Process Parameters Analysis in Diamond Wire Saw Cutting NdFeB Magnet

Abstract

1. Introduction

2. Materials and Methods

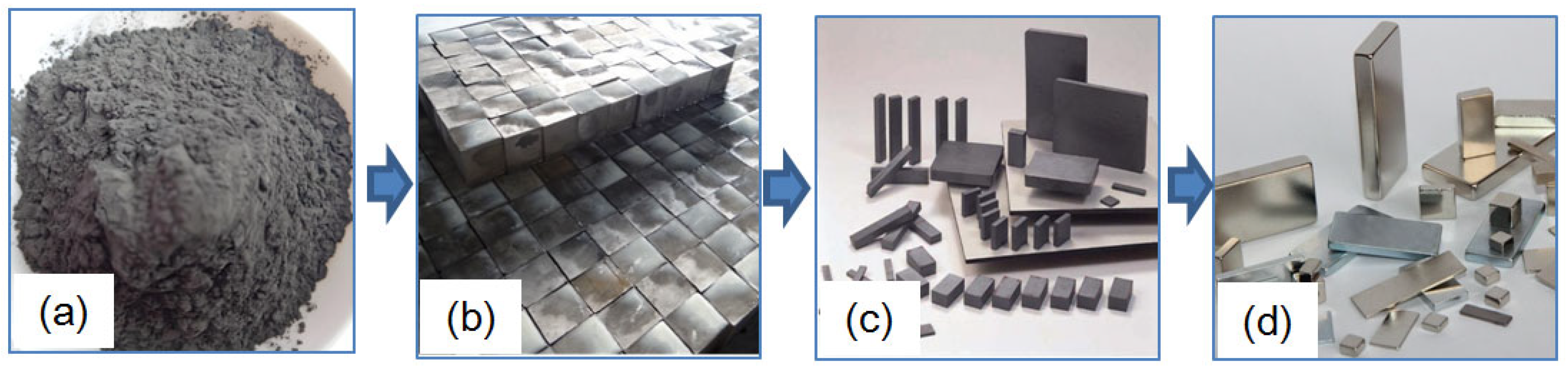

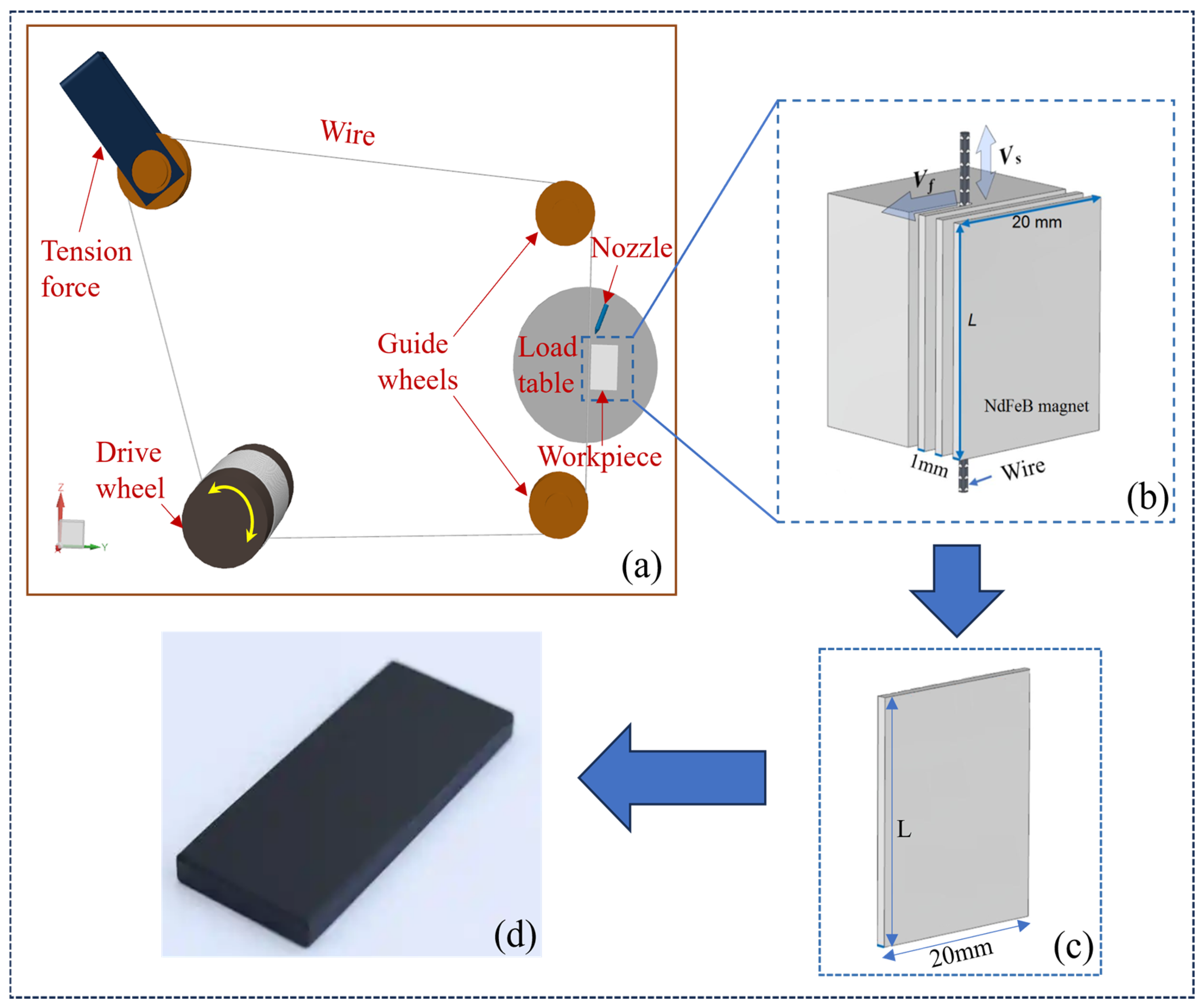

2.1. Experimental Materials and Equipment

2.2. Experimental Design

2.3. Evaluation Methods for Slice Surface Characteristics

3. Results and Discussion

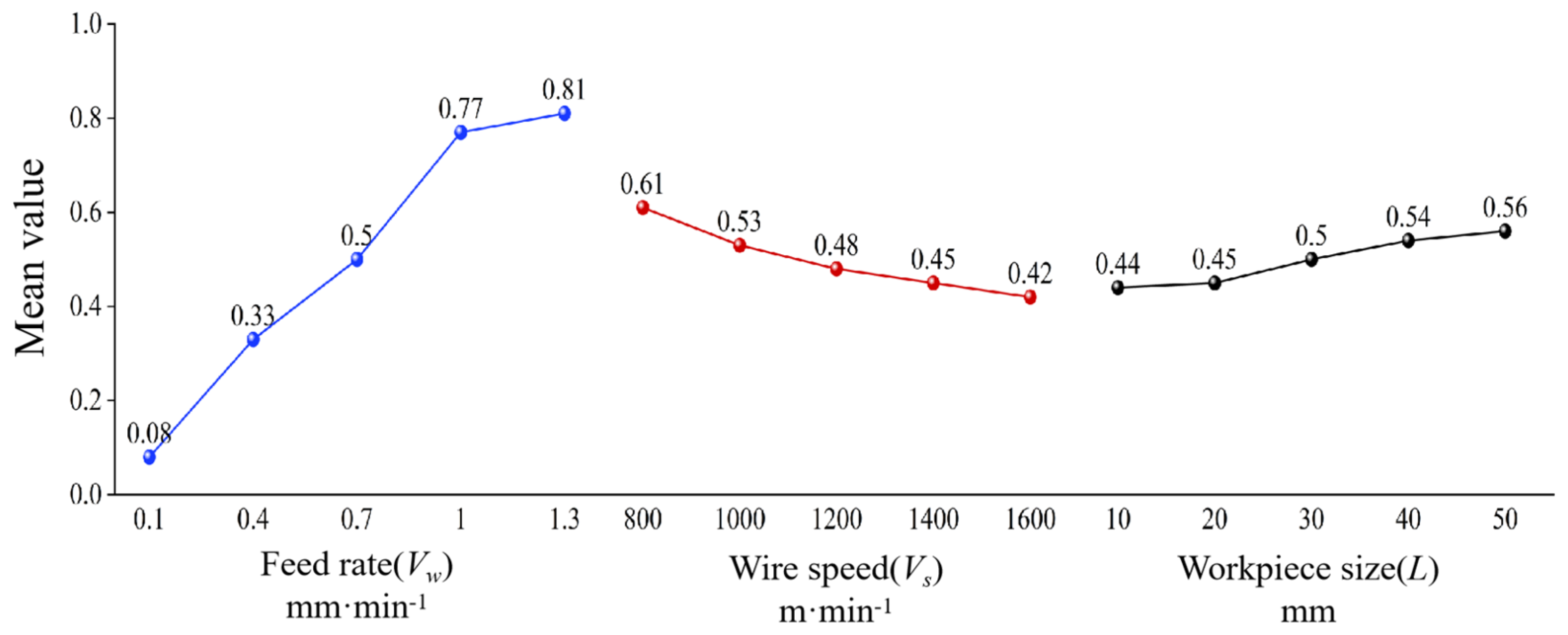

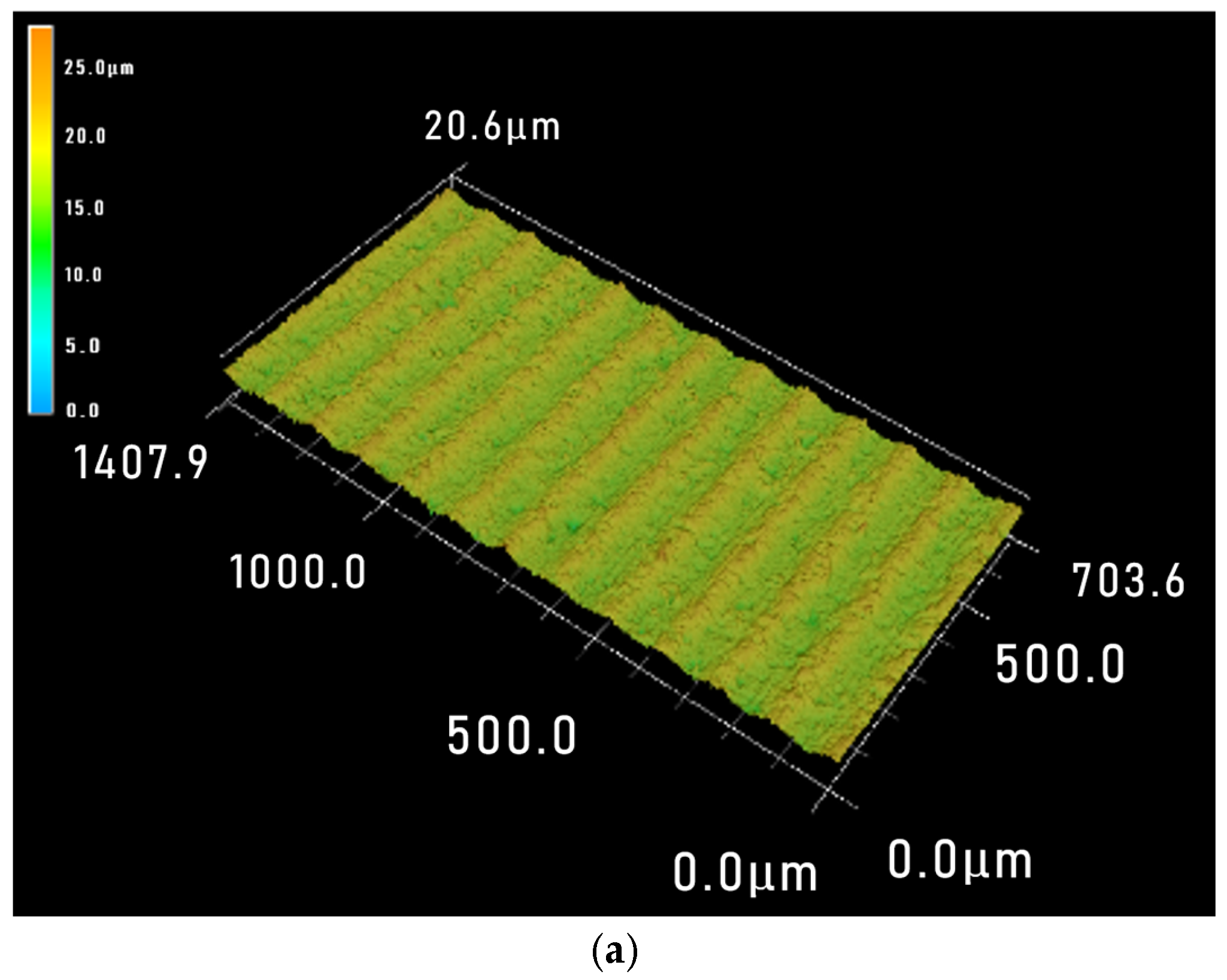

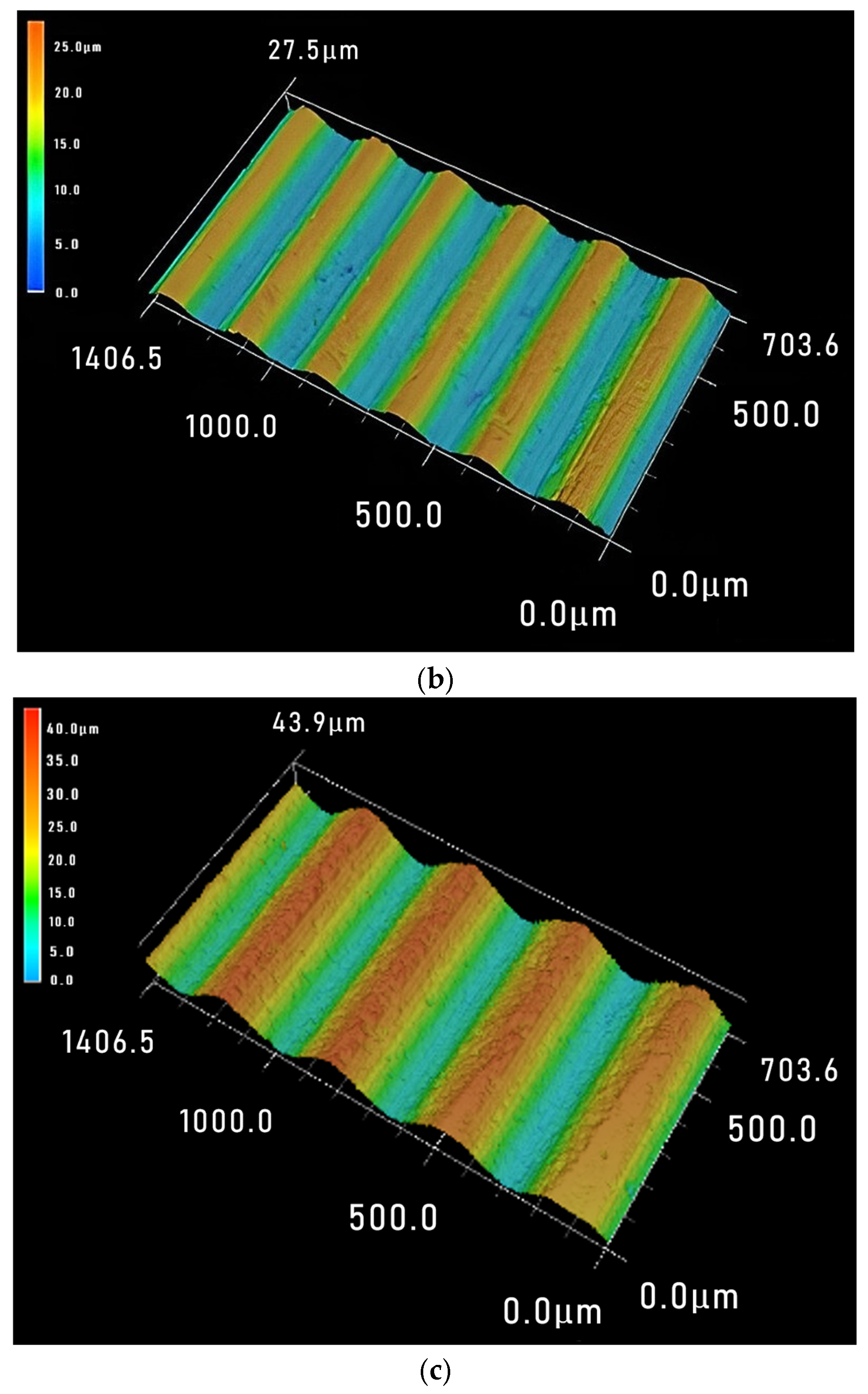

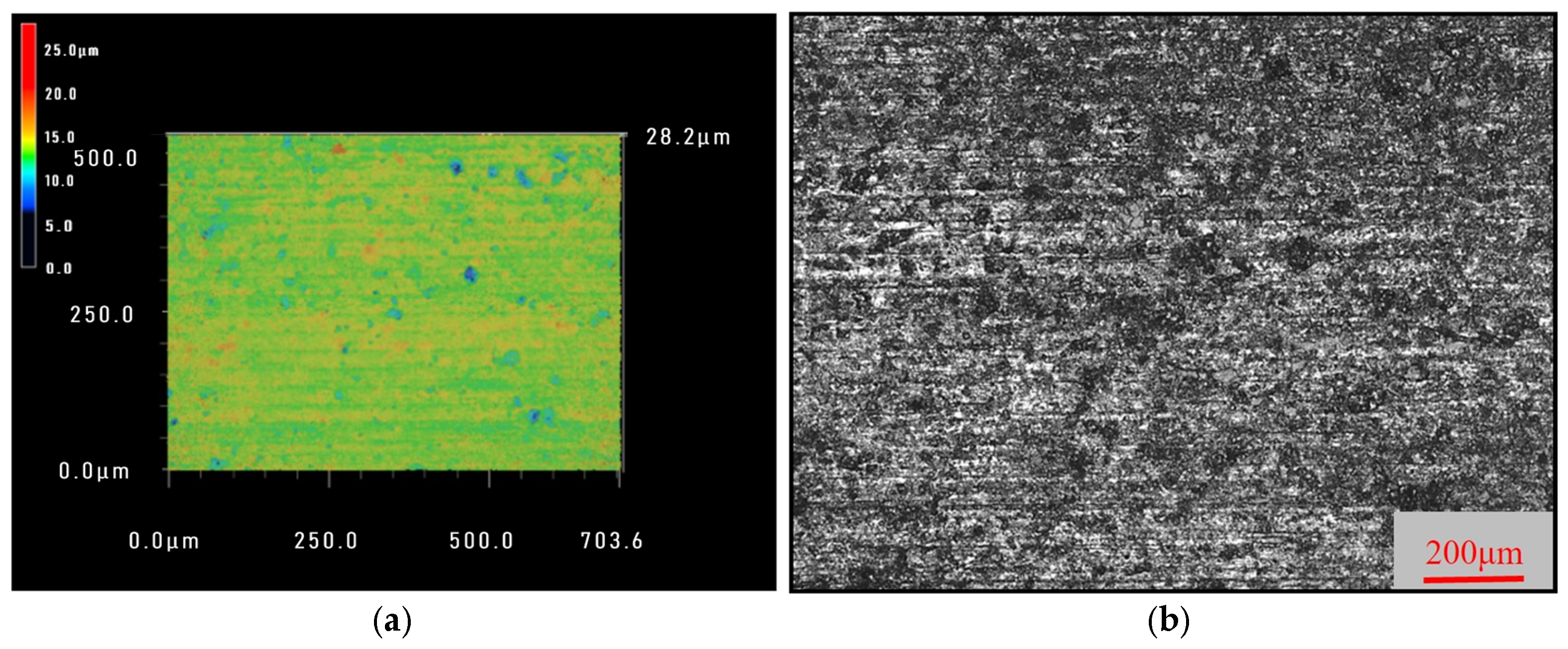

3.1. Effect of Process Parameters on Surface Roughness

3.2. Effect of Process Parameters on Surface Waviness

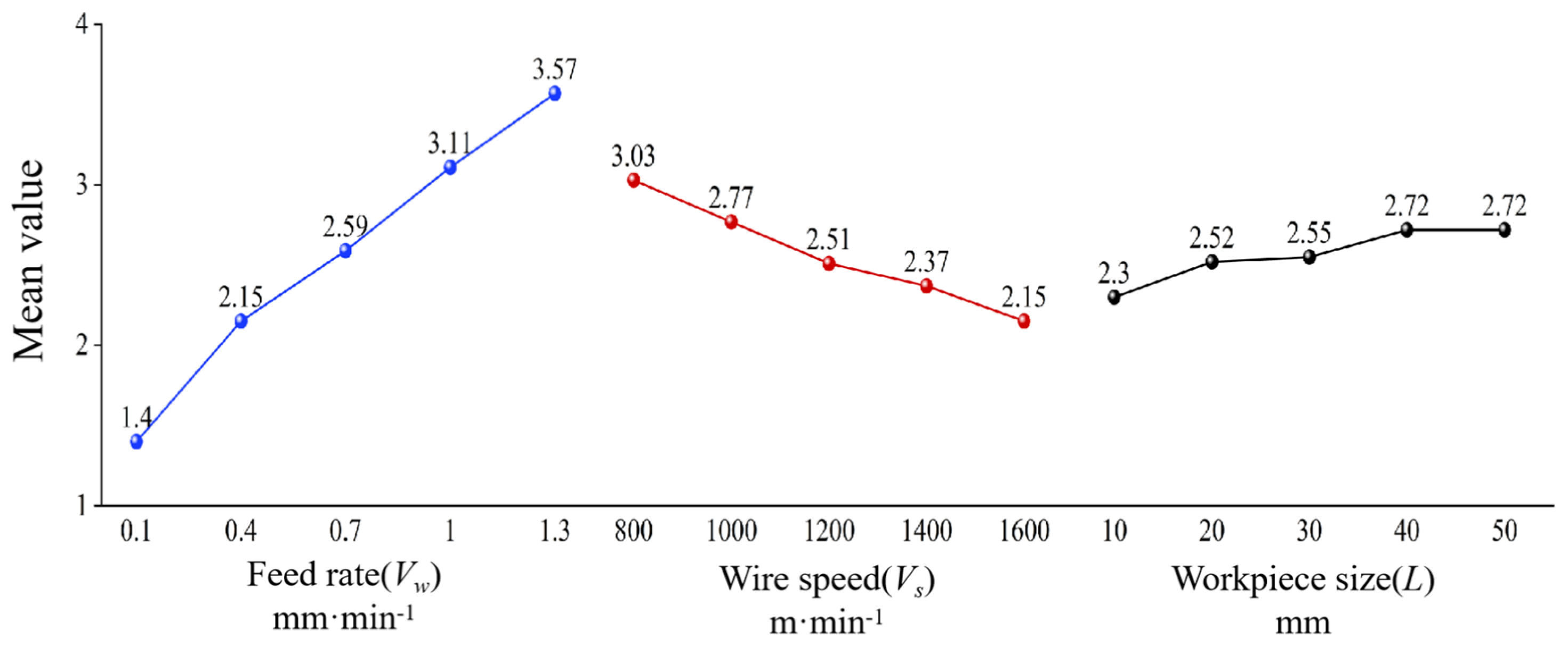

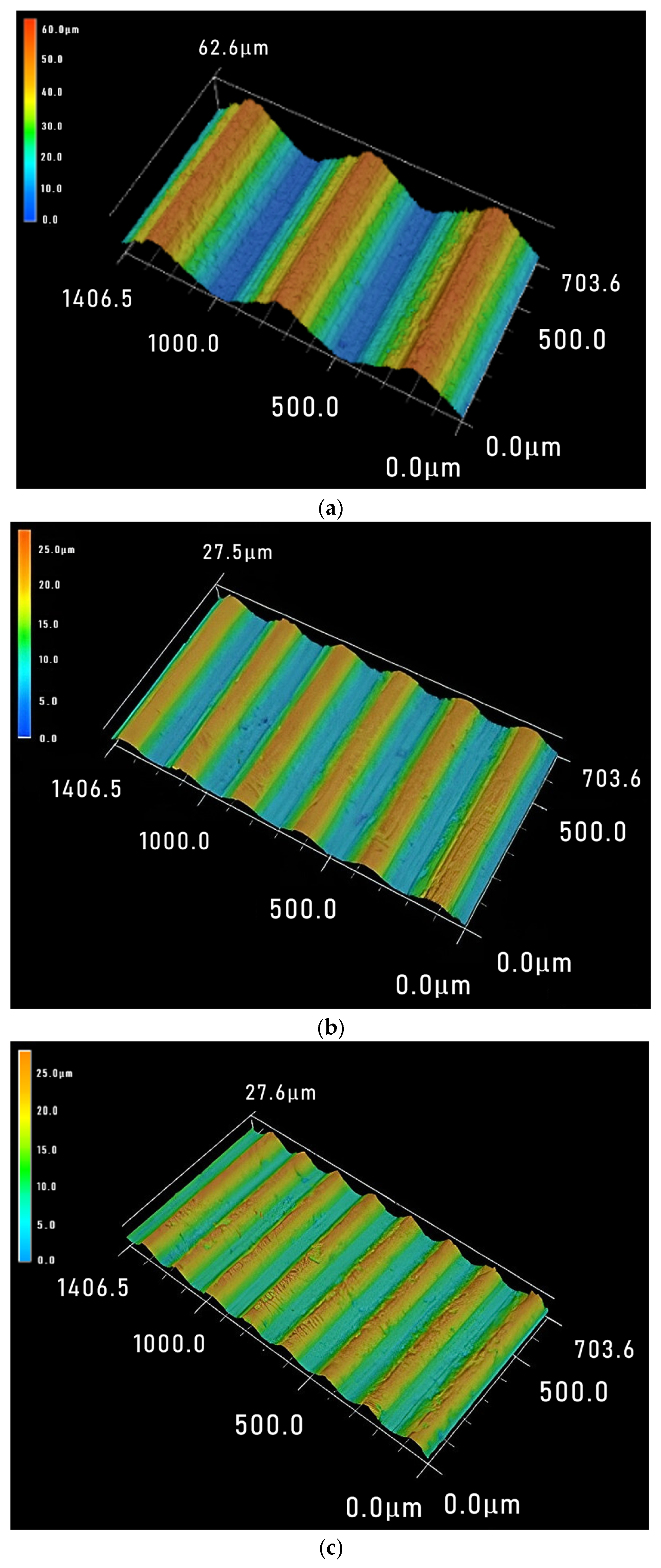

3.3. Sawing Results by Using Optimal Process Parameter Combination

4. Conclusions

- (1)

- The sawing process parameters show a consistent trend in their impact on surface roughness Ra and waviness Wa. The decrease in workpiece feed rate and size, as well as the increase in wire speed, are beneficial for improving surface roughness and waviness. The order of the influence of various processing parameters on surface roughness Ra and waviness Wa is workpiece feed rate, wire speed, and workpiece size, and the influence of process parameters on the waviness PV value also shows a consistent trend.

- (2)

- The optimal combination of process parameters based on minimum Ra and Wa is consistent, which is that workpiece feed rate is 0.1 mm·min−1, wire speed is 1600 m·min−1, and workpiece size is 10 mm. Correspondingly, Ra is 0.433 μm and Wa is 0.037 μm. The regression equation for PV values established based on experimental data are PV = 0.747 × Vs−0.342 × Vw0.546 × L0.109.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Chang, S.; Bao, X.; Yu, H.; Guan, S.; Zhu, K.; Zheng, Y.; Li, J.; Gao, X. Interpretable Prediction of Remanence in Sintered NdFeB through Machine Learning Strategy. J. Alloys Compd. 2024, 1008, 176727. [Google Scholar] [CrossRef]

- Yang, Y.; Jiang, N.; Sun, Y.; Yang, L.; Guan, C.; Zhang, E.; Fanf, X.; Liu, J. Structure and Corrosion Resistance Characteristics of ZnAl/EP Coating on Bonded NdFeB Magnet. J. Mater. Eng. Perform. 2023, 32, 5475–5482. [Google Scholar] [CrossRef]

- Yang, T.; Zhu, X.; Zhao, W.; Zhao, Q.; Liu, G. Low Temperature Machining Advantages for Sintered NdFeB Magnets: A Comparative Experimental Study of WAWJ with Laser and WEDM. J. Mater. Eng. Perform. 2024, 610, 172589. [Google Scholar] [CrossRef]

- Greer, J.; Petruska, A.; Mahoney, A.; Nambi, M.; Bamberg, E.; Abbott, J. Experimental Investigation of Wire Electrical Discharge Machining of NdFeB Permanent Magnets with an RC-Type Machine. J. Mater. Eng. Perform. 2014, 23, 1392–1401. [Google Scholar] [CrossRef]

- Wang, C.; Lian, Z.; Yu, P.; Xu, J. Experimental Study on Magnetic Field Assisted WEDM Machining Sintered NdFeB. Mach. Des. Manuf. 2022, 10, 32–40. [Google Scholar] [CrossRef]

- Ma, X.; Teng, K. Research on High Efficiency and Low Loss Cutting of NdFeB Permanent Magnet Material by WEDM. Manuf. Technol. Mach. Tool. 2017, 4, 97–101. [Google Scholar]

- Wang, L.; Zhang, J.; Xu, Y.; Han, W.; Zhou, L. Effect of Fiber Laser Cutting Technology on Sintered NdFeB Magnetic Performance. Met. Funct. Mater. 2023, 30, 80–86. [Google Scholar] [CrossRef]

- Ren, N.; Liu, G.; Li, X.; Tong, Z. Simulation Analysis of Temperature Field of Laser Cut Ndfeb Magnetic Material. Manuf. Technol. Mach. Tool 2020, 1, 25–29. [Google Scholar] [CrossRef]

- Ma, C.; Liu, G.; Li, X.; Ding, L. Study on the Effect of Sintered NdFeB Laser Cutting Quality Technology. Manuf. Technol. Mach. Tool 2019, 3, 113–117. [Google Scholar] [CrossRef]

- Yao, C.; Yu, X.; Feng, L.; Wang, F.; Wang, F.; Yuan, Q. Development of Microencapsulated Phase Change Material Slurry for Diamond Wire Sawing Silicon Wafer and Its Effect on Cutting Quality. J. Manuf. Process. 2024, 127, 421–432. [Google Scholar] [CrossRef]

- Qiu, J.; Li, X.; Ge, R.; Wu, R.; Liu, C. Surface Formation, Morphology, Integrity and Wire Marks in Diamond Wire Slicing of Mono-Crystalline Silicon in the Photovoltaic Industry. Wear 2022, 488–489, 204186. [Google Scholar] [CrossRef]

- Wang, J.; Li, S.; Liang, L.; Hao, Z.; Liu, F.; Landers, R. Cutting Force Modeling and Control of Single Crystal Silicon using Wire Saw Velocity Reciprocation. Proc. Inst. Mech. Eng. B-J. Eng. Manuf. 2024, 238, 823–836. [Google Scholar] [CrossRef]

- Ban, X.; Li, Y.; Han, S.; Qiu, H.; Wang, X.; Cui, Z. Parameters optimization for ferrite slicing based on grey theory. Diam. Abras. Eng. 2022, 42, 332–337. [Google Scholar] [CrossRef]

- Sefene, E.; Chen, C.; Yang, J. Sustainable Assessment of Diamond Wire Sawing for Monocrystalline Silicon Wafers: Conventional and Electrophoretic Cooling strategies. Manuf. Lett. 2025, 43, 46–50. [Google Scholar] [CrossRef]

- Costa, E.; Bellen, B.; Werner, M.; Sousa, P.; Xavier, F. Optimizing the Diamond Wire Sawing of Polycrystalline Silicon: An Experimental Approach. Mater. Sci. Semicond. Proc. 2024, 185, 108938. [Google Scholar] [CrossRef]

- Zhu, Z.; Gao, Y.; Zhang, X. Study on Subsurface Microcrack Damage Depth of Diamond Wire as-Sawn Sapphire Crystal Wafers. Eng. Fract. Mech. 2023, 28, 109347. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, H.; Wang, L.; Liao, X. Experimental Study on Normal Force of Cutting Sapphire with Multi-Wire Swing Reciprocating Wire Saw. Diam. Abras. Eng. 2024, 44, 143–150. [Google Scholar] [CrossRef]

- Yang, H.; Fu, M.; Zhang, X.; Zhu, K.; Cao, L.; Hu, C. Material Removal Mechanisms of Polycrystalline Silicon Carbide Ceramic Cut by a Diamond Wire Saw. Materials 2024, 17, 4238. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, S.; Zhang, X.; Yuchi, G.; Duan, J.; Jiang, R.; Zhou, Y. Study on Mechanism and Process of Cutting Silicon Carbide Ceramics with Diamond Wire Saw. Diam. Abras. Eng. 2021, 41, 60–67. [Google Scholar] [CrossRef]

- Seeholzer, L.; Süssmaier, S.; Kneubühler, F.; Wegener, K. Experimental Investigation of The Machining Characteristics in Diamond Wire Sawing of Unidirectional CFRP. Int. J. Adv. Manuf. Technol. 2021, 117, 2197–2212. [Google Scholar] [CrossRef]

- Magdalena, W.; Mateusz, P.; Christian, G.; Dariusz, P. Investigation of Abrasive Cutting of Ceramic Matrix Composites Based on Thin-Walled Elements using Diamond Wire. Tehnički Vjesnik 2022, 29, 641–645. [Google Scholar] [CrossRef]

- Liu, Y.; Gao, Y.; Li, G.; Shi, Z. Influences of Fiber Orientation and Process Parameters on Diamond Wire Sawn Surface Characteristics of 2.5D Cf/SiC Composites. Mater. Today Commun. 2024, 41, 110421. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Z.; Wan, S.; Wu, B.; Feng, J.; Zhang, T.; Zhou, C. Experimental and Theoretical Investigations on Diamond Wire Sawing for a NdFeb Magnet. Materials 2022, 15, 3034. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.; Zhang, Z.; Feng, J.; Meng, F.; Wan, S.; Zhuang, X.; Li, L.; Liu, H.; Zhang, F. Experimental Investigation on the Surface Formation Mechanism of Ndfeb During Diamond Wire Sawing. Materials 2023, 16, 1521. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, Y.; Yang, C.; Shi, Z. Surface Characteristics of Precision As-Cut NdFeB Magnet Considering Diamond Wire Wear. Precis. Eng. 2024, 89, 23–36. [Google Scholar] [CrossRef]

- Costa, E.; Lima, A.; Santos, M.; Souza, R.; Wendhausen, P.; Xavier, F. On the Mechanical Behavior of the Sintered Nd-Fe-B Permanent Magnet during Diamond Scratching. J. Manuf. Process. 2023, 94, 79–93. [Google Scholar] [CrossRef]

- Sopori, B.; Basnyat, P.; Devayajanam, S.; Schnepf, R.; Sahoo, S.; Gee, J.; Severico, F.; Manens, A.; Seigneur, H.; Scjoenfeld, W. Analyses of Diamond Wire Sawn Wafers: Effect of Various Cutting Parameters. In Proceedings of the IEEE 42nd Photovoltaic Specialist Conference, New Orleans, LA, USA, 14–19 June 2015. [Google Scholar] [CrossRef]

- Gupta, A.; Chen, C.; Hsu, H. Study on Diamond Wire Wear, Surface Quality, and Subsurface Damage during Multi-Wire Slicing of C-Plane Sapphire Wafer. Int. J. Adv. Manuf. Technol. 2019, 100, 1801–1814. [Google Scholar] [CrossRef]

- Costa, E.; Weingaertner, W.; Xavier, F. Influence of Single Diamond Wire Sawing of Photovoltaic Monocrystalline Silicon on the Feed Force, Surface Roughness and Micro-crack Depth. Mater. Sci. Semicond. Proc. 2022, 143, 106525. [Google Scholar] [CrossRef]

- Wang, J.; Li, S.; Liang, L. Experiment Comparative Analysis of Feed Rate with Velocity Control in Cutting Mono Crystalline Silicon Using a Diamond Wire Saw. Micromachines 2024, 15, 473. [Google Scholar] [CrossRef]

- Guo, Y.; Gao, Y.; Yang, C. Sawing Force Modeling and Analysis for Diamond Wire Sawing PV Monocrystalline Silicon Considering Abrasive Wear. Wear 2025, 562–563, 205669. [Google Scholar] [CrossRef]

- Guo, Y.; Gao, Y.; Zhang, X.; Shi, Z. Wire Bow Analysis Based on Process Parameters in Diamond Wire Sawing. Int. J. Adv. Manuf. Technol. 2024, 131, 2909–2924. [Google Scholar] [CrossRef]

- Yin, Y.; Gao, Y.; Li, X.; Pu, T.; Wang, L. Experimental Study on Slicing Photovoltaic Polycrystalline Silicon with Diamond Wire Saw. Mater. Sci. Semicond. Proc. 2020, 106, 104779. [Google Scholar] [CrossRef]

- Liedke, T.; Kuna, M. A Macroscopic Mechanical Model of the Wire Sawing Process. Int. J. Mach. Tools Manuf. 2011, 51, 711–720. [Google Scholar] [CrossRef]

- Lai, Z.; Liao, X.; Yang, H.; Hu, Z.; Huang, H. Experimental Study on the Formation Mechanism of Saw Marks in Wire Sawing. Int. J. Mech. Sci. 2024, 265, 108894. [Google Scholar] [CrossRef]

- Louise, C.; Roland, R.; Daniel, N.; Marion, F.; Fabrice, C.; Ainal, C. Comparative Analysis of Mechanical Strength of Diamond-Sawn Silicon Wafers Depending on Saw Mark Orientation, Crystalline Nature and Thickness. Sol. Energy Mater. Sol. Cells 2019, 201, 110068. [Google Scholar] [CrossRef]

- Jung, I.; Song, S.; Choi, M.; Yu, H.; Kim, S. Evolution of Mechanically Formed Bow Due to Surface Waviness and Residual Stress Difference on Sapphire (0001) Substrate. J. Mater. Process. Technol. 2019, 269, 102–108. [Google Scholar] [CrossRef]

- Teomete, E. Investigation of Long Waviness Induced by the Wire Saw Process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 1153–1162. [Google Scholar] [CrossRef]

- Li, G.; Gao, Y.; Huang, W.; Shi, Z. Improvement of Wire Marks on the Surface of Si3N4 Ceramics Cut by Diamond Wire Saw. Mater. Sci. Eng. B-Adv. 2024, 310, 117725. [Google Scholar] [CrossRef]

- Wen, B. Mechanical Design Manual, 6th ed.; China Machine Press: Beijing, China, 1997. [Google Scholar]

| Parameters | Values |

|---|---|

| Diamond saw wire length (m) | 70 |

| Diameter of saw wire core (μm) | 220 |

| Type of abrasives | Nickel-coated diamond |

| Abrasive size (μm) | 70–85 |

| Abrasive distribution density (grits·mm−1) | 15–20 |

| Tensile limit of saw wire (MPa) | 3275 |

| Moh’s hardness of saw wire (nickel plating) | 5 |

| Levels | Factors | ||

|---|---|---|---|

| (A) Feed Rate (Vw) /mm·min−1 | (B) Wire Speed (Vs) /m·min−1 | (C) Workpiece Size (L) /mm | |

| 1 | 0.1 (A1) | 800 (B1) | 10 (C1) |

| 2 | 0.4 (A2) | 1000 (B2) | 20 (C2) |

| 3 | 0.7 (A3) | 1200 (B3) | 30 (C3) |

| 4 | 1.0 (A4) | 1400 (B4) | 40 (C4) |

| 5 | 1.3 (A5) | 1600 (B5) | 50 (C5) |

| No. | Parameter Combinations | No. | Parameter Combinations | ||||

|---|---|---|---|---|---|---|---|

| 1 | 14 | ||||||

| 2 | 15 | ||||||

| 3 | 16 | ||||||

| 4 | 17 | ||||||

| 5 | 18 | ||||||

| 6 | 19 | ||||||

| 7 | 20 | ||||||

| 8 | 21 | ||||||

| 9 | 22 | ||||||

| 10 | 23 | ||||||

| 11 | 24 | ||||||

| 12 | 25 | ||||||

| 13 | |||||||

| No. | Ra (μm) | No. | Ra (μm) | No. | Ra (μm) |

|---|---|---|---|---|---|

| 1 | 0.634 | 10 | 1.129 | 19 | 2.501 |

| 2 | 0.679 | 11 | 3.489 | 20 | 1.720 |

| 3 | 0.732 | 12 | 2.247 | 21 | 4.847 |

| 4 | 0.522 | 13 | 2.051 | 22 | 4.319 |

| 5 | 0.579 | 14 | 2.239 | 23 | 2.979 |

| 6 | 2.382 | 15 | 1.512 | 24 | 2.732 |

| 7 | 1.281 | 16 | 4.416 | 25 | 3.263 |

| 8 | 1.387 | 17 | 3.875 | ||

| 9 | 0.964 | 18 | 2.378 |

| Parameters | Levels | K Values | Kavg Values | Optimal Level | Range R Value |

|---|---|---|---|---|---|

| A | 3.15 | 0.63 | 3.00 | ||

| 7.14 | 1.43 | ||||

| 11.54 | 2.31 | ||||

| 14.89 | 2.98 | ||||

| 18.14 | 3.63 | ||||

| B | 15.77 | 3.15 | 1.51 | ||

| 12.40 | 2.48 | ||||

| 9.53 | 1.91 | ||||

| 8.96 | 1.79 | ||||

| 8.20 | 1.64 | ||||

| C | 8.54 | 1.71 | 0.79 | ||

| 10.54 | 2.11 | ||||

| 11.01 | 2.20 | ||||

| 12.27 | 2.45 | ||||

| 12.49 | 2.50 |

| No. | Wa (μm) | No. | Wa (μm) | No. | Wa (μm) |

|---|---|---|---|---|---|

| 1 | 0.083 | 10 | 0.244 | 19 | 0.709 |

| 2 | 0.085 | 11 | 0.713 | 20 | 0.645 |

| 3 | 0.086 | 12 | 0.489 | 21 | 0.866 |

| 4 | 0.069 | 13 | 0.497 | 22 | 0.879 |

| 5 | 0.074 | 14 | 0.475 | 23 | 0.756 |

| 6 | 0.513 | 15 | 0.327 | 24 | 0.767 |

| 7 | 0.303 | 16 | 0.897 | 25 | 0.803 |

| 8 | 0.346 | 17 | 0.913 | ||

| 9 | 0.237 | 18 | 0.695 |

| Parameters | Levels | K Values | Kavg Values | Optimal Level | Range R Value |

|---|---|---|---|---|---|

| A | 0.40 | 0.08 | 0.73 | ||

| 1.64 | 0.33 | ||||

| 2.50 | 0.50 | ||||

| 3.86 | 0.77 | ||||

| 4.07 | 0.81 | ||||

| B | 3.07 | 0.61 | 0.2 | ||

| 2.67 | 0.53 | ||||

| 2.38 | 0.48 | ||||

| 2.26 | 0.45 | ||||

| 2.09 | 0.42 | ||||

| C | 2.21 | 0.44 | 0.12 | ||

| 2.26 | 0.45 | ||||

| 2.49 | 0.50 | ||||

| 2.72 | 0.54 | ||||

| 2.79 | 0.56 |

| No. | PV (μm) | No. | PV (μm) | No. | PV (μm) |

|---|---|---|---|---|---|

| 1 | 1.415 | 10 | 1.789 | 19 | 2.916 |

| 2 | 1.425 | 11 | 1.802 | 20 | 2.317 |

| 3 | 1.432 | 12 | 3.271 | 21 | 4.024 |

| 4 | 1.345 | 13 | 2.631 | 22 | 3.885 |

| 5 | 1.375 | 14 | 2.553 | 23 | 3.373 |

| 6 | 2.785 | 15 | 2.005 | 24 | 3.315 |

| 7 | 2.217 | 16 | 3.633 | 25 | 3.243 |

| 8 | 2.149 | 17 | 3.673 | ||

| 9 | 1.789 | 18 | 3.021 |

| Parameters | Levels | K Values | Kavg Values | Optimal Level | Range R Value |

|---|---|---|---|---|---|

| A | 6.99 | 1.40 | 2.17 | ||

| 10.74 | 2.15 | ||||

| 12.94 | 2.59 | ||||

| 15.56 | 3.11 | ||||

| 17.84 | 3.57 | ||||

| B | 15.13 | 3.03 | 0.88 | ||

| 13.83 | 2.77 | ||||

| 12.53 | 2.51 | ||||

| 11.84 | 2.37 | ||||

| 10.74 | 2.15 | ||||

| C | 11.52 | 2.30 | 0.42 | ||

| 12.61 | 2.52 | ||||

| 12.73 | 2.55 | ||||

| 13.60 | 2.72 | ||||

| 13.61 | 2.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, C.; Li, G.; Zhang, X.; Gao, Y. Process Parameters Analysis in Diamond Wire Saw Cutting NdFeB Magnet. Materials 2025, 18, 1173. https://doi.org/10.3390/ma18051173

Peng C, Li G, Zhang X, Gao Y. Process Parameters Analysis in Diamond Wire Saw Cutting NdFeB Magnet. Materials. 2025; 18(5):1173. https://doi.org/10.3390/ma18051173

Chicago/Turabian StylePeng, Chengwanli, Guanzheng Li, Xingchun Zhang, and Yufei Gao. 2025. "Process Parameters Analysis in Diamond Wire Saw Cutting NdFeB Magnet" Materials 18, no. 5: 1173. https://doi.org/10.3390/ma18051173

APA StylePeng, C., Li, G., Zhang, X., & Gao, Y. (2025). Process Parameters Analysis in Diamond Wire Saw Cutting NdFeB Magnet. Materials, 18(5), 1173. https://doi.org/10.3390/ma18051173