Contribution of Oxygen and Ultraviolet Light to the Adhesion Properties of Warm Mix Asphalt During the Light-Oxidative Coupling Ultraviolet Aging Process

Abstract

1. Introduction

2. Materials and Methods

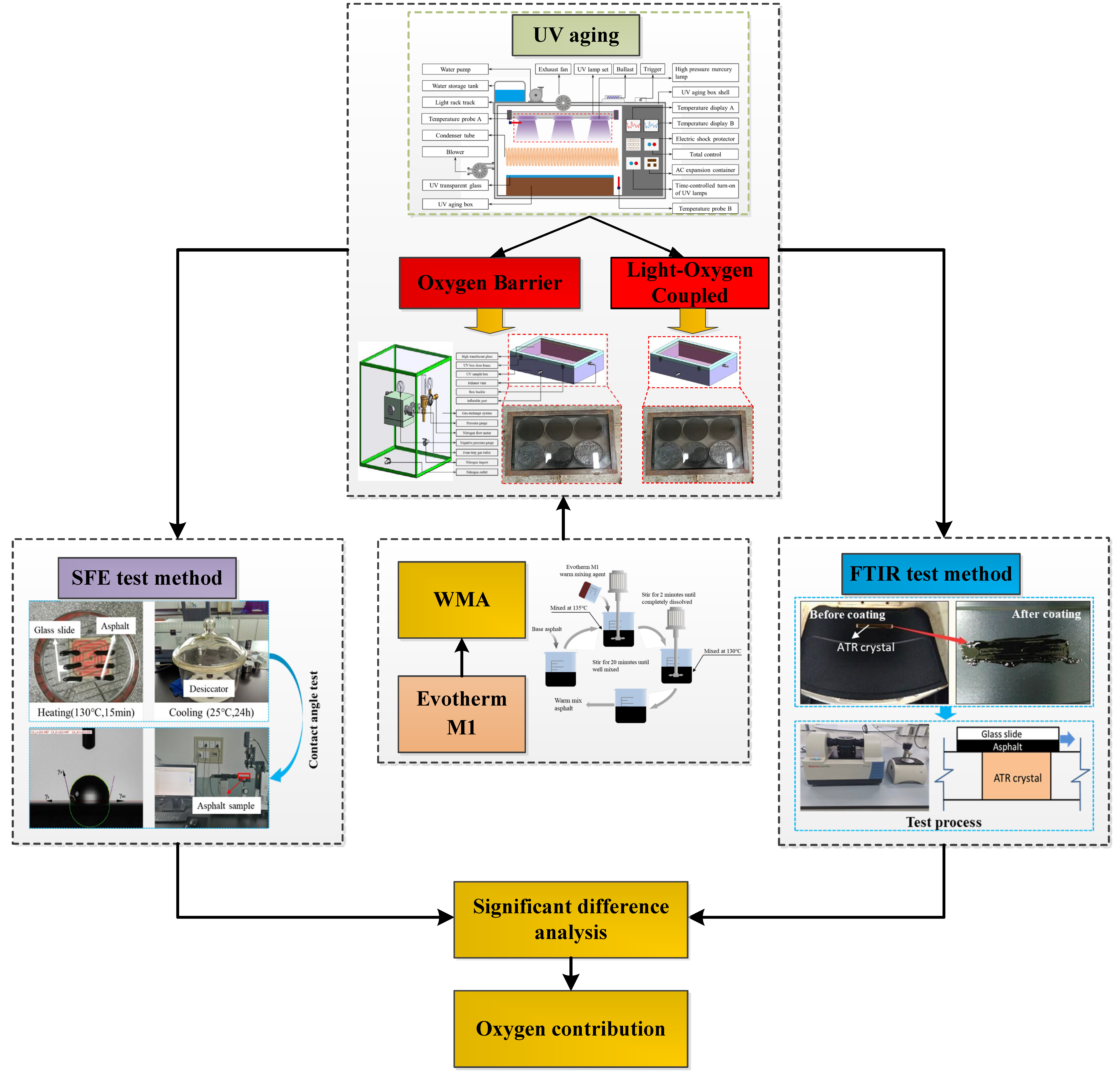

2.1. Experimental Design

2.2. Experiment Design of UV Aging

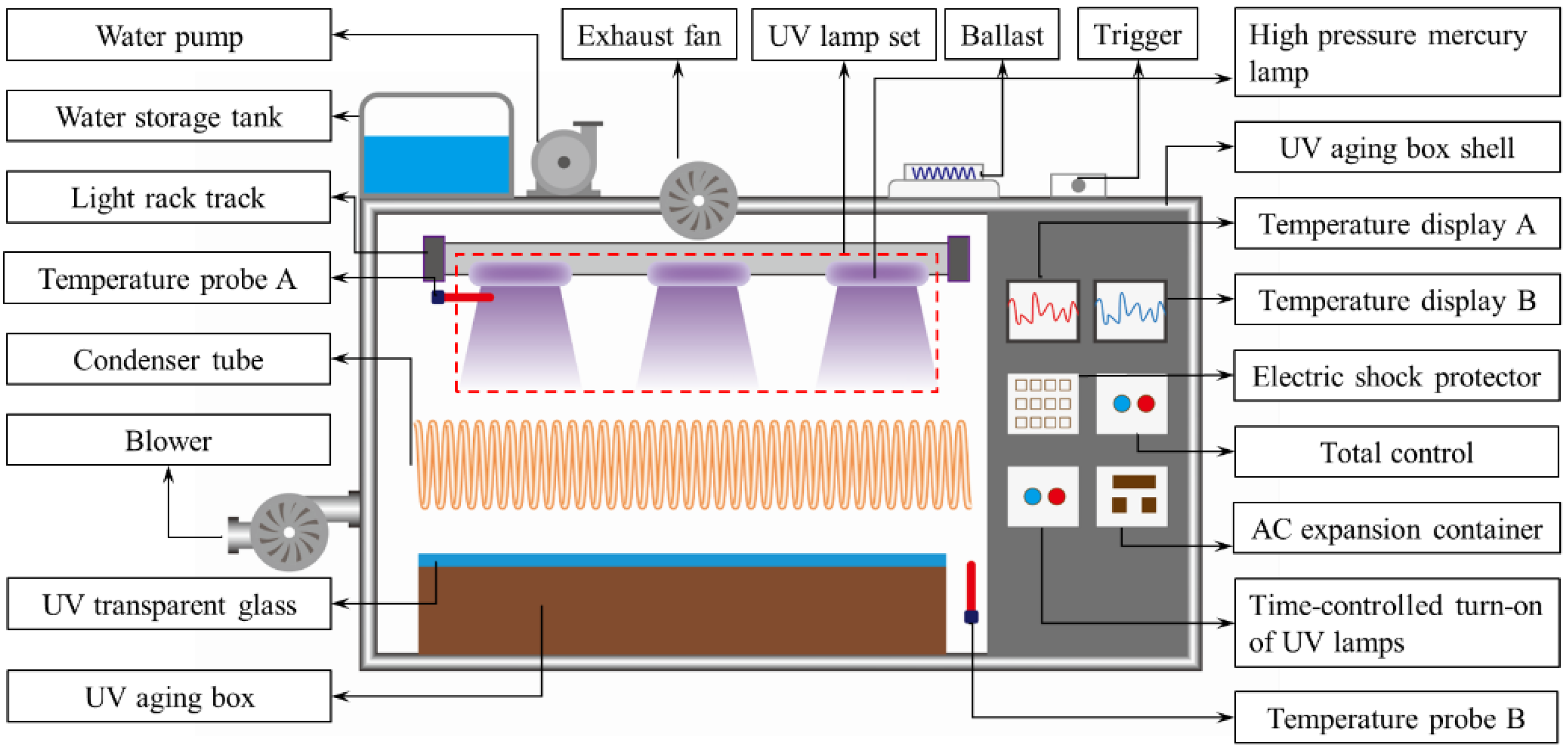

2.2.1. UV Aging Device Design

- (1)

- UV aging environment device design

- (2)

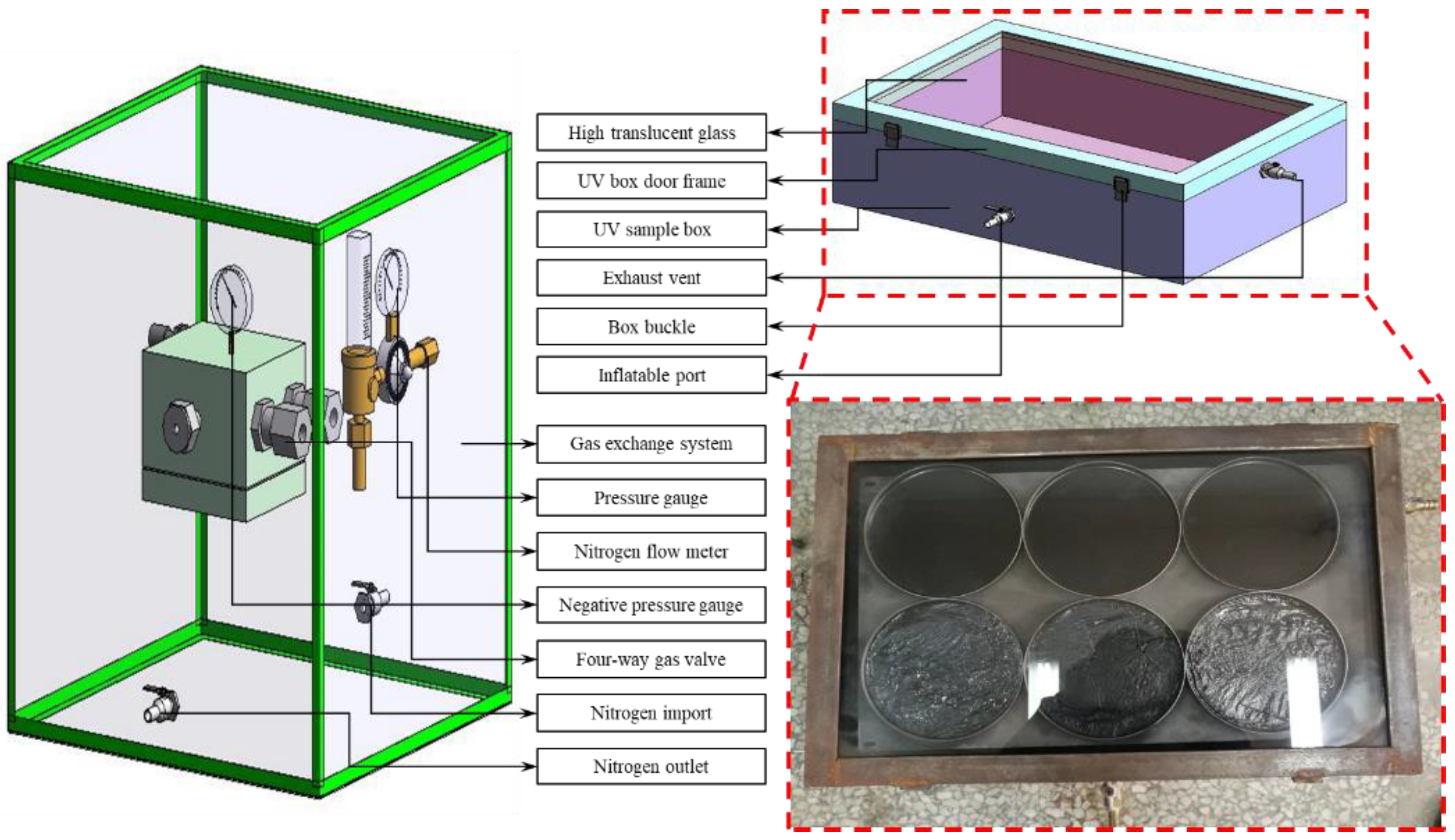

- Design of oxygen insulation aging box

- a.

- Inject nitrogen into the oxygen-barrier aging box through the air inlet of the external nitrogen bottle, so that the air in the aging box is completely discharged.

- b.

- Use ignition test at the air outlet to verify the oxygen concentration in the box.

- c.

- After the gas exchange is over, close the air inlet and air outlet in time to avoid the entry of outside air.

2.2.2. UV Aging Parameter Selection

2.2.3. Determination of Laboratory-Simulated UV Aging Parameters

2.3. Sample Preparation

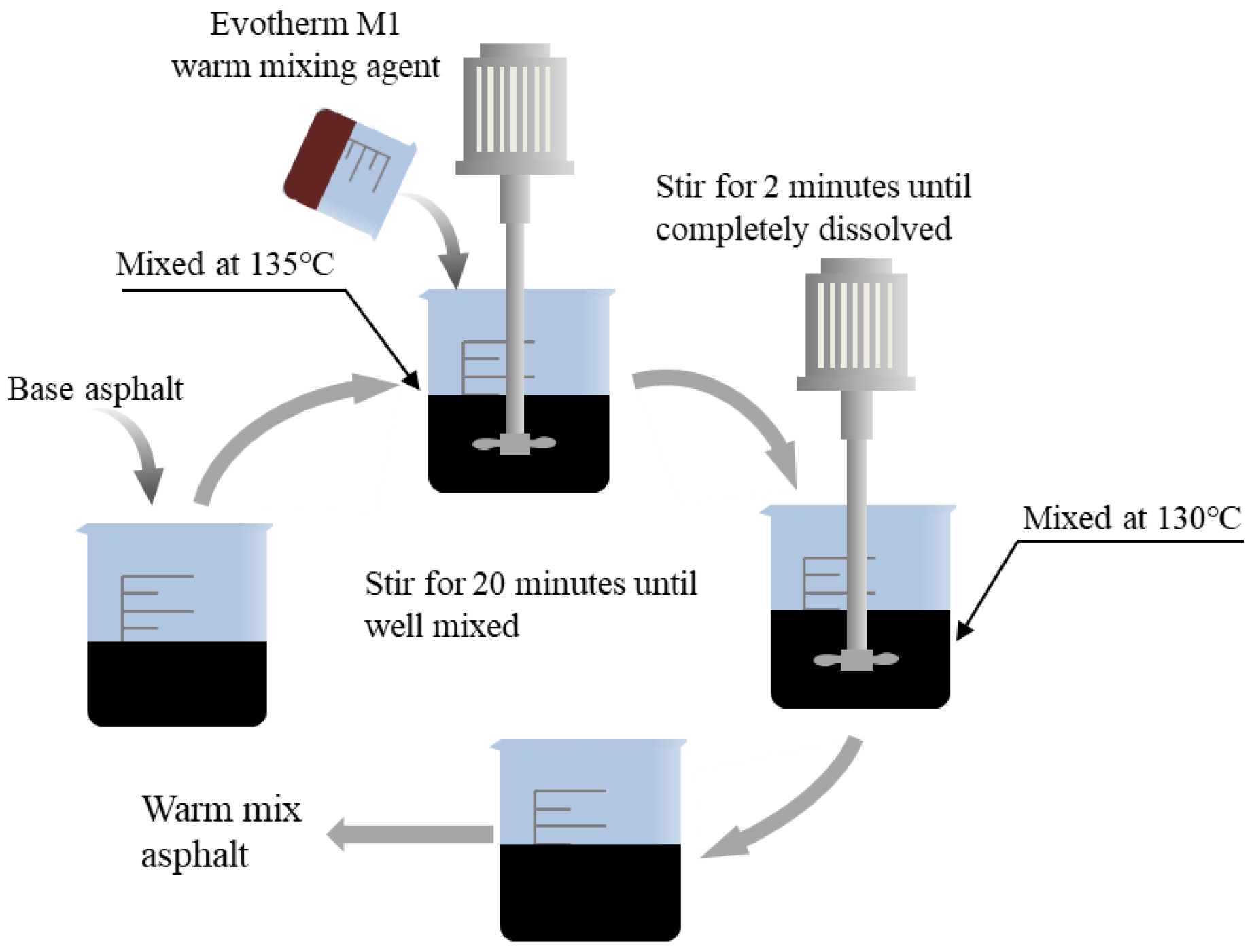

2.3.1. WMA Samples

2.3.2. Short-Term Aging Samples

2.3.3. Long-Term Aging Samples

2.3.4. UV Aging Samples

2.4. Test Methods

2.4.1. Contact Angle Tests

2.4.2. FTIR Tests

2.5. Surface Free Energy Theory

2.5.1. Cohesive Work

2.5.2. Adhesive Work

2.6. Contribution Rate Calculation Model

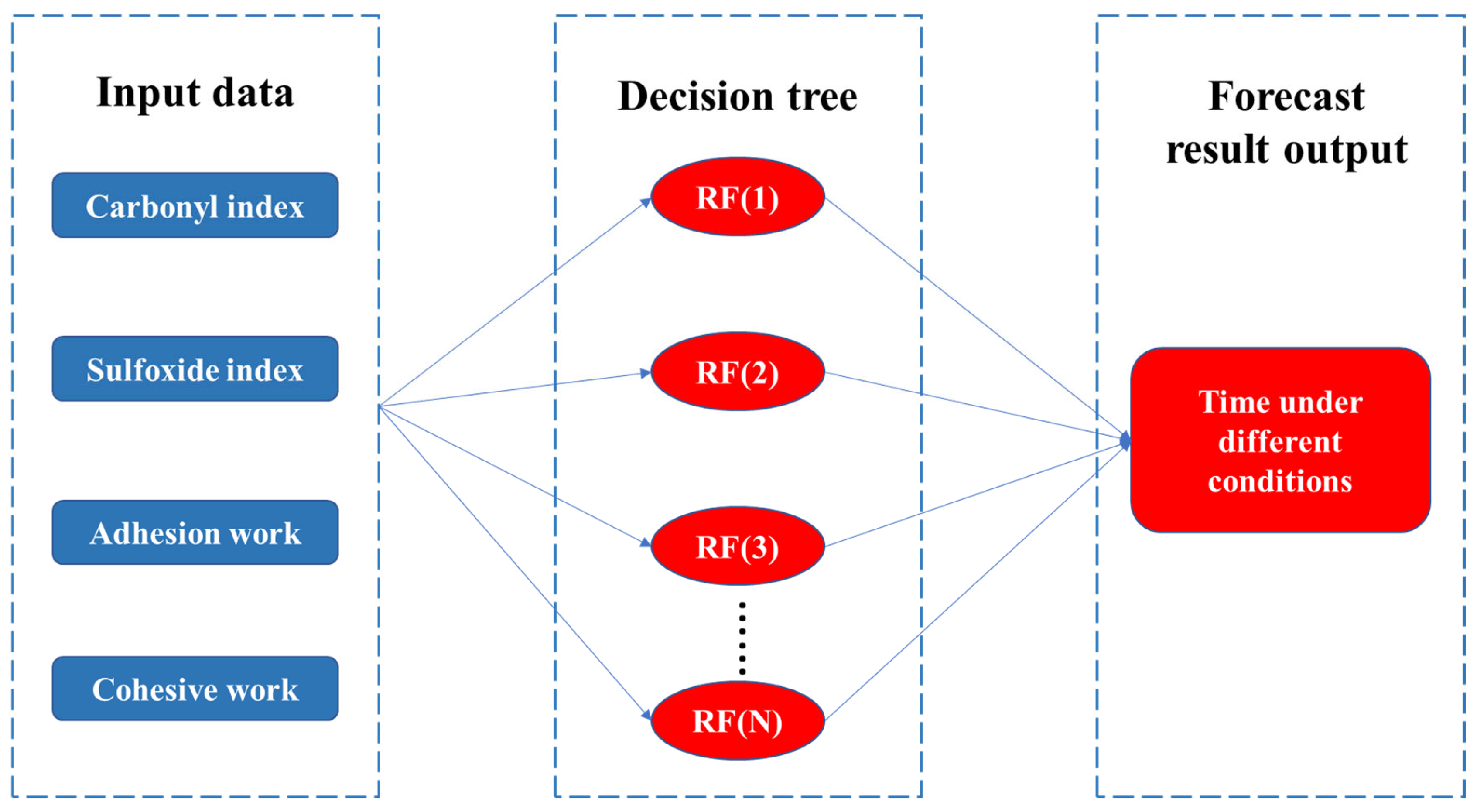

2.7. Random Forest Model

3. Results and Discussion

3.1. Adhesive Performance Analysis Based on SFE

3.1.1. Contact Angle

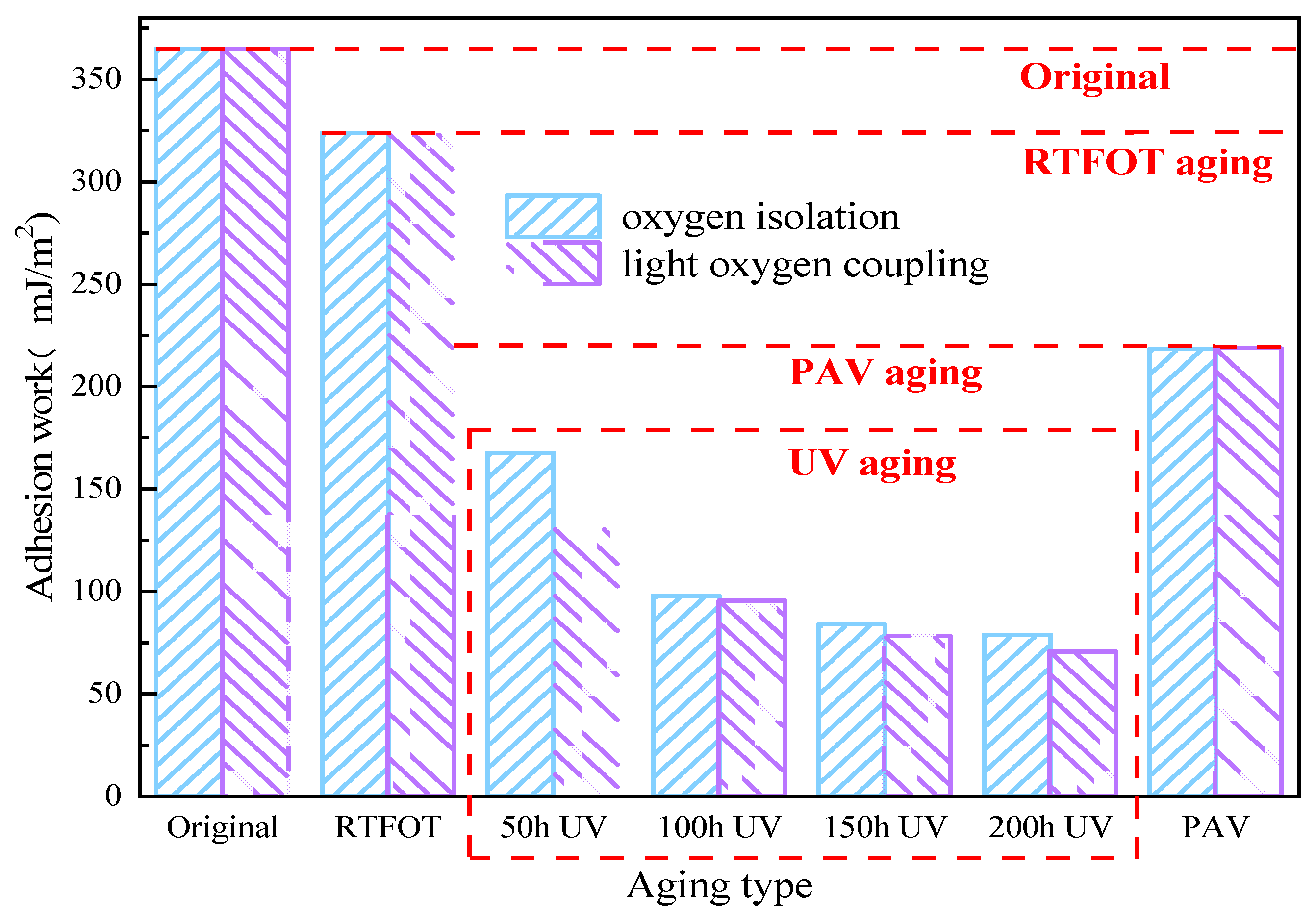

3.1.2. Adhesive Work

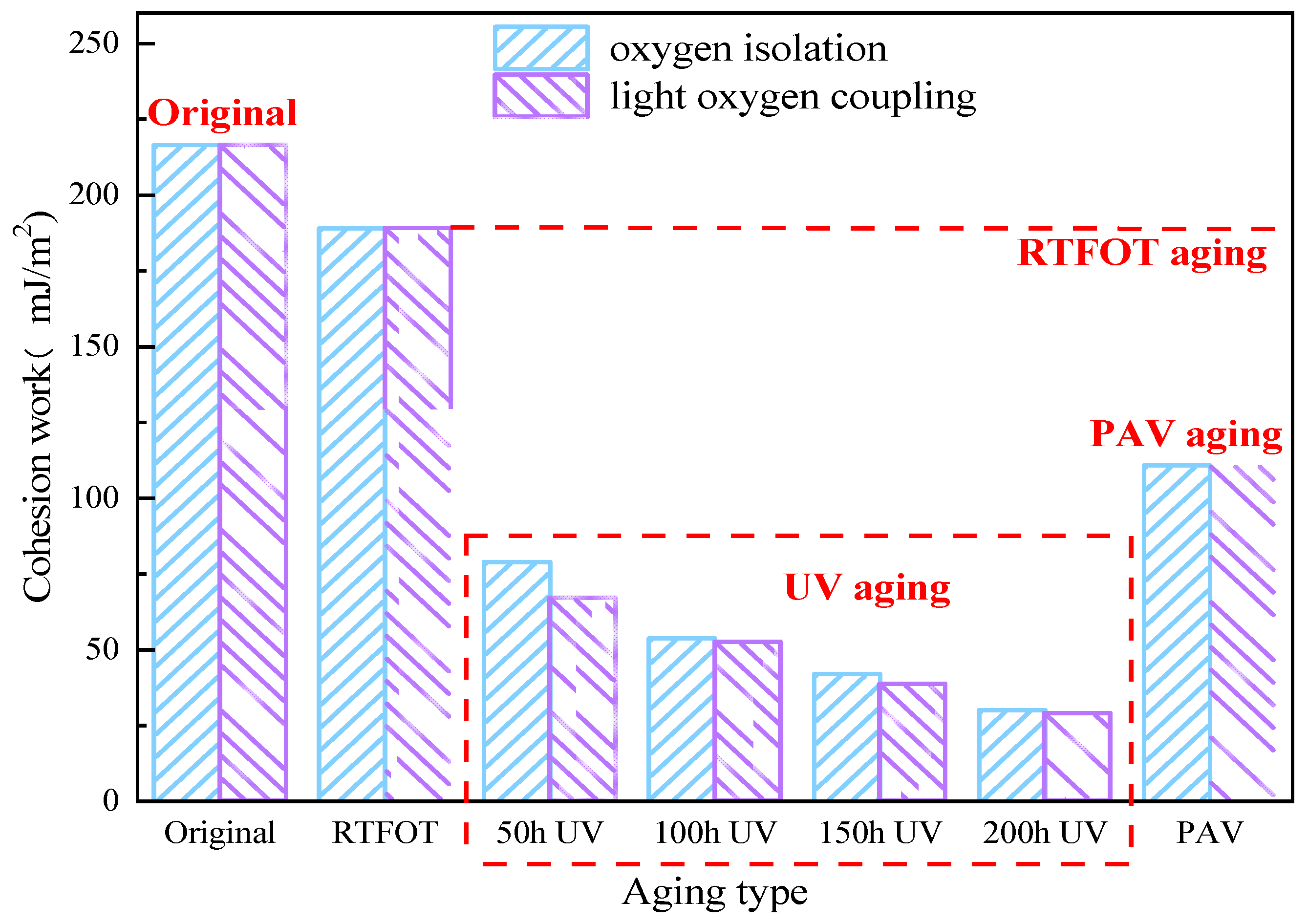

3.1.3. Cohesive Work

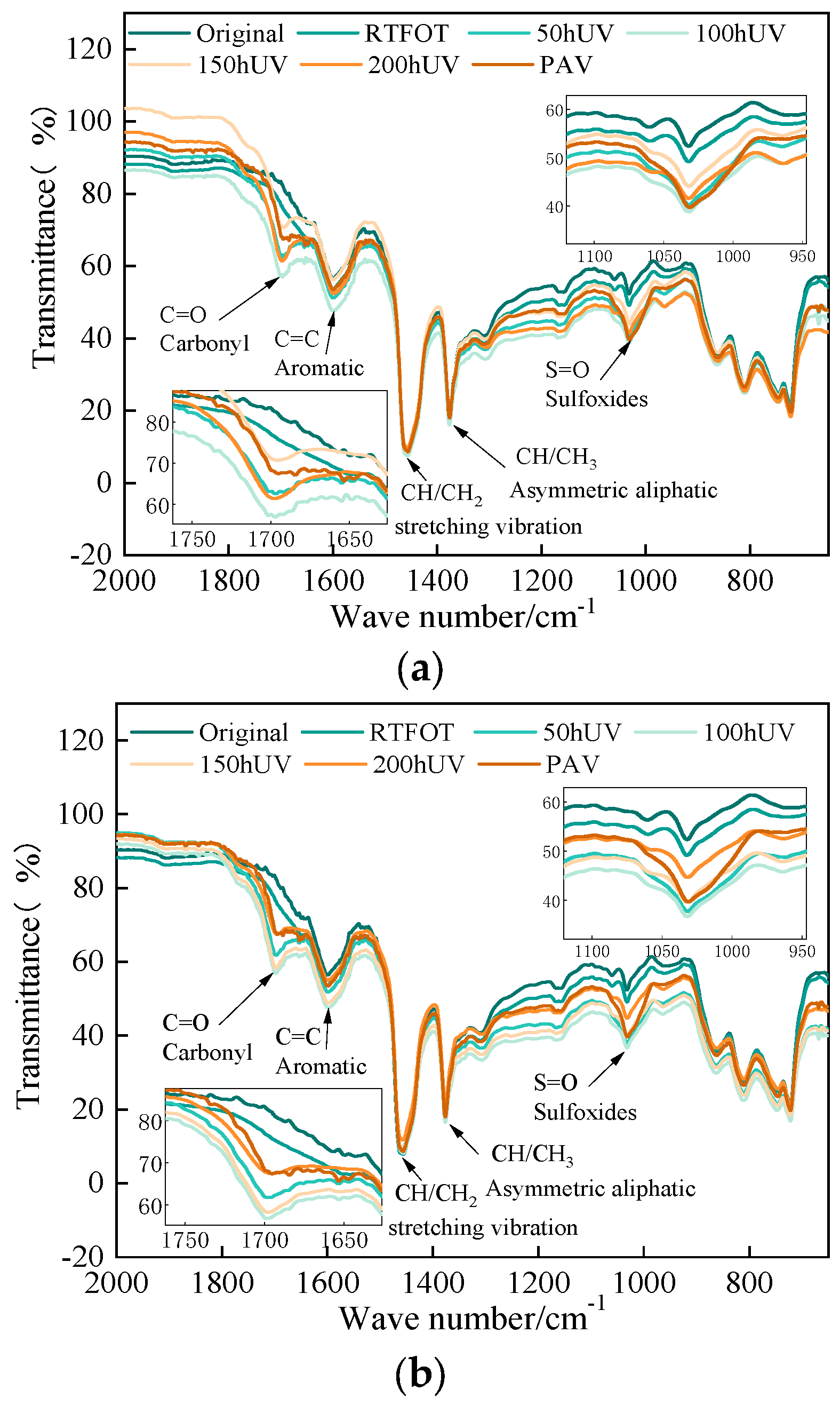

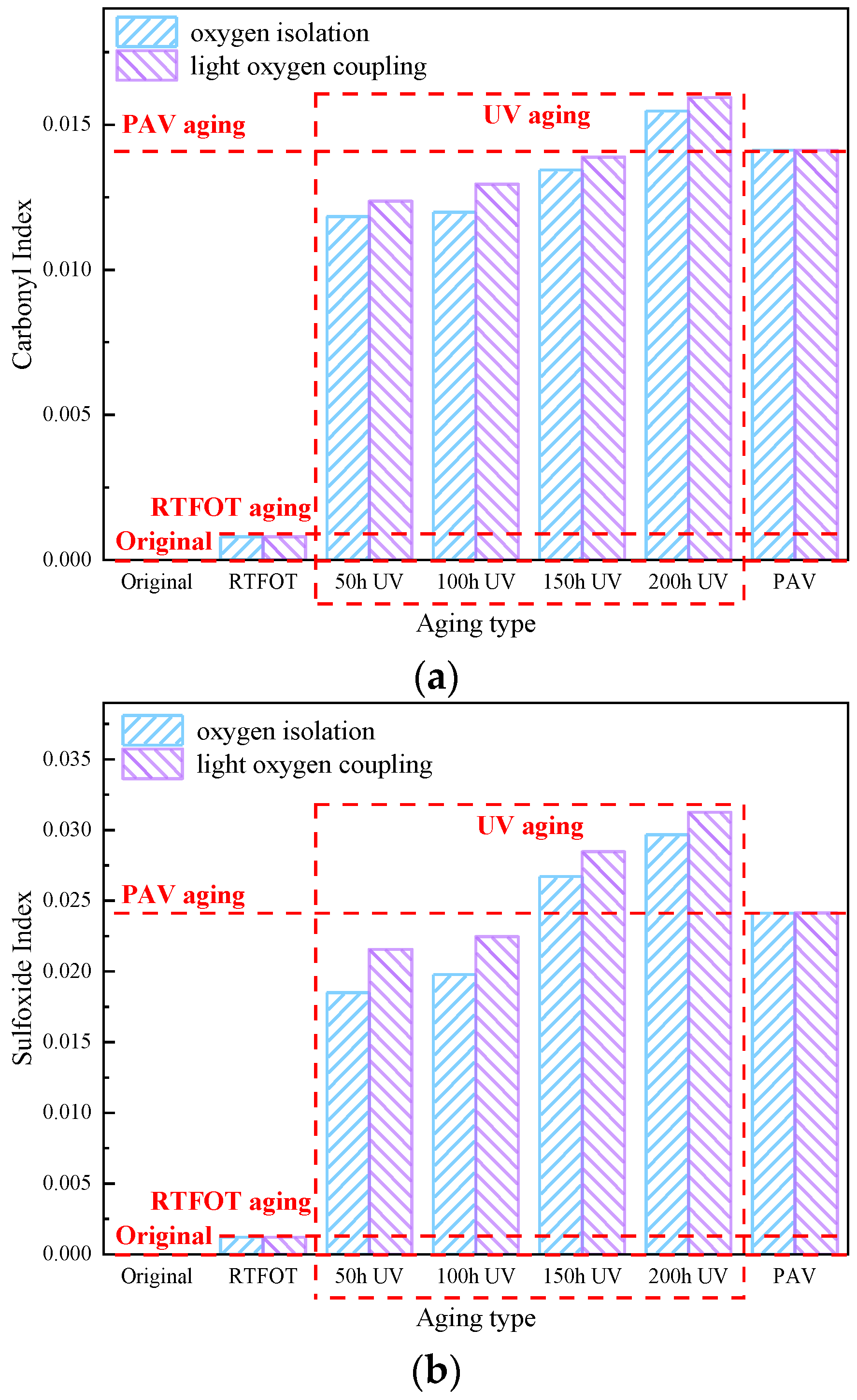

3.2. Functional Groups Analysis Based on FTIR

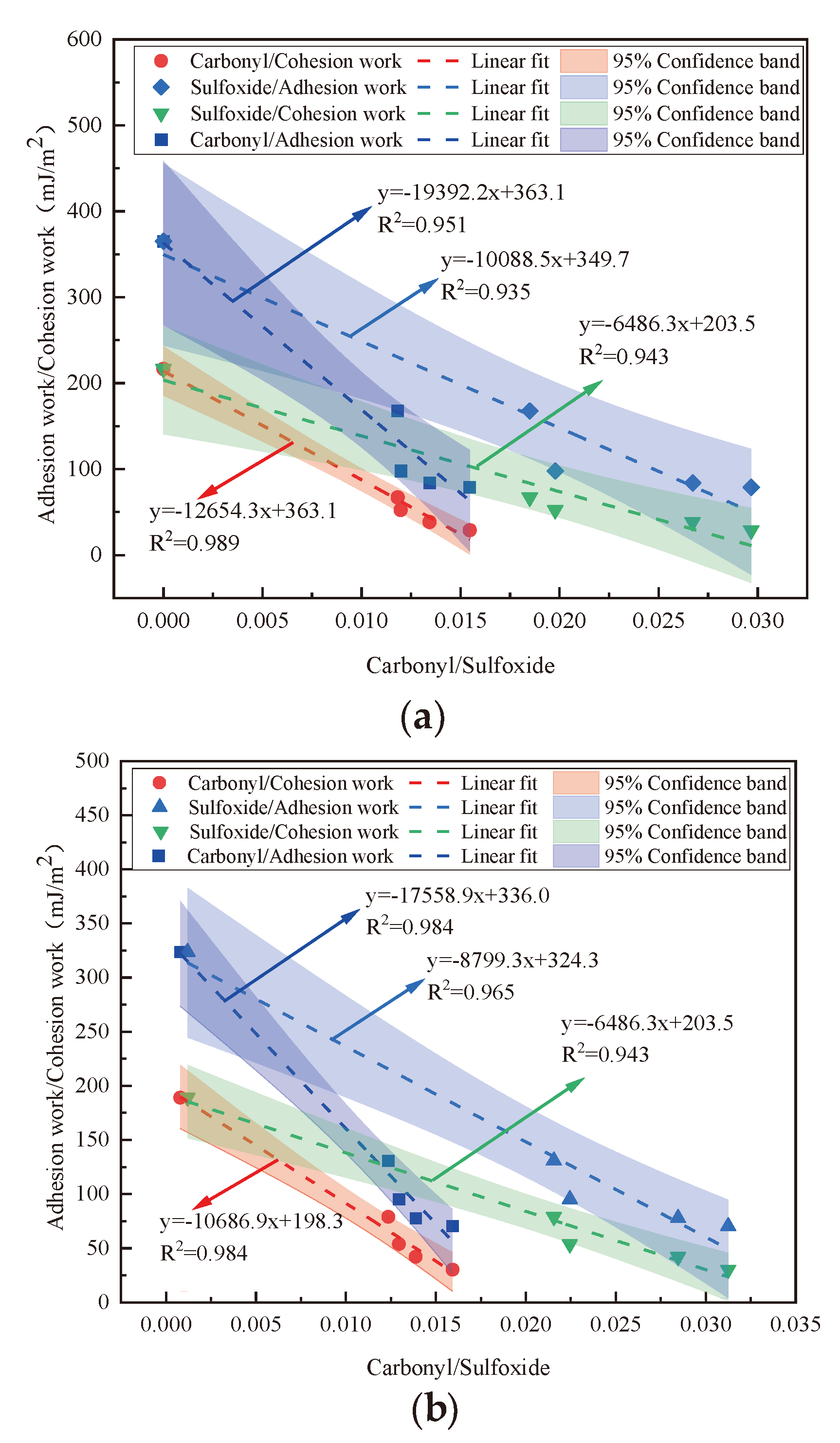

3.3. Correlation Analysis

3.4. Significant Difference Analysis

3.5. Contribution Rate of Ultraviolet and Oxygen

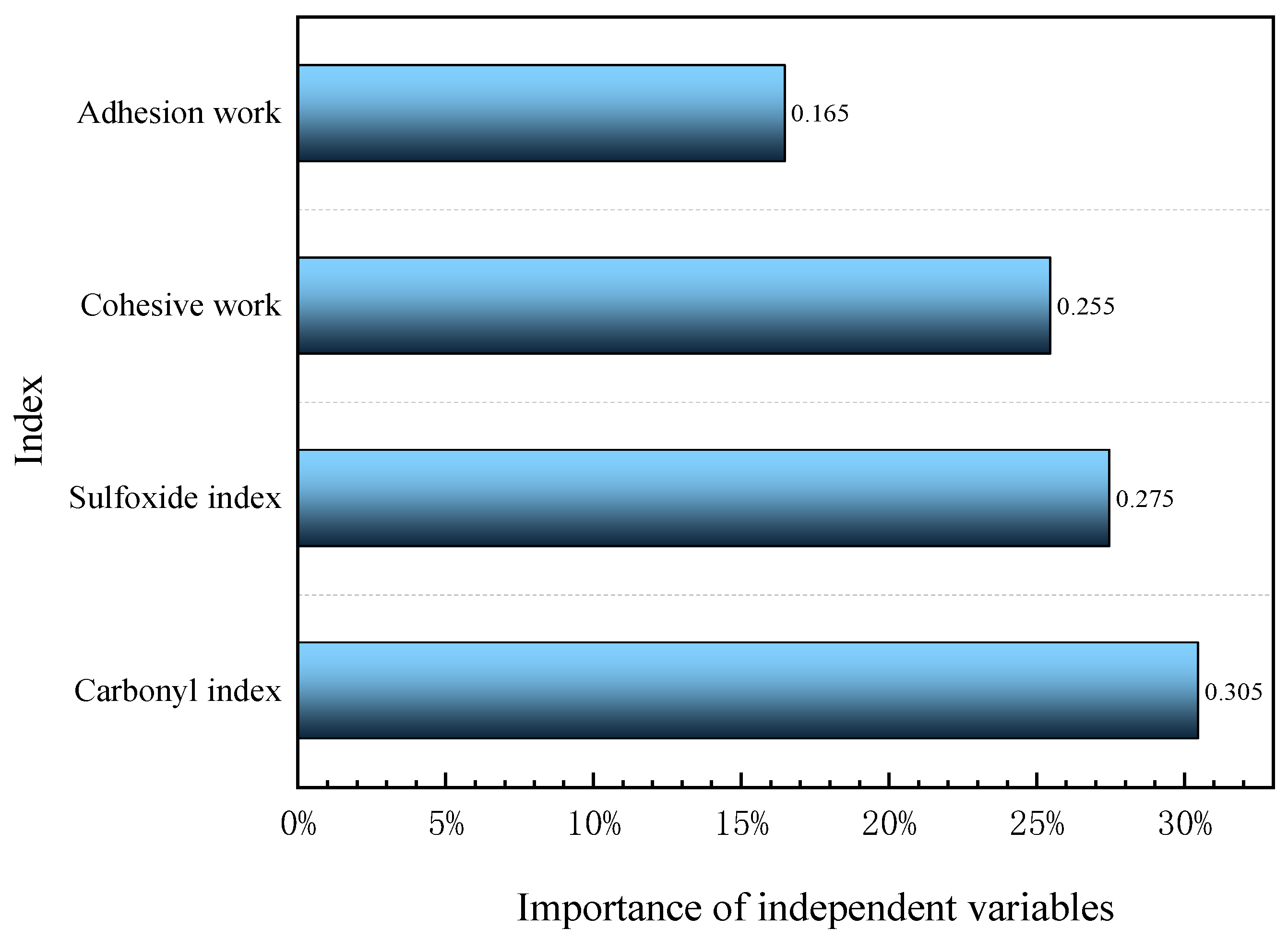

3.6. Importance of Independent Variables

4. Conclusions

- (1)

- RTFOT, PAV and UV aging all cause deterioration of bonding properties and significant changes in the functional group index of WMA, with the main chemical changes occurring during the aging process. Among them, UV aging has the greatest effect, followed by PAV aging, and RTFOT aging has the least effect.

- (2)

- The increase in UV aging time leads to the hardening of WMA and thus to a decrease in the bonding and cohesion functions. The carbonyl index and sulfoxide index increased with the increase in UV aging time, and the main WMA mainly absorbed oxygen with asphalt during the photo-oxidative coupling process and accelerated its aging. After 150 h of UV aging, the bonding performance index and functional group index gradually tend to stabilize.

- (3)

- The correlation coefficients for photo-oxidative coupling UV aging are higher than those for oxygen barrier UV aging. Photo-oxidative coupling and oxygen-free UV aging have significant effects on the adhesion and cohesive work of WMA. The effects of the carboxyl index and sulfoxide index were extremely significant.

- (4)

- There is a significant difference in the cohesion function of WMA after UV aging. The main reason for this significant difference may be the change in cohesion caused by molecular reactions within WMA due to the presence of oxygen.

- (5)

- The random forest model shows that during the light–oxygen-coupled UV aging process of warm mix asphalt, the contribution rate of UV is 79.9%, and the contribution rate of oxygen is 20.1%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pakenari, M.M.; Hamedi, G.H. Investigating the Effective Laboratory Parameters on the Stiffness Modulus and Fatigue Cracking of Warm Mix Asphalt. Int. J. Civ. Eng. 2021, 19, 685–698. [Google Scholar] [CrossRef]

- Liu, Q.; Cao, D. Research on material composition and performance of porous asphalt pavement. J. Mater. Civ. Eng. 2009, 21, 135–140. [Google Scholar] [CrossRef]

- Bekheet, W.; Hassan, Y.; El Halim, A. Modelling in situ shear strength testing of asphalt concrete pavements using the finite element method. Can. J. Civ. Eng. 2001, 28, 541–544. [Google Scholar] [CrossRef]

- Kargari, A.; Arabani, M.; Mirabdolazimi, S.M. Effect of palm oil capsules on the self-healing properties of aged and unaged asphalt mixtures gained by resting period and microwave heating. Constr. Build. Mater. 2022, 316, 125901. [Google Scholar] [CrossRef]

- Bell, C.A.; Abwahab, Y.; Cristi, M.E. Laboratory Aging of Asphalt-Aggregate Mixtures. In Serviceability and Durability of Construction Materials; ASCE: Reston, VI, USA, 1994. [Google Scholar]

- Che, T.; Pan, B.; Li, Y.; Ge, D.; Jin, D.; You, Z. The effect of styrene-butadiene rubber modification on the properties of asphalt binders: Aging and restoring. Constr. Build. Mater. 2022, 316, 126034. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.; Wang, H.; Hao, P. Rheological property investigations for polymer and polyphosphoric acid modified asphalt binders at high temperatures. Constr. Build. Mater. 2014, 64, 316–323. [Google Scholar] [CrossRef]

- Farrokhzade, F.; Sabouri, M.; Tabatabaee, N. Aging characteristics of neat and modified asphalt binders based on rheological evaluations at intermediate temperatures. Constr. Build. Mater. 2022, 322, 126387. [Google Scholar] [CrossRef]

- Crucho, J.; Picado-Santos, L.; Neves, J.; Capitão, S. Accelerated laboratory ageing of bituminous mixtures using the TEAGE method. In Proceedings of the 8th Transport Research Arena TRA 2020, Helsinki, Finland, 27–30 April 2020. [Google Scholar]

- Duan, B.A.; Er, A. Research into effect of asphalt mixture aging on stiffness. Transp. Res. Procedia 2021, 55, 1251–1257. [Google Scholar]

- Li, D.; Leng, Z.; Wang, H.; Chen, R.; Wellner, F. Structural and mechanical evolution of the multiphase asphalt rubber during aging based on micromechanical back-calculation and experimental methods. Mater. Des. 2022, 215, 110421. [Google Scholar] [CrossRef]

- Diouri, K.; De, A.; Dave, E.V.; Sias, J.; Mallick, R.B. Effect of aging and temperature on milling-induced stresses and cracks in Hot Mix Asphalt (HMA) pavements. Constr. Build. Mater. 2021, 313, 125493. [Google Scholar] [CrossRef]

- Li, F.; Wang, Y.; Miljkovi, M.; Chan, K.M. Changes in the Nanoscale Asphaltene Particles and Relaxation Spectra of Asphalt Binders During Aging and Rejuvenation. Mater. Des. 2022, 219, 110808. [Google Scholar] [CrossRef]

- Liu, Q.; Yu, B.; Falchetto, A.C.; Wang, D.; Liu, J.; Bo, W. Characterization and molecular mechanism of the thermal-oxidative gradient aging behavior in asphalt films. Measurement 2022, 199, 111567. [Google Scholar] [CrossRef]

- Wang, Z.; Ye, F. Experimental investigation on aging characteristics of asphalt based on rheological properties. Constr. Build. Mater. 2020, 231, 117158. [Google Scholar] [CrossRef]

- Petersen, J.; Harnsberger, P. Asphalt Aging: Dual Oxidation Mechanism and Its Interrelationships with Asphalt Composition and Oxidative Age Hardening. Transp. Res. Rec. J. Transp. Res. Board 1998, 1638, 47–55. [Google Scholar] [CrossRef]

- Mikhailenko, P.; Kou, C.; Baaj, H.; Poulikakos, L.; Cannone-Falchetto, A.; Besamusca, J.; Hofko, B. Comparison of ESEM and physical properties of virgin and laboratory aged asphalt binders. Fuel 2019, 235, 627–638. [Google Scholar] [CrossRef]

- Adolfo, F.R.; Claussen, L.E.; Cargnin, R.S.; Brudi, L.C.; Grasmann, C.S.; do Nascimento, P.C.; Cravo, M.; Nascimento, L.A.; Alcantara, A.P.; Branco, V.T.C.; et al. Influence of thermal aging and long term-aging on Ni and V content in asphalt fractions and their determination in air particulate matter from asphalt mixing plants. Fuel 2022, 324, 124289. [Google Scholar] [CrossRef]

- Montepara, A.; Santagata, E.; Tosi, G. Lightchemical degradation of pure bitumen by UVradiation. In Proceedings of the Eurasphalt and Eurobitume Congress, Strasbourg, France, 7–10 May 1996; Volume 5, p. 133. [Google Scholar]

- Montepara, A.; Giuliani, F. Performance testing and specification teses of road bitumen. In Proceedings of the Papers Submitted for Review at 2nd Eurasphalt and Eurobitume Congress, Barcelona, Spain, 20–22 September 2000; pp. 518–523. [Google Scholar]

- Bocci, M.; Cerni, G. The ultraviolet radiation in short-and long-term aging of bitumen. In Proceedings of the 2nd Eurasphalt & Eurobitume Congress, Barcelona, Spain, 20–22 September 2000; Volume 1, pp. 49–58. [Google Scholar]

- Ye, F.; Huang, P. Establishment of asphalt aging emulation system under ultraviolet radiation. J. Build. Mater. 2005, 15, 133–140. [Google Scholar]

- Pang, L.; Long, L.; Wu, S.P.; Lu, W. Effects of UV Aging on the High-Temperature and Fatigue Performances of Asphalt Mortar. Adv. Mater. Res. 2011, 306–307, 1698–1701. [Google Scholar] [CrossRef]

- Zeng, W.B.; Wu, S.P.; Pang, L.; Chen, H.; Hu, J.; Sun, Y.; Chen, Z. Research on ultraviolet (UV) aging depth of asphalts. Constr. Build. Mater. 2018, 160, 620–627. [Google Scholar] [CrossRef]

- Li, Y.Y.; Wu, S.P.; Liu, Q.T. Aging effects of ultraviolet lights with same dominant wavelength and different wavelength ranges on a hydrocarbon-based polymer (asphalt). Polym. Test. 2019, 75, 64–75. [Google Scholar] [CrossRef]

- Xiao, M.M.; Fan, L. Ultraviolet aging mechanism of asphalt molecular based on microscopic simulation. Constr. Build. Mater. 2022, 319, 126157. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Q.T.; Wu, S.P.; Rao, Y.; Sun, Y.; Xie, J.; Pan, P. Investigation of the flow and self-healing properties of UV aged asphalt binders. Constr. Build. Mater. 2018, 174, 401–409. [Google Scholar] [CrossRef]

- Zeng, W.B.; Wu, S.P.; Wen, J.; Chen, Z. The temperature effects in aging index of asphalt during UV aging process. Constr. Build. Mater. 2015, 93, 1125–1131. [Google Scholar] [CrossRef]

- Jamal, M.; Martinez-Arguelles, G.; Giustozzi, F. Effect of waste tyre rubber size on physical, rheological and UV resistance of high-content rubber-modified bitumen. Constr. Build. Mater. 2021, 304, 124638. [Google Scholar] [CrossRef]

- Rajib, A.; Saadeh, S.; Katawal, P.; Mobasher, B.; Fini, E.H. Enhancing Biomass Value Chain by Utilizing Biochar as A Free Radical Scavenger to Delay Ultraviolet Aging of Bituminous Composites Used in Outdoor Construction. Resour. Conserv. Recycl. 2021, 168, 105302. [Google Scholar] [CrossRef]

- Liu, H.B.; Zhang, Z.Q.; Tian, Z.N.; Lu, C. Exploration for UV Aging Characteristics of Asphalt Binders based on Response Surface Methodology: Insights from the UV Aging Influencing Factors and Their Interactions. Constr. Build. Mater. 2022, 347, 128460. [Google Scholar] [CrossRef]

- Manolis, S.; Lum, P. Cold Weather Paving Using Warm Mix Asphalt Technology. In Proceedings of the Annual Conference of the Transportation Association of Canada, Toronto, ON, Canada, 2–5 October 2022. [Google Scholar]

- Sun, M.; Li, B.; Yi, Z.; Cao, K.; Li, A.; Wang, Y. Optimization of surface free energy parameters for asphalt binder-aggregate system based on RBF neural network model. Constr. Build. Mater. 2022, 357, 129382. [Google Scholar] [CrossRef]

- Awanti, S.S.; Anilkumar, L. Studies on Characterisation of SBS Polymer Modified and Neat Bituminous Mixes Using Warm Mix Asphalt for Paving Applications. Int. J. Fluid Mech. Therm. Sci. 2021, 7, 37. [Google Scholar]

- Liu, S.; Zhou, S.; Peng, A. Analysis of moisture susceptibility of foamed warm mix asphalt based on cohesion, adhesion, bond strength, and morphology. J. Clean. Prod. 2020, 277, 123334. [Google Scholar] [CrossRef]

- Xiong, F.; Zarei, M.; Tabasi, E.; Naseri, A.; Khordehbinan, M.W.; Kh, T.I. Effect of nano-reduced graphene oxide (NRGO) on long-term fracture behavior of Warm Mix Asphalt (WMA). Constr. Build. Mater. 2023, 392, 131934. [Google Scholar] [CrossRef]

- Wang, X.; Ren, J.; Gu, X.; Li, N.; Tian, Z.; Chen, H. Investigation of the adhesive and cohesive properties of asphalt, mastic, and mortar in porous asphalt mixtures. Constr. Build. Mater. 2021, 276 (Suppl. S2), 122255. [Google Scholar] [CrossRef]

- Wang, C.; Chen, Y.; Gong, G. Cohesive and adhesive healing evaluation of asphalt binders by means of the LASH and BBSH tests. Constr. Build. Mater. 2021, 282, 122684. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, G.; Liu, Z.; Feng, M.; Li, C. Influence of coupled aging condition of heat, light and water on performance of warm mix asphalt. J. Highw. Trans. Res. Dev. 2018, 36, 10–19. [Google Scholar]

- Wu, S.P.; Pang, L.; Mo, L.T.; Chen, Y.-C.; Zhu, G.-J. Influence of aging on the evolution of structure, morphology and rheology of base and SBS modified bitumen. Constr. Build. Mater. 2009, 23, 1005–1010. [Google Scholar] [CrossRef]

| Indoor UV aging time/h | 50 | 100 | 150 | 200 |

| Outdoor UV aging time/month | 1 | 2 | 3 | 4 |

| Items | Units | Requirement | Result | |

|---|---|---|---|---|

| 25 °C penetration/(100 g, 5 s) | 0.1 mm | 80~100 | 86.2 | |

| Softening point/(R&B) | °C | ≥42 | 47.3 | |

| 10 °C ductility | cm | ≥20 | 25.2 | |

| RTFOT (163 °C, 85 min) | Mass loss | % | ≤±0.8 | 0.04 |

| Penetration ratio | % | ≥57 | 67.2 | |

| Ductility/10 °C | cm | ≥8 | 11.4 | |

| Probe Liquids | |||||

|---|---|---|---|---|---|

| Distilled water | 72.8 | 21.8 | 51.0 | 25.50 | 25.5 |

| Glycerol | 64.0 | 34.0 | 30.0 | 3.92 | 57.4 |

| Formamide | 58.0 | 38.0 | 19.0 | 2.28 | 39.6 |

| Test Liquids | Contact Angle (°) | |||||||

|---|---|---|---|---|---|---|---|---|

| Original | RTFOT | Oxygen (Yes or No) | 50 h UV | 100 h UV | 150 h UV | 200 h UV | PAV | |

| Distilled water | 99.42 | 97.72 | No | 101.96 | 103.97 | 103.15 | 99.26 | 104.96 |

| Yes | 99.97 | 98.11 | 99.68 | 101.18 | ||||

| Glycerol | 103.46 | 100.29 | No | 95.89 | 94.82 | 94.04 | 92.42 | 101.04 |

| Yes | 97.03 | 97.32 | 94.53 | 95.11 | ||||

| Formamide | 80.87 | 79.85 | No | 85.13 | 85.48 | 86.89 | 88.71 | 85.53 |

| Yes | 81.50 | 85.68 | 84.75 | 85.31 | ||||

| Source of Difference | SS | df | MS | F-Value | p-Value | F Crit |

|---|---|---|---|---|---|---|

| Adhesive work | 6909.03 | 3 | 2303.01 | 18.71219 | 0.0191 | 9.276628 |

| Cohesive work | 3.22895 | 3 | 1.076317 | 11.65896 | 0.006786 | 9.276628 |

| Carbonyl index | 1.58 × 10−5 | 3 | 5.27 × 10−6 | 169.1818 | 0.000763 | 9.276628 |

| Sulfoxide index | 0.000152 | 3 | 5.08 × 10−5 | 196.085 | 0.000613 | 9.276628 |

| Index | Contribution Rate | |

|---|---|---|

| Ultraviolet | Oxygen | |

| Carbonyl index | 78.6% | 21.4% |

| Sulfoxide index | 79.0% | 21.0% |

| Adhesive work | 79.2% | 20.8% |

| Cohesive work | 82.8% | 18.2% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Li, B.; Wang, Y.; Li, X.; Li, D.; Ren, X.; Fu, M. Contribution of Oxygen and Ultraviolet Light to the Adhesion Properties of Warm Mix Asphalt During the Light-Oxidative Coupling Ultraviolet Aging Process. Materials 2025, 18, 1345. https://doi.org/10.3390/ma18061345

Ma J, Li B, Wang Y, Li X, Li D, Ren X, Fu M. Contribution of Oxygen and Ultraviolet Light to the Adhesion Properties of Warm Mix Asphalt During the Light-Oxidative Coupling Ultraviolet Aging Process. Materials. 2025; 18(6):1345. https://doi.org/10.3390/ma18061345

Chicago/Turabian StyleMa, Jianbing, Bo Li, Yongning Wang, Xiaomin Li, Dongna Li, Xiaoyu Ren, and Mingxing Fu. 2025. "Contribution of Oxygen and Ultraviolet Light to the Adhesion Properties of Warm Mix Asphalt During the Light-Oxidative Coupling Ultraviolet Aging Process" Materials 18, no. 6: 1345. https://doi.org/10.3390/ma18061345

APA StyleMa, J., Li, B., Wang, Y., Li, X., Li, D., Ren, X., & Fu, M. (2025). Contribution of Oxygen and Ultraviolet Light to the Adhesion Properties of Warm Mix Asphalt During the Light-Oxidative Coupling Ultraviolet Aging Process. Materials, 18(6), 1345. https://doi.org/10.3390/ma18061345