Additive Manufacturing and Influencing Factors of Lattice Structures: A Review

Abstract

1. Introduction

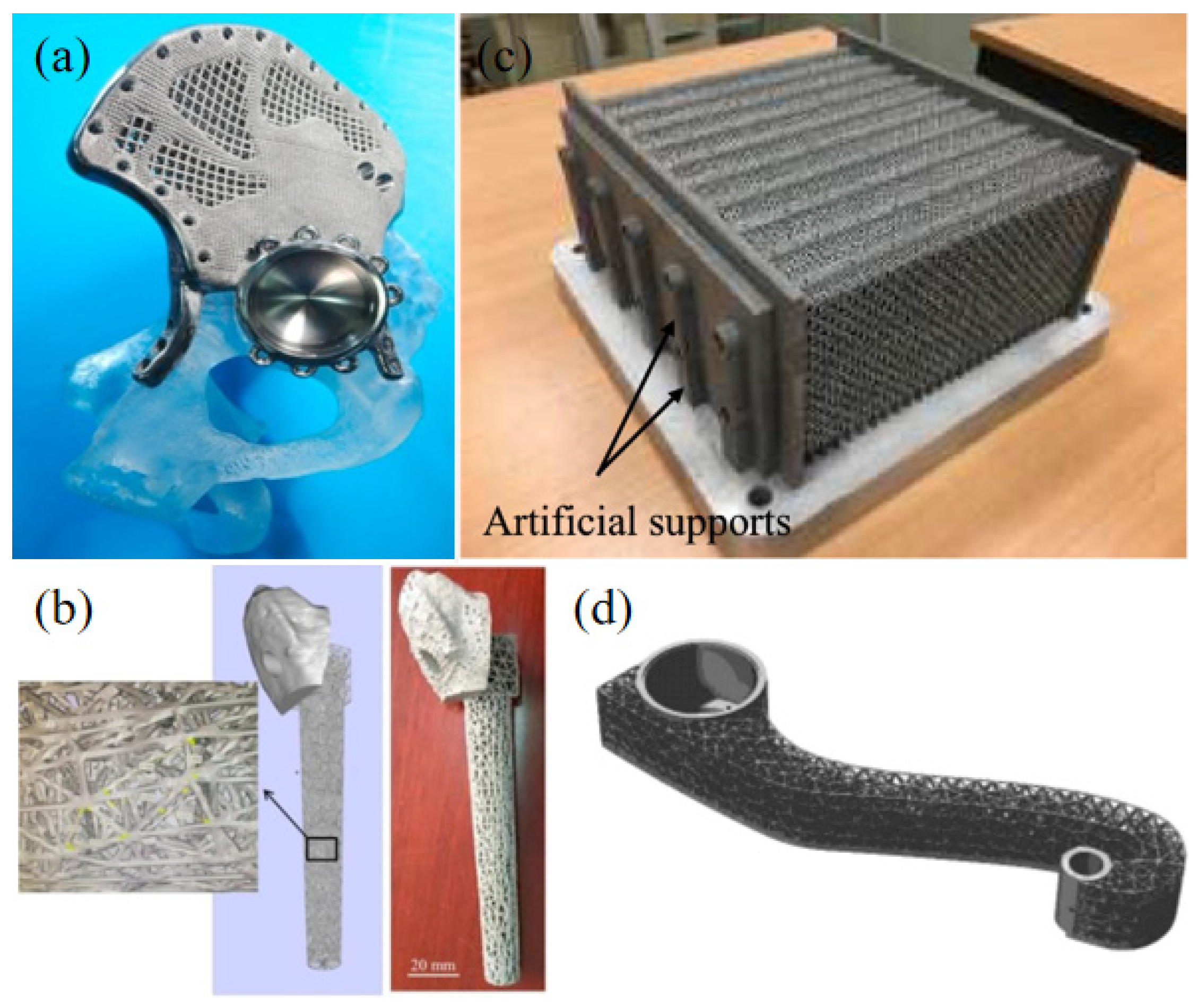

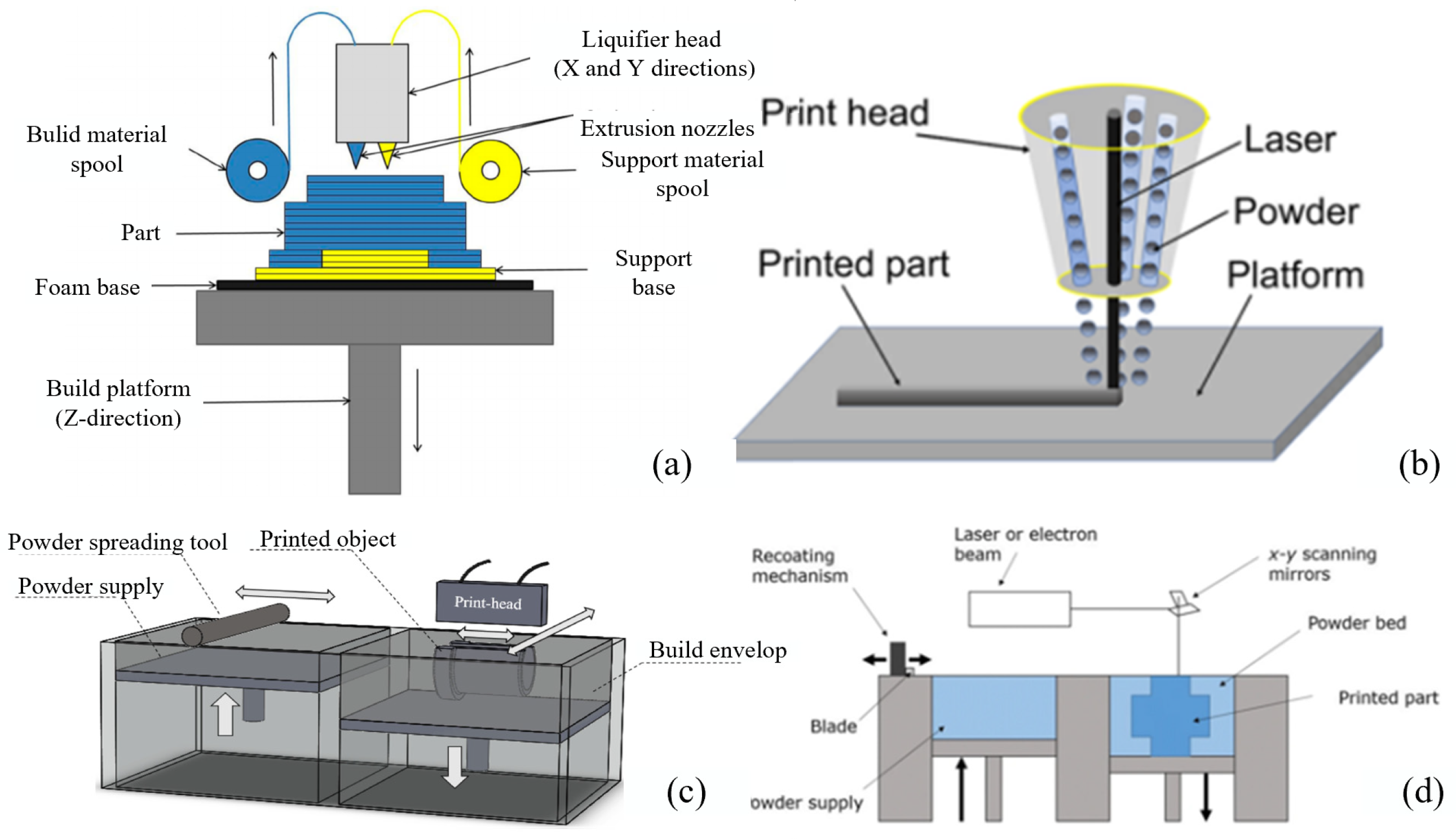

2. Additive Manufacturing Processes of Lattice Structures

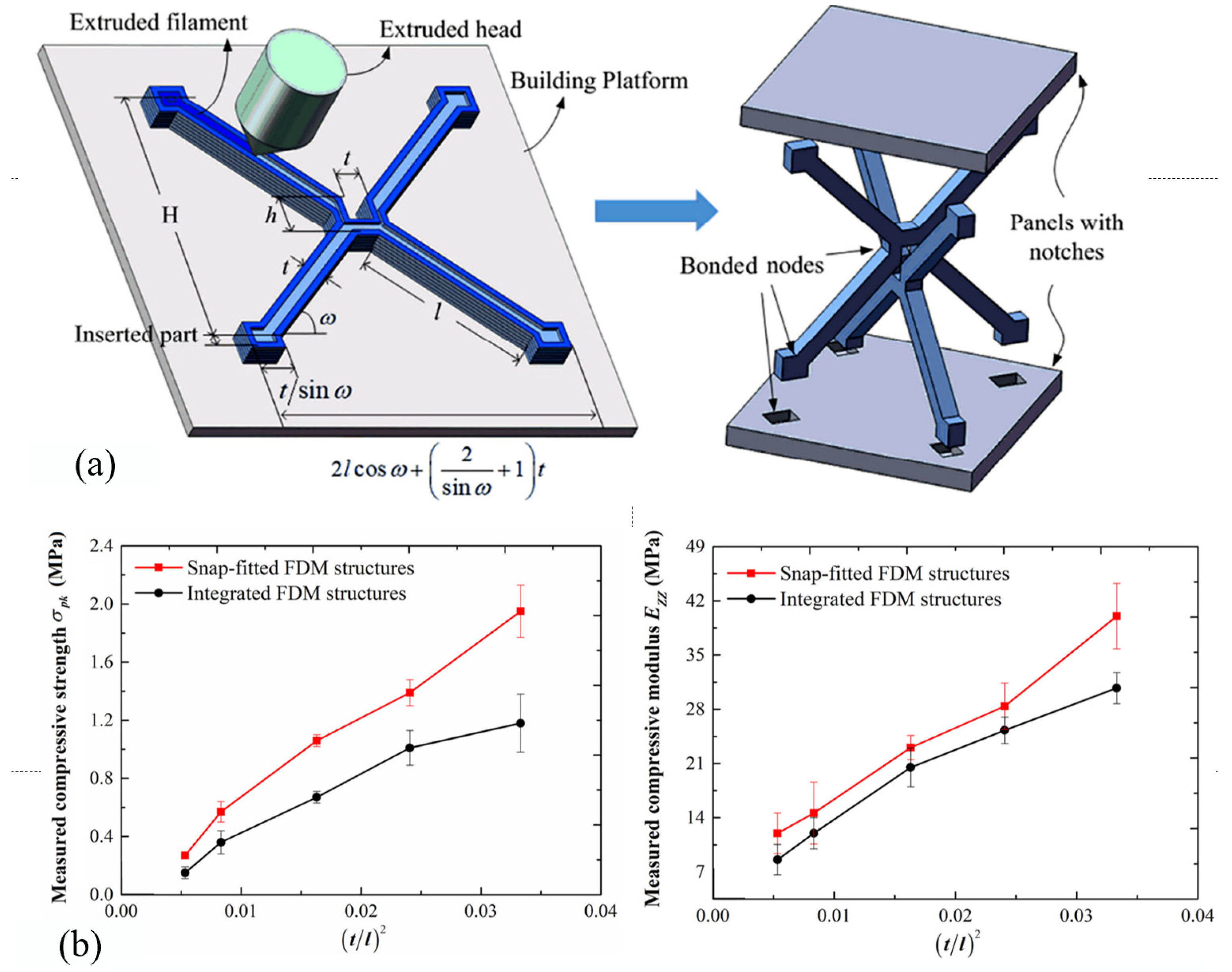

2.1. Fused Deposition Modeling

2.2. Directed Energy Deposition

2.3. Binder Jetting

2.4. Powder Bed Fusion

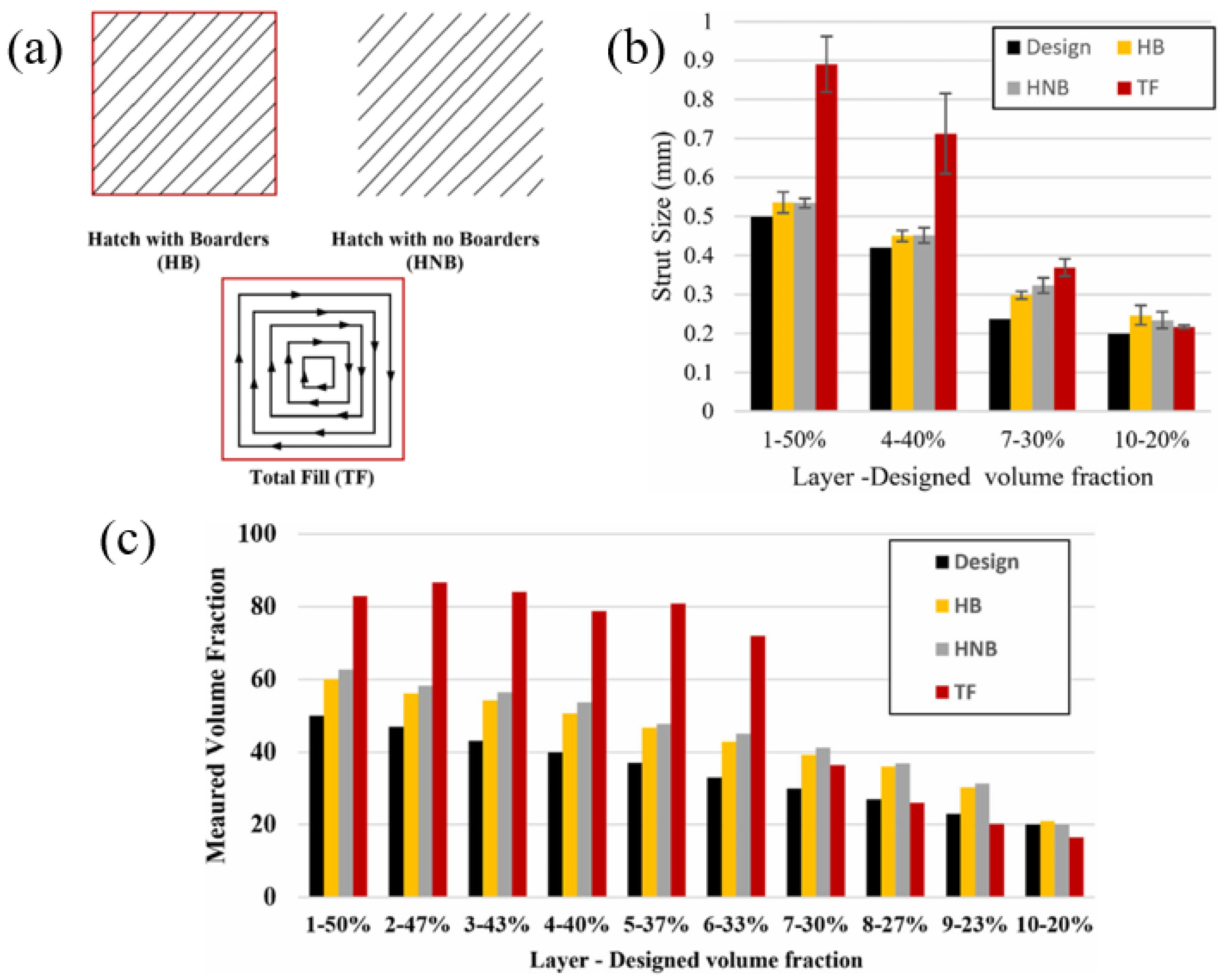

3. Processing Parameters

4. Post-Processing

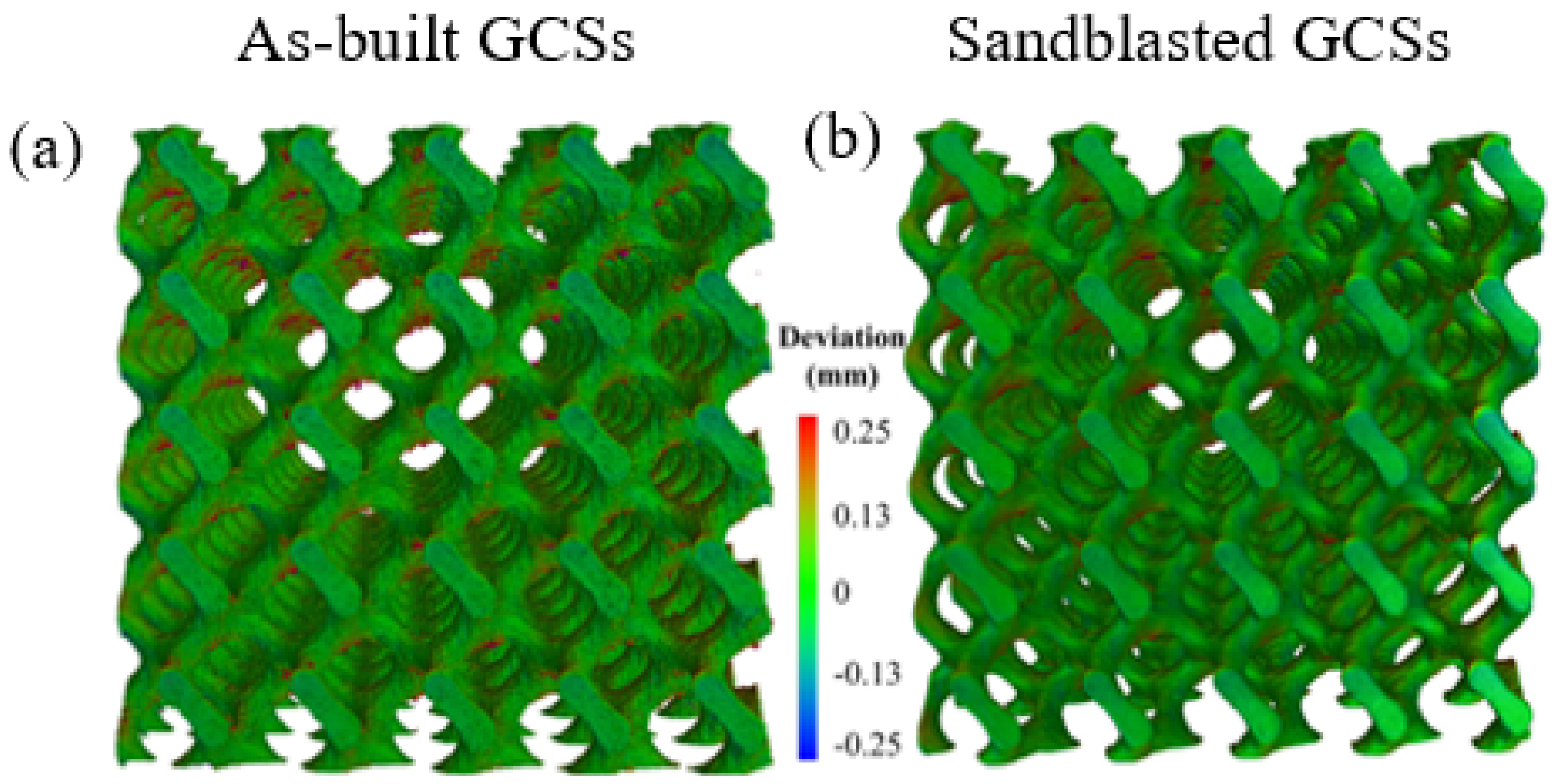

4.1. Surface Modification

4.2. Heat Treatment

4.3. Hot Isostatic Pressing

5. Structural Optimization and Design

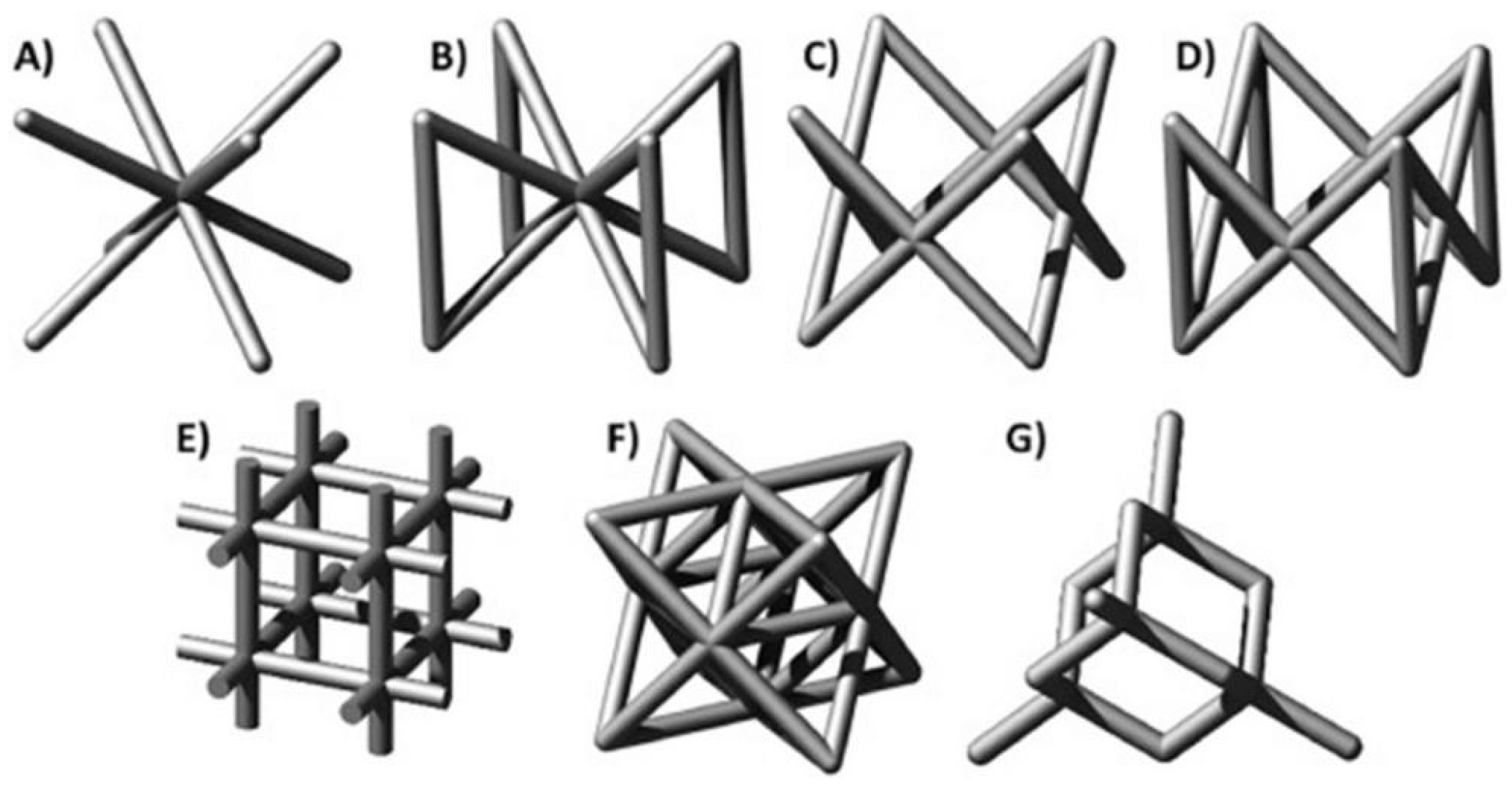

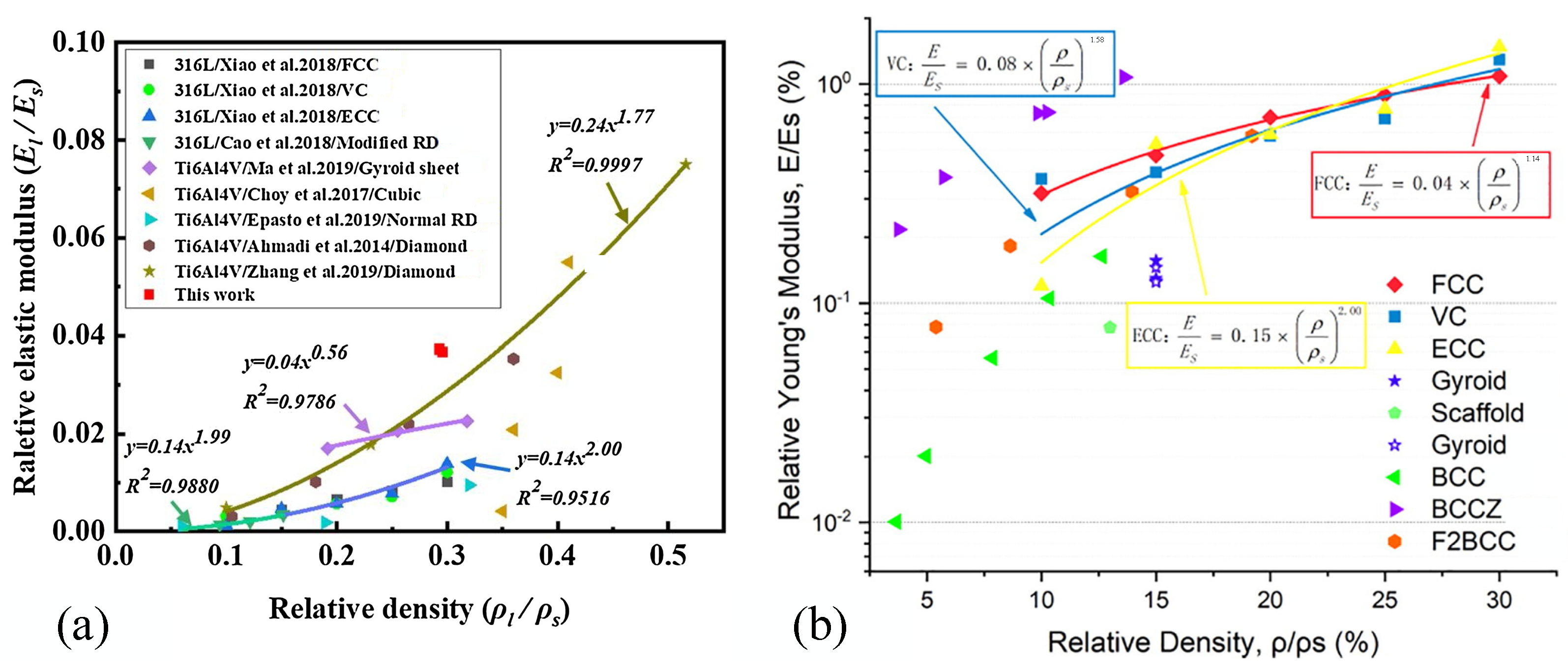

5.1. Design of the Lattice Structure

5.2. Topology Structure

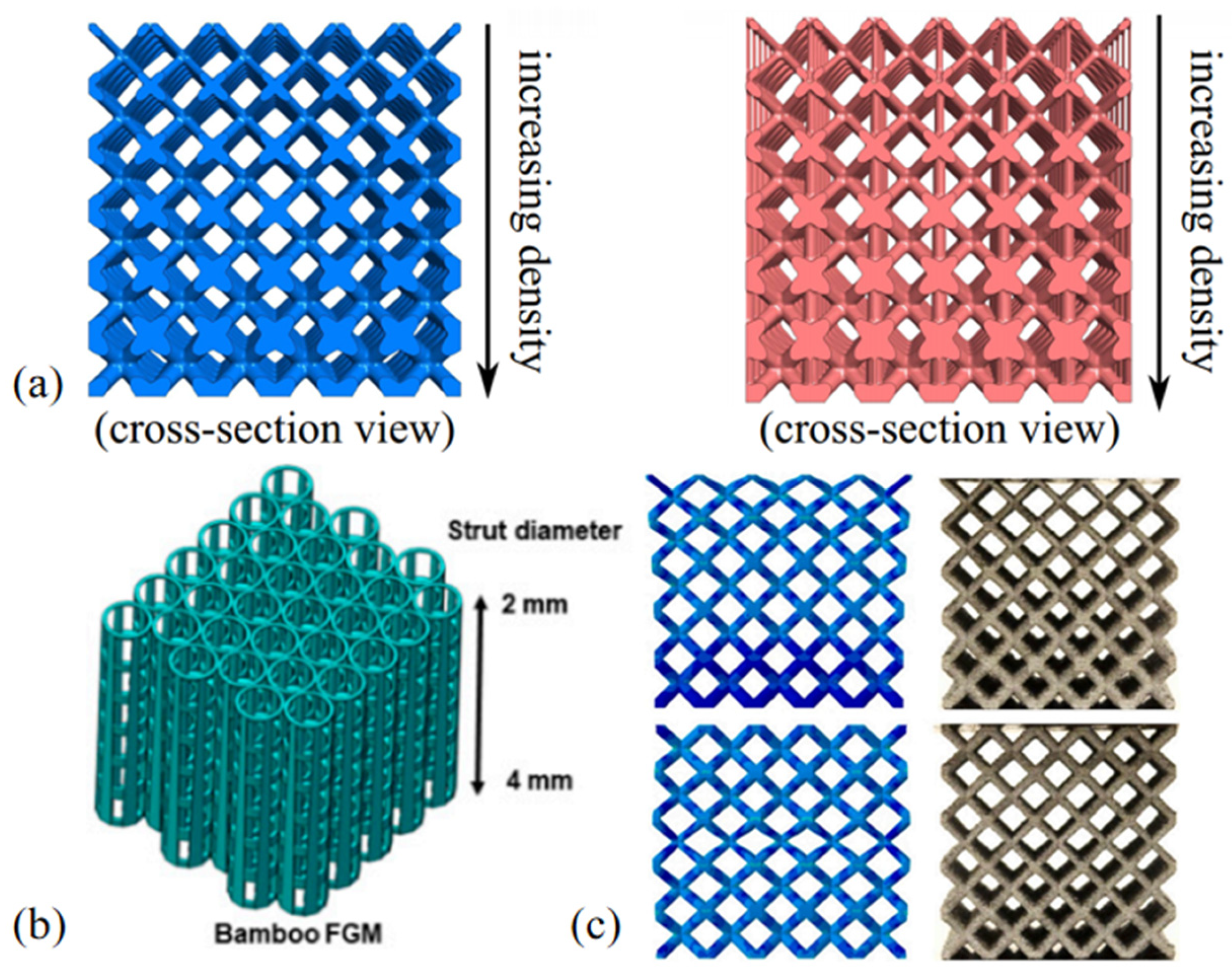

5.3. Graded Structure

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Seharing, A.; Azman, A.H.; Abdullah, S. A review on integration of lightweight gradient lattice structures in additive manufacturing parts. Adv. Mech. Eng. 2020, 12, 1687814020916951. [Google Scholar]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.X.; Qian, M.; Farque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar]

- Paneasr, A.; Abdi, M.; Hickman, D.; Ashcroft, I. Strategies for functionally graded lattice structures derived using topology optimisation for Additive Manufacturing. Addit. Manuf. 2018, 19, 81–94. [Google Scholar]

- Pan, C.; Han, Y.; Lu, J. Design and Optimization of Lattice Structures: A Review. Appl. Sci. 2020, 10, 6374. [Google Scholar] [CrossRef]

- Liu, J.; Chen, T.; Zhang, Y.; Wen, G.; Qing, Q.; Wang, H.; Sedaghati, R.M.; Xie, Y. On sound insulation of pyramidal lattice sandwich structure. Compos. Struct. 2018, 208, 385–394. [Google Scholar]

- Xue, Y.; Gao, P.; Zhou, L.; Han, F. An Enhanced Three-Dimensional Auxetic Lattice Structure with Improved Property. Materials 2020, 13, 1008. [Google Scholar] [CrossRef]

- Li, C.; Lei, H.; Liu, Y.; Zhang, X.; Xiong, J.; Zhou, H.; Fang, D. Crushing behavior of multi-layer metal lattice panel fabricated by selective laser melting. Int. J. Mech. Sci. 2018, 145, 389–399. [Google Scholar]

- Li, D.; Qin, R.; Chen, B.; Zhou, J. Analysis of mechanical properties of lattice structures with stochastic geometric defects in additive manufacturing. Mater. Sci. Eng. A 2021, 822, 141666. [Google Scholar]

- Garcia-Moreno, F. Commercial Applications of Metal Foams: Their Properties and Production. Materials 2016, 9, 85. [Google Scholar] [CrossRef]

- Izard, A.; Alfonso, R.; McKnigh, G.; Valdevit, L. Optimal design of a cellular material encompassing negative stiffness elements for unique combinations of stiffness and elastic hysteresis. Mater. Des. 2017, 135, 37–50. [Google Scholar]

- Nagesha, B.K.; Dhinakaran, V.; Shree, M.V.; Kumar, K.P.M.; Chalawadi, D.; Sathish, T. Review on characterization and impacts of the lattice structure in additive manufacturing. Mater. Today Proc. 2020, 21, 916–919. [Google Scholar]

- Wang, X.; Wang, C.; Zhou, X.; Wang, D.; Zhang, M.; Gao, Y.; Wang, L.; Zhang, P. Evaluating Lattice Mechanical Properties for Lightweight Heat-Resistant Load-Bearing Structure Design. Materials 2020, 13, 4786. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.Z.; Leary, M.; Tang, H.P.; Song, T.; Qian, M. Selective electron beam manufactured Ti-6Al-4V lattice structures for orthopedic implant applications: Current status and outstanding challenges. Curr. Opin. Solid State Mat. Sci. 2018, 22, 75–99. [Google Scholar]

- Liu, J.; Xu, M.Y.; Zhang, R.D.; Zhang, X.R.; Xi, W.X. Progress of Porous/Lattice Structures Applied in Thermal Management Technology of Aerospace Applications. Aerospace 2022, 9, 827. [Google Scholar] [CrossRef]

- Maskery, I.; Aremu, A.O.; Simonelli, M.; Tuck, C.; Wildman, R.D.; Ashcroft, I.A.; Hague, R.J.M. Mechanical Properties of Ti-6Al-4V Selectively Laser Melted Parts with Body-Centred-Cubic Lattices of Varying cell size. Exp. Mech. 2015, 55, 1261–1272. [Google Scholar]

- Zhang, L.; Chen, Y.; He, R.; Bai, X.; Zhang, S.; Ai, S.G.; Yang, Y.; Fang, D. Bending behavior of lightweight C/SiC pyramidal lattice core sandwich panels. Int. J. Mech. Sci. 2020, 171, 105409. [Google Scholar]

- Dong, L.; Deshpande, V.; Wadley, H. Mechanical response of Ti-6Al-4V octet-truss lattice structures. Int. J. Solids. Struct. 2015, 60, 107–124. [Google Scholar]

- Kooistra, G.; Wadley, H.N.G. Lattice truss structures from expanded metal sheet. Mater. Des. 2007, 28, 507–514. [Google Scholar]

- Kang, K.J. Wire-woven cellular metals: The present and future. Prog Mater. Sci. 2015, 69, 213–307. [Google Scholar]

- Queheillalt, D.T.; Murty, Y.; Wadley, H.N.G. Mechanical properties of an extruded pyramidal lattice truss sandwich structure. Scr. Mater. 2008, 58, 76–79. [Google Scholar]

- Borikar, G.P.; Patil, A.R.; Kolekar, S.B. Additively Manufactured Lattice Structures and Materials: Present Progress and Future Scope. Int. J. Precis. Eng. Manuf. 2023, 24, 2133–2180. [Google Scholar] [CrossRef]

- Salem, H.; Carter, L.N.; Attallah, M.M.; Salem, H.G. Influence of processing parameters on internal porosity and types of defects formed in Ti6Al4V lattice structure fabricated by selective laser melting. Mater. Sci. Eng. A 2019, 767, 138387. [Google Scholar] [CrossRef]

- Bagherifard, S.; Beretta, N.; Monti, S.; Riccio, M.; Bandini, M.; Guagliano, M. On the fatigue strength enhancement of additive manufactured AlSi10Mg parts by mechanical and thermal post-processing. Mater. Des. 2018, 145, 28–41. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Jiang, X.; Ye, T.; Zhu, Y. Effect of process parameters on residual stress in selective laser melting of AlSi10Mg. Mater. Sci. Technol. 2020, 36, 342–352. [Google Scholar] [CrossRef]

- Li, D.M.; Zhang, X.; Qin, R.X.; Xu, J.X.; Yue, D.Y.; Chen, B.Z. Influence of processing parameters on AlSi10Mg lattice structure during selective laser melting: Manufacturing defects, thermal behavior and compression properties. Opt. Laser Technol. 2023, 161, 109182. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Foteinopoulos, P. Modelling of Additive Manufacturing Processes: A Review and Classification. Manuf. Rev. 2018, 5, 8–34. [Google Scholar] [CrossRef]

- Majeed, M.; Khan, H.M.; Wheatley, G.; Situ, R. Influence of post-processing on additively manufactured lattice structures. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 389. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Abu Al-Rub, R.K. Multifunctional mechanical-metamaterials based on triply periodic minimal surface lattices. Adv. Eng. Mater. 2019, 21, 1900524. [Google Scholar] [CrossRef]

- Junio, R.F.P.; da Silveira, P.H.P.M.; Neuba, L.D.; Monteriro, S.N.; Nascimento, L.F.C. Development and Applications of 3D Printing-Processed Auxetic Structures for High-Velocity Impact Protection: A Review. Eng 2023, 4, 903–940. [Google Scholar] [CrossRef]

- Joseph, A.; Mahesh, V.; Harursampath, D. On the application of additive manufacturing methods for auxetic structures: A review. Adv. Manuf. 2021, 9, 342–368. [Google Scholar] [CrossRef] [PubMed]

- Isaac, C.W.; Diddeck, F. Current trends in additively manufactured (3D printed) energy absorbing structures for crashworthiness application—A review. Virtual Phys. Prototyp. 2022, 17, 1058–1101. [Google Scholar]

- Chen, L.Y.; Liang, S.X.; Liu, Y.J.; Zhang, L.C. Additive manufacturing of metallic lattice structures: Unconstrained design, accurate fabrication, fascinated performances, and challenges. Mater. Sci. Eng. R Rep. 2021, 146, 100648. [Google Scholar]

- Askari, M.; Hutchins, D.A.; Thomas, P.J.; Astolfi, L.; Watson, R.L.; Abdi, M.; Ricci, M.; Laureti, S.; Nie, L.Z.; Freear, S.; et al. Additive manufacturing of metamaterials: A review. Addit. Manuf. 2021, 36, 101562. [Google Scholar]

- Fan, J.X.; Zhang, L.; Wei, S.S.; Zhang, Z.; Choi, S.K.; Song, B.; Shi, Y.S. A review of additive manufacturing of metamaterials and developing trends. Mater. Today 2021, 50, 303–328. [Google Scholar]

- Mazur, E.; Shishkovsky, I. Additively Manufactured Hierarchical Auxetic Mechanical Metamaterials. Materials 2022, 15, 5600. [Google Scholar] [CrossRef]

- Chen, L.; He, Y.; Yang, Y.; Niu, S.; Ren, H. The research status and development trend of additive manufacturing technology. Int. J. Adv. Manuf. Technol. 2017, 89, 3651–3660. [Google Scholar]

- Huang, S.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive manufacturing: Challenges, trends, and applications. Adv. Mech. Eng. 2019, 11, 1687814018822880. [Google Scholar]

- Huang, Y.; Xue, Y.; Wang, X.; Han, F. Effect of cross sectional shape of struts on the mechanical properties of aluminum based pyramidal lattice structures. Mater. Lett. 2017, 202, 55–58. [Google Scholar]

- Hernandez-Nava, E.; Smith, C.J.; Derguti, F.; Tammas-Williams, S.; Leonard, F.; Withers, P.J.; Todd, I.; Goodall, R. The effect of defects on the mechanical response of Ti-6Al-4V cubic lattice structures fabricated by electron beam melting. Acta Mater. 2016, 108, 279–292. [Google Scholar]

- Crupi, V.; Kara, E.; Epasto, G.; Guglielmino, E.; Aykul, H. Static behavior of lattice structures produced via direct metal laser sintering technology. Mater. Des. 2017, 135, 246–256. [Google Scholar]

- Yan, C.; Hao, L.; Hussein, A.; Raymont, D. Evaluations of cellular lattice structures manufactured using selective laser melting. Int. J. Mach. Tools Manuf. 2012, 62, 32–38. [Google Scholar]

- Kumar, A.; Verma, S.; Jeng, J.Y. Supportless Lattice Structures for Energy Absorption Fabricated by Fused Deposition Modeling. 3D Print. Addit. Manuf. 2020, 7, 85–96. [Google Scholar] [CrossRef]

- Mishra, A.K.; Chavan, H.; Kumar, A. Effect of material variation on the uniaxial compression behavior of FDM manufactured polymeric TPMS lattice materials. Mater. Today Proc. 2021, 46, 7752–7759. [Google Scholar] [CrossRef]

- Swapnil, V.; Soham, T.; Deepak, P.; Shailendra, K. Fused deposition modelling: A review. Rapid Prototyp. J. 2020, 26, 176–201. [Google Scholar]

- Ziaee, M.; Crane, N.B. Binder jetting: A review of process, materials, and methods. Addit. Manuf. 2019, 28, 781–801. [Google Scholar]

- Echeta, I.; Feng, X.; Dutton, B.; Leach, R.; Piano, S. Review of defects in lattice structures manufactured by powder bed fusion. Int. J. Adv. Manuf. Technol. 2020, 106, 2649–2668. [Google Scholar] [CrossRef]

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A review on composite materials and process parameters optimisation for the fused deposition modelling process. Virtual. Phys. Prototyp. 2017, 12, 47–59. [Google Scholar]

- Liu, W.; Song, H.; Wang, Z.; Wang, J.; Huang, C. Improving mechanical performance of fused deposition modeling lattice structures by a snap-fitting method. Mater. Des. 2019, 181, 108065. [Google Scholar]

- Corvi, A.; Collini, L.; Sciancalepore, C.; Kumar, A. Analysis and modelling of damage mechanism in FDM 3D-printed lattice structure under compression loading. J. Mech. Sci. Technol. 2023, 37, 1089–1095. [Google Scholar] [CrossRef]

- Saboori, A.; Gallo, D.; Biamino, S.; Fino, P.; Lombardi, M. An Overview of Additive Manufacturing of Titanium Components by Directed Energy Deposition: Microstructure and Mechanical Properties. Appl. Sci. 2017, 7, 883. [Google Scholar] [CrossRef]

- Shim, D.S.; Baek, G.Y.; Seo, J.S.; Shin, G.Y.; Kim, K.P.; Lee, K.Y. Effect of layer thickness setting on deposition characteristics in direct energy deposition (DED) process. Opt. Laser Technol. 2016, 86, 69–78. [Google Scholar]

- Svetlizky, D.; Das, M.; Zheng, B.; Vytskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials. methods, applications and challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar]

- Baranowski, P.; Platek, P.; Antolak-Dudka, A.; Sarzynski, M.; Kucewicz, M.; Durejko, T.; Malachowski, J.; Janiszewski, J.; Czujko, T. Deformation of honeycomb cellular structures manufactured with Laser Engineered Net Shaping (LENS) technology under quasi-static loading: Experimental testing and simulation. Addit. Manuf. 2019, 25, 307–316. [Google Scholar] [CrossRef]

- Krishna, B.V.; Bose, S.; Bandyopadhyay, A. Low stiffness porous Ti structures for load-bearing implants. Acta Biomater. 2007, 3, 997–1006. [Google Scholar]

- Antolak-Dudka, A.; Platek, P.; Durejko, T.; Baranowski, P.; Malachowski, J.; Sarzynski, M.; Czujko, T. Static and Dynamic Loading Behavior of Ti6Al4V Honeycomb Structures Manufactured by Laser Engineered Net Shaping (LENSTM) Technology. Materials 2019, 12, 1225. [Google Scholar] [CrossRef]

- Maskery, I.; Aboulkhair, N.T.; Aremu, A.O.; Tuck, C.J.; Ashcroft, I.A.; Wildman, R.D.; Hague, R.J.M. A mechanical property evaluation of graded density Al-Si10-Mg lattice structures manufactured by selective laser melting. Mater. Sci. Eng. A 2016, 670, 264–274. [Google Scholar]

- Al-Saedi, D.S.J.; Masood, S.H.; Faizan-Ur-Rab, M.; Alomarah, A.; Ponnusamy, P. Mechanical properties and energy absorption capability of functionally graded F2BCC lattice fabricated by SLM. Mater. Des. 2018, 144, 32–44. [Google Scholar]

- Sienkiew, J.; Platek, P.; Jiang, F.; Sun, X.; Rusinek, A. Investigations on the Mechanical Response of Gradient Lattice Structures Manufactured via SLM. Metals 2020, 10, 213. [Google Scholar] [CrossRef]

- Li, M.; Du, W.; Elwany, A.; Pei, Z.; Ma, C. Metal Binder Jetting Additive Manufacturing: A Literature Review. J. Manuf. Sci. Eng. 2020, 142, 090801. [Google Scholar]

- Lv, X.; Ye, F.; Cheng, L.; Fan, S.; Liu, Y. Binder jetting of ceramics: Powders, binders, printing parameters, equipment, and post-treatment. Ceram. Int. 2019, 45, 12609–12624. [Google Scholar]

- Bai, Y.; Wall, C.; Pham, H.; Esker, A.; Williams, C.B. Characterizing Binder-Powder Interaction in Binder Jetting Additive Manufacturing Via Sessile Drop Goniometry. J. Manuf. Sci. Eng. 2018, 141, 011005. [Google Scholar]

- Bai, Y.; Williams, C.B. Binder jetting additive manufacturing with a particle-free metal ink as a binder precursor. Mater. Des. 2018, 147, 146–156. [Google Scholar]

- Lecis, N.; Mariani, M.; Beltrami, R.; Emanuelli, L.; Casati, R.; Vedani, M.; Molinari, A. Effects of process parameters, debinding and sintering on the microstructure of 316L stainless steel produced by binder jetting. Mater. Sci. Eng. A 2021, 828, 142108. [Google Scholar]

- Snelling, D.; Li, N.; Meisel, Q.; Williams, C.B.; Batra, R.C.; Druschitz, A.P. Lightweight Metal Cellular Structures Fabricated via 3D Printing of Sand Cast Molds. Adv. Eng. Mater. 2015, 17, 923–932. [Google Scholar]

- Xu, M.; Guo, H.; Wang, Y.; Hou, Y.; Dong, Z.; Zhang, L. Mechanical properties and microstructural characteristics of 316L stainless steel fabricated by laser powder bed fusion and binder jetting. J. Mater. Res. Technol. 2023, 24, 4427–4439. [Google Scholar]

- Xie, Y.; Mao, Y.; Heng, Y.; Tao, J.; Xiang, L.; Qin, X.; Wei, Q. Mechanical responses of triply periodic minimal surface gyroid lattice structures fabricated by binder jetting additive manufacturing. J. Mater. Res. Technol. 2025, 35, 2803–2814. [Google Scholar]

- Uribe-Lam, E.; Trevino-Quintanilla, C.D.; Cuan-Urquizo, E.; Olvera-Silva, O. Use of additive manufacturing for the fabrication of cellular and lattice materials: A review. Mater. Manuf. Process. 2020, 36, 257–280. [Google Scholar]

- Luo, Z.; Zhao, Y. A survey of finite element analysis of temperature and thermal stress fields in powder bed fusion Additive Manufacturing. Addit. Manuf. 2018, 21, 318–332. [Google Scholar]

- Sabzi, H.E. Powder bed fusion additive layer manufacturing of titanium alloys. Mater. Sci. Technol. 2019, 35, 875–890. [Google Scholar]

- McCann, R.; Obeidi, M.A.; Hughes, C.; McCarthy, E.; Egan, D.S.; Vijayaraghavan, R.K.; Joshi, A.M.; Garzon, V.A.; Dowling, D.P.; McNally, P.J. In-situ sensing, process monitoring and machine control in Laser Powder Bed Fusion: A review. Addit. Manuf. 2021, 45, 102058. [Google Scholar]

- Sanchez, S.; Smith, P.; Xu, Z.; Gaspard, G.; Hyde, C.J.; Wits, W.W.; Ashcroft, I.A.; Chen, H.; Clare, A.T. Powder Bed Fusion of nickel-based superalloys: A review. Int. J. Mach. Tools. Manuf. 2021, 165, 103729. [Google Scholar]

- Helou, M.; Vongbunyong, S.; Kara, S. Finite Element Analysis and Validation of Cellular Structures. Procedia CIRP 2016, 50, 94–99. [Google Scholar]

- Shirazi, S.F.S.; Gharehkhani, S.; Mehrali, M.; Yarmand, H.; Metselaar, H.S.C.; Kadri, N.A.; Abu Osman, N.A. A review on powder-based additive manufacturing for tissue engineering: Selective laser sintering and inkjet 3D printing. Sci. Technol. Adv. Mater. 2015, 16, 033502. [Google Scholar]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashicroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar]

- Yap, C.Y.; Chua, C.K.; Dong, Z.; Liu, Z.; Zhang, D.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar]

- Koerner, C. Additive manufacturing of metallic components by selective electron beam melting—A review. Int. Mater. Rev. 2016, 61, 361–377. [Google Scholar]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and Mechanical Properties of Ti6Al4V Parts Fabricated by Selective Laser Melting and Electron Beam Melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar]

- Zhang, L.; Liu, Y.; Li, S.; Hao, Y. Additive Manufacturing of Titanium Alloys by Electron Beam Melting: A Review. Adv. Eng. Mater. 2018, 20, 1700842. [Google Scholar] [CrossRef]

- Ma, S.; Zhu, R.; Yang, S.; Yang, Q.; Wei, K.; Qu, Z. Influence of geometric imperfections on the mechanical behavior for Invar 36 alloy lattice structures fabricated by selective laser melting. Int. J. Mech. Sci. 2024, 274, 109252. [Google Scholar] [CrossRef]

- Peng, K.; Cai, G.S.; Hu, B.; Huang, X.N. Investigation on effect of pillar size on the comprehensive properties of Ti6Al4V lattice fabricated by selective laser melting. Mater. Sci. Eng. A 2023, 892, 146037. [Google Scholar] [CrossRef]

- Wally, Z.J.; Haque, A.M.; Feteira, A.; Claeyssens, F.; Godall, R.; Reilly, G.C. Selective laser melting processed Ti6Al4V lattices with graded porosities for dental applications. J. Mech. Behav. Biomed. Mater. 2019, 90, 20–29. [Google Scholar] [CrossRef]

- Jabarzadeh, S.; Ghasemi-Ghalebahman, A.; Najibi, A. Investigation into microstructure, mechanical properties, and compressive failure of functionally graded porous cylinders fabricated by SLM. Eng. Fail. Anal. 2024, 165, 108794. [Google Scholar] [CrossRef]

- Condruz, M.; Badea, T.; Paraschiv, A. Numerical and experimental investigation on flexural properties of selective laser melting (SLM) manufactured strut lattices structures from Ti-6Al-4V and Inconel 625. Mater. Today Commun. 2024, 40, 110150. [Google Scholar] [CrossRef]

- Helou, M.; Kara, S. Design, analysis and manufacturing of lattice structures: An overview. Int. J. Comput. Integr. Manuf. 2018, 31, 243–261. [Google Scholar] [CrossRef]

- Tsopanos, S.; Mines, R.A.W.; McKown, S.; Cantwell, W.J.; Brooks, W.; Sutcliffe, C.J. The Influence of Processing Parameters on the Mechanical Properties of Selectively Laser Melted Stainless Steel Microlattice Structures. J. Manuf. Sci. Eng. 2010, 132, 041011. [Google Scholar] [CrossRef]

- Rashid, R.A.R.; Mallavarapu, J.; Palanisamy, S.; Masood, S.H. A comparative study of flexural properties of additively manufactured aluminium lattice structures. Mater. Today Proc. 2017, 4, 8597–8604. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Yang, C.; Wang, Q.; Li, D. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Tang, C.; Liu, J.; Yang, Y.; Liu, Y.; Jiang, S.; Hao, W. Effect of process parameters on mechanical properties of 3D printed PLA lattice structures. Compos. Part C Open Access 2020, 3, 100076. [Google Scholar]

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of Layer Thickness and Raster Angle on the Mechanical Properties of 3D-Printed PEEK and a Comparative Mechanical Study between PEEK and ABS. Materials 2015, 8, 5834–5846. [Google Scholar] [CrossRef] [PubMed]

- Egan, D.S.; Dowling, D.P. Influence of process parameters on the correlation between in-situ process monitoring data and the mechanical properties of Ti-6Al-4V non-stochastic cellular structures. Addit. Manuf. 2019, 30, 100890. [Google Scholar] [CrossRef]

- Sing, S.L.; Wiria, F.E.; Yeong, W.Y. Selective laser melting of lattice structures: A statistical approach to manufacturability and mechanical behavior. Robot Comput. Integr. Manuf. 2018, 49, 170–180. [Google Scholar]

- Vangapally, S.; Agarwal, K.; Sheldon, A.; Cai, S. Effect of Lattice Design and Process Parameters on Dimensional and Mechanical Properties of Binder Jet Additively Manufactured Stainless Steel 316 for Bone Scaffolds. Procedia Manuf. 2017, 10, 750–759. [Google Scholar]

- Jia, H.; Sun, H.; Wang, H.; Wu, Y.; Wang, H. Scanning strategy in selective laser melting (SLM): A review. Int. J. Adv. Manuf. Technol. 2021, 113, 2413–2435. [Google Scholar]

- Vrana, R.; Jaros, J.; Koutny, D.; Nosek, J.; Zikmund, T.; Kaiser, J.; Palousek, D. Contour laser strategy and its benefits for lattice structure manufacturing by selective laser melting technology. J. Manuf. Process. 2022, 74, 640–657. [Google Scholar]

- Mahmoud, D.; Elbestawi, M.A. Selective laser melting of porosity graded lattice structures for bone implants. Int. J. Adv. Manuf. Technol. 2019, 100, 2915–2927. [Google Scholar]

- Foteinopoulos, P.; Papacharalampopoulos, A.; Stavropoulos, P. Additive manufacturing simulations: An approach based on space partitioning and dynamic 3D mesh adaptation. Addit. Manuf. Lett. 2024, 11, 100256. [Google Scholar] [CrossRef]

- Yang, L.; Yan, C.; Cao, W.; Liu, Z.; Song, B.; Wen, S.; Zhang, C.; Shi, Y.; Yang, S. Compression-compression fatigue behaviour of gyroid-type triply periodic minimal surface porous structures fabricated by selective laser melting. Acta Mater. 2019, 181, 49–66. [Google Scholar]

- Pyka, G.; Burakowski, A.; Kerckhofs, G.; Moesen, M.; Van Bael, S.; Schrooten, J.; Wevers, M. Surface Modification of Ti6Al4V Open Porous Structures Produced by Additive Manufacturing. Adv. Eng. Mater. 2012, 14, 363–370. [Google Scholar]

- Van Hooreweder, B.; Lietaert, K.; Neirinck, B.; Lippiatt, N.; Weves, M. CoCr F75 scaffolds produced by additive manufacturing: Influence of chemical etching on powder removal and mechanical performance. J. Mech. Behav. Biomed. Mater. 2017, 68, 216–223. [Google Scholar] [PubMed]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar]

- Maskery, I.; Aboulkhair, N.T.; Aremu, A.O.; Tuck, C.J.; Ashicroft, I.A. Compressive failure modes and energy absorption in additively manufactured double gyroid lattices. Addit. Manuf. 2018, 16, 24–29. [Google Scholar]

- Liu, Y.; Li, S.; Wang, H.; Hou, W.; Hao, Y.; Yang, R.; Sercombe, T.B.; Zhang, L. Microstructure, defects and mechanical behavior of beta-type titanium porous structures manufactured by electron beam melting and selective laser melting. Acta Mater. 2016, 113, 56–67. [Google Scholar]

- Tillmann, W.; Schaak, C.; Nellesen, J.; Schaper, M.; Aydinoz, M.E.; Hoyer, K.P. Hot isostatic pressing of IN718 components manufactured by selective laser melting. Addit. Manuf. 2017, 13, 93–102. [Google Scholar]

- Mower, T.M.; Long, M.J. Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Mater. Sci. Eng A 2016, 651, 198–213. [Google Scholar]

- Wu, M.; Chen, J.; Lin, B.; Chiang, P. Improved fatigue endurance ratio of additive manufactured Ti-6Al-4V lattice by hot isostatic pressing. Mater. Des. 2017, 134, 163–170. [Google Scholar]

- Wu, M.W.; Lai, P. The positive effect of hot isostatic pressing on improving the anisotropies of bending and impact properties in selective laser melted Ti-6Al-4V alloy. Mater. Sci. Eng. A 2016, 658, 429–438. [Google Scholar]

- Tao, W.J.; Leu, M.C. Design of Lattice Structure for Additive Manufacturing. In Proceedings of the 2016 International Symposium on Flexible Automation, Cleveland, OH, USA, 1–3 August 2016; p. 7790182. [Google Scholar]

- Lin, J.K.; Gaynor, A.T.; Chen, S.K.; Kang, Z.; Suresh, K.; Takezawa, A.; Li, L.; Kato, J.; Tang, J.Y.; Wang, C.L.; et al. Current and future trends in topology optimization for additive manufacturing. Struct. Multidiscip. Optim. 2018, 57, 2457–2483. [Google Scholar]

- Checa, A.G.; Cartwright, J.H.E.; Sánchez-Almazo, I.; Andrade, J.P.; Ruiz-Raya, F. The cuttlefish Sepia officinalis (Sepiidae, Cephalopoda) constructs cuttlebone from a liquid-crystal precursor. Sci. Rep. 2015, 5, 11513. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Gadipudi, V.K.; Salem, D.R. Topology Optimization of Lightweight Lattice Structural Composites Inspired by Cuttlefish Bone. Appl. Compos. Mater. 2019, 26, 15–27. [Google Scholar] [CrossRef]

- Li, H.; Liu, R.Y.; Wang, H.J.; Xin, R.L.; Xu, Z.B.; Yu, Z.L. Ant-Inspired Bionic Design Method for the Support Structure of the Fengyun-3 Satellite Payload Infilled with Lattice Structure. Materials 2023, 16, 736. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Song, B.; Fu, J.; Wei, S.; Yang, L.; Yan, C.; Li, H.; Gao, L.; Shi, Y. Topology-optimized lattice structures with simultaneously high stiffness and light weight fabricated by selective laser melting: Design, manufacturing and characterization. J. Manuf. Process. 2020, 56, 1166–1177. [Google Scholar] [CrossRef]

- Xiao, Z.; Yang, Y.; Xiao, R.; Bai, Y.; Song, C.; Wang, D. Evaluation of topology-optimized lattice structures manufactured via selective laser melting. Mater. Des. 2018, 143, 27–37. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, J.; Wu, M.; Hou, J.; Zhou, H.; Meng, L.; Li, C.; Zhang, W. Multi-scale design and optimization for solid-lattice hybrid structures and their application to aerospace vehicle components. Chin. J. Aeronaut. 2021, 34, 386–398. [Google Scholar]

- Dong, G.; Tang, Y.; Li, D.; Zhao, Y.F. Design and optimization of solid lattice hybrid structures fabricated by additive manufacturing. Addit. Manuf. 2020, 33, 01116. [Google Scholar] [CrossRef]

- Maskey, I.; Hussey, A.; Panesar, A.; Aremu, A.; Tuck, C.; Shcroft, I.A.; Hague, R. An investigation into reinforced and functionally graded lattice structures. J. Cell. Plast. 2017, 53, 151–165. [Google Scholar] [CrossRef]

- Wen, Z.; Li, M. Compressive Properties of Functionally Graded Bionic Bamboo Lattice Structures Fabricated by FDM. Materials 2021, 14, 4410. [Google Scholar] [CrossRef]

- Rodrigo, C.; Xu, S.Q.; Durandet, Y.; Fraser, D.; Ruan, D. Quasi-static and dynamic compression of additively manufactured functionally graded lattices: Experiments and simulations. Eng. Struct. 2023, 284, 115909. [Google Scholar]

- Lin, Y.X.; Shi, W.T.; Sun, X.H.; Liu, S.; Li, J.H.; Zhou, Y.S.; Han, Y.F. Influence of Density Gradient on the Compression of Functionally Graded BCC Lattice Structure. Materials 2023, 16, 520. [Google Scholar] [CrossRef]

| Method | Material | Principle | Characteristic | Refs. |

|---|---|---|---|---|

| FDM | Metal, thermoplastic materials | The material is melted and extruded in the nozzle, cooled and solidified | Low maintenance cost and simple printing process | [44,45,46,49,50] |

| DED | Metal, ceramic | The material is melted and cooled to solidify | Flexible control | [51,55,56,57,58] |

| BJ | Metals, ceramics, polymers | Sprayed and sewed with adhesive | Low cost, wide range of available materials, low part strength | [33,68,69] |

| PBF | Metal, ceramic, thermoplastic materials | The material is melted and cooled to solidify | High material utilization rate, high precision | [70,75,76] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Liu, H.; Cai, G.; Jin, H. Additive Manufacturing and Influencing Factors of Lattice Structures: A Review. Materials 2025, 18, 1397. https://doi.org/10.3390/ma18071397

Yang J, Liu H, Cai G, Jin H. Additive Manufacturing and Influencing Factors of Lattice Structures: A Review. Materials. 2025; 18(7):1397. https://doi.org/10.3390/ma18071397

Chicago/Turabian StyleYang, Jinlin, Hui Liu, Gaoshen Cai, and Haozhe Jin. 2025. "Additive Manufacturing and Influencing Factors of Lattice Structures: A Review" Materials 18, no. 7: 1397. https://doi.org/10.3390/ma18071397

APA StyleYang, J., Liu, H., Cai, G., & Jin, H. (2025). Additive Manufacturing and Influencing Factors of Lattice Structures: A Review. Materials, 18(7), 1397. https://doi.org/10.3390/ma18071397