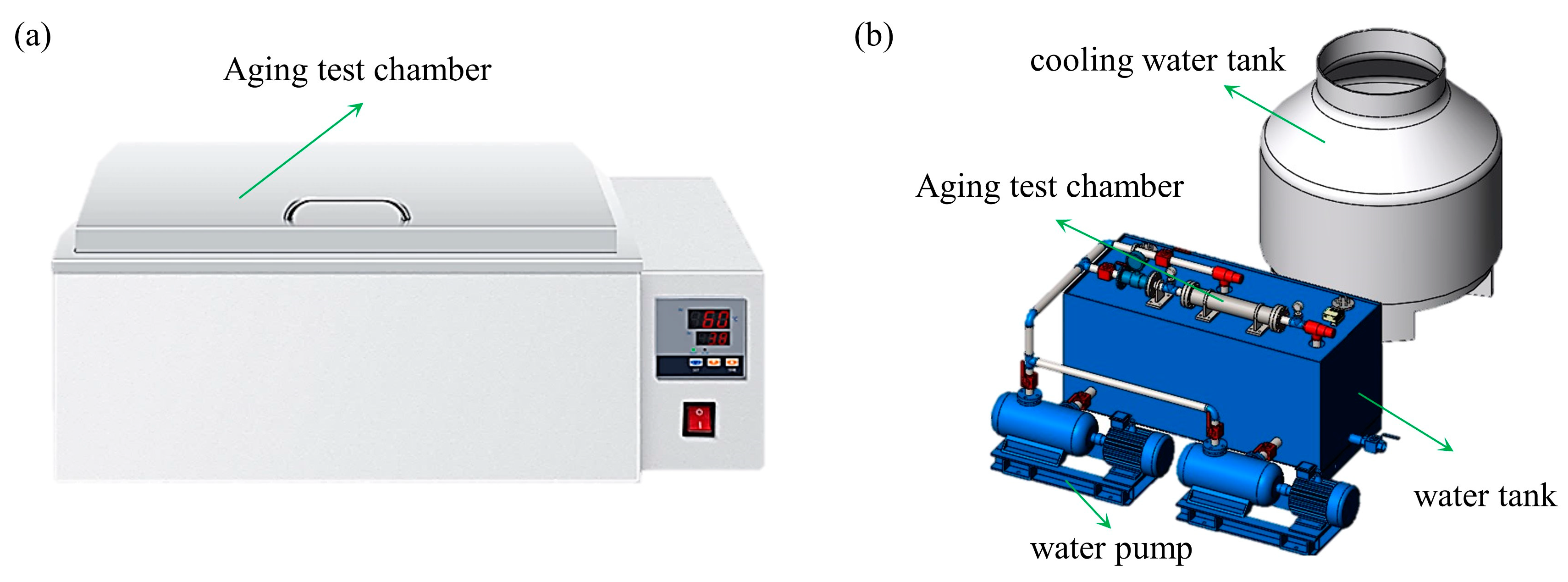

2.2.2. Aging Test Device

2.2.3. Experimental Design

3. Results

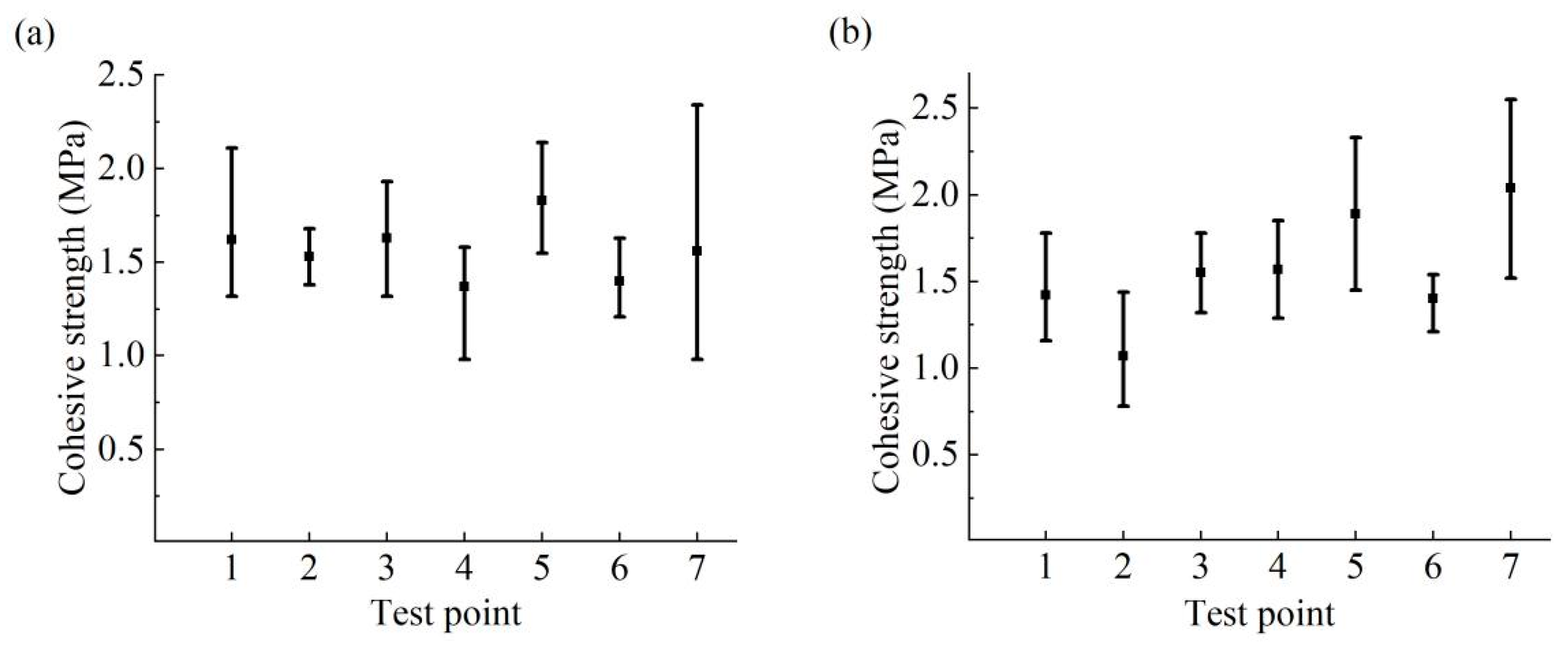

3.1. The Results of In Situ Testing

3.2. Aging Test Results in the Laboratory

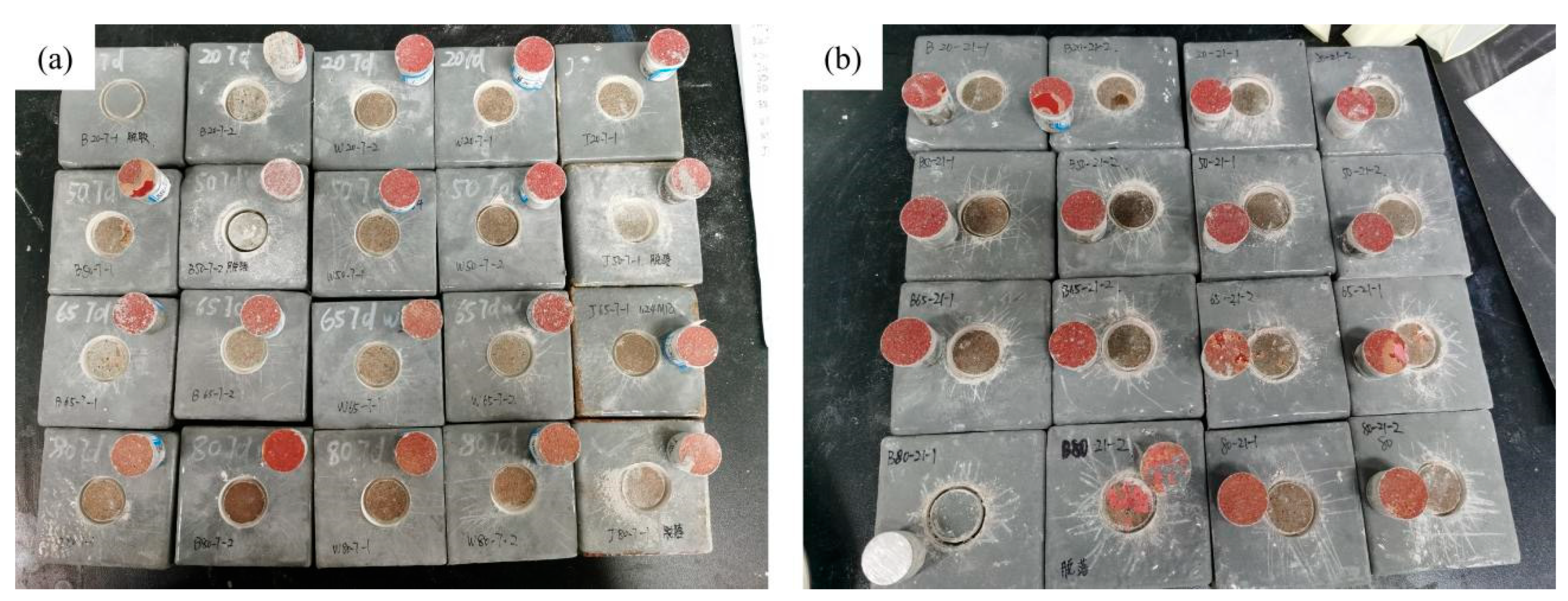

3.2.1. Hydrothermal Aging Test

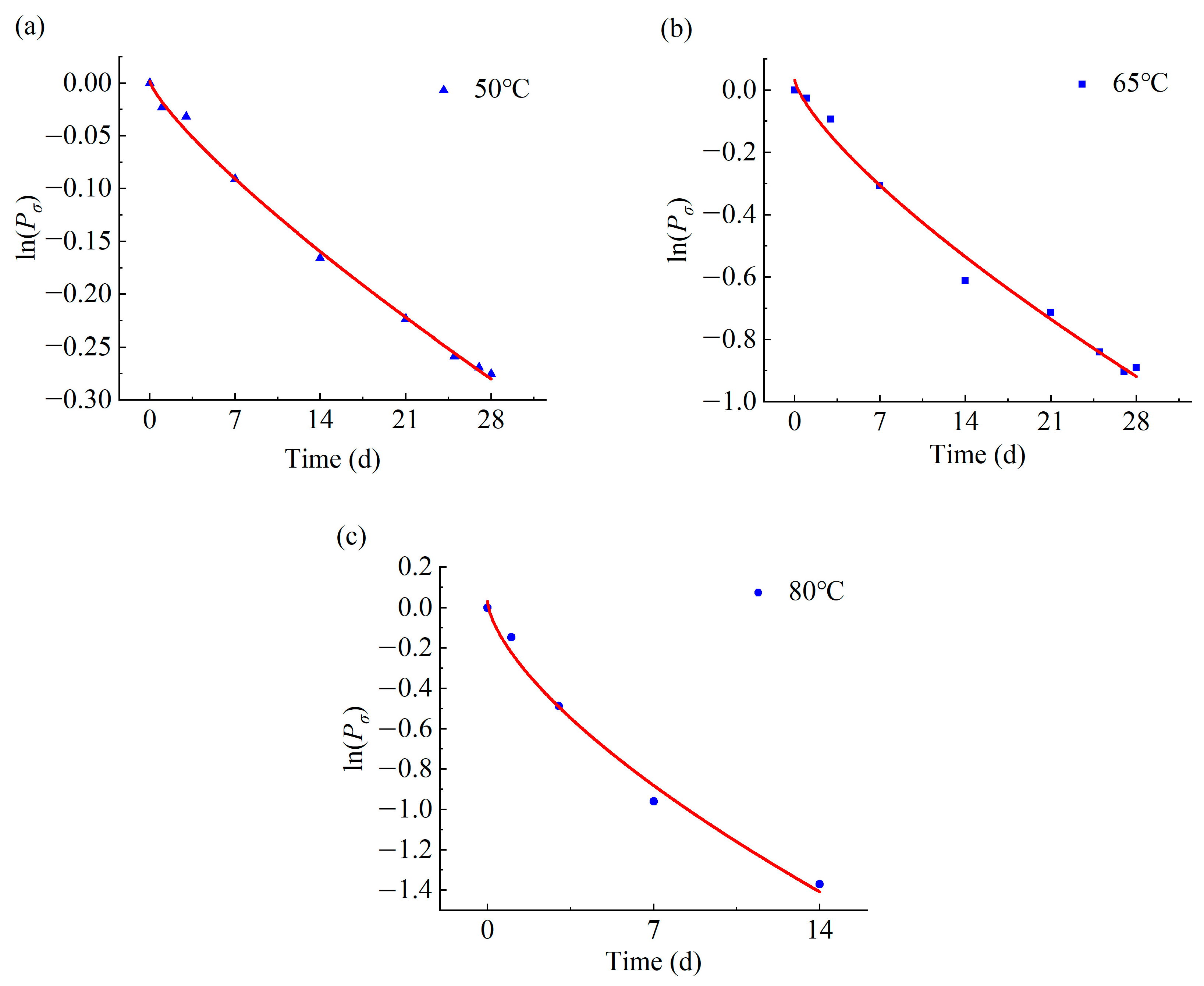

3.2.2. Aging Test under Simulated On-Site Environment

4. Discussion

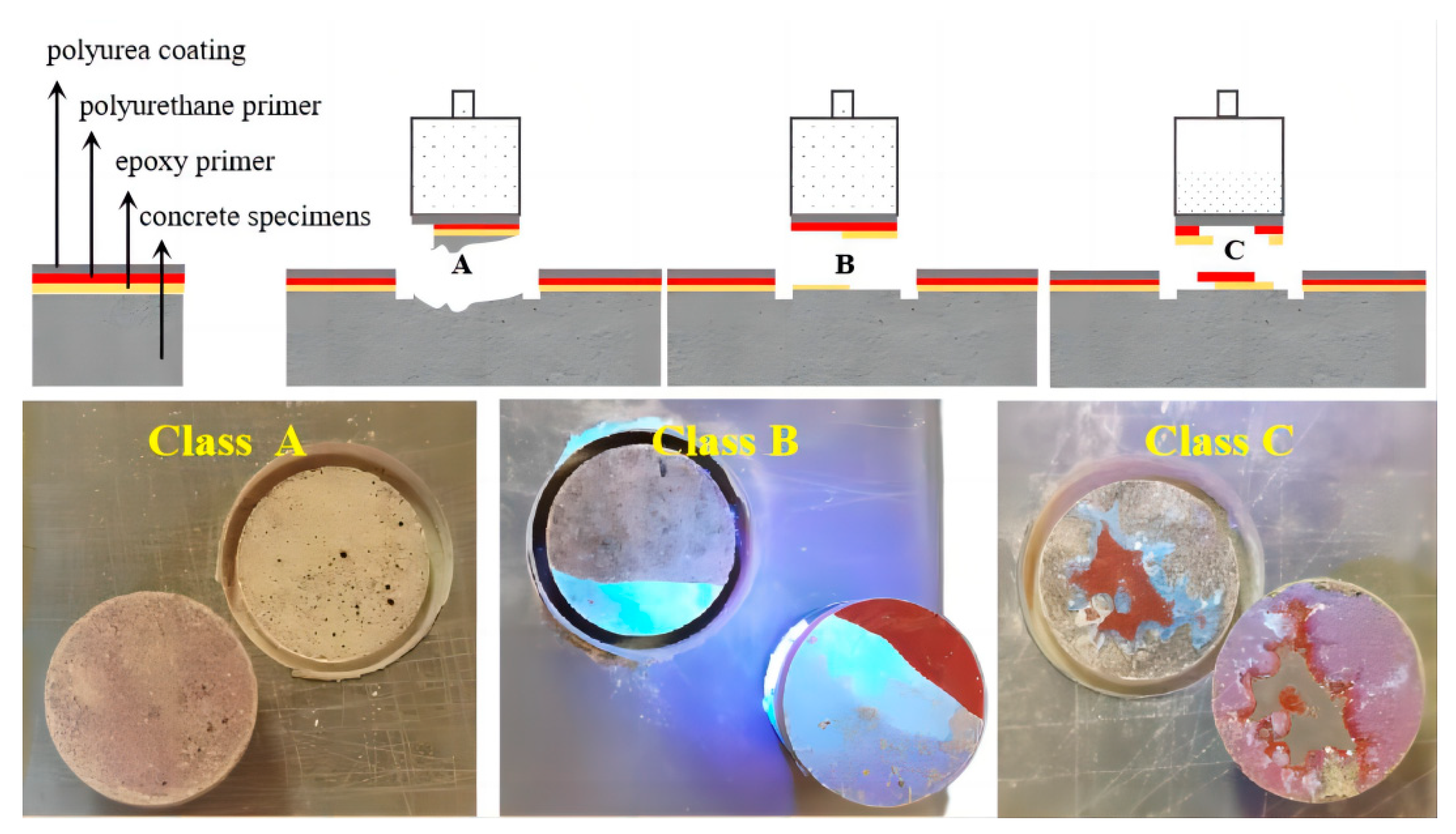

4.1. Failure Types Analysis

4.1.1. Failure Types of the Hydrothermal Aging Test

4.1.2. Failure Types of the Simulated Tunnel Environment Aging Test

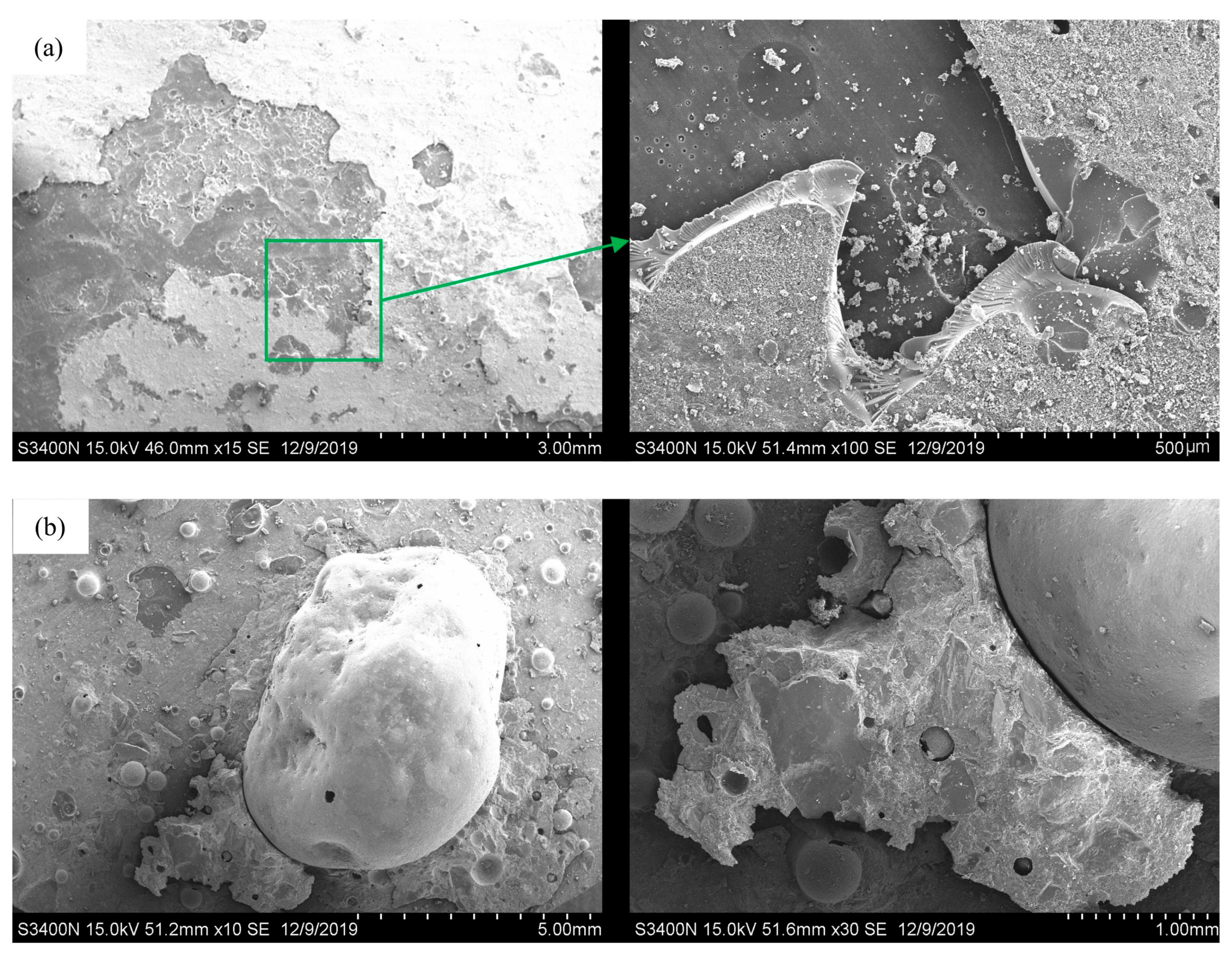

4.1.3. SEM Characterization of Typical Failure Types

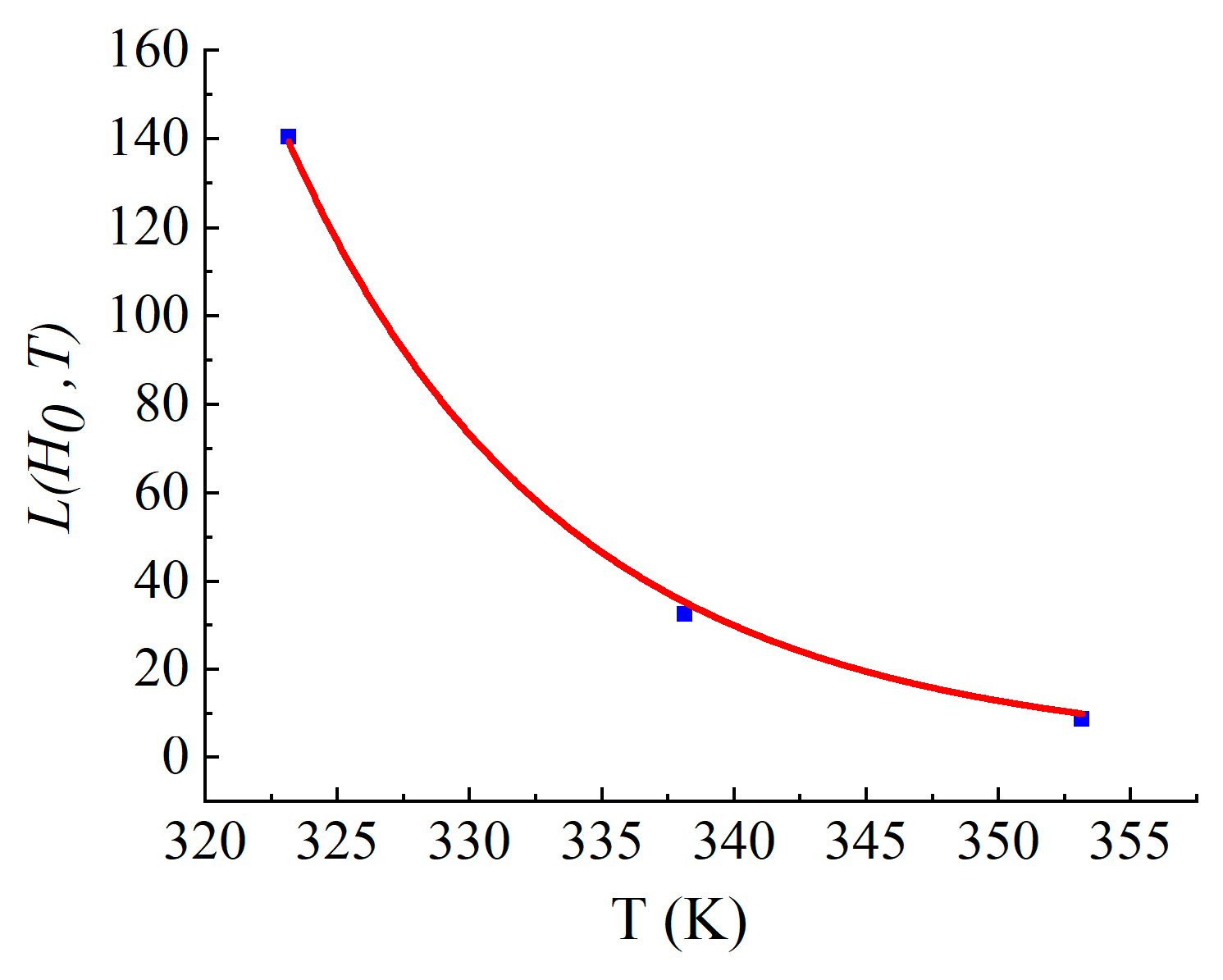

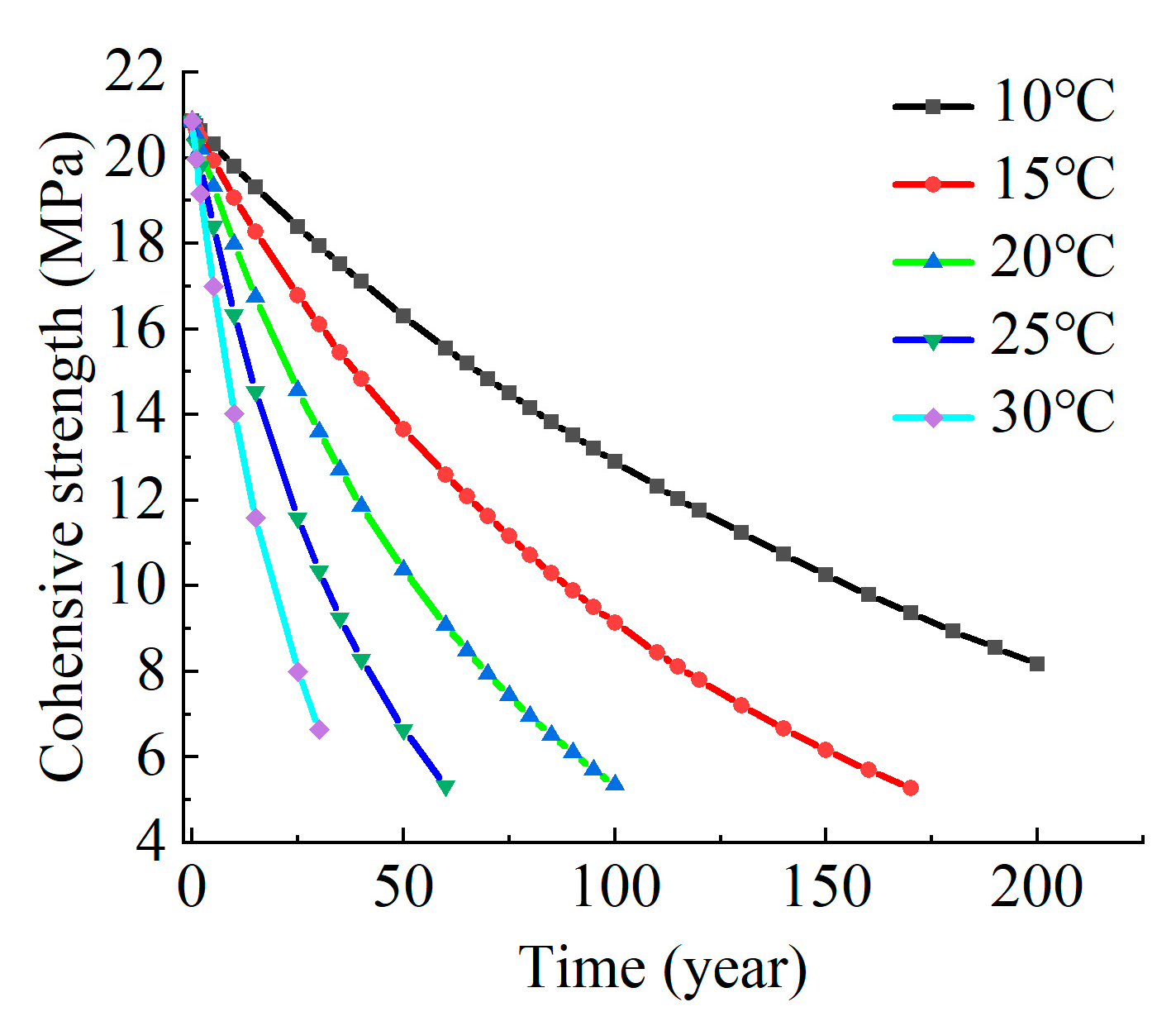

4.2. Lifetime Prediction

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Barbucci, A.; Delucchi, M.; Cerisola, G. Organic coatings for concrete protection: Liquid water and water vapour permeabilities. Prog. Org. Coat. 1997, 30, 293–297. [Google Scholar] [CrossRef]

- Basheer, L.; Kropp, J.; Cleland, D.J. Assessment of the durability of concrete from its permeation properties: A review. Constr. Build. Mater. 2001, 15, 93–103. [Google Scholar] [CrossRef]

- Kanagaraj, B.; Kiran, T.; Gunasekaran, J.; Nammalvar, A.; Arulraj, P.; Gurupatham, B.G.A.; Roy, K. Performance of Sustainable Insulated Wall Panels with Geopolymer Concrete. Materials 2022, 15, 8801. [Google Scholar] [CrossRef]

- Roy, K.; Gurupatham, B.G.A. Editorial for the Special Issue on Sustainable Composite Construction Materials. J. Compos. Sci. 2023, 7, 491. [Google Scholar] [CrossRef]

- Khanzadeh Moradllo, M.; Shekarchi, M.; Hoseini, M. Time-dependent performance of concrete surface coatings in tidal zone of marine environment. Constr. Build. Mater. 2012, 30, 198–205. [Google Scholar] [CrossRef]

- Almusallam, A.F.M.K. Performance of concrete coatings under varying exposure conditions. Mater. Struct. 2002, 35, 487–494. [Google Scholar] [CrossRef]

- Almusallam, A.A.; Khan, F.M.; Dulaijan, S.U.; Al-Amoudi, O.S.B. Effectiveness of surface coatings in improving concrete durability. Cem. Concr. Compos. 2003, 25, 473–481. [Google Scholar] [CrossRef]

- Iqbal, N.; Tripathi, M.; Parthasarathy, S.; Kumar, D.; Roy, P.K. Polyurea spray coatings: Tailoring material properties through chemical crosslinking. Prog. Org. Coat. 2018, 123, 201–208. [Google Scholar] [CrossRef]

- Iqbal, N.; Tripathi, M.; Parthasarathy, S.; Kumar, D.; Roy, P.K. Polyurea coatings for enhanced blast-mitigation: A review. RSC Adv. 2016, 6, 1976–19717. [Google Scholar] [CrossRef]

- Shojaei, B.; Najafi, M.; Yazdanbakhsh, A.; Abtahi, M.; Zhang, C. A review on the applications of polyurea in the construction industry. Polym. Advan Technol. 2021, 32, 2797–2812. [Google Scholar] [CrossRef]

- Zur, E. Polyurea—The New Generation of Lining and Coating. Adv. Mater. Res. 2010, 95, 85–86. [Google Scholar] [CrossRef]

- Toutanji, H.A.; Choi, H.; Wong, D.; Gilbert, J.A.; Alldredge, D.J. Applying a polyurea coating to high-performance organic cementitious materials. Constr. Build. Mater. 2013, 38, 1170–1179. [Google Scholar] [CrossRef]

- Alldredge, D.J.; Gilbert, J.A.; Toutanji, H.; Lavin, T.; Balasubramanyam, M. Structural Enhancement of Framing Members Using Polyurea; Springer New York: New York, NY, USA, 2011; pp. 49–63. ISBN 2191-5644. [Google Scholar]

- Ha, S.K.; Lee, H.K.; Kang, I.S. Structural behavior and performance of water pipes rehabilitated with a fast-setting polyurea–urethane lining. Tunn. Undergr. Sp. Tech. 2016, 52, 192–201. [Google Scholar] [CrossRef]

- Liu, F.; Yin, M.; Xiong, B.; Zheng, F.; Mao, W.; Chen, Z.; He, C.; Zhao, X.; Fang, P. Evolution of microstructure of epoxy coating during UV degradation progress studied by slow positron annihilation spectroscopy and electrochemical impedance spectroscopy. Electrochim. Acta 2014, 133, 283–293. [Google Scholar] [CrossRef]

- Yang, X.F.; Tallman, D.E.; Bierwagen, G.P.; Croll, S.G.; Rohlik, S. Blistering and degradation of polyurethane coatings under different accelerated weathering tests. Polym. Degrad. Stabil. 2002, 77, 103–109. [Google Scholar] [CrossRef]

- Youssef, G.; Whitten, I. Dynamic properties of ultraviolet-exposed polyurea. Mech. Time-Depend. Mat. 2017, 21, 351–363. [Google Scholar] [CrossRef]

- Le Gac, P.Y.; Choqueuse, D.; Melot, D. Description and modeling of polyurethane hydrolysis used as thermal insulation in oil offshore conditions. Polym. Test. 2013, 32, 1588–1593. [Google Scholar] [CrossRef]

- Wang, H.; Feng, P.; Lv, Y.; Geng, Z.; Liu, Q.; Liu, X. A comparative study on UV degradation of organic coatings for concrete: Structure, adhesion, and protection performance. Prog. Org. Coat. 2020, 149, 105892. [Google Scholar] [CrossRef]

- Kumano, N.; Mori, K.; Kato, M.; Ishii, M. Degradation of scratch resistance of clear coatings by outdoor weathering. Prog. Org. Coat. 2019, 135, 574–581. [Google Scholar] [CrossRef]

- Pal, G.; Al-Ostaz, A.; Li, X.; Alkhateb, H.; Cheng, A.H.D. Molecular Dynamics Simulations and Hygrothermal Aging of Polyurea–POSS Nanocomposites. J. Polym. Environ. 2015, 23, 171–182. [Google Scholar] [CrossRef]

- Wang, Z. Study on the variation law of the thickness of spraying quick-setting waterproof coating materials with time and temperature. IOP Conf. Ser. Earth Environ. Sci. 2019, 267, 32057. [Google Scholar] [CrossRef]

- Li, B.; Li, J.; Yin, X. Study on the Performance of Polyurea Anti-Seepage Spray Coating for Hydraulic Structures. Sustainability 2023, 15, 9863. [Google Scholar] [CrossRef]

- Wang, X.; Luo, S.; Liu, G.; Zhang, L.C.; Wang, Y. Abrasion test of flexible protective materials on hydraulic structures. Water Sci. Eng. 2014, 7, 106–116. [Google Scholar] [CrossRef]

- Lyon, S.B.; Bingham, R.; Mills, D.J. Advances in corrosion protection by organic coatings: What we know and what we would like to know. Prog. Org. Coat. 2017, 102, 2–7. [Google Scholar] [CrossRef]

- Horgnies, M.; Willieme, P.; Gabet, O. Influence of the surface properties of concrete on the adhesion of coating: Characterization of the interface by peel test and FT-IR spectroscopy. Prog. Org. Coat. 2011, 72, 360–379. [Google Scholar] [CrossRef]

- Garbacz, A.; Courard, L.; Kostana, K. Characterization of concrete surface roughness and its relation to adhesion in repair systems. Mater. Charact. 2006, 56, 281–289. [Google Scholar] [CrossRef]

- Delucchi, M.; Barbucci, A.; Cerisola, G. Crack-bridging ability and liquid water permeability of protective coatings for concrete. Prog. Org. Coat. 1998, 33, 76–82. [Google Scholar] [CrossRef]

- Negele, O.A.W.F. Internal Stress and Wet Adhension of Organic Coatings. Prog. Org. Coat. 1996, 28, 285–289. [Google Scholar] [CrossRef]

- Nguyen, T.; Byrd, E.; Bentz, D.; Lint, C. In situ measurement of water at the organic coating/substrate interface. Prog. Org. Coat. 1996, 27, 181–193. [Google Scholar] [CrossRef]

- Fazli, H.; Yassin, A.Y.M.; Shafiq, N.; Teo, W. Pull-off testing as an interfacial bond strength assessment of CFRP-concrete interface exposed to a marine environment. Int. J. Adhes. Adhes. 2018, 84, 335–342. [Google Scholar] [CrossRef]

- Li, B.; Zhou, Y.; Xiao, J.; Li, X. Study on the new polyurea-composite impervious system of expansion joints under reverse pressure. Shuili Xuebao 2015, 46, 1479–1486. (In Chinese) [Google Scholar] [CrossRef]

- Momayez, A.; Ehsani, M.R.; Ramezanianpour, A.A.; Rajaie, H. Comparison of methods for evaluating bond strength between concrete substrate and repair materials. Cem. Concr. Res. 2005, 35, 748–757. [Google Scholar] [CrossRef]

- Mayer-Trzaskowska, P.; Robakowska, M.; Gierz, Ł.; Pach, J.; Mazur, E. Observation of the Effect of Aging on the Structural Changes of Polyurethane/Polyurea Coatings. Polymers 2024, 16, 23. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.J. Study on Degradation Rule of Physical Mechanical Property of Vulcanizate During the Period of Heat Ageing. China Synth. Rubber Ind. 1997, 2, 44–53. (In Chinese) [Google Scholar] [CrossRef]

- Symposium, R.M. Annual Reliability and Maintainability Symposium. In Proceedings of the International Symposium on Product Quality & Integrity, Tampa, FL, USA, 27–30 January 2003. [Google Scholar]

- Zhang, X.; Chang, X.; Chen, S.; Fan, S. Hygrothermal aging testing and life assessment for adhesive interface of solid rocket motor. J. Solid Rocket. Technol. 2013, 36, 27–31. (In Chinese) [Google Scholar] [CrossRef]

- GBT 23446-2009; Spray Polyurea Waterproofing Coating. National Standards of the People’s Republic of China: Beijing, China, 2021.

| Experiment Type | Case | Aging Temperature (°C) | Aging Duration (d) |

|---|---|---|---|

| Hydrothermal aging test | Case 1-1 | 20 | 7 |

| Case 1-2 | 20 | 21 | |

| Case 1-3 | 50 | 7 | |

| Case 1-4 | 50 | 21 | |

| Case 1-5 | 65 | 7 | |

| Case 1-6 | 65 | 21 | |

| Case 1-7 | 80 | 7 | |

| Case 1-8 | 80 | 21 | |

| Aging test under simulated on-site environment | Case 2-1 | 50 | 1 |

| Case 2-2 | 50 | 3 | |

| Case 2-3 | 50 | 7 | |

| Case 2-4 | 50 | 14 | |

| Case 2-5 | 50 | 21 | |

| Case 2-6 | 50 | 25 | |

| Case 2-7 | 50 | 27 | |

| Case 2-8 | 50 | 28 | |

| Case 3-1 | 65 | 1 | |

| Case 3-2 | 65 | 3 | |

| Case 3-3 | 65 | 7 | |

| Case 3-4 | 65 | 14 | |

| Case 3-5 | 65 | 21 | |

| Case 3-6 | 65 | 25 | |

| Case 3-7 | 65 | 27 | |

| Case 3-8 | 65 | 28 | |

| Case 4-1 | 80 | 1 | |

| Case 4-2 | 80 | 3 | |

| Case 4-3 | 80 | 7 | |

| Case 4-4 | 80 | 14 | |

| Case 4-5 | 80 | 21 | |

| Case 4-6 | 80 | 25 | |

| Case 4-7 | 80 | 27 | |

| Case 4-8 | 80 | 28 |

| Case | Testing Location | Chainage of Land Sections | Chainage of Underwater Sections |

|---|---|---|---|

| 1 | The wall of the structural joint | 27-28 | 96–97 |

| 2 | 68–69 | 255–256 | |

| 3 | 174–175 | 342–343 | |

| 4 | The bottom of the structural joint | 27–28 | 96–97 |

| 5 | 67–68 | 255–256 | |

| 6 | 174–175 | 342–343 | |

| 7 | Anchor channel | 69 | 342 |

| Case | Wrapped around Polyurea | Wrapped on Both Sides of Polyurea | ||||||

|---|---|---|---|---|---|---|---|---|

| Values in MPa | Average | Standard Deviation | Values in MPa | Average | Standard Deviation | |||

| Case 1-1 | * | 3.72 | 3.72 | - | 3.05 | 3.82 | 3.44 | 0.39 |

| Case 1-2 | 2.93 | 3.53 | 3.23 | 0.30 | 3.00 | 3.49 | 3.25 | 0.25 |

| Case 1-3 | 3.28 | - | 3.28 | - | 3.84 | 3.38 | 3.61 | 0.23 |

| Case 1-4 | 3.07 | 3.49 | 3.43 | 0.21 | 3.42 | 3.09 | 3.26 | 0.17 |

| Case 1-5 | 2.52 | 2.97 | 2.75 | 0.23 | 3.10 | 2.77 | 2.94 | 0.17 |

| Case 1-6 | 2.22 | 2.45 | 2.34 | 0.12 | 2.16 | 2.04 | 2.10 | 0.06 |

| Case 1-7 | 1.63 | 1.50 | 1.57 | 0.06 | 2.18 | 1.92 | 2.05 | 0.13 |

| Case 1-8 | * | - | - | - | 1.04 | 0.45 | 0.75 | 0.30 |

| Temperature/°C | Parameter | Correlation | ||

|---|---|---|---|---|

| A1 | B1 | α | ||

| 50 | 0.00185 ± 0.00587 | −0.01937 ± 0.00359 | 0.80354 ± 0.05232 | 0.99719 |

| 65 | 0.03319 ± 0.03828 | −0.07949 ± 0.02575 | 0.74491 ± 0.09072 | 0.98999 |

| 80 | 0.03273 ± 0.08136 | −0.25358 ± 0.07937 | 0.65825 ± 0.10981 | 0.98892 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, C.; Ren, J.; Wang, Y. Degradation Behavior and Lifetime Prediction of Polyurea Anti-Seepage Coating for Concrete Lining in Water Conveyance Tunnels. Materials 2024, 17, 1782. https://doi.org/10.3390/ma17081782

Peng C, Ren J, Wang Y. Degradation Behavior and Lifetime Prediction of Polyurea Anti-Seepage Coating for Concrete Lining in Water Conveyance Tunnels. Materials. 2024; 17(8):1782. https://doi.org/10.3390/ma17081782

Chicago/Turabian StylePeng, Chengcheng, Jie Ren, and Yuan Wang. 2024. "Degradation Behavior and Lifetime Prediction of Polyurea Anti-Seepage Coating for Concrete Lining in Water Conveyance Tunnels" Materials 17, no. 8: 1782. https://doi.org/10.3390/ma17081782

APA StylePeng, C., Ren, J., & Wang, Y. (2024). Degradation Behavior and Lifetime Prediction of Polyurea Anti-Seepage Coating for Concrete Lining in Water Conveyance Tunnels. Materials, 17(8), 1782. https://doi.org/10.3390/ma17081782