A Critical Review of the Decarbonisation Potential in the U.K. Cement Industry

Highlights

- Decarbonizing the UK cement industry is essential to meet 2050 net-zero goals, with key pathways including carbon capture, alternative fuels and clinker substitution.

- Reducing clinker content offers a practical approach to lower CO₂ emissions, while carbon capture holds promise for significant large-scale reductions.

- Biomass and hydrogen fuels show potential as alternatives but are limited by resource availability and infrastructure limitations.

- Low-cost, high-impact solutions remain scarce, challenging further decarbonization as progress plateaus.

- Policy incentives and innovation support are crucial to advance sustainable practices in cement production.

Abstract

1. Introduction

2. Methodology

2.1. Data Sources and Selection Process

2.2. Inclusion Criteria

2.3. Review and Analysis Process

2.3.1. Thematic Progression

2.3.2. Quantitative and Qualitative Data Synthesis

2.4. Limitations

- Limited availability of peer-reviewed studies focused exclusively on the U.K. cement industry;

- Variability in the accuracy of industrial and market reports;

- Challenges in applying global insights to the specific U.K. context.

3. Cement Overview

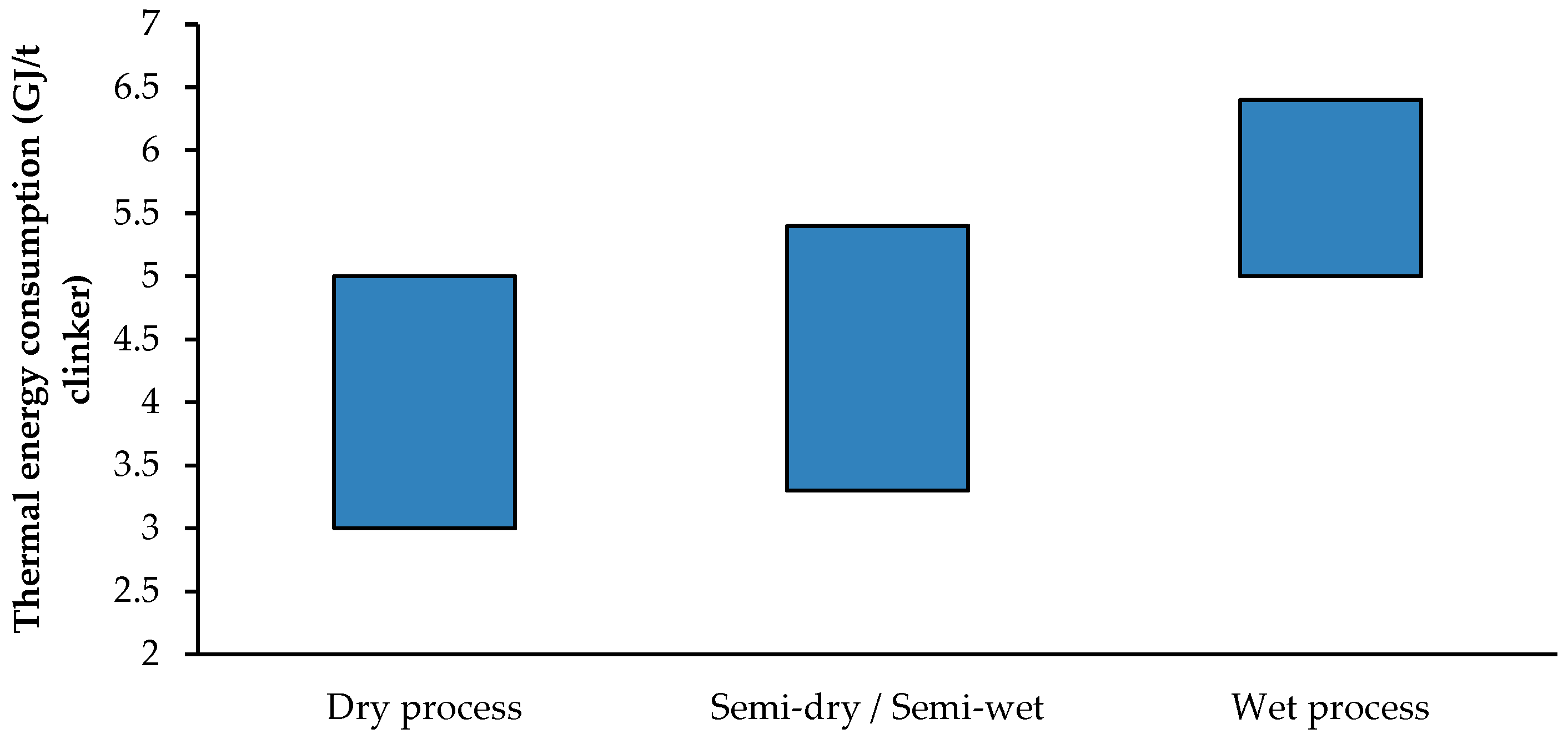

3.1. Cement Production Methods

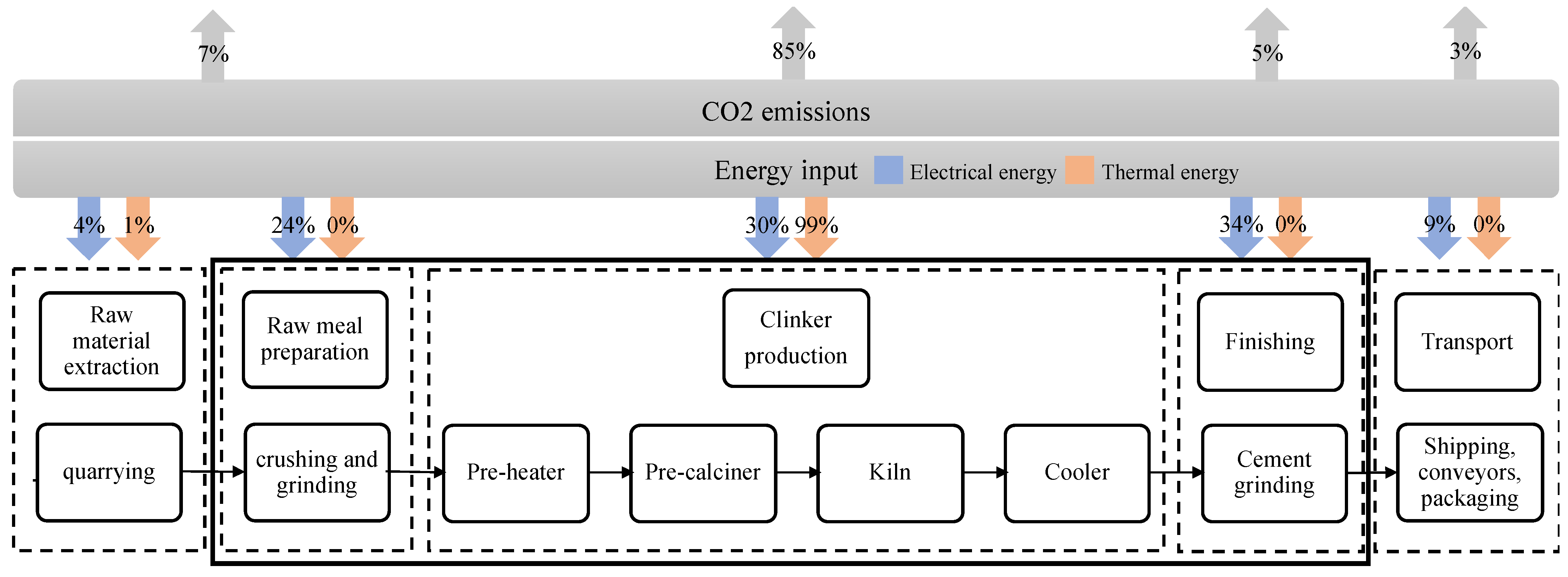

3.2. Cement Production Process

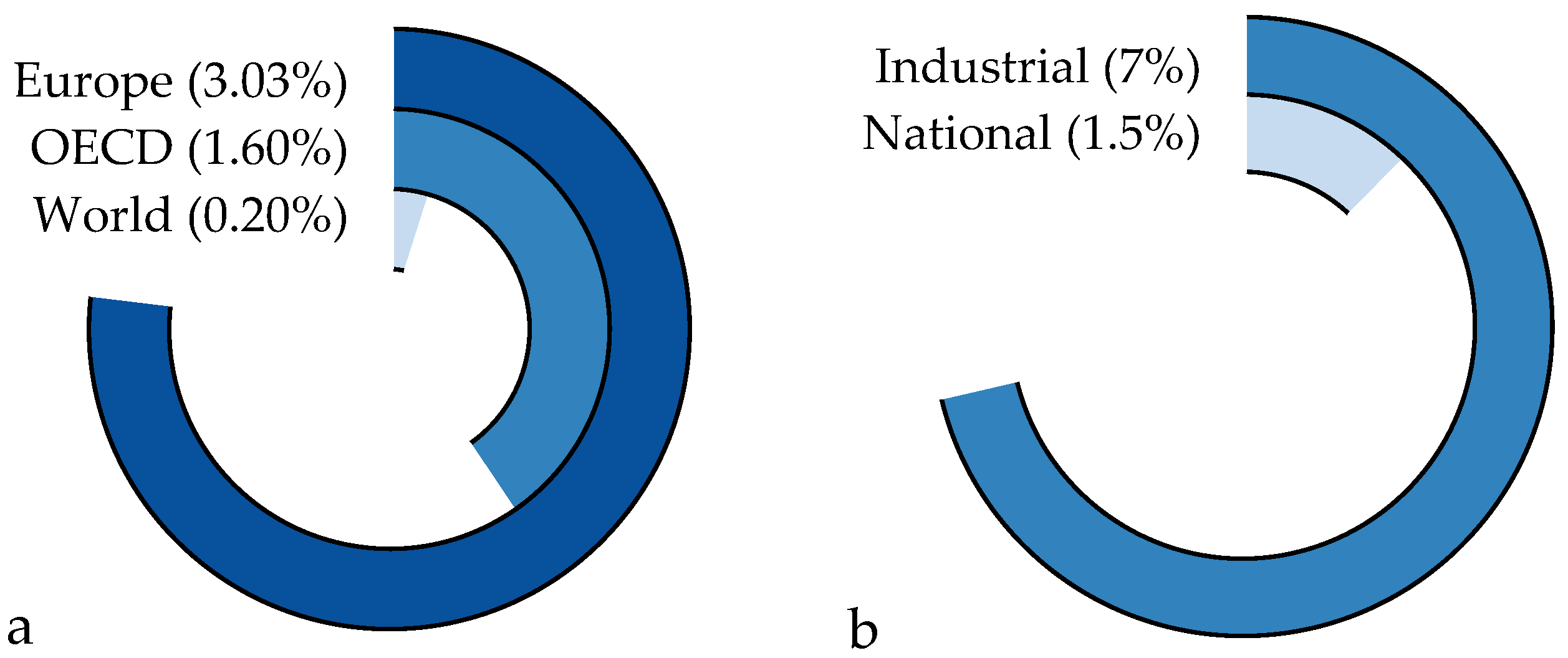

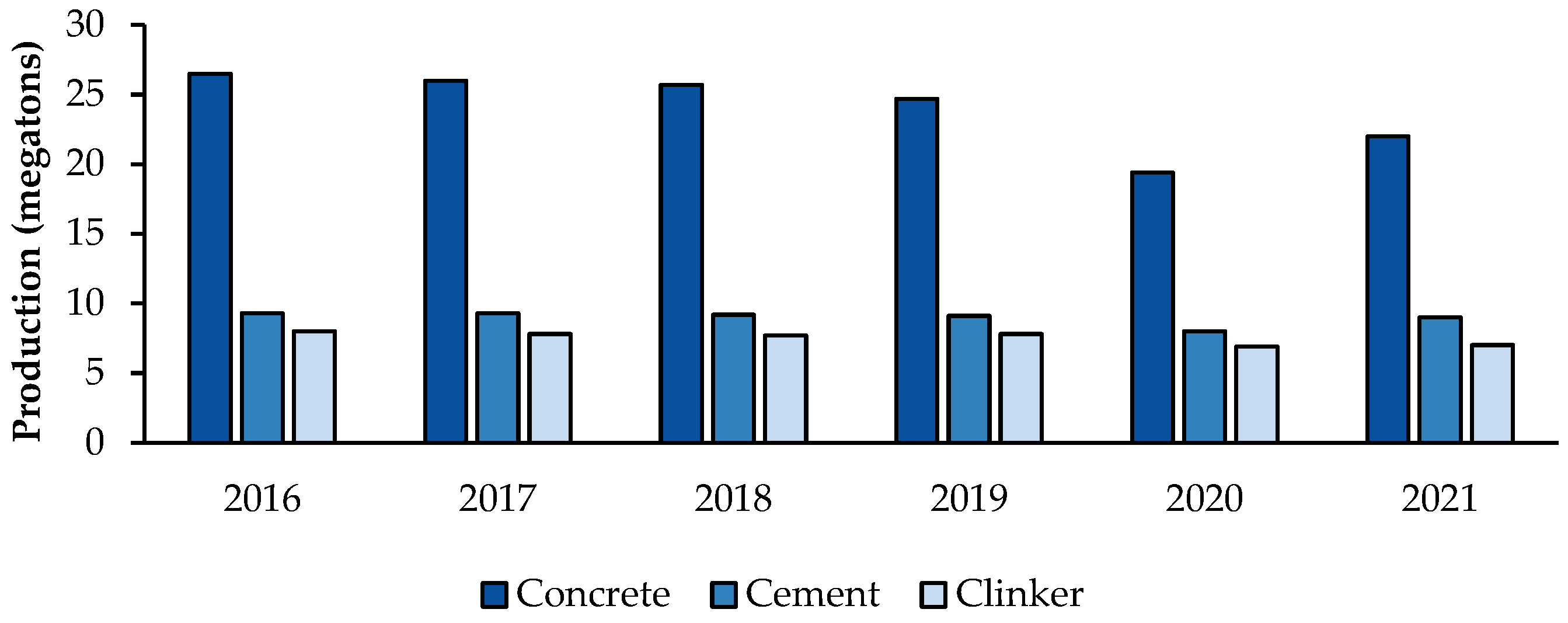

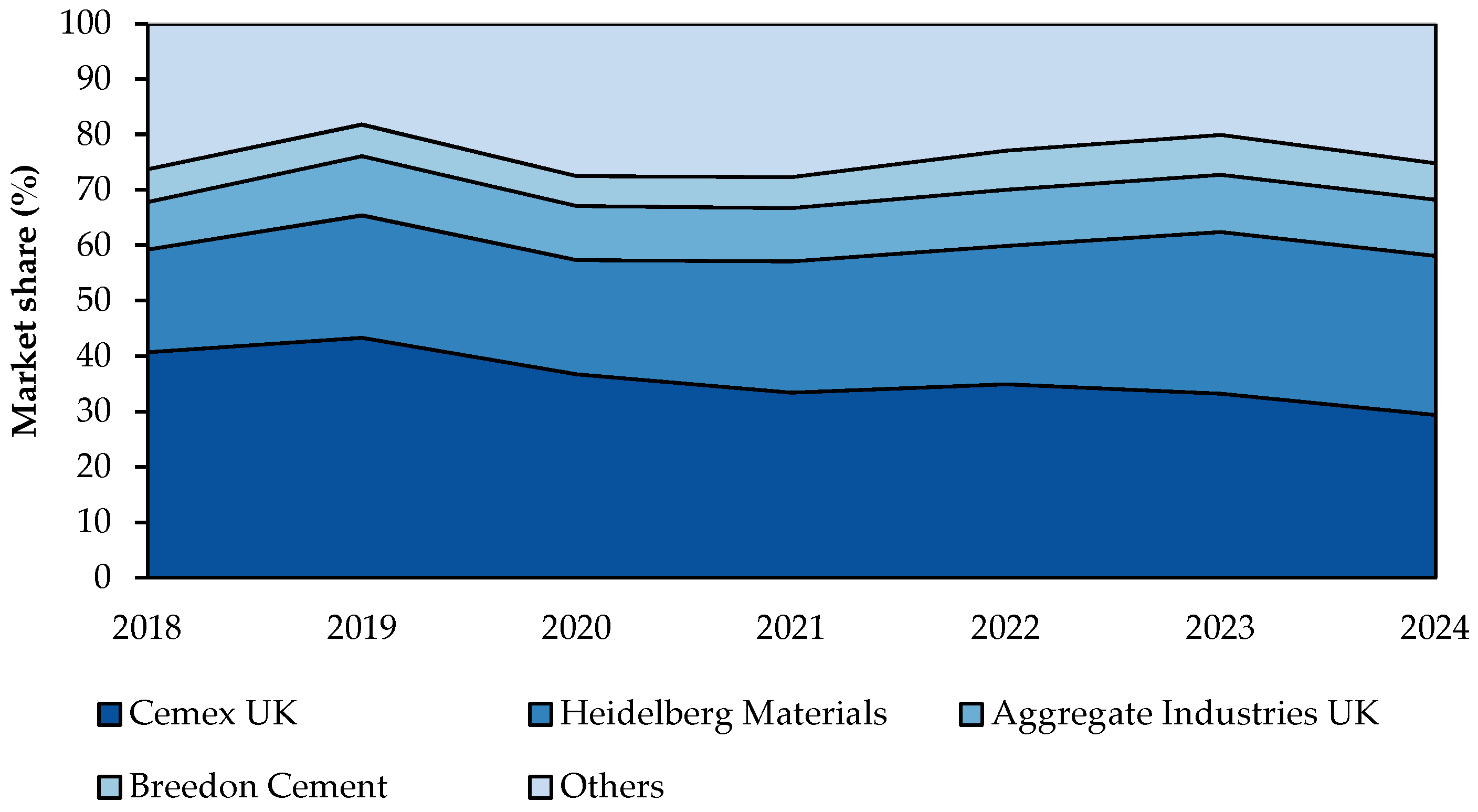

3.3. U.K. Cement Sector

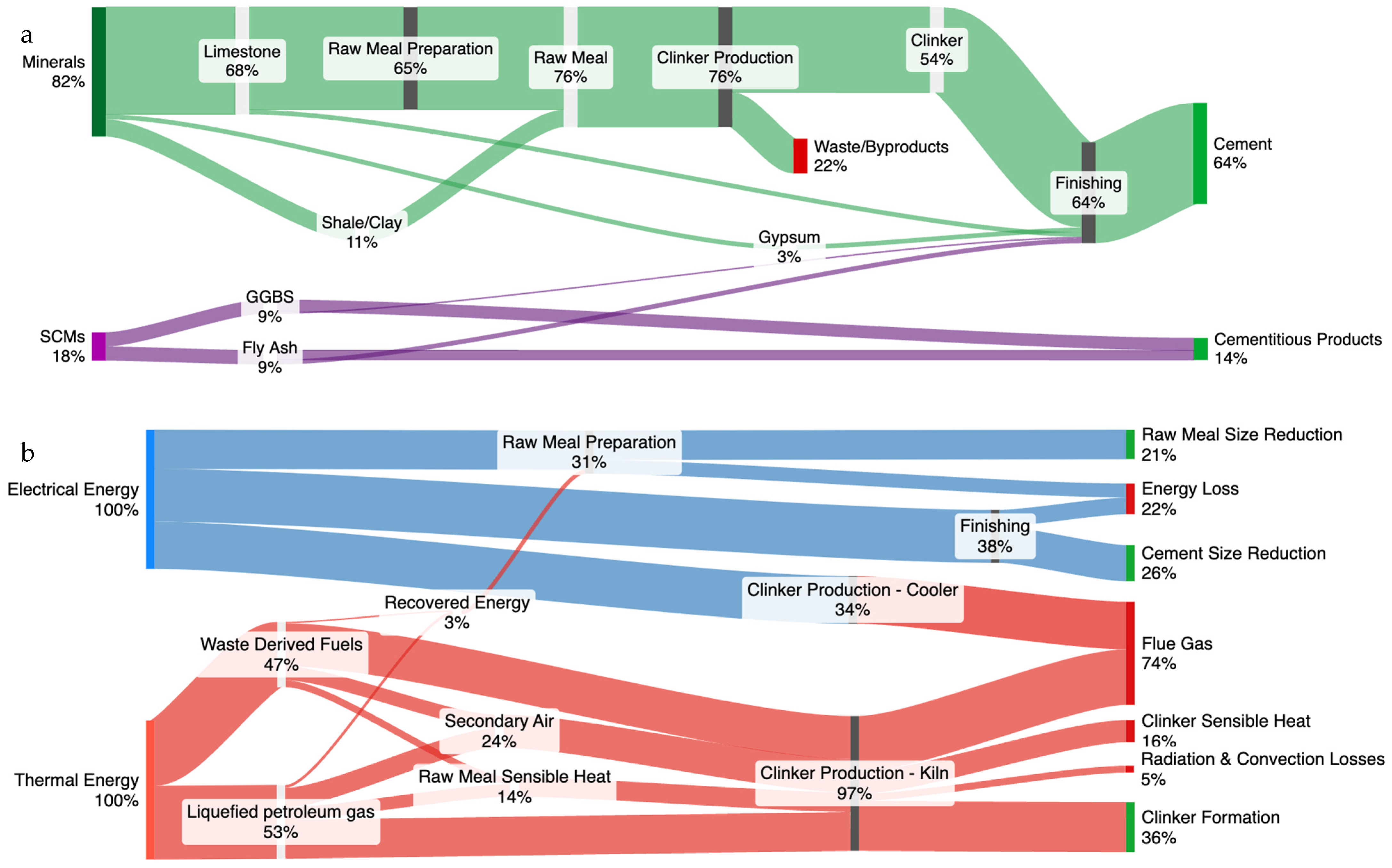

3.3.1. U.K. Cement Energy and Material Flow Analysis

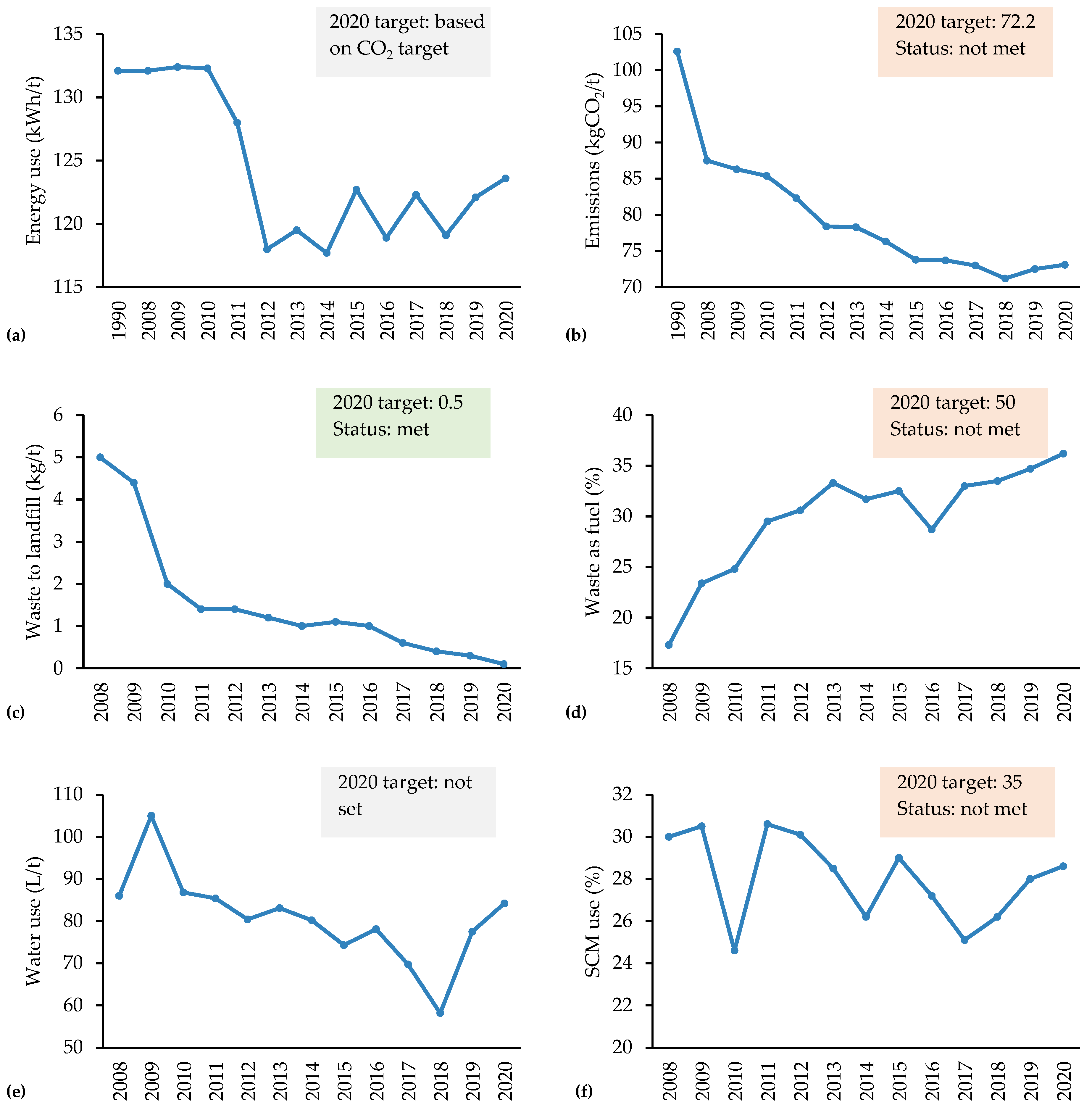

3.3.2. U.K. Concrete Sector Performance

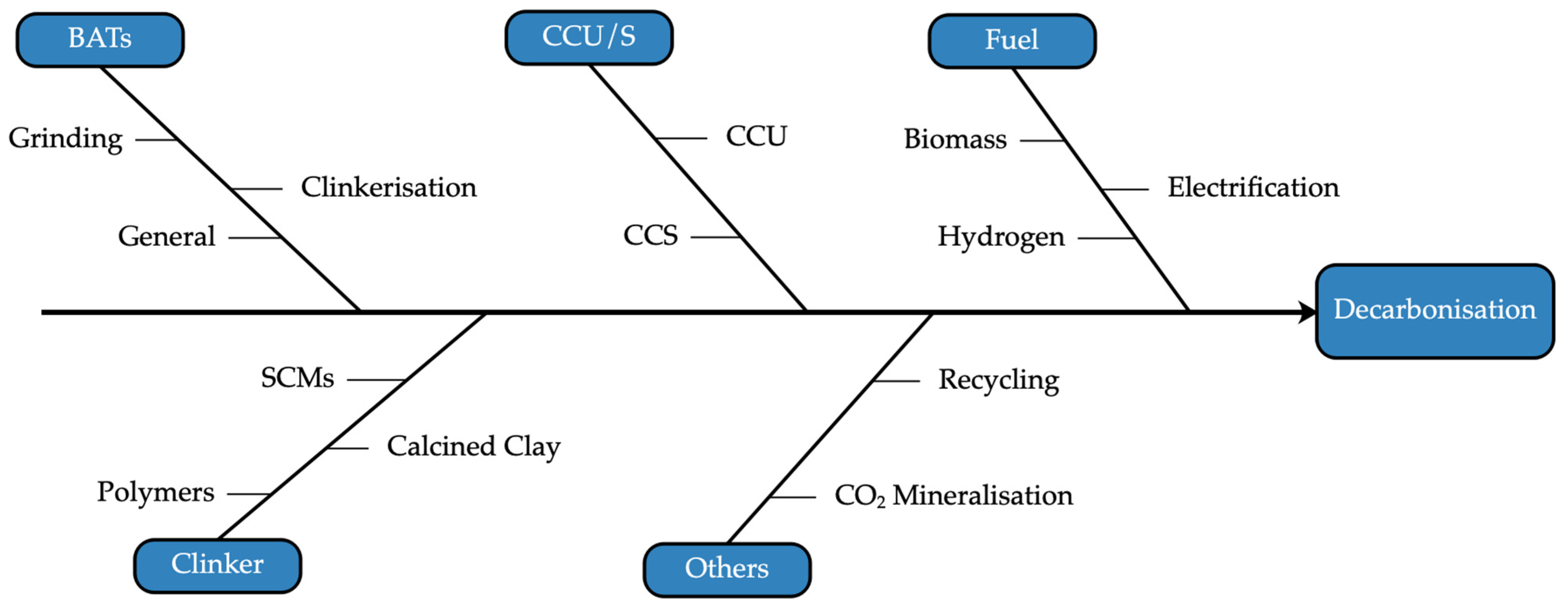

4. Decarbonisation Technologies and Their Progress

4.1. Best Available Technologies

4.2. Fuel Switching (Biomass, Hydrogen, Electrification)

4.3. Carbon Capture and Storage/Utilisation

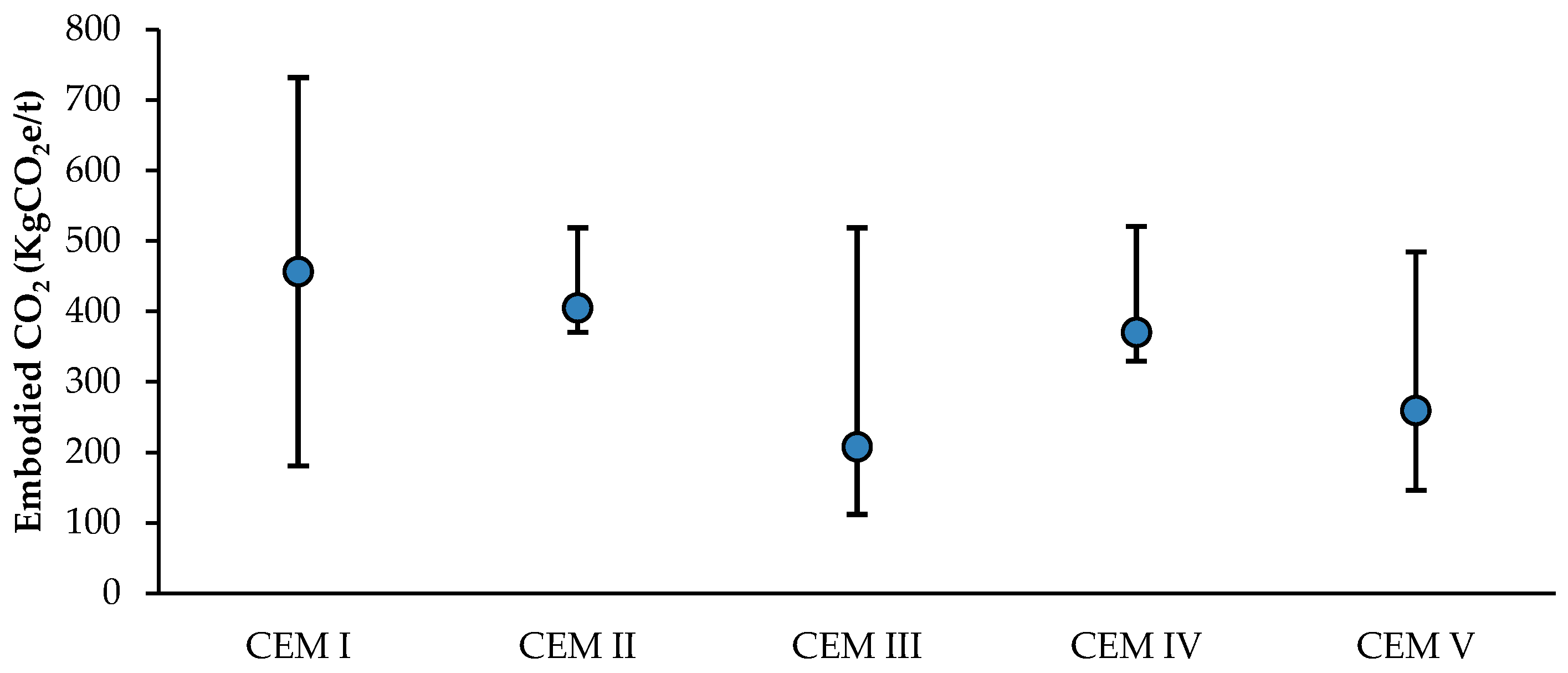

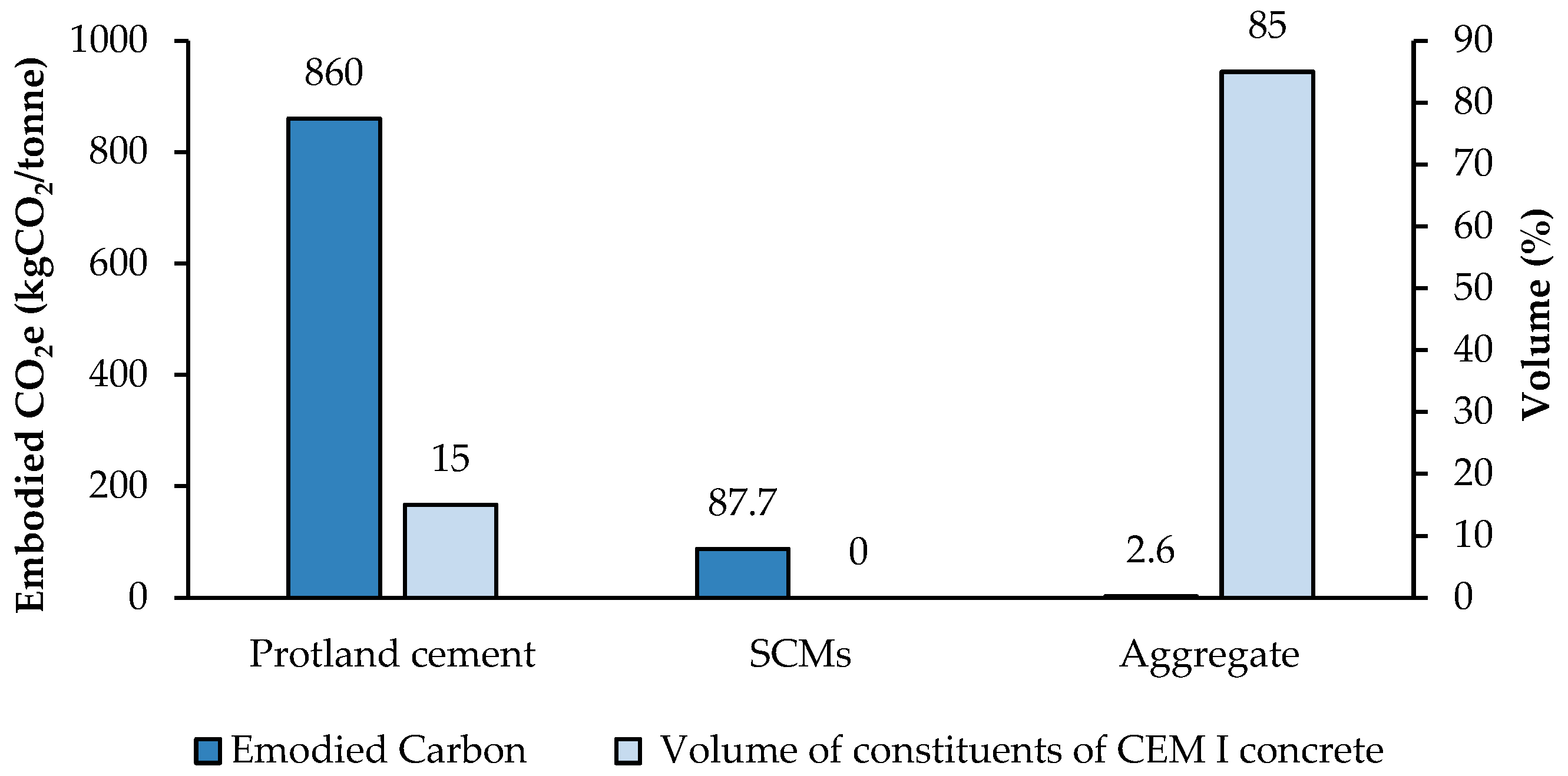

4.4. Clinker Substitution

| Company | Product | Type | Impact Claim (vs. CEM I Concrete) |

|---|---|---|---|

| Aggregate Industries | ECOPlanet | CEM III * | 30% less CO2 |

| Breedon Cement | BREEDON Eco | CEM III | Lowers embodied CO2, no value |

| Cemex U.K. | Vertua | CEM III and geopolymer ** | 30% to 70% less embodied CO2 |

| Heidelberg Materials | EcoCrete | CEM III and geopolymer | 30% to 85% less emissions |

| Tarmac | CEVO | CEM II *** and geopolymer | Reduce emissions by up to 70% |

4.5. Other Innovations in Sustainable Cement Production

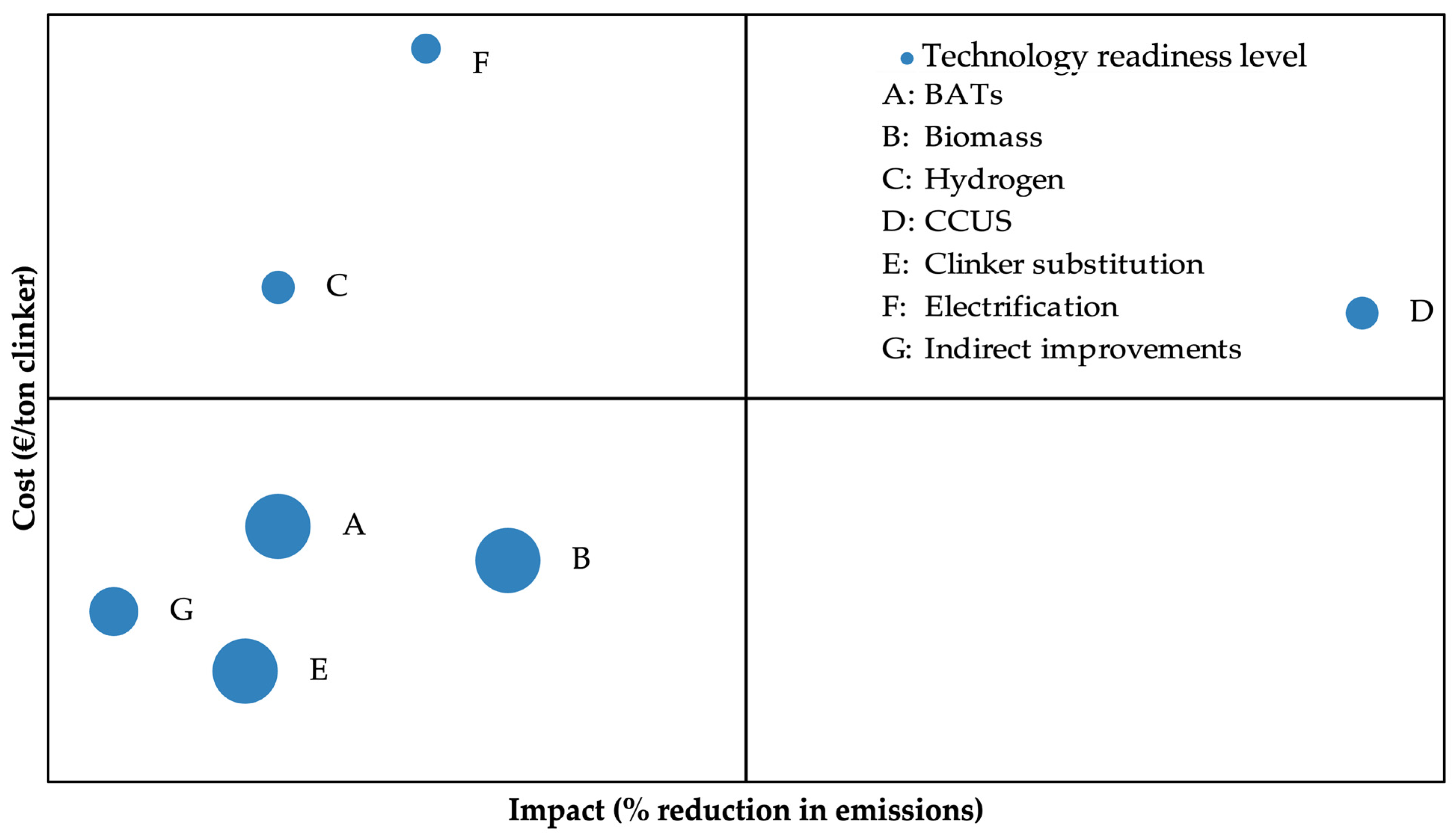

4.6. An Overview of the Cost vs. Impact of Cement Decarbonisation Options and Summary

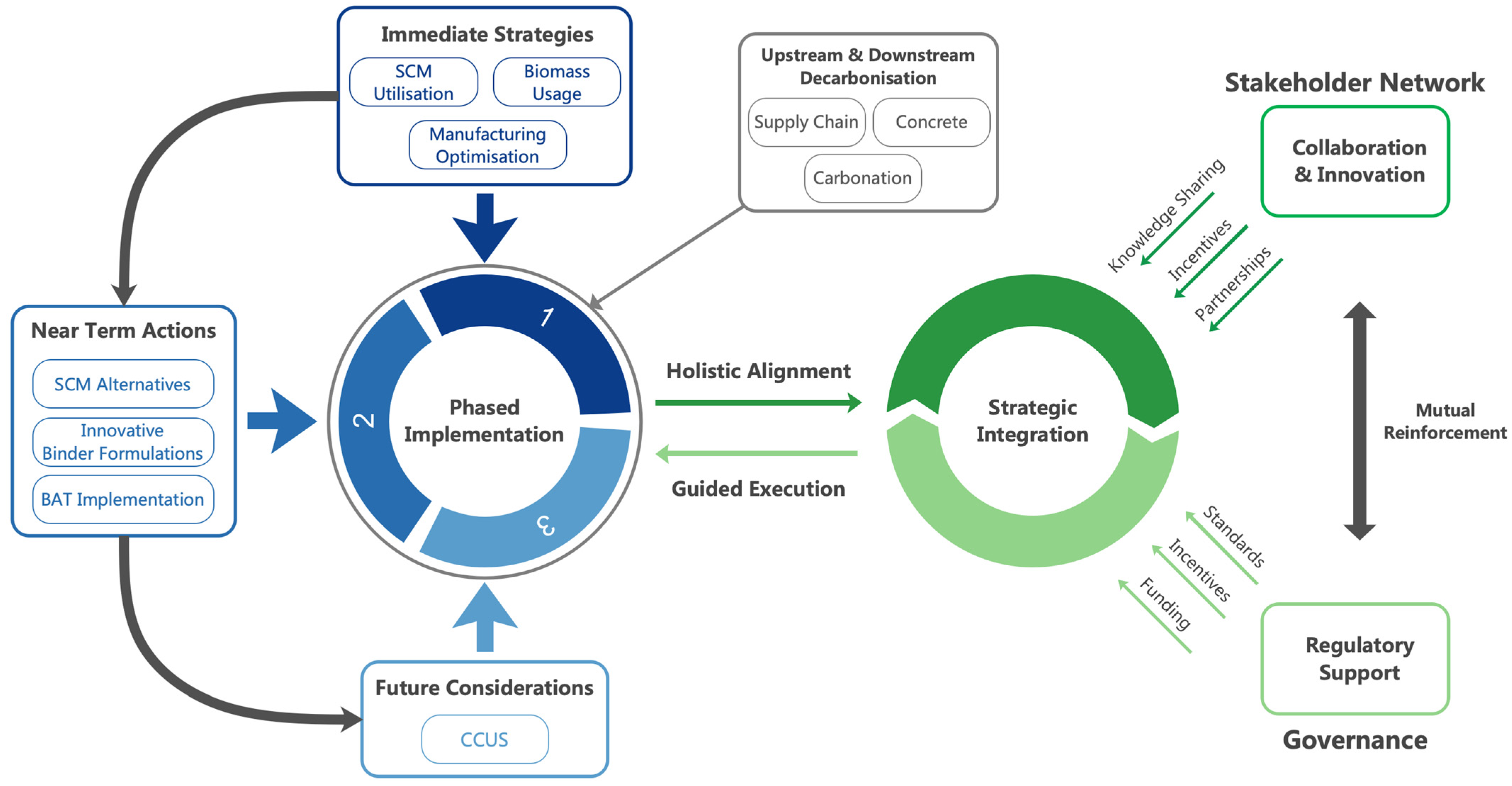

5. Viable Strategies and Recommendations for Reduction of Cement Sector Emissions

5.1. Immediate Strategies

5.1.1. Increased Utilisation of Cementitious Materials

5.1.2. Optimisation of Clinker Manufacturing and Use in Concrete Production

5.1.3. Biomass as Fuel

5.2. Near-Term Considerations and Future Recommendations

5.2.1. Exploration of Alternative SCM Sources

- Recovery and processing of stockpiled fly ash from legacy coal combustion activities;

- Utilisation of calcined clays and other natural pozzolanic materials abundant in the U.K.;

- Collaboration with other industries to identify and valorise suitable by-product streams.

5.2.2. Adoption of Innovative Cement Formulations

5.2.3. BATs Implementation

5.2.4. Development of CCUS Infrastructure

- Establishing pipelines and identifying suitable geological storage sites or utilisation pathways for CO2 transportation and storage infrastructure;

- Continue research and development efforts to drive down the capital and operational costs associated with CCUS implementation with a focus on calcium looping technology;

- Implementing supportive policies, such as carbon pricing mechanisms and incentives, to enhance the economic viability of CCUS projects.

5.3. Demand-Driven Innovations and Policy Solutions

5.3.1. Fostering Collaboration and Innovation

- Public–private partnerships: Facilitating collaboration between industry, academia and government agencies can accelerate research, development and knowledge transfer at a large scale;

- Innovation incentives: Providing financial incentives, such as grants, tax credits or low-interest loans, can encourage industry players to invest in decarbonisation technologies and innovative processes;

- Knowledge-sharing platforms: Establishing platforms for sharing best practices, case studies and lessons learned can promote cross-pollination of ideas and accelerate the adoption of successful strategies.

5.3.2. Supportive Regulatory and Policy Framework

- Regulatory standards and guidelines: Updating building codes, material standards and policies to incorporate sustainability considerations can drive demand for low-carbon cement and concrete products [146]. Specifically, the inclusion of alternative binders such as geopolymers in material standards like BS EN 197 and CE marking frameworks will be vital for ensuring their acceptance and widespread use in the construction sector;

- Targeted financial incentives: Offering tax incentives, subsidies or other financial support mechanisms can offset the initial costs of adopting decarbonisation technologies and processes;

- Research and development funding: Allocating dedicated funding for research into novel cement formulations, alternative raw materials and innovative production methods can foster technological breakthroughs.

5.3.3. Upstream and Downstream Decarbonisation Strategies

- Upstream

- Downstream

5.4. Roadmap to Net Zero

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

List of Abbreviations

| APC | Advanced process control | LC3 | Limestone calcined clay cement |

| BATs | Best available techniques | LCA | Life cycle analysis |

| BFRP | Basalt fibre-reinforced polymer | MCs | Microbial cements |

| CaCO3 | Calcium carbonate | MBM | Meat and bone meal |

| CACs | Calcium aluminates cements | MPA | Mineral Products Association |

| CaO | Calcium oxide | SCM | Supplementary cementitious material |

| CCUS | Carbon capture utilisation and storage | SCR | Selective catalytic reduction |

| CEC | Cambridge Electric Cement | SSCs | Super sulphated slag cements |

| GCCA | Global Cement and Concrete Association | TRL | Technology Readiness Level |

| GGBS | Ground granulated blast furnace slag | VCFR | Variable coal feeding rate |

| GHG | Greenhouse gases | U.K. | United Kingdom |

References

- Schneider, M. The Cement Industry on the Way to a Low-Carbon Future. Cem. Concr. Res. 2019, 124, 105792. [Google Scholar] [CrossRef]

- Petroche, D.M.; Ramirez, A.D. The Environmental Profile of Clinker, Cement, and Concrete: A Life Cycle Perspective Study Based on Ecuadorian Data. Buildings 2022, 12, 311. [Google Scholar] [CrossRef]

- GCCA. Concrete Future—The GCCA 2050 Cement and Concrete Industry Roadmap for Net Zero Concrete; Global Cement and Concrete Association (GCCA): London, UK, 2021. [Google Scholar]

- Andrew, R.M. Global CO2 Emissions from Cement Production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards Sustainable Concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef] [PubMed]

- Miller, S.A.; Habert, G.; Myers, R.J.; Harvey, J.T. Achieving Net Zero Greenhouse Gas Emissions in the Cement Industry via Value Chain Mitigation Strategies. One Earth 2021, 4, 1398–1411. [Google Scholar] [CrossRef]

- IEA. Technology Roadmap: Low-Carbon Transition in the Cement Industry; IEA: Paris, France, 2018. [Google Scholar]

- Cheng, D.; Reiner, D.M.; Yang, F.; Cui, C.; Meng, J.; Shan, Y.; Liu, Y.; Tao, S.; Guan, D. Projecting Future Carbon Emissions from Cement Production in Developing Countries. Nat. Commun. 2023, 14, 8213. [Google Scholar] [CrossRef] [PubMed]

- Weale, T. Cement Manufacturing in the UK; C23.510; IBISWorld: London, UK, 2024. [Google Scholar]

- USGS. U.S. Geological Survey Cement Statistics and Information; USGS: Reston, VA, USA, 2022. Available online: https://www.usgs.gov/centers/national-minerals-information-center/cement-statistics-and-information (accessed on 30 July 2024).

- Chang, I.; Lee, M.; Cho, G.-C. Global CO2 Emission-Related Geotechnical Engineering Hazards and the Mission for Sustainable Geotechnical Engineering. Energies 2019, 12, 2567. [Google Scholar] [CrossRef]

- Office for National Statistics Index of Production, UK. Available online: https://www.ons.gov.uk/economy/economicoutputandproductivity/output/bulletins/indexofproduction/may2024 (accessed on 30 July 2024).

- Department for Business and Trade Building Materials and Components Statistics. Available online: https://www.data.gov.uk/dataset/75ee36ed-21f7-4d7b-9e7c-f5bf4546145d/building-materials-and-components-statistics (accessed on 30 July 2024).

- Bizley, D. Opportunities & Challenges For UK Cement; World Cement: London, UK, 2023. [Google Scholar]

- MPA. UK Concrete and Cement Industry Roadmap to Beyond Net Zero; MPA: London, UK, 2020. [Google Scholar]

- MPA. Profile of the UK Mineral Products Industry; MPA: London, UK, 2023. [Google Scholar]

- Department for Energy Security and Net Zero Final UK Greenhouse Gas Emissions National Statistics: 1990 to 2022—GOV.UK. Available online: https://www.gov.uk/government/statistics/final-uk-greenhouse-gas-emissions-national-statistics-1990-to-2022 (accessed on 30 July 2024).

- Department for Business, Energy & Industrial Strategy. Building Materials and Components Statistics: November 2022. Available online: https://www.gov.uk/government/statistics/building-materials-and-components-statistics-november-2022 (accessed on 30 July 2024).

- Climate Change Act 2008 (2050 Target Amendment) Order 2019; United Kingdom, 2019. Available online: https://www.legislation.gov.uk/uksi/2019/1056/contents/made (accessed on 20 June 2024).

- UK Climate Change Committee. The Sixth Carbon Budget-The UK’s Path to Net Zero; Climate Change Committee: London, UK, 2020. [Google Scholar]

- Idoine, N.E.; Raycraft, E.R.; Hobbs, S.F.; Everett, P.; Evans, E.J.; Mills, A.J.; Currie, D.; Horn, S.; Shaw, R.A. World Mineral Production 2018-22; British Geological Survey: Nottingham, UK, 2024. [Google Scholar]

- Rutkowski, E.; Pitt, H.; Larsen, K. The Global Cement Challenge—Rhodium Group. Available online: https://rhg.com/research/the-global-cement-challenge/ (accessed on 30 July 2024).

- Department for Energy Security and Net Zero. Annex 2: 2022 UK Greenhouse Gas Emissions, by Standard Industrial Classification; Department for Energy Security and Net Zero: London, UK, 2024. [Google Scholar]

- Department for Energy Security and Net Zero. 2022 UK Greenhouse Gas Emissions: Provisional Figures—Statistical Release; Department for Energy Security and Net Zero: London, UK, 2022. [Google Scholar]

- Low Carbon Concrete Group; The Green Construction Board. Low Carbon Concrete Routemap: Setting the Agenda for a Path to Net Zero; ICE: London, UK, 2022; Available online: https://www.ice.org.uk/media/q12jkljj/low-carbon-concrete-routemap.pdf (accessed on 20 June 2024).

- WSP; DNV-GL. Industrial Decarbonisation & Energy Efficiency Roadmaps to 2050: Cement; Department for Business, Innovation and Skills: London, UK, 2015. [Google Scholar]

- BS EN 197-1:2011; Cement: Composition, Specifications and Conformity Criteria for Common Cements. British Standards Institution (BSI): London, UK, 2019.

- Plaza, M.G.; Martínez, S.; Rubiera, F. CO2 Capture, Use, and Storage in the Cement Industry: State of the Art and Expectations. Energies 2020, 13, 5692. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-Efficient Cements: Potential Economically Viable Solutions for a Low-CO2 Cement-Based Materials Industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Busch, P.; Kendall, A.; Murphy, C.W.; Miller, S.A. Literature Review on Policies to Mitigate GHG Emissions for Cement and Concrete. Resour. Conserv. Recycl. 2022, 182, 106278. [Google Scholar] [CrossRef]

- Griffiths, S.; Sovacool, B.K.; Furszyfer Del Rio, D.D.; Foley, A.M.; Bazilian, M.D.; Kim, J.; Uratani, J.M. Decarbonizing the Cement and Concrete Industry: A Systematic Review of Socio-Technical Systems, Technological Innovations, and Policy Options. Renew. Sustain. Energy Rev. 2023, 180, 113291. [Google Scholar] [CrossRef]

- Adesina, A. Recent Advances in the Concrete Industry to Reduce Its Carbon Dioxide Emissions. Environ. Chall. 2020, 1, 100004. [Google Scholar] [CrossRef]

- CEMEX UK CEM I Portland Cement. Available online: https://www.cemex.co.uk/bulk-portland-cement (accessed on 10 March 2024).

- Walden, J.; Steinbrecher, A.; Marinkovic, M. Digital Product Passports as Enabler of the Circular Economy. Chem. Ing. Tech. 2021, 93, 1717–1727. [Google Scholar] [CrossRef]

- Panza, L.; Bruno, G.; Lombardi, F. Integrating Absolute Sustainability and Social Sustainability in the Digital Product Passport to Promote Industry 5.0. Sustainability 2023, 15, 12552. [Google Scholar] [CrossRef]

- Antunes, M.; Santos, R.L.; Pereira, J.; Rocha, P.; Horta, R.B.; Colaço, R. Alternative Clinker Technologies for Reducing Carbon Emissions in Cement Industry: A Critical Review. Materials 2021, 15, 209. [Google Scholar] [CrossRef]

- MPA The Concrete Centre. Specifying Sustainable Concrete; MPA The Concrete Centre: London, UK, 2020. [Google Scholar]

- Schorcht, F.; Kourti, I.; Scalet, B.M.; Roudier, S.; Sancho, L.D. Best Available Techniques (BAT) Reference Document for the Production of Cement, Lime and Magnesium Oxide: Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control); Publications Office of the European Union: Luxembourg, 2013. [Google Scholar]

- Gökcekuş, H.; Ghaboun, N.; Ozsahin, D.U.; Uzun, B. Evaluation of Cement Manufacturing Methods Using Multi Criteria Decision Analysis (MCDA). In Proceedings of the 14th International Conference on Developments in eSystems Engineering (DeSE), Sharjah, United Arab Emirates, 7–10 December 2021; pp. 39–43. [Google Scholar]

- Chopperla, S.T.; Jupalli, R.; Kanraj, D.; Bahurudeen, A.; Haneefa, M.K.; Santhanam, M. Development of an Efficient Procedure for Sustainable Low Carbon Cement Manufacturing Process. Appl. Mech. Mater. 2015, 787, 142–146. [Google Scholar] [CrossRef]

- Umid, K.; Turgunbayev, S. Methods and Tools of Cement Production Process (Comparative Analysis), Potential of Uzbekistan in This Area. Tech. Sci. Innov. 2020, 2020, 193–198. [Google Scholar] [CrossRef]

- Ige, O.E.; Olanrewaju, O.A.; Duffy, K.J.; Obiora, C. A Review of the Effectiveness of Life Cycle Assessment for Gauging Environmental Impacts from Cement Production. J. Clean. Prod. 2021, 324, 129213. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global Strategies and Potentials to Curb CO2 Emissions in Cement Industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Ali, M.; Markkanen, S. Cement Sector Deep Dive: How Could Demand Drive Low Carbon Innovation in the Cement Industry; Cambridge Institute for Sustainability Leadership (CISL): Cambridge, UK, 2023. [Google Scholar]

- Marmier, A. Decarbonisation Options for the Cement Industry; Publications Office of the European Union: Luxembourg, 2023. [Google Scholar]

- Sousa, V.; Bogas, J.A. Comparison of Energy Consumption and Carbon Emissions from Clinker and Recycled Cement Production. J. Clean. Prod. 2021, 306, 127277. [Google Scholar] [CrossRef]

- European Cement Research Academy. Development of State of the Art Techniques in Cement Manufacturing: Trying to Look Ahead -Technology Papers; European Cement Research Academy: Dusseldorf, Germany, 2017. [Google Scholar]

- Bide, T.; Evans, E.; Idoine, N.E.; Mankelow, J. British Geological Survey Decarbonisation and Resource Management Programme United Kingdom Minerals Yearbook 2022; British Geological Survey: Nottingham, UK, 2023. [Google Scholar]

- MPA. The Concrete Centre Concrete Futures, Spring 2023; MPA: London, UK, 2023. [Google Scholar]

- MPA; Cinar Ltd.; VDZ gGmbH. Options for Switching UK Cement Production Sites to near Zero CO2 Emission Fuel: Technical and Financial Feasibility; MPA: London, UK, 2019. [Google Scholar]

- MPA Cement About Us. Available online: https://cement.mineralproducts.org/About-Us.aspx (accessed on 19 August 2024).

- Ke, P.; Deng, Z.; Zhu, B.; Zheng, B.; Wang, Y.; Boucher, O.; Arous, S.B.; Zhou, C.; Andrew, R.M.; Dou, X.; et al. Carbon Monitor Europe Near-Real-Time Daily CO2 Emissions for 27 EU Countries and the United Kingdom. Sci. Data 2023, 10, 374. [Google Scholar] [CrossRef] [PubMed]

- U.S. Department of the Interior. Mineral Commodity Summaries 2024; U.S. Department of the Interior: Washington, DC, USA, 2024. [Google Scholar]

- Global Carbon Project Carbon Emissions—Global Carbon Atlas. Available online: https://globalcarbonatlas.org/emissions/carbon-emissions/ (accessed on 31 July 2024).

- Department for Business, I. and S. Production Volume of Cement in Great Britain (GB) from 2001 to 2022 (in 1000 Metric Tons). In Statista. Available online: https://www.statista.com/statistics/472849/annual-cement-production-great-britain/ (accessed on 30 July 2024).

- Shanks, W.; Dunant, C.F.; Drewniok, M.P.; Lupton, R.C.; Serrenho, A.; Allwood, J.M. How Much Cement Can We Do without? Lessons from Cement Material Flows in the UK. Resour. Conserv. Recycl. 2019, 141, 441–454. [Google Scholar] [CrossRef]

- Gao, T.; Shen, L.; Shen, M.; Liu, L.; Chen, F. Analysis of Material Flow and Consumption in Cement Production Process. J. Clean. Prod. 2016, 112, 553–565. [Google Scholar] [CrossRef]

- MPA. Sustainable Development Report 2020/2021—Data and Developments; MPA: London, UK, 2021. [Google Scholar]

- Ghalandari, V. A Comprehensive Study on Energy and Exergy Analyses for an Industrial-Scale Pyro-Processing System in Cement Plant. Clean. Energy Syst. 2022, 3, 100030. [Google Scholar] [CrossRef]

- Ma, X.; Shao, W.; Cui, Z. Energy and Thermodynamic Analysis of a Typical Cement Production System Based on Experimental and Simulated Investigations. Case Stud. Therm. Eng. 2022, 38, 102357. [Google Scholar] [CrossRef]

- Mittal, A.; Rakshit, D. Energy Audit and Waste Heat Recovery from Kiln Hot Shell Surface of a Cement Plant. Therm. Sci. Eng. Prog. 2020, 19, 100599. [Google Scholar] [CrossRef]

- Marenco-Porto, C.A.; Fierro, J.J.; Nieto-Londoño, C.; Lopera, L.; Escudero-Atehortua, A.; Giraldo, M.; Jouhara, H. Potential Savings in the Cement Industry Using Waste Heat Recovery Technologies. Energy 2023, 279, 127810. [Google Scholar] [CrossRef]

- Ghalandari, V.; Iranmanesh, A. Energy and Exergy Analyses for a Cement Ball Mill of a New Generation Cement Plant and Optimizing Grinding Process: A Case Study. Adv. Powder Technol. 2020, 31, 1796–1810. [Google Scholar] [CrossRef]

- Pérez, J. CEMEX Leads in Clean Energy with Focus on Renewable Power Sources. Available online: https://www.cemex.com/w/cemex-leads-in-clean-energy-with-focus-on-renewable-power-sources (accessed on 31 July 2024).

- MPA. The Thirteenth Concrete Industry Sustainability Performance Report; MPA: London, UK, 2021. [Google Scholar]

- MPA. Concrete Industry Guidance Document on Sustainability Performance Indicators—Supporting the Concrete Industry Sustainability Performance Report; MPA: London, UK, 2020. [Google Scholar]

- Hammond, G.P. The UK Industrial Decarbonisation Strategy Revisited. Proc. Inst. Civ. Eng. Energy 2022, 175, 30–44. [Google Scholar] [CrossRef]

- Napp, T.A.; Gambhir, A.; Hills, T.P.; Florin, N.; Fennell, P.S. A Review of the Technologies, Economics and Policy Instruments for Decarbonising Energy-Intensive Manufacturing Industries. Renew. Sustain. Energy Rev. 2014, 30, 616–640. [Google Scholar] [CrossRef]

- Ogwumike, C.; Akponeware, A.; Oyewole, A.; Dawood, H.; Pinedo-Cuenca, R.; Ling-Chin, J.; Roskilly, A.P.; Dawood, N. Transitioning or Tinkering at a Net-Zero Economy? Introducing an Assessment Framework for Industrial Cluster Decarbonisation in the United Kingdom. Energy Res. Soc. Sci. 2024, 110, 103459. [Google Scholar] [CrossRef]

- Nurdiawati, A.; Urban, F. Towards Deep Decarbonisation of Energy-Intensive Industries: A Review of Current Status, Technologies and Policies. Energies 2021, 14, 2408. [Google Scholar] [CrossRef]

- Sealey, B.J.; Phillips, P.S.; Hill, G.J. Waste Management Issues for the UK Ready-Mixed Concrete Industry. Resour. Conserv. Recycl. 2001, 32, 321–331. [Google Scholar] [CrossRef]

- Chaves, G.d.L.D.; Siman, R.R.; Ribeiro, G.M.; Chang, N. Bin The Potential of Refuse-Derived Fuel Production in Reducing the Environmental Footprint of the Cement Industry. In Environmental Footprints and Eco-Design of Products and Processes; Springer: Singapore, 2022; pp. 35–64. [Google Scholar] [CrossRef]

- Kim, D.; Phae, C. Analysis of the Environmental and Economic Effect of the Co-Processing of Waste in the Cement Industry in Korea. Sustainability 2022, 14, 15820. [Google Scholar] [CrossRef]

- Meddah, M.S.; Al-Harthy, A.; Ismail, M.A. Recycled Concrete Aggregates and Their Influences on Performances of Low and Normal Strength Concretes. Buildings 2020, 10, 167. [Google Scholar] [CrossRef]

- MPA. Concrete Industry Sustainability Performance Report—14th Report: 2020 Performance Data; MPA: London, UK, 2020. [Google Scholar]

- Garvey, A.; Taylor, P. Industrial Decarbonisation Policies for a UK Net Zero Target; Centre for Research into Energy Demand Solutions: Oxford, UK, 2020. [Google Scholar]

- Sarfraz, S.; Sherif, Z.; Jolly, M.; Salonitis, K. Benchmarking of Energy Consumption and CO2 Emissions in Cement Production: A Case Study; Springer: Cham, Switzerland, 2024; pp. 53–65. [Google Scholar] [CrossRef]

- Barrett, J.; Cooper, T.; Hammond, G.P.; Pidgeon, N. Industrial Energy, Materials and Products: UK Decarbonisation Challenges and Opportunities. Appl. Therm. Eng. 2018, 136, 643–656. [Google Scholar] [CrossRef]

- Heidelberg Materials UK Ribblesdale and Ketton Upgrades. Available online: https://www.heidelbergmaterials.co.uk/en/sustainability-case-study/ribblesdale-and-ketton-upgrades (accessed on 27 March 2024).

- CEMEX UK Rugby Cement Plant—Mill 7 Project. Available online: https://www.cemex.co.uk/rugby-cement-plant-mill-7-project (accessed on 27 March 2024).

- Sherif, Z.; Sarfraz, S.; Jolly, M.; Salonitis, K. Greening Foundation Industries: Shared Processes and Sustainable Pathways. Sustainability 2023, 15, 14422. [Google Scholar] [CrossRef]

- MPA; VDZ gGmbH; Cinar Ltd.; Hanson; Tarmac. State of the Art Fuel Mix for UK Cement Production to Test the Path for “Net Zero”: A Technical, Environmental and Safety Demonstration; MPA: London, UK, 2022. Available online: https://assets.publishing.service.gov.uk/media/637e4d85d3bf7f154955962d/phase_3_state_of_the_art_fuel_mix_for_UK_cement_production_to_test_the_path_for_net_zero.pdf (accessed on 15 June 2024).

- Kusuma, R.T.; Hiremath, R.B.; Rajesh, P.; Kumar, B.; Renukappa, S. Sustainable Transition towards Biomass-Based Cement Industry: A Review. Renew. Sustain. Energy Rev. 2022, 163, 112503. [Google Scholar] [CrossRef]

- He, M.; Sun, Y.; Han, B. Green Carbon Science: Efficient Carbon Resource Processing, Utilization, and Recycling towards Carbon Neutrality. Angew. Chem. 2022, 134, e202112835. [Google Scholar] [CrossRef]

- Welfle, A.; Gilbert, P.; Thornley, P. Securing a Bioenergy Future without Imports. Energy Policy 2014, 68, 1–14. [Google Scholar] [CrossRef]

- Thrän, D.; Seidenberger, T.; Zeddies, J.; Offermann, R. Global Biomass Potentials—Resources, Drivers and Scenario Results. Energy Sustain. Dev. 2010, 14, 200–205. [Google Scholar] [CrossRef]

- Akhtar, S.S.; Abbas, T.; Akritopoulos, M. Decarbonization Through Oxy-Combustion and H 2 as A Fuel. In Proceedings of the 2022 IEEE-IAS/PCA Cement Industry Conference (IAS/PCA), Las Vegas, NV, USA, 1–5 May 2022; IEEE: New York, NY, USA, 2022; pp. 1–6. [Google Scholar]

- MPA. The Concrete Centre Concrete Futures, Spring 2024; MPA: London, UK, 2024. [Google Scholar]

- Cemex CEMEX Invests US$25 Million to Phase Out Fossil Fuels at Rugby Cement Plant in the UK|CEMEX UK. Available online: https://www.cemex.co.uk/-/cemex-invests-us-25-million-to-phase-out-fossil-fuels-at-rugby-cement-plant-in-the-uk (accessed on 6 January 2025).

- Global Cement Cemex to Deploy Hydrogen-Enriched Fuel Mix across All Cement Plants in 2021—Cement Industry News from Global Cement. Available online: https://www.globalcement.com/news/item/12045-cemex-to-deploy-hydrogen-enriched-fuel-mix-across-all-cement-plants-in-2021 (accessed on 6 January 2025).

- Edwards, R.L.; Font-Palma, C.; Howe, J. The Status of Hydrogen Technologies in the UK: A Multi-Disciplinary Review. Sustain. Energy Technol. Assess. 2021, 43, 100901. [Google Scholar] [CrossRef]

- Juangsa, F.B.; Cezeliano, A.S.; Darmanto, P.S.; Aziz, M. Thermodynamic Analysis of Hydrogen Utilization as Alternative Fuel in Cement Production. S. Afr. J. Chem. Eng. 2022, 42, 23–31. [Google Scholar] [CrossRef]

- Wilhelmsson, B.; Kollberg, C.; Larsson, J.; Eriksson, J.; Eriksson, M. CemZero—A Feasibility Study Evaluating Ways to Reach Sustainable Cement Production via the Use of Electricity. CamZero: Stockholm, Sweden, 2018; Available online: https://www.cement.heidelbergmaterials.se/sites/default/files/assets/document/65/de/final_cemzero_2018_public_version_2.0.pdf.pdf (accessed on 27 March 2024).

- National Grid How Much of the UK’s Energy Is Renewable? Available online: https://www.nationalgrid.com/stories/energy-explained/how-much-uks-energy-renewable (accessed on 27 March 2024).

- Cemnet The Electrified Commercial Cement Kiln. Available online: https://www.cemnet.com/News/story/174030/the-electrified-commercial-cement-kiln.html (accessed on 27 March 2024).

- Coolbrook Industrial Process Heating: Replacing Fossil Fuels with RotoDynamic Heater. Available online: https://coolbrook.com/electrification-solutions/rdh-industrial-process-heating/ (accessed on 27 March 2024).

- Gaurina-Međimurec, N.; Novak-Mavar, K.; Majić, M. Carbon Capture and Storage (CCS): Technology, Projects and Monitoring Review. Min.-Geol.-Pet. Eng. Bull. 2018, 33, 1–15. [Google Scholar] [CrossRef]

- Leeson, D.; Mac Dowell, N.; Shah, N.; Petit, C.; Fennell, P.S. A Techno-Economic Analysis and Systematic Review of Carbon Capture and Storage (CCS) Applied to the Iron and Steel, Cement, Oil Refining and Pulp and Paper Industries, as Well as Other High Purity Sources. Int. J. Greenh. Gas. Control 2017, 61, 71–84. [Google Scholar] [CrossRef]

- Monteiro, J.; Roussanaly, S. CCUS Scenarios for the Cement Industry: Is CO2 Utilization Feasible? J. CO2 Util. 2022, 61, 102015. [Google Scholar] [CrossRef]

- Antzaras, A.N.; Papalas, T.; Heracleous, E.; Kouris, C. Techno–Economic and Environmental Assessment of CO2 Capture Technologies in the Cement Industry. J. Clean. Prod. 2023, 428, 139330. [Google Scholar] [CrossRef]

- Gibbins, J.; Lucquiaud, M. The Development of UK CCUS Strategy and Current Plans for Large-Scale Deployment of This Technology. Ann. Des. Mines Responsab. Environ. 2022, 105, 26–30. [Google Scholar] [CrossRef]

- Hart, J. Cement: Raising Ambitions, Reducing Emissions. Ecocem: Moerdijk, The Netherlands, 2022. Available online: https://alliancelccc.com/wp-content/uploads/2023/11/Ecocem-Raising-ambitions-reducing-emissions-November-2022.pdf (accessed on 15 June 2024).

- Snellings, R.; Suraneni, P.; Skibsted, J. Future and Emerging Supplementary Cementitious Materials. Cem. Concr. Res. 2023, 171, 107199. [Google Scholar] [CrossRef]

- Karadumpa, C.S.; Pancharathi, R.K. Study on Energy Use and Carbon Emission from Manufacturing of OPC and Blended Cements in India. Environ. Sci. Pollut. Res. 2023, 31, 5364–5383. [Google Scholar] [CrossRef] [PubMed]

- Champan, J.; Thompson, R.; Hughes, D.; Abdalqadir, M.; Gomari, S.R. Introducing a Novel Optimised Binder Activator with Redcar Mudstone Feedstock in the UK for Geopolymer Cement Formation. Colloids Surf. A Physicochem. Eng. Asp. 2024, 699. [Google Scholar] [CrossRef]

- Preston, F.; Lehne, J. Making Concrete Change: Innovation in Low-Carbon Cement and Concrete; Chatham House: London, UK, 2018; Available online: https://www.chathamhouse.org/sites/default/files/publications/2018-06-13-making-concrete-change-cement-lehne-preston-exec-sum.pdf (accessed on 10 May 2024).

- Fiala, L.; Lin, W.T.; Hotěk, P.; Cheng, A. Feasibility Study of Developing Cementless Blended Materials as 3D Printable Materials. Case Stud. Constr. Mater. 2023, 19, e02675. [Google Scholar] [CrossRef]

- Lin, W.T.; Lin, K.L.; Korniejenko, K.; Fiala, L.; Cheng, A.; Chen, J. Composite Properties of Non-Cement Blended Fiber Composites without Alkali Activator. Materials 2020, 13, 1443. [Google Scholar] [CrossRef] [PubMed]

- Millward-Hopkins, J.; Zwirner, O.; Purnell, P.; Velis, C.A.; Iacovidou, E.; Brown, A. Resource Recovery and Low Carbon Transitions: The Hidden Impacts of Substituting Cement with Imported ‘Waste’ Materials from Coal and Steel Production. Glob. Environ. Change 2018, 53, 146–156. [Google Scholar] [CrossRef]

- Kelly, F. A review of GGBS use in the UK and its role in reducing embodied. Struct. Eng. 2023, 101, 24–27. [Google Scholar] [CrossRef]

- Sentucq, E.; Clayton, M. Beyond Portland Cement: Low-Carbon Alternatives. Available online: https://www.istructe.org/resources/guidance/beyond-portland-cement-low-carbon-alternatives/ (accessed on 27 March 2024).

- Mullane, J. Ultra-Low Carbon Limestone Calcined Clay LC3 Cement Used in UK “for First Time”. Available online: https://www.homebuilding.co.uk/news/lc3-cement (accessed on 27 March 2024).

- Aggregate Industries ECOPlanet the Green Cement. Available online: https://www.aggregate.com/products-and-services/cement/bulk/ecoplanet-green-cement (accessed on 27 March 2024).

- Breedon Group BREEDON Eco—Sustainable Concrete. Available online: https://www.breedongroup.com/products-and-services/gb/our-products/ready-mixed-concrete/sustainable-concrete (accessed on 27 March 2024).

- AggNet Cemex See High Cut-Through for Low-Carbon Cement. Available online: https://www.agg-net.com/news/cemex-see-high-cut-through-for-low-carbon-cement (accessed on 27 March 2024).

- Beumelburg, C. Significant CO2 Reduction: HeidelbergCement Expands Sustainable Concrete Portfolio in Germany under EcoCrete Brand. Available online: https://www.heidelbergmaterials.com/en/pr-20-01-2022 (accessed on 27 March 2024).

- Woodford, G. Tarmac Launches CEVO Lower Carbon Concrete Brand. Available online: https://www.aggbusiness.com/ab10/news/tarmac-launches-cevo-lower-carbon-concrete-brand (accessed on 27 March 2024).

- Bell, S. Cement 2 Zero Project. Available online: https://www.mpiuk.com/research-project-cement-2-zero.htm (accessed on 27 March 2024).

- Langley, J. Explore Manufacturing Sustainability Performance Report. 2022. Available online: https://www.laingorourke.com/media/fjygwbnl/sustainability-performance-report-2022-explore-manufacturing-cemc.pdf (accessed on 12 May 2024).

- CEMBUREAU. 2050 Carbon Neutrality Roadmap; CEMBUREAU: Brussels, Belgium, 2020. [Google Scholar]

- Zajac, M.; Skocek, J.; Ben Haha, M.; Deja, J. CO2 Mineralization Methods in Cement and Concrete Industry. Energies 2022, 15, 3597. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Andrade, C.; Mora, P.; Zaragoza, A. Carbon Dioxide Uptake by Mortars and Concretes Made with Portuguese Cements. Appl. Sci. 2020, 10, 646. [Google Scholar] [CrossRef]

- Torrenti, J.M.; Amiri, O.; Barnes-Davin, L.; Bougrain, F.; Braymand, S.; Cazacliu, B.; Colin, J.; Cudeville, A.; Dangla, P.; Djerbi, A.; et al. The FastCarb Project: Taking Advantage of the Accelerated Carbonation of Recycled Concrete Aggregates. Case Stud. Constr. Mater. 2022, 17, e01349. [Google Scholar] [CrossRef]

- Chhetri, V. This UK Startup Cements £2.5M Funding to Pioneer CO2 Mineralisation in Concrete. Available online: https://techfundingnews.com/this-uk-startup-cements-2-5m-funding-to-pioneer-co2-mineralisation-in-concrete/ (accessed on 27 March 2024).

- Marsh, A.T.M.; Dillon, T.; Bernal, S.A. Cement and Concrete Decarbonisation Roadmaps—A Meta-Analysis within the Context of the United Kingdom. RILEM Tech. Lett. 2023, 8, 94–105. [Google Scholar] [CrossRef]

- Quevedo Parra, S.; Romano, M.C. Decarbonization of Cement Production by Electrification. J. Clean. Prod. 2023, 425, 138913. [Google Scholar] [CrossRef]

- Cavalett, O.; Watanabe, M.D.B.; Voldsund, M.; Roussanaly, S.; Cherubini, F. Paving the Way for Sustainable Decarbonization of the European Cement Industry. Nat. Sustain. 2024, 7, 568–580. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental Impacts and Decarbonization Strategies in the Cement and Concrete Industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- BS 8500-2:2019; Concrete—Complementary British Standard to BS EN 206, Part 2: Specification for Constituent Materials and Concrete. British Standards Institution (BSI): London, UK, 2019.

- McGarry, H.; Martin, B.; Winslow, P. Delivering Low Carbon Concrete for Network Rail on the Routemap to Net Zero. Case Stud. Constr. Mater. 2022, 17, e01343. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Zhang, Q.; Yuan, Z. Optimal Control for Thermal Energy Efficiency of the Cement Clinker Manufacturing Process. In Proceedings of the 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; IEEE: New York, NY, USA, 2018; pp. 7444–7449. [Google Scholar]

- Liu, Z.; Wang, Z.; Yuan, M.Z.; Yu, H.B. Thermal Efficiency Modelling of the Cement Clinker Manufacturing Process. J. Energy Inst. 2015, 88, 76–86. [Google Scholar] [CrossRef]

- Zanoli, S.M.; Orlietti, L.; Cocchioni, F.; Astolfi, G.; Pepe, C. Optimization of the Clinker Production Phase in a Cement Plant; Springer: Cham, Switzerland, 2021; ISBN 9783030586522. [Google Scholar]

- Papanikola, K.; Papadopoulou, K.; Tsiliyannis, C.; Fotinopoulou, I.; Katsiampoulas, A.; Chalarakis, E.; Georgiopoulou, M.; Rontogianni, V.; Michalopoulos, I.; Mathioudakis, D.; et al. Food Residue Biomass Product as an Alternative Fuel for the Cement Industry. Environ. Sci. Pollut. Res. 2019, 26, 35555–35564. [Google Scholar] [CrossRef]

- Matalkah, F.; Soroushian, P.; Ul Abideen, S.; Peyvandi, A. Use of Non-Wood Biomass Combustion Ash in Development of Alkali-Activated Concrete. Constr. Build. Mater. 2016, 121, 491–500. [Google Scholar] [CrossRef]

- Cheah, C.B.; Ramli, M. The Implementation of Wood Waste Ash as a Partial Cement Replacement Material in the Production of Structural Grade Concrete and Mortar: An Overview. Resour. Conserv. Recycl. 2011, 55, 669–685. [Google Scholar] [CrossRef]

- Phillips, D.; Mitchell, E.J.S.; Lea-Langton, A.R.; Parmar, K.R.; Jones, J.M.; Williams, A. The Use of Conservation Biomass Feedstocks as Potential Bioenergy Resources in the United Kingdom. Bioresour. Technol. 2016, 212, 271–279. [Google Scholar] [CrossRef]

- Barnett, B. An Evaluation of the UK’s Use of SFM Standards to Procure Solid Woody Biomass for Electricity Generation Using Sustainable Bioenergy Criteria. Biofuels 2016, 7, 1–17. [Google Scholar] [CrossRef]

- Bibby, J. The Death of CEM I? Available online: https://www.lkabminerals.com/news/uk-cement-updates/ (accessed on 28 March 2024).

- MPA Revised Version of BS 8500. Available online: https://www.concretecentre.com/News/2023/BS-8500-1-2023.aspx (accessed on 28 March 2024).

- Ayati, B.; Newport, D.; Wong, H.; Cheeseman, C. Low-Carbon Cements: Potential for Low-Grade Calcined Clays to Form Supplementary Cementitious Materials. Clean. Mater. 2022, 5. [Google Scholar] [CrossRef]

- Valente, M.; Sambucci, M.; Sibai, A. Geopolymers vs. Cement Matrix Materials: How Nanofiller Can Help a Sustainability Approach for Smart Construction Applications—A Review. Nanomaterials 2021, 11, 2007. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.B.; Middendorf, B. Geopolymers as an Alternative to Portland Cement: An Overview. Constr. Build. Mater. 2020, 237, 117455. [Google Scholar] [CrossRef]

- Hills, T.; Florin, N.; Fennell, P.S. Decarbonising the Cement Sector: A Bottom-up Model for Optimising Carbon Capture Application in the UK. J. Clean. Prod. 2016, 139, 1351–1361. [Google Scholar] [CrossRef]

- Dunant, C.F.; Allwood, J.M. What Investments in Material Production Are Needed to Achieve Net-Zero Construction in the UK by 2050? J. Clean. Prod. 2024, 464, 142709. [Google Scholar] [CrossRef]

- Dunster, A.; Marriott, E. Lower Carbon Dioxide Cements and Concretes: Bringing New Materials into UK Industrial Use. Proc. Inst. Civ. Eng. Struct. Build. 2023, 176, 972–985. [Google Scholar] [CrossRef]

- Pamenter, S.; Myers, R.J. Decarbonizing the Cementitious Materials Cycle: A Whole-Systems Review of Measures to Decarbonize the Cement Supply Chain in the UK and European Contexts. J. Ind. Ecol. 2021, 25, 359–376. [Google Scholar] [CrossRef]

- Nehdi, M.L.; Marani, A.; Zhang, L. Is Net-Zero Feasible: Systematic Review of Cement and Concrete Decarbonization Technologies. Renew. Sustain. Energy Rev. 2024, 191, 114169. [Google Scholar] [CrossRef]

- Kim, J.; Sovacool, B.K.; Bazilian, M.; Griffiths, S.; Yang, M. Energy, Material, and Resource Efficiency for Industrial Decarbonization: A Systematic Review of Sociotechnical Systems, Technological Innovations, and Policy Options. Energy Res. Soc. Sci. 2024, 112, 103521. [Google Scholar] [CrossRef]

- Lopez, S.; Sutter, L.; Douglas Hooton, R.; Van Dam, T.; Innis, A.; Senn, K. Breaking Barriers to Low Carbon Concrete Pavements. Transp. Res. Rec. 2024. [Google Scholar] [CrossRef]

- Hafez, H.; Bajić, P.; Aidarov, S.; Malija, X.; Drewniok, M.; Purnell, P.; Tošić, N. Parametric Study on the Decarbonization Potential of Structural System and Concrete Mix Design Choices for Mid-Rise Concrete Buildings. Mater. Struct. Mater. Constr. 2024, 57, 85. [Google Scholar] [CrossRef]

| Technology | Environmental Effectiveness | Technology Readiness | Implementation Challenges | Comments | |

|---|---|---|---|---|---|

| BATs | Clinkerisation | ★★★☆☆ | ★★★★★ | ★★★☆☆ | High capital costs |

| Grinding | ★☆☆☆☆ | ★★★★★ | ★★★☆☆ | High capital costs | |

| Generic | ★★☆☆☆ | ★★★★★ | ★★☆☆☆ | Capital costs | |

| Fuel | Biomass | ★★★☆☆ | ★★★★☆ | ★★☆☆☆ | Supply limitations |

| Hydrogen | ★★★★☆ | ★★★☆☆ | ★★★★☆ | Infrastructure, cost | |

| Electrification | ★★★★☆ | ★★☆☆☆ | ★★★★☆ | Maturity, energy supply | |

| CC | Calcium looping | ★★★★★ | ★★★☆☆ | ★★★★☆ | High capital costs |

| Clinker | Geopolymer cement | ★★★★☆ | ★★★★☆ | ★★★★☆ | Plant modification costs |

| SCMs | ★★★☆☆ | ★★★★★ | ★★☆☆☆ | Supply, quality | |

| Geopolymer cement | ★★★★★ | ★★★☆☆ | ★★★☆☆ | Supply, quality | |

| LC3 | ★★★★☆ | ★★★★☆ | ★★☆☆☆ | Early adoption phase | |

| Initiatives | Cement recycling | ★★★☆☆ | ★★☆☆☆ | ★★★☆☆ | Development phase |

| CO2 mineralisation | ★★★★☆ | ★★★☆☆ | ★★☆☆☆ | Early adoption phase | |

| Graphene-enhanced cement | ★☆☆☆☆ | ★★☆☆☆ | ★★★☆☆ | Development phase |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sherif, Z.; Sarfraz, S.; Jolly, M.; Salonitis, K. A Critical Review of the Decarbonisation Potential in the U.K. Cement Industry. Materials 2025, 18, 292. https://doi.org/10.3390/ma18020292

Sherif Z, Sarfraz S, Jolly M, Salonitis K. A Critical Review of the Decarbonisation Potential in the U.K. Cement Industry. Materials. 2025; 18(2):292. https://doi.org/10.3390/ma18020292

Chicago/Turabian StyleSherif, Ziyad, Shoaib Sarfraz, Mark Jolly, and Konstantinos Salonitis. 2025. "A Critical Review of the Decarbonisation Potential in the U.K. Cement Industry" Materials 18, no. 2: 292. https://doi.org/10.3390/ma18020292

APA StyleSherif, Z., Sarfraz, S., Jolly, M., & Salonitis, K. (2025). A Critical Review of the Decarbonisation Potential in the U.K. Cement Industry. Materials, 18(2), 292. https://doi.org/10.3390/ma18020292