Bamboo–PCM: Comparative Analysis of Phase Change Material-Impregnated Dendrocalamus giganteus Culm Behavior Exposed to Thermal Variation in Wind Tunnel Assay

Abstract

1. Introduction

2. Materials and Methods

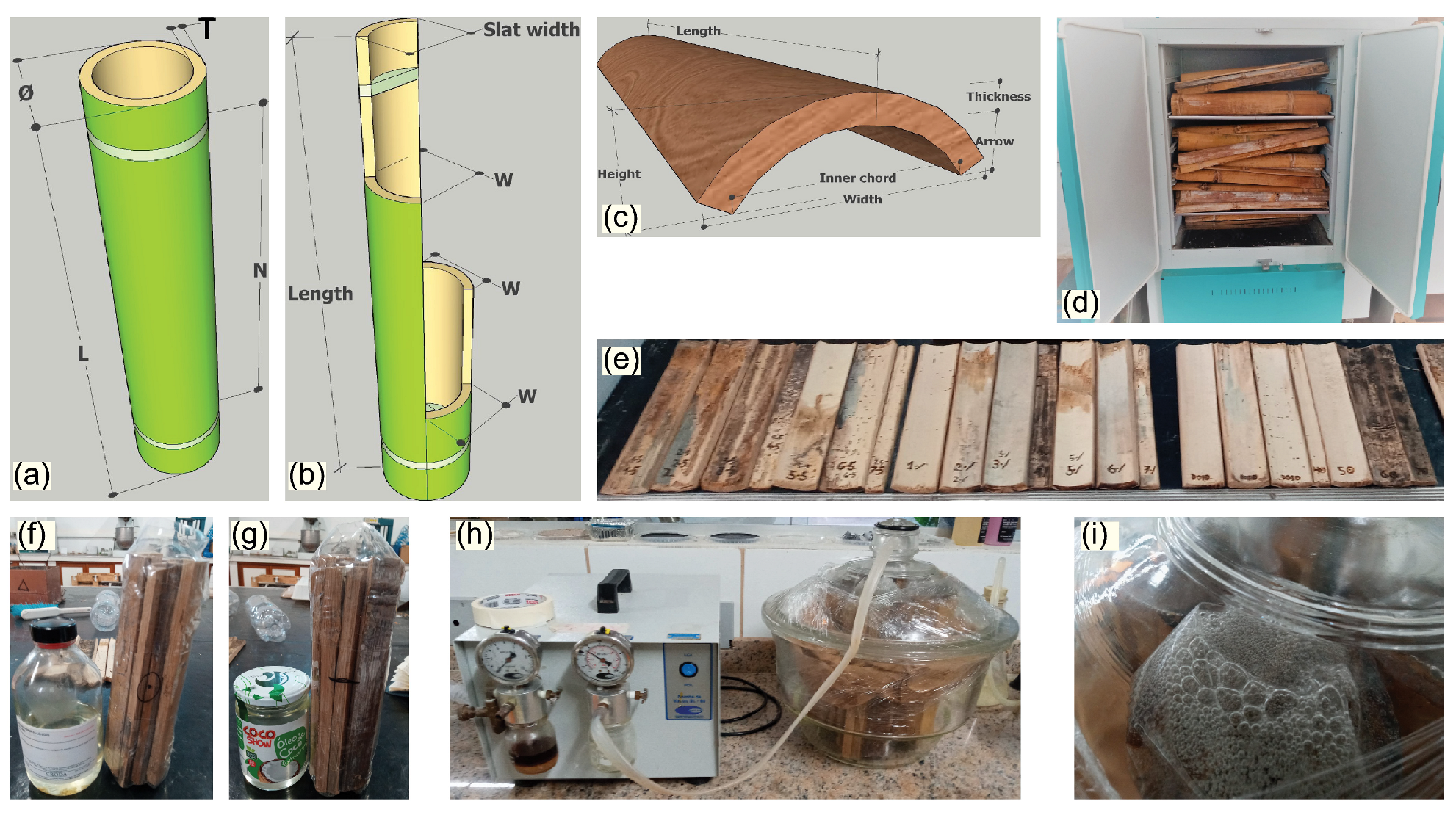

2.1. Cutting and Preparation of Stalks

2.2. PCM Impregnation and Coating of Specimens

2.3. Characterization

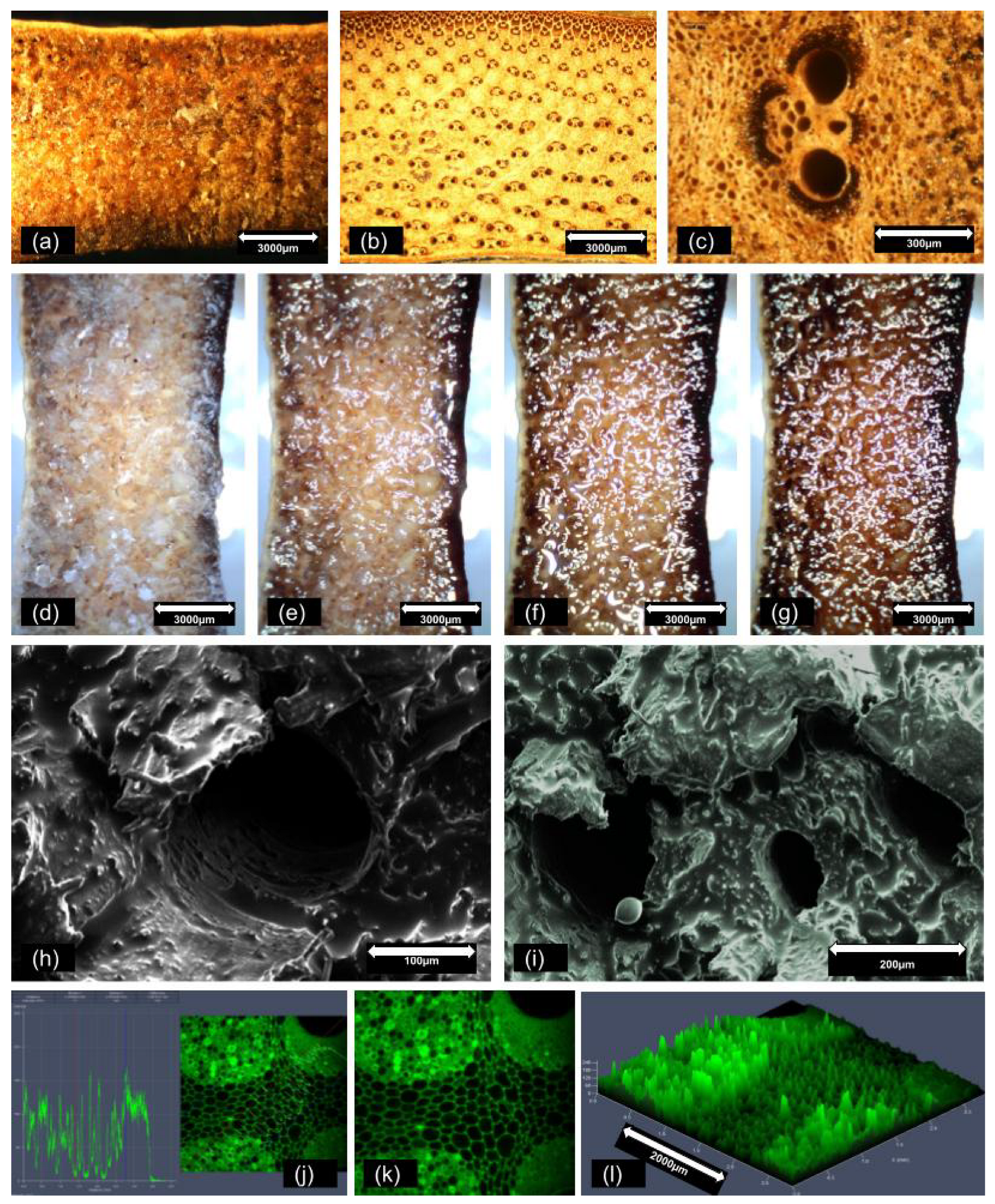

2.3.1. Microscopy and Ultrastructural Analyses

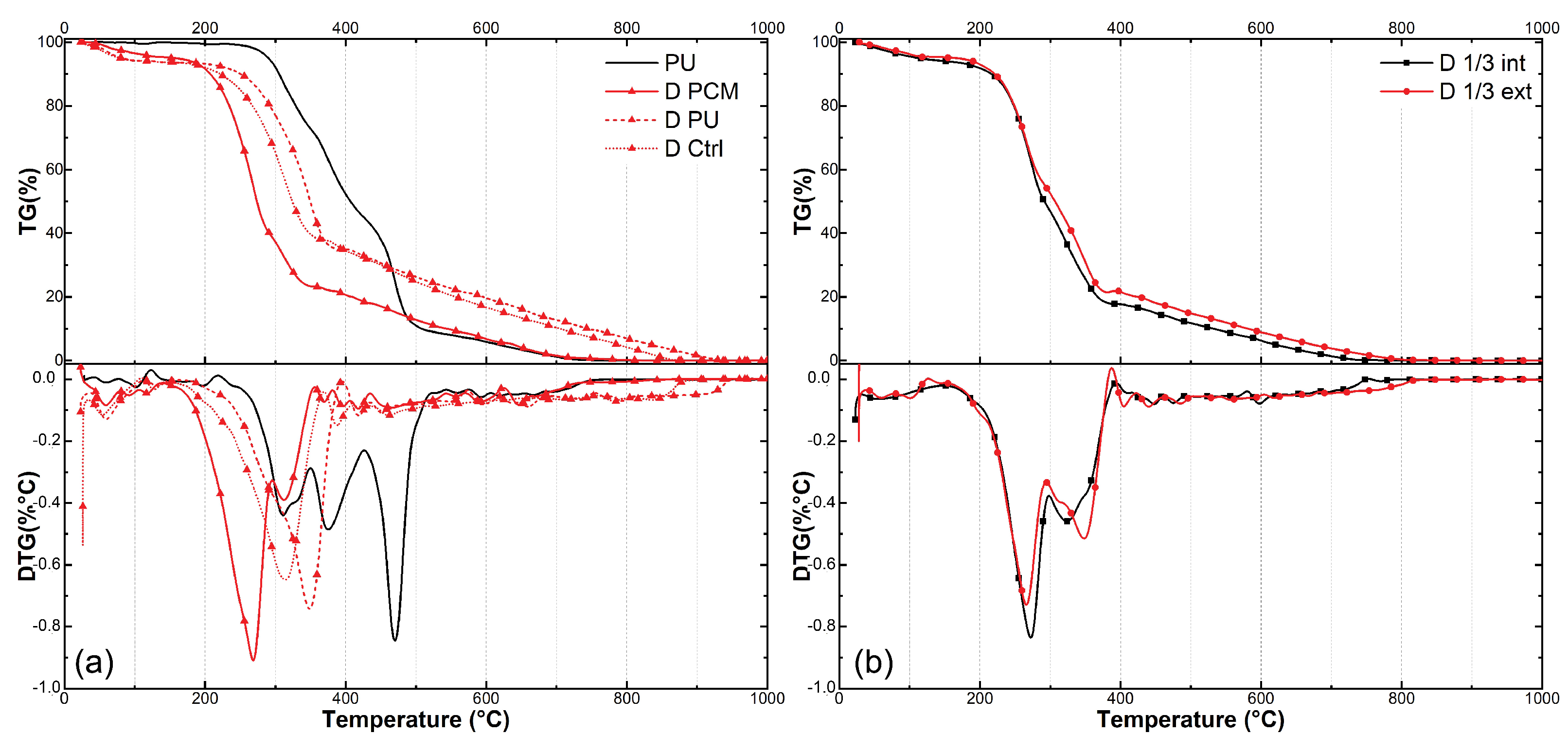

2.3.2. Thermogravimetric Analysis (TGA)

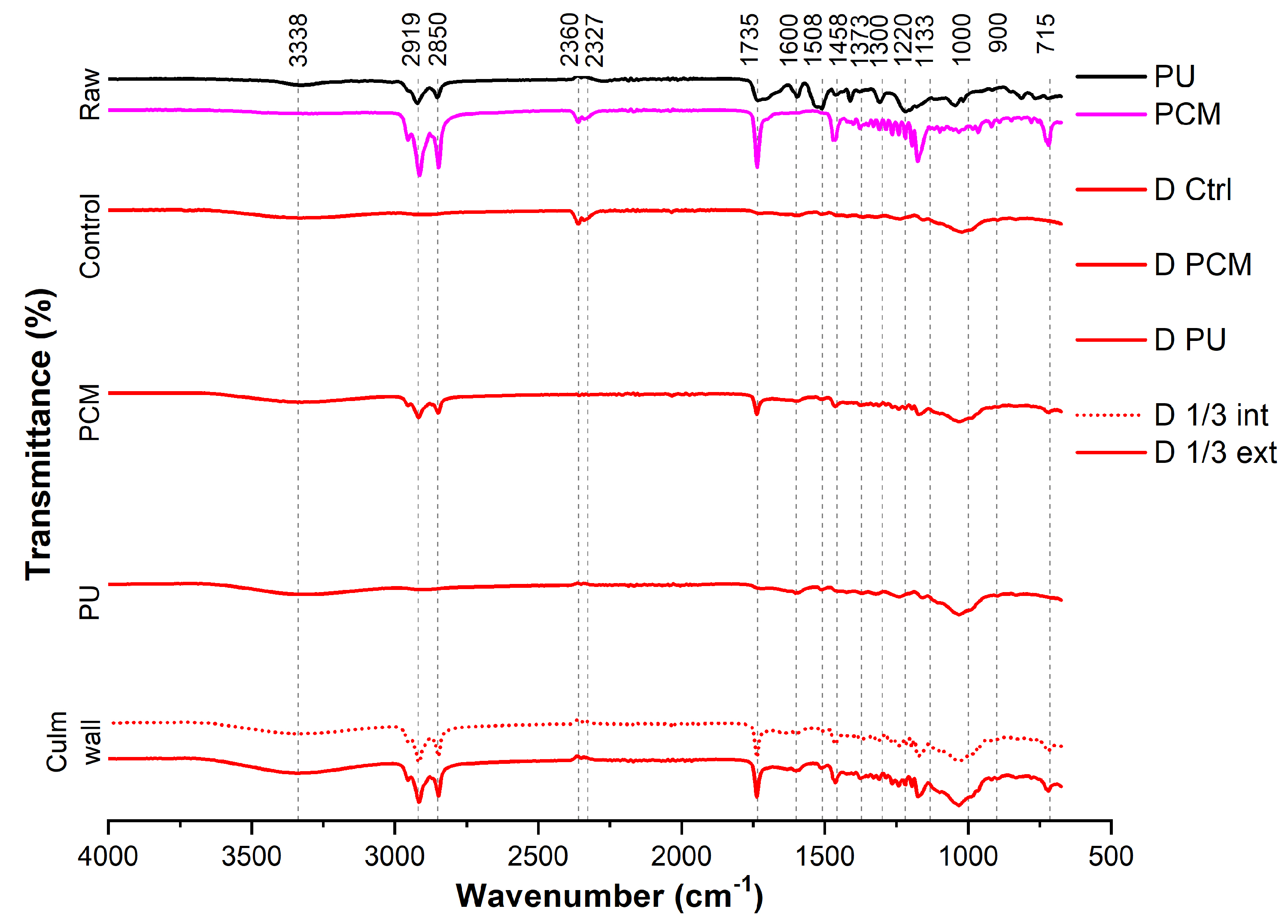

2.3.3. Fourier-Transform Infrared Spectroscopy (FTIR)

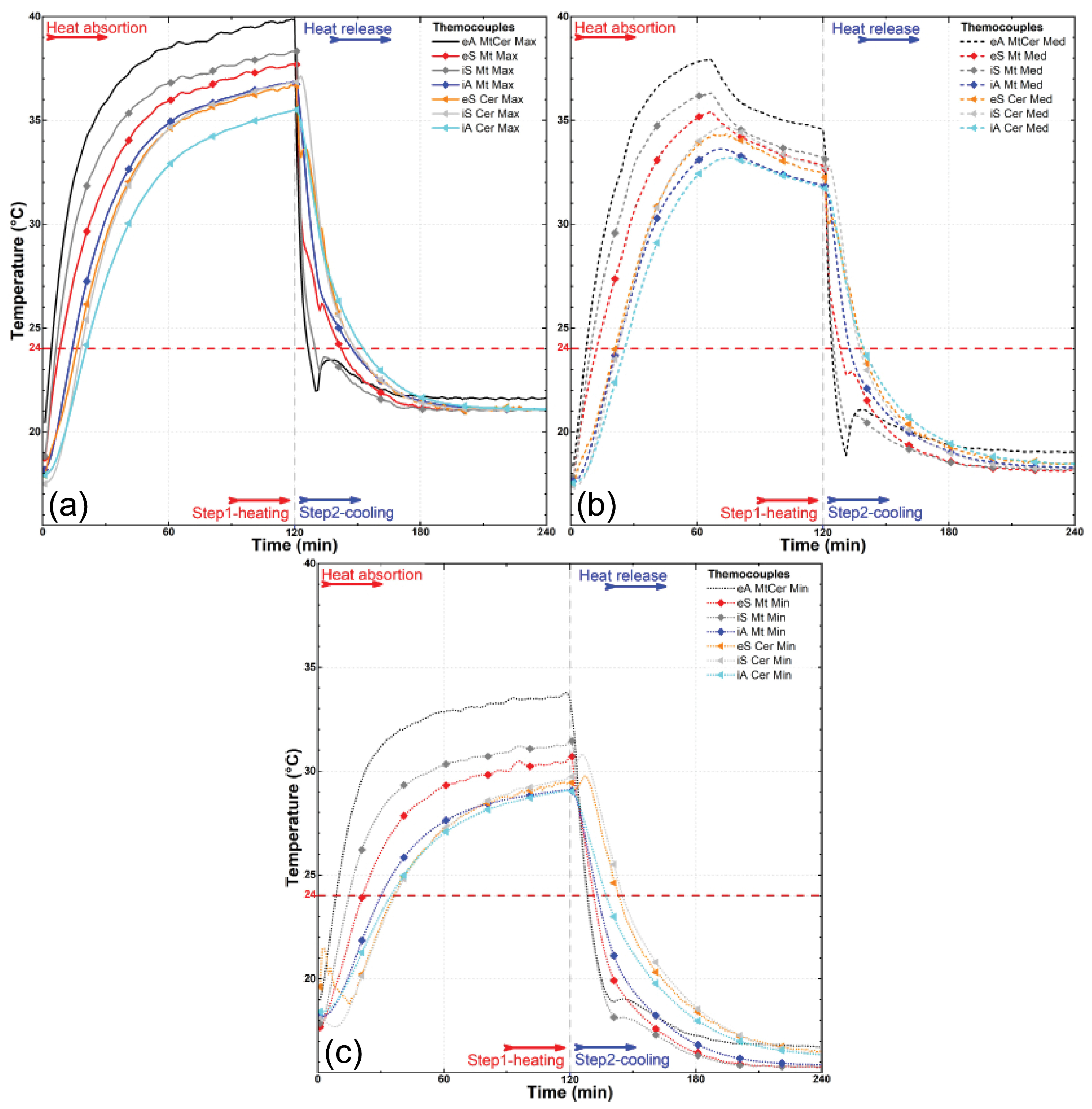

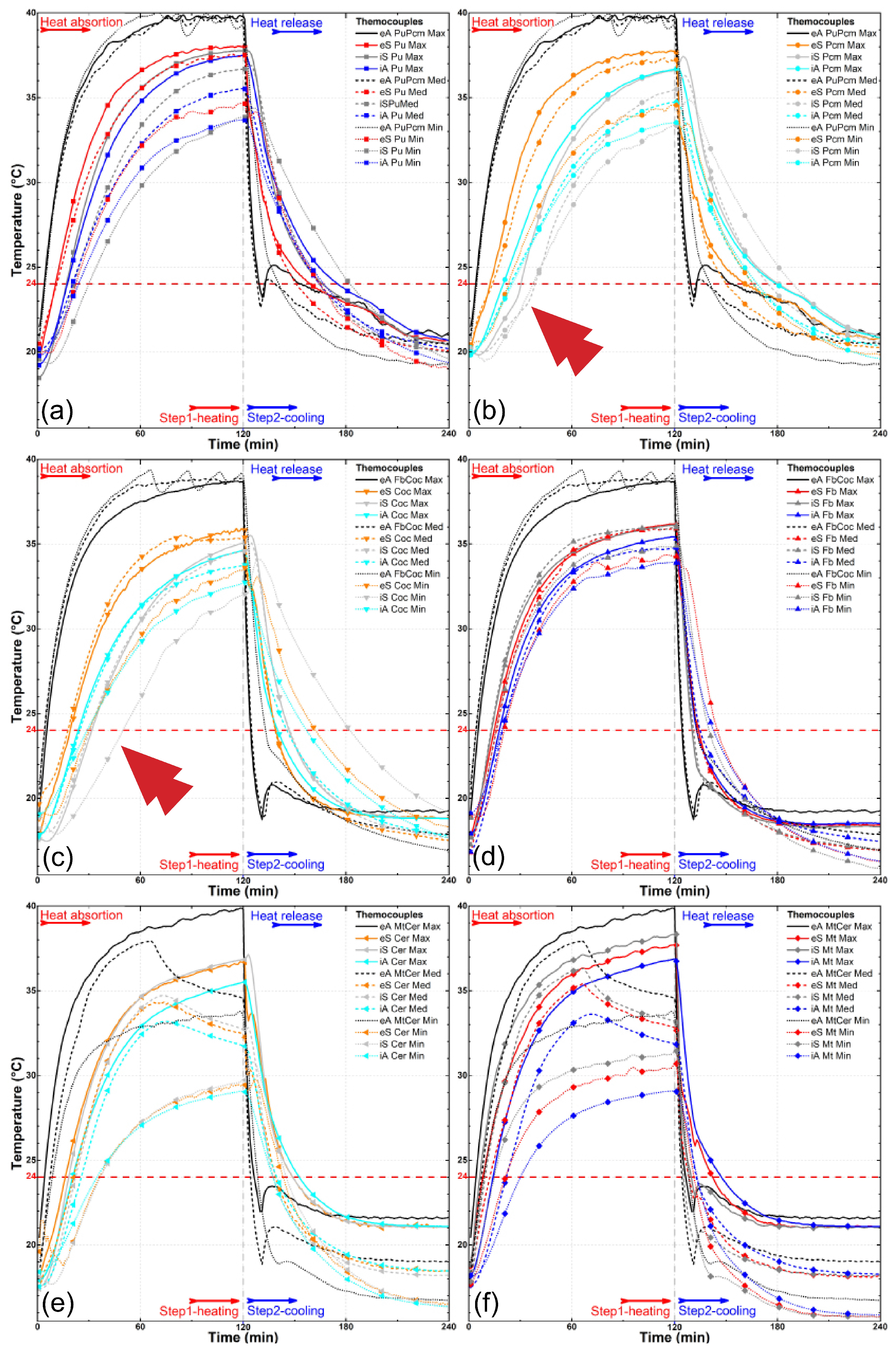

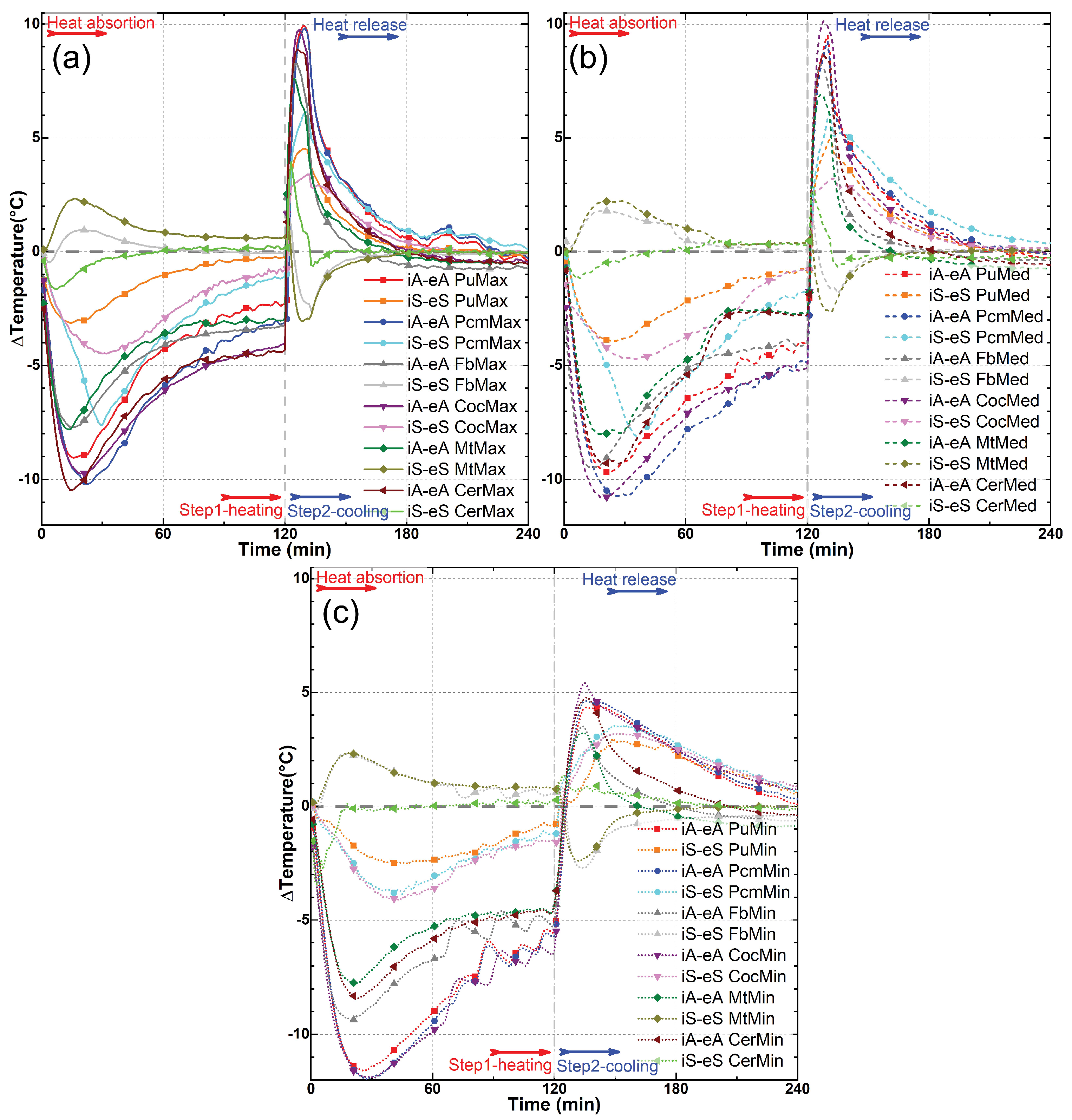

2.4. Thermal Variation in Wind Tunnel Assay

- External Air (eA) Temperature sensors: positioned at the geometric center of the wind tunnel volume.

- External Surface of the specimen (eS) temperature sensors: placed on the surface exposed to the environment of the wind tunnel of the evaluated barrier.

- Internal Surface of the specimen (iS) temperature sensors: placed on the surface exposed to the environment of the passive chamber of the evaluated barrier.

- Internal Air (iA) temperature sensors: positioned at the geometric center of the volume of the passive chambers.

3. Results and Discussion

3.1. Characterization

3.1.1. Microscopy and Ultrastructural Analysis

3.1.2. Thermogravimetric Analysis (TGA)

3.1.3. Fourier Transform Infrared Spectroscopy (FTIR)

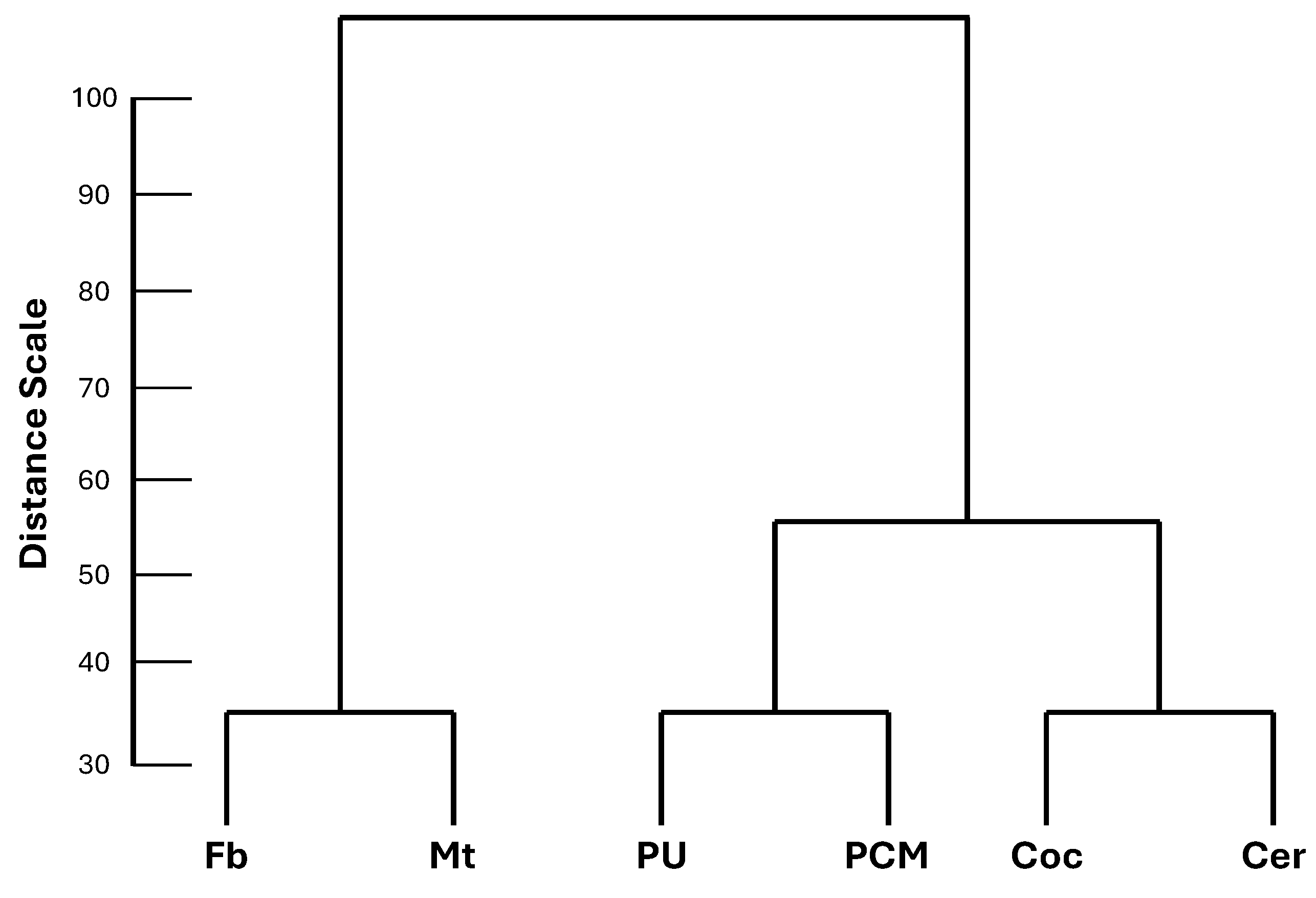

3.2. Thermal Variation in Wind Tunnel Assay

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Palani, V.; Goutham, P.; Ayyappadasan, R.; Praveena, E. The role of bamboo in sustainable business environment. In Degeneration to Regeneration-Alternative Approaches; Royal Book Publishing-International: Salem, India, 2020; pp. 27–32. [Google Scholar]

- Zhang, S.; Feng, D.; Shi, L.; Wang, L.; Jin, Y.; Tian, L.; Li, Z.; Wang, G.; Zhao, L.; Yan, Y. A review of phase change heat transfer in shape-stabilized phase change materials (ss-PCMs) based on porous supports for thermal energy storage. Renew. Sustain. Energy Rev. 2021, 135, 110127. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.; Chen, C.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Váz Sá, A.; Almeida, R.M.S.F.; Sousa, H.; Delgado, J.M.P.Q. Numerical Analysis of the Energy Improvement of Plastering Mortars with Phase Change Materials. Adv. Mater. Sci. Eng. 2014, 2014, 1–12. [Google Scholar] [CrossRef][Green Version]

- Silalahi, A.O.; Sukmawati, N.; Sutjahja, I.; Kurnia, D.; Wonorahardjo, S. Thermophysical Parameters of Organic PCM Coconut Oil from T-History Method and Its Potential as Thermal Energy Storage in Indonesia. IOP Conf. Ser. Mater. Sci. Eng. 2017, 214, 012034. [Google Scholar] [CrossRef]

- Huang, X.; Chen, X.; Li, A.; Atinafu, D.; Gao, H.; Dong, W.; Wang, G. Shape-stabilized phase change materials based on porous supports for thermal energy storage applications. Chem. Eng. J. 2019, 356, 641–661. [Google Scholar] [CrossRef]

- Liu, C.; Xiao, T.; Zhao, J.; Liu, Q.; Sun, W.; Guo, C.; Ali, H.M.; Chen, X.; Rao, Z.; Gu, Y. Polymer engineering in phase change thermal storage materials. Renew. Sustain. Energy Rev. 2023, 188, 113814. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, Y.; Liu, X.; Li, R.; Li, S.; Li, C. SiC-based porous ceramic carriers for heat-conductive phase change materials through carbothermal reduction method. Int. J. Appl. Ceram. Technol. 2021, 18, 91–99. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, W.; Shi, X.; Yao, C.; Kuai, C. Use of PEG/SiO2 phase change composite to control porous asphalt concrete temperature. Constr. Build. Mater. 2020, 245, 118459. [Google Scholar] [CrossRef]

- Zhang, X.; Yin, Z.; Meng, D.; Huang, Z.; Wen, R.; Huang, Y.; Min, X.; Liu, Y.; Fang, M.; Wu, X. Shape-stabilized composite phase change materials with high thermal conductivity based on stearic acid and modified expanded vermiculite. Renew. Energy 2017, 112, 113–123. [Google Scholar] [CrossRef]

- Liu, Y.; Xia, Y.; An, K.; Huang, C.; Cui, W.; Wei, S.; Ji, R.; Xu, F.; Zhang, H.; Sun, L. Fabrication and characterization of novel meso-porous carbon/n-octadecane as form-stable phase change materials for enhancement of phase-change behavior. J. Mater. Sci. Technol. 2019, 35, 939–945. [Google Scholar] [CrossRef]

- Fang, G.; Li, H.; Chen, Z.; Liu, X. Preparation and characterization of stearic acid/expanded graphite composites as thermal energy storage materials. Energy 2010, 35, 4622–4626. [Google Scholar] [CrossRef]

- Guimarães, T.C.; Gomes, O.d.F.M.; Oliveira de Araújo, O.M.; Tadeu Lopes, R.; da Gloria, M.Y.R.; Toledo Filho, R.D.; Koenders, E.; Caggiano, A.; Mankel, C.; Nazari Sam, M.; et al. PCM-Impregnated Textile-Reinforced Cementitious Composite for Thermal Energy Storage. Textiles 2023, 3, 98–114. [Google Scholar] [CrossRef]

- Rios, R.; Farias, G. Invasão de bambu dourado (phyllostachys aurea) altera a estrutura e a diversidade da regeneração natural em um fragmento florestal urbano localizado em curitiba, pr. Enciclopédia Biosf. 2021, 18. [Google Scholar] [CrossRef]

- Fontenelle, F.; Ferreira, S.R. Bamboo-PCM: The use of Phyllostachys aurea culms as a receptacle for thermal storage through phase change material impregnation. In Proceedings of the 12th World Bamboo Congress, Hong Kong, 10–12 April 2024; p. 20. [Google Scholar]

- Cattafesta, L.; Bahr, C.; Mathew, J. Fundamentals of Wind-Tunnel Design. In Encyclopedia of Aerospace Engineering; Number November 2017; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar] [CrossRef]

- Crodatherm. CrodaTherm™ 24 Ambient Temperature Phase Change Material; Technical Report; Croda International: Snaith, UK, 2020. [Google Scholar]

- Sinergia. PU Vegetal-Tipo “V”; Technical report; Sinergia Service Ltd.: Araraquara, Brazil, 2020. [Google Scholar]

- NBR 16828-2:2020; Bamboo Structures Part 2: Determination of Physical and Mechanical Properties of Bamboo. ABNT: Rio de Janeiro, Brazil, 2020.

- Forest Products Laboratory (US). Wood Handbook: Wood as an Engineering Material; Number 72; Forest Products Laboratory (US): Madison, WI, USA, 2010. [Google Scholar]

- Moreschi, J.C. Propriedades da Madeira. 2005. Available online: http://www.madeira.ufpr.br/disciplinasmoreschi/PROPRIEDADES%20DA%20MADEIRA.pdf (accessed on 20 September 2024).

- Moura, C.R.; Dalla, L.V.O.; Vieira, A.J.T. Avaliação da perda de massa de colmos de bambu durante o processo de secagem. Engevista 2018, 20, 476. [Google Scholar] [CrossRef]

- Zen, L.R.; Monteiro, T.C.; Schaeffer, W.; Kaminski, J.M.; Klitzke, R.J. Secagem ao ar livre da madeira serrada de eucalipto. J. Biotechnol. Biodivers. 2019, 7, 291–298. [Google Scholar] [CrossRef]

- Krause, J.Q. Micro e Macromecânica de lâMinas de Bambu Dendrocalamus Giganteus Para Aplicações Estruturais. Ph.D. Thesis, PUC-Rio, Rio de Janeiro, Brazil, 2015. [Google Scholar]

- Júnior, A.d.S.S. Avaliação do Efeito de Parâmetros Microestruturais e de Processo de Impregnação de Fluidos em Colmos de Bambusa Vulgaris. Ph.D. Thesis, UFPB, Joao Pessoa, Brazil, 2012. [Google Scholar]

- Bahuti, M.; Yanagi Junior, T.; de Lima, R.R.; Fassani, É.J.; Ribeiro, B.P.V.B.; Campos, A.T.; Abreu, L.H.P. Statistical and fuzzy modeling for accurate prediction of feed intake and surface temperature of laying hens subjected to light challenges. Comput. Electron. Agric. 2023, 211, 108050. [Google Scholar] [CrossRef]

- Dominick, D.; Juahir, H.; Latif, M.T.; Zain, S.M.; Aris, A.Z. Spatial assessment of air quality patterns in Malaysia using multivariate analysis. Atmos. Environ. 2012, 60, 172–181. [Google Scholar] [CrossRef]

- Lau, J.; Hung, W.T.; Cheung, C.S. Interpretation of air quality in relation to monitoring station’s surroundings. Atmos. Environ. 2009, 43, 769–777. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, S.; Kim, H.J.; Yang, H.S. Thermal properties of bio-flour-filled polyolefin composites with different compatibilizing agent type and content. Thermochim. Acta 2006, 451, 181–188. [Google Scholar] [CrossRef]

- Poletto, M.; Ornaghi, H.; Zattera, A. Native Cellulose: Structure, Characterization and Thermal Properties. Materials 2014, 7, 6105–6119. [Google Scholar] [CrossRef] [PubMed]

- Azevedo, E.C.; Santana, S.S.d.M.; Nascimento, E.M.d.; Claro Neto, S.; Lepienski, C.M. Caracterização de adesivo de poliuretano derivada do óleo de mamona por FTIR, TGA e XRD. In Proceedings of the Congresso Brasileiro de Polímeros; Associação Brasileira de Polímeros—ABPol: São Carlos, Brazil, 2009; p. 590. [Google Scholar]

- Müller, L.; Rubio-Pérez, G.; Bach, A.; Muñoz-Rujas, N.; Aguilar, F.; Worlitschek, J. Consistent DSC and TGA Methodology as Basis for the Measurement and Comparison of Thermo-Physical Properties of Phase Change Materials. Materials 2020, 13, 4486. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, A.D.G.; Galzerani, J.C. Espectroscopias de infravermelho, Raman e de fotoluminescência: Potencialidades e complementaridades. Rev. Bras. Ensino Física 2012, 34, 4309. [Google Scholar] [CrossRef]

- Fredericci, C.; Ferreira, D.C.; Oliveira, M.C.B.; Pinto, N.d.S. Aplicação da espectroscopia raman na identificação de minerais asbestiformes. Revista IPT 2016, 1. [Google Scholar]

- Sánchez, M.L.; Morales, L.Y.; Caicedo, J.D. Physical and mechanical properties of agglomerated panels made from bamboo fiber and vegetable resin. Constr. Build. Mater. 2017, 156, 330–339. [Google Scholar] [CrossRef]

- Liu, Z.; Fei, B. Characteristics of Moso Bamboo with Chemical Pretreatment. In Sustainable Degradation of Lignocellulosic Biomass—Techniques, Applications and Commercialization; InTech: Houston, TX, USA, 2013. [Google Scholar] [CrossRef][Green Version]

| Property | Typical Value | Unit |

|---|---|---|

| Thermal properties by differential scanning calorimetry (DSC) | ||

| Peak melting temperature | 24 | °C |

| Latent heat (melting) | 184 | kJ/kg |

| Peak crystallization temperature | 22 | °C |

| Latent heat (crystallization) | −182 | kJ/kg |

| Thermal properties by three-layer calorimetry (3LC) | ||

| Peak melting temperature | 23 | °C |

| Total heat capacity (melting) | 207 | kJ/kg |

| Peak crystallization temperature | 23 | °C |

| Total heat capacity (crystallization) | 213 | kJ/kg |

| Other properties | ||

| Bio-based content | 100 | % |

| Density at 20 °C (solid) | 906 | kg/m³ |

| Density at 40 °C (liquid) | 843 | kg/m³ |

| Flash point | 226 | °C |

| Specific heat capacity (solid) | 3.7 | kJ/kg °C |

| Specific heat capacity (liquid) | 2.2 | kJ/kg °C |

| Volume expansion 20–40 °C | 7.5 | % |

| Thermal conductivity (solid) | 0.22 | W/m °C |

| Thermal conductivity (liquid) | 0.16 | W/m °C |

| Thermal cycles without change in properties | 10,000 | cicles |

| Treatment | Objective | Label |

|---|---|---|

| Bamboo specimens (Dendrocalamus giganteus) | ||

| Sealed with PU | control | PU |

| PCM impregnated and sealed with PU | analysis 1 | PCM |

| Coconut oil impregnated and sealed with PU | analysis 2 | Coc |

| Commonly used building materials | ||

| Ceramic tiles | reference 1 | Cer |

| Fiber cement tile | reference 2 | Fb |

| Metal sheet | reference 3 | Mt |

| Culms Average General Dimensions (mm) | Average Characteristics of the Nodes | |||

|---|---|---|---|---|

| Diameter [Ø] | Length [l] | Wall thickness [t] | Amount | Average distance (mm) [n] |

| 140 | 250 | 8 | 0 | 450 |

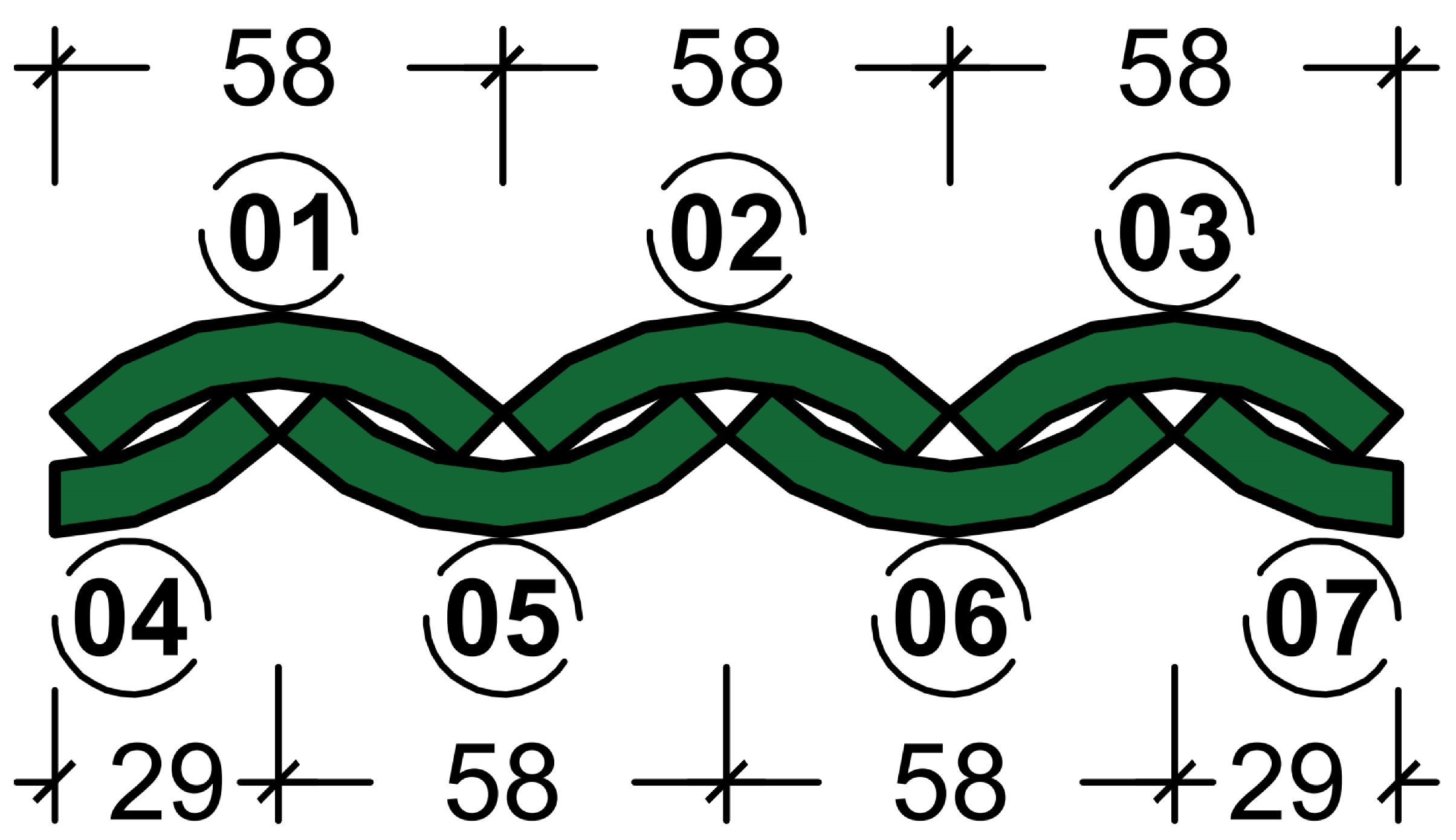

| Species | Cross-Sectional Diagram and Sample Organization |  |

|---|---|---|

| Average dimensions (mm) | ||

| Dendrocalamus giganteus |  | a = 58; b = 50; c = 8; d = 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fontenelle, F.R.; Guimarães, T.C.; Yanagi Junior, T.; Bahuti, M.; Toledo Filho, R.D.; Koenders, E.; Ferreira, S.R. Bamboo–PCM: Comparative Analysis of Phase Change Material-Impregnated Dendrocalamus giganteus Culm Behavior Exposed to Thermal Variation in Wind Tunnel Assay. Materials 2025, 18, 675. https://doi.org/10.3390/ma18030675

Fontenelle FR, Guimarães TC, Yanagi Junior T, Bahuti M, Toledo Filho RD, Koenders E, Ferreira SR. Bamboo–PCM: Comparative Analysis of Phase Change Material-Impregnated Dendrocalamus giganteus Culm Behavior Exposed to Thermal Variation in Wind Tunnel Assay. Materials. 2025; 18(3):675. https://doi.org/10.3390/ma18030675

Chicago/Turabian StyleFontenelle, Fabrício Rezende, Túlio Caetano Guimarães, Tadayuki Yanagi Junior, Marcelo Bahuti, Romildo Dias Toledo Filho, Eddie Koenders, and Saulo Rocha Ferreira. 2025. "Bamboo–PCM: Comparative Analysis of Phase Change Material-Impregnated Dendrocalamus giganteus Culm Behavior Exposed to Thermal Variation in Wind Tunnel Assay" Materials 18, no. 3: 675. https://doi.org/10.3390/ma18030675

APA StyleFontenelle, F. R., Guimarães, T. C., Yanagi Junior, T., Bahuti, M., Toledo Filho, R. D., Koenders, E., & Ferreira, S. R. (2025). Bamboo–PCM: Comparative Analysis of Phase Change Material-Impregnated Dendrocalamus giganteus Culm Behavior Exposed to Thermal Variation in Wind Tunnel Assay. Materials, 18(3), 675. https://doi.org/10.3390/ma18030675