Designing Prepregnation and Fused Filament Fabrication Parameters for Recycled PP- and PA-Based Continuous Carbon Fiber Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

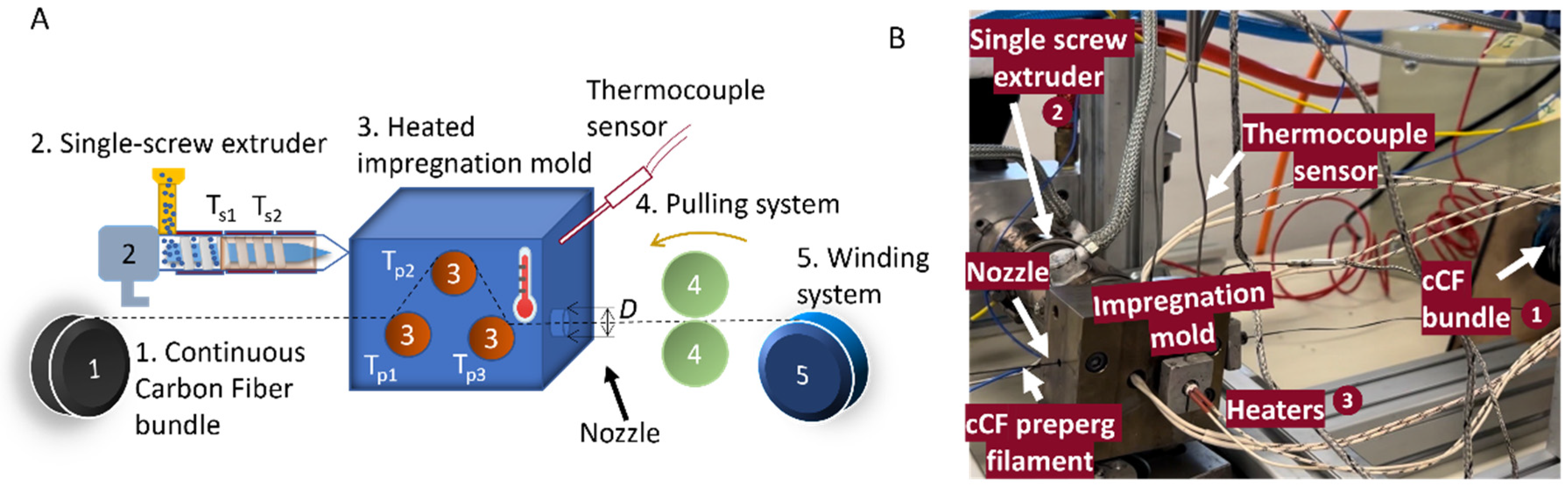

2.2. Manufacturing cCF Prepreg Filaments

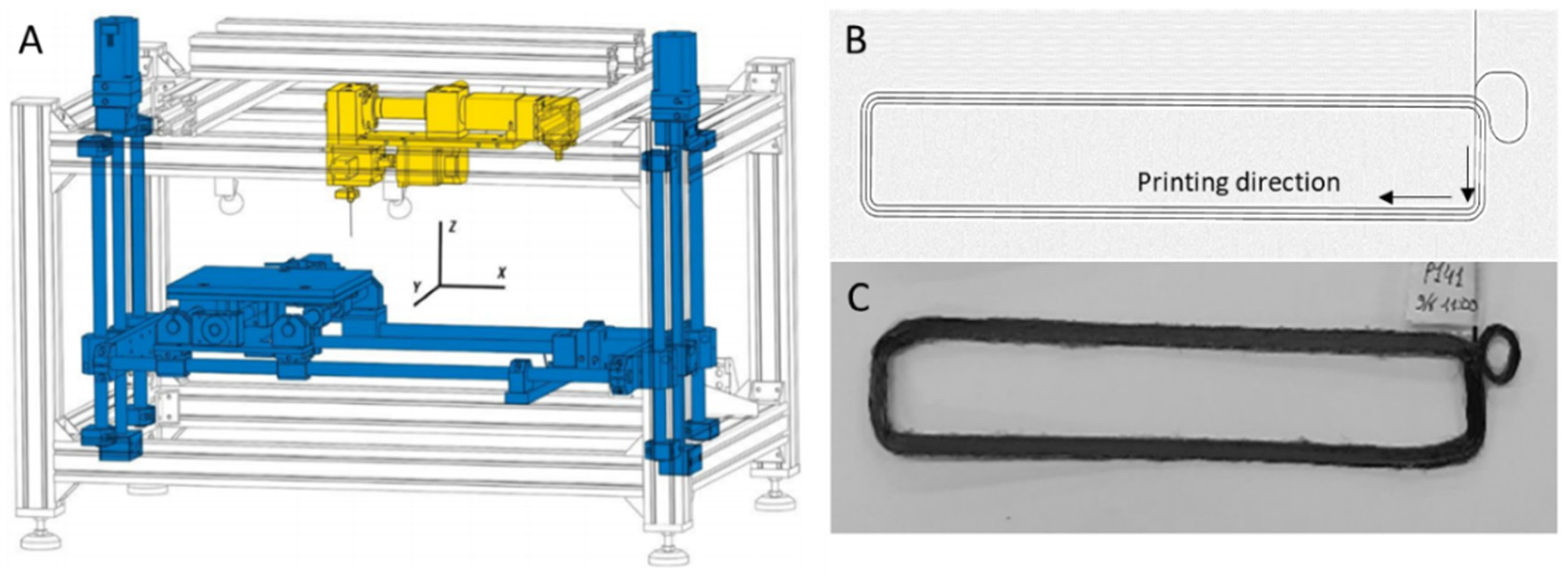

2.3. Fused Filament Fabrication of cCF Prepreg Filaments

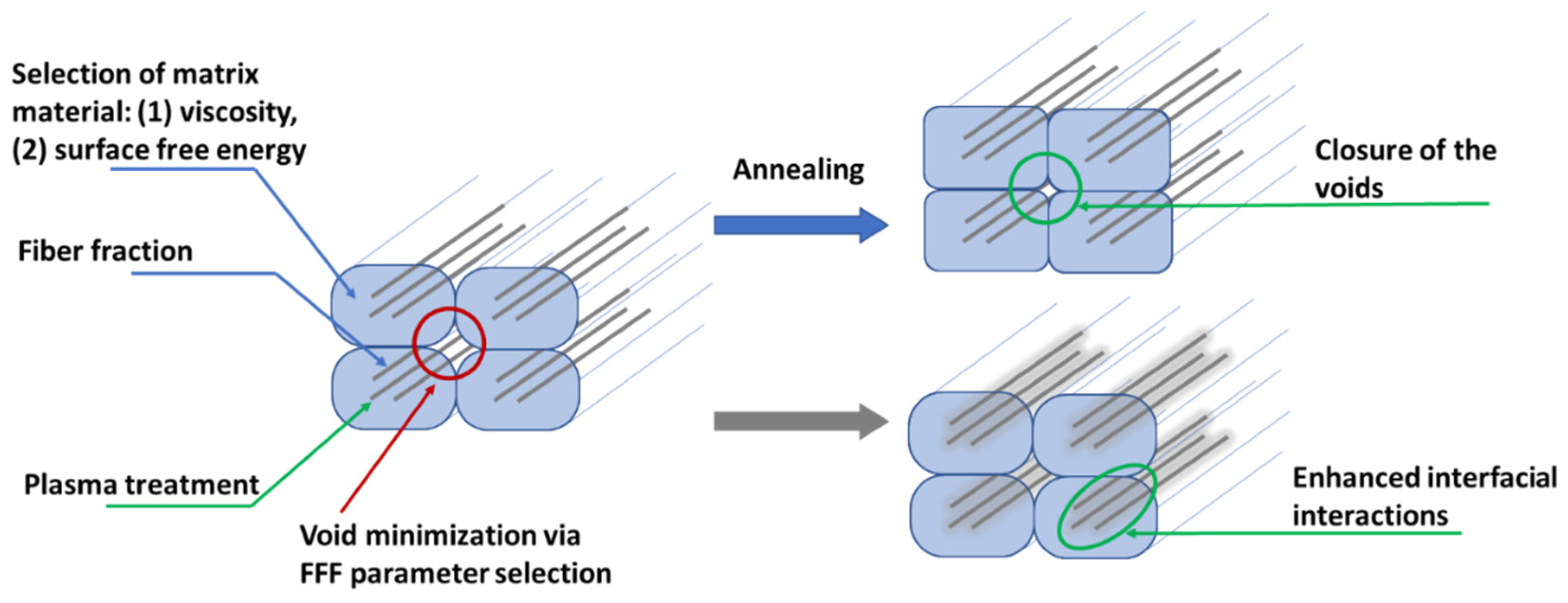

2.4. Plasma Treatment

2.5. Annealing

2.6. Rheological, Morphological, and Thermal Property Characterization

2.7. Flexural Property Measurements

3. Results and Discussion

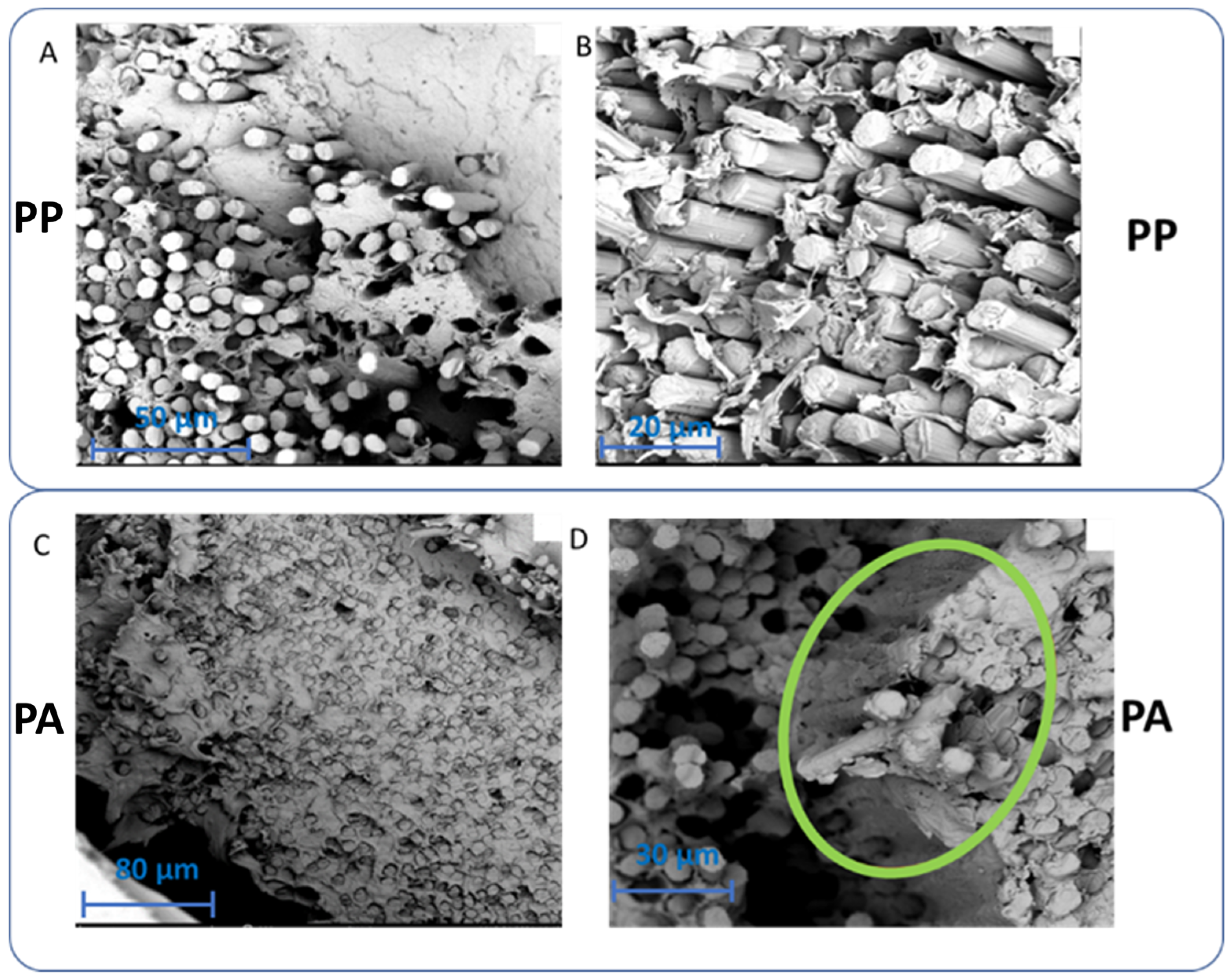

3.1. Wetting Degree after Impregnation

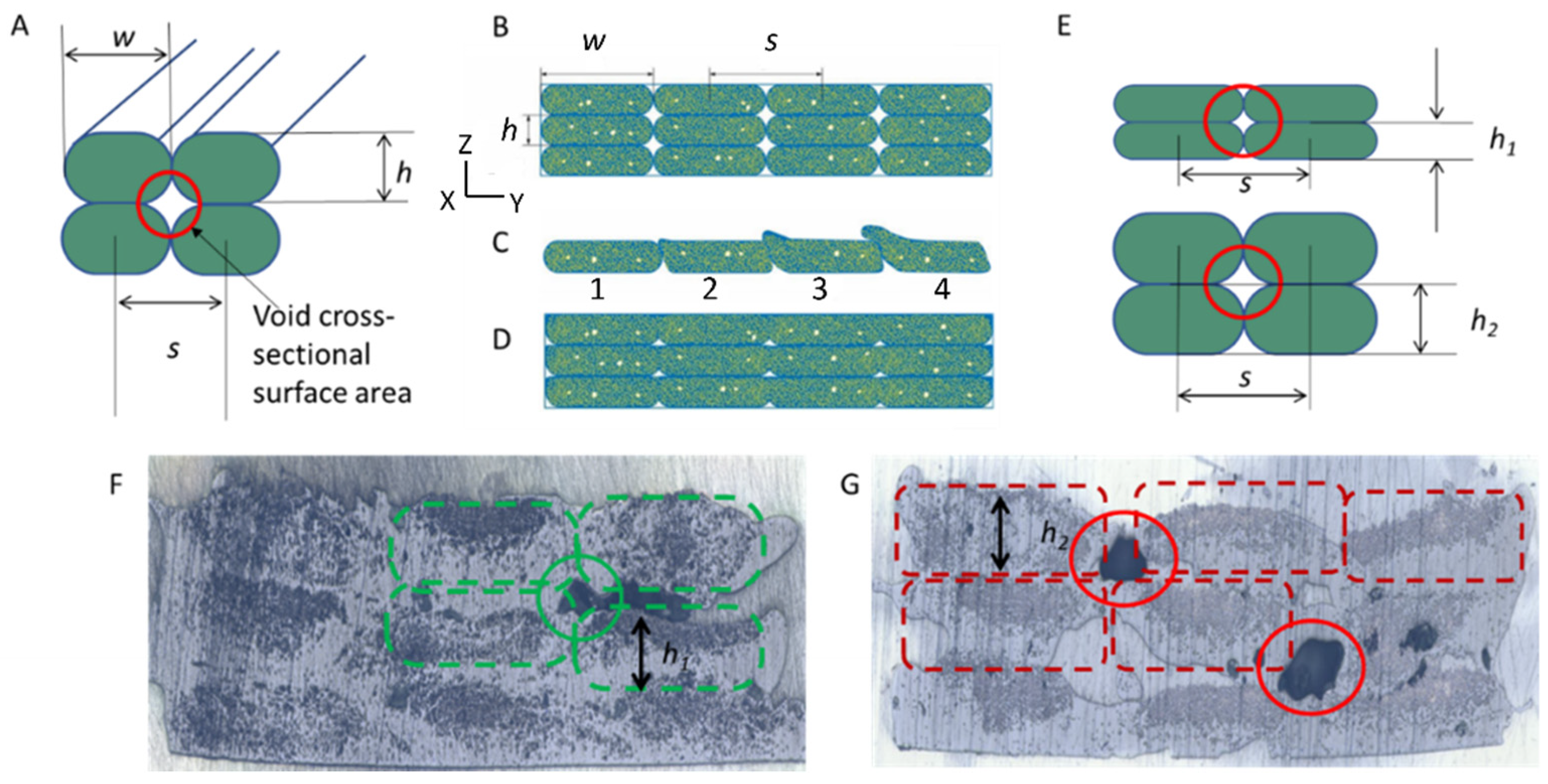

3.2. Optimization of FFF Parameters to Decrease Voids

3.3. Optimal FFF Parameters to Tune Flexural Properties

3.4. Effect of Plasma Treatment and Annealing

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, N.; Huang, S.; Zhang, G.; Qin, R.; Liu, W.; Xiong, H.; Shi, G.; Blackburn, J. Progress in Additive Manufacturing on New Materials: A Review. J. Mater. Sci. Technol. 2019, 35, 242–269. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Zhai, X.; Jin, L.; Jiang, J. A Survey of Additive Manufacturing Reviews. Mater. Sci. Addit. Manuf. 2022, 1, 21. [Google Scholar] [CrossRef]

- Joshi, S.C.; Sheikh, A.A. 3D Printing in Aerospace and Its Long-Term Sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; Casciaro, R.; Corcione, C.E. A Review of Polymer-Based Materials for Fused Filament Recycled Materials. Polymers 2022, 14, 465. [Google Scholar] [CrossRef] [PubMed]

- Cuan-Urquizo, E.; Barocio, E.; Tejada-Ortigoza, V.; Pipes, R.; Rodriguez, C.; Roman-Flores, A. Characterization of the Mechanical Properties of FFF Structures and Materials: A Review on the Experimental, Computational and Theoretical Approaches. Materials 2019, 12, 895. [Google Scholar] [CrossRef] [PubMed]

- Shanmugam, V.; Pavan, M.V.; Babu, K.; Karnan, B. Fused Deposition Modeling Based Polymeric Materials and Their Performance: A Review. Polym. Compos. 2021, 42, 5656–5677. [Google Scholar] [CrossRef]

- Patel, A.; Taufik, M. Nanocomposite Materials for Fused Filament Fabrication. Mater. Today Proc. 2021, 47, 5142–5150. [Google Scholar] [CrossRef]

- Lalehpour, A.; Barari, A. Post Processing for Fused Deposition Modeling Parts with Acetone Vapour Bath. IFAC-PapersOnLine 2016, 49, 42–48. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, T.; Yeh, Y. Advanced 3D Printing Technologies for the Aircraft Industry: A Fuzzy Systematic Approach for Assessing the Critical Factors. Int. J. Adv. Manuf. Technol. 2019, 105, 4059–4069. [Google Scholar] [CrossRef]

- Pei, E.; Shen, J.; Watling, J. Direct 3D Printing of Polymers onto Textiles: Experimental Studies and Applications. Rapid Prototyp. J. 2015, 21, 556–571. [Google Scholar] [CrossRef]

- Vithani, K.; Goyanes, A.; Jannin, V.; Basit, A.W.; Gaisford, S.; Boyd, B.J. A Proof of Concept for 3D Printing of Solid Lipid-Based Formulations of Poorly Water-Soluble Drugs to Control Formulation Dispersion Kinetics. Pharm. Res. 2019, 36, 102. [Google Scholar] [CrossRef] [PubMed]

- Revilla-León, M.; Özcan, M. Additive Manufacturing Technologies Used for Processing Polymers: Current Status and Potential Application in Prosthetic Dentistry. J. Prosthodont. 2019, 28, 146–158. [Google Scholar] [CrossRef] [PubMed]

- Van Waeleghem, T.; Marchesini, F.H.; Cardon, L.; D’hooge, D.R. In Silico Quantification of 3D Thermal Gradients and Voids during Fused Filament Fabrication Deposition to Enhance Mechanical and Dimensional Stability. Addit. Manuf. 2023, 72, 103624. [Google Scholar] [CrossRef]

- Ćwikła, G.; Grabowik, C.; Kalinowski, K.; Paprocka, I.; Ociepka, P. The Influence of Printing Parameters on Selected Mechanical Properties of FDM/FFF 3D-Printed Parts. IOP Conf. Ser. Mater. Sci. Eng. 2017, 227, 012033. [Google Scholar] [CrossRef]

- Rajpurohit, S.R.; Dave, H.K.; Rajurkar, K.P. Prediction of Tensile Strength of Fused Deposition Modeling (FDM) Printed PLA Using Classic Laminate Theory. Eng. Solid Mech. 2022, 10, 13–24. [Google Scholar] [CrossRef]

- Ali, Z.; Gao, Y.; Tang, B.; Wu, X.; Wang, Y.; Li, M.; Hou, X.; Li, L.; Jiang, N.; Yu, J. Preparation, Properties and Mechanisms of Carbon Fiber/Polymer Composites for Thermal Management Applications. Polymers 2021, 13, 169. [Google Scholar] [CrossRef]

- Das, T.K.; Ghosh, P.; Das, N.C. Preparation, Development, Outcomes, and Application Versatility of Carbon Fiber-Based Polymer Composites: A Review. Adv. Compos. Hybrid Mater. 2019, 2, 214–233. [Google Scholar] [CrossRef]

- Czyżewski, P.; Bieliński, M.; Sykutera, D.; Jurek, M.; Gronowski, M.; Ryl, Ł.; Hoppe, H. Secondary Use of ABS Co-Polymer Recyclates for the Manufacture of Structural Elements Using the FFF Technology. Rapid Prototyp. J. 2018, 24, 1447–1454. [Google Scholar] [CrossRef]

- Isobe, T.; Tanaka, T.; Nomura, T.; Yuasa, R. Comparison of Strength of 3D Printing Objects Using Short Fiber and Continuous Long Fiber. IOP Conf. Ser. Mater. Sci. Eng. 2018, 406, 012042. [Google Scholar] [CrossRef]

- Alarifi, I.M. PETG/Carbon Fiber Composites with Different Structures Produced by 3D Printing. Polym. Test. 2023, 120, 107949. [Google Scholar] [CrossRef]

- Tian, X.; Todoroki, A.; Liu, T.; Wu, L.; Hou, Z.; Ueda, M.; Hirano, Y.; Matsuzaki, R.; Mizukami, K.; Iizuka, K.; et al. 3D Printing of Continuous Fiber Reinforced Polymer Composites: Development, Application, and Prospective. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100016. [Google Scholar] [CrossRef]

- Li, C.; Xian, G.; Li, H. Effect of Postcuring Immersed in Water under Hydraulic Pressure on Fatigue Performance of Large-diameter Pultruded Carbon/Glass Hybrid Rod. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1148–1160. [Google Scholar] [CrossRef]

- Wu, J.; Zhu, Y.; Li, C. Experimental Investigation of Fatigue Capacity of Bending-Anchored CFRP Cables. Polymers 2023, 15, 2483. [Google Scholar] [CrossRef] [PubMed]

- Blyweert, P.; Nicolas, V.; Fierro, V.; Celzard, A. 3D Printing of Carbon-Based Materials: A Review. Carbon 2021, 183, 449–485. [Google Scholar] [CrossRef]

- Liu, T.; Tian, X.; Zhang, Y.; Cao, Y.; Li, D. High-Pressure Interfacial Impregnation by Micro-Screw in-Situ Extrusion for 3D Printed Continuous Carbon Fiber Reinforced Nylon Composites. Compos. Part A Appl. Sci. Manuf. 2020, 130, 105770. [Google Scholar] [CrossRef]

- Hu, Q.; Duan, Y.; Zhang, H.; Liu, D.; Yan, B.; Peng, F. Manufacturing and 3D Printing of Continuous Carbon Fiber Prepreg Filament. J. Mater. Sci. 2018, 53, 1887–1898. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Talreja, R. Effects of Void Geometry on Elastic Properties of Unidirectional Fiber Reinforced Composites. Compos. Sci. Technol. 2005, 65, 1964–1981. [Google Scholar] [CrossRef]

- Bijsterbosch, H.; Gaymans, R.J. Polyamide 6—Long Glass Fiber Injection Moldings. Polym. Compos. 1995, 16, 363–369. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, T.; Jiang, Q.; He, L.; Bismarck, A.; Hu, Q. Recent Progress of 3D Printed Continuous Fiber Reinforced Polymer Composites Based on Fused Deposition Modeling: A Review. J. Mater. Sci. 2021, 56, 12999–13022. [Google Scholar] [CrossRef]

- Shih, C.-C.; Burnette, M.; Staack, D.; Wang, J.; Tai, B.L. Effects of Cold Plasma Treatment on Interlayer Bonding Strength in FFF Process. Addit. Manuf. 2019, 25, 104–111. [Google Scholar] [CrossRef]

- Yuan, L.Y.; Shyu, S.S.; Lai, J.Y. Plasma Surface Treatments of Carbon Fibers. Part 2: Interfacial Adhesion with Poly(Phenylene Sulfide). Compos. Sci. Technol. 1992, 45, 9–16. [Google Scholar] [CrossRef]

- Yuan, L.Y.; Chen, C.S.; Shyu, S.S.; Lai, J.Y. Plasma Surface Treatment on Carbon Fibers. Part 1: Morphology and Surface Analysis of Plasma Etched Fibers. Compos. Sci. Technol. 1992, 45, 1–7. [Google Scholar] [CrossRef]

- Cho, B.-G.; Hwang, S.-H.; Park, M.; Park, J.K.; Park, Y.-B.; Chae, H.G. The Effects of Plasma Surface Treatment on the Mechanical Properties of Polycarbonate/Carbon Nanotube/Carbon Fiber Composites. Compos. Part B Eng. 2019, 160, 436–445. [Google Scholar] [CrossRef]

- Ma, K.; Chen, P.; Wang, B.; Cui, G.; Xu, X. A Study of the Effect of Oxygen Plasma Treatment on the Interfacial Properties of Carbon Fiber/Epoxy Composites. J. Appl. Polym. Sci. 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Giannotta, G.; Morra, M.; Occhiello, E.; Garbassi, F.; Nicolais, L.; D’Amore, A. Dynamic Wetting of Carbon Fibers by Viscous Fluids. J. Colloid Interface Sci. 1992, 148, 571–578. [Google Scholar] [CrossRef]

- Park, S.-J.; Kim, M.-H.; Lee, J.-R.; Choi, S. Effect of Fiber–Polymer Interactions on Fracture Toughness Behavior of Carbon Fiber-Reinforced Epoxy Matrix Composites. J. Colloid Interface Sci. 2000, 228, 287–291. [Google Scholar] [CrossRef] [PubMed]

- Marissen, R.; van der Drift, L.T.; Sterk, J. Technology for Rapid Impregnation of Fibre Bundles with a Molten Thermoplastic Polymer. Compos. Sci. Technol. 2000, 60, 2029–2034. [Google Scholar] [CrossRef]

- Van De Steene, W. A Generic Process for Impregnation and Additive Manufacturing of Endless Fibre-Reinforced Thermoplastic Composites. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2020. [Google Scholar]

- Kuznetsov, V.; Solonin, A.; Urzhumtsev, O.; Schilling, R.; Tavitov, A. Strength of PLA Components Fabricated with Fused Deposition Technology Using a Desktop 3D Printer as a Function of Geometrical Parameters of the Process. Polymers 2018, 10, 313. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Ding, S.; Li, L.; Huang, C. Effects of FDM-3D Printing Parameters on Mechanical Properties and Microstructure of CF/PEEK and GF/PEEK. Chin. J. Aeronaut. 2021, 34, 236–246. [Google Scholar] [CrossRef]

- Li, H.; Liu, B.; Ge, L.; Chen, Y.; Zheng, H.; Fang, D. Mechanical Performances of Continuous Carbon Fiber Reinforced PLA Composites Printed in Vacuum. Compos. Part B Eng. 2021, 225, 109277. [Google Scholar] [CrossRef]

- Garzon-Hernandez, S.; Garcia-Gonzalez, D.; Jérusalem, A.; Arias, A. Design of FDM 3D Printed Polymers: An Experimental-Modelling Methodology for the Prediction of Mechanical Properties. Mater. Des. 2020, 188, 108414. [Google Scholar] [CrossRef]

- Papon, E.A.; Haque, A.; Spear, S.K. Effects of Functionalization and Annealing in Enhancing the Interfacial Bonding and Mechanical Properties of 3D Printed Fiber-Reinforced Composites. Mater. Today Commun. 2020, 25, 101365. [Google Scholar] [CrossRef]

- Wang, K.; Long, H.; Chen, Y.; Baniassadi, M.; Rao, Y.; Peng, Y. Heat-Treatment Effects on Dimensional Stability and Mechanical Properties of 3D Printed Continuous Carbon Fiber-Reinforced Composites. Compos. Part A Appl. Sci. Manuf. 2021, 147, 106460. [Google Scholar] [CrossRef]

- Nassar, A.; Younis, M.; Elzareef, M.; Nassar, E. Effects of Heat-Treatment on Tensile Behavior and Dimension Stability of 3D Printed Carbon Fiber Reinforced Composites. Polymers 2021, 13, 4305. [Google Scholar] [CrossRef] [PubMed]

- Bhandari, S.; Lopez-Anido, R.A.; Gardner, D.J. Enhancing the Interlayer Tensile Strength of 3D Printed Short Carbon Fiber Reinforced PETG and PLA Composites via Annealing. Addit. Manuf. 2019, 30, 100922. [Google Scholar] [CrossRef]

- Van De Steene, W.; Verstockt, J.; Degrieck, J.; Ragaert, K.; Cardon, L. An Evaluation of Three Different Techniques for Melt Impregnation of Glass Fiber Bundles with Polyamide 12. Polym. Eng. Sci. 2018, 58, 601–608. [Google Scholar] [CrossRef]

- La Gala, A.; Fiorio, R.; Erkoç, M.; Cardon, L.; D’hooge, D.R. Theoretical Evaluation of the Melting Efficiency for the Single-Screw Micro-Extrusion Process: The Case of 3D Printing of ABS. Processes 2020, 8, 1522. [Google Scholar] [CrossRef]

- ISO 11358-1; Plastics—Thermogravimetry (TG) of Polymers—General Principles. ISO: Geneva, Switzerland, 2022.

- ISO 14125; Fibre-Reinforced Plastic Composites—Determination of Flexural Properties. ISO: Geneva, Switzerland, 2015.

- Stachewicz, U.; Barber, A.H. Enhanced Wetting Behavior at Electrospun Polyamide Nanofiber Surfaces. Langmuir 2011, 27, 3024–3029. [Google Scholar] [CrossRef]

- Cheng, S.; Janimak, J.; Zhang, A. Regime Transitions in Fractions of Isotatic Polypropylene. Macromolecules 1995, 34, 1. [Google Scholar]

- Tsutsumi, K.; Ishida, S.; Shibata, K. Determination of the Surface Free Energy of Modified Carbon Fibers and Its Relation to the Work of Adhesion. Colloid Polym. Sci. 1990, 268, 31–37. [Google Scholar] [CrossRef]

- Feng, K.-C.; Pinkas-Sarafova, A.; Ricotta, V.; Cuiffo, M.; Zhang, L.; Guo, Y.; Chang, C.-C.; Halada, G.P.; Simon, M.; Rafailovich, M. The Influence of Roughness on Stem Cell Differentiation Using 3D Printed Polylactic Acid Scaffolds. Soft Matter 2018, 14, 9838–9846. [Google Scholar] [CrossRef] [PubMed]

- Pawlak, A.; Galeski, A.; Rozanski, A. Cavitation during Deformation of Semicrystalline Polymers. Prog. Polym. Sci. 2014, 39, 921–958. [Google Scholar] [CrossRef]

- Herrera, N.; Roch, H.; Salaberria, A.M.; Pino-Orellana, M.A.; Labidi, J.; Fernandes, S.C.M.; Radic, D.; Leiva, A.; Oksman, K. Functionalized Blown Films of Plasticized Polylactic Acid/Chitin Nanocomposite: Preparation and Characterization. Mater. Des. 2016, 92, 846–852. [Google Scholar] [CrossRef]

- Ohnmacht, H.; Fiorio, R.; Wieme, T.; D’hooge, D.R.; Cardon, L.; Edeleva, M. Response-Surface-Methodology-Based Increasing of the Isotropic Thermal Conductivity of Polyethylene Composites Containing Multiple Fillers. Polymers 2022, 15, 39. [Google Scholar] [CrossRef]

| Matrix | Filament | (%) | Vpultrusion [mm/min] | TS1 [°C] | TS2 [°C] | TC [°C] | TP1 [°C] | TP2 [°C] | TP3 [°C] | D [mm] | N [rpm] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PP | F001 | 16.43 | 300 | 180 | 230 | 230 | 230 | 230 | 230 | 1.1 | 0.68–0.8 |

| F002 1 | 14.84 | 300 | 180 | 230 | 230 | 230 | 230 | 230 | 1.1 | 2.05 | |

| F003 2 | 15.23 | 300 | 180 | 230 | 230 | 230 | 230 | 230 | 1.1 | 2.05–2.2 | |

| F004 | 16.37 | 300 | 180 | 230 | 230 | 230 | 230 | 230 | 1.1 | 2.05–2.2 | |

| F005 | 11.27 | 300 | 185 | 225 | 215 | 240 | 240 | 240 | 1.1 | 0.65 | |

| PA | F006 | 13.50 | 300 | 185 | 225 | 225 | 240 | 240 | 240 | 1.1 | 1.15 |

| F007 | 12.63 | 300 | 185 | 225 | 225 | 240 | 240 | 240 | 1.1 | 1.1 | |

| F008 | 14.91 | 300 | 185 | 225 | 225 | 240 | 240 | 240 | 1.1 | 1.1 | |

| F009 | 14.73 | 550 | 185 | 225 | 225 | 240 | 240 | 240 | 1.1 | 2 | |

| F010 | 14.02 | 425 | 185 | 225 | 225 | 240 | 240 | 240 | 1.1 | 1.8 | |

| F011 | 14.39 | 675 | 185 | 225 | 225 | 240 | 240 | 240 | 1.1 | 2.3 | |

| F012 | 14.33 | 800 | 185 | 225 | 225 | 240 | 240 | 240 | 1.1 | 2.3 | |

| F013 | 18.70 | 300 | 185 | 225 | 225 | 240 | 240 | 240 | 0.9 | 0.95 | |

| F014 | 30 | 300 | 185 | 225 | 225 | 240 | 240 | 240 | 0.7 | 0.47 | |

| F015 | 30 | 300 | 185 | 225 | 225 | 240 | 240 | 240 | 0.7 | 0.47 | |

| F016 | 37.60 | 300 | 185 | 225 | 225 | 240 | 240 | 240 | 0.6 | 0.35 | |

| F017 | 37.60 | 300 | 185 | 225 | 225 | 240 | 240 | 240 | 0.6 | 0.35 |

| D (mm) | Filament | Sample | Tn (°C) | h (mm) | s (mm) | sactual (3 × sactual) (mm) |

|---|---|---|---|---|---|---|

| 1.1 | F001 | P002 | 215–235 | 0.35 | 1.67 | 7.02 |

| F001 | P004 | 215–235 | 0.45 | 1.30 | 5.46 | |

| F001 | P005 | 215–235 | 0.55 | 1.06 | 4.46 | |

| 0.9 | F013 | P126 | 215–235 | 0.29 | 1.37 | 5.50 |

| F013 | P135 | 215–235 | 0.37 | 1.06 | 4.50 | |

| F013 | P145 | 215–235 | 0.45 | 0.87 | 3.85 | |

| 0.7 | F014 | P154 | 205–235 | 0.22 | 1.06 | 4.85 |

| F014 | P164 | 205–235 | 0.29 | 0.83 | 4.10 | |

| F014 | P172 | 205–235 | 0.35 | 0.68 | 3.75 | |

| 0.6 | F016 | P184 | 200–225 | 0.19 | 0.91 | 4.40 |

| F017 | P185 | 200–225 | 0.25 | 0.71 | 3.80 | |

| F017 | P195 | 200–225 | 0.30 | 0.58 | 3.35 |

| Filament | Printing Conditions | cCF | h (mm) | s (mm) | Tn (°C) | Tbed (°C) |

|---|---|---|---|---|---|---|

| F001 | P004 | untreated | 0.45 | 1.30 | 230 | 60 |

| F002 | P093 | He/O2 | 0.45 | 1.30 | 235 | 80 |

| F003 | P095 | He/Ar | 0.45 | 1.30 | 235 | 80 |

| Matrix | Printing Conditions | Filament | D (mm) | h (mm) | s (mm) | Tn (°C) | Tb (°C) | Annealing Temperature (°C) |

|---|---|---|---|---|---|---|---|---|

| PP | P088 | F004 | 0.9 | 0.45 | 1.30 | 235 | 80 | 90, 120, and 140 |

| P089 | ||||||||

| P092 | ||||||||

| PA12 | P113–P115 | F009 | 0.9 | 0.35 | 1.67 | 215 | 110 | 140, and 165 |

| P122–P125 | F010 | |||||||

| P116–P119 | F011 | |||||||

| P120–P121 | F012 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baddour, M.; Garcia-Campà, R.; Reyes, P.; D’hooge, D.R.; Cardon, L.; Edeleva, M. Designing Prepregnation and Fused Filament Fabrication Parameters for Recycled PP- and PA-Based Continuous Carbon Fiber Composites. Materials 2024, 17, 1788. https://doi.org/10.3390/ma17081788

Baddour M, Garcia-Campà R, Reyes P, D’hooge DR, Cardon L, Edeleva M. Designing Prepregnation and Fused Filament Fabrication Parameters for Recycled PP- and PA-Based Continuous Carbon Fiber Composites. Materials. 2024; 17(8):1788. https://doi.org/10.3390/ma17081788

Chicago/Turabian StyleBaddour, Marah, Ruth Garcia-Campà, Pablo Reyes, Dagmar R. D’hooge, Ludwig Cardon, and Mariya Edeleva. 2024. "Designing Prepregnation and Fused Filament Fabrication Parameters for Recycled PP- and PA-Based Continuous Carbon Fiber Composites" Materials 17, no. 8: 1788. https://doi.org/10.3390/ma17081788