Study on Characteristics of Ultrasound-Assisted Fracture Splitting for AISI 1045 Quenched and Tempered Steel

Abstract

1. Introduction

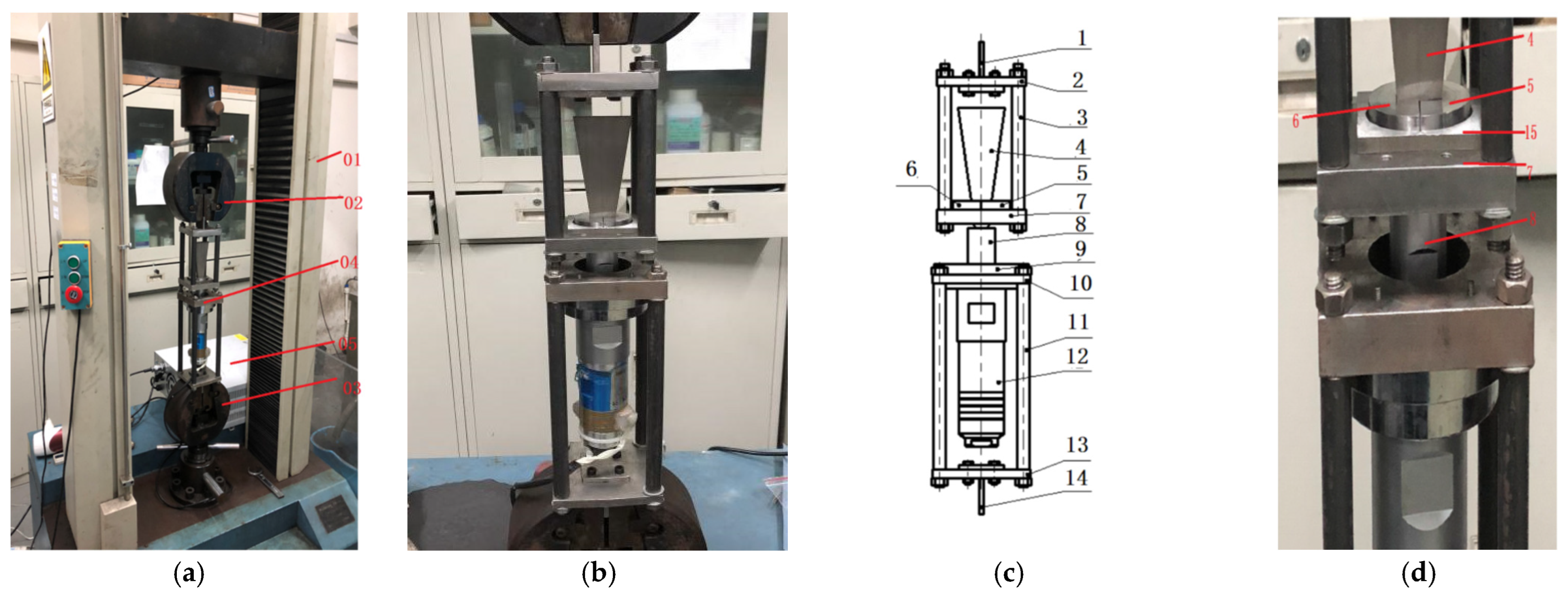

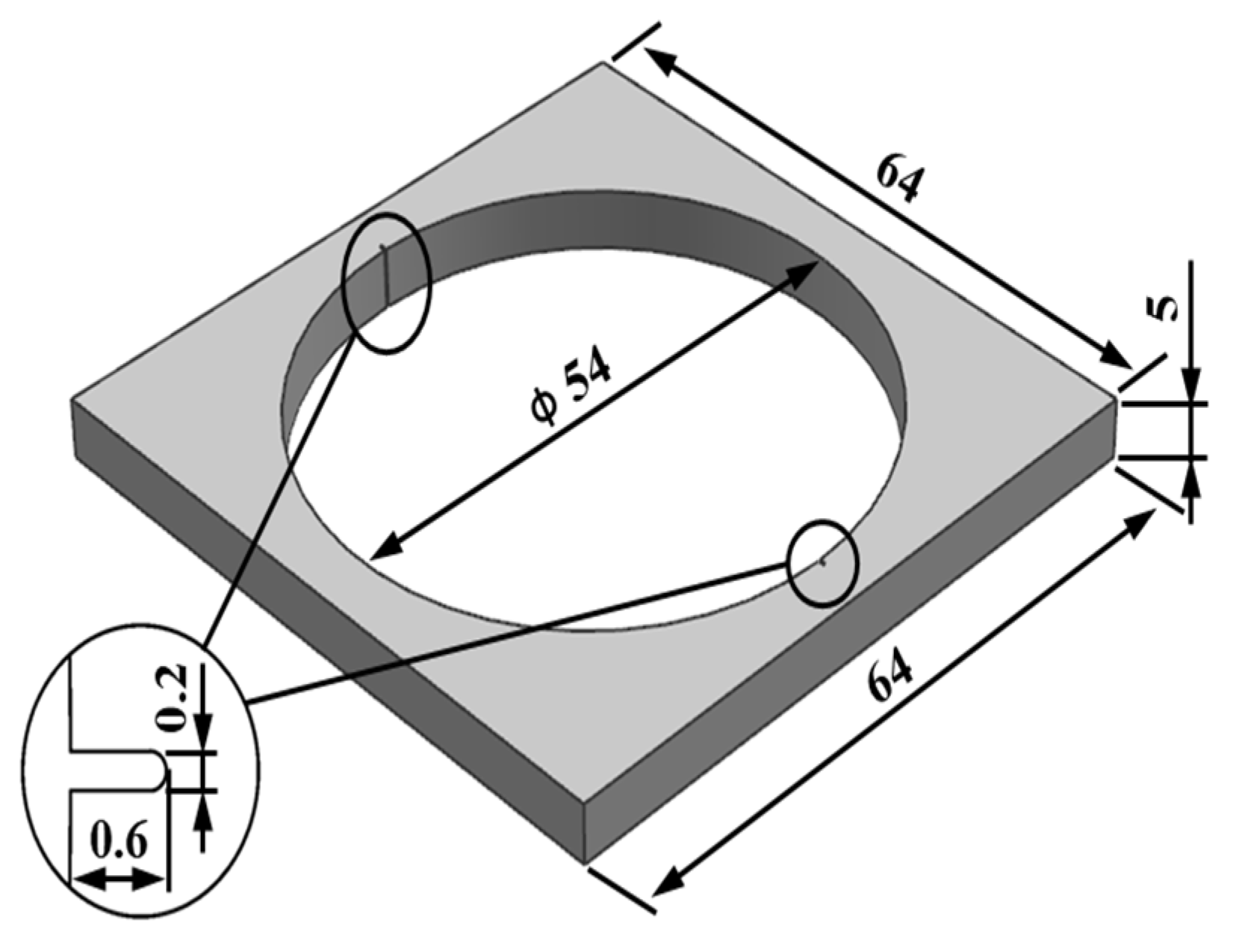

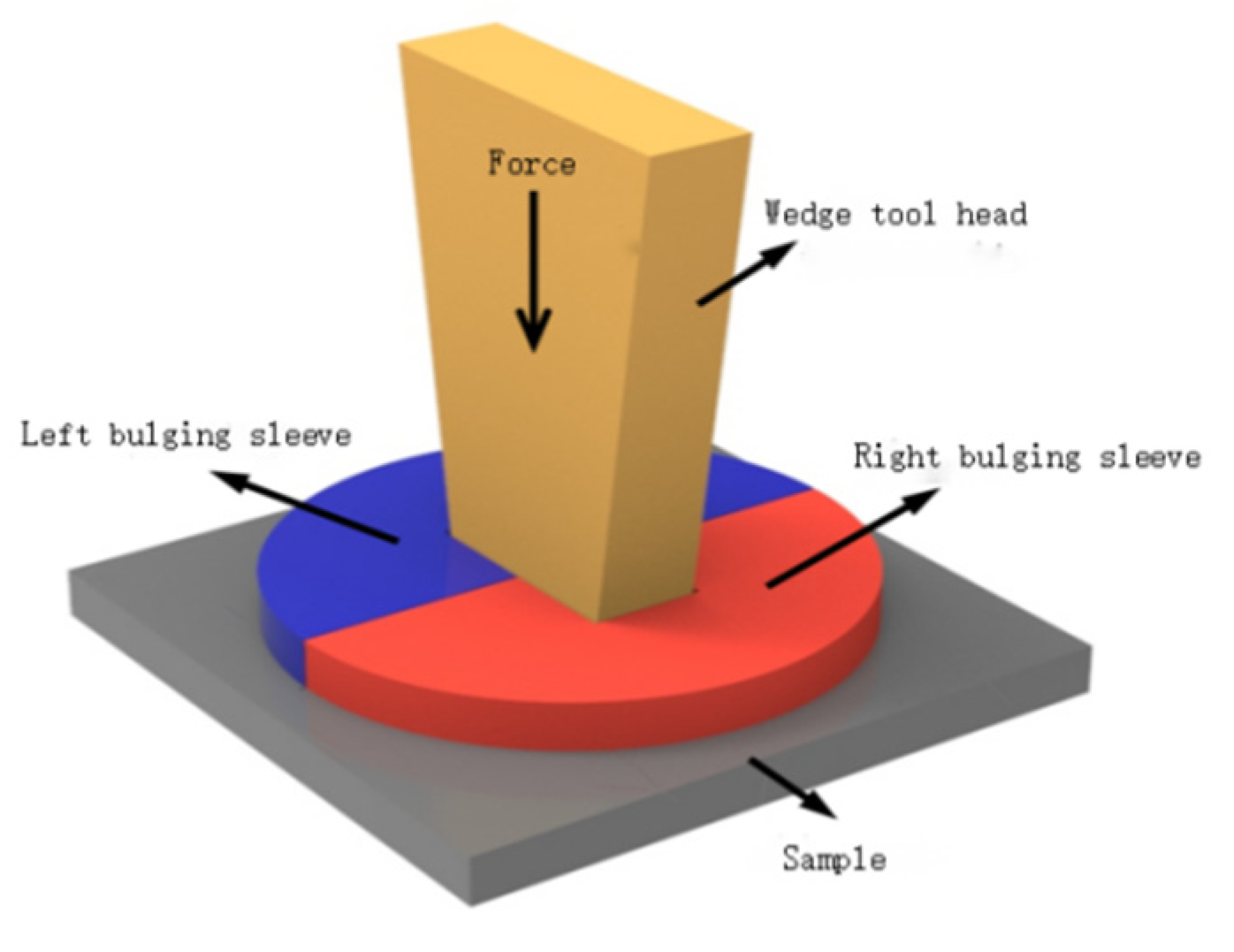

2. Materials and Methods

2.1. Materials and Devices

2.2. Cracking Force

2.3. Characterization Methods

3. Results

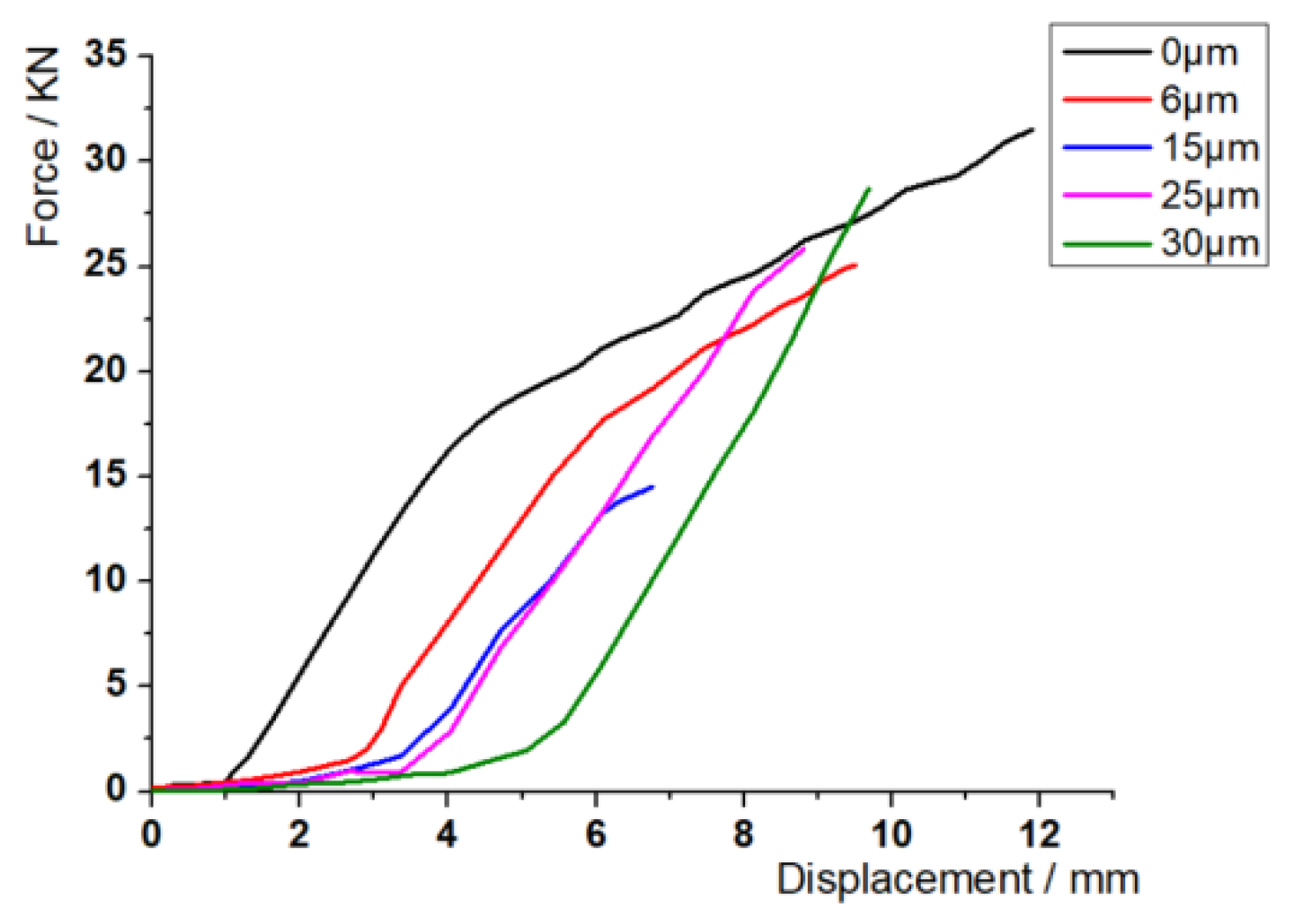

3.1. Effect of Ultrasonic Amplitude on Cracking Force

3.2. Effect of Ultrasonic Amplitude on Hole Deformation

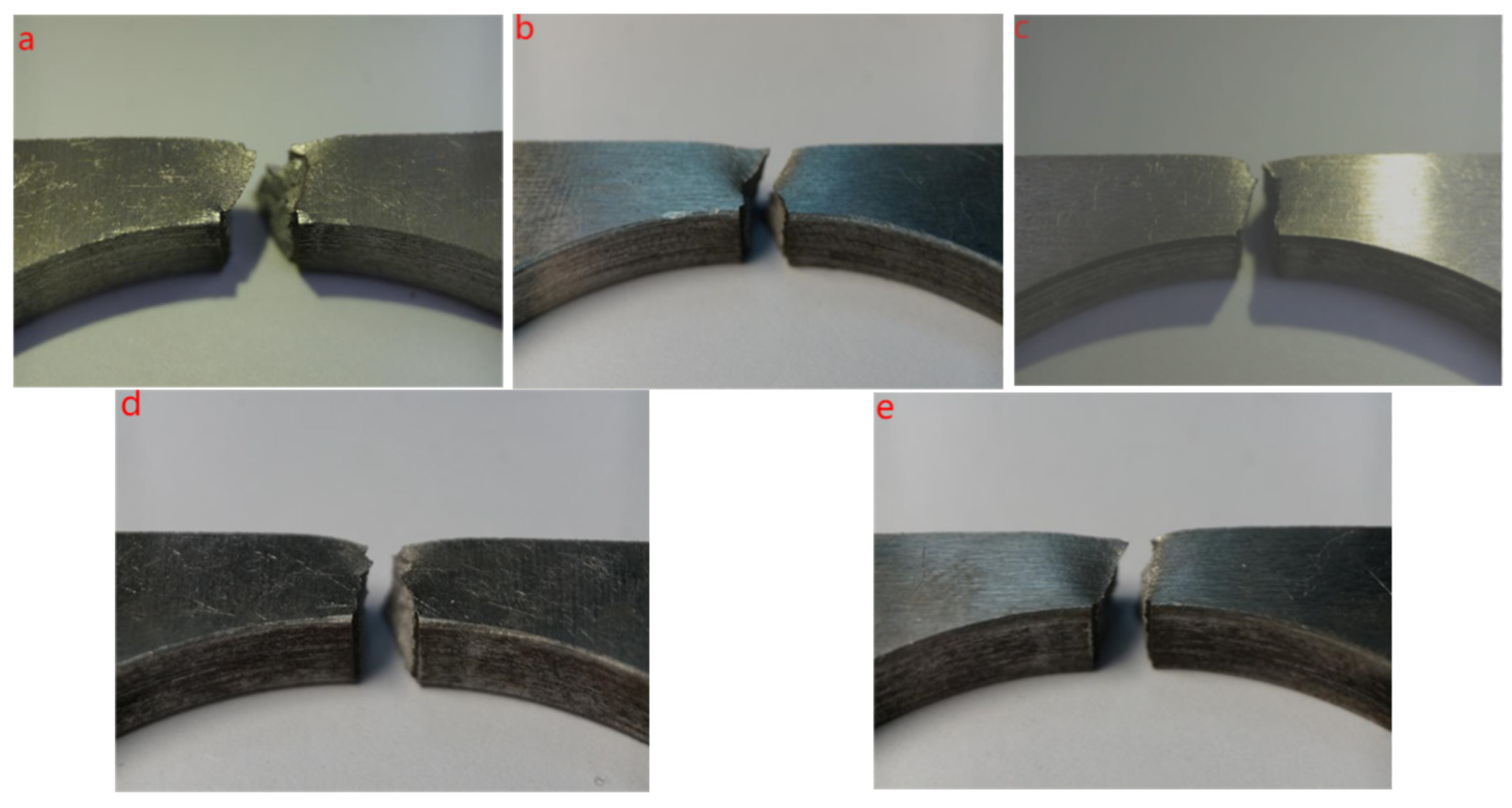

3.2.1. Macro-Deformation at the Cracking Section

3.2.2. Hole Deformation after Cracking

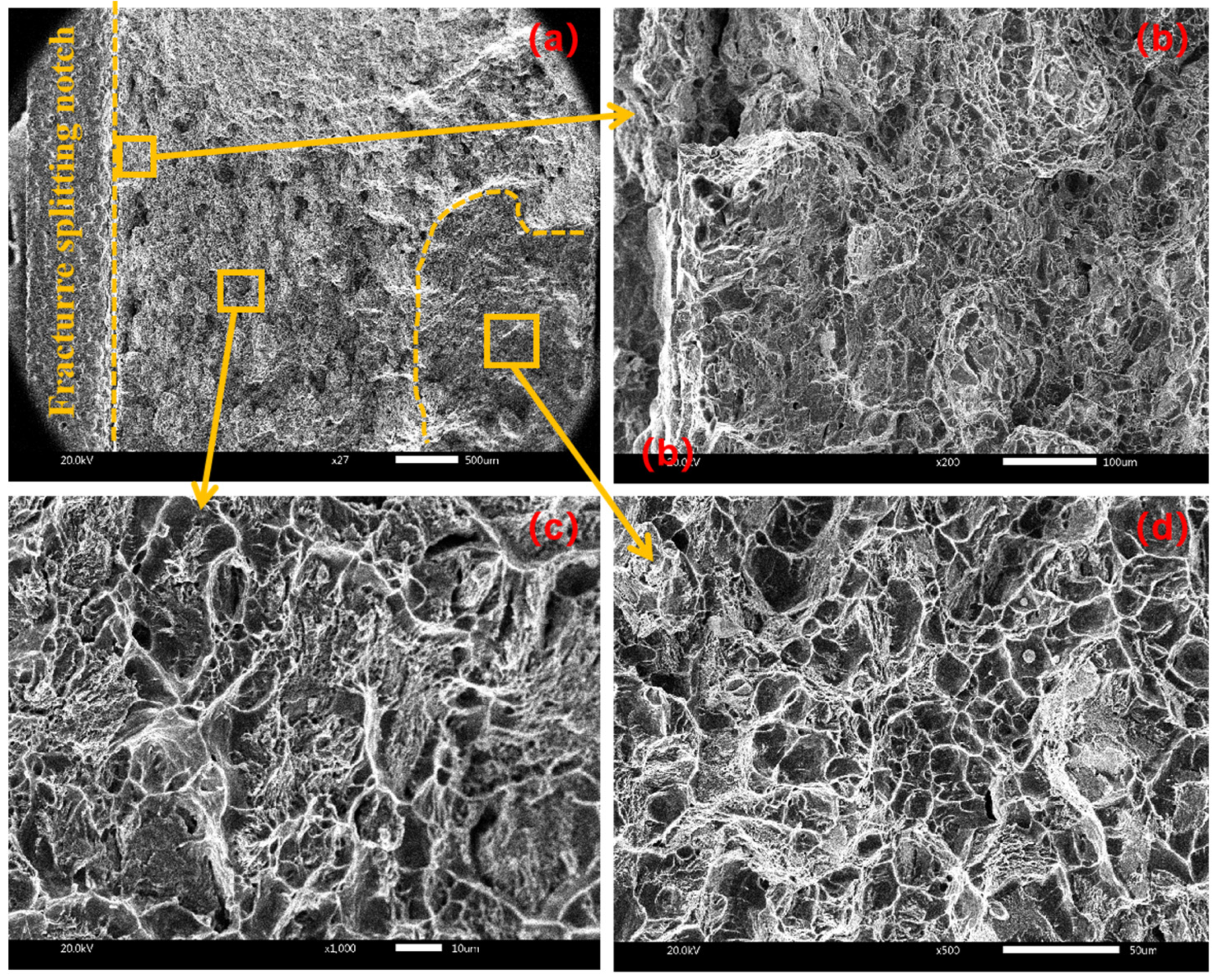

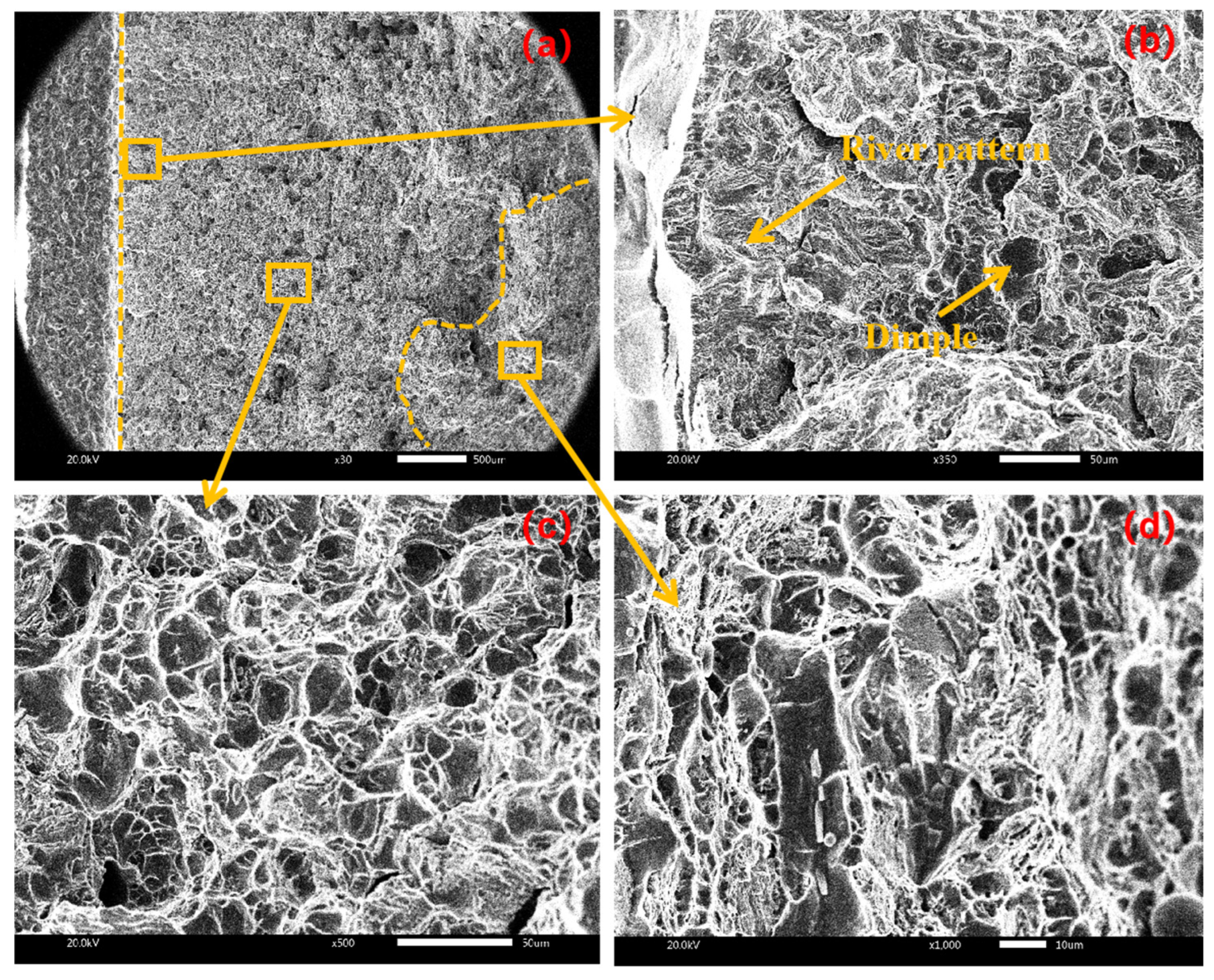

3.3. Effect of Ultrasonic Amplitude on Microstructure

3.4. The Effect of Ultrasonic Amplitude on the Change in Dislocation

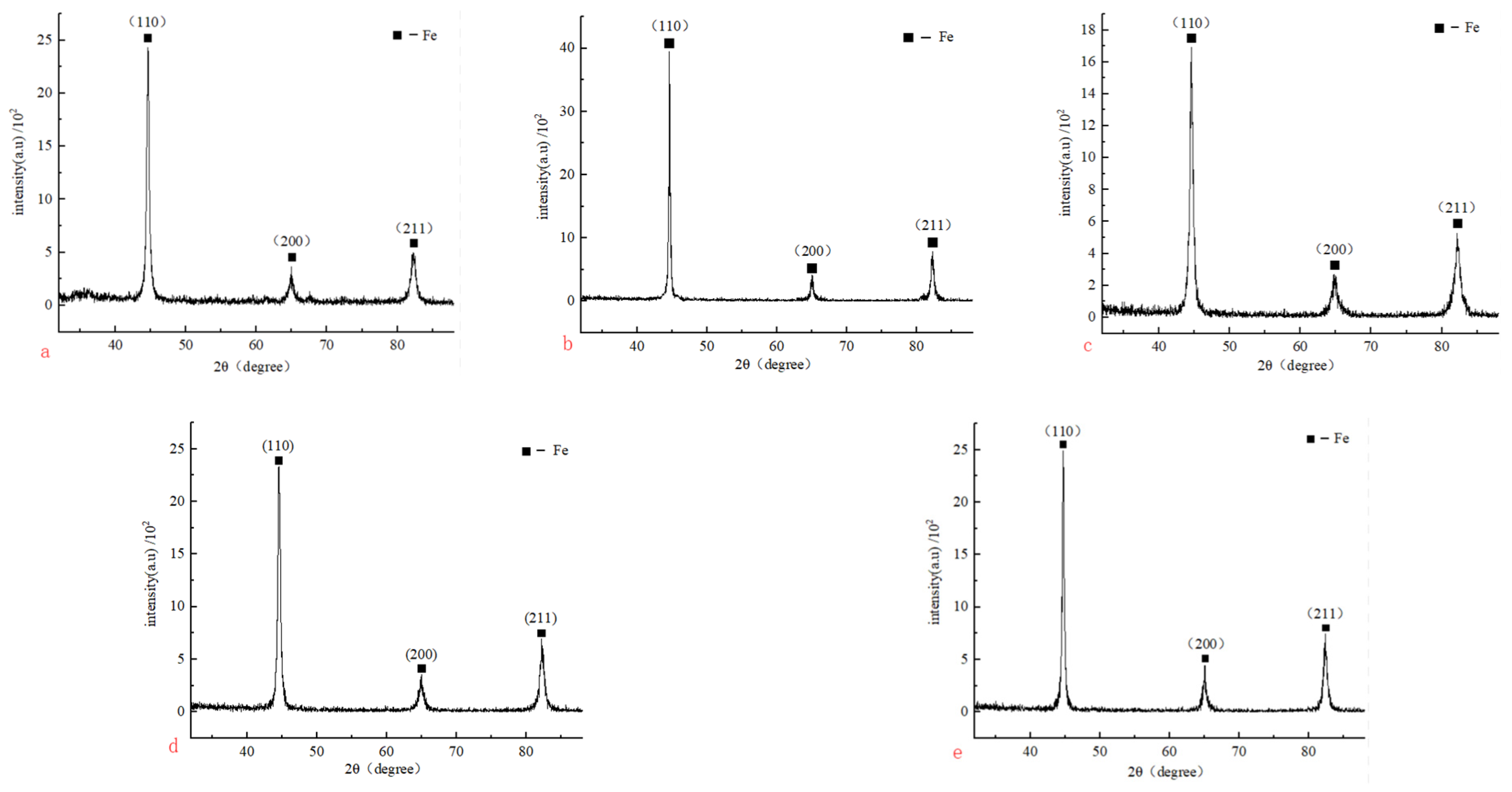

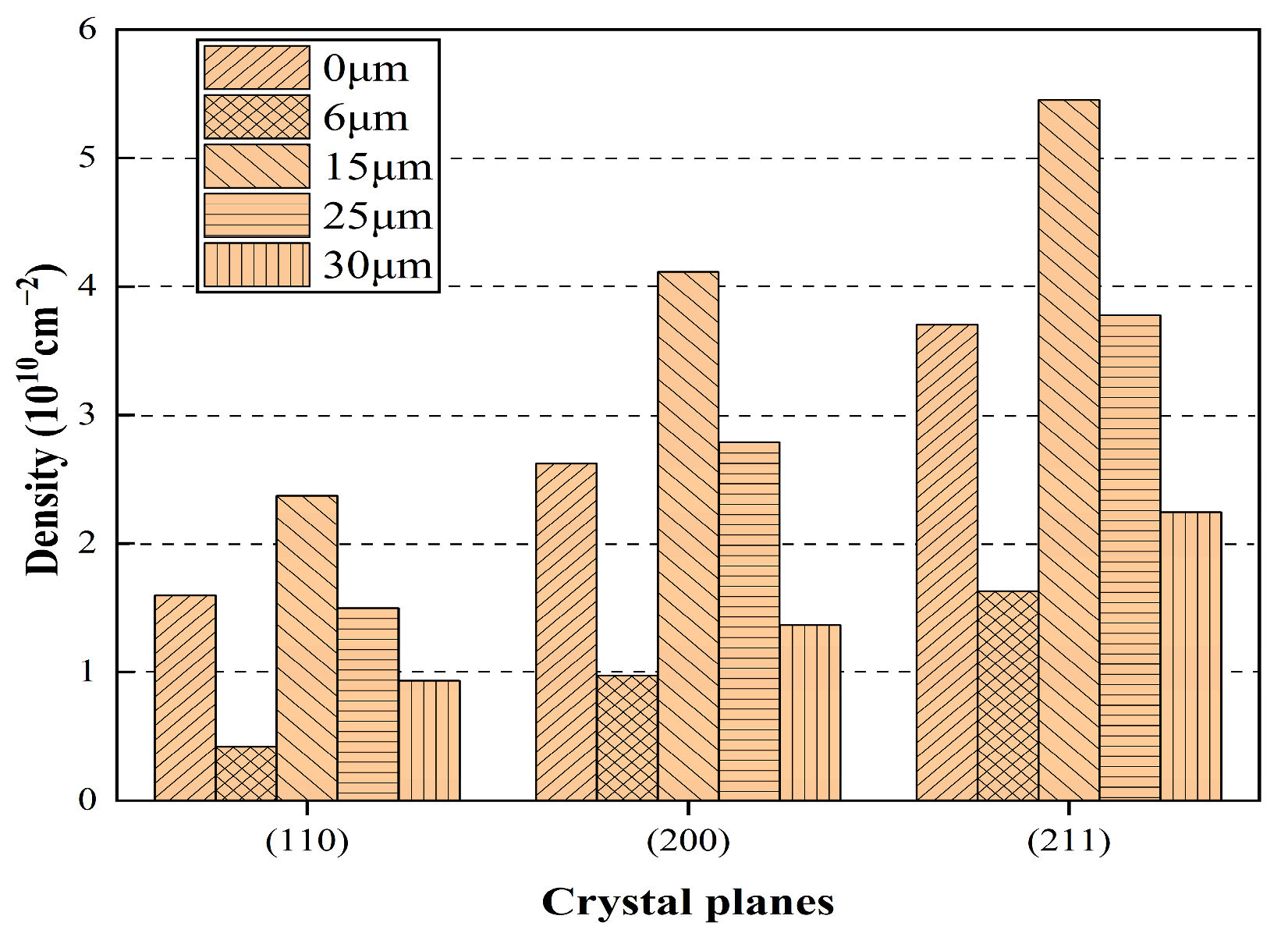

3.4.1. XRD Analysis

3.4.2. TEM Analysis

4. Discussion—An Analysis of the Mechanism of Ultrasound-Assisted Cracking

5. Conclusions

- (1)

- When the amplitude increases from 0 μm to 15 μm and then to 30 μm, the cracking force and the displacement of the stretcher decrease at first and then increase. At 15 μm, the cracking force of the sample is the smallest and the deformation of the sample is the smallest.

- (2)

- There is a threshold near the amplitude of 15 μm. When the amplitude is lower than this threshold, ultrasonic vibration plays a major role in cracking, and the low-amplitude “softening” and high-amplitude “hardening” effects of ultrasound are consistent with the experimental results.

- (3)

- When the amplitude increases from 0 μm to 6 μm, the dislocation density decreases, the dislocation lines at the center depth of the fracture 2 mm become reduced and the direction of the dislocation movement becomes less obvious. When the amplitude increases from 6 μm to 15 μm, the dislocation density increases, resulting in dislocation entanglement and grain fragmentation. When the amplitude increases from 15 μm to 30 μm, the dislocation density decreases, and multiple dislocation slip trajectories appear.

- (4)

- The increase in amplitude will lead to the decrease in dislocation density at first, then an increase and then a decrease; the plasticity of the fracture surface will increase, then decrease and then increase. The effect of amplitude on dislocation leads to the change in fracture morphology.

- (5)

- There is a threshold near the amplitude of 15 μm. When the amplitude is this threshold, the minimum cracking force and sample deformation can be guaranteed, the fracture surface is smooth without a necking phenomenon and the fracture surface is brittle and flat.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bhamdare, A.; Atulkar, A.; Porwal, R. Design, static structural analysis and topology optimization of a four wheeler connecting rod. Mater. Today Proc. 2022, 66, 829–833. [Google Scholar] [CrossRef]

- Kuldeep, B.; Ravikumar, K.P.; Guruprasad, B.S.; Tasneem, H.A.; Ashrith, H.S.; Shree, N.; Ali, M.M.; Bashir, M.N.; Ahamad, T. A novel composite connecting rod: Study on mechanical and dynamic behaviour through experimental and finite element approach. Compos. Part C Open Access 2023, 12, 100413. [Google Scholar] [CrossRef]

- Shi, Z.; Kou, S. Inverse reconstruction of fracture splitting connecting rod and its strength and fatigue life. J. Fail. Anal. Prev. 2018, 18, 619–627. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, Y. Setting of Natural Fracture Splitting Surface on Connecting Rod and Its Formation Mechanism. Metals 2020, 10, 590. [Google Scholar] [CrossRef]

- Gu, Z.; Yang, S.; Ku, S.; Zhao, Y.; Dai, X. Fracture splitting technology of automobile engine connecting rod. Int. J. Adv. Manuf. Technol. 2005, 25, 883–887. [Google Scholar] [CrossRef]

- Shi, Z.; Kou, S. Analysis of quality defects in the fracture surface of fracture splitting connecting rod based on three-dimensional crack growth. Results Phys. 2018, 10, 1022–1029. [Google Scholar] [CrossRef]

- Liu, J.; Kou, S.; He, D. Comparative analysis of the fracture splitting deformation of the big end for C70S6, 36MnVS4 and 46MnVS5 connecting rods. IOP Conf. Ser. Mater. Sci. Eng. 2020, 772, 012113. Available online: https://iopscience.iop.org/article/10.1088/1757-899X/772/1/012113/pdf (accessed on 29 April 2024). [CrossRef]

- Zhang, C.L.; Fang, W.; Cai, B.R.; Sun, X.H.; Liu, Y.Z. Austenite grain growth and its effect on splitting fracture property of a V–N microalloyed medium carbon steel connecting rod. J. Iron Steel Res. Int. 2019, 26, 875–881. [Google Scholar] [CrossRef]

- Liu, B.X.; Fan, K.Y.; Yin, F.X.; Feng, J.H.; Ji, P.G. Effect of caliber rolling reduction ratios on the microstructure and mechanical properties of 45 medium carbon steel. Mater. Sci. Eng. A 2020, 774, 138954. [Google Scholar] [CrossRef]

- Ji, Y.; Sun, X.; Zhao, F.; Zhang, C.; Jiang, B.; Liu, Y. Austenite grain growth behavior and its effects on fracture splitting performance of 36MnVS4 connecting rod for automobile engine. Kov. Mater. Met. Mater. 2018, 56, 113–120. [Google Scholar] [CrossRef]

- Ouyang, J.; Qiu, Z.; Wang, L. Investigation of 2D ultrasonic-assisted micro-injection molding. J. Mater. Process. Technol. 2024, 328, 118397. [Google Scholar] [CrossRef]

- Qin, S.; Zhu, L.; Wiercigroch, M.; Ren, T.; Hao, Y.; Ning, J.; Zhao, J. Material removal and surface generation in longitudinal-torsional ultrasonic assisted milling. Int. J. Mech. Sci. 2022, 227, 107375. [Google Scholar] [CrossRef]

- Ni, C.; Zhu, L. Investigation on machining characteristics of TC4 alloy by simultaneous application of ultrasonic vibration assisted milling (UVAM) and economical-environmental MQL technology. J. Mater. Process. Technol. 2020, 278, 116518. [Google Scholar] [CrossRef]

- Shao, G.; Li, H.; Zhang, X.; Zhan, M.; Xiang, Z. Characteristics and mechanism in ultrasonic vibration-assisted deformation of Ni-based superalloy thin-walled sheet by quasi-in-situ EBSD. J. Alloys Compd. 2022, 908, 164591. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, Y.; Liao, J. Effects of process parameters on the mechanical properties and microstructure in ultrasonic vibration-assisted warm tensile deformation of AZ31 magnesium alloy. Int. J. Lightweight Mater. Manuf. 2024, 7, 378–383. [Google Scholar] [CrossRef]

- Storck, H.; Littmann, W.; Wallaschek, J.; Mracek, M. The effect of friction reduction in presence of ultrasonic vibrations and its relevance to travelling wave ultrasonic motors. Ultrasonics 2022, 40, 379–383. [Google Scholar] [CrossRef]

- Wen, T.; Wei, L.; Chen, X.; Pei, C.-L. Effects of ultrasonic vibration on plastic deformation of AZ31 during the tensile process. Int. J. Miner. Metall. Mater. 2011, 18, 70–76. [Google Scholar] [CrossRef]

- Yao, Z.; Kim, G.Y.; Wang, Z.; Faidley, L.; Zou, Q.; Mei, D.; Chen, Z. Acoustic softening and residual hardening in aluminum: Modeling and experiments. Int. J. Plast. 2012, 39, 75–87. [Google Scholar] [CrossRef]

- Zhong, C. Study on Plastic Forming of Aluminum Alloy with High Frequency Vibration. Master’s Thesis, Shandong University, Jinan, China, 2015. (In Chinese). [Google Scholar]

- Chen, L.; Wang, H.; Liu, D.; Ye, X.; Li, X.; Tang, G. Effects of electropulsing cutting on the quenched and tempered 45 steel rods. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2018, 33, 204–211. [Google Scholar] [CrossRef]

- Jia, R.; Zhang, Y.; Zhang, Y.; Guo, H. The dislocation density in 4H-Si C epitaxial single crystals is calculated by XRD method. Spectrosc. Spectr. Anal. 2010, 30, 1995–1997. (In Chinese) [Google Scholar]

- Zhang, J.; Wang, J.; Wang, Y.; Yang, H. The effect of the ratio of In source flow to group III flow on the properties of In Ga N/Ga N multiple quantum wells. Acta Phys. Sin. 2004, 53, 2467–2471. (In Chinese) [Google Scholar] [CrossRef]

- Wang, X.; Cui, F.; Yan, G.; Li, Y. Study on the change of dislocation density in 40Cr cold rolling forming. China Mech. Eng. 2013, 24, 2248. Available online: http://www.cmemo.org.cn/CN/Y2013/V24/I16/2248 (accessed on 29 April 2024). (In Chinese).

- Su, J.; Sun, H.; Ren, F.; Chen, X. Dislocation evolution analysis of XRD’s TA10 titanium alloy after hot compression deformation. J. Harbin Eng. Univ. 2019, 40, 406–411. (In Chinese) [Google Scholar] [CrossRef]

- Huang, P. In-Situ Transmission Electron Microscopic Study on the Size Effect and Temperature Effect of Titanium Alloy Deformation Mechanism. Master’s Thesis, Zhejiang University, Hangzhou, China, 2019. (In Chinese). [Google Scholar]

- Petch, N.J. The ductile-brittle transition in the fracture of α-iron: I. Philos. Mag. 1958, 3, 1089–1097. [Google Scholar] [CrossRef]

- Xie, Z.-D.; Guan, Y.-J.; Yu, X.-H.; Zhu, L.-H.; Lin, J. Effects of ultrasonic vibration on performance and microstructure of AZ31 magnesium alloy under tensile deformation. J. Cent. South Univ. 2018, 25, 1545–1559. [Google Scholar] [CrossRef]

- Zhou, X. Discussion on the Essence of Temperature and Load Rate Affecting Brittleness of Structural Steel and Brittle Fracture Control. Master’s Thesis, Harbin Engineering University, Harbin, China, 2005. (In Chinese). [Google Scholar]

| C | Si | Mn | P | S | Cr | Ni | Cu |

|---|---|---|---|---|---|---|---|

| 0.42~0.50 | 0.17~0.37 | 0.50~0.80 | ≤0.045 | ≤0.06~0.07 | ≤0.25 | ≤0.30 | ≤0.25 |

| Material | E/MPa | Poisson’s Ratio (v) | Yield Strength /MPa | Tensile Strength /MPa | Rupture Stress /MPa | Rupture Strain /MPa |

|---|---|---|---|---|---|---|

| 1045 steel | 210 | 0.3 | 710 | 993 | 1727 | 0.21545 |

| NO. | Amp/μm | Before L/2/mm | After L/2/mm | (L/2)/mm | Before H/mm | After H/mm | H/mm | Deform/mm |

|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 26.940 | 26.739 | 0.201 | 26.718 | 27.423 | 0.705 | 0.906 |

| 2 | 26.933 | 26.718 | 0.215 | 26.708 | 27.428 | 0.720 | 0.935 | |

| 3 | 26.899 | 26.665 | 0.234 | 26.634 | 27.362 | 0.728 | 0.962 | |

| 4 | 6 | 26.960 | 26.635 | 0.325 | 26.817 | 28.305 | 1.488 | 1.813 |

| 5 | 26.863 | 26.523 | 0.340 | 26.713 | 28.128 | 1.415 | 1.755 | |

| 6 | 26.930 | 26.583 | 0.347 | 26.655 | 28.145 | 1.490 | 1.837 | |

| 7 | 15 | 26.945 | 26.727 | 0.218 | 26.869 | 27.255 | 0.386 | 0.604 |

| 8 | 26.864 | 26.632 | 0.232 | 26.734 | 27.130 | 0.396 | 0.628 | |

| 9 | 26.835 | 26.597 | 0.238 | 26.708 | 27.101 | 0.393 | 0.631 | |

| 10 | 25 | 26.945 | 26.690 | 0.255 | 26.723 | 27.354 | 0.631 | 0.886 |

| 11 | 26.860 | 26.597 | 0.263 | 26.321 | 27.060 | 0.739 | 1.002 | |

| 12 | 26.935 | 26.668 | 0.267 | 26.708 | 27.404 | 0.696 | 0.963 | |

| 13 | 30 | 27.028 | 26.711 | 0.317 | 26.302 | 27.282 | 0.980 | 1.297 |

| 14 | 26.946 | 26.648 | 0.298 | 26.450 | 27.423 | 0.973 | 1.271 | |

| 15 | 26.867 | 26.563 | 0.304 | 26.653 | 27.708 | 1.055 | 1.359 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Wang, Y.; Liu, X.; Sha, D.; Zhu, M. Study on Characteristics of Ultrasound-Assisted Fracture Splitting for AISI 1045 Quenched and Tempered Steel. Materials 2024, 17, 2143. https://doi.org/10.3390/ma17092143

Jiang Y, Wang Y, Liu X, Sha D, Zhu M. Study on Characteristics of Ultrasound-Assisted Fracture Splitting for AISI 1045 Quenched and Tempered Steel. Materials. 2024; 17(9):2143. https://doi.org/10.3390/ma17092143

Chicago/Turabian StyleJiang, Yinfang, Yangyang Wang, Xiancheng Liu, Deli Sha, and Mengcheng Zhu. 2024. "Study on Characteristics of Ultrasound-Assisted Fracture Splitting for AISI 1045 Quenched and Tempered Steel" Materials 17, no. 9: 2143. https://doi.org/10.3390/ma17092143

APA StyleJiang, Y., Wang, Y., Liu, X., Sha, D., & Zhu, M. (2024). Study on Characteristics of Ultrasound-Assisted Fracture Splitting for AISI 1045 Quenched and Tempered Steel. Materials, 17(9), 2143. https://doi.org/10.3390/ma17092143