Study on the Microstructure and Properties of AISI 304 Stainless Steel Corrugated Pipes by Aging and Solution Treatments

Abstract

1. Introduction

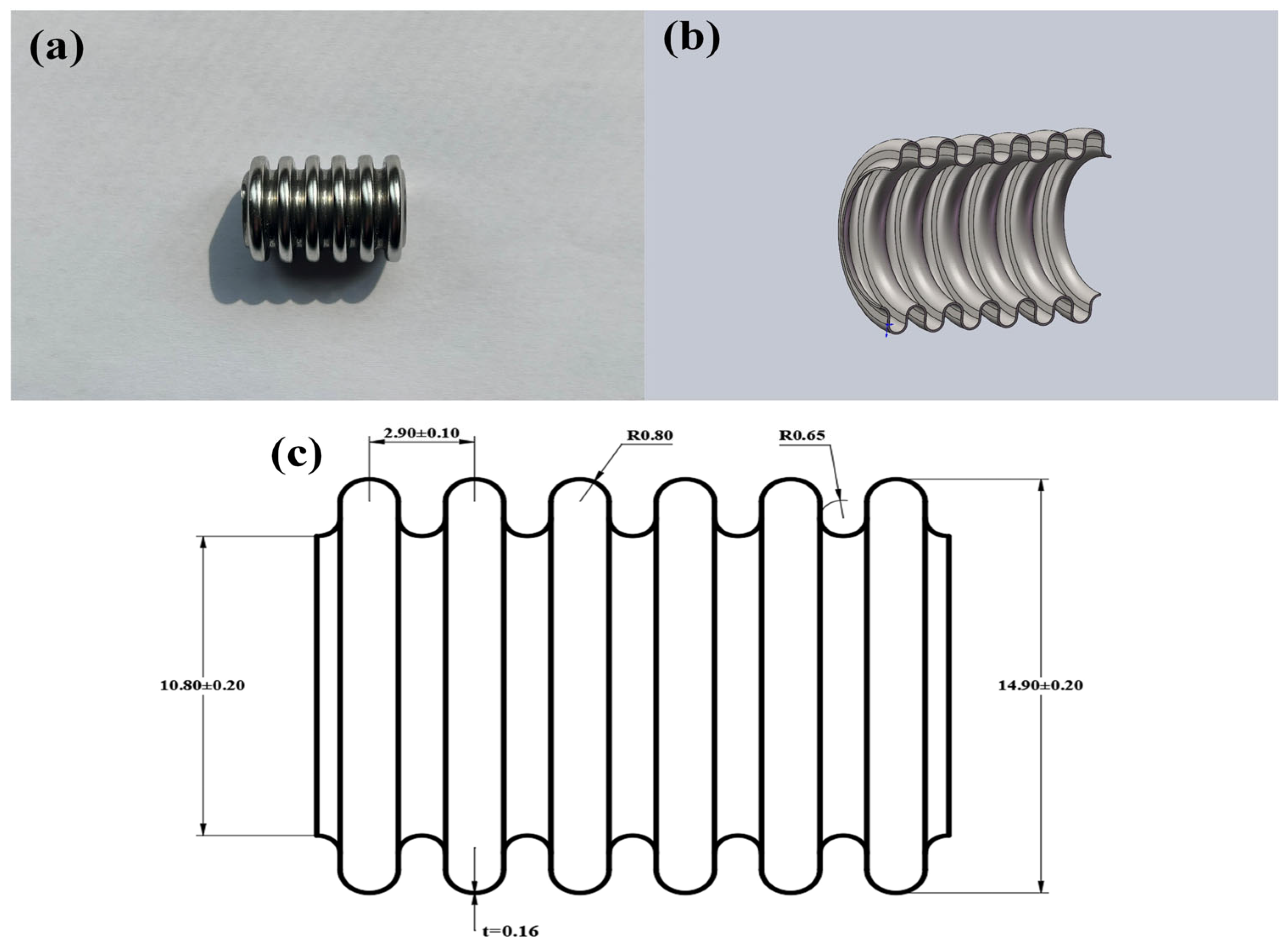

2. Material and Sample Preparation

3. Experimental Section

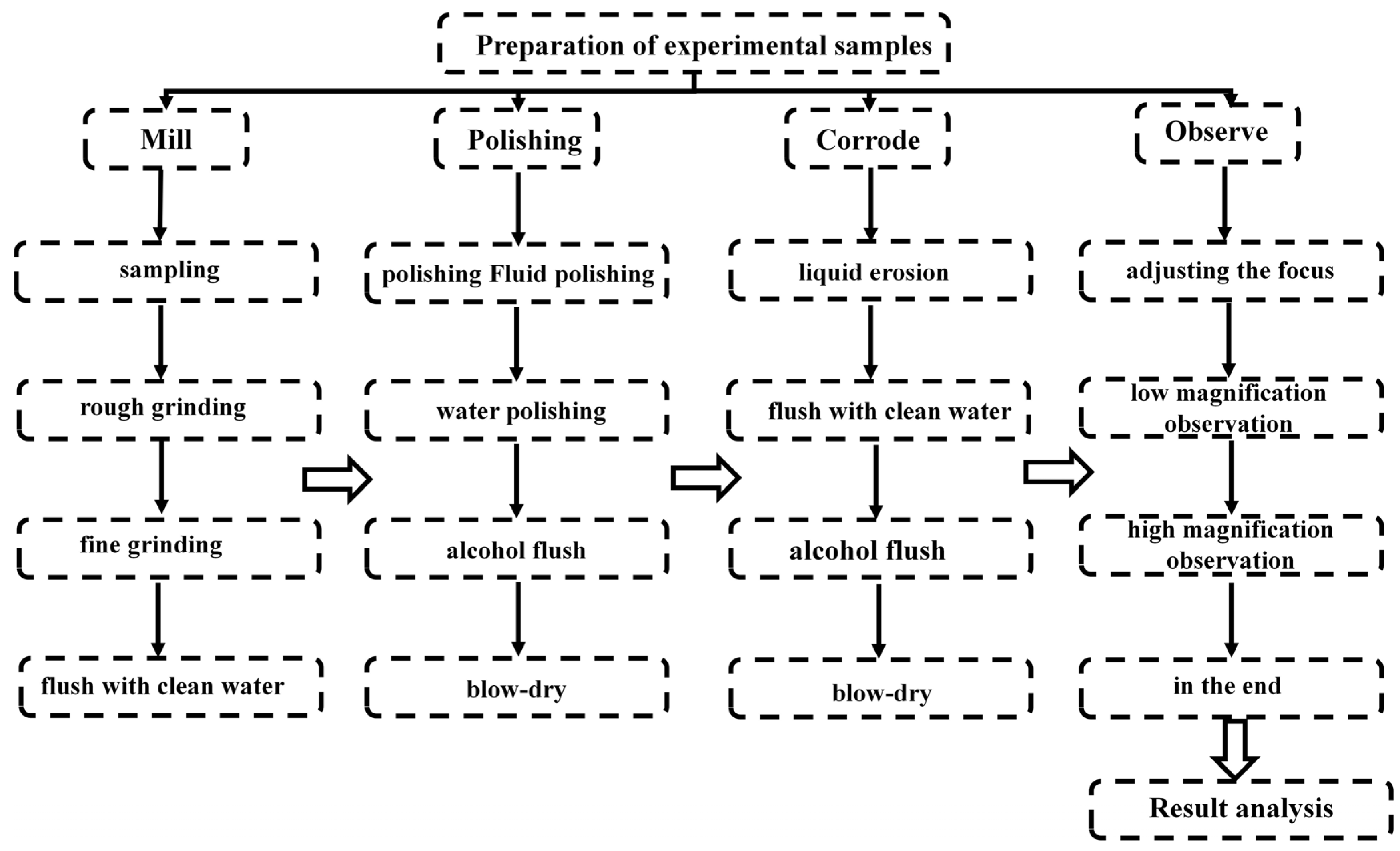

3.1. Microstructure Experiments

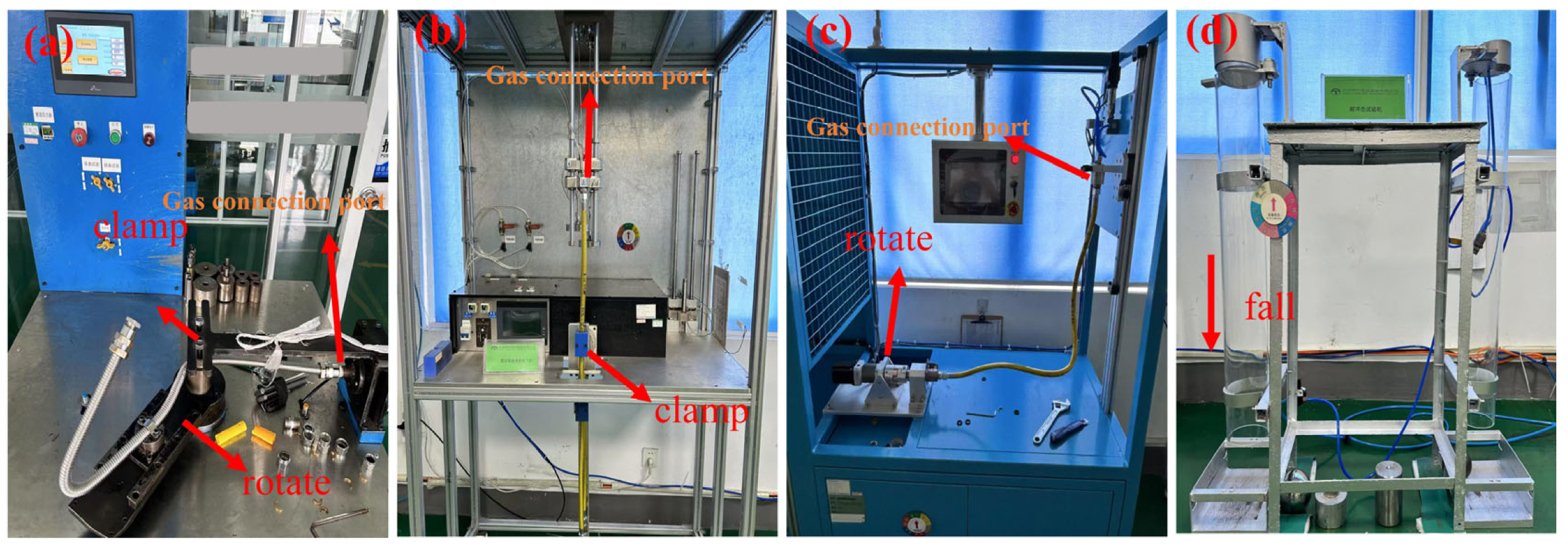

3.2. Fatigue Performance Experiments

3.3. Hardness Test

3.4. Corrosion Resistance Test

4. Results and Analysis

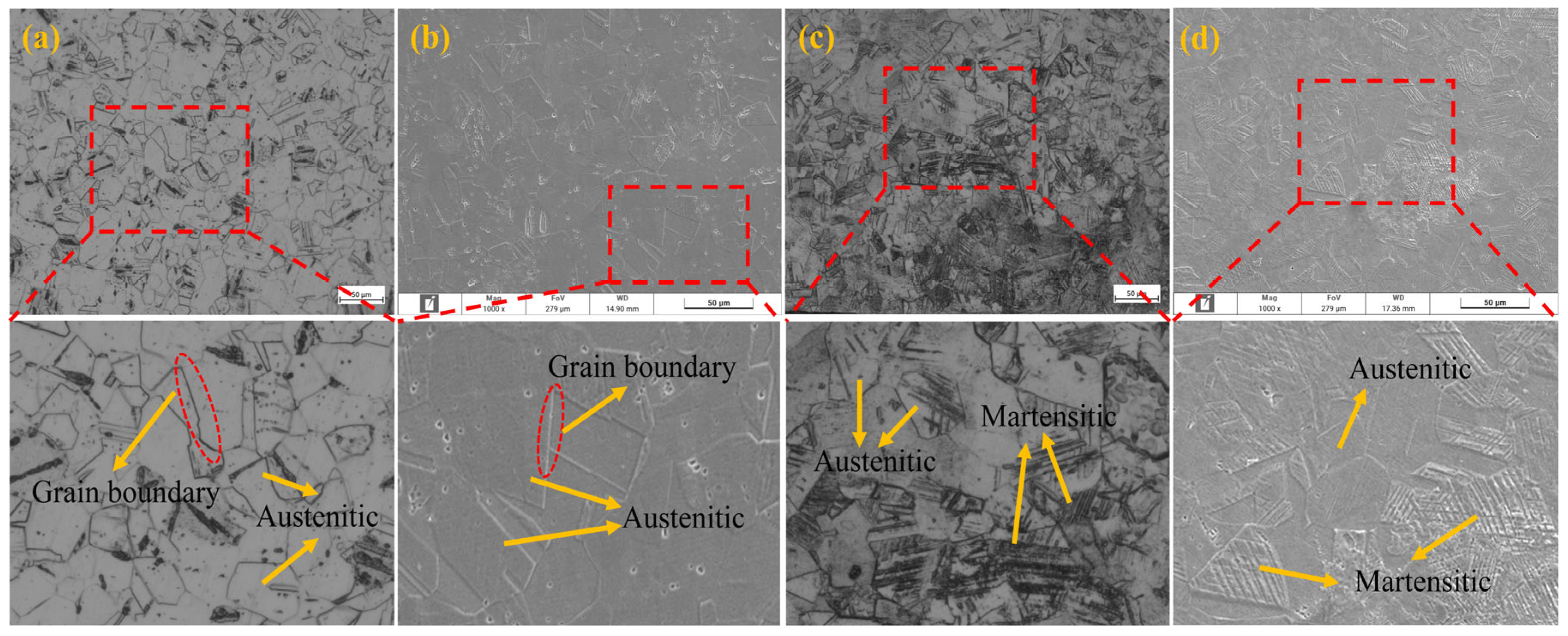

4.1. Metallographic Results and Analysis

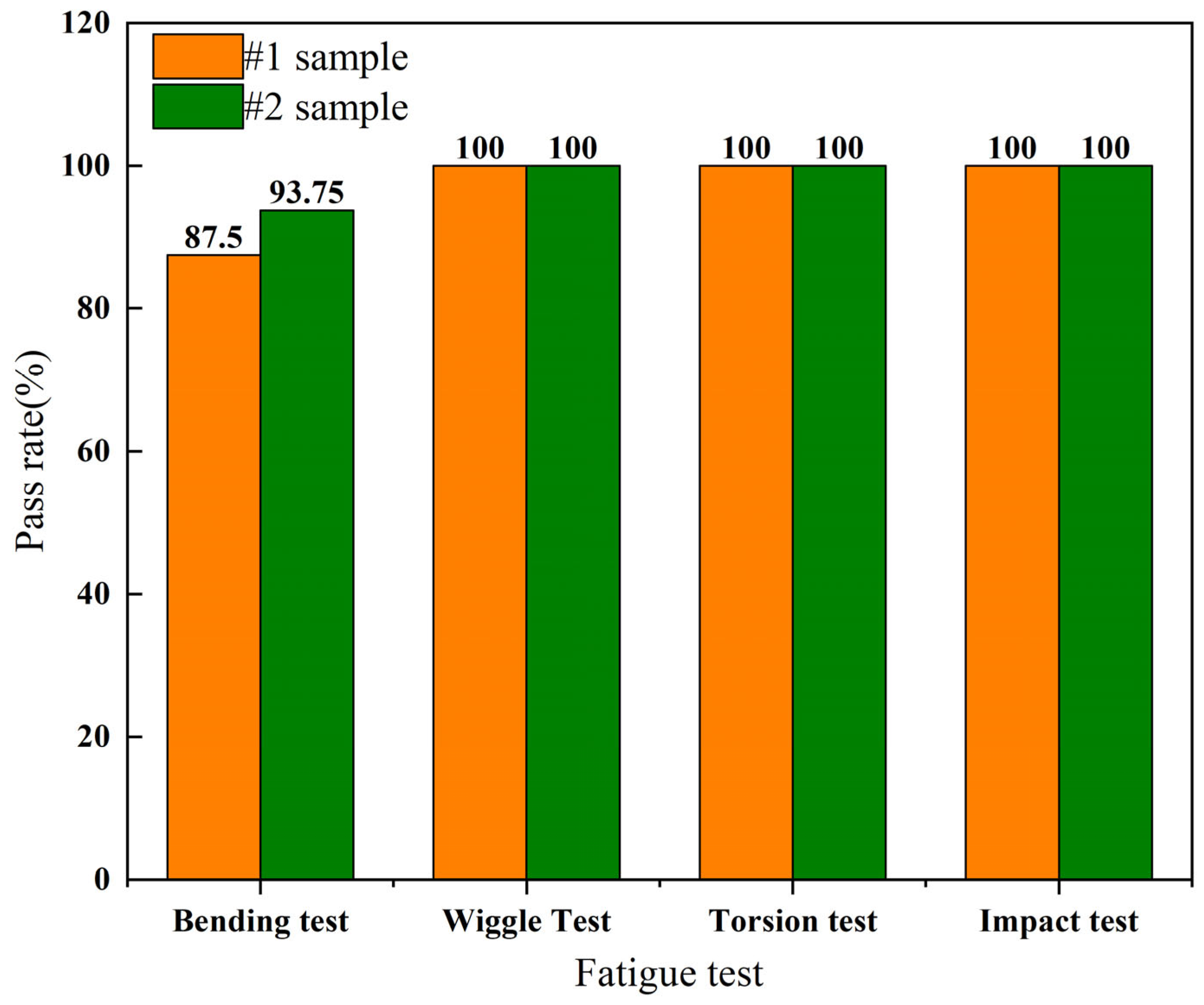

4.2. Fatigue Performance Results and Analysis

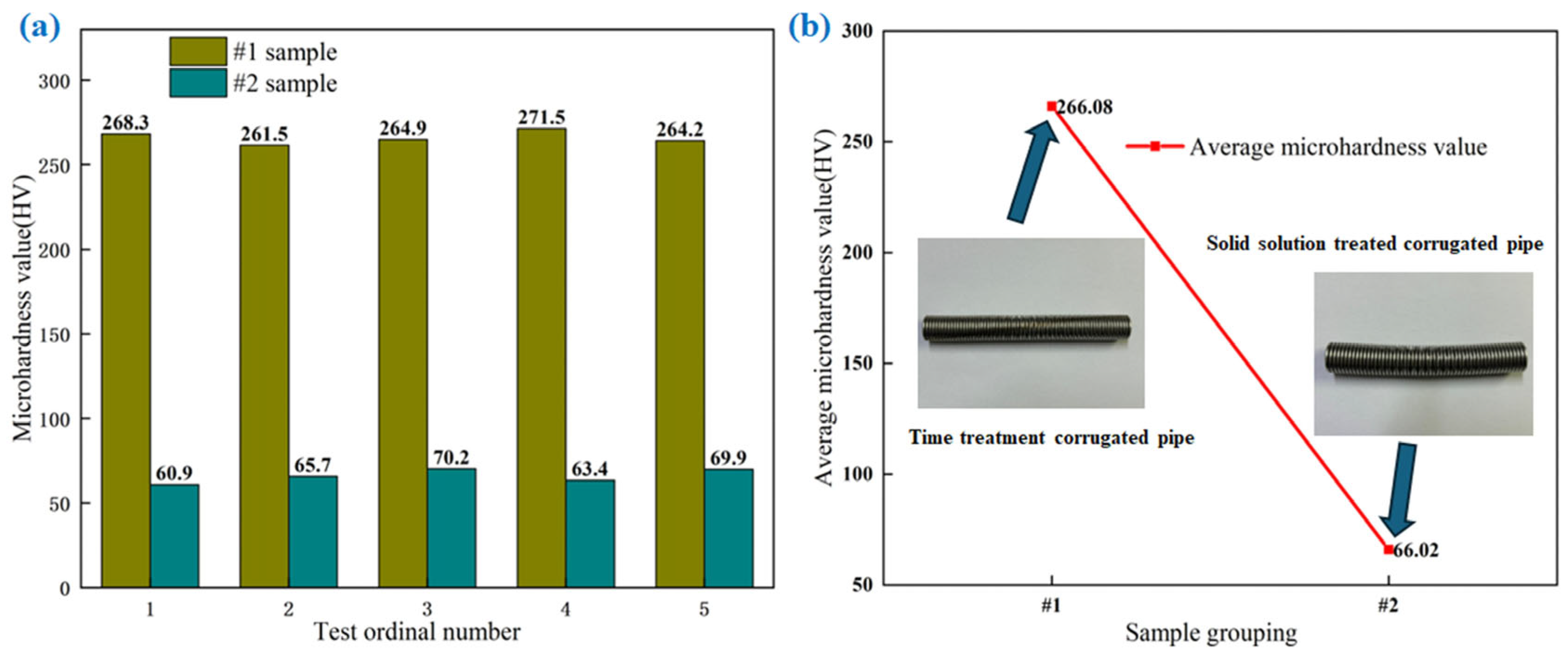

4.3. Hardness Results and Analysis

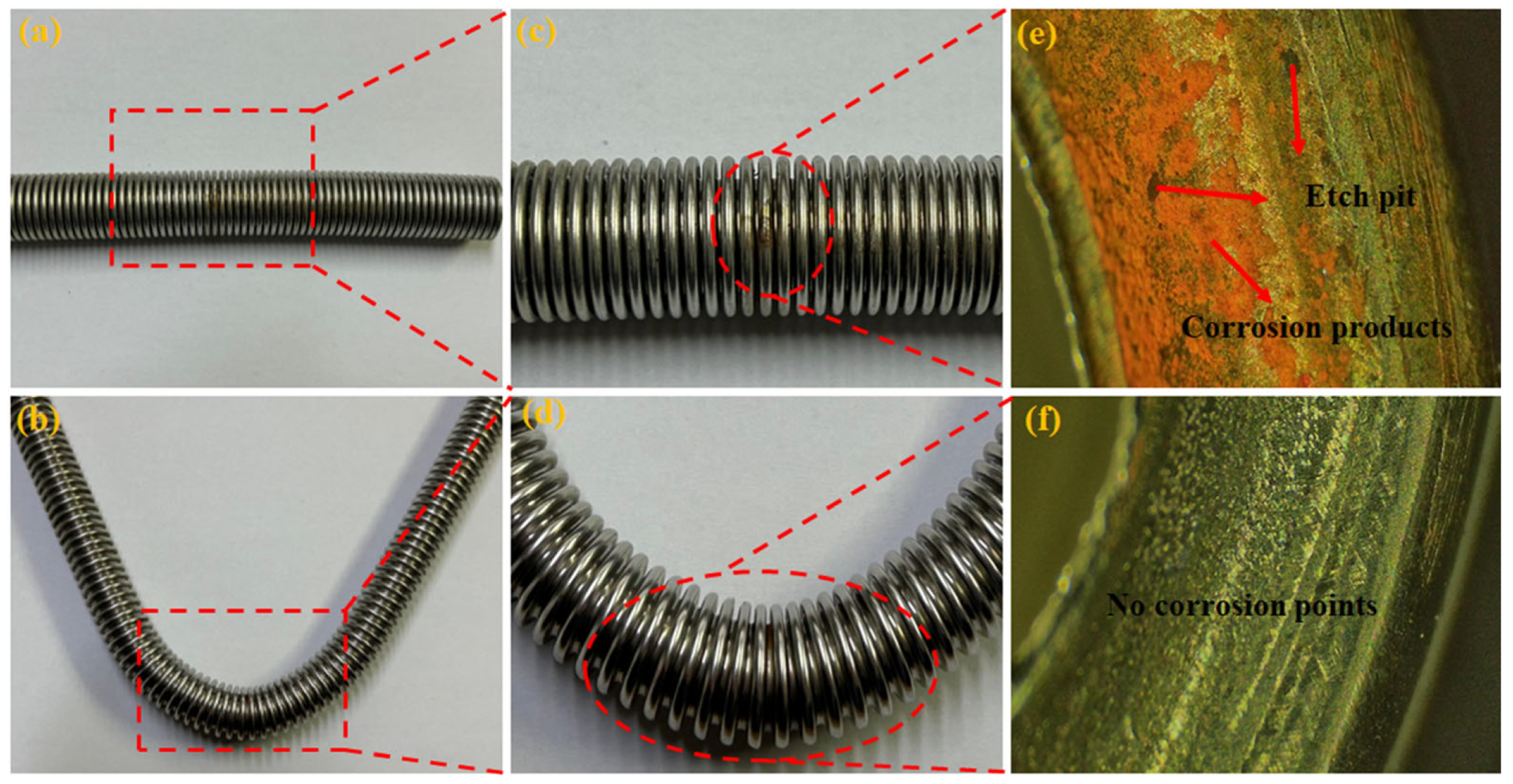

4.4. Corrosion Results and Analysis

5. Conclusions

- Solid solution treatment effectively eliminated the deformation-induced martensite generated during the processing of corrugated pipes, restored a uniform austenite single-phase structure, and no obvious carbide precipitation was observed at the grain boundaries. After aging treatment, the deformation martensite generated by the spinning of the corrugated tube was not completely eliminated, and a small amount of carbides were precipitated in the microstructure.

- After solution treatment, the austenite single-phase structure was restored, the grain boundary carbides were fully dissolved, and the grain size was homogenized. This process significantly reduced the hardness of the bellows and improved the work hardening problem associated with the forming process. After aging treatment, the second phase was precipitated, and the hardness of the bellows was not significantly reduced nor was the work hardening problem caused by the spinning of bellows improved.

- The solid solution-treated corrugated tube exhibited excellent uniform corrosion and intergranular corrosion resistance in the corrosion resistance experiments, with no tendency toward corrosion. After aging treatment of the corrugated tube, the depletion of Cr elements at the grain boundaries significantly increased the sensitivity to intergranular corrosion, and the corrugated tube exhibited obvious corrosion behavior in the corrosion resistance experiments.

- Solution treatment is more suitable for the heat treatment process of AISI 304 austenitic stainless steel corrugated pipes than aging treatment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wankhede, S.D.; Gawande, S.H. Design and Analysis Aspect of Metal Expansion Bellows: A Review. Forces Mech. 2023, 13, 100244. [Google Scholar] [CrossRef]

- Wang, M.; Yan, M.; Yang, C.; Liu, Y.; Huang, H. A study on the evolution mechanism of small diameter thin-walled stainless steel bellows during a bending process. Eng. Fail. Anal. 2023, 152, 107462. [Google Scholar] [CrossRef]

- Yuan, Z.; Huo, S.; Ren, J. Mathematical description and mechanical characteristics of reinforced S-shaped bellows. Int. J. Press. Vessel. Pip. 2019, 175, 103931. [Google Scholar]

- Peng, Y.; Xue, S.; Yang, T.; Liu, X.; Ren, Y. Failure analysis of 316L stainless steel bellows serving in steam tube. Int. J. Press. Vessel. Pip. 2022, 199, 104718. [Google Scholar]

- Lin, J.; Wang, X.; Lei, Y.; Ding, J.; Li, K.; Guo, F. Residual stress analysis and measurement in multi-layer bellows. J. Manuf. Process. 2021, 72, 179–194. [Google Scholar]

- Hao, Z.; Luo, S.; Zhao, H.; Zhang, C.; Luo, J. Effect of plate hardening behavior on the deformation of stainless steel metal bellows. J. Mater. Eng. Perform. 2017, 26, 5385–5395. [Google Scholar]

- Yi, H.Y.; Yan, F.K.; Tao, N.R.; Lu, K. Work hardening behavior of nanotwinned austenitic grains in a metastable austenitic stainless steel. Scr. Mater. 2016, 114, 133–136. [Google Scholar] [CrossRef]

- Belattar, A.; Keller, C.; Taleb, L. Multiscale analysis of the pre-hardening effect on the cyclic behavior and fatigue life of 304L stainless steel. Mater. Sci. Eng. 2016, 662, 468–480. [Google Scholar] [CrossRef]

- Shi, J.; Hou, L.; Zuo, J.; Zhuang, L.; Zhang, J. Effect of cryogenic rolling and annealing on the microstructure evolution and mechanical properties of 304 stainless steel. Int. J. Miner. Metall. Mater. 2017, 24, 638–645. [Google Scholar]

- Roy, B.; Kumar, R.; Das, J. Effect of cryorolling on the microstructure and tensile properties of bulk nano-austenitic stainless steel. Mater. Sci. Eng. 2015, 631, 241–247. [Google Scholar] [CrossRef]

- Essoussi, H.; Elmouhri, S.; Ettaqi, S.; Essadiqi, E. Heat treatment effect on mechanical properties of AISI 304 austenitic stainless steel. Procedia Manuf. 2019, 32, 883–888. [Google Scholar] [CrossRef]

- Pham, H.T.; Doan, T.Y.; Nguyen, T. A Study on Effect of Heat Treatment on Strain-Induced Martensitic Transformation in Type-304 Austenitic Stainless Steel; Springer: New York, NY, USA, 2021; pp. 584–591. [Google Scholar]

- Marikkannan, S.K.; Gnanasekaran, S.; Rakkiyannan, J.; Veluchamy, M.; Subramanian, P.; Sujatha, V.I. Heat Treatment Effect on Sensitization Behavior of 304 Grade Stainless Steel; AIP Publishing: New York, NY, USA, 2023. [Google Scholar]

- Kumar Krovvidi SC, S.P.; Das, C.R.; Goyal, S.; Arun Kumar, S.; Mahadevan, S.; Albert, S.K.; Raghupathy, S. Influence of heat treatment condition on tensile properties of AM350 stainless steel. Trans. Indian Inst. Met. 2023, 76, 87–95. [Google Scholar] [CrossRef]

- Moloi, T.; Dzogbewu, T.C.; Maringa, M.; Muiruri, A. Quasi-static tensile properties of DMLS TI6AL4V (ELI) specimens exposed to two different heat treatment processes and tested at different elevated temperatures. Results Eng. 2024, 22, 102290. [Google Scholar] [CrossRef]

- Milad, M.; Zreiba, N.; Elhalouani, F.; Baradai, C. The effect of cold work on structure and properties of AISI 304 stainless steel. J. Mater. Process. Technol. 2008, 203, 80–85. [Google Scholar]

- Lee, K.J.; Chun, M.S.; Kim, M.H.; Lee, J.M. A new constitutive model of austenitic stainless steel for cryogenic applications. Comput. Mater. Sci. 2009, 46, 1152–1162. [Google Scholar]

- Regulation SAFM. Stainless Steel Corrugated Tubes for the Connection of Gas Appliances; China National Standards: Shenzhen, China, 2022. (In Chinese) [Google Scholar]

| C | Si | Mn | P | S | Ni | Cr | N | |

|---|---|---|---|---|---|---|---|---|

| Measured value | 0.067 | 0.42 | 0.95 | 0.042 | 0.0052 | 8.45 | 18.46 | 0.045 |

| GB/T 3280-2015 | ≤0.07 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.00~10.50 | 17.50~19.50 | ≤0.10 |

| Experimental Condition | Experimental Sample Set | Number of Samples |

|---|---|---|

| Aging treatment | #1 | 64 |

| Solution treatment | #2 | 64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Wang, A.; Wang, J.; Ling, C.; Gui, X. Study on the Microstructure and Properties of AISI 304 Stainless Steel Corrugated Pipes by Aging and Solution Treatments. Materials 2025, 18, 1387. https://doi.org/10.3390/ma18061387

Zhao X, Wang A, Wang J, Ling C, Gui X. Study on the Microstructure and Properties of AISI 304 Stainless Steel Corrugated Pipes by Aging and Solution Treatments. Materials. 2025; 18(6):1387. https://doi.org/10.3390/ma18061387

Chicago/Turabian StyleZhao, Xiang, Anheng Wang, Jianbin Wang, Chuanwen Ling, and Xiaolong Gui. 2025. "Study on the Microstructure and Properties of AISI 304 Stainless Steel Corrugated Pipes by Aging and Solution Treatments" Materials 18, no. 6: 1387. https://doi.org/10.3390/ma18061387

APA StyleZhao, X., Wang, A., Wang, J., Ling, C., & Gui, X. (2025). Study on the Microstructure and Properties of AISI 304 Stainless Steel Corrugated Pipes by Aging and Solution Treatments. Materials, 18(6), 1387. https://doi.org/10.3390/ma18061387