Description of the Lubricant Behavior Based on the Theory of Elasto-Viscoplastic

Abstract

:1. Introduction

1.1. Research Objectives

1.2. Problem Context

1.3. Problem Description

- Study of tribological, thermophysical, electromechanical and other grease properties.

- Experimental study of the greases behavior under thermal and force influence.

- Mathematical description of grease behavior for possible use in computer aided design (CAD) systems.

1.4. About Mathematical Model

- -

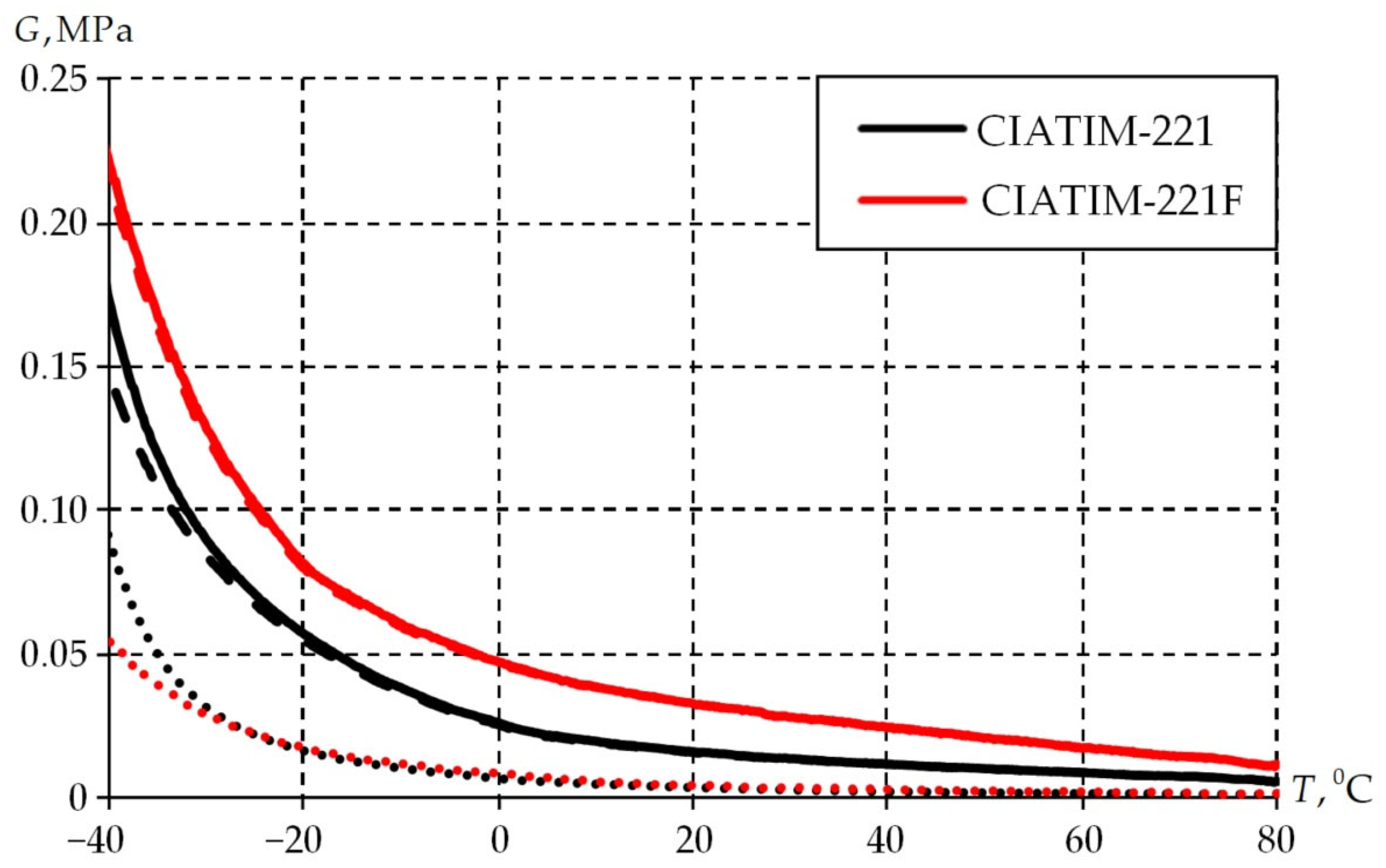

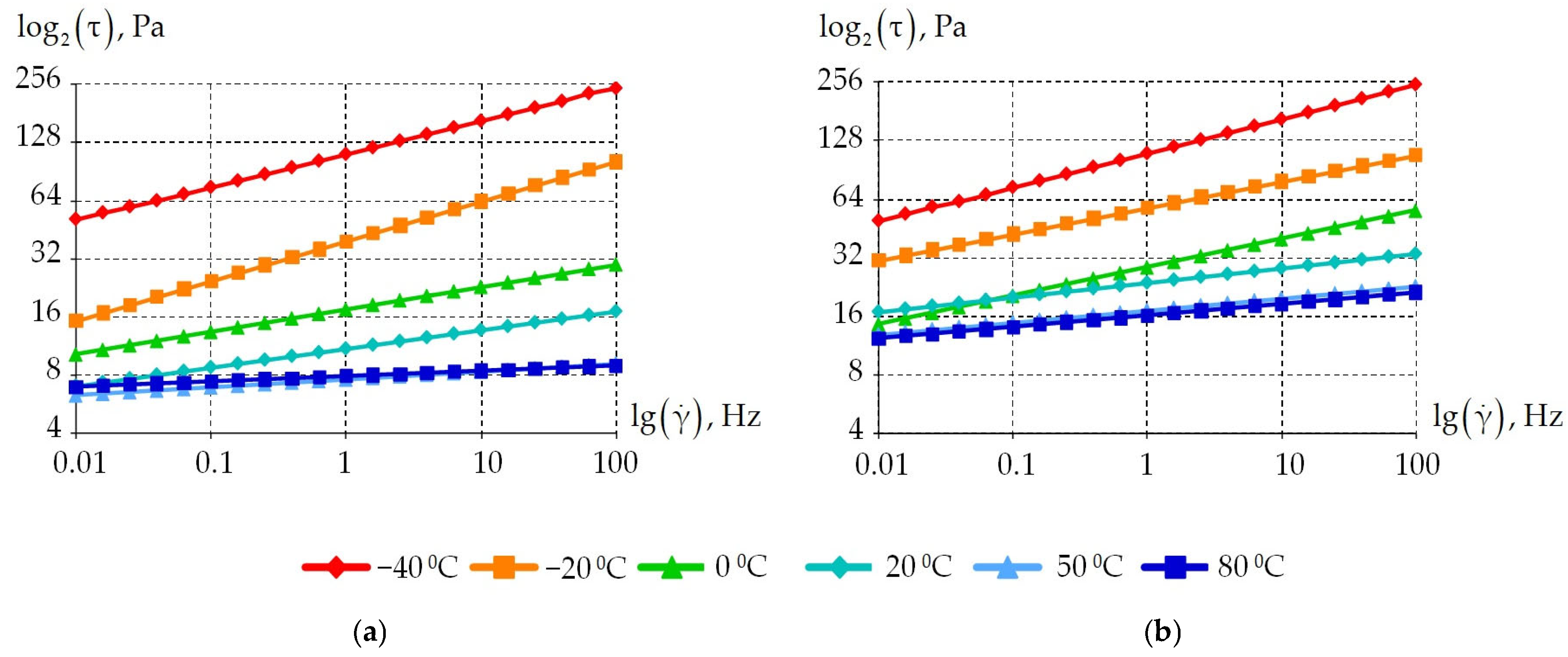

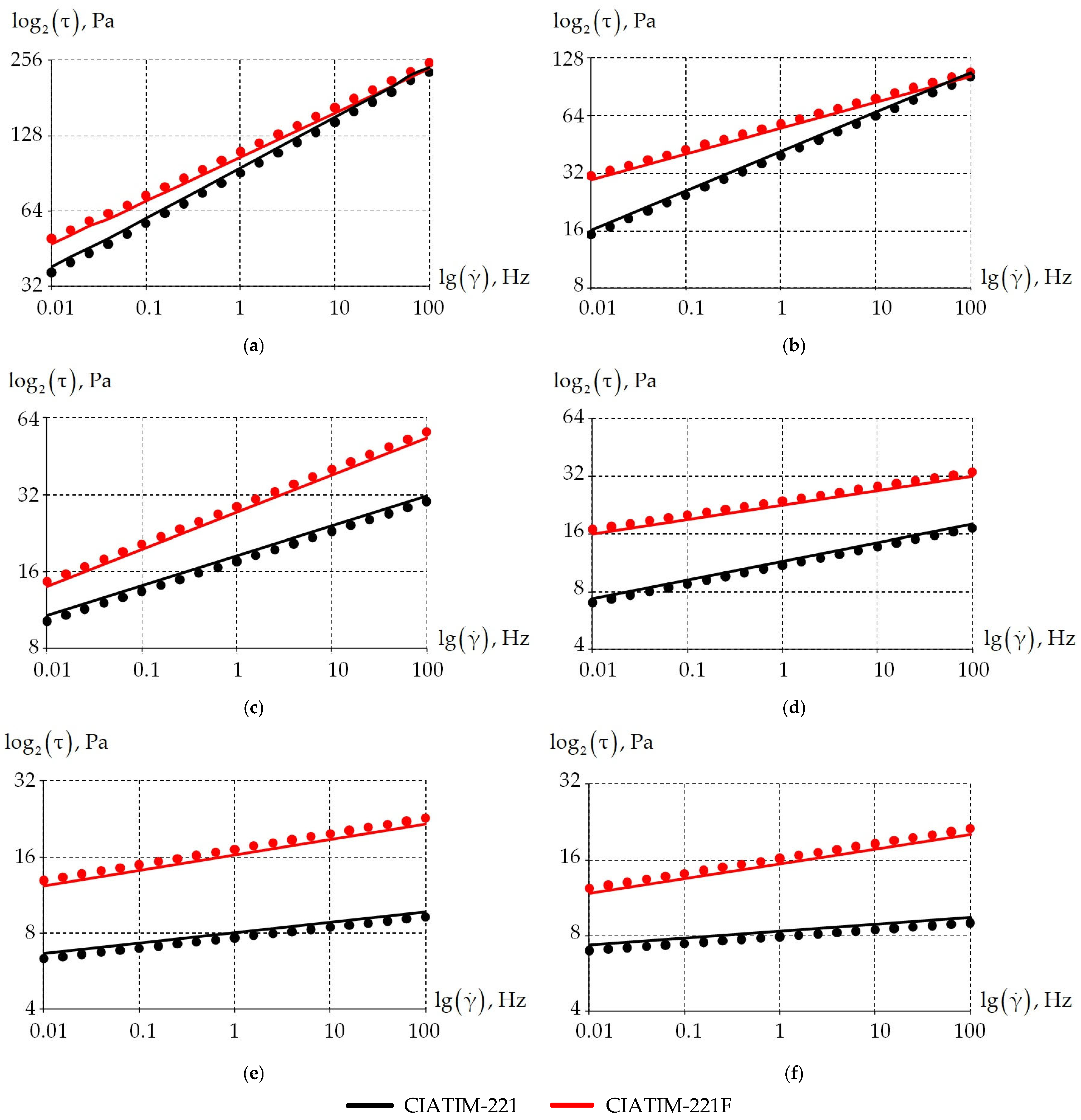

- the mathematical model describes quite accurately the behavior of materials under temperature changes and at frequencies from 1 Hz to 100 Hz;

- -

- there is an increase in the error relative to experimental data at frequencies from 0.01 to 1 Hz.

2. Materials and Methods

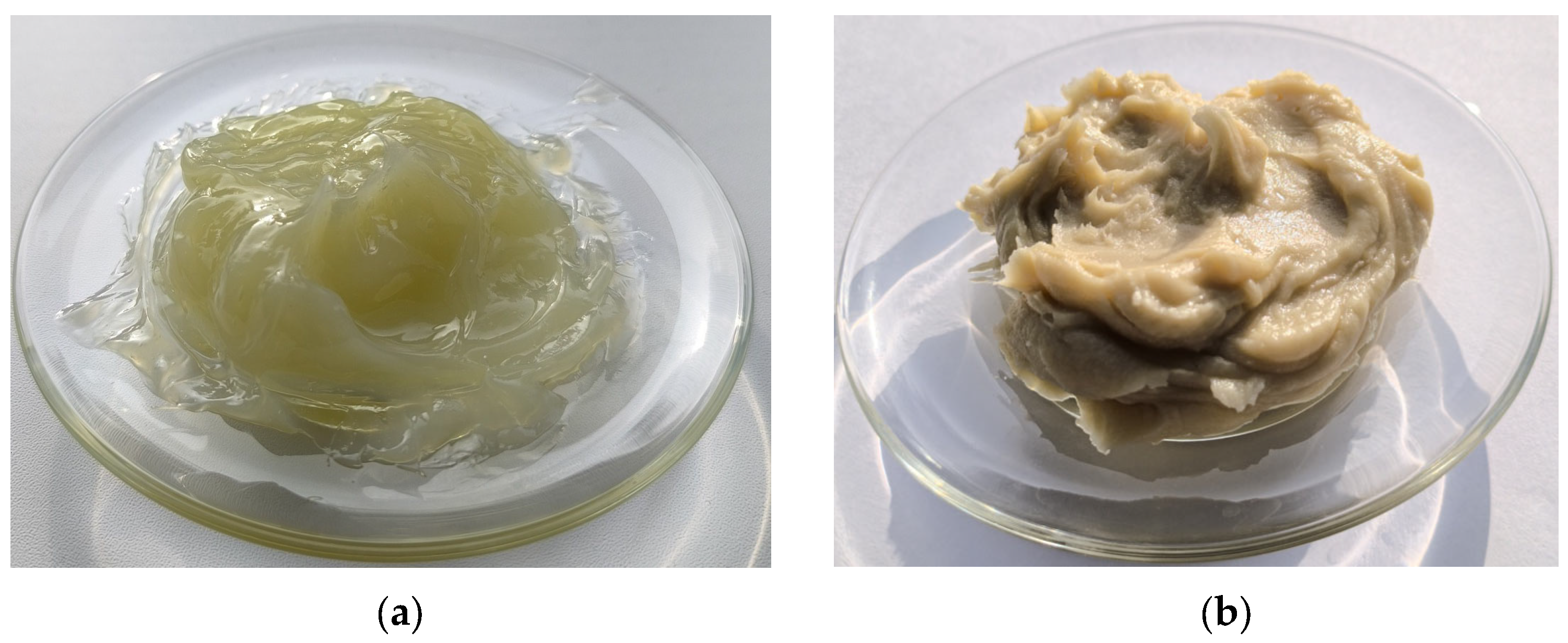

2.1. Materials

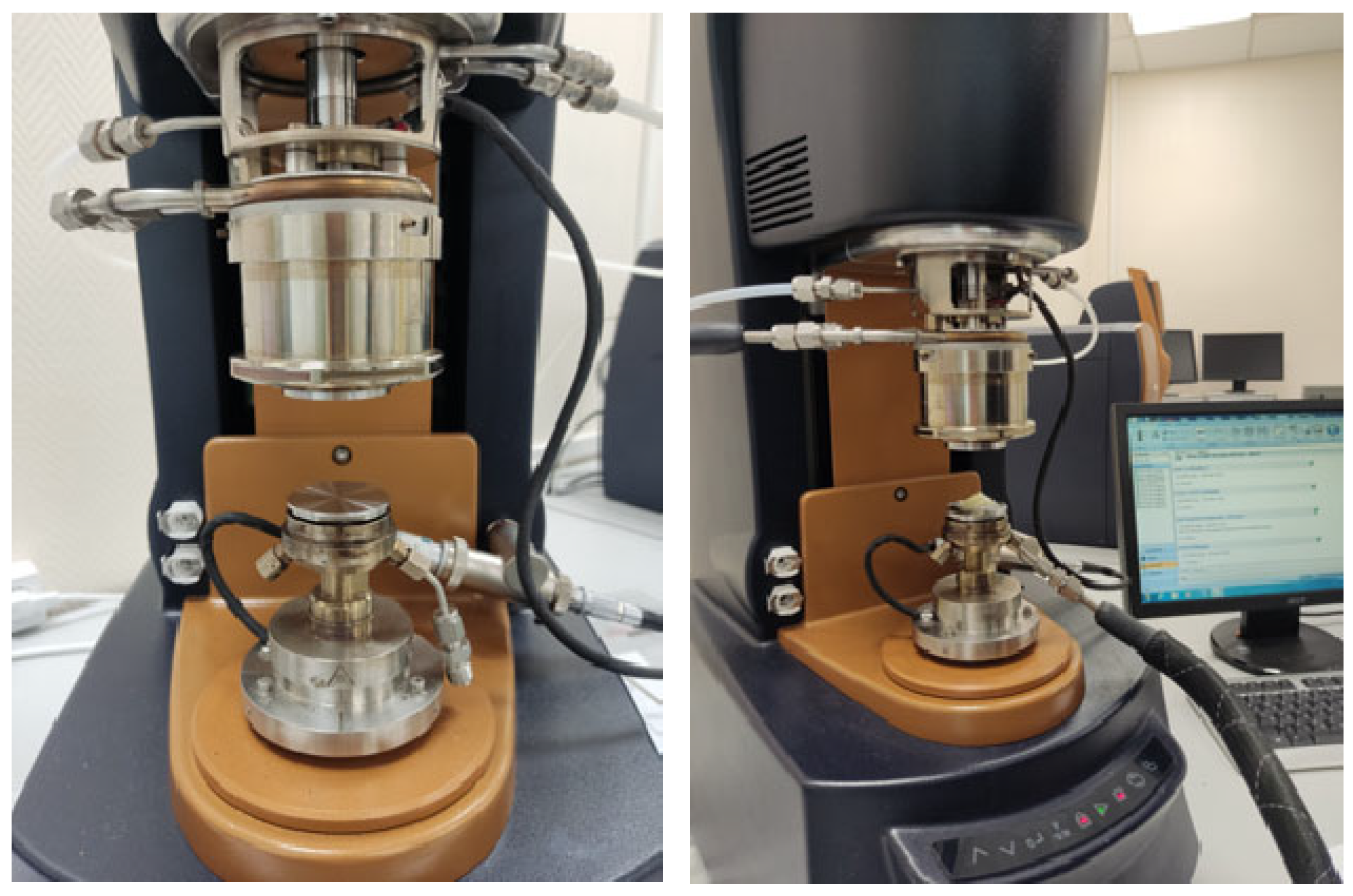

2.2. Experimental Study

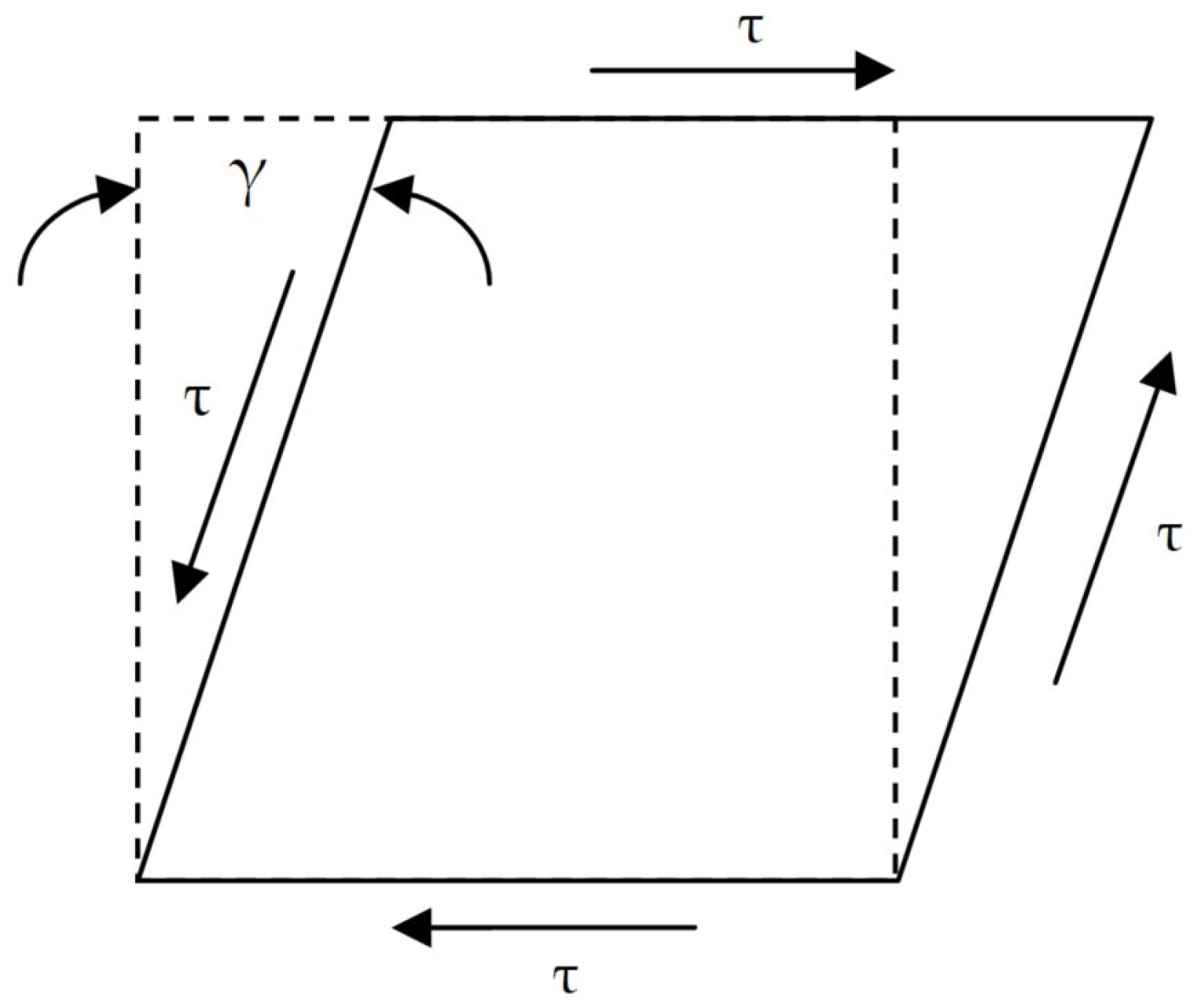

2.3. Mathematical Model

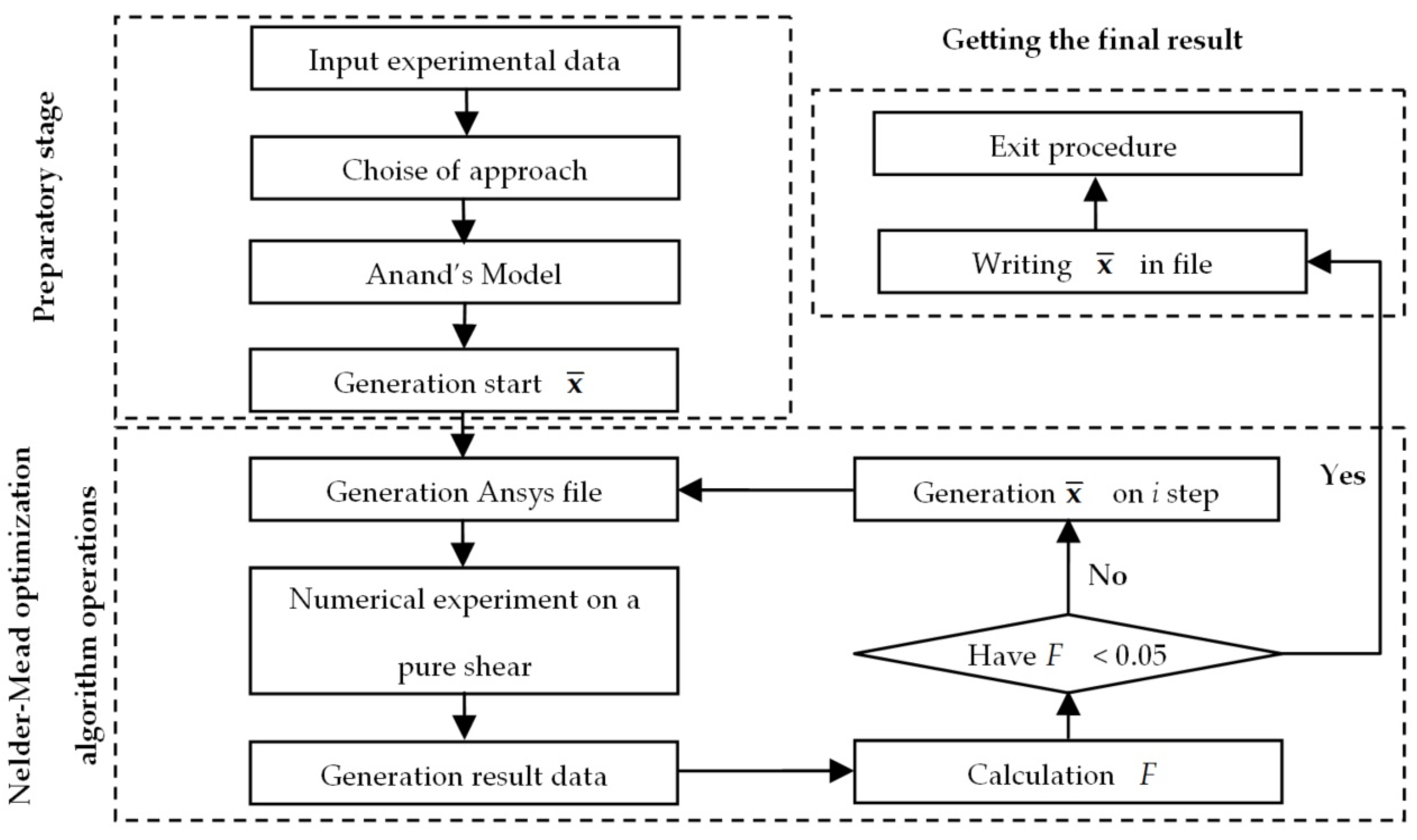

2.4. Anand Model Identification Procedure

- (1)

- Experimental data are loaded. The type of mathematical model is selected. The initial vector of unknowns is formed. Section 2.3 describes the mathematical equations of the algorithm detail.

- (2)

- A numerical experiment is realized.

- -

- the changes in the frequency from 0.01 to 100 Hz at constant temperatures;

- -

- the temperature change from −40 to +80 °C in a step of 2° per min, with a constant frequency (1 Hz).

- (3)

- The work of the numerical procedure is completed. The file with the found parameters of the vector of unknowns is formed.

3. Results

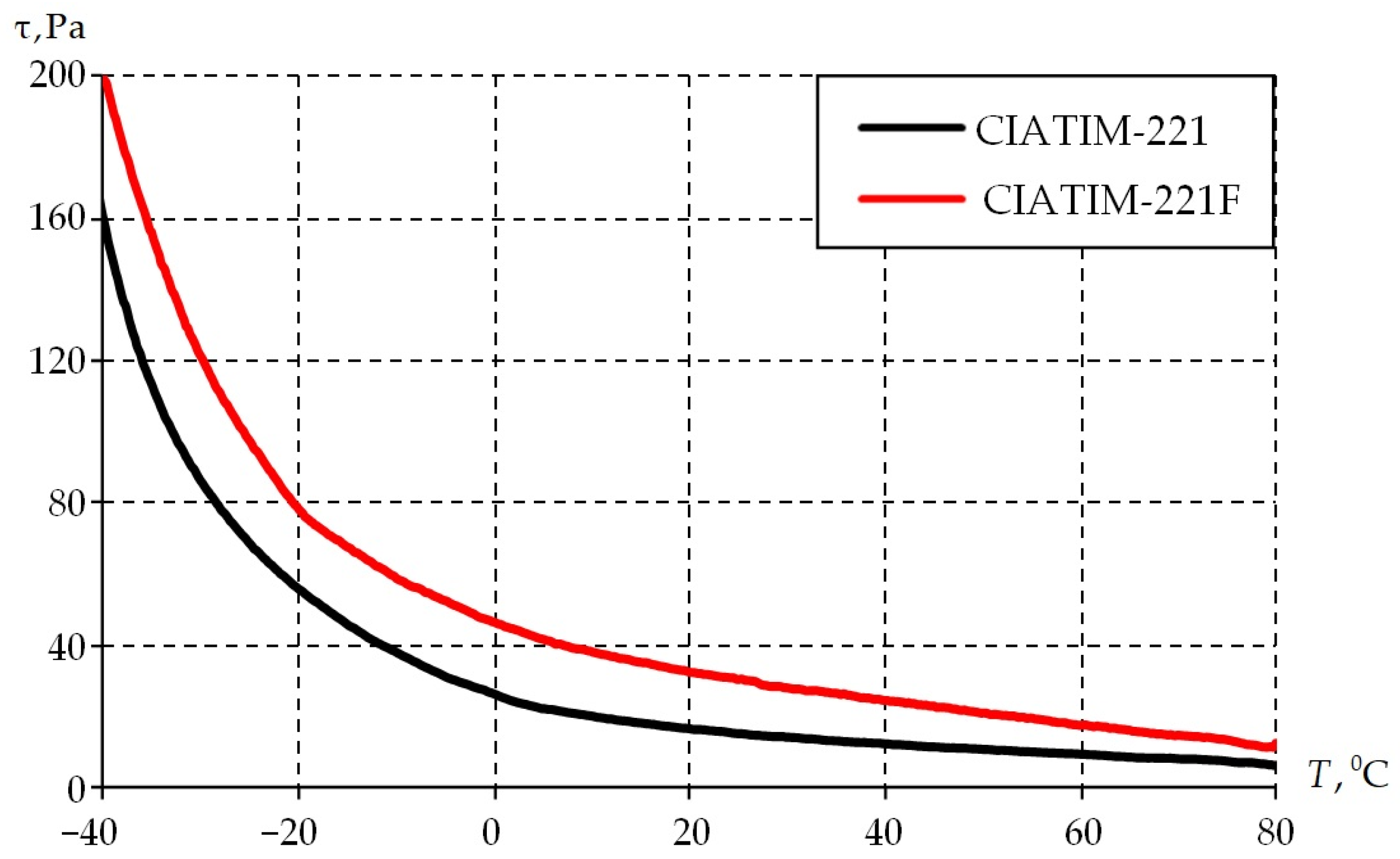

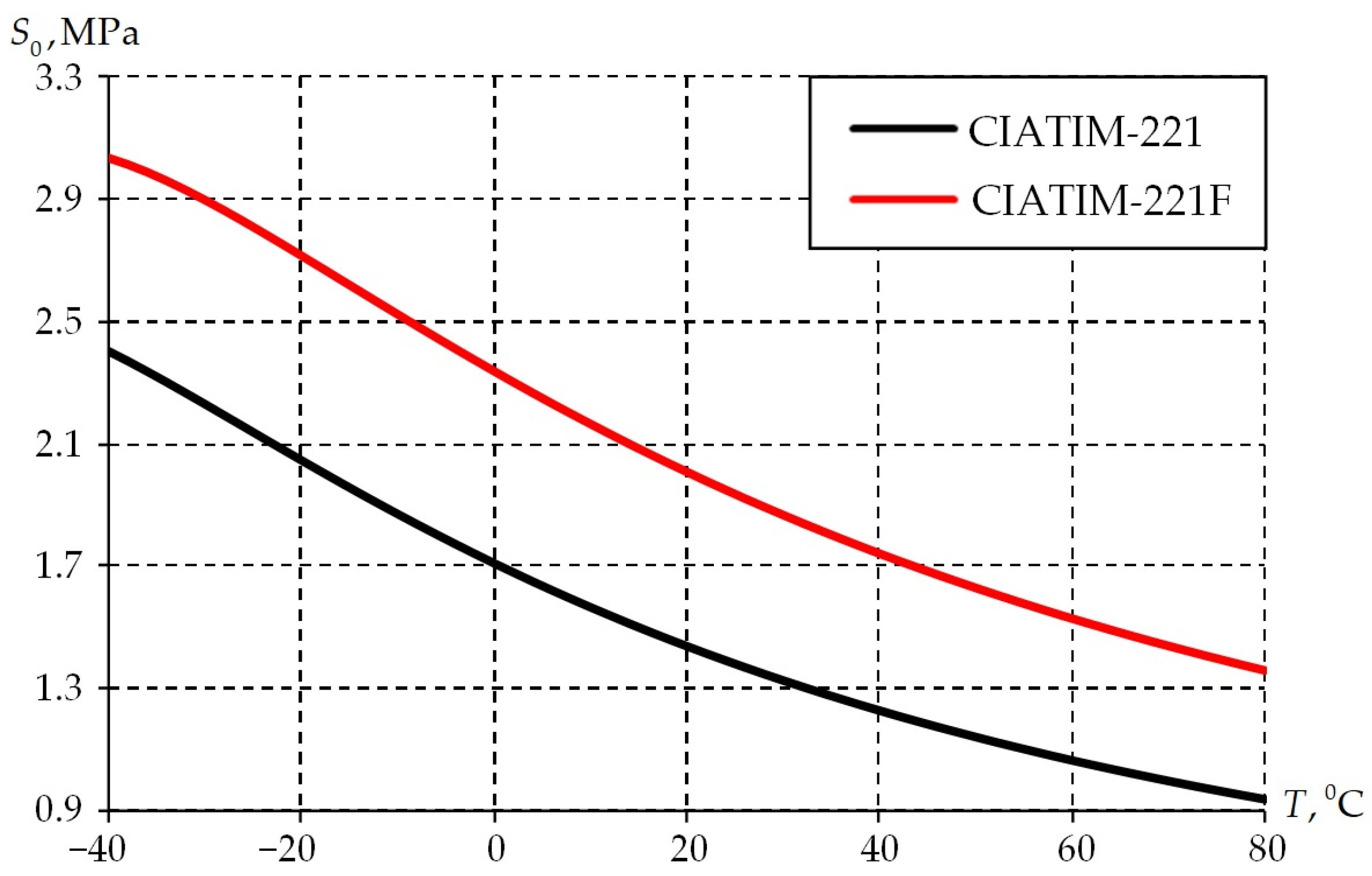

3.1. Results of the Experimental Study

3.2. Results of the Anand Mathematical Model Identification

3.3. Frequency and Temperature Dependence of Physical and Mechanical Characteristics

4. Discussion

4.1. Limitation Statement

- -

- considered a temperature range of −40 °C to +80 °C, with −60 °C and +150 °C being the minimum and maximum temperature values for the feasibility of the grease, respectively;

- -

- there is no possibility to carry out the experiment by means of non-contact impact on the sample using DWS technology [78];

- -

- there is no open database of test materials and information on initial vectors for Equation (5), which leads to increased time for identification of the mathematical model of material behavior;

- -

- there are no separate experimental studies on the determination of the rheology and creep of greases in open sources.

- -

- conducting material studies at near-critical temperatures (−60 °C and +150 °C);

- -

- enriching the experimental database to reduce the time required to identify mathematical models of greases for future studies;

- -

- conducting additional experiments on the rheology and creep of materials;

- -

- conducting experiments by means of non-contact impact on the sample using DWS technology;

- -

- extending the applicability of the mathematical model to describe the behavior of polymers and composites.

4.2. About the Mathematical Models

4.3. About Grease Composition

5. Conclusions

- -

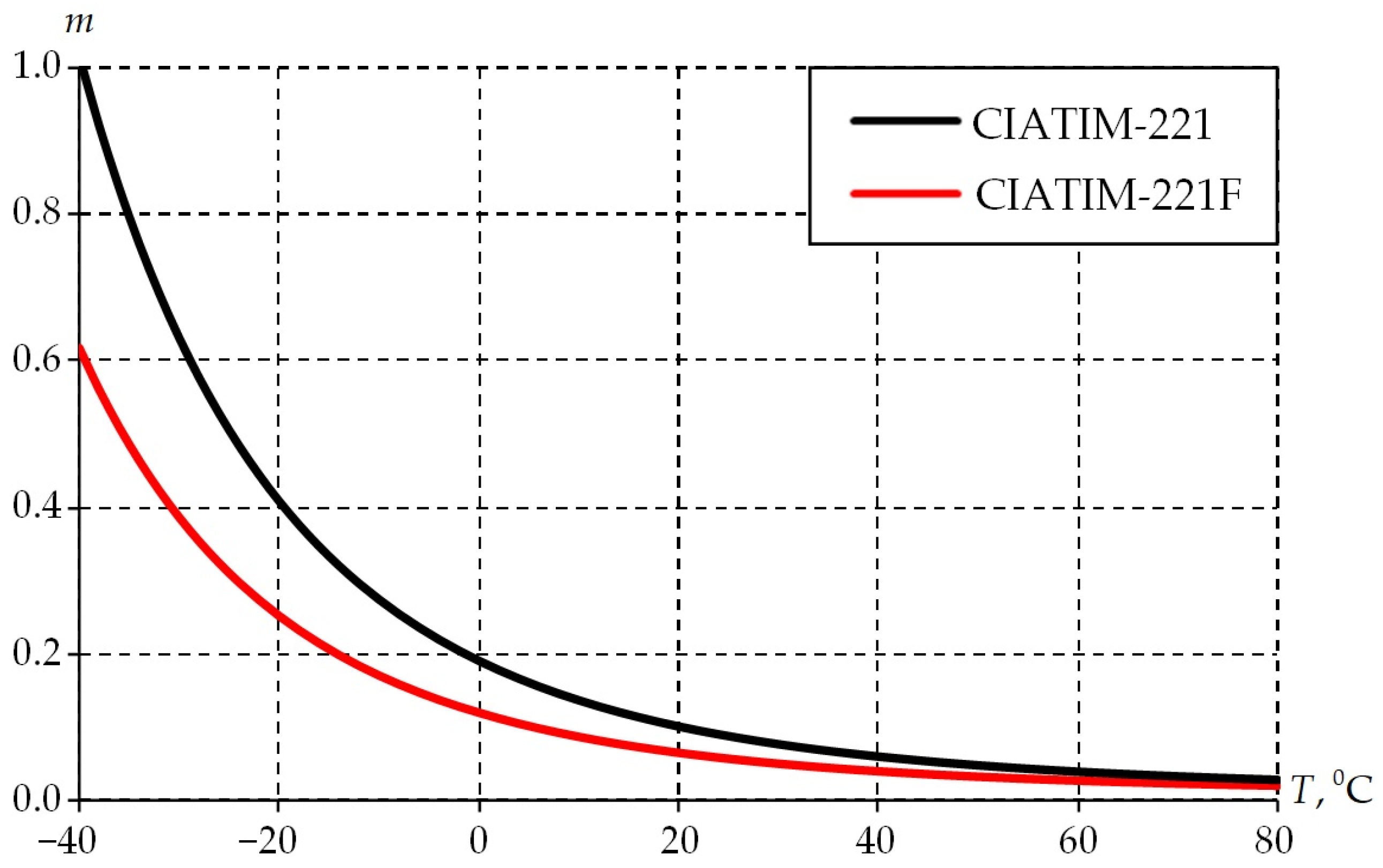

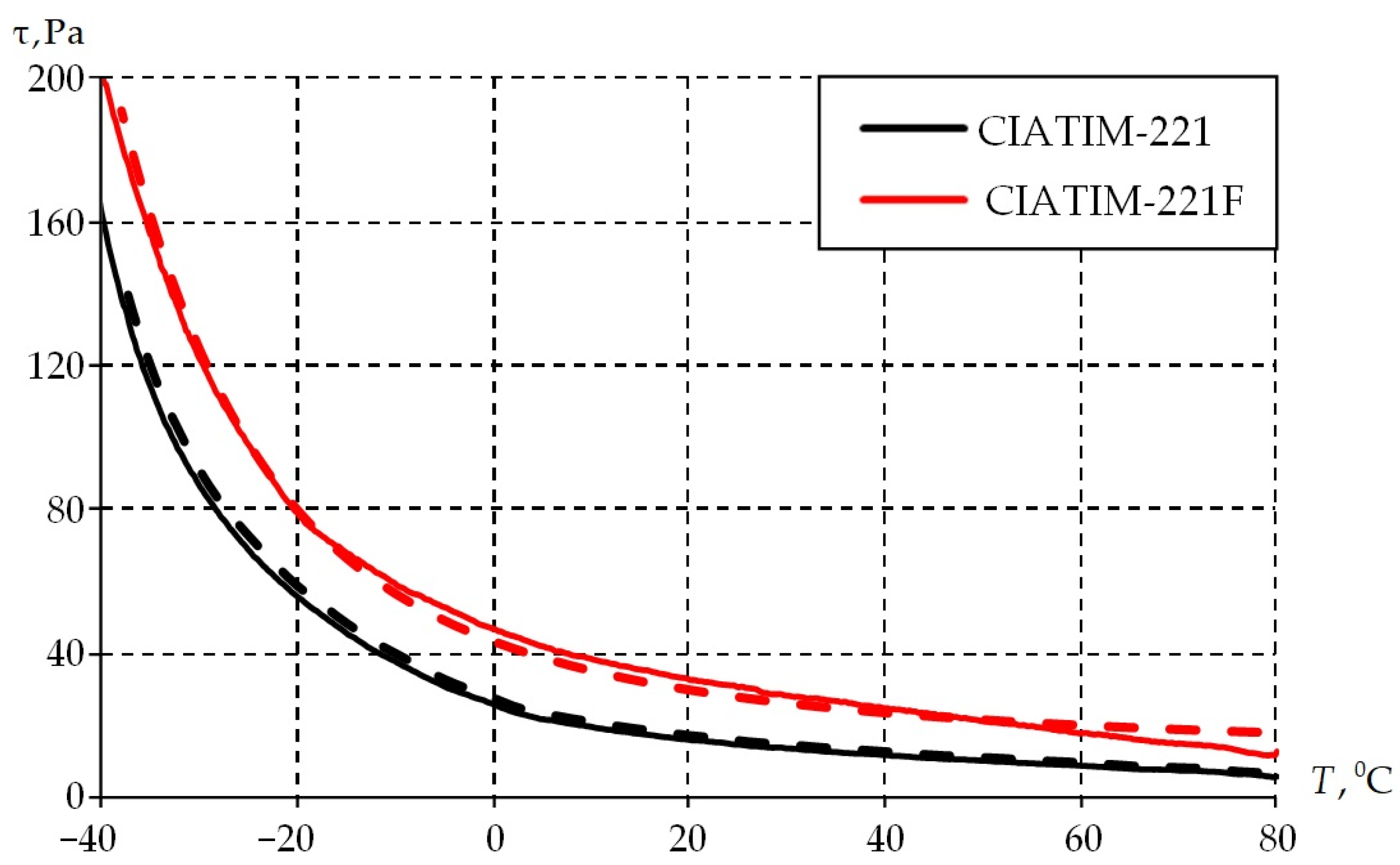

- The strength properties of greases increase with decreasing temperature.

- -

- Consideration of the temperature effect on material behavior is necessary for qualitative and quantitative descriptions of thermophysical grease properties.

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kamenskikh, A.A.; Nosov, Y.O. Mathematical Model Identification of the Maxwell Body Viscoelastic Behavior Based on Prony Series. RU Patent 2023618695, 27 April 2023. (In Russian). [Google Scholar]

- Janic’, M. Resilience, Robustness, and Vulnerability of Transport Systems; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Singh, S.; Martinetti, A.; Majumdar, A.; van Dongen, L. Transportation Systems: Managing Performance Through Advanced Maintenance Engineering; Springer: Singapore, 2019. [Google Scholar] [CrossRef]

- Adamov, A.A.; Kamenskikh, A.A.; Pankova, A.P.; Strukova, V.I. Comparative Analysis of the Work of Bridge Spherical Bearing at Different Antifriction Layer Locations. Lubricants 2022, 10, 207. [Google Scholar] [CrossRef]

- Qian, Y.; Sun, L.; Ai, L.; Zhou, Y.; Li, M. Theoretical Analysis of the Influence of Bearing Plate Position on the Bearing Performance of Soil around the CEP Antipull Force Double Pile. Buildings 2023, 13, 2613. [Google Scholar] [CrossRef]

- Wu, C.; Wu, P.; Wang, J.; Jiang, R.; Chen, M.; Wang, X. Critical review of data-driven decision-making in bridge operation and maintenance. Struct. Infrastruct. Eng. 2020, 18, 47–70. [Google Scholar] [CrossRef]

- Devitofranceschi, A.; Paolieri, E. Integral bridges: A construction method to minimize maintenance problems. Lect. Notes Civ. Eng. 2020, 42, 515–529. [Google Scholar] [CrossRef]

- Huang, W.; Pei, M.; Liu, X.; Liu, X. Design and construction of super-long span bridges in China: Review and future perspectives. Front. Struct. Civ. Eng. 2020, 14, 803–838. [Google Scholar] [CrossRef]

- Su, M.; Wang, J.; Peng, H.; Cai, C.; Dai, G. State-of-the-art review of the development and application of bridge rotation construction methods in China. Sci. China Technol. Sci. 2020, 64, 1137–1152. [Google Scholar] [CrossRef]

- Eggert, H.; Kauschke, W. Structural Bearings; Ernst & Sohn: Berlin, Germany, 2002. [Google Scholar]

- Kuznetsov, D.N.; Grigorash, V.V.; Sventikov, A.A. Work power of the support unit of the steel I-beam. Russ. J. Build. Constr. Archit. 2021, 1, 19–29. [Google Scholar] [CrossRef]

- Khan, A.K.M.T.A.; Bhuiyan, M.A.R.; Ali, S.B. Seismic responses of a bridge pier isolated by high damping rubber bearing: Effect of rheology modeling. Int. J. Civ. Eng. 2019, 17, 1767–1783. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J. Effect of material characteristics of high damping rubber bearings on aseismic behaviors of a two-span simply supported beam bridge. Adv. Mater. Sci. Eng. 2020, 2020, 9231382. [Google Scholar] [CrossRef]

- Choi, E.; Choi, S. Analysis of dynamic behavior of railroad steel bridges according to bridge bearing type. J. Korean Soc. Railw. 2012, 15, 62–70. [Google Scholar] [CrossRef]

- Itoh, Y.; Gu, H. Prediction of aging characteristics in natural rubber bearings used in bridges. J. Bridge Eng. 2009, 14, 122–128. [Google Scholar] [CrossRef]

- Ono, K. Structural materials: Metallurgy of bridges. In Metallurgical Design and Industry; Springer: Cham, Switzerland, 2018; pp. 193–269. [Google Scholar] [CrossRef]

- Yi, X.; Du, S.; Zhang, L. Composite Materials Engineering, Volume 1: Fundamentals of Composite Materials; Springer: Singapore, 2018. [Google Scholar] [CrossRef]

- Wang, Q.J.; Chung, Y.W. Encyclopedia of Tribology; Springer: Boston, MA, USA, 2013. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, P.; Wang, M. Pressure Characteristics of Landslide-Generated Waves on Bridge Piers. Water 2023, 15, 3623. [Google Scholar] [CrossRef]

- Cooper, A.H.; Saunders, J.M. Road and bridge construction across gypsum karst in England. Eng. Geol. 2002, 65, 217–223. [Google Scholar] [CrossRef]

- Wang, L.; Yu, L.; Du, X.; Zhang, X.; Li, Z. Seismic Response of a PC Continuous Box Girder Bridge under Extreme Ambient Temperature. Sustainability 2023, 15, 14763. [Google Scholar] [CrossRef]

- Nosov, Y.O.; Kamenskikh, A.A. Influence Analysis of Lubricant Recesses on the Working Capacity of the Bridge Span Spherical Bearing. Lubricants 2022, 10, 283. [Google Scholar] [CrossRef]

- Bukvić, M.; Gajević, S.; Skulić, A.; Savić, S.; Ašonja, A.; Stojanović, B. Tribological Application of Nanocomposite Additives in Industrial Oils. Lubricants 2024, 12, 6. [Google Scholar] [CrossRef]

- Su, R.; Cao, W.; Jin, Z.; Wang, Y.; Ding, L.; Maqsood, M.; Wang, D. Deterioration Mechanism and Status Prediction of Hydrocarbon Lubricants under High Temperatures and Humid Environments. Lubricants 2024, 12, 116. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I.; Aguilar-Rosas, O.A.; Pérez-González, J.; Marín-Santibañez, B.M.; Rodríguez-González, F. Viscoelastic Water-Based Lubricants with Nopal Cactus Mucilage as Green Metalworking Fluids. Lubricants 2024, 12, 56. [Google Scholar] [CrossRef]

- Tormos, B.; Bermúdez, V.; Balaguer, A.; Giménez, E. Compatibility Study of Polyamide (PA6) with Lubricant Bases for Electric Vehicle Applications. Lubricants 2024, 12, 54. [Google Scholar] [CrossRef]

- Cui, P.; Hou, Z.; He, L.; Zheng, H.; He, Y.; Fan, Y.; An, L.; Huang, Y. Experimental Study on In Situ Storage of Grease-Lubricated Ball Screws. Appl. Sci. 2024, 14, 2734. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, G.; Zhou, X.; Su, X.; Gu, L. A Promising Conductive Lubricant for Space Sliding Electrical Contact: NbSe2-Ti Film. Lubricants 2024, 12, 44. [Google Scholar] [CrossRef]

- Panin, S.V.; Alexenko, V.O.; Buslovich, D.G.; Kornienko, L.A.; Byakov, A.V.; Lyukshin, B.A.; Shil’ko, S.V. Optimal Material Selection for Polymer–Polymer Prosthetic Implants by Tribological Criteria. J. Frict. Wear 2022, 43, 8–19. [Google Scholar] [CrossRef]

- Fang, J.; Liu, X.; Wang, T.; Song, Z. Micro Lubrication and Heat Transfer in Wedge-Shaped Channel Slider with Convex Surface Texture Based on Lattice Boltzmann Method. Nanomaterials 2024, 14, 295. [Google Scholar] [CrossRef]

- Yin, X.; Mu, L.; Jia, Z.; Pang, H.; Chai, C.; Liu, H.; Liang, C.; Zhang, B.; Liu, D. Nanostructure of Superlubricating Tribofilm Based on Friction-Induced a-C:H Films under Various Working Conditions: A Review of Solid Lubrication. Lubricants 2024, 12, 40. [Google Scholar] [CrossRef]

- Obata, T.; Fujiwara, H.; Itoigawa, F.; Maegawa, S. Effect of Grease Viscosity on Channeling Properties of Ball Bearings. Lubricants 2024, 12, 13. [Google Scholar] [CrossRef]

- Galpaya, C.; Induranga, A.; Vithanage, V.; Mantilaka, P.; Koswattage, K.R. Comparative Study on the Thermal Properties of Engine Oils and Their Nanofluids Incorporating Fullerene-C60, TiO2 and Fe2O3 at Different Temperatures. Energies 2024, 17, 732. [Google Scholar] [CrossRef]

- Hedayati, H.; Mofidi, A.; Al-Fadhli, A.; Aramesh, M. Solid Lubricants Used in Extreme Conditions Experienced in Machining: A Comprehensive Review of Recent Developments and Applications. Lubricants 2024, 12, 69. [Google Scholar] [CrossRef]

- Zhao, X.; Tian, C.; Hao, L.; Xu, H.; Dong, J. Tribology and Rheology of Polypropylene Grease with MoS2 and ZDDP Additives at Low Temperatures. Lubricants 2023, 11, 464. [Google Scholar] [CrossRef]

- Liang, H.; Lu, Y.; Wang, W.; Sun, Y.; Zhao, J.; Guo, Y. An Experimental Study on the Distribution of Grease in Cylindrical Roller Bearings. Lubricants 2024, 12, 145. [Google Scholar] [CrossRef]

- Hong, S.-H.; Jeon, W.-J. Lubrication Performance of Misaligned Journal Bearings with Flexible Structure under Shock Load Conditions. Lubricants 2023, 11, 500. [Google Scholar] [CrossRef]

- Tomanik, E.; Christinelli, W.; Souza, R.M.; Oliveira, V.L.; Ferreira, F.; Zhmud, B. Review of Graphene-Based Materials for Tribological Engineering Applications. Eng 2023, 4, 2764–2811. [Google Scholar] [CrossRef]

- Kozdrach, R.; Drabik, J.; Szczerek, M. Influence of Silicon Additives on Tribological and Rheological Test Results for Vegetable Lubricants. Materials 2023, 16, 6245. [Google Scholar] [CrossRef] [PubMed]

- Ishchuk, Y.L. Lubricating Grease Manufacturing Technology; New Age International: New Delhi, India, 2008. [Google Scholar]

- Peng, H.; Li, S.; Shangguan, L.; Zhang, H.; Zhao, D. Research on the Rheological Characteristics of Wind Power Grease Based on Rheological Parameters. Lubricants 2023, 11, 299. [Google Scholar] [CrossRef]

- Peng, H.; Zhao, D.; Shangguan, L.; Li, S.; Cheng, R.; Li, Y. The Optimization Study of Rheological Characteristics of Wind Power Grease Based on Gel-State. Gels 2024, 10, 253. [Google Scholar] [CrossRef]

- Lyu, Y.; Li, Y.; Li, C.; Jiang, L.; Liu, Z. Oil-Air Distribution Prediction Inside Ball Bearing with Under-Race Lubrication Based on Numerical Simulation. Appl. Sci. 2024, 14, 3770. [Google Scholar] [CrossRef]

- Sun, H.; Yan, Z.; Wu, S.; Liu, Z.; Jiang, Y. A Study on the Cavitation Effect of Elastic Material with Textured Surfaces under Fluid Lubrication Conditions. Machines 2024, 12, 267. [Google Scholar] [CrossRef]

- Llopis-Albert, C.; Rubio, F.; Devece, C.; García-Hurtado, D. Digital Twin-Based Approach for a Multi-Objective Optimal Design of Wind Turbine Gearboxes. Mathematics 2024, 12, 1383. [Google Scholar] [CrossRef]

- Pawlewski, P. Scientific and Practical Challenges for the Development of a New Approach to the Simulation of Remanufacturing. Sustainability 2024, 16, 3857. [Google Scholar] [CrossRef]

- Gharaibeh, M.; Pitarresi, J. Anand Model Constants of Sn-Ag-Cu Solders: What Do They Actually Mean? J. Electron. Packag. 2024, 24, 021001. [Google Scholar] [CrossRef]

- Fusek, M.; Paška, Z.; Rojíček, J.; Fojtík, F. Parameters Identification of the Anand Material Model for 3D Printed Structures. Materials 2021, 14, 587. [Google Scholar] [CrossRef]

- Dundar, M.A.; Dhaliwal, G.S.; Nuraliyev, M.; Ayorinde, E.O. Numerical prediction of mechanical behavior of acrylonitrile-butadiene-styrene under three-point bending and impact loadings by Anand–Gurtin material model. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 11024–11040. [Google Scholar] [CrossRef]

- Li, K.; Deng, H.; Xu, W.; Liu, Y. Modelling of fracture-involved large strain behaviors of amorphous glassy polymers via a unified physically-based constitutive model coupled with phase field method. Eng. Fract. Mech. 2024, 311, 110546. [Google Scholar] [CrossRef]

- Zeng, C.; Hu, Y.; Liu, L.; Xin, X.; Zhao, W.; Liu, Y.; Leng, J. A 3D finite deformation constitutive model for anisotropic shape memory polymer composites integrating viscoelasticity and phase transition concept. Int. J. Plast. 2024, 183, 104139. [Google Scholar] [CrossRef]

- Wismans, M.; van Dommelen, J.A.W.; Engels, T.A.P.; van Breemen, L.C.A. A macroscopic viscoelastic viscoplastic constitutive model for porous polymers under multiaxial loading conditions. J. Mech. Phys. Solids 2024, 183, 105499. [Google Scholar] [CrossRef]

- Kamenskikh, A.A.; Sakhabutdinova, L.; Strazhec, Y.A.; Bogdanova, A.P. Assessment of the Influence of Protective Polymer Coating on Panda Fiber Performance Based on the Results of Multivariant Numerical Simulation. Polymers 2023, 15, 4610. [Google Scholar] [CrossRef]

- Anssari-Benam, A. Hyperinelasticity: An energy-based constitutive modelling approach to isothermal large inelastic deformation of polymers. Part I. J. Mech. Phys. Solids 2024, 192, 105790. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, X.; Wang, X.; Zeng, Q.; Wu, M. The prediction method for the saturation stress of materials used in the Anand model parameters identification. J. Mech. Sci. Technol. 2024, 38, 1775–1787. [Google Scholar] [CrossRef]

- López, E.J.; Leyva, P.A.L.; López, A.A.; Estrella, F.J.O.; Vázquez, J.J.D.; Velázquez, B.L.; Molina, V.M.M. Mechanics 4.0 and Mechanical Engineering Education. Machines 2024, 12, 320. [Google Scholar] [CrossRef]

- Wan, L.; Lin, F. Research on Material Viscoelasticity and Its Influence on Indentation Rolling Resistance. Appl. Sci. 2024, 14, 3750. [Google Scholar] [CrossRef]

- Nosov, Y.O.; Kamenskikh, A.A. Experimental Study of the Rheology of Grease by the Example of CIATIM-221 and Identification of Its Behavior Model. Lubricants 2023, 11, 295. [Google Scholar] [CrossRef]

- Shchipunov, J.A.; Postnova, I.V.; Buznik, V.M. Lubricant Material and Method of Producing Said Material. RU Patent 2467061C1, 20 November 2011. (In Russian). [Google Scholar]

- Randisi, S.A. Lubricating Composition and Method for Making. U.S. Patent 4396514, 4 February 1982. [Google Scholar]

- Rylski, A.; Siczek, K. The Effect of Addition of Nanoparticles, Especially ZrO2-Based, on Tribological Behavior of Lubricants. Lubricants 2020, 8, 23. [Google Scholar] [CrossRef]

- Tsvetnikov, A.K.; Buznik, V.M.; Matveenko, L.A. Method for Production of Finely Dispersed Polytetrafluoroethylene, Lubrication Composition Comprising it and Concentrate of Lubrication Composition. RU Patent 2100376C1, 27 December 1997. (In Russian). [Google Scholar]

- Schramm, G. A Practical Approach to Rheology and Rheometry; Gebrueder HAAKE GmbH: Karlsruhe, Germany, 1994; 290p. [Google Scholar]

- Fang, J.; Ran, L.; Huang, W.; Pan, K.; Gong, Y. Prediction of BGA solder joint array shape using improved Perzyna model and Anand model. Weld World 2023, 67, 2765–2778. [Google Scholar] [CrossRef]

- Li, X.K.; Luo, Y.; Qi, Y.; Zhang, R. On non-Newtonian lubrication with the upper convected Maxwell model. Appl. Math. Model. 2011, 35, 2309–2323. [Google Scholar] [CrossRef]

- Madsen, E.; Rosenlund, O.S.; Brandt, D.; Zhang, X. Adaptive feedforward control of a collaborative industrial robot manipulator using a novel extension of the Generalized Maxwell-Slip friction model. Mech. Mach. Theory 2021, 155, 104109. [Google Scholar] [CrossRef]

- Larson, R.G.; Wei, Y. A Review of Thixotropy and its Rheological Modeling. J. Rheol. 2019, 63, 477–501. [Google Scholar] [CrossRef]

- Barnes, A.H. A Handbook of Elementary Rheology; The University of Wales Institute of Non-Newtonian Fluid Mechanics, Department of Mathematics, University of Wales Aberystwyth: Aberystwyth, UK, 2000; 200p. [Google Scholar]

- Khan, U.; Zaib, A.; Ishak, A.; Waini, I.; Raizah, Z.; Boonsatit, N.; Jirawattanapanit, A.; Galal, A.M. Significance of Thermophoretic Particle Deposition, Arrhenius Activation Energy and Chemical Reaction on the Dynamics of Wall Jet Nanofluid Flow Subject to Lorentz Forces. Lubricants 2022, 10, 228. [Google Scholar] [CrossRef]

- Tripathi, A.K.; Vinu, R. Characterization of Thermal Stability of Synthetic and Semi-Synthetic Engine Oils. Lubricants 2015, 3, 54–79. [Google Scholar] [CrossRef]

- Bogdanova, A.P.; Kamenskikh, A.A.; Nosov, Y.O. The Geometric Configuration of Lubricant Recesses of the Polymer Sliding Layer of the Bearing. Designs 2023, 7, 144. [Google Scholar] [CrossRef]

- Chen, Z.; Song, X.; Lei, L.; Chen, X.; Fei, C.; Chiu, C.T.; Qian, X.; Ma, T.; Yang, Y.; Shung, K.; et al. 3D printing of piezoelectric element for energy focusing and ultrasonic sensing. Nano Energy 2016, 27, 78–86. [Google Scholar] [CrossRef]

- González-Henríquez, C.M.; Sarabia-Vallejos, M.A.; Rodriguez-Hernandez, J. Polymers for additive manufacturing and 4D-printing: Materials, methodologies, and biomedical applications. Prog. Polym. Sci. 2019, 94, 57–116. [Google Scholar] [CrossRef]

- Shumkov, A.A.; Ablyaz, T.R.; Muratov, K.R.; Sidhu, S.S. Prediction of the properties of photopolymer prototypes. IOP Conf. Ser. Mater. Sci. Eng. 2020, 862, 022008. [Google Scholar] [CrossRef]

- Gong, L.; Qian, S.; Wang, W.; Ni, Z.; Tang, L. Influence of nano-additives (nano-PTFE and nano-CaCO3) on tribological properties of food-grade aluminum-based grease. Tribol. Int. 2021, 160, 107014. [Google Scholar] [CrossRef]

- Jiang, Z.; Sun, Y.; Liu, B.; Yu, L.; Tong, Y.; Yan, M.; Yang, Z.; Hao, Y.; Shangguan, L.; Zhang, S.; et al. Research progresses of nanomaterials as lubricant additives. Friction 2024, 12, 1347–1391. [Google Scholar] [CrossRef]

- Guru, S.R.; Venugopal, C.; Sarangi, M. Effect of polymer additives on the tribological performance of soybean oil. Ind. Lubr. Tribol. 2023, 75, 607–618. [Google Scholar] [CrossRef]

- Kozdrach, R. The Innovative Research Methodology of Tribological and Rheological Properties of Lubricating Grease. Tribol. Ind. 2021, 43, 117–130. [Google Scholar] [CrossRef]

- Gamaniel, S.S.; Dini, D.; Biancofiore, L. The Effect of Fluid Viscoelasticity in Lubricated Contacts in the Presence of Cavitation. Tribol. Int. 2021, 160, 107011. [Google Scholar] [CrossRef]

- Ivins, E.R.; Caron, L.; Adhikari, S.; Larour, E. Notes on a Compressible Extended Burgers Model of Rheology. Geophys. J. Int. 2022, 228, 1975–1991. [Google Scholar] [CrossRef]

- Kvarda, D.; Skurka, S.; Galas, R.; Omasta, M.; Shi, L.; Ding, H.; Wang, W.; Krupka, I.; Hartl, M. The Effect of Top of Rail Lubricant Composition on Adhesion and Rheological Behaviour. Eng. Sci. Technol. Int. J. 2022, 35, 101100. [Google Scholar] [CrossRef]

- Mujumdar, A.; Beris, A.N.; Metzner, A.B. Transient Phenomena in Thixotropic Systems. J. Non-Newton. Fluid Mech. 2002, 102, 157–178. [Google Scholar] [CrossRef]

- Mendes, P.R.; Thompson, R.L. A Critical Overview of Elasto-Viscoplastic Thixotropic Modeling. J. Non-Newton. Fluid Mech. 2012, 187–188, 8–15. [Google Scholar] [CrossRef]

- Radhakrishnan, R.; Divous, T.; Manneville, S.; Fielding, S.M. Understanding Rheological Hysteresis in Soft Glassy Materials. Soft Matter 2017, 9, 1834–1852. [Google Scholar] [CrossRef] [PubMed]

- Tichy, J.; Menut, M.; Oumahi, C.; Muller, S.; Bou-Saïd, B. Grease flow based on a two-component mixture model. Tribol. Int. 2021, 153, 106638. [Google Scholar] [CrossRef]

- Wang, D.; de Boer, G.; Neville, A.; Ghanbarzadeh, A. A Review on Modelling of Viscoelastic Contact Problems. Lubricants 2022, 10, 358. [Google Scholar] [CrossRef]

- Radulescu, A.V.; Radulescu, I. Rheological models for lithium and calcium greases. Mechanika 2006, 59, 67–70. [Google Scholar]

- Wozniak, M.; Rylski, A.; Lason-Rydel, M.; Orczykowska, M.; Obraniak, A.; Siczek, K. Some rheological properties of plastic greases by Carreau-Yasuda model. Tribol. Int. 2023, 183, 108372. [Google Scholar] [CrossRef]

- Meijer, R.J.; Lugt, P.M. The Grease Worker and Its Applicability to Study Mechanical Aging of Lubricating Greases for Rolling Bearings. Tribol. Trans. 2021, 65, 32–45. [Google Scholar] [CrossRef]

- Westerberg, L.G.; Sarkar, C.; Farré-Llados, J.; Höglund, E.; Lundström, T. Lubricating Grease Flow in a Double Restriction Seal Geometry: A Computational Fluid Dynamics Approach. Tribol. Lett. 2017, 65, 82. [Google Scholar] [CrossRef]

- Osara, J.A.; Chatra, S.; Lugt, P.M. Grease material properties from first principles thermodynamics. Lubr. Sci. 2024, 36, 36–50. [Google Scholar] [CrossRef]

- Peng, H.; Chen, Y.; Shangguan, L.; Li, Y.; Wang, Q. Influence of Sulfur-Phosphorus Additive Interaction Effects on the Performance of Roller Bearing Greases. Lubricants 2025, 13, 5. [Google Scholar] [CrossRef]

- Liu, N.; Che, Q.; Li, Y.; Hu, L.; Zhang, J.; Zhang, S. Effect of hydroxyl functionalized ionic liquid additives on rheological and tribological properties of titanium complex grease. Tribol. Int. 2024, 193, 109416. [Google Scholar] [CrossRef]

- Shafi, W.K.; Charoo, M.S. An overall review on the tribological, thermal and rheological properties of nanolubricants. Tribol.-Mater. Surf. Interfaces 2021, 15, 20–54. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Y.; Li, C.; Zhou, Z.; Nie, X.; Chen, Y.; Cao, H.; Liu, B.; Zhang, N.; Said, Z.; et al. Extreme pressure and antiwear additives for lubricant: Academic insights and perspectives. Int. J. Adv. Manuf. Technol. 2022, 120, 1–27. [Google Scholar] [CrossRef]

- Li, J.; Chen, D.; Zhang, H.; Jiang, Z.; Sun, K.; Fan, J.; Tang, Y. The tribological properties of nano-lubricants and their application on bearings: Recent research progress. Int. J. Adv. Manuf. Technol. 2024, 134, 3051–3082. [Google Scholar] [CrossRef]

- Solanki, R.; Saini, V.; Bijwe, J. Exploration of PTFE sub-micron particles for enhancing the performance of commercial oils. Surf. Topogr. Metrol. Prop. 2021, 9, 2. [Google Scholar] [CrossRef]

- Kumar, N.; Saini, V.; Bijwe, J. Performance properties of lithium greases with PTFE particles as additive: Controlling parameter-size or shape? Tribol. Int. 2020, 148, 106302. [Google Scholar] [CrossRef]

- Dubey, M.K.; Bijwe, J.; Ramakumar, S.S.V. Nano-PTFE: New entrant as a very promising EP additive. Tribol. Int. 2015, 87, 121–131. [Google Scholar] [CrossRef]

- Esfe, M.H.; Zabihi, F.; Rostamian, H.; Esfandeh, S. Experimental investigation and model development of the non-Newtonian behavior of CuO-MWCNT-10w40 hybrid nano-lubricant for lubrication purposes. J. Mol. Liq. 2018, 249, 677–687. [Google Scholar] [CrossRef]

- Baghoolizadeh, M.; Pirmoradian, M.; Sajadi, S.M.; Salahshour, S.; Baghaei, S. Prediction and extensive analysis of MWCNT-MgO/oil SAE 50 hybrid nano-lubricant rheology utilizing machine learning and genetic algorithms to find ideal attributes. Tribol. Int. 2024, 195, 109582. [Google Scholar] [CrossRef]

| Values | |||||||

|---|---|---|---|---|---|---|---|

| Initial | 1 × 10−6 | 1000 | 1 × 10−2 | 1 × 10−1 | 1 × 10−1 | 1 | 1 |

| 1.389 × 10−3 | 1839.31 | 9.825 × 10−2 | 162.62 | 4.705 × 10−1 | 2.813 × 10−1 | 2.954 | |

| 8.697 × 10−4 | 1662.98 | 5.067 × 10−2 | 201.06 | 8.617 × 10−1 | 2.142 × 10−1 | 4.277 |

| Values | |||||

|---|---|---|---|---|---|

| Initial | 1 × 10−6 | 1 | 100 | 1 | 100 |

| 1.437 × 10−1 | −6.021 × 10−3 | 966.53 | 3.824 × 10−1 | 983.29 | |

| 1.959 × 10−1 | −6.766 × 10−3 | 1070.53 | 4.886 × 10−1 | 927.01 |

| Values | |||||

|---|---|---|---|---|---|

| Initial | 1 | 1 | 100 | 1 | 100 |

| 9.060 × 10−3 | 5.894 × 10−3 | −688.582 | 9.221 × 10−4 | 2728.20 | |

| 6.750 × 10−3 | 7.140 × 10−2 | 23.397 | 7.728 × 10−4 | 2703.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nosov, Y.O.; Kamenskikh, A.A.; Bogdanova, A.P. Description of the Lubricant Behavior Based on the Theory of Elasto-Viscoplastic. Materials 2025, 18, 1360. https://doi.org/10.3390/ma18061360

Nosov YO, Kamenskikh AA, Bogdanova AP. Description of the Lubricant Behavior Based on the Theory of Elasto-Viscoplastic. Materials. 2025; 18(6):1360. https://doi.org/10.3390/ma18061360

Chicago/Turabian StyleNosov, Yuriy O., Anna A. Kamenskikh, and Anastasia P. Bogdanova. 2025. "Description of the Lubricant Behavior Based on the Theory of Elasto-Viscoplastic" Materials 18, no. 6: 1360. https://doi.org/10.3390/ma18061360

APA StyleNosov, Y. O., Kamenskikh, A. A., & Bogdanova, A. P. (2025). Description of the Lubricant Behavior Based on the Theory of Elasto-Viscoplastic. Materials, 18(6), 1360. https://doi.org/10.3390/ma18061360