Upcycling Calcium Carbonate as an Alternative Filler in Layered Wood Composite Technology

Abstract

1. Introduction

2. Materials and Methods

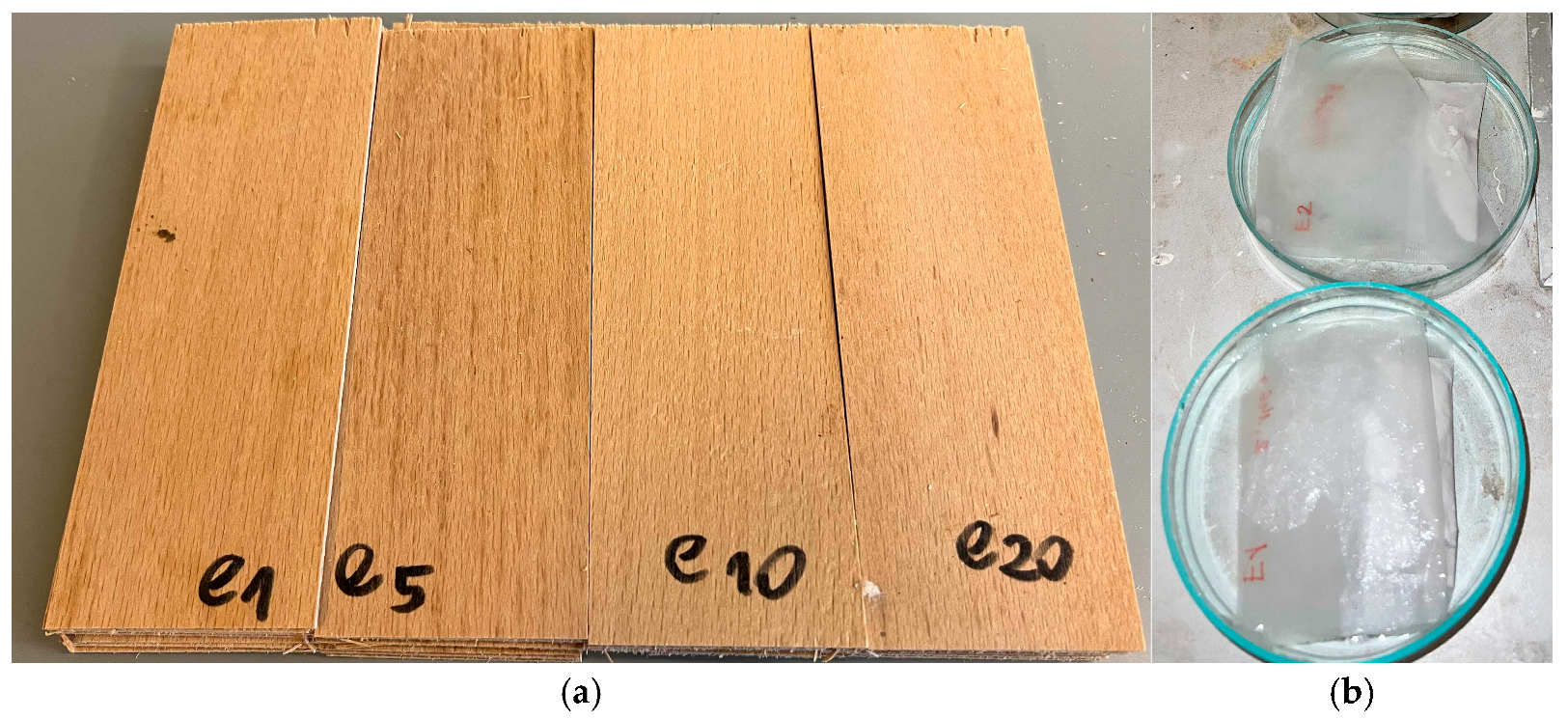

2.1. Materials

2.2. Samples Preparation

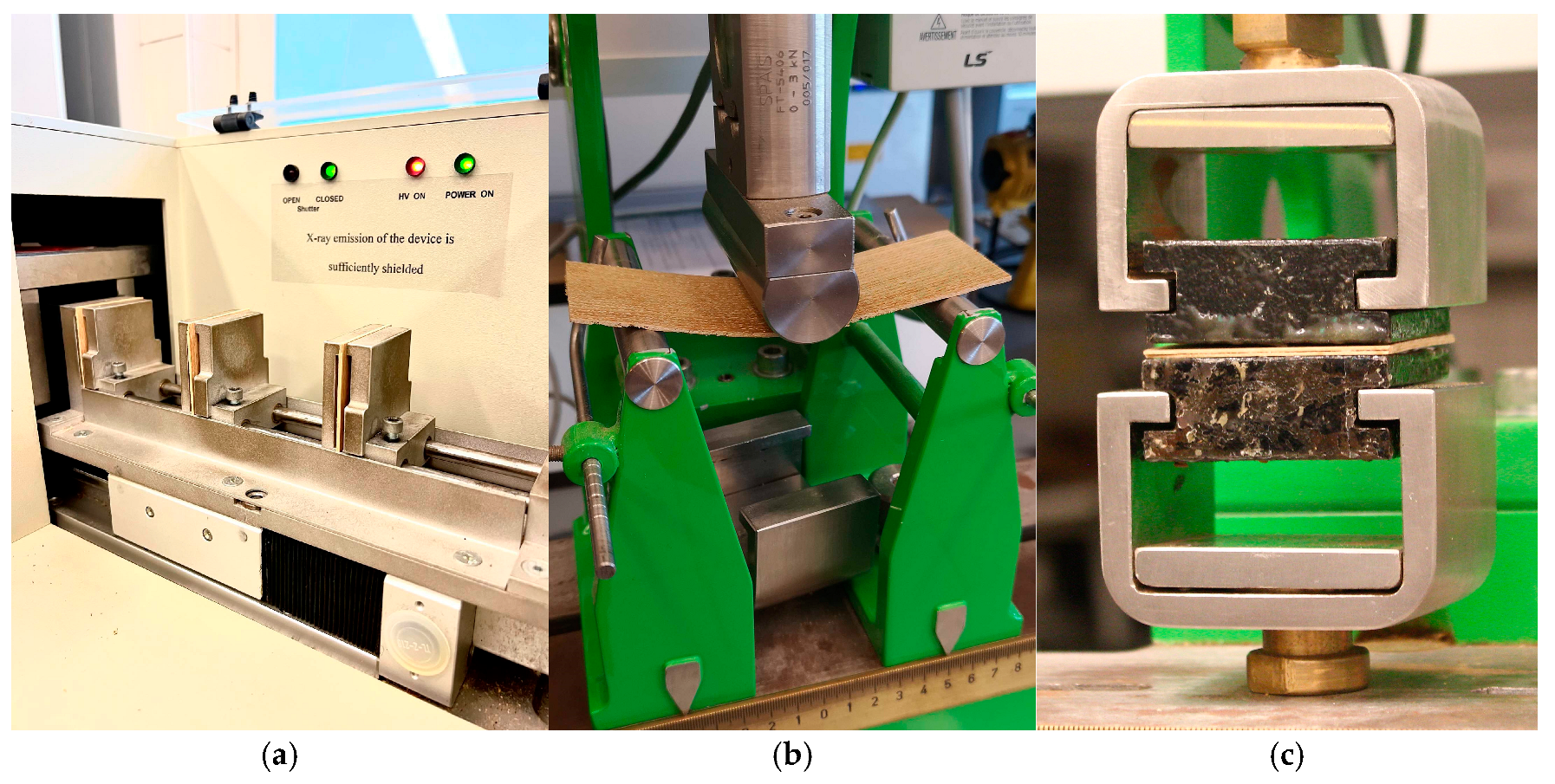

2.3. Characterization of the Manufactured Panels

2.4. Statistical Analysis

3. Results and Discussion

3.1. Density Profile

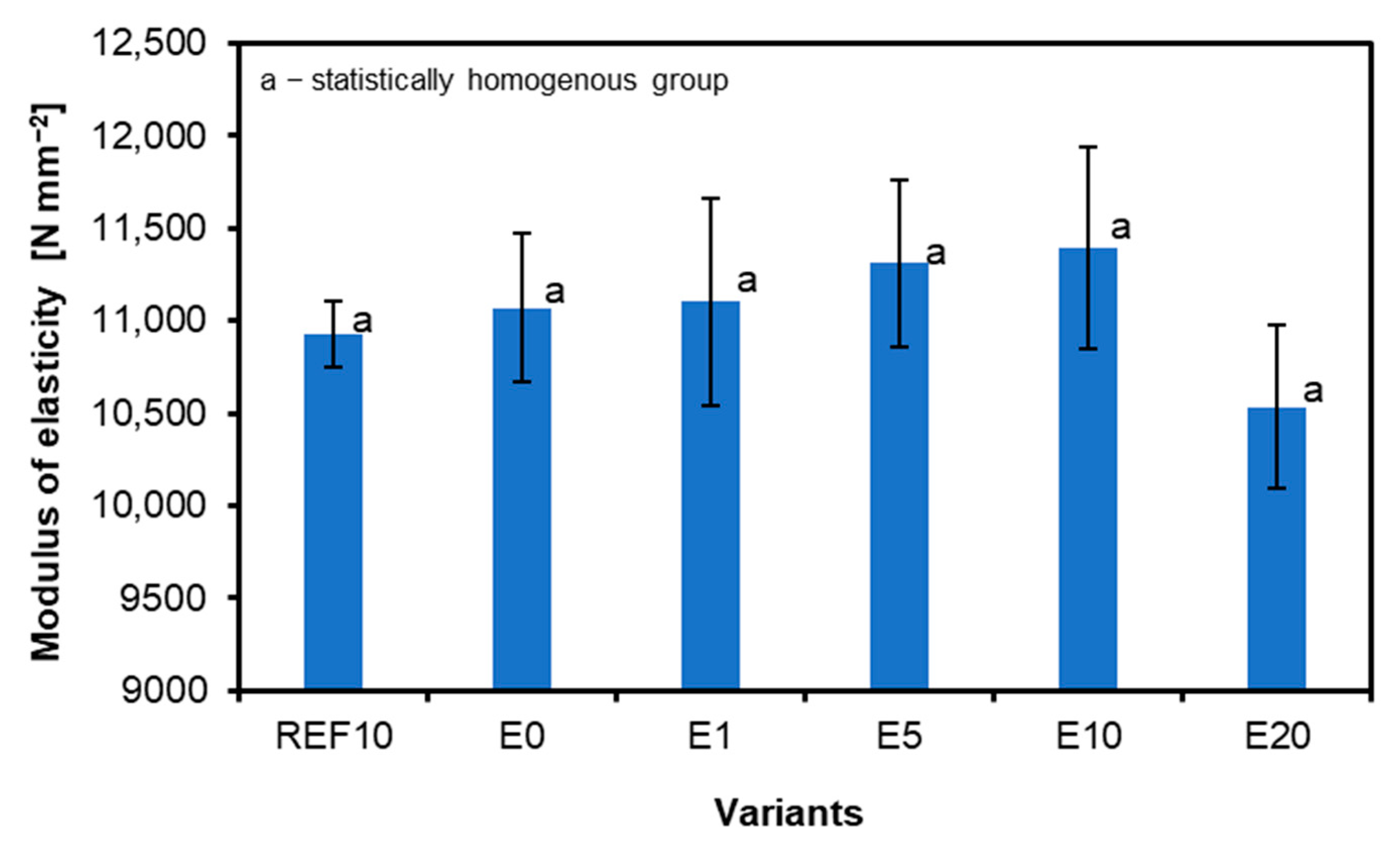

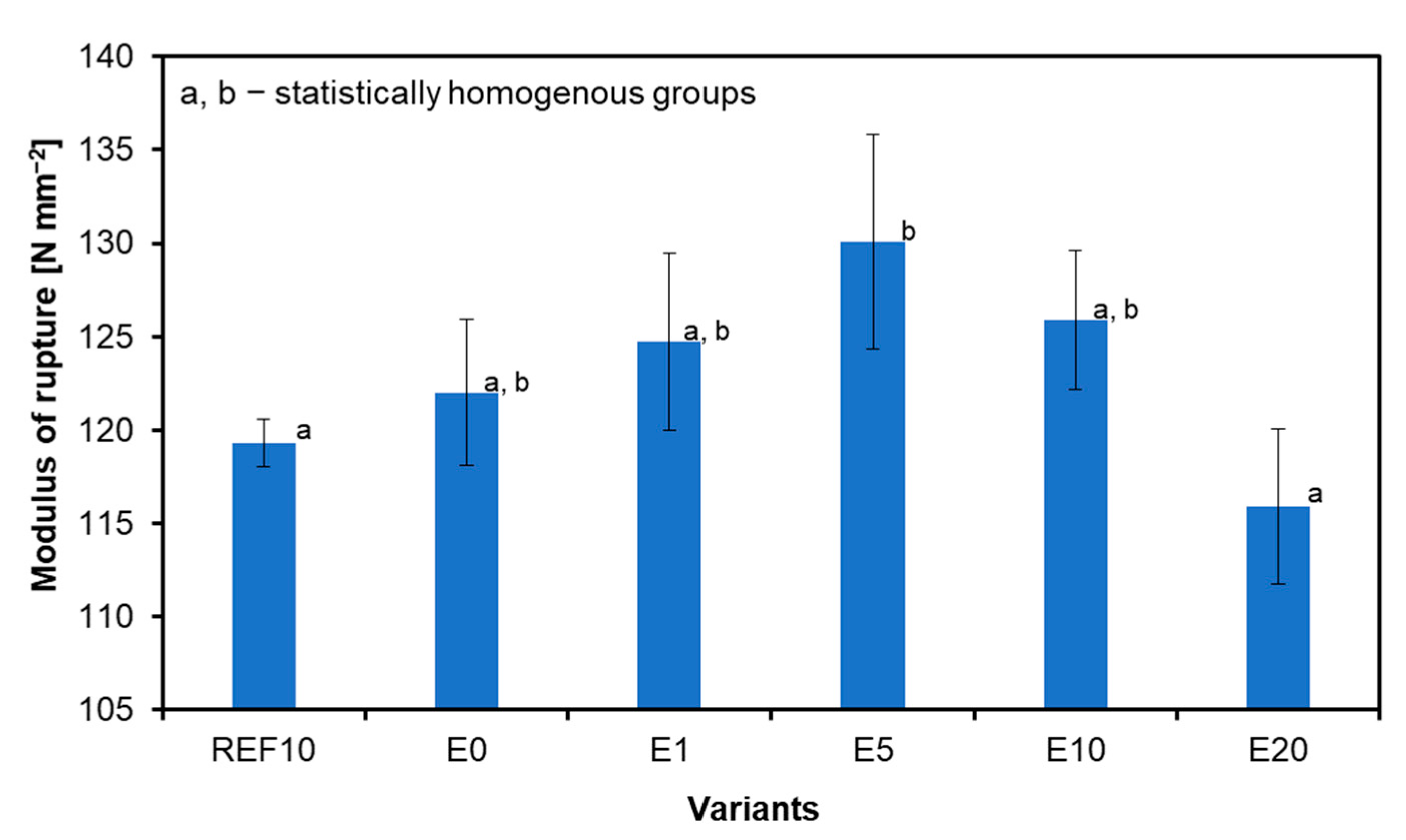

3.2. Determination of Modulus of Elasticity in Bending and of Bending Strength

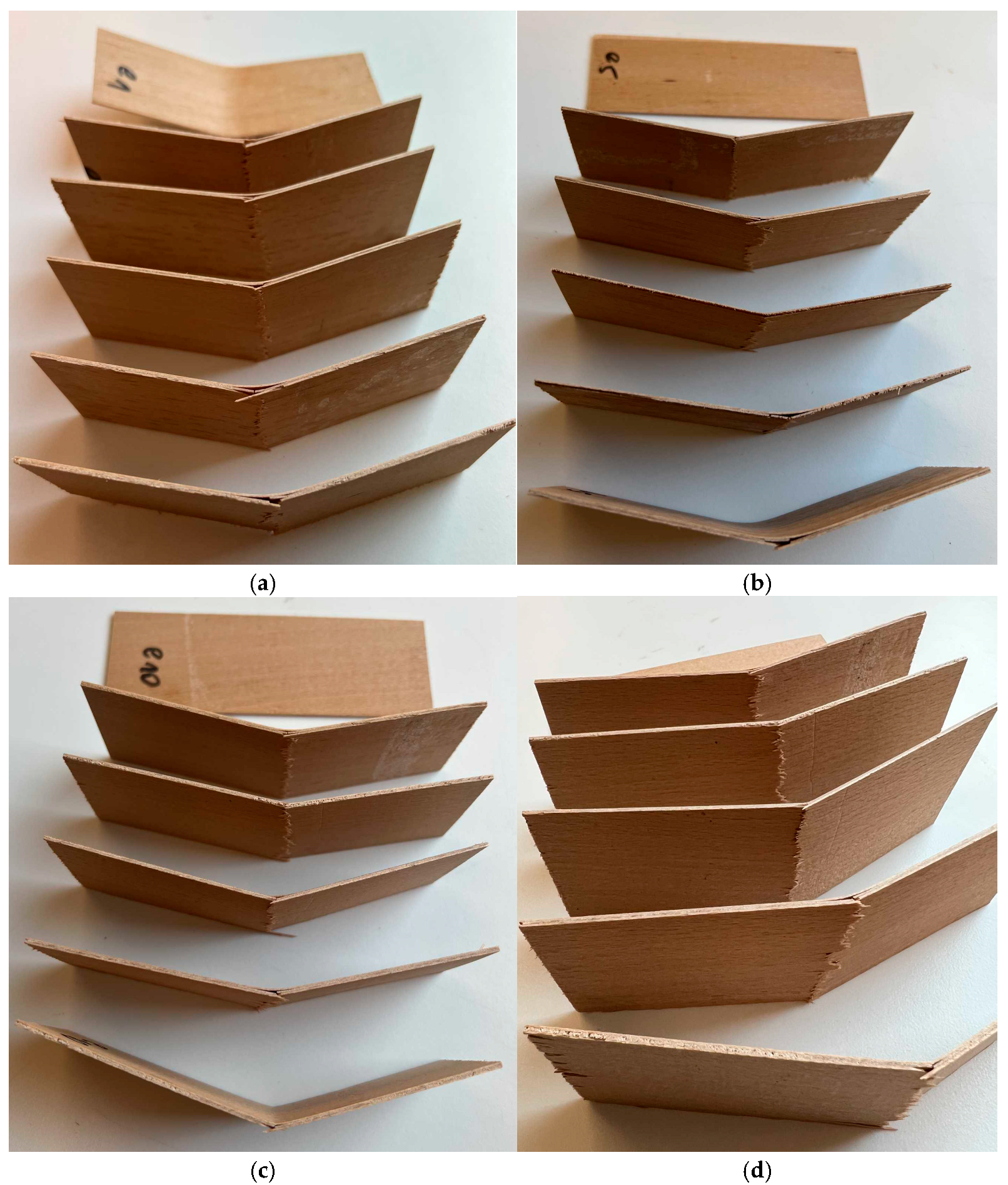

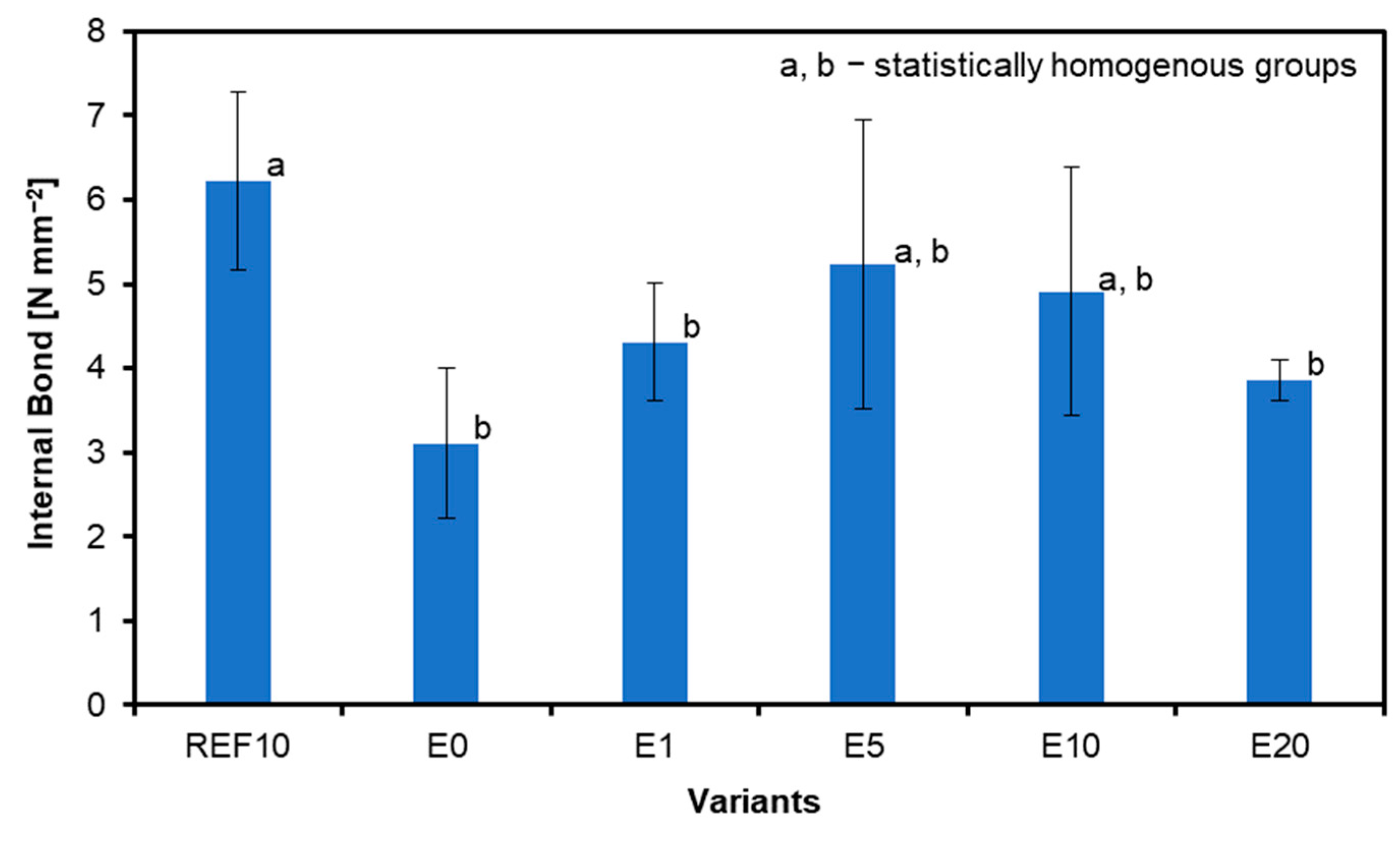

3.3. Internal Bond

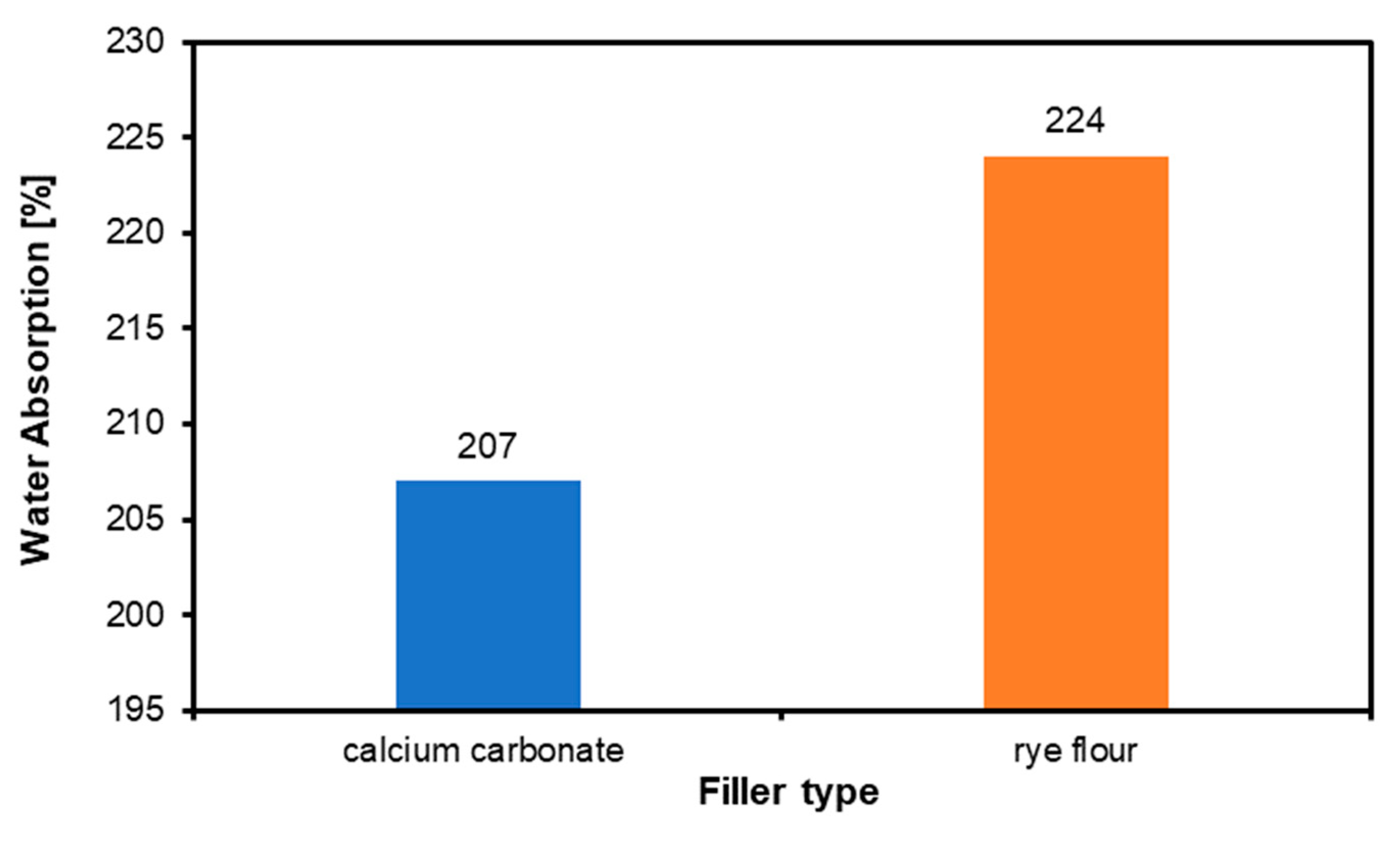

3.4. Filler Water Absorption

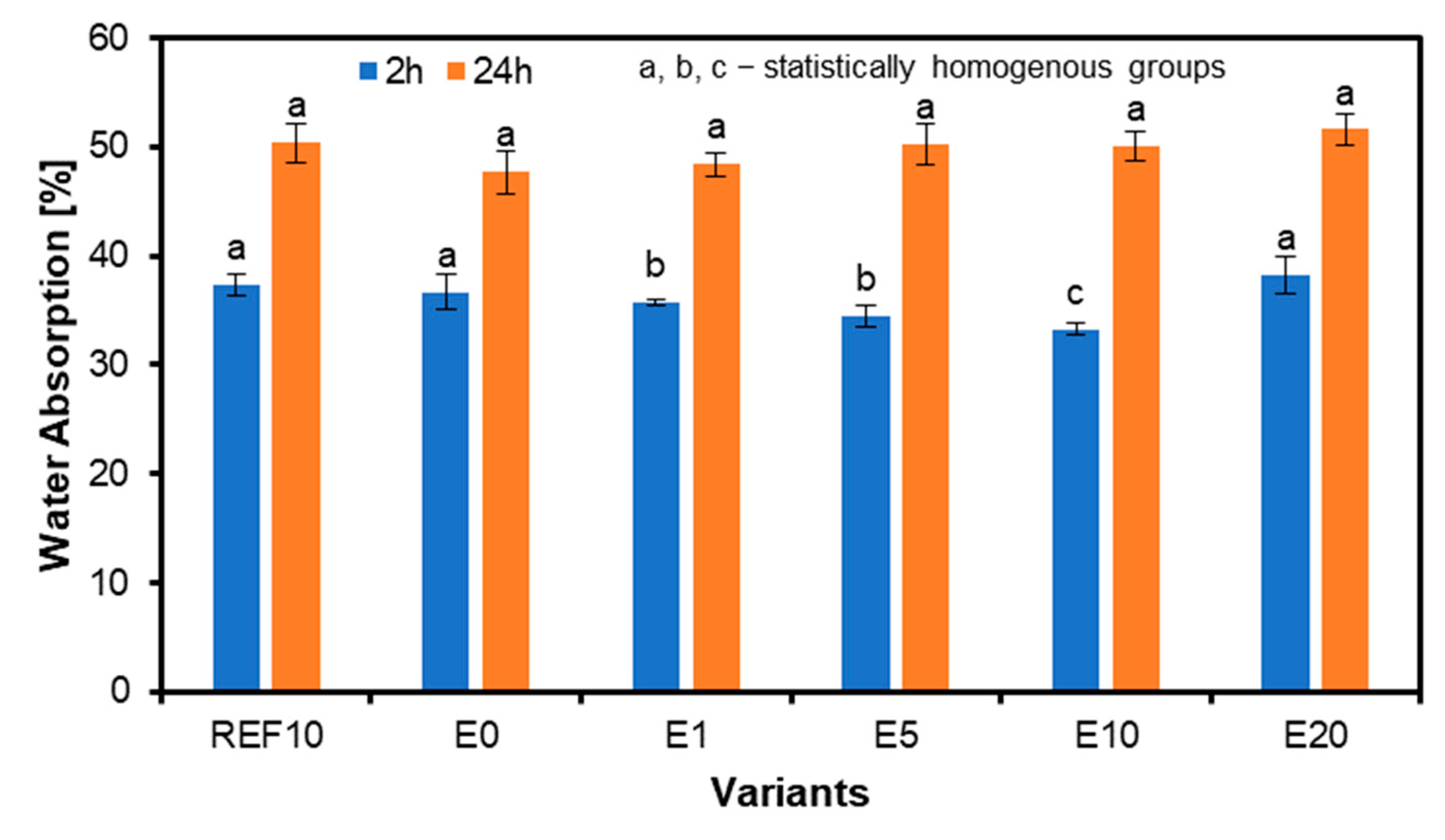

3.5. Swelling in Thickness and Water Absorption

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Elkhalifa, S.; Al-Ansari, T.; Mackey, H.R.; McKay, G. Food waste to biochars through pyrolysis: A review. Resour. Conserv. Recycl. 2019, 144, 310–320. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M.; Skórczewska, K.; Matykiewicz, D. Correlation between processing parameters and degradation of different polylactide grades during twin-screw extrusion. Polymers 2020, 12, 1333. [Google Scholar] [CrossRef]

- Awogbemi, O.; Von Kallon, D.V.; Aigbodion, V.S. Pathways for Sustainable Utilization of Waste Chicken Eggshell. J. Renew. Mater. 2022, 10, 2217–2246. [Google Scholar] [CrossRef]

- Muyassir, M.; Helmi, H.; Ilyas, I.; Khalil, M.; Zakaria, S. Chicken eggshells as a soil amendment and their relationship with the morphological response of mustard plants (Brassica juncea, L.). IOP Conf. Ser. Earth Environ. Sci. 2022, 1116, 012056. [Google Scholar] [CrossRef]

- European Commission (DG ESTAT, D.A.). Eggs and Poultry. Market Data on National and European Agriculture Provided by the European Commission’s Agricultural and Rural Development Department. Browse Visualisations About Imports, Exports, Prices and Production. Available online: https://agridata.ec.europa.eu/extensions/DataPortal/eggs-and-poultry.html (accessed on 1 December 2024).

- Rozkrut, D. (Ed.) Statistical Yearbook of the Republic of Poland 2023; Statistical Publishing Establishment: Warsaw, Poland, 2024; ISBN 1506-0632. [Google Scholar]

- Kalpana, V.N.; Devi Rajeswari, V. Biosynthesis of Metal and Metal Oxide Nanoparticles for Food Packaging and Preservation: A Green Expertise; Elsevier Inc.: Amsterdam, The Netherlands, 2017; ISBN 9780128113721. [Google Scholar]

- Lokaewmanee, K.; Yamauchi, K.E.; Komori, T.; Saito, K. Eggshell quality, eggshell structure and small intestinal histology in laying hens fed dietary pantoea-6® and plant extracts. Ital. J. Anim. Sci. 2014, 13, 332–339. [Google Scholar] [CrossRef]

- Laohavisuti, N.; Boonchom, B.; Boonmee, W.; Chaiseeda, K.; Seesanong, S. Simple recycling of biowaste eggshells to various calcium phosphates for specific industries. Sci. Rep. 2021, 11, 15143. [Google Scholar] [CrossRef] [PubMed]

- Munusamya, Y.; Kchaou, M. Usage of eggshell as potential bio-filler for acrylonitrile butadiene rubber (NBR) latex film for glove applications. Ain Shams Eng. J. 2023, 14, 102512. [Google Scholar] [CrossRef]

- Mahmood, L.J.; Rafiq, S.K.; Muhammad, M.A. Punching shear behavior of reinforced concrete flat slab column connection containing recycled eggshell powder. Structures 2022, 46, 1016–1028. [Google Scholar] [CrossRef]

- Luo, M.; Zhang, G.; Fang, Y.; Cao, L.; Guo, Z.; Wang, K.; Li, J. Calcium carbonate crystallization process from the mineralization of calcium chloride waste. Sep. Purif. Technol. 2023, 319, 124066. [Google Scholar] [CrossRef]

- Łęcka, J.; Dukarska, D.; Matelewski, H. Effect of addition of titanium dioxide and talc on properties of phenolic resin and water-resistant plywood. Ann. Warsaw Univ. Life Sci. SGGW-For. Wood Technol. 2013, 83, 191–195. [Google Scholar]

- Bartoszuk, K.; Kowaluk, G. Utilization of Fibrous Mat Residues from Upholstered Furniture as Sustainable Fillers in Plywood Production. Materials 2024, 17, 4080. [Google Scholar] [CrossRef]

- Walkiewicz, J.; Kawalerczyk, J.; Mirski, R.; Dziurka, D. The Application of Various Bark Species as a Fillers for UF Resin in Plywood Manufacturing. Materials 2022, 15, 7201. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Duan, Z.; Yan, S.; Wu, H.; Huang, H.; He, L.; Essawy, H.; Huang, H.; Zhou, X.; Chen, X. Camellia oleifera shell powder and palm kernel meal as an environmentally-friendly, low-cost compound filler in MUF adhesive for plywood preparation. Int. J. Adhes. Adhes. 2024, 131, 103648. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Walkiewicz, J.; Sedliačik, J.; Dukarska, D.; Woźniak, M.; Mirski, R. Modified Buckwheat Husk as a Filler for Urea–Formaldehyde Resin in Plywood Production. Polymers 2024, 16, 1350. [Google Scholar] [CrossRef]

- Dasiewicz, J.; Wronka, A. Influence of the use of chestnut starch as a binder filler in plywood technology. Ann. Warsaw Univ. Life Sci. SGGW For. Wood Technol. 2023, 148, 137–148. [Google Scholar] [CrossRef]

- Wojciechowska, M.; Kowaluk, G. Waste Banana Peel Flour as a Filler in Plywood Binder. Ann. WULS For. Wood Technol. 2023, 123, 143–152. [Google Scholar] [CrossRef]

- Wronka, M.; Wojnicz, D.; Kowaluk, G. The Influence of Various Modifications of Hazelnut Shell Flour as Potential Filler in Plywood Technology. Materials 2024, 17, 4128. [Google Scholar] [CrossRef]

- Daniłowska, A.; Kowaluk, G. The use of coffee bean post-extraction residues as a filler in plywood technology. Ann. Warsaw Univ. Life Sci.-SGGW For. Wood Technol. 2020, 109, 24–31. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Dziurka, D.; Mirski, R.; Trociński, A. Flour fillers with urea-formaldehyde resin in plywood. BioResources 2019, 14, 6727–6735. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Li, J.; Gao, Q. Effect of Sepiolite Filler in Malamine-Urea-Formaldehyde Resin on the Properties of Three-ply Plywood. BioResources 2015, 10, 6624–6634. [Google Scholar] [CrossRef]

- Ozyhar, T.; Depnering, T.; Ridgway, C.; Welker, M.; Schoelkopf, J.; Mayer, I.; Thoemen, H. Utilization of inorganic mineral filler material as partial replacement for wood fiber in medium density fiberboard (MDF) and its effect on material properties. Eur. J. Wood Wood Prod. 2020, 78, 75–84. [Google Scholar] [CrossRef]

- Özdemir, F. Effect of mineral materials content as filler in medium density fiberboard. BioResources 2019, 14, 2277–2286. [Google Scholar] [CrossRef]

- ASTM D2196-20; Standard Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2020.

- EN 310 Wood-Based Panels; Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 319 Particleboards and Fibreboards; Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 317 Particleboards and Fibreboards; Determination of Swelling in Thickness After Immersion in Water. CEN, European Committee for Standardization: Brussels, Belgium, 1993.

- Jeżo, A.; Wronka, A.; Dębiński, A.; Kristak, L.; Reh, R.; Rizhikovs, J.; Kowaluk, G. Influence of Upcycled Post-Treatment Bark Biomass Addition to the Binder on Produced Plywood Properties. Forests 2023, 14, 110. [Google Scholar] [CrossRef]

- Dasiewicz, J.; Kowaluk, G. Selected aspects of production and characterization of layered biopolymer composite bonded with a cellulose-based binder. Ann. WULS-SGGW. For. Wood Technol. 2022, 119, 24–34. [Google Scholar] [CrossRef]

- Réh, R.; Igaz, R.; Krišt’ák, L.; Ružiak, I.; Gajtanska, M.; Božíková, M.; Kučerka, M. Functionality of beech bark in adhesive mixtures used in plywood and its effect on the stability associated with material systems. Materials 2019, 12, 1298. [Google Scholar] [CrossRef]

- Syarifuddin; Husin, H.; Mahidin; Zaki, M.; Syafiie, S.; Nasution, F.; Ahmadi; Fathullah; Sy, Y. Reutilization of Real Waste Calcium Carbonate (CaCO3) from the Palm Oil Industry (POI) for Palm Kernel and Shell Separation Through Clay Bath Systems. Recycling 2024, 9, 103. [Google Scholar] [CrossRef]

- Ružiak, I.; Igaz, R.; Krišták, L.; Réh, R.; Mitterpach, J.; Očkajová, A.; Kučerka, M. Influence of urea-formaldehyde adhesive modification with beech bark on chosen properties of plywood. BioResources 2017, 12, 3250–3264. [Google Scholar] [CrossRef]

- Li, J.; Wang, X.; Zhang, J.; Gao, Q. Technics and properties of plywood manufacture with modified urea-formaldehyde resin. Adv. Mater. Res. 2013, 602–604, 743–746. [Google Scholar] [CrossRef]

- Réh, R.; Krišťák, Ľ.; Sedliačik, J.; Bekhta, P.; Božiková, M.; Kunecová, D.; Vozárová, V.; Tudor, E.M.; Antov, P.; Savov, V. Utilization of birch bark as an eco-friendly filler in urea-formaldehyde adhesives for plywood manufacturing. Polymers 2021, 13, 511. [Google Scholar] [CrossRef]

- Vázquez, G.; Antorrena, G.; González, J.; Alvarez, J.C. Tannin-based adhesives for bonding high-moisture Eucalyptus veneers: Influence of tannin extraction and press conditions. Holz Als Roh-Und Werkst. 1996, 54, 93–97. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Park, B.D. Enhancing the performance of low molar ratio urea–formaldehyde resin adhesives via in-situ modification with intercalated nanoclay. J. Adhes. 2021, 97, 1271–1290. [Google Scholar] [CrossRef]

- Nemli, G.; Kirci, H.; Temiz, A. Influence of impregnating wood particles with mimosa bark extract on some properties of particleboard. Ind. Crops Prod. 2004, 20, 339–344. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Dziurka, D.; Mirski, R.; Siuda, J.; Babicka, M. Possibility of use of NCC-reinforced melamine-urea- formaldehyde adhesive in plywood manufacturing. Drv. Ind. 2021, 72, 279–289. [Google Scholar] [CrossRef]

- Wirts-Rütters, M.; Heimann, M.; Kolbe, J.; Wolter, K.-J. Carbon nanotube (CNT) filled adhesives for microelectronic packaging. In Proceedings of the 2008 2nd Electronics Systemintegration Technology Conference, ESTC, Greenwich, UK, 1–4 September 2008; pp. 1057–1062. [Google Scholar]

- Karaman, A.; Nuri Yildirim, M. Effect of Material, Adhesive and Loading on the Stiffness of Wooden Dowel Joints. Wood Res. 2023, 68, 768–780. [Google Scholar] [CrossRef]

- Bal, B.C.; Bektaş, I. The effects of wood species, load direction, and adhesives on bending properties of laminated veneer lumber. BioResources 2012, 7, 3104–3112. [Google Scholar] [CrossRef]

- Mirski, R.; Kawalerczyk, J.; Dziurka, D.; Wieruszewski, M.; Trociński, A. Effects of using bark particles with various dimensions as a filler for urea-formaldehyde resin in plywood. BioResources 2020, 15, 1692–1701. [Google Scholar] [CrossRef]

- Dai, C.P.; Yu, C.M.; Jin, J.W. Theoretical modeling of bonding characteristics and performance of wood composites. Part IV. Internal bond strength. Wood Fiber Sci. 2008, 40, 146–160. [Google Scholar]

- Suzuki, S.; Miyagawa, H. Effect of element type on the internal bond quality of wood-based panels determined by three methods. J. Wood Sci. 2003, 49, 513–518. [Google Scholar] [CrossRef]

- Xu, W.; Steiner, P.R. Rationalizing Internal Bond and Thickness Swell Test Specimen Size. Wood Fiber Sci. 1995, 27, 389–394. [Google Scholar]

- Fan, D.B.; Qin, T.F.; Chu, F.X. A new interior plywood adhesive based on oil-tea cake. Adv. Mater. Res. 2011, 194–196, 2183–2186. [Google Scholar] [CrossRef]

- Jin, F.; Wang, S.; Duan, H.; Xia, Y.; Yang, T.; Yang, D. Study on the Water Absorption Characteristics of Anthracite Particles after Immersion in Water. ACS Omega 2024, 9, 28841–28851. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, S.; Romanias, M.N.; Alleman, L.Y.; Zeineddine, M.N.; Angeli, G.K.; Trikalitis, P.N.; Thevenet, F. Water Interaction with Mineral Dust Aerosol: Particle Size and Hygroscopic Properties of Dust. ACS Earth Space Chem. 2018, 2, 376–386. [Google Scholar] [CrossRef]

- Wang, N.; Tan, Y.; Du, X.; Yin, Q. Study on the difference in adsorption thermodynamics for water on swelling and non-swelling clays with implications for prevention and treatment of pneumoconiosis. Arab. J. Chem. 2022, 15, 103895. [Google Scholar] [CrossRef]

- Omrani, P.; Abdolzadeh, H.; Roshan, F.; Ganjkhani, M. Applicational Properties of Reinforced Plywood with Nanomaterials and Kenaf Fiber. BioResources 2023, 18, 7054–7065. [Google Scholar] [CrossRef]

- Pawlik, J.; Kowaluk, G. Influence of the amount and type of anti-adhesive agent on selected properties of fibreboards. Ann. WULS For. Wood Technol. 2023, 123, 153–163. [Google Scholar] [CrossRef]

- Ferŕndez-García, C.E.; Andreu-Rodríguez, J.; Ferŕndez-García, M.T.; Ferŕndez-Villena, M.; García-Ortuño, T. Panels made from giant reed bonded with non-modified starches. BioResources 2012, 7, 5904–5916. [Google Scholar] [CrossRef]

- Auriga, R.; Gumowska, A.; Szymanowski, K.; Wronka, A.; Robles, E.; Ocipka, P.; Kowaluk, G. Performance properties of plywood composites reinforced with carbon fibers. Compos. Struct. 2020, 248, 112533. [Google Scholar] [CrossRef]

- Dasiewicz, J.; Kowaluk, G. Characteristics of high-density fibreboard produced with the use of rice starch as a binder. Ann. Warsaw Univ. Life Sci. SGGW For. Wood Technol. 2023, 181, 169–181. [Google Scholar] [CrossRef]

| Varieties of Tested Composites |

|---|

| Plywood with 0 pbw of filler (without added filler) (hereafter called E0) Plywood with 1 pbw ES as a filler (hereafter called E1) Plywood with 5 pbw ES as a filler (hereafter called E5) Plywood with 10 pbw ES as a filler (hereafter called E10) Plywood with 20 pbw ES as a filler (hereafter called E20) Plywood with 10 pbw rye flour (reference; hereafter called REF10) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dasiewicz, J.; Kowaluk, G. Upcycling Calcium Carbonate as an Alternative Filler in Layered Wood Composite Technology. Materials 2025, 18, 226. https://doi.org/10.3390/ma18020226

Dasiewicz J, Kowaluk G. Upcycling Calcium Carbonate as an Alternative Filler in Layered Wood Composite Technology. Materials. 2025; 18(2):226. https://doi.org/10.3390/ma18020226

Chicago/Turabian StyleDasiewicz, Julia, and Grzegorz Kowaluk. 2025. "Upcycling Calcium Carbonate as an Alternative Filler in Layered Wood Composite Technology" Materials 18, no. 2: 226. https://doi.org/10.3390/ma18020226

APA StyleDasiewicz, J., & Kowaluk, G. (2025). Upcycling Calcium Carbonate as an Alternative Filler in Layered Wood Composite Technology. Materials, 18(2), 226. https://doi.org/10.3390/ma18020226