Coffee Silverskin as a Sustainable Alternative Filler for Plywood: Characterization and Performance Analysis

Abstract

:1. Introduction

2. Materials and Methods

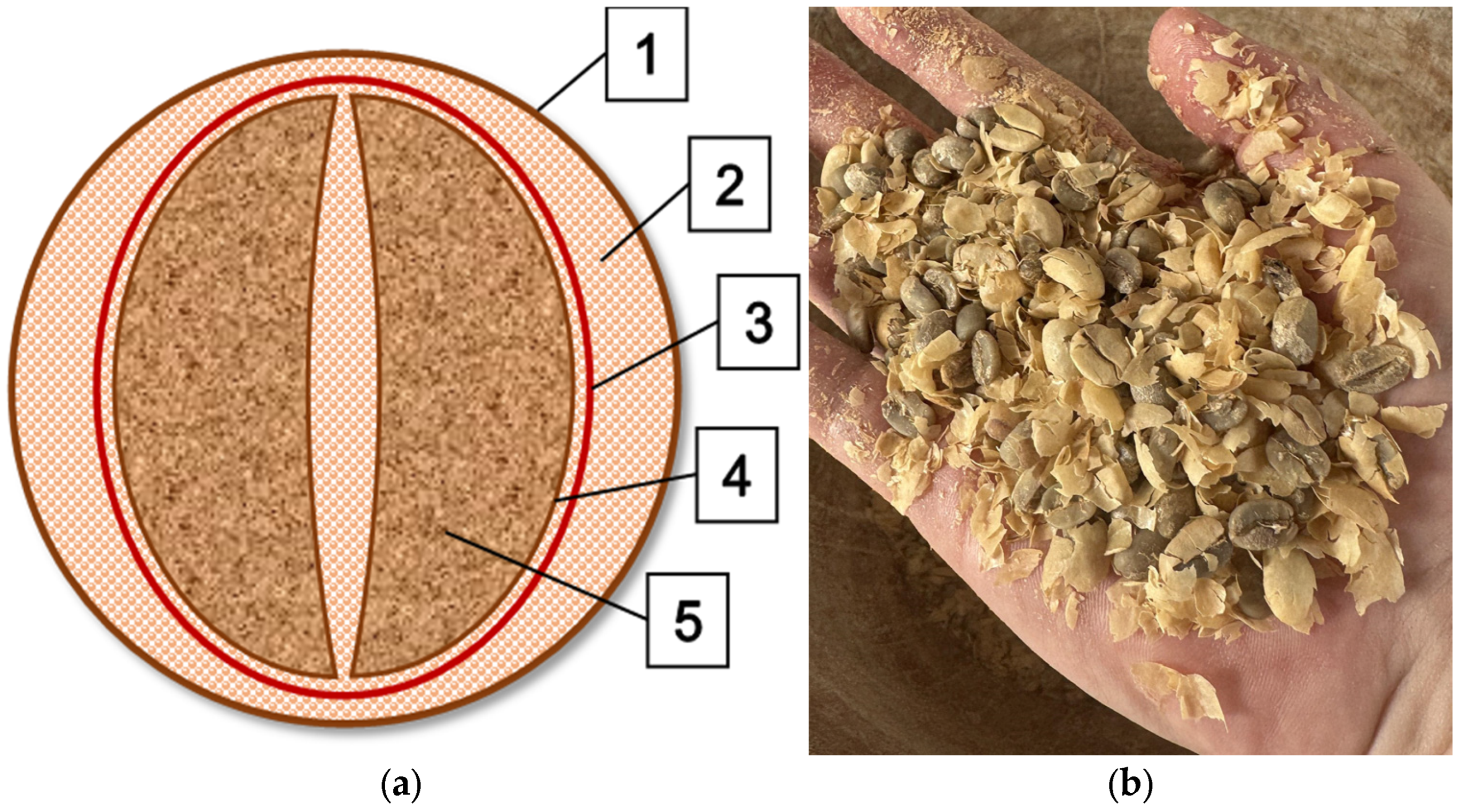

2.1. Materials

2.2. Composites Samples Preparation

2.3. Characterization of the Manufactured Composites

2.4. Statistical Analysis

3. Results and Discussion

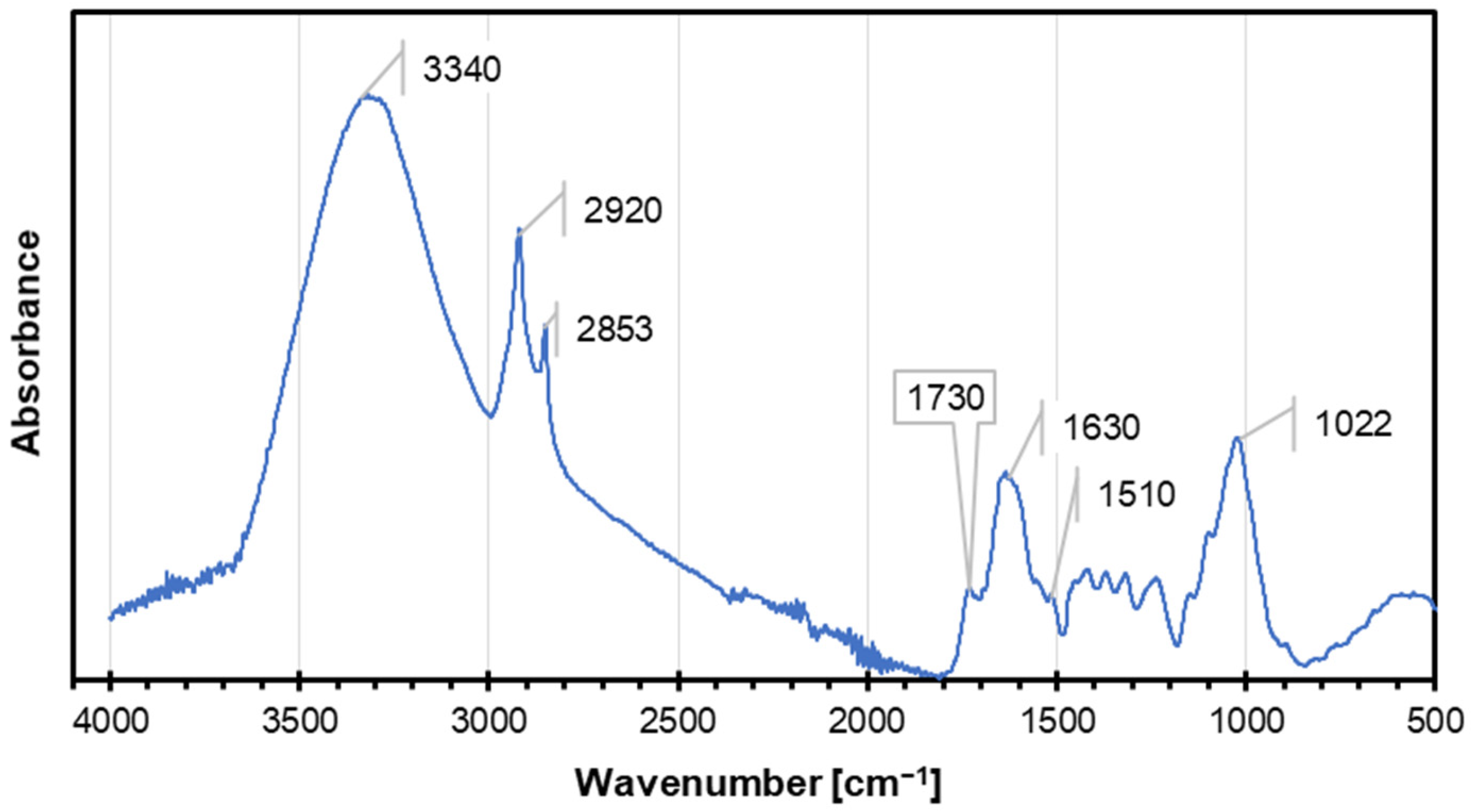

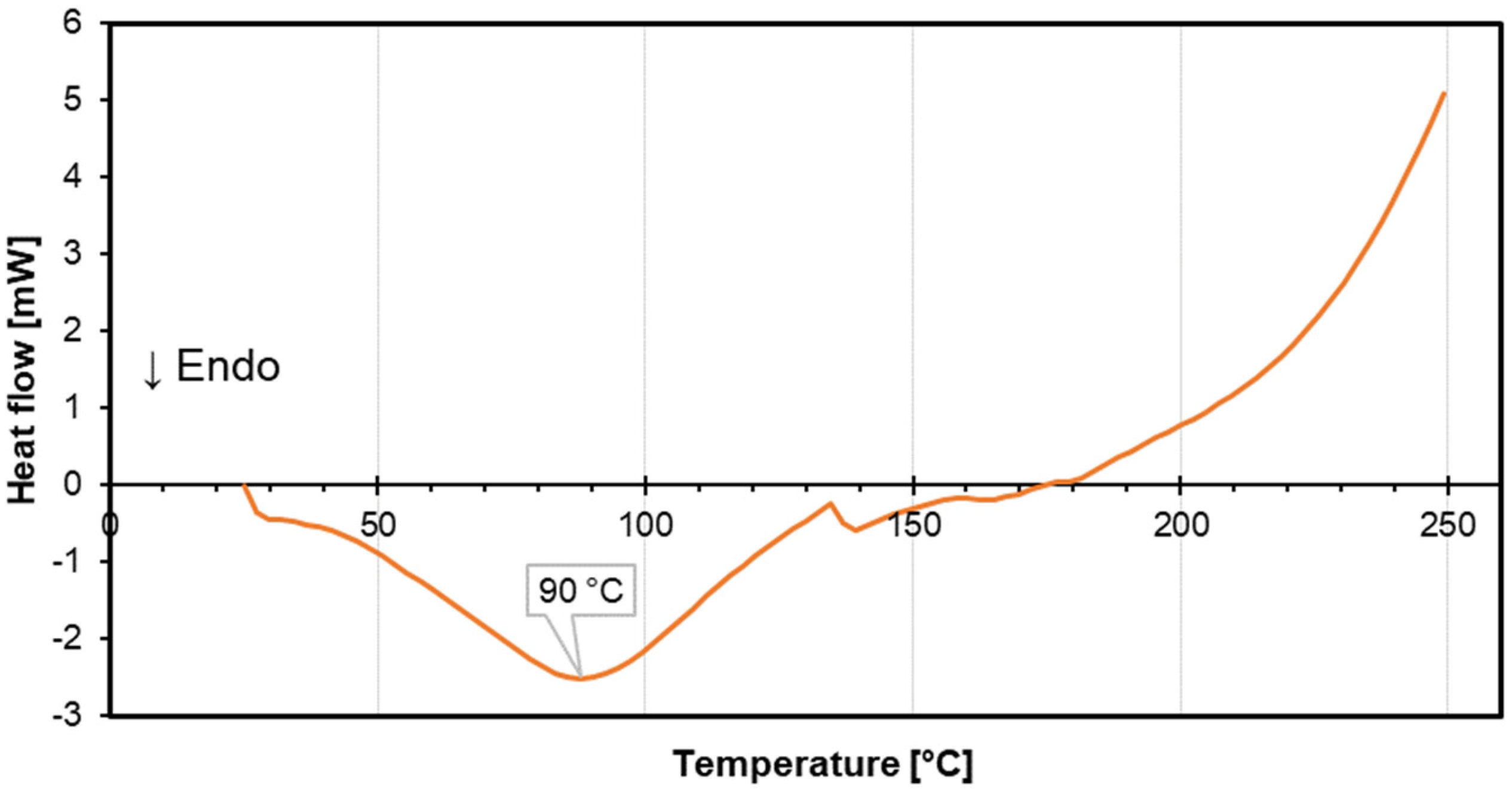

3.1. FTIR, DSC, and TGA Characteristics

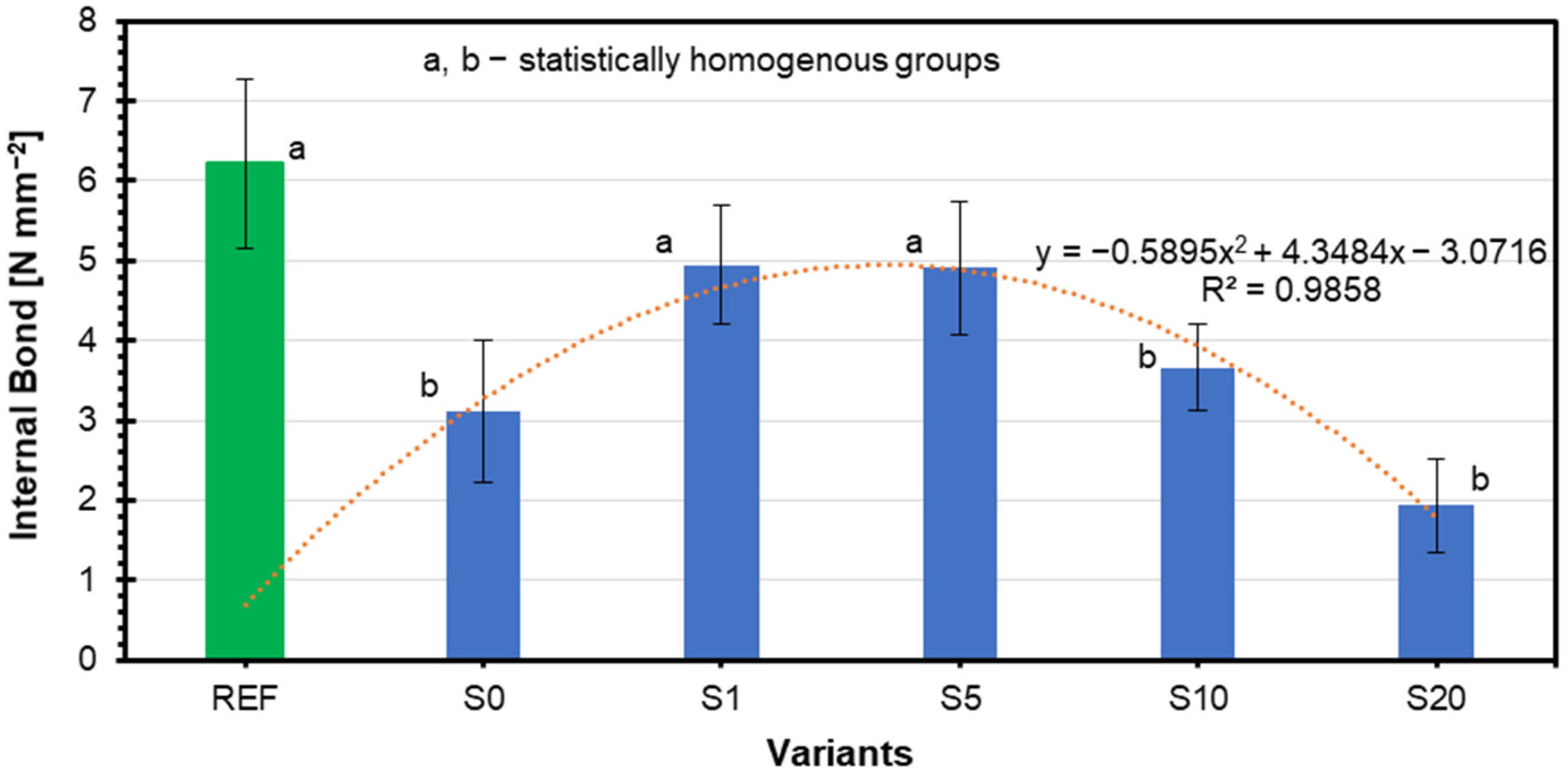

3.2. Internal Bond

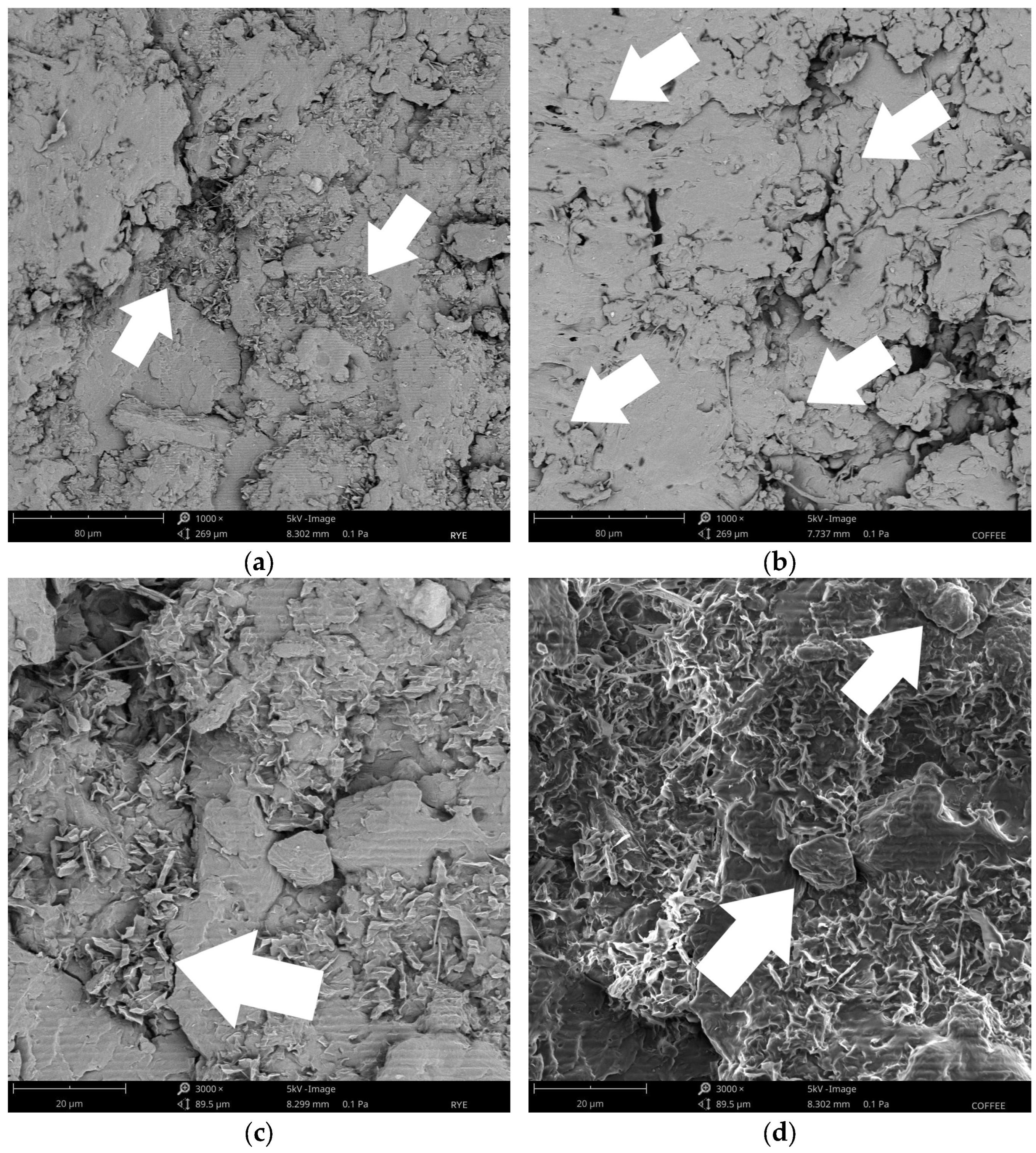

3.3. SEM Image Analyses

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tamilselvan, K.; Sundarajan, S.; Ramakrishna, S.; Amirul, A.A.A.; Vigneswari, S. Sustainable Valorisation of Coffee Husk into Value Added Product in the Context of Circular Bioeconomy: Exploring Potential Biomass-Based Value Webs. Food Bioprod. Process. 2024, 145, 187–202. [Google Scholar] [CrossRef]

- Hoseini, M.; Cocco, S.; Casucci, C.; Cardelli, V.; Corti, G. Coffee By-Products Derived Resources. A Review. Biomass Bioenergy 2021, 148, 106009. [Google Scholar] [CrossRef]

- Sisti, L.; Celli, A.; Totaro, G.; Cinelli, P.; Signori, F.; Lazzeri, A.; Bikaki, M.; Corvini, P.; Ferri, M.; Tassoni, A.; et al. Monomers, Materials and Energy from Coffee by-Products: A Review. Sustainability 2021, 13, 6921. [Google Scholar] [CrossRef]

- Saldaña-Mendoza, S.A.; Martínez-Hernandez, J.L.; Rodríguez-Herrera, R.; Palacios-Ponce, A.S.; Sugathan, S.; Aguilar, C.N. Use of Coffee Waste for the Production of Biofuels. Environ. Qual. Manag. 2022, 32, 463–471. [Google Scholar] [CrossRef]

- Czekała, W.; Łukomska, A.; Pulka, J.; Bojarski, W.; Pochwatka, P.; Kowalczyk-Juśko, A.; Oniszczuk, A.; Dach, J. Waste-to-Energy: Biogas Potential of Waste from Coffee Production and Consumption. Energy 2023, 276, 127604. [Google Scholar] [CrossRef]

- Divyashri, G.; Tulsi, N.P.; Murthy, T.P.K.; Shreyas, S.; Kavya, R.; Jaishree, I.K. Valorization of Coffee Bean Processing Waste for Bioethanol Production: Comparison and Evaluation of Mass Transfer Effects in Fermentations Using Free and Encapsulated Cells of Saccharomyces Cerevisiae. Bioprocess Biosyst. Eng. 2024, 47, 169–179. [Google Scholar] [CrossRef]

- Kasutjianingati; Wahyono, A.; Brilliantin, A.; Sari, E.K.N.; Prayitno. The Production of Pak Choy (Brassica Rapa L) Based on Cleaner Coffee Production. IOP Conf. Ser. Earth Environ. Sci. 2021, 672, 012094. [Google Scholar] [CrossRef]

- Santinato, F.; Caione, G.; Tavares, T.O.; Prado, R.d.M. Doses of Phosphorus Associated with Nitrogen on Development of Coffee Seedlings [Doses de Fósforo Associadas Ao Nitrogênio No Desenvolvimento de Mudas de Cafeeiro]. Coffee Sci. 2014, 9, 419–426. [Google Scholar]

- Mantovani, J.R.; De Paula, D.W.; Rezende, T.T.; Da Silva, A.B.; Andrade, P.C.C.; Landgraf, P.R.C. Early Growth of Coffee Plants and Soil Fertility Properties Response to Coffee Husk Application [Crescimento Inicial Do Cafeeiro e Atributos de Fertilidade Do Solo Com Aplicação de Casca de Café]. Coffee Sci. 2018, 13, 356–364. [Google Scholar] [CrossRef]

- de Morais, E.G.; Silva, C.A.; Maluf, H.J.G.M.; Paiva, I.d.O.; de Paula, L.H.D. Effects of Compost-Based Organomineral Fertilizers on the Kinetics of NPK Release and Maize Growth in Contrasting Oxisols. Waste Biomass Valorization 2023, 14, 2299–2321. [Google Scholar] [CrossRef]

- Markos, D.; Gurmu, F. Effects of Soil Amendments on Growth and Biomass Yield of Early Generation Seeds of Sweet Potato (Ipomoea batatas (L.) Lam) Grown in Net Tunnels. PLoS ONE 2023, 18, e0290585. [Google Scholar] [CrossRef] [PubMed]

- Sukmadewi, D.K.T.; Udayana, I.G.B.; Agus Saputra, I.P.A.; Diah Prawerti, D.A. Viability of Aspergillus Costaricaensis in a Coffee Husk Carrier Material and Its Effect on Soil Fertility and Growth of Coffee Seedlings. J. Degrad. Min. Lands Manag. 2023, 10, 4823–4828. [Google Scholar] [CrossRef]

- de Morais, E.G.; Silva, C.A.; Maluf, H.J.G.M.; de Oliveira Paiva, I.; de Paula, L.H.D. How Do NPK-Organomineral Fertilizers Affect the Soil Availability and Uptake of Iron, Manganese, Copper, and Zinc by Maize Cultivated in Red and Yellow Oxisols? J. Soil Sci. Plant Nutr. 2023, 23, 6284–6298. [Google Scholar] [CrossRef]

- Munirwan, R.P.; Mohd Taib, A.; Taha, M.R.; Abd Rahman, N.; Munirwansyah, M. Utilization of Coffee Husk Ash for Soil Stabilization: A Systematic Review. Phys. Chem. Earth 2022, 128, 103252. [Google Scholar] [CrossRef]

- Acchar, W.; Dultra, E.J.V.; Segadães, A.M. Untreated Coffee Husk Ashes Used as Flux in Ceramic Tiles. Appl. Clay Sci. 2013, 75, 141–147. [Google Scholar] [CrossRef]

- Dewi, R.P.; Saputra, T.J.; Widodo, S. Techno Economic Analysis of Utilization of Coffee Husk Waste as an Alternative Energy Source. AIP Conf. Proc. 2023, 2706, 020164. [Google Scholar] [CrossRef]

- Scariot, M.R.; Dal-Bó, V.; da Silva Arrieche, L. Emergy Accounting of Coffee Husks for the Generation of Energy. Fuel 2024, 362, 130862. [Google Scholar] [CrossRef]

- Lule, Z.C.; Wondu, E.; Kim, J. Highly Rigid, Fire-Resistant, and Sustainable Polybutylene Adipate Terephthalate/Polybutylene Succinate Composites Reinforced with Surface-Treated Coffee Husks. J. Clean. Prod. 2021, 315, 128095. [Google Scholar] [CrossRef]

- Gamiz-Conde, A.K.; Burelo, M.; Franco-Urquiza, E.A.; Martínez-Franco, E.; Luna-Barcenas, G.; Bravo-Alfaro, D.A.; Treviño-Quintanilla, C.D. Development and Properties of Bio-Based Polymer Composites Using PLA and Untreated Agro-Industrial Residues. Polym. Test. 2024, 139, 108576. [Google Scholar] [CrossRef]

- Rodríguez Espejel, K.; Pérez Bueno, J.d.J.; Magdaleno López, C.; Mendoza López, M.L.; Algara Siller, M.; Reyes Araiza, J.L.; Manzano-Ramírez, A.; Morales Hernández, J. Geopolymeric Composite Materials Made of Sol-Gel Silica and Agroindustrial Wastes of Rice, Barley, and Coffee Husks with Wood-Like Finishing. Sustainability 2022, 14, 16689. [Google Scholar] [CrossRef]

- Biswas, S.; Hossiney, N.; Mohan, M.K.; Kumar, S.L. Valorisation of Coffee Husk as Replacement of Sand in Alkali-Activated Bricks. Case Stud. Constr. Mater. 2024, 21, e03440. [Google Scholar] [CrossRef]

- Huang, L.; Mu, B.; Yi, X.; Li, S.; Wang, Q. Sustainable Use of Coffee Husks For Reinforcing Polyethylene Composites. J. Polym. Environ. 2018, 26, 48–58. [Google Scholar] [CrossRef]

- Fenklie, E.G.; Singh, B.; Beri, H.; Gelaw, M. Performance Analysis of Coffee Husk with Nano-SiO2particles Reinforced Unsaturated Polyester Composites. AIP Conf. Proc. 2022, 2393, 020099. [Google Scholar] [CrossRef]

- Ilangovan, M.; Guna, V.; Hu, C.; Takemura, A.; Leman, Z.; Reddy, N. Dehulled Coffee Husk-Based Biocomposites for Green Building Materials. J. Thermoplast. Compos. Mater. 2021, 34, 1623–1638. [Google Scholar] [CrossRef]

- Bellili, N.; Djidjelli, H.; Boukerrou, A.; Dairi, B.; Bendib, R. Effect of Acetylation on Composite Materials Based on Polypropylene/Coffee Husk Waste. Compos. Mech. Comput. Appl. 2021, 11, 309–322. [Google Scholar] [CrossRef]

- Milawarni; Nurlaili, N.; Ernayusnianti, E. Investigation on the Feasibility of Coffee Husk (Endocarp) as Efficient Filler Material for Enhancing Physical and Mechanical Properties of Styrofoam Based Particleboard. IOP Conf. Ser. Mater. Sci. Eng. 2018, 334, 012080. [Google Scholar] [CrossRef]

- Setter, C.; Ataíde, C.H.; Mendes, R.F.; de Oliveira, T.J.P. Influence of Particle Size on the Physico-Mechanical and Energy Properties of Briquettes Produced with Coffee Husks. Environ. Sci. Pollut. Res. 2021, 28, 8215–8223. [Google Scholar] [CrossRef]

- Sanchez-Zuiga, J.V.; Sanchez-Molina, J.; Diaz-Fuentes, C.X. Improvements in the Thermal Behavior in the Manufacture of the H10 Block Using Coffee Husks as an Alternative Industrial Additive. J. Phys. Conf. Ser. 2020, 1645, 012013. [Google Scholar] [CrossRef]

- Lubwama, M.; Yiga, V.A. Characteristics of Briquettes Developed from Rice and Coffee Husks for Domestic Cooking Applications in Uganda. Renew. Energy 2018, 118, 43–55. [Google Scholar] [CrossRef]

- Aniszewska, M.; Gendek, A.; Tamelová, B.; Malaťák, J.; Velebil, J.; Krilek, J.; Čabalová, I.; Výbohová, E.; Bubeníková, T. Changes in the Physical, Mechanical, Chemical and Energy Parameters of Coffee Husk Pellets during Short-Term Storage. Fuel 2025, 386, 134191. [Google Scholar] [CrossRef]

- Poyilil, S.; Palatel, A.; Chandrasekharan, M. Physico-Chemical Characterization Study of Coffee Husk for Feasibility Assessment in Fluidized Bed Gasification Process. Environ. Sci. Pollut. Res. 2022, 29, 51041–51053. [Google Scholar] [CrossRef] [PubMed]

- Van Nguyen, D.; Duong, C.T.T.; Vu, C.N.M.; Nguyen, H.M.; Pham, T.T.; Tran-Thuy, T.M.; Nguyen, L.Q. Data on Chemical Composition of Coffee Husks and Lignin Microparticles as Their Extracted Product. Data Br. 2023, 51, 109781. [Google Scholar] [CrossRef] [PubMed]

- Emma, A.F.; Sathyabhama, A.; Yadav, A.K. Extraction and characterization of biodiesel derived from the coffee husk and its effect on diesel engine performance and emission characteristics. Int. J. Energy Clean Environ. 2023, 24, 19–40. [Google Scholar] [CrossRef]

- Loryuenyong, V.; Khamsawat, J.; Danwong, P.; Buasri, A.; Pattananuwat, P. Application of Coffee Silverskin Cellulose/Polyacrylamide Gel Polymer Electrolytes for Rechargeable Zinc-Ion Batteries. Sci 2024, 6, 50. [Google Scholar] [CrossRef]

- Bravi, M.; Brucato, A.; Marzocchella, A.; Posilipo, A.; Russo, M.E. Initial Rate of Hydrolysis of Coffee Silverskin by a Commercial Cellulase Cocktail. Chem. Eng. Trans. 2022, 93, 25–30. [Google Scholar] [CrossRef]

- Nolasco, A.; Squillante, J.; Velotto, S.; D’Auria, G.; Ferranti, P.; Mamone, G.; Errico, M.E.; Avolio, R.; Castaldo, R.; Cirillo, T.; et al. Valorization of Coffee Industry Wastes: Comprehensive Physicochemical Characterization of Coffee Silverskin and Multipurpose Recycling Applications. J. Clean. Prod. 2022, 370, 133520. [Google Scholar] [CrossRef]

- Tommasini Vieira Ramos, F.J.H.; Vieira Marques, M.d.F.; de Oliveira Aguiar, V.; Fabbri Gondim, F.; dos Santos Gomes, L.; de Oliveira Gomes, P.H. Geopolymer Composites Reinforced with Silverskin Fibers from the Coffee Industry Waste. J. Mater. Res. Technol. 2024, 31, 3287–3300. [Google Scholar] [CrossRef]

- Vimercati, W.C.; Macedo, L.L.; da Silva Araújo, C. Health Benefits of Bioactive Compounds and Nutrients in Coffee Silverskin. In Plant-Based Bioactive Compounds and Food Ingredients: Encapsulation, Functional, and Safety Aspects; Apple Academic Press: Burlington, ON, USA, 2023; pp. 237–250. ISBN 9781000845143. [Google Scholar]

- Narita, Y.; Inouye, K. Review on Utilization and Composition of Coffee Silverskin. Food Res. Int. 2014, 61, 16–22. [Google Scholar] [CrossRef]

- Gottstein, V.; Bernhardt, M.; Dilger, E.; Keller, J.; Breitling-Utzmann, C.M.; Schwarz, S.; Kuballa, T.; Lachenmeier, D.W.; Bunzel, M. Coffee Silver Skin: Chemical Characterization with Special Consideration of Dietary Fiber and Heat-Induced Contaminants. Foods 2021, 10, 1705. [Google Scholar] [CrossRef]

- Asfaw, F.B.; Hareru, W.K.; Ghebrab, T. Physical and Chemical Characterization of Coffee Husk Ash Effect on Partial Replacement of Cement in Concrete Production. Int. J. Sustain. Constr. Eng. Technol. 2022, 13, 167–184. [Google Scholar] [CrossRef]

- Amena, B.T.; Altenbach, H.; Tibba, G.S.; Hossain, N. Investigation of Mechanical Properties of Coffee Husk-HDPE-ABS Polymer Composite Using Injection-Molding Method. J. Compos. Sci. 2022, 6, 354. [Google Scholar] [CrossRef]

- Muñoz-Pabon, K.S.; Castillo, H.S.V.; Concha, J.L.H.; Ayala Aponte, A.A.; Solanilla Duque, J.F. Development of a Composite Based on Polylactic Acid and Lignocellulosic Waste: New Packaging for Meat Food Storage. Front. Sustain. Food Syst. 2023, 7, 1265091. [Google Scholar] [CrossRef]

- Oh, Y.-S. Evaluation of Chestnut Shell and Coffee Waste with Phenol-Formaldehyde Resin for Plywood Filler. Ciência Florest. 2021, 31, 1991–2001. [Google Scholar] [CrossRef]

- Wronka, M.; Wojnicz, D.; Kowaluk, G. The Influence of Various Modifications of Hazelnut Shell Flour as Potential Filler in Plywood Technology. Materials 2024, 17, 4128. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Walkiewicz, J.; Sedliačik, J.; Dukarska, D.; Woźniak, M.; Mirski, R. Modified Buckwheat Husk as a Filler for Urea–Formaldehyde Resin in Plywood Production. Polymers 2024, 16, 1350. [Google Scholar] [CrossRef]

- Reh, R.; Kristak, L.; Sedliacik, J.; Bekhta, P.; Wronka, A.; Kowaluk, G. Molded Plywood with Proportions of Beech Bark in Adhesive Mixtures: Production on an Industrial Scale. Polymers 2024, 16, 966. [Google Scholar] [CrossRef]

- Daniłowska, A.; Kowaluk, G. The Use of Coffee Bean Post-Extraction Residues as a Filler in Plywood Technology. Ann. Warsaw Univ. Life Sci. SGGW, For. Wood Technol. 2020, 109, 24–31. [Google Scholar] [CrossRef]

- Lorbeer, L.; Schwarz, S.; Franke, H.; Lachenmeier, D.W. Toxicological Assessment of Roasted Coffee Silver Skin (Testa of Coffea Sp.) as Novel Food Ingredient. Molecules 2022, 27, 6839. [Google Scholar] [CrossRef]

- ASTM D2196-20; Standard Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2020; pp. 19428–22959.

- EN 319; Particleboards and Fibreboards. Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization: Brussels, Belgium, 1993.

- Zhang, J.L.; Zhou, J.; Bi, F.Q.; Huo, H.; Hu, H.M.; Wang, B.Z. Progress on Synthesis of Heat-Resistant Aromatic Energetic Compounds. Hanneng Cailiao/Chinese J. Energ. Mater. 2017, 25, 873–880. [Google Scholar] [CrossRef]

- Lv, G.; Jensen, E.; Shan, N.; Evans, C.M.; Cahill, D.G. Effect of Aromatic/Aliphatic Structure and Cross-Linking Density on the Thermal Conductivity of Epoxy Resins. ACS Appl. Polym. Mater. 2021, 3, 1555–1562. [Google Scholar] [CrossRef]

- Pareras, G.; Palusiak, M.; Duran, M.; Solà, M.; Simon, S. Tuning the Strength of the Resonance-Assisted Hydrogen Bond in o-Hydroxybenzaldehyde by Substitution in the Aromatic Ring1. J. Phys. Chem. A 2018, 122, 2279–2287. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ma, R.; Wang, B.; Liu, X.; Zhao, X.; Liu, L.; Zhang, L.; Gao, Y. Influence of Number and Strength of Hydrogen Bonds on Fracture Property and Microscopic Mechanisms of Associative Hydrogen-Bonded Polymers via Molecular Dynamics Simulation. Langmuir 2024, 40, 27501–27510. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Wang, J.; Wang, X.; Tian, W.; Dong, Y.; Jiang, S. Finite Element Analysis of Strengthening Mechanism of Ultrastrong and Tough Cellulosic Materials. Polymers 2022, 14, 4490. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Peng, L.; Liu, Y.; Gao, X.; Zhang, Y.; Tang, C.; Zhai, Z.; Yang, L.; Wu, W.; He, X.; et al. Conjugated Polymers Based on Metalla-Aromatic Building Blocks. Proc. Natl. Acad. Sci. USA 2022, 119, e2203701119. [Google Scholar] [CrossRef]

- Ishikawa, T.; Kobayashi, M.; Takahara, A. Elastohydrodynamics of Farm-Based Blends Comprising Amphiphilic Oils. In Surfactants in Tribology; CRC Press: Boca Raton, FL, USA, 2013; Volume 3, pp. 265–300. ISBN 9781439889619. [Google Scholar]

- Fleckenstein, C.A. Optimization Strategies Based on the Structure of the Analytes. In Optimization in HPLC: Concepts and Strategies; Wiley: Hoboken, NJ, USA, 2021; pp. 141–164. ISBN 9783527837489. [Google Scholar]

- Chang, C.M. DFT-Based Linear Solvation Energy Relationships for the Infrared Spectral Shifts of Acetone in Polar and Nonpolar Organic Solvents. J. Phys. Chem. A 2008, 112, 2482–2488. [Google Scholar] [CrossRef]

- Abdul Mudalip, S.K.; Abu Bakar, M.R.; Jamal, P.; Adam, F. Solubility and Dissolution Thermodynamic Data of Mefenamic Acid Crystals in Different Classes of Organic Solvents. J. Chem. Eng. Data 2013, 58, 3447–3452. [Google Scholar] [CrossRef]

- Zhang, H.; Mao, X.; Du, S.; Chai, H.; Wang, T. Micromechanism of the Effect of Coal Functional Groups on the Catalytic/Esterification Reaction of Acetic Acid. J. Mol. Liq. 2024, 411, 125796. [Google Scholar] [CrossRef]

- Wang, X.Q.; Chu, P.Z.; Xiong, W.; Ye, S.; Gan, Y.Y.; Zhang, W.T.; Li, S.; Wang, F.Y. Study on Monomer Simulation of Cellulose Raman Spectrum. Guang Pu Xue Yu Guang Pu Fen Xi/Spectroscopy Spectr. Anal. 2024, 44, 164–168. [Google Scholar]

- Watanabe, A.; Morita, S.; Ozaki, Y. Temperature-Dependent Structural Changes in Hydrogen Bonds in Microcrystalline Cellulose Studied by Infrared and near-Infrared Spectroscopy with Perturbation-Correlation Moving-Window Two-Dimensional Correlation Analysis. Appl. Spectrosc. 2006, 60, 611–618. [Google Scholar] [CrossRef]

- Kostryukov, S.G.; Matyakubov, H.B.; Masterova, Y.Y.; Kozlov, A.S.; Pryanichnikova, M.K.; Pynenkov, A.A.; Khluchina, N.A. Determination of Lignin, Cellulose, and Hemicellulose in Plant Materials by FTIR Spectroscopy. J. Anal. Chem. 2023, 78, 718–727. [Google Scholar] [CrossRef]

- Yu, G.; Ji, G.; Gao, Y.; Xu, H.; Wang, F. Molecular Dynamics Elucidation of Melting and Solidification Mechanisms in Sodium Sulfate Decahydrate for Solar Thermal Storage. Sol. Energy Mater. Sol. Cells 2025, 282, 113368. [Google Scholar] [CrossRef]

- Pereira, B.L.C.; Carneiro, A.d.C.O.; Carvalho, A.M.M.L.; Trugilho, P.F.; Melo, I.C.N.A.; Oliveira, A.C. Study of Thermal Degradation of Eucalyptus Wood by Thermogravimetry and Calorimetry [Estudo Da Degradação Térmica Da Madeira de Eucalyptus Através de Termogravimetria e Calorimetria]. Rev. Arvore 2013, 37, 567–576. [Google Scholar] [CrossRef]

- Chacon, W.D.C.; Valencia, G.A.; Rojas, G.M.A.; Henao, A.C.A. Drying and Pyrolysis of Lulo Peel: Non-Isothermal Analysis of Physicochemical, Kinetics, and Master Plots. Bioenergy Res. 2020, 13, 927–938. [Google Scholar] [CrossRef]

- Mahdiyanti, S.H.; Asaoka, M.; Inagaki, T.; Tsuchikawa, S. Cellulose Crystalline Structure and Thermal Properties under Heat Treatment: An Investigation by Two-Dimensional Correlation of near Infrared Spectroscopy and Differential Scanning Calorimetry. J. Near Infrared Spectrosc. 2024, 32, 113–124. [Google Scholar] [CrossRef]

- Zor, M.; Şen, F.; Yazıcı, H.; Candan, Z. Thermal, Mechanical and Morphological Properties of Cellulose/Lignin Nanocomposites. Forests 2023, 14, 1715. [Google Scholar] [CrossRef]

- Górska, A.; Brzezińska, R.; Wirkowska-Wojdyła, M.; Bryś, J.; Domian, E.; Ostrowska-Ligęza, E. Application of Thermal Methods to Analyze the Properties of Coffee Silverskin and Oil Extracted from the Studied Roasting By-Product. Appl. Sci. 2020, 10, 8790. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Rayung, M.; Norrrahim, M.N.F.; Shazleen, S.S.; Rani, M.S.A.; Shafi, A.R.; Aisyah, H.A.; Radzi, M.H.M.; Sabaruddin, F.A.; et al. Thermogravimetric Analysis Properties of Cellulosic Natural Fiber Polymer Composites: A Review on Influence of Chemical Treatments. Polymers 2021, 13, 2710. [Google Scholar] [CrossRef]

- Watkins, D.; Nuruddin, M.; Hosur, M.; Tcherbi-Narteh, A.; Jeelani, S. Extraction and Characterization of Lignin from Different Biomass Resources. J. Mater. Res. Technol. 2015, 4, 26–32. [Google Scholar] [CrossRef]

- Acharjee, T.C.; Coronella, C.J.; Vasquez, V.R. Effect of Thermal Pretreatment on Equilibrium Moisture Content of Lignocellulosic Biomass. Bioresour. Technol. 2011, 102, 4849–4854. [Google Scholar] [CrossRef]

- Apaydın Varol, E.; Mutlu, Ü. TGA-FTIR Analysis of Biomass Samples Based on the Thermal Decomposition Behavior of Hemicellulose, Cellulose, and Lignin. Energies 2023, 16, 3674. [Google Scholar] [CrossRef]

- Ramírez-Estrada, A.; Mena-Cervantes, V.Y.; Mederos-Nieto, F.S.; Pineda-Flores, G.; Hernández-Altamirano, R. Assessment and Classification of Lignocellulosic Biomass Recalcitrance by Principal Components Analysis Based on Thermogravimetry and Infrared Spectroscopy. Int. J. Environ. Sci. Technol. 2022, 19, 2529–2544. [Google Scholar] [CrossRef]

- Ballesteros, L.F.; Teixeira, J.A.; Mussatto, S.I. Chemical, Functional, and Structural Properties of Spent Coffee Grounds and Coffee Silverskin. Food Bioprocess Technol. 2014, 7, 3493–3503. [Google Scholar] [CrossRef]

- Sarasini, F.; Luzi, F.; Dominici, F.; Maffei, G.; Iannone, A.; Zuorro, A.; Lavecchia, R.; Torre, L.; Carbonell-Verdu, A.; Balart, R.; et al. Effect of Different Compatibilizers on Sustainable Composites Based on a PHBV/PBAT Matrix Filled with Coffee Silverskin. Polymers 2018, 10, 1256. [Google Scholar] [CrossRef]

- Hejna, A.; Korol, J.; Kosmela, P.; Kuzmin, A.; Piasecki, A.; Kulawik, A.; Chmielnicki, B. By-Products from Food Industry as a Promising Alternative for the Conventional Fillers for Wood–Polymer Composites. Polymers 2021, 13, 893. [Google Scholar] [CrossRef]

- Bellili, N.; Dairi, B.; Hammour, N.; Djidjelli, H.; Boukerrou, A. Physicomechanical Behavior of Agro Waste-Filled Polypropylene Composites Materials. Mater. Today Proc. 2022, 53, 42–45. [Google Scholar] [CrossRef]

- Mirski, R.; Kawalerczyk, J.; Dziurka, D.; Wieruszewski, M.; Trociński, A. Effects of Using Bark Particles with Various Dimensions as a Filler for Urea-Formaldehyde Resin in Plywood. BioResources 2020, 15, 1692–1701. [Google Scholar] [CrossRef]

| Chemical Composition | Amount [%] | References |

|---|---|---|

| Cellulose | 23.8 | [34] |

| Hemicellulose | 16.7 | [34] |

| Lignin | 30.0 | [35] |

| Feature | Description | References |

|---|---|---|

| Density | Varies with particle size; higher for smaller particles | [26,27] |

| Water Absorption | Generally high, affecting mechanical properties | [22,28] |

| Thermal Properties | Good thermal insulation; high calorific value | [28,29,30,31] |

| Chemical Composition | Contains i.e., cellulose, hemicellulose, and lignin | [32,33] |

| Compressive Strength | Better with smaller particle size; enhanced in concrete | [27,41] |

| Tensile Strength | Enhanced with treated fibers in composites | [23,42] |

| Abrasion Resistance | Good; important for handling and storage | [27] |

| Flexural Strength | Improved with coupling agents or fillers | [22,43] |

| Variant Code | Filler Type | Bonding Mass Composition * (by Weight) |

|---|---|---|

| REF | Rye flour | 100:4:10:5 |

| S0 | Silverskin powder | 100:4:0:5 |

| S1 | 100:4:1:5 | |

| S5 | 100:4:5:5 | |

| S10 | 100:4:10:5 | |

| S20 | 100:4:20:5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wronka, A.; Del Valle Raydan, N.; Robles, E.; Kowaluk, G. Coffee Silverskin as a Sustainable Alternative Filler for Plywood: Characterization and Performance Analysis. Materials 2025, 18, 1525. https://doi.org/10.3390/ma18071525

Wronka A, Del Valle Raydan N, Robles E, Kowaluk G. Coffee Silverskin as a Sustainable Alternative Filler for Plywood: Characterization and Performance Analysis. Materials. 2025; 18(7):1525. https://doi.org/10.3390/ma18071525

Chicago/Turabian StyleWronka, Anita, Nidal Del Valle Raydan, Eduardo Robles, and Grzegorz Kowaluk. 2025. "Coffee Silverskin as a Sustainable Alternative Filler for Plywood: Characterization and Performance Analysis" Materials 18, no. 7: 1525. https://doi.org/10.3390/ma18071525

APA StyleWronka, A., Del Valle Raydan, N., Robles, E., & Kowaluk, G. (2025). Coffee Silverskin as a Sustainable Alternative Filler for Plywood: Characterization and Performance Analysis. Materials, 18(7), 1525. https://doi.org/10.3390/ma18071525