Experimental Study on Deep-Drawing Dies Made of Pre-Stressed UHPC

Abstract

1. Introduction

2. Materials

2.1. UHPC Composition and Admixtures

2.2. PLA Molds

2.3. Specimen Preparation and Curing

2.4. Sheet Metal Material

3. Methods

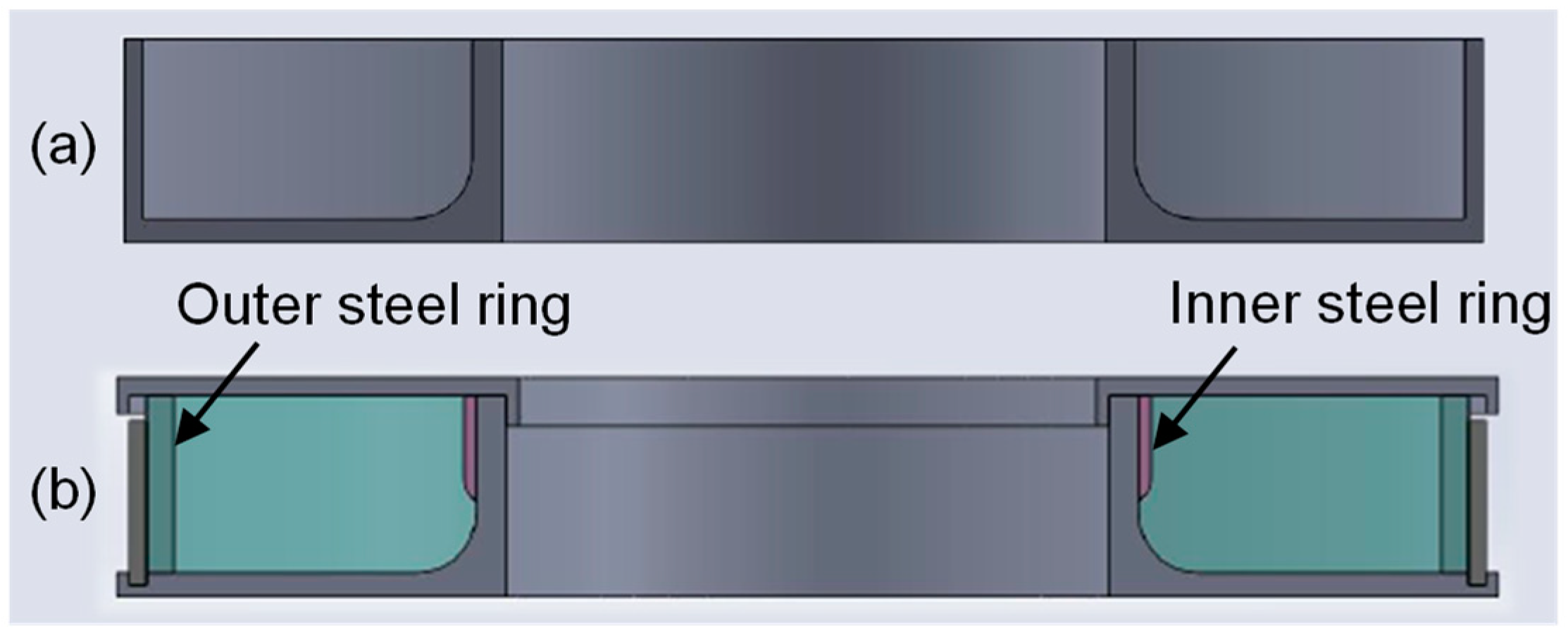

3.1. Test Setup of the Free Volume Increase Test

3.2. Test Setup of the Push-Out Test

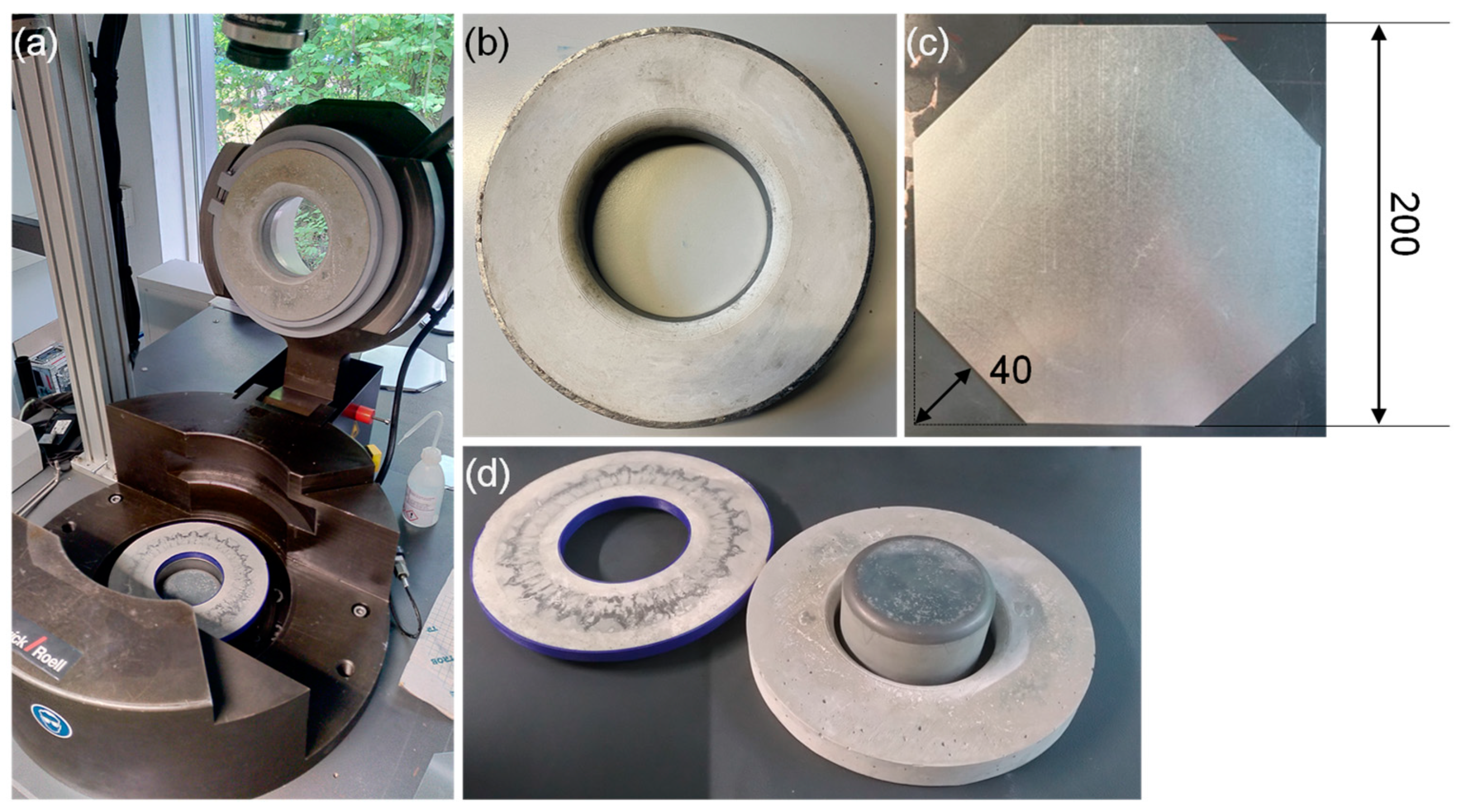

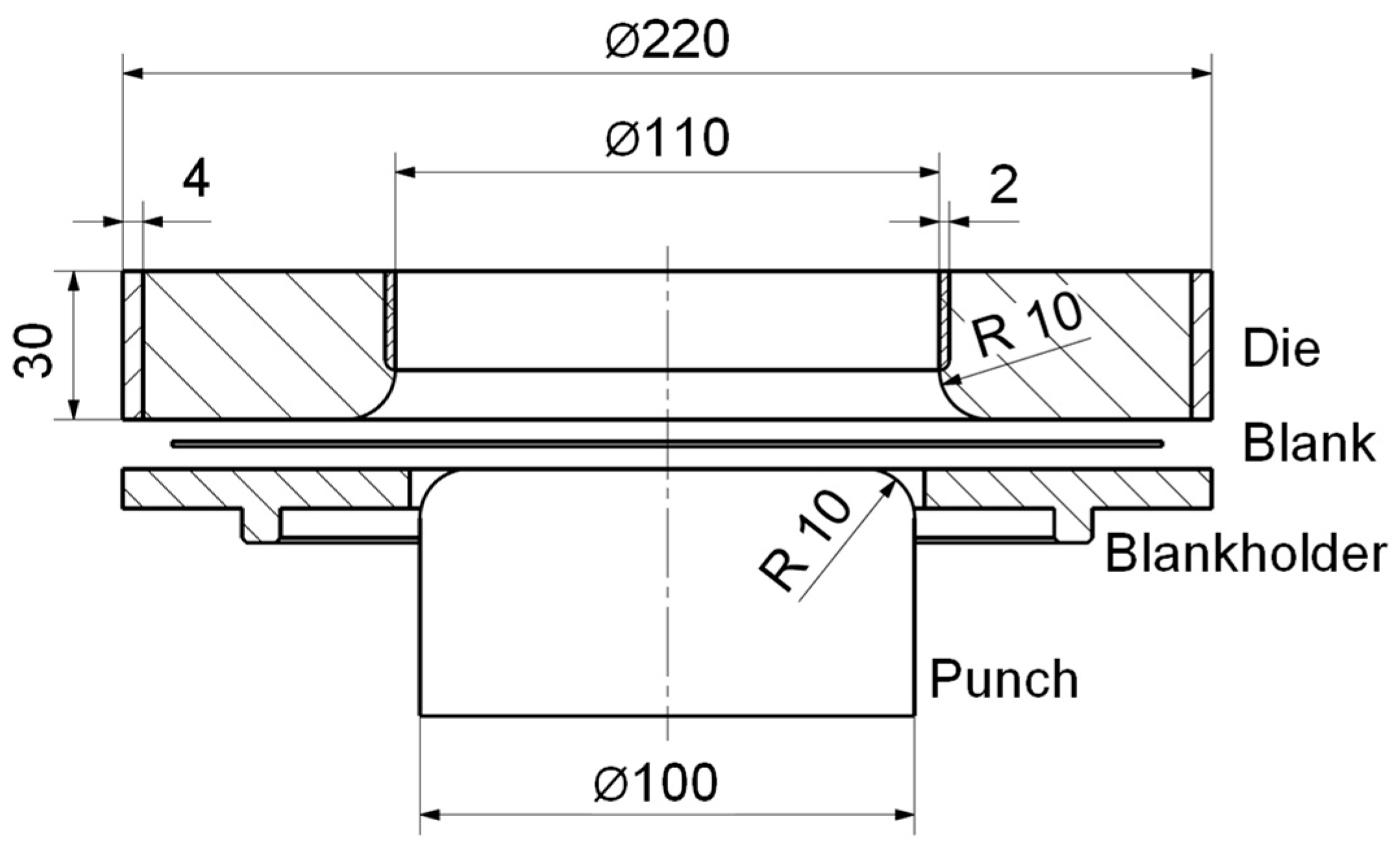

3.3. Test Setup of the Deep-Drawing Experiments

4. Results and Discussion

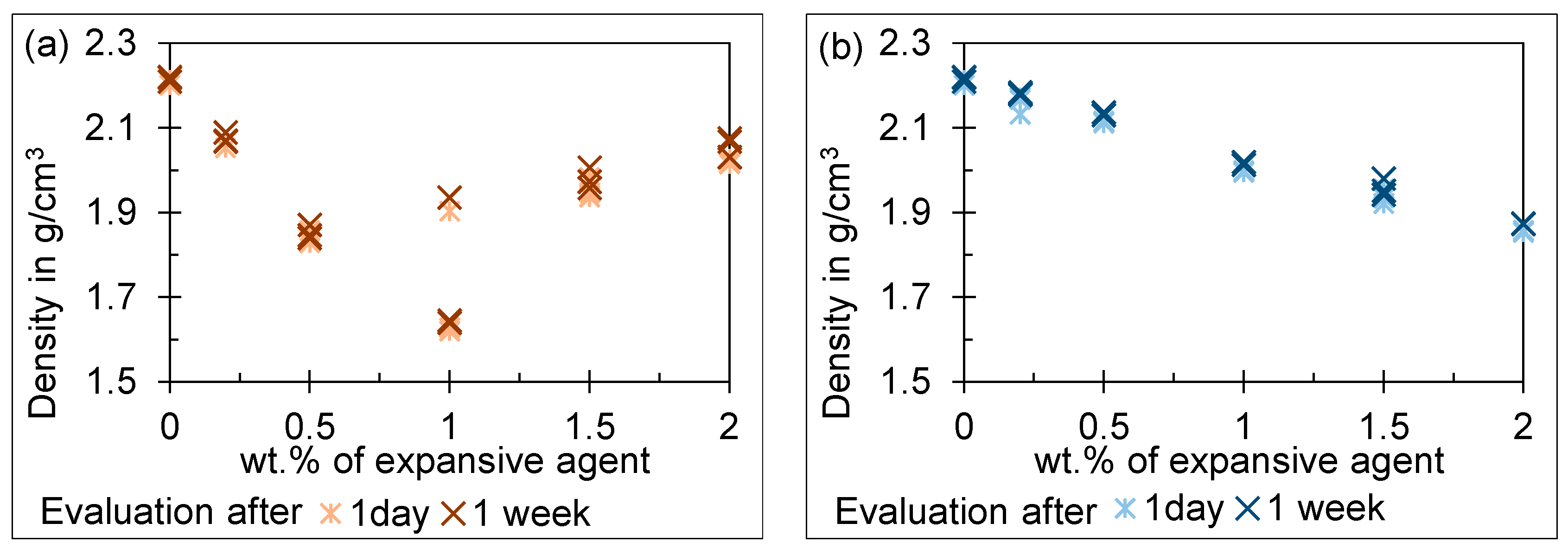

4.1. Results of the Free Volume Increase Test

4.2. Discussion of the Free Volume Increase Test

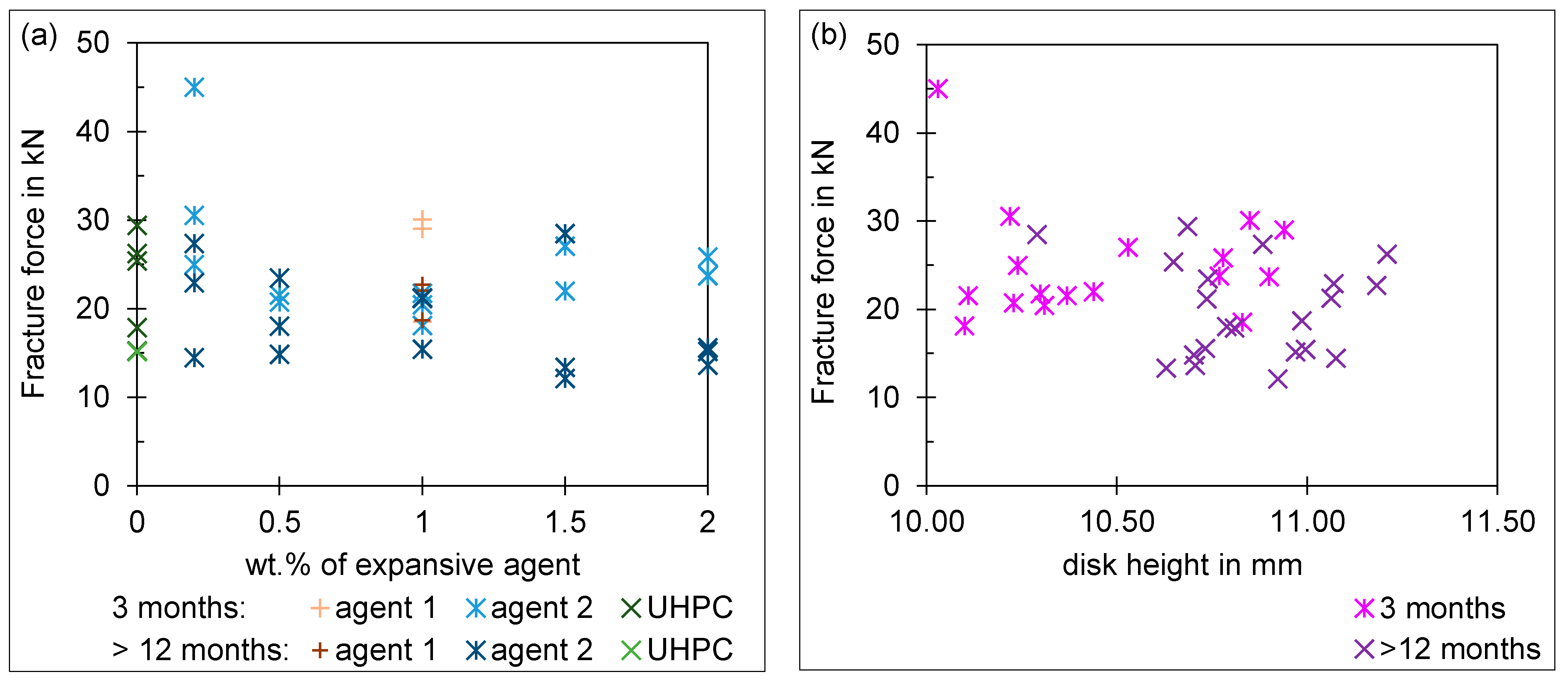

4.3. Results of the Push-Out Test

4.4. Discussion of the Push-Out Test

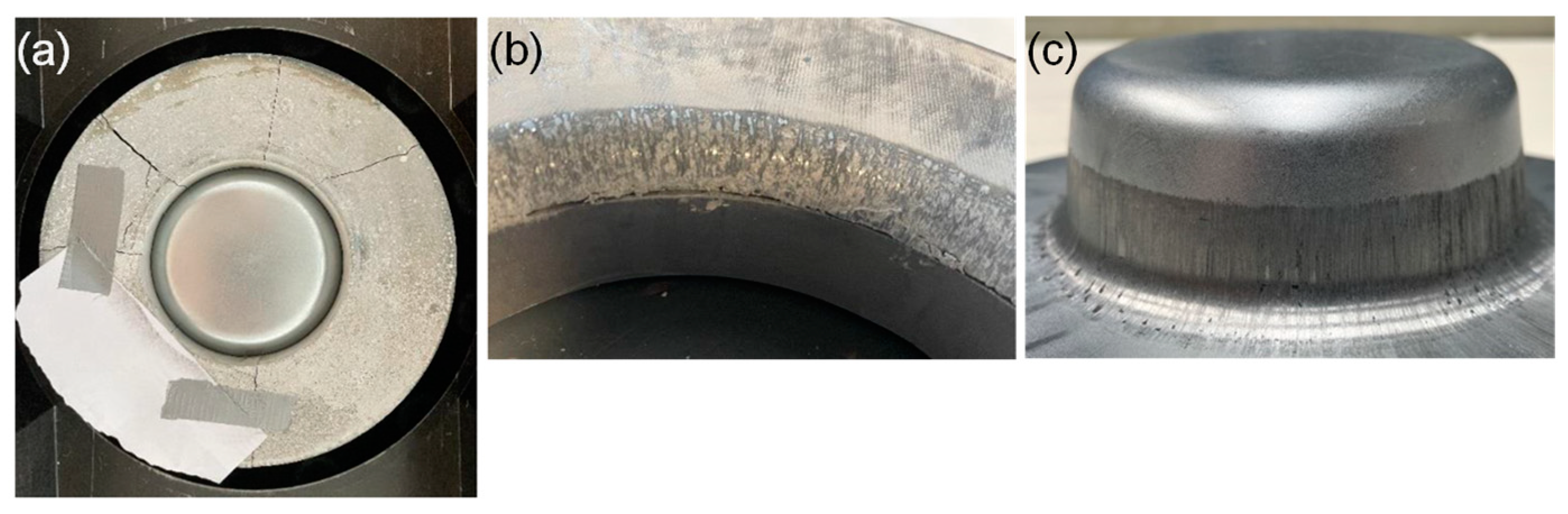

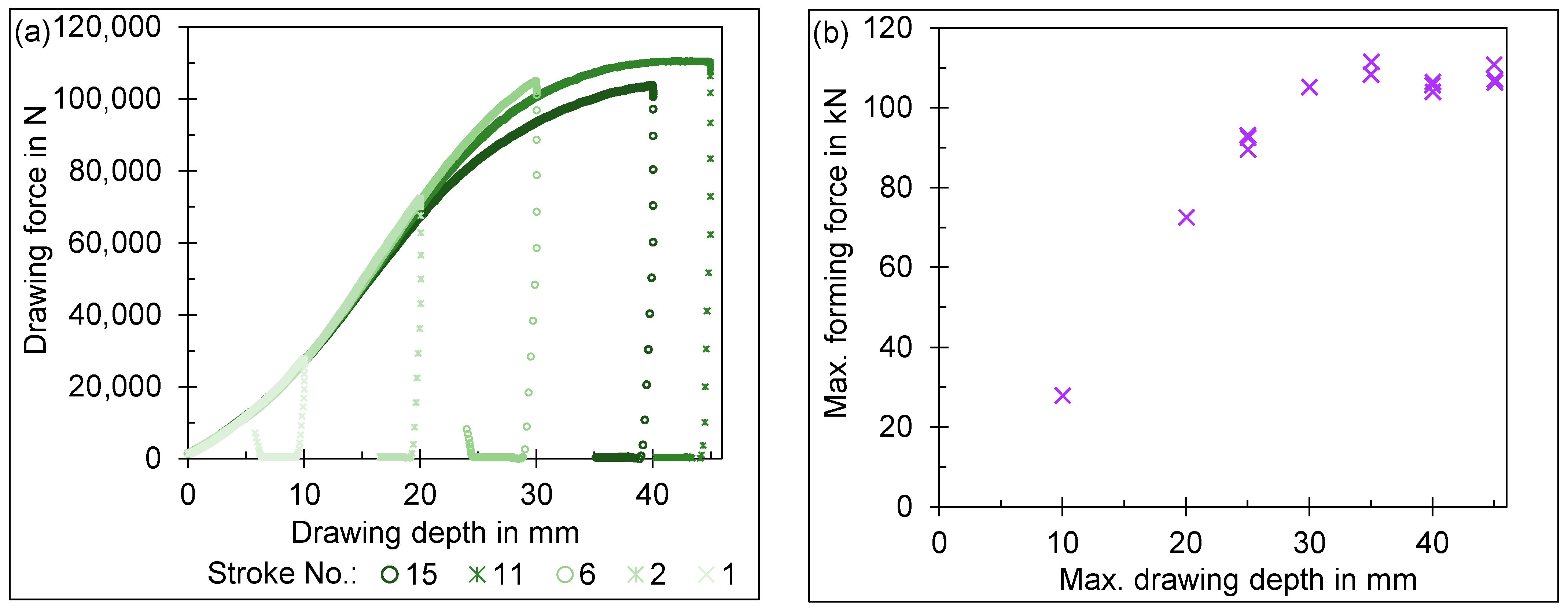

4.5. Results of the Deep-Drawing Experiments

4.6. Discussion of the Deep-Drawing Experiments

5. Conclusions

- (1)

- Aluminum powder-based expansive agents lead to an increase in volume (or decrease in density) of UHPC by increasing the gas content.

- (2)

- The expansive agents used did not induce the same expansive behavior in UHPC even though both are based on aluminum powder. The careful testing of commercial products is advised.

- (3)

- After 3 and 12 months, no notable pre-stressing with aluminum powder-based expansive agents can be achieved when restraining the expansion of the UHPC.

- (4)

- Reinforcing a deep-drawing die with an inner and outer steel ring improves performance compared to a UHPC die without reinforcement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Witulski, J.; Trompeter, M.; Tekkaya, A.E.; Kleiner, M. High wear resistant deep drawing tools made of coated polymers. CIRP Ann. 2011, 60, 311–314. [Google Scholar] [CrossRef]

- Mennecart, T.; Kolbe, J.; Kleiner, M. Hybrid Deep Drawing Tools for High Strength Steels. In 60 Excellent Inventions in Metal Forming; Tekkaya, A.E., Homberg, W., Brosius, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 83–88. ISBN 978-3-662-46311-6. [Google Scholar]

- Liewald, M.; de Souza, J.H.C. New developments on the use of polymeric materials in sheet metal forming. Prod. Eng. Res. Devel. 2008, 2, 63–72. [Google Scholar] [CrossRef]

- Schuh, G.; Bergweiler, G.; Bickendorf, P.; Fiedler, F.; Colag, C. Sheet Metal Forming Using Additively Manufactured Polymer Tools. Procedia CIRP 2020, 93, 20–25. [Google Scholar] [CrossRef]

- Nakagawa, T. Advances in prototype and low volume sheet forming and tooling. J. Mater. Process. Technol. 2000, 98, 244–250. [Google Scholar] [CrossRef]

- Frohn-Sörensen, P.; Geueke, M.; Engel, B.; Löffler, B.; Bickendorf, P.; Asimi, A.; Bergweiler, G.; Schuh, G. Design for 3D Printed Tools: Mechanical Material Properties for Direct Polymer Additive Tooling. Polymers 2022, 14, 1694. [Google Scholar] [CrossRef] [PubMed]

- Bergweiler, G.; Fiedler, F.; Shaukat, A.; Löffler, B. Experimental Investigation of Dimensional Precision of Deep Drawn Cups Using Direct Polymer Additive Tooling. JMMP 2021, 5, 3. [Google Scholar] [CrossRef]

- Durgun, I. Sheet metal forming using FDM rapid prototype tool. Rapid Prototyp. J. 2015, 21, 412–422. [Google Scholar] [CrossRef]

- Schuh, G.; Bergweiler, G.; Fiedler, F.; Bickendorf, P.; Schumacher, P. Small Series Production and Geometric Analysis of Sheet Metal Car Body Parts Using Forming Tools Made of Fused Filament Fabricated PLA. In Proceedings of the 2020 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 14–17 December 2020; IEEE: Piscataway, NJ, USA; pp. 156–160, 12142020. ISBN 978-1-5386-7220-4. [Google Scholar]

- Nakamura, N.; Mori, K.; Abe, Y. Applicability of plastic tools additively manufactured by fused deposition modelling for sheet metal forming. Int. J. Adv. Manuf. Technol. 2020, 108, 975–985. [Google Scholar] [CrossRef]

- Holzer, K.; Schaal-Mulacek, H.; Marker, E.; Volk, W. Kostenreduktion in der Prototypenfertigung. Z. Für Wirtsch. Fabr. 2023, 118, 511–515. [Google Scholar] [CrossRef]

- Fehling, E.; Schmidt, M.; Walraven, J.C.; Leutbecher, T.; Fröhlich, S. Ultra-High Performance Concrete UHPC: Fundamentals—Design—Examples; Ernst & Sohn: Berlin, Germany, 2014; ISBN 978-3-433-60406-9. [Google Scholar]

- Schwartzentruber, A.; Bournazel, J.-P.; Gacel, J.-N. Hydraulic concrete as a deep-drawing tool of sheet steel. Cem. Concr. Res. 1999, 29, 267–271. [Google Scholar] [CrossRef]

- Kleiner, M.; Curbach, M.; Tekkaya, A.E.; Ritter, R.; Speck, K.; Trompeter, M. Development of ultra high performance concrete dies for sheet metal hydroforming. Prod. Eng. Res. Devel. 2008, 2, 201–208. [Google Scholar] [CrossRef]

- Ritter, R.; Curbach, M.; Trompeter, M.; Tekkaya, A.E. Material Behavior of an Ultra-High-Performance Concrete Forming Die for Sheet Metal Hydroforming. ACI Mater. J. 2009, 106, 515–522. [Google Scholar]

- Ritter, R.; Curbach, M. Material Behavior of Ultra-High-Strength Concrete under Multiaxial Stress States. ACI Mater. J. 2015, 112, 641–651. [Google Scholar] [CrossRef]

- Billington, D.P. Historical perspective on prestressed concrete. PCI J. 1976, 21, 48–71. [Google Scholar] [CrossRef]

- Collepardi, M. A state-of-the-art review on delayed ettringite attack on concrete. Cem. Concr. Compos. 2003, 25, 401–407. [Google Scholar] [CrossRef]

- Dhahir, M.K.; Marx, S.; Zdanowicz, K. Chemical prestressing of concrete structures; state of the art review. Struct. Concr. 2024, 25, 1450–1464. [Google Scholar] [CrossRef]

- Kawakami, M.; Gamski, K.; Tokuda, H.; Kagaya, M. Chemical prestress and strengths of reinforced concrete pipes using expansive concrete. Mat. Constr. 1989, 22, 83–90. [Google Scholar] [CrossRef]

- Zdanowicz, K. Chemical Prestressing of Thin Concrete Elements with Carbon Textile Reinforcement. Ph.D. Thesis, Gottfried Wilhelm Leibniz Universität Hannover, Hannover, Germany, 2021. [Google Scholar]

- Wyrzykowski, M.; Terrasi, G.; Lura, P. Chemical prestressing of high-performance concrete reinforced with CFRP tendons. Compos. Struct. 2020, 239, 112031. [Google Scholar] [CrossRef]

- Wyrzykowski, M.; Terrasi, G.; Lura, P. Expansive high-performance concrete for chemical-prestress applications. Cem. Concr. Res. 2018, 107, 275–283. [Google Scholar] [CrossRef]

- Nagataki, S.; Gomi, H. Expansive admixtures (mainly ettringite). Cem. Concr. Compos. 1998, 20, 163–170. [Google Scholar] [CrossRef]

- Hay, R.; Ostertag, C.P. On utilization and mechanisms of waste aluminium in mitigating alkali-silica reaction (ASR) in concrete. J. Clean. Prod. 2019, 212, 864–879. [Google Scholar] [CrossRef]

- Linger, D.A. Chemical Expansion of Fresh Concrete By Use of Aluminium Powder and Its Effect on Strength. In Highway Research Record; Highway Research Board: Washington, DC, USA, 1968; pp. 34–39. [Google Scholar]

- Özkılıç, Y.O.; Karalar, M.; Aksoylu, C.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban, E.M.; Qaidi, S.; Da Pereira, I.S.; Monteiro, S.N.; Azevedo, A.R. Shear performance of reinforced expansive concrete beams utilizing aluminium waste. J. Mater. Res. Technol. 2023, 24, 5433–5448. [Google Scholar] [CrossRef]

- Liu, Y.; Leong, B.S.; Hu, Z.-T.; Yang, E.-H. Autoclaved aerated concrete incorporating waste aluminum dust as foaming agent. Constr. Build. Mater. 2017, 148, 140–147. [Google Scholar] [CrossRef]

- Serelis, E.; Vaitkevicius, V.; Salehi, S.; Sinka, M.; Sapata, A. Synergistic Effects of Waste Glass Powder, High-Frequency Ultrasonic Dispersion, and Liquid Glass Treatment on the Properties of Aluminum-Based Ultra-Lightweight Concrete. Materials 2024, 17, 5430. [Google Scholar] [CrossRef]

- Carballosa, P.; Calvo, J.; Revuelta, D. Influence of expansive calcium sulfoaluminate agent dosage on properties and microstructure of expansive self-compacting concretes. Cem. Concr. Compos. 2020, 107, 103464. [Google Scholar] [CrossRef]

- DIN EN 934-4:2009-09; Admixtures for Concrete, Mortar and Grout—Part 4: Admixtures for Grout for Prestressing Tendons—Definitions, Requirements, Conformity, Marking and Labelling. DIN: Berlin, Germany, 2009.

- Gcp Applied Technologies. Datasheet DARAGROUT Expand (ST). 2022. Available online: https://gcpat.de/solutions/products/betec-grouts-and-cementitious-mortars/daragrout-expand-st (accessed on 20 December 2024).

- BT3 Betontechnik GmbH. Datasheet Premadd Stabilisator QM 25; BT3 Betontechnik GmbH: Theresienfeld, Austria, 2024; Available online: https://bt3.at/shop/deutschland/weitere-betonzusatzmittel-deutschland/stabilisator-weitere-betonzusatzmittel-deutschland/premadd-stabilisator-qm-25/ (accessed on 20 December 2024).

- DYCKERHOFF GMBH. Dyckerhoff NANODUR® Compound 5941: …Zur Einfachen Herstellung Von UHPC. 2017. Available online: https://www.dyckerhoff.com/nanodur (accessed on 20 December 2024).

- Gcp Applied Technologies. ADVA Flow 375 (BV/FM). 2022. Available online: https://gcpat.de/solutions/products/adva-high-range-water-reducers/adva-flow-375-bvfm (accessed on 20 December 2024).

- Kashani, A.; Provis, J.L.; Xu, J.; Kilcullen, A.R.; Qiao, G.G.; van Deventer, J.S.J. Effect of molecular architecture of polycarboxylate ethers on plasticizing performance in alkali-activated slag paste. J. Mater. Sci. 2014, 49, 2761–2772. [Google Scholar] [CrossRef]

- DIN EN 10346:2015-10; Continuously Hot-Dip Coated Steel Flat Products for Cold Forming—Technical Delivery Conditions. German version EN 10346:2015. ICS 77.140.50. DIN: Berlin, Germany, 2015.

- DIN EN ISO 10123:2019-10; Adhesives—Determination of Shear Strength of Anaerobic Adhesives Using Pin-and-Collar Specimens. ICS 83.180. DIN: Berlin, Germany, 2019.

- Zhao, Y.-C.; Lei, H.-G.; Guo, L.-K.; Lu, G.-Y. Experimental Investigation on Interface Performance of UHPC-Strengthened NC Structure through Push-Out Tests. Materials 2023, 16, 1766. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Xu, X. Static and Fatigue Behavior of Rubber-Sleeved Stud Shear Connectors as Part of Field-Cast Ultra-High Performance Concrete Connections. Materials 2020, 13, 2269. [Google Scholar] [CrossRef]

- Azarhomayun, F.; Haji, M.; Kioumarsi, M.; Shekarchi, M. Effect of calcium stearate and aluminum powder on free and restrained drying shrinkage, crack characteristic and mechanical properties of concrete. Cem. Concr. Compos. 2022, 125, 104276. [Google Scholar] [CrossRef]

- Zein, H.; Irfan, O.M. Optimization and Mapping of the Deep Drawing Force Considering Friction Combination. Appl. Sci. 2021, 11, 9235. [Google Scholar] [CrossRef]

- Dilmec, M.; Arap, M. Effect of geometrical and process parameters on coefficient of friction in deep drawing process at the flange and the radius regions. Int. J. Adv. Manuf. Technol. 2016, 86, 747–759. [Google Scholar] [CrossRef]

- Fereshteh-Saniee, F.; Montazeran, M.H. A comparative estimation of the forming load in the deep drawing process. J. Mater. Process. Technol. 2003, 140, 555–561. [Google Scholar] [CrossRef]

- Müller, M.; Weiser, I.F.; Herrig, T.; Bergs, T. Numerical Prediction of the Influence of Process Parameters and Process Set-Up on Damage Evolution during Deep Drawing of Rectangular Cups. In Proceedings of the 28th Saxon Conference on Forming Technology SFU and the 7th International Conference on Accuracy in Forming Technology ICAFT, SFU/ICAFT Conference, Chemnitz, Germany, 2–3 November 2022; MDPI: Basel, Switzerland; p. 6. [Google Scholar]

- Sezek, S.; Savas, V.; Aksakal, B. Effect of Die Radius on Blank Holder Force and Drawing Ratio: A Model and Experimental Investigation. Mater. Manuf. Process. 2010, 25, 557–564. [Google Scholar] [CrossRef]

- Padmanabhan, R.; Oliveira, M.C.; Alves, J.L.; Menezes, L.F. Influence of process parameters on the deep drawing of stainless steel. Finite Elem. Anal. Des. 2007, 43, 1062–1067. [Google Scholar] [CrossRef]

- Holzer, K.; Maier, L.; Böhm, V.; Volk, W. Dimensional precision and wear of a new approach for prototype tooling in deep drawing. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1284, 12078. [Google Scholar] [CrossRef]

| Binder Nanodur Compound 5941 | Water | Superplasticizer ADVA Flow375 (BV/FM) |

|---|---|---|

| kg/m3 | kg/m3 | kg/m3 |

| 2100.00 | 316.00 | 30.00 |

| wt.% of Expansive Agent | 0.2 | 0.5 | 1 | 1.5 | 2 |

| w/b | 0.1647 | 0.1644 | 0.1631 | 0.1623 | 0.1615 |

| Total Volume | Binder | Water | Super- Plasticizer | Expansive Agent 2 | |

|---|---|---|---|---|---|

| cm3 | g | g | g | g | |

| Restrained expansive UHPC | 850 | 1785.00 | 268.60 | 25.50 | 35.70 |

| UHPC | 850 | 1785.00 | 268.60 | 25.50 | 0.00 |

| No. | Clamping Force FC | Set Drawing Depth | Max. Forming Force FF | Drawing Depth at Max. ff | Measured Drawing Depth |

|---|---|---|---|---|---|

| kN | mm | kN | mm | mm | |

| 1 | 10 | 10 | 25.30 | 10.01 | 10.06 |

| 2 | 10 | 10 | 25.25 | 9.97 | 10.01 |

| 3 | 10 | 10 | 25.42 | 9.94 | 9.98 |

| 4 | 10 | 20 | 68.26 | 19.94 | 19.99 |

| 5 | 10 | 20 | 65.78 | 19.94 | 20.00 |

| 6 | 10 | 20 | 64.58 | 19.94 | 20.00 |

| 7 | 10 | 25 | 83.62 | 24.99 | 25.06 |

| No. | Clamping Force FC | SET Drawing Depth | Max. Forming Force FF | Drawing Depth at Max. FF | Measured Drawing Depth |

|---|---|---|---|---|---|

| kN | mm | kN | mm | mm | |

| 1 | 10 | 10 | 27.87 | 9.98 | 10.03 |

| 2 | 10 | 20 | 72.49 | 19.99 | 20.04 |

| 3 | 10 | 25 | 89.43 | 25.01 | 25.06 |

| 4 | 16 | 25 | 92.42 | 24.98 | 25.04 |

| 5 | 20 | 25 | 93.09 | 21.34 | 25.03 |

| 6 | 20 | 30 | 105.08 | 29.95 | 30.01 |

| 7 | 20 | 35 | 111.46 | 34.96 | 35.03 |

| 8 | 20 | 40 | 106.43 | 39.96 | 40.02 |

| 9 | 20 | 45 | 106.26 | 42.15 | 45.04 |

| 10 | 20 | 45 | 107.04 | 43.26 | 45.04 |

| 11 | 20 | 45 | 110.70 | 42.15 | 45.00 |

| 12 | 20 | 35 | 111.46 | 34.96 | 35.03 |

| 13 | 20 | 35 | 108.24 | 34.94 | 35.00 |

| 14 | 20 | 40 | 105.56 | 39.89 | 40.00 |

| 15 | 20 | 40 | 103.92 | 39.97 | 40.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Holzer, K.; Zhang, Y.; Martinitz, L.; Hoyer, J.; Volk, W. Experimental Study on Deep-Drawing Dies Made of Pre-Stressed UHPC. Materials 2025, 18, 277. https://doi.org/10.3390/ma18020277

Holzer K, Zhang Y, Martinitz L, Hoyer J, Volk W. Experimental Study on Deep-Drawing Dies Made of Pre-Stressed UHPC. Materials. 2025; 18(2):277. https://doi.org/10.3390/ma18020277

Chicago/Turabian StyleHolzer, Katja, Yuqi Zhang, Lukas Martinitz, Julika Hoyer, and Wolfram Volk. 2025. "Experimental Study on Deep-Drawing Dies Made of Pre-Stressed UHPC" Materials 18, no. 2: 277. https://doi.org/10.3390/ma18020277

APA StyleHolzer, K., Zhang, Y., Martinitz, L., Hoyer, J., & Volk, W. (2025). Experimental Study on Deep-Drawing Dies Made of Pre-Stressed UHPC. Materials, 18(2), 277. https://doi.org/10.3390/ma18020277