Examination of Stress Corrosion Cracking of Rock Bolts in Simulated Underground Environments

Abstract

1. Introduction

2. Materials and Methods

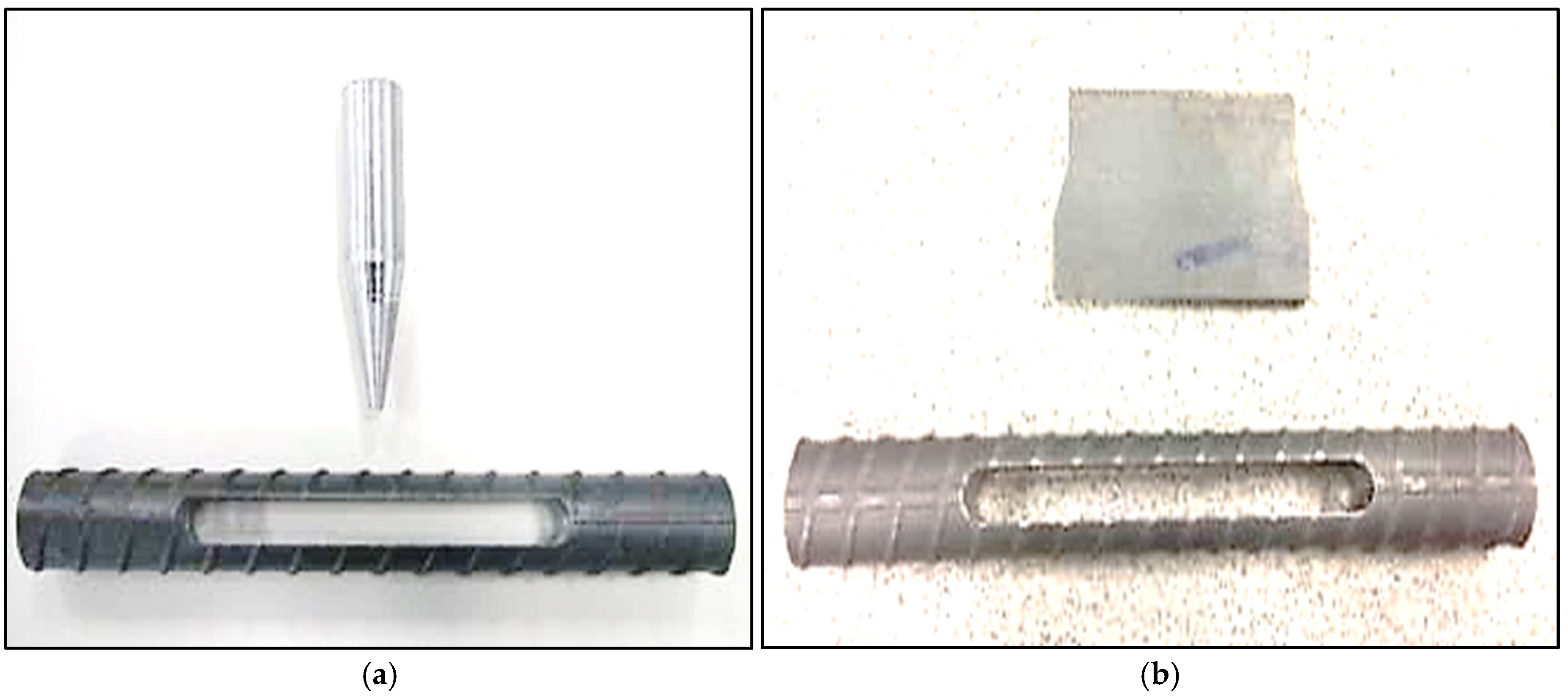

2.1. Testing Specimens

2.2. Stress and Corrosive Conditions

2.3. Testing Procedures

3. Results and Failure Characteristics

3.1. Testing Results

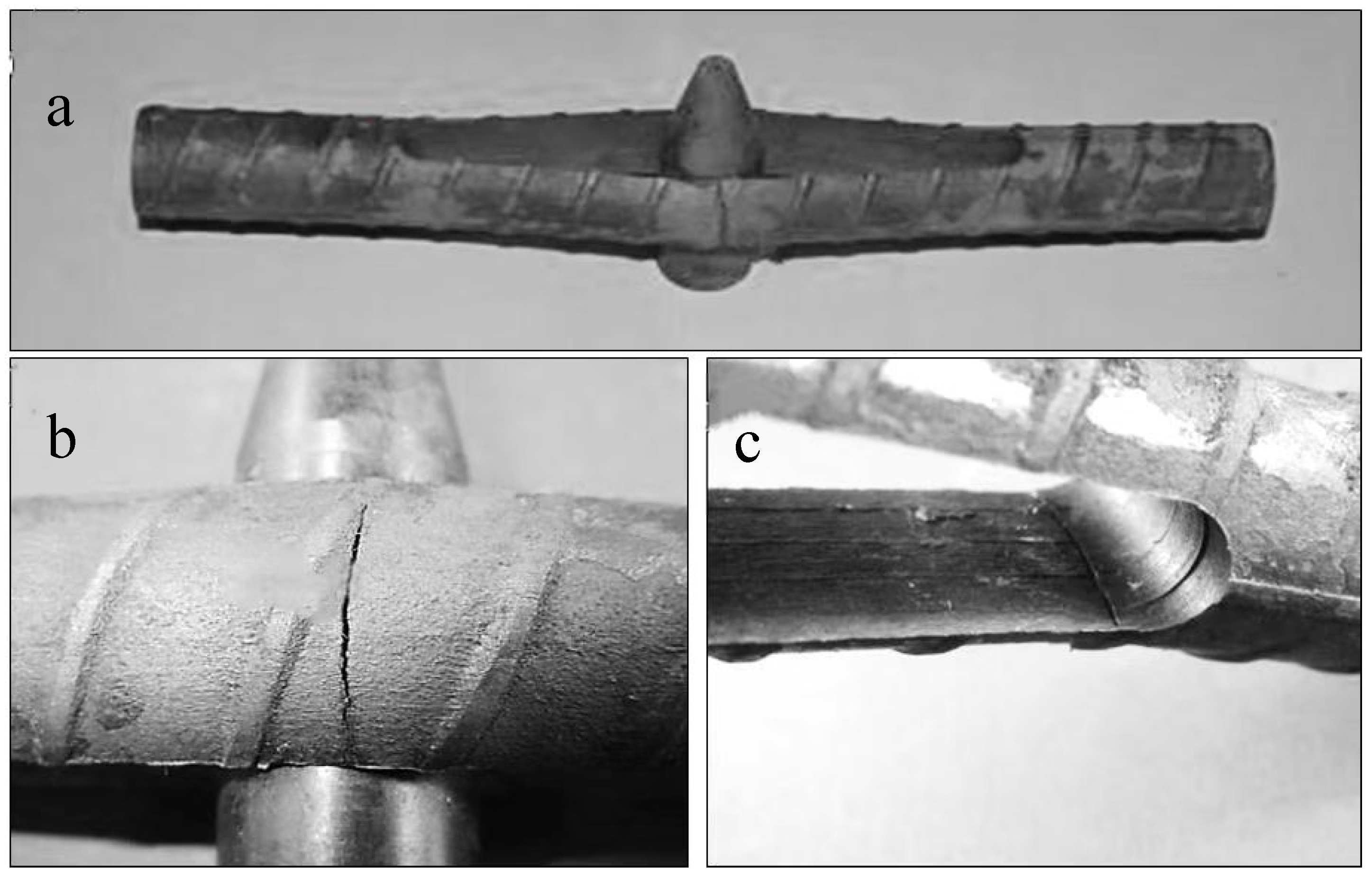

3.2. Failure Characteristics

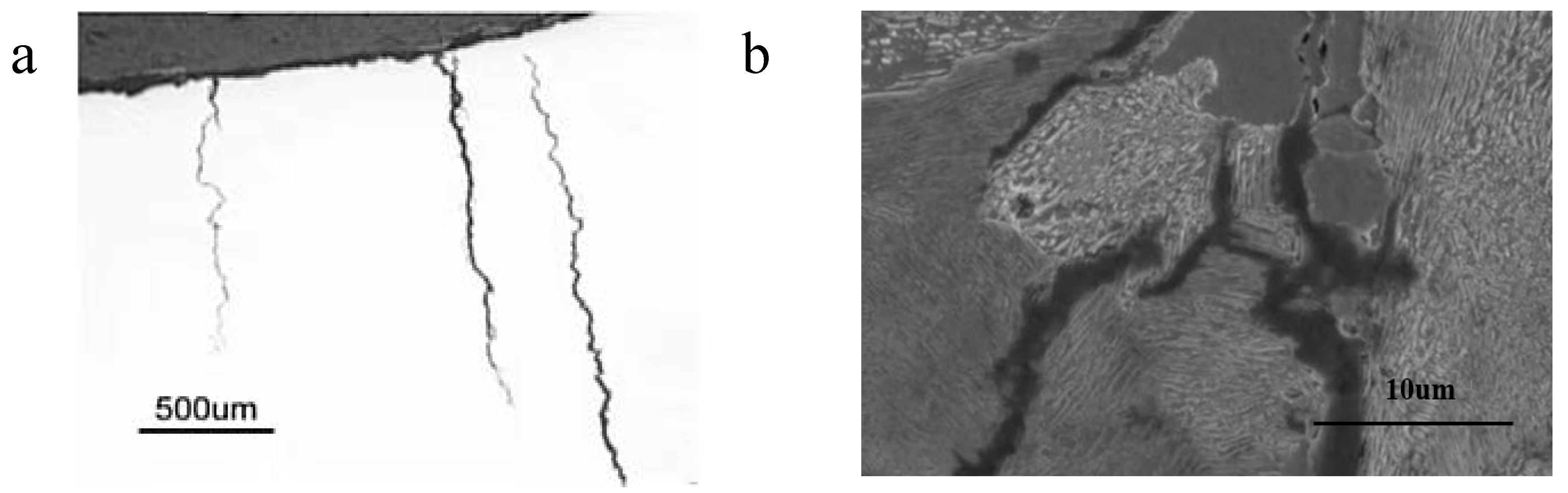

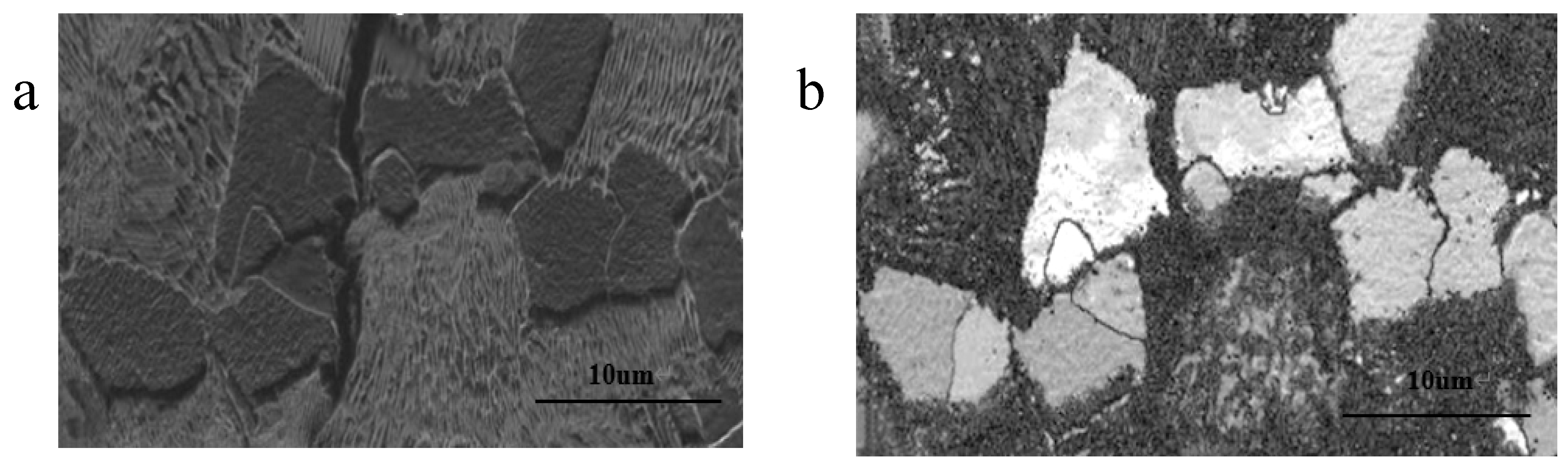

3.3. Crack Path Examinations

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, J.; Ma, J.; Zeng, X.; Zeng, B.; Skrzypkowski, K.; Zagórski, K.; Zagórska, A.; Wu, S. An Enhanced Numerical Calculation Method to Study the Anchorage Performance of Rebars. Materials 2024, 17, 3987. [Google Scholar] [CrossRef] [PubMed]

- Gardner, F.J. History of rock bolting. In Proceedings of the Symposium on Rock Bolting, Wollongong, Australia, 17–19 February 1971. [Google Scholar]

- Rawat, N.S. Corrosivity of Underground Mine Atmospheres and Mine Waters: A Review and Preliminary Study. Br. Corros. J. 1976, 11, 86–91. [Google Scholar] [CrossRef]

- Dorion, J.F.; Hadjigeorgiou, J. Corrosion considerations in design and operation of rock support systems. Min. Technol. 2014, 123, 59–68. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, W.; Chen, J.; Skrzypkowski, K.; Zagórski, K.; Zagórska, A. Investigation into Effects of Coating on Stress Corrosion of Cable Bolts in Deep Underground Environments. Materials 2024, 17, 3563. [Google Scholar] [CrossRef]

- Chen, H.; Kimyon, Ö.; Gunawan, C.; Lamei Ramandi, H.; Craig, P.; Chen, R.; Kabir, I.; Kumar, N.; Manefield, M.; Crosky, A.; et al. An Effective Barrier Coating Technology Against Premature Bolt Failures in Underground Mines. Rock Mech. Rock Eng. 2024, 1–18. [Google Scholar] [CrossRef]

- Lynch, S.P. Mechanisms of Hydrogen Assisted Cracking. Met. Forum 1979, 3, 189–200. [Google Scholar]

- Lynch, S.P. Environmentally assisted cracking: Overview of evidence for an adsorption-induced localised-slip process. Acta Metall. 1988, 36, 2639–2661. [Google Scholar] [CrossRef]

- Reddy, D.; Edouard, J.-B.; Sobhan, K. Durability of Fly Ash–Based Geopolymer Structural Concrete in the Marine Environment. J. Mater. Civ. Eng. 2013, 25, 781–787. [Google Scholar] [CrossRef]

- Wu, S.; Ma, X.; Zhang, X.; Chen, J.; Yao, Y.; Li, D. Investigation into hydrogen induced fracture of cable bolts under deep stress corrosion coupling conditions. Tunn. Undergr. Space Technol. 2024, 147, 105729. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, Z.; Chen, J.; Yao, Y.; Li, D. Characterisation of stress corrosion durability and time-dependent performance of cable bolts in underground mine environments. Eng. Fail. Anal. 2023, 150, 107292. [Google Scholar] [CrossRef]

- Diaz, A.; Alegre, J.M.; Cuesta, I.I. A review on diffusion modelling in hydrogen related failures of metals. Eng. Fail. Anal. 2016, 66, 577–595. [Google Scholar] [CrossRef]

- Craig, P.; Lamei Ramandi, H.; Chen, H.; Vandermaat, D.; Crosky, A.; Hagan, P.; Hebblewhite, B.; Saydam, S. Stress corrosion cracking of rockbolts: An in-situ testing approach. Constr. Build. Mater. 2021, 269, 121275. [Google Scholar] [CrossRef]

- Ramandi, H.L.; Chen, H.H.; Crosky, A.; Saydam, S. Interactions of stress corrosion cracks in cold drawn pearlitic steel wires: An X-ray micro-computed tomography study. Corros. Sci. 2018, 145, 170–179. [Google Scholar] [CrossRef]

- Wu, S.S.; Guo, J.P.; Shi, G.B.; Li, J.; Lu, C.W. Laboratory-Based Investigation into Stress Corrosion Cracking of Cable Bolts. Materials 2019, 12, 16. [Google Scholar] [CrossRef]

- Wu, S.; Hao, W.; Yao, Y.; Li, D. Investigation into durability degradation and fracture of cable bolts through laboratorial tests and hydrogeochemical modelling in underground conditions. Tunn. Undergr. Space Technol. 2023, 138, 105198. [Google Scholar] [CrossRef]

- Eliaz, N.; Shachar, A.; Tal, B.; Eliezer, D. Characteristics of hydrogen embrittlement, stress corrosion cracking and tempered martensite embrittlement in high-strength steels. Eng. Fail. Anal. 2002, 9, 167–184. [Google Scholar] [CrossRef]

- Niazi, H.; Eadie, R.; Chen, W.; Zhang, H. High pH stress corrosion cracking initiation and crack evolution in buried steel pipelines: A review. Eng. Fail. Anal. 2021, 120, 105013. [Google Scholar] [CrossRef]

- Galvele, J. A stress corrosion cracking mechanism based on surface mobility. Corros. Sci. 1987, 27, 1–33. [Google Scholar] [CrossRef]

- Hirose, Y.; Mura, T. Nucleation mechanism of stress corrosion cracking from notches. Eng. Fract. Mech. 1984, 19, 317–329. [Google Scholar] [CrossRef]

- Vandermaat, D.; Saydam, S.; Hagan, P.C.; Crosky, A.G. Back-calculation of failure stress of rockbolts affected by Stress Corrosion Cracking in underground coal mines. Int. J. Rock Mech. Min. Sci. 2017, 100, 310–317. [Google Scholar] [CrossRef]

- Wu, S.S.; Li, J.P.; Guo, J.P.; Shi, G.B.; Gu, Q.H.; Lu, C.W. Stress corrosion cracking fracture mechanism of cold-drawn high-carbon cable bolts. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2020, 769, 10. [Google Scholar] [CrossRef]

- Chen, H.; Kimyon, Ö.; Ramandi, H.L.; Craig, P.; Gunawan, C.; Wu, S.; Manefield, M.; Crosky, A.; Saydam, S. Microbiologically influenced stress corrosion cracking responsible for catastrophic failure of cable bolts. Eng. Fail. Anal. 2022, 131, 105884. [Google Scholar] [CrossRef]

- Wu, S.; Northover, M.; Craig, P.; Canbulat, I.; Hagan, P.C.; Saydam, S. Environmental influence on mesh corrosion in underground coal mines. Int. J. Min. Reclam. Environ. 2018, 32, 519–535. [Google Scholar] [CrossRef]

- Elias, E.; Vandermaat, D.; Craig, P.; Chen, H.; Crosky, A.; Saydam, S.; Hagan, P.; Hebblewhite, B. Metallurgical examination of rock bolts failed in service due to stress corrosion cracking. In Proceedings of the Ground Support 2013: Proceedings of the Seventh International Symposium on Ground Support in Mining and Underground Construction, Perth, Australia, 13–15 May 2013. [Google Scholar]

- Wu, S.S.; Ramandi, H.L.; Chen, H.H.; Crosky, A.; Hagan, P.; Saydam, S. Mineralogically influenced stress corrosion cracking of rockbolts and cable bolts in underground mines. Int. J. Rock Mech. Min. Sci. 2019, 119, 109–116. [Google Scholar] [CrossRef]

- Winzer, N.; Atrens, A.; Dietzel, W.; Song, G.; Kainer, K. Comparison of the linearly increasing stress test and the constant extension rate test in the evaluation of transgranular stress corrosion cracking of magnesium. Mater. Sci. Eng. 2008, A472, 97–106. [Google Scholar] [CrossRef]

- Sanchez, J.; Fullea, J.; Andrade, C.; Alonso, C. Stress corrosion cracking mechanism of prestressing steels in bicarbonate solutions. Corros. Sci. 2007, 49, 4069–4080. [Google Scholar] [CrossRef]

- Atrens, A.; Brosnan, C.; Ramamurthy, S.; Oelhlert, A.; Smith, I. Linearly Increasing Stress Test (LIST) for SCC Research. Meas. Sci. Technol. 1993, 4, 1281–1292. [Google Scholar] [CrossRef]

- Sprowls, D.O.; Summerson, T.J.; Ugiansky, G.M.; Epstein, S.G.; Craig, J.H.L. Evaluation of a proposed standard method of testing for susceptibility to stress corrosion cracking of high strength 7XXX series aluminium alloy products. In Stress Corrosion—New Approaches; Craig, J.H.L., Ed.; American Society for Testing and Materials: Philadelphia, PA, USA, 1976; Volume STP 610, p. 430. [Google Scholar]

- Wu, S.S.; Chen, H.H.; Ramandi, F.L.; Hagan, P.C.; Hebblewhite, B.; Crosky, A.; Saydam, S. Investigation of cable bolts for stress corrosion cracking failure. Constr. Build. Mater. 2018, 187, 1224–1231. [Google Scholar] [CrossRef]

- Yamoaka, Y.; Tanaka, Y. Comparison of the Mechanisms of Hydrogen Embrittlement and Stress Corrosion Cracking of High Carbon Steel Wire. In Proceedings of the International Workshop on Prestressing Wire, Denver, Colorado, USA, 14 October 1961. [Google Scholar]

- Villalba, E.; Atrens, A. Metallurgical aspects of rock bolt stress corrosion cracking. Mater. Sci. Eng. A 2008, 491, 8–18. [Google Scholar] [CrossRef]

- McLaren, T.B.; Thompson, A.W. Effect of hydrogen and microstructure on fatigue crack propagation in a medium carbon steel. Mater. Sci. Eng. 1983, 57, L21–L25. [Google Scholar] [CrossRef]

- Hatzor, Y.H.; Zur, A.; Mimran, Y. Microstructure effects on microcracking and brittle failure of dolomites. Tectonophysics 1997, 281, 141–161. [Google Scholar] [CrossRef]

- David, C.; Menéndez, B.; Darot, M.; Sciences, M. Influence of stress-induced and thermal cracking on physical properties and microstructure of La Peyratte granite. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1999, 36, 433–448. [Google Scholar] [CrossRef]

- Wu, S.S.; Chen, H.H.; Craig, P.; Ramandi, H.L.; Timms, W.; Hagan, P.C.; Crosky, A.; Hebblewhite, B.; Saydam, S. An experimental framework for simulating stress corrosion cracking in cable bolts. Tunn. Undergr. Space Technol. 2018, 76, 121–132. [Google Scholar] [CrossRef]

- Vandermaat, D.; Saydam, S.; Hagan, P.C.; Crosky, A.G. Examination of rockbolt stress corrosion cracking utilising full size rockbolts in a controlled mine environment. Int. J. Rock Mech. Min. Sci. 2016, 81, 86–95. [Google Scholar] [CrossRef]

- Wu, S.S.; Chen, H.H.; Ramandi, H.L.; Hagan, P.C.; Crosky, A.; Saydam, S. Effects of environmental factors on stress corrosion cracking of cold-drawn high-carbon steel wires. Corros. Sci. 2018, 132, 234–243. [Google Scholar] [CrossRef]

- Li, J.; Elboujdaini, M.; Fang, B.; Revie, R.W.; Phaneuf, M.W. Microscopy Study of Intergranular Stress Corrosion Cracking of X-52 Line Pipe Steel. Corrosion 2006, 62, 316–322. [Google Scholar] [CrossRef]

- Gamboa, E.; Atrens, A. Environmental influence on the stress corrosion cracking of rock bolts. Eng. Fail. Anal. 2003, 10, 521–558. [Google Scholar] [CrossRef]

- Crosky, A.; Smith, B.; Elias, E.; Chen, H.; Craig, P.; Hagan, P.; Saydam, S.; Hebblewhite, B. Stress corrosion cracking failure of rockbolts in underground mines in Australia. In Proceedings of the Seventh International Conference on Rockbolting and Rock Mechanics in Mining, Aachen, Germany, 30–31 May 2012. [Google Scholar]

- Villalba, E.; Atrens, A. An evaluation of steels subjected to rock bolt SCC conditions. Eng. Fail. Anal. 2007, 14, 1351–1393. [Google Scholar] [CrossRef]

- Villalba, E.; Atrens, A. SCC of commercial steels exposed to high hydrogen fugacity. Eng. Fail. Anal. 2008, 15, 617–641. [Google Scholar] [CrossRef]

- Gamboa, E.; Atrens, A. Stress corrosion cracking fracture mechanisms in rock bolts. J. Mater. Sci. 2003, 38, 16. [Google Scholar] [CrossRef]

- Villalba, E.; Atrens, A. Hydrogen embrittlement and rock bolt stress corrosion cracking. Eng. Fail. Anal. 2009, 16, 164–175. [Google Scholar] [CrossRef]

- Woodtli, J.; Kieselbach, R. Damage due to hydrogen embrittlement and stress corrosion cracking. Eng. Fail. Anal. 2000, 7, 427–450. [Google Scholar] [CrossRef]

- Hassell, R.; Villaescusa, E.; Thompson, A.G.; Kinsella, B. Corrosion assessment of ground support systems. In Ground Support in Mining and Underground Construction; Taylor & Francis: Abingdon, UK, 2004; pp. 521–528. [Google Scholar]

| Chemical Compositions (wt. %) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specimen | C | Mn | Si | Ni | Cr | Mo | S | P | Cu | V | Ti | Al |

| Type I | 0.56 | 1.63 | 0.26 | 0.05 | 0.15 | 0.011 | 0.035 | 0.014 | 0.21 | 0.02 | 0.001 | 0.004 |

| Type II | 0.39 | 1.53 | 1.08 | 0.02 | 0.03 | 0.004 | 0.019 | 0.017 | 0.01 | 0.038 | 0.001 | 0.004 |

| Mechanical Properties | ||||||||||||

| Yield (MPa) | UTS (MPa) | Elongation (%) | Impact Strength (Joules) | Hardness (HV 30) | ||||||||

| Type I | 600 | 850 | 12 | 9 | 326 | |||||||

| Type II | 600 | 840 | 15 | 5 | 301 | |||||||

| Solution | Water (mL) | Sodium Chloride (g) | Acetic Acid (mL) | Sodium Sulfide (g) | pH |

|---|---|---|---|---|---|

| 1 | 1940 | 60.0 | 60 | 3.0 | 3.4 |

| 2 | 1940 | 60.0 | 60 | 2.0 | 3.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Cao, X.; Zhu, Y.; Skrzypkowski, K.; Zagórski, K. Examination of Stress Corrosion Cracking of Rock Bolts in Simulated Underground Environments. Materials 2025, 18, 1275. https://doi.org/10.3390/ma18061275

Wu S, Cao X, Zhu Y, Skrzypkowski K, Zagórski K. Examination of Stress Corrosion Cracking of Rock Bolts in Simulated Underground Environments. Materials. 2025; 18(6):1275. https://doi.org/10.3390/ma18061275

Chicago/Turabian StyleWu, Saisai, Xinting Cao, Yiran Zhu, Krzysztof Skrzypkowski, and Krzysztof Zagórski. 2025. "Examination of Stress Corrosion Cracking of Rock Bolts in Simulated Underground Environments" Materials 18, no. 6: 1275. https://doi.org/10.3390/ma18061275

APA StyleWu, S., Cao, X., Zhu, Y., Skrzypkowski, K., & Zagórski, K. (2025). Examination of Stress Corrosion Cracking of Rock Bolts in Simulated Underground Environments. Materials, 18(6), 1275. https://doi.org/10.3390/ma18061275