Metadynamic Recrystallization in the Isothermal Double Compression of CP800 Steel

Abstract

1. Introduction

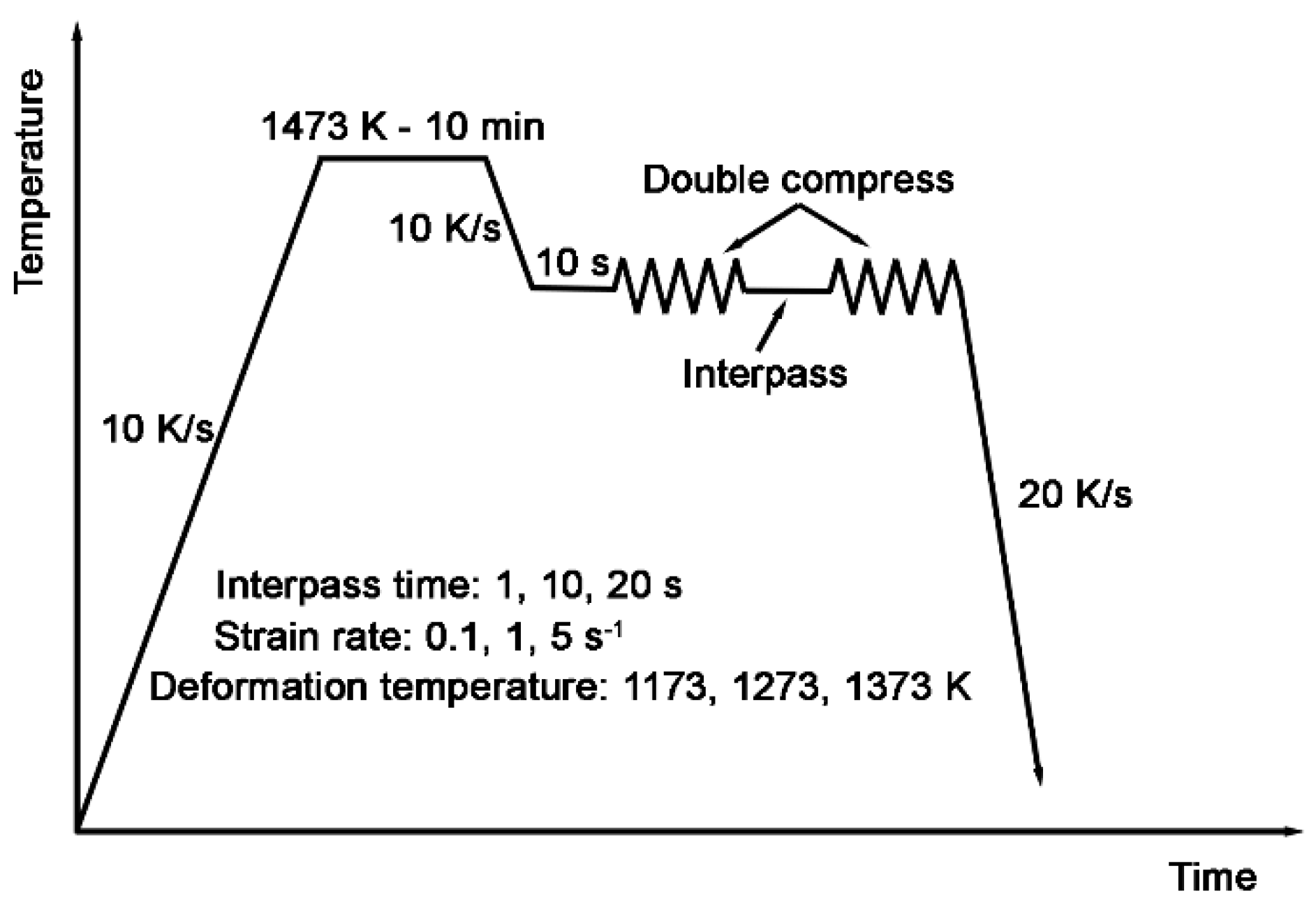

2. Materials and Methods

3. Results and Discussion

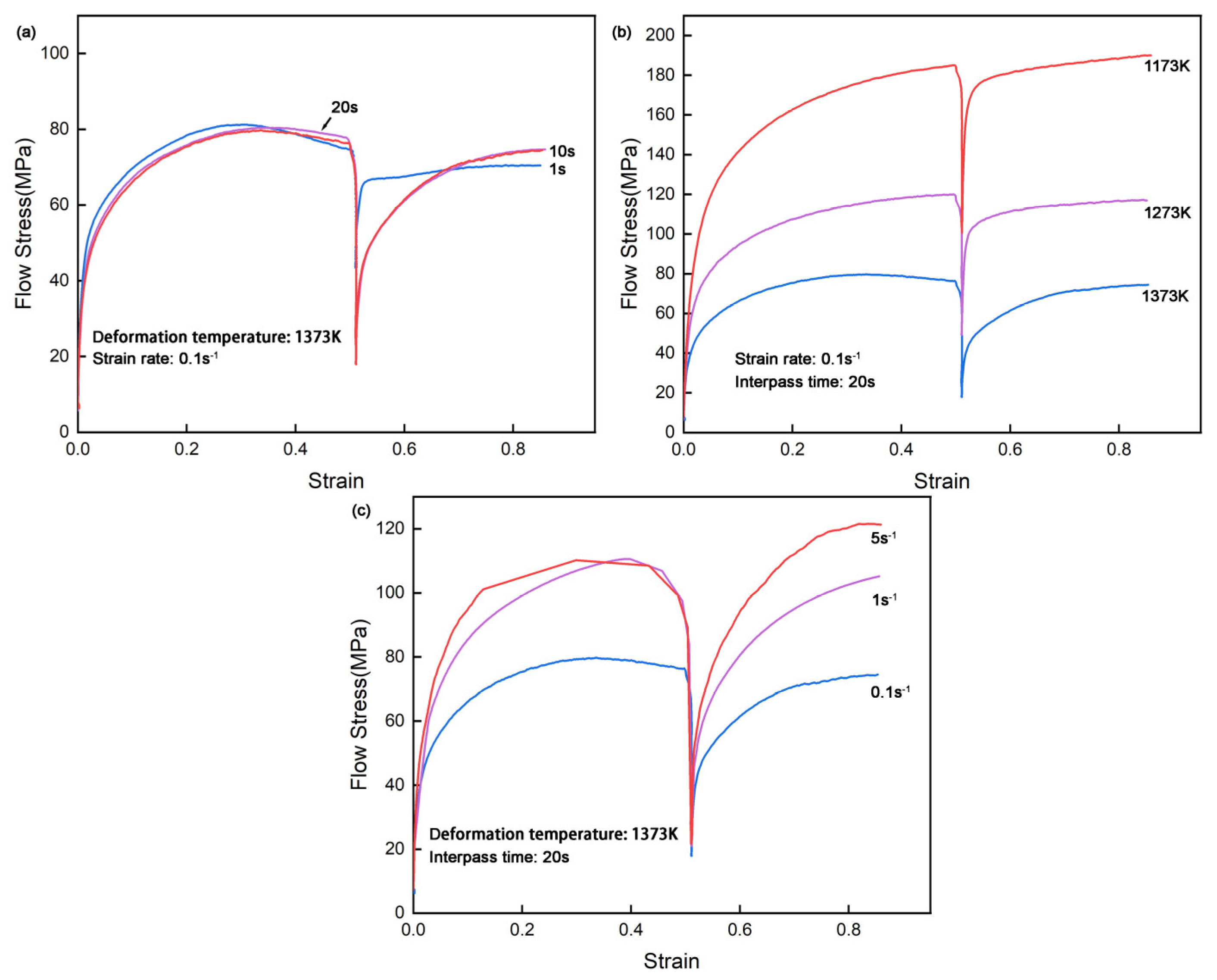

3.1. Flow Stress–Strain Behavior in CP800 Steel

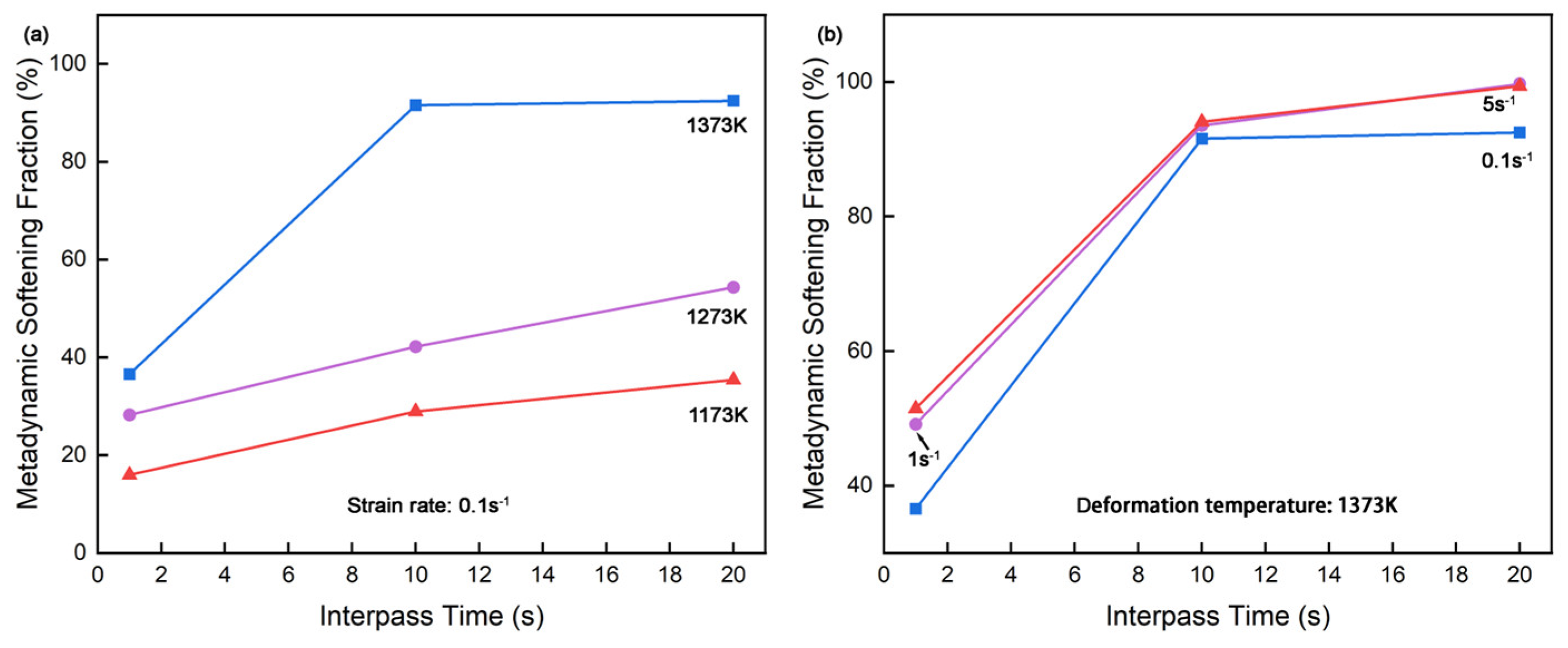

3.2. Process Effect on the Metadynamic Softening of CP800 Steel

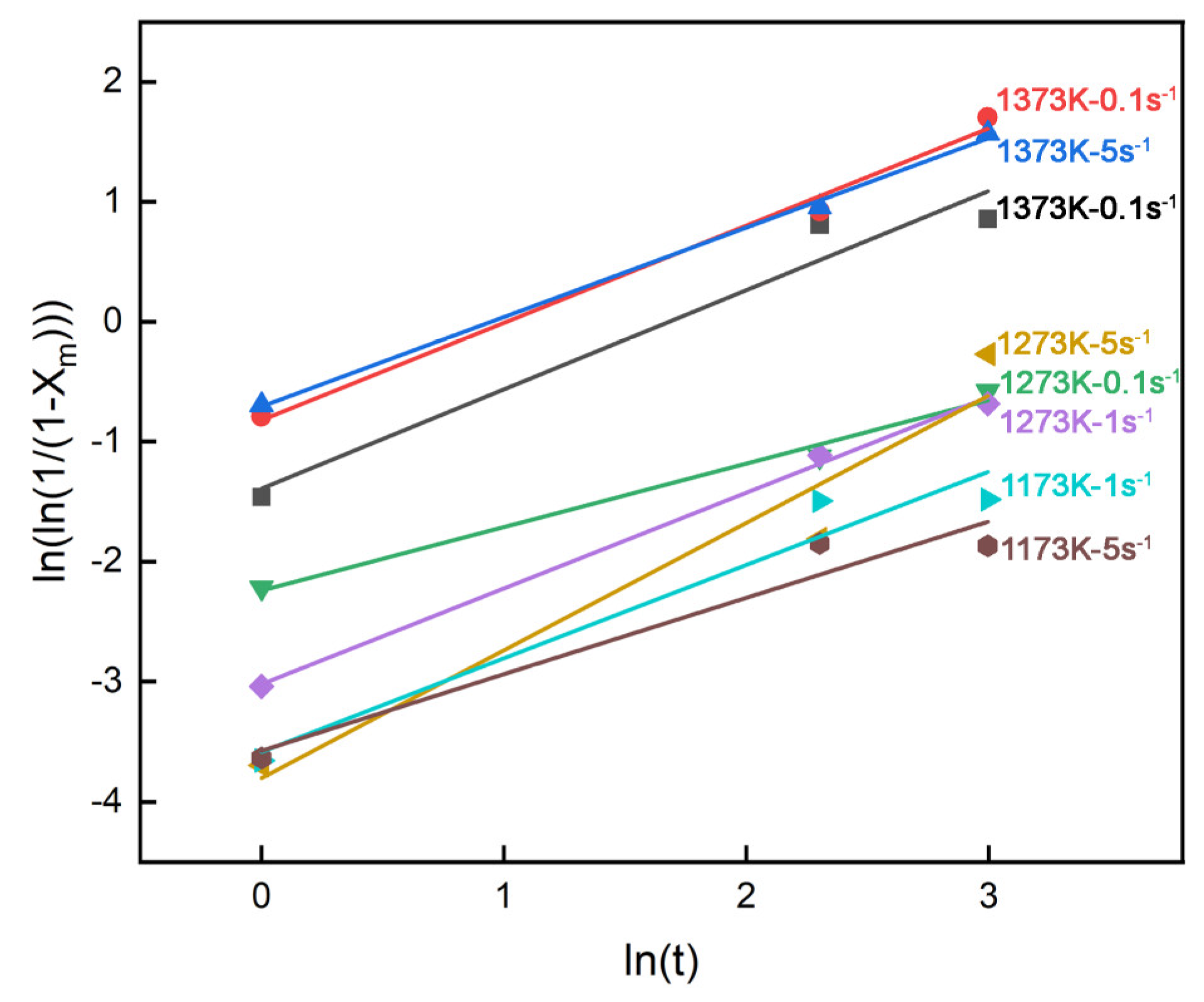

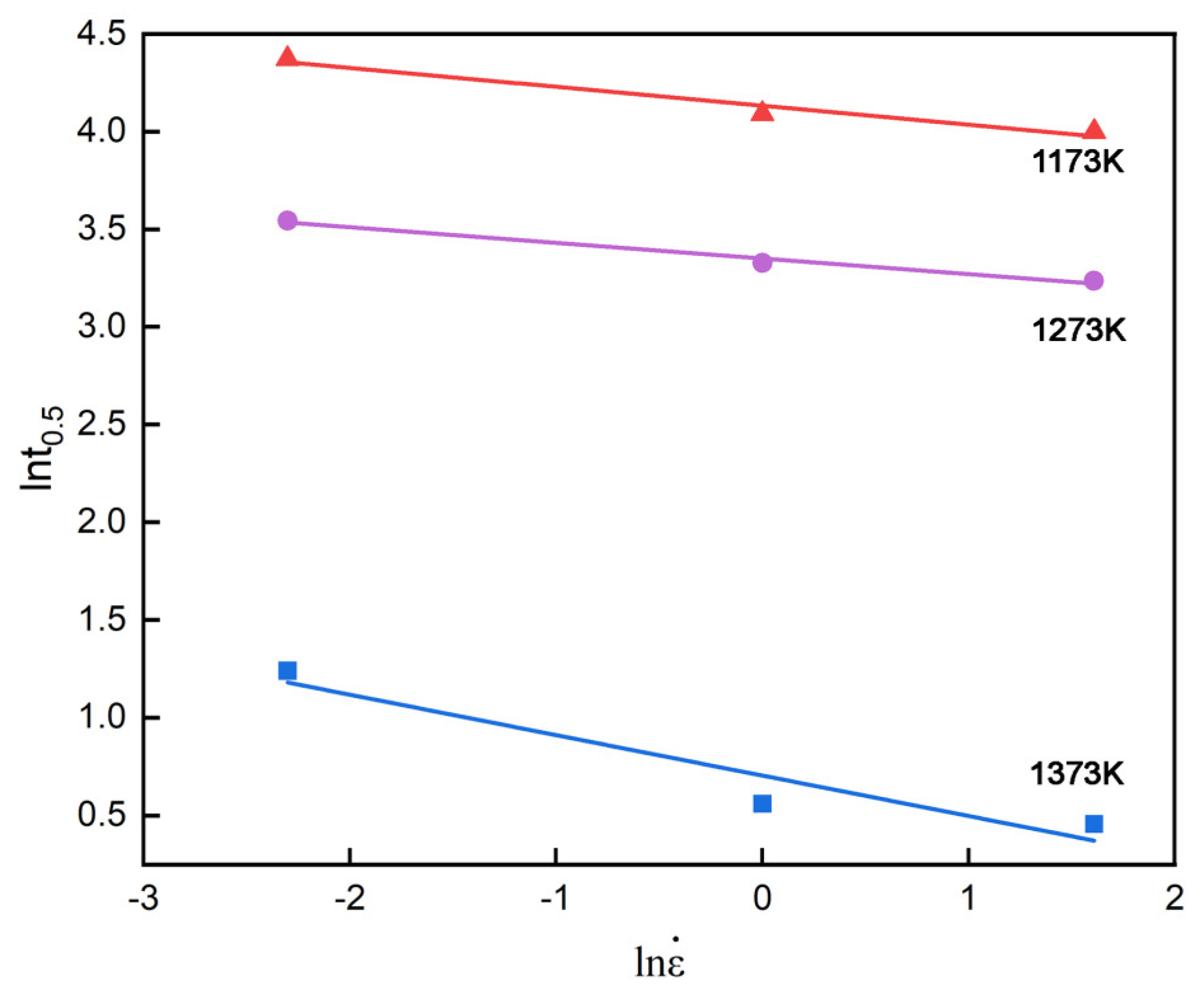

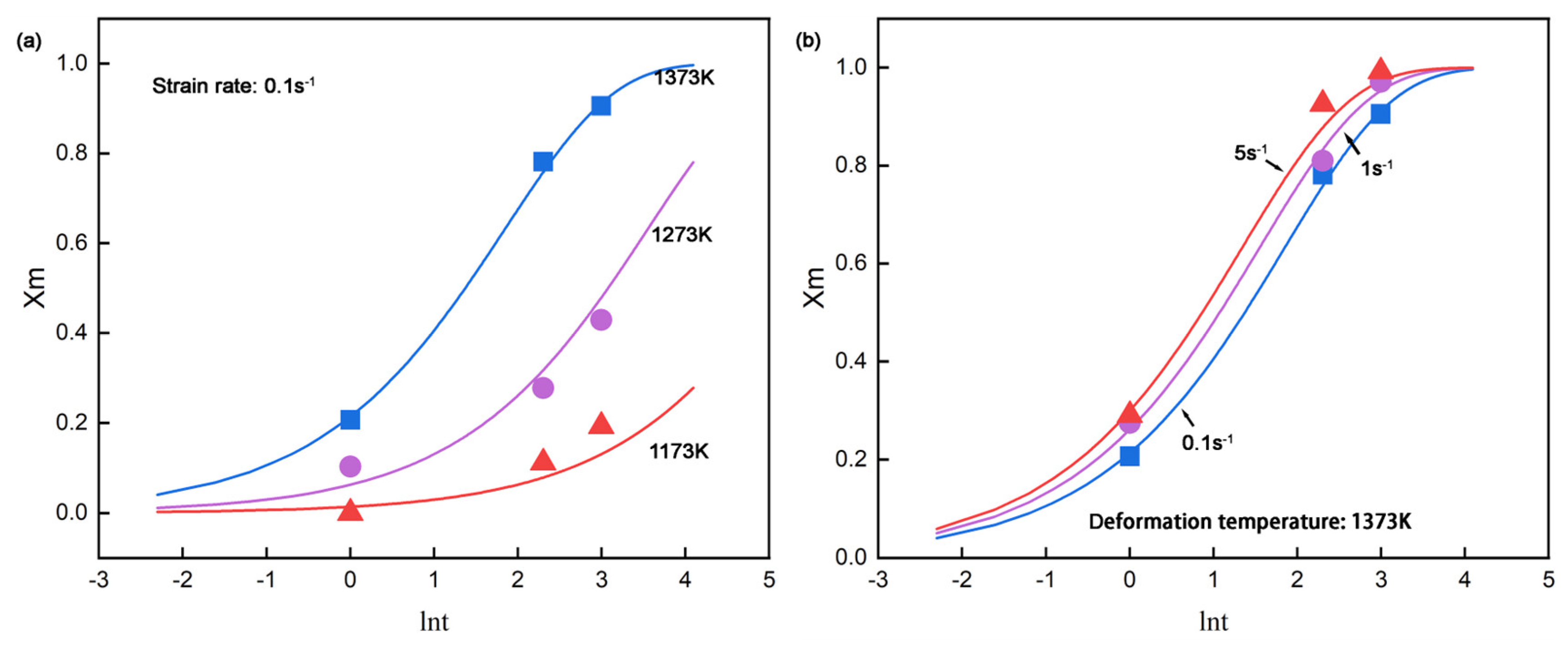

3.3. Kinetic Study of the Metadynamic Recrystallization of CP800 Steel

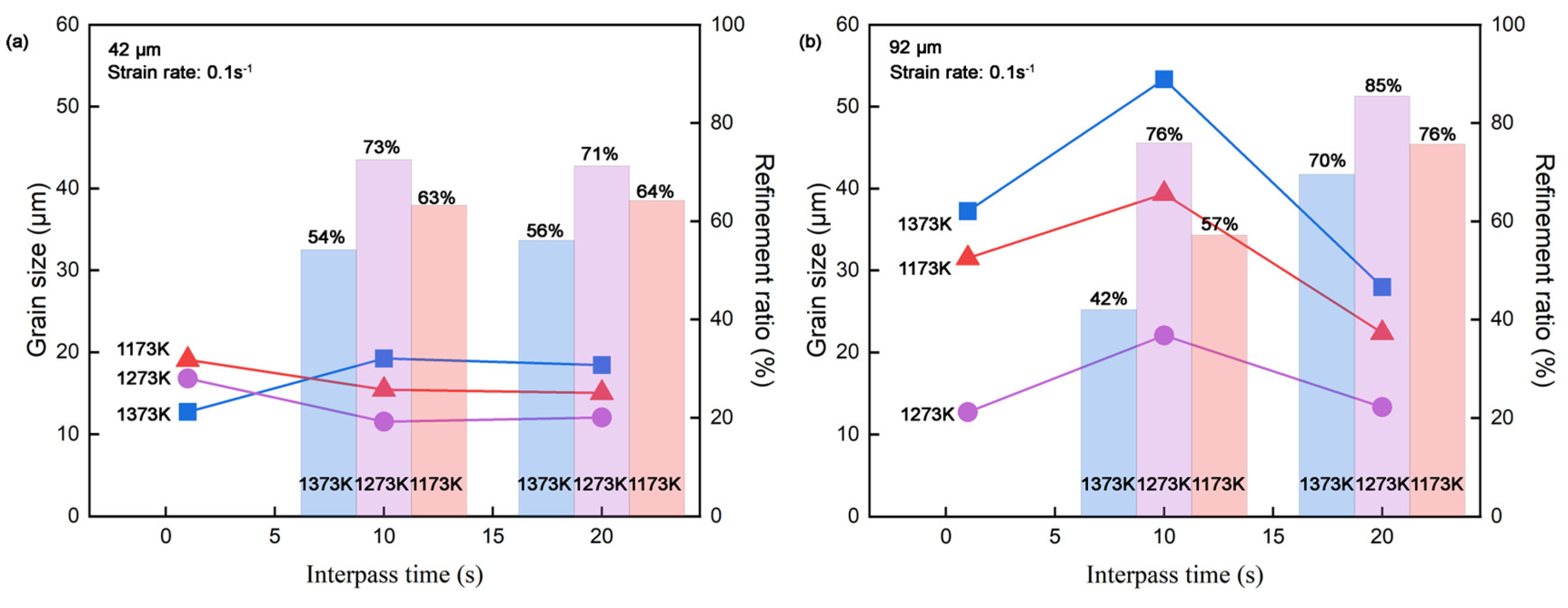

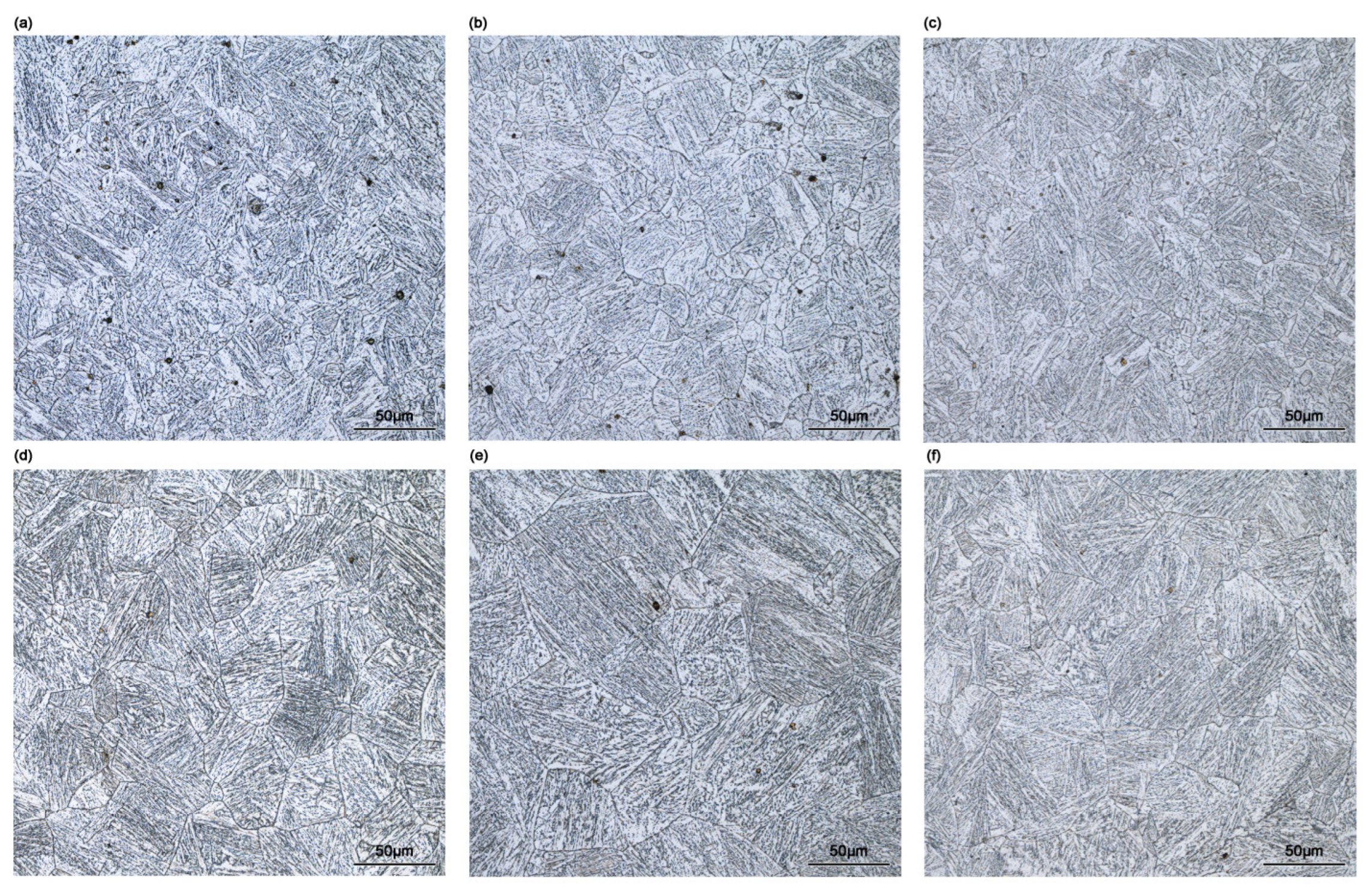

3.4. Initial Grain Size Effect on the Metadynamic Softening of CP800 Steel

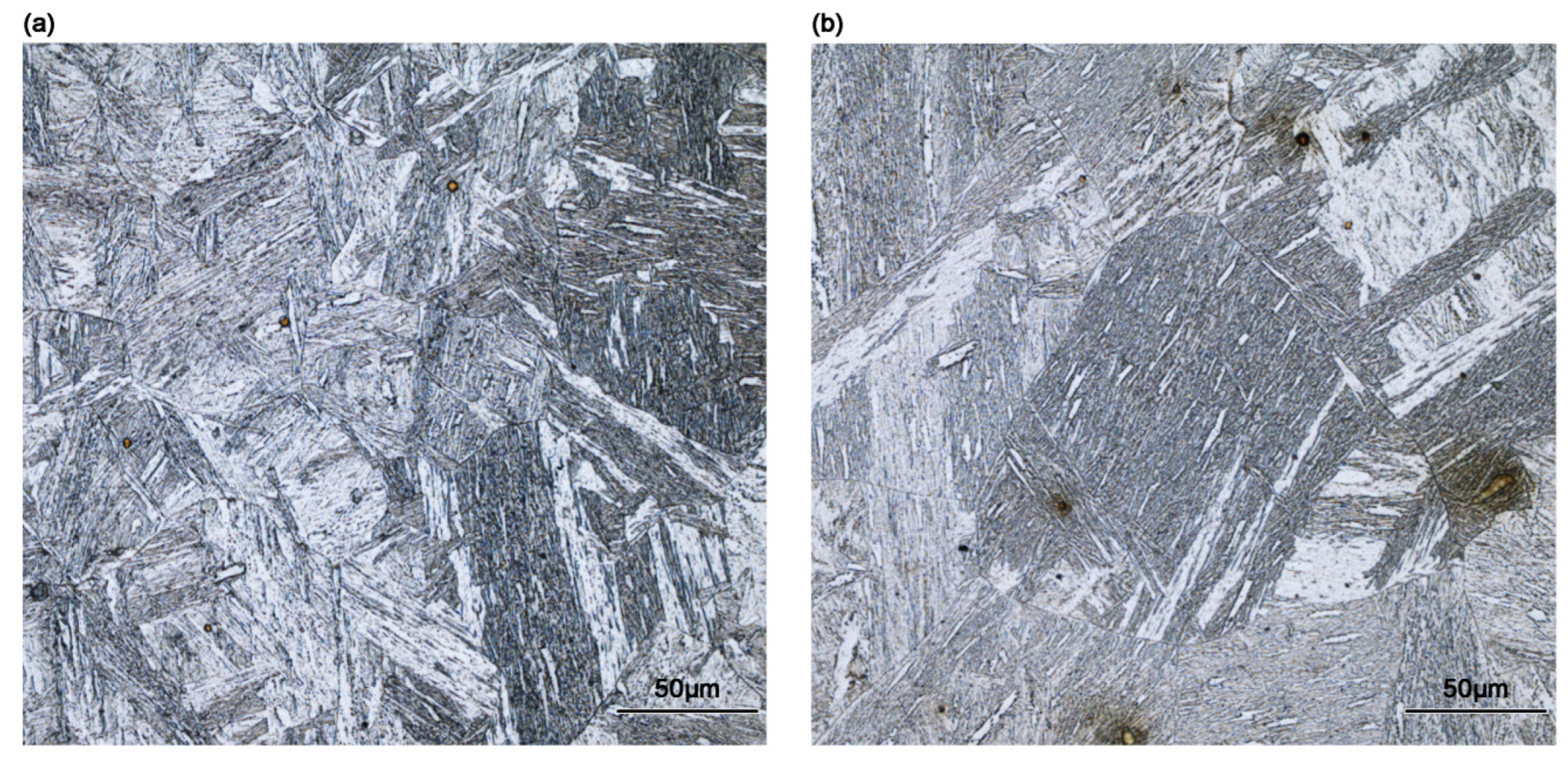

3.5. Grain Size After Metadynamic Softening of CP800 Steel

4. Conclusions

- The metadynamic recrystallization fraction increases with rising deformation temperature, strain rate, and interpass time. At 1373 K deformation, the metadynamic softening occurs sufficiently at 10 s interpass time under all experimental strain rates. It seems the metadynamic softening was hardly carried out at 1173 K under the studied conditions.

- The fraction of the metadynamic recrystallization of CP800 steel can be accurately represented by the kinetic equation , and the time (s) for 50% metadynamic recrystallization predicted as . The fitting is in good agreement with the experimental results.

- Under the conditions studied, the initial grain size has minimal influence on the metadynamic softening fraction, although it significantly affects the final recrystallized grain size. The 92 μm initial austenite grains samples have higher refinement efficiency; however, the 42 μm initial austenite grains samples present a smaller size on the final recrystallization grain size. The most efficient deformation temperature is 1273 K among these experimental conditions.

- Based on the above discussion, it is recommended that the final pass of rolling should be conducted at temperatures above 1173 K to avoid undesirable mixed grains. Additionally, a lower holding temperature and shorter holding time before rolling are advised for compact process and energy saving under the premise of chemical composition homogeneity and final deformation temperature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Raabe, D.; Jovičević-Klug, M.; Ponge, D.; Gramlich, A.; Kwiatkowski da Silva, A.; Grundy, A.N.; Springer, H.; Souza Filho, I.; Ma, Y. Circular Steel for Fast Decarbonization: Thermodynamics, Kinetics, and Microstructure Behind Upcycling Scrap into High-Performance Sheet Steel. Annu. Rev. Mater. Res. 2024, 54, 247–297. [Google Scholar] [CrossRef]

- Ojha, S.N. Processing of Microalloyed Steels by CSP Process. Mater. Manuf. Process. 2010, 25, 72–75. [Google Scholar] [CrossRef]

- Lu, B.; Chen, G.; Chen, D.; Yu, W. An energy intensity optimization model for production system in iron and steel industry. Appl. Therm. Eng. 2016, 100, 285–295. [Google Scholar] [CrossRef]

- Hoen, K.K.; Krämer, C.; Caballero, S.; Acainas, L. CSP®–The Flexible and Profitable Technology to Produce a Wide Range of Steel Products. In Proceedings of the 11th International Rolling Conference (IRC 2019), Sao Paulo, Brazil, 1–3 October 2019. [Google Scholar] [CrossRef]

- Reip, C.P.; Hennig, W.; Kempken, J.; Hagmann, R. Development of CSP® Processed High Strength Pipe Steels. Mater. Sci. Forum 2005, 500–501, 287–294. [Google Scholar] [CrossRef]

- Hilditch, T.B.; de Souza, T.; Hodgson, P.D. 2-Properties and automotive applications of advanced high-strength steels (AHSS). In Welding and Joining of Advanced High Strength Steels (AHSS); Shome, M., Tumuluru, M., Eds.; Woodhead Publishing: Sawston, UK, 2015; pp. 9–28. [Google Scholar] [CrossRef]

- Ma, G.; Chen, Y.; Wang, S.; Wu, H.; Gao, J.; Wu, G.; Mao, X. Study on Corrosion Behavior and Mechanism of Ultrahigh-Strength Hot-Stamping Steel Based on Traditional and Compact Strip-Production Processes. Materials 2023, 16, 3064. [Google Scholar] [CrossRef]

- Reip, C.P.; Shanmugam, S.; Misra, R.D.K. High strength microalloyed CMn(V–Nb–Ti) and CMn(V–Nb) pipeline steels processed through CSP thin-slab technology: Microstructure, precipitation and mechanical properties. Mater. Sci. Eng. A 2006, 424, 307–317. [Google Scholar] [CrossRef]

- Klinkenberg, C.; Kintscher, B.; Hoen, K.; Reifferscheid, M. More than 25 Years of Experience in Thin Slab Casting and Rolling Current State of the Art and Future Developments. Steel Res. Int. 2017, 88, 1700272. [Google Scholar] [CrossRef]

- Sun, W.P. Microstructure and Property Characteristics of CSP®-Produced Advanced High Strength Steels. Mater. Sci. Forum 2012, 706–709, 2830–2835. [Google Scholar] [CrossRef]

- Venturini, R.; Bianchi, A.; Andraghetti, M.; Guarnaschelli, C.; Cesile, M.; Di Nunzio, P.E. Industry news–Automotive Metallurgical design and production of AHSS grades DP800 and CP800 ISP and ESP thin slab technology at Acciaieria Arvedi in Cremona, Italy. La. Metall. Ital. 2020, 2020, 43–51. [Google Scholar]

- Hu, X.; He, G.; Peng, H.; Jiang, B.; Zhang, C.; Liu, Y. Microstructures and Mechanical Properties of Low Carbon Steel Hot Rolled in Ferrite Region Based on CSP Line. Steel Res. Int. 2019, 90, 1800643. [Google Scholar] [CrossRef]

- Zhu, X.-S.; Zhu, G.-H.; Mao, W.-M. Comparison of Grain Size in Plain Carbon Hot-Rolled Sheets Manufactured by CSP and Conventional Rolling Processing. J. Iron Steel Res. Int. 2012, 19, 17–22. [Google Scholar] [CrossRef]

- Dong, R.F.; Sun, L.G.; Liu, Z.; Wang, X.L.; Liu, Q.Y. Microstructures and Properties of X60 Grade Pipeline Strip Steel in CSP Plant. J. Iron Steel Res. Int. 2008, 15, 71–75. [Google Scholar] [CrossRef]

- Deardo, A.; Marraccini, R.; Hua, M.; Garcia, C. Producing High Quality Niobium-Bearing Steels Using the CSP Process at Nucor Steel Berkeley. In Proceedings of the Fifth International Conference on HSLA Steels, Sanya, China, 8–10 November 2005. [Google Scholar]

- Romano-Acosta, L.F.; García-Rincon, O.; Pedraza, J.P.; Palmiere, E.J. Influence of thermomechanical processing parameters on critical temperatures to develop an Advanced High-Strength Steel microstructure. JMTSAS 2021, 56, 18710–18721. [Google Scholar] [CrossRef]

- Stumpf, W. Grain size modelling of a low carbon strip steel during hot rolling in a Compact Strip Production (CSP) plant using the Hot Charge Route. J. South. Afr. Inst. Min. Metall. 2003, 103, 617–631. [Google Scholar]

- Lenard, J.G.; Pietrzyk, M.; Cser, L. Chapter 6-Microstructure Evolution and Mechanical Properties of the Final Product. In Mathematical and Physical Simulation of the Properties of Hot Rolled Products; Lenard, J.G., Pietrzyk, M., Cser, L., Eds.; Elsevier Science Ltd.: Amsterdam, The Netherlands, 1999; pp. 151–236. [Google Scholar]

- Roucoules, C.; Yue, S.; Jonas, J.J. Effect of alloying elements on metadynamic recrystallization in HSLA steels. Metall. Mater. Trans. A 1995, 26, 181–190. [Google Scholar] [CrossRef]

- Lee, J.W.; De Cooman, B.C. Studying the Hot Working Characteristics and Dynamic Recrystallization Behavior of Conventional Low Carbon Steel during In-Line Strip Production Process. In Proceedings of the 8th Pacific Rim International Congress on Advanced Materials and Processing; Marquis, F., Ed.; Springer International Publishing: Cham, Germany, 2016; pp. 695–702. [Google Scholar]

- Zhao, Z.Z.; Kang, Y.L.; Mao, X.P.; Chen, Y.L.; Chen, G.J.; Chen, X.W. Study on Recrystallization Behavior of High Strength Automobile Steel Sheets Produced by CSP. Mater. Sci. Forum 2005, 475–479, 153–156. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.G.; Lin, H.; Li, M.Q. The metadynamic recrystallization in the two-stage isothermal compression of 300M steel. Mater. Sci. Eng. A 2013, 565, 126–131. [Google Scholar] [CrossRef]

- Tang, G.-B.; Liu, Z.-D.; Dong, H.; Gan, Y.; Kang, Y.-L.; Li, L.-J.; Mao, X.-P. Numerical Simulation of Austenite Recrystallization in CSP Hot Rolled C-Mn Steel Strip. J. Iron Steel Res. Int. 2007, 14, 49–55. [Google Scholar] [CrossRef]

- Dembiczak, T.; Knapiński, M. Shaping Microstructure and Mechanical Properties of High-Carbon Bainitic Steel in Hot-Rolling and Long-Term Low-Temperature Annealing. Materials 2021, 14, 384. [Google Scholar] [CrossRef]

- Sozańska-Jędrasik, L.; Mazurkiewicz, J.; Matus, K.; Borek, W. Structure of Fe-Mn-Al-C Steels after Gleeble Simulations and Hot-Rolling. Materials 2020, 13, 739. [Google Scholar] [CrossRef]

- Thorvaldsen, A. The intercept method—2. Determination of spatial grain size. Acta Mater. 1997, 45, 595–600. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Chapter 6-Recovery After Deformation. In Recrystallization and Related Annealing Phenomena, 2nd ed.; Humphreys, F.J., Hatherly, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2004; pp. 169–213. [Google Scholar]

- Lee, S.W.; Park, S.H. Static recrystallization mechanism in cold-rolled magnesium alloy with off-basal texture based on quasi in situ EBSD observations. J. Alloys Compd. 2020, 844, 156185. [Google Scholar] [CrossRef]

- Chen, R.; Zeng, J.; Yao, G.; Feng, F. Flow-Stress Model of 300M Steel for Multi-Pass Compression. Metals 2020, 10, 438. [Google Scholar] [CrossRef]

- Ding, S.; Khan, S.A.; Yanagimoto, J. Metadynamic recrystallization behavior of 5083 aluminum alloy under double-pass compression and stress relaxation tests. Mater. Sci. Eng. A 2021, 822, 141673. [Google Scholar] [CrossRef]

- Taylor, A.S.; Hodgson, P.D. The post-deformation recrystallization behaviour of 304 stainless steel following high strain rate deformation. Mater. Sci. Eng. A 2011, 529, 164–169. [Google Scholar] [CrossRef]

- Andrade, H.L.; Akben, M.G.; Jonas, J.J. Effect of molybdenum, niobium, and vanadium on static recovery and recrystallization and on solute strengthening in microalloyed steels. Metall. Mater. Trans. A 1983, 14, 1967–1977. [Google Scholar] [CrossRef]

- Djaic, R.A.P.; Jonas, J.J. Recrystallization of high carbon steel between intervals of high temperature deformation. Metall. Trans. 1973, 4, 621–624. [Google Scholar] [CrossRef]

- Shen, W.-F.; Zhang, C.; Zhang, L.-W.; Xia, Y.-N.; Xu, Y.-F.; Shi, X.-H. Metadynamic recrystallization of Nb–V microalloyed steel during hot deformation. J. Mater. Res. 2017, 32, 656–665. [Google Scholar] [CrossRef]

- Armstrong, R.W.; Walley, S.M. High strain rate properties of metals and alloys. Int. Mater. Rev. 2008, 53, 105–128. [Google Scholar] [CrossRef]

- Fan, H.; Wang, Q.; El-Awady, J.A.; Raabe, D.; Zaiser, M. Strain rate dependency of dislocation plasticity. Nat. Commun. 2021, 12, 1845. [Google Scholar] [CrossRef]

- Sun, W.P.; Hawbolt, E.B. Comparison between Static and Metadynamic Recrystallization-An Application to the Hot Rolling of Steels. ISIJ Int. 1997, 37, 1000–1009. [Google Scholar] [CrossRef]

- Sellars, C.; Davies, G.J.; Metallurgical, S. Hot Working and Forming Processes: Proceedings of an International Conference on Hot Working and Forming Processes; Metals Society: Pittsburgh, PA, USA, 1980. [Google Scholar]

- Hodgson, P.D.; Gibbs, R.K. A Mathematical Model to Predict the Mechanical Properties of Hot Rolled C-Mn and Microalloyed Steels. ISIJ Int. 1992, 32, 1329–1338. [Google Scholar] [CrossRef]

- Kutumarao, V.V.; Rajagopalachary, T. Recent developments in modeling the hot working behavior of metallic materials. Bull. Mater. Sci. 1996, 19, 677–698. [Google Scholar] [CrossRef]

- Morgridge, A.R. Metadynamic recrystallization in C steels. Bull. Mater. Sci. 2002, 25, 291–299. [Google Scholar] [CrossRef]

- Hodgson, P.D.; Zahiri, S.H.; Whale, J.J. The Static and Metadynamic Recrystallization Behaviour of an X60 Nb Microalloyed Steel. ISIJ Int. 2004, 44, 1224–1229. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Mi, Z.; Mu, W. Metadynamic Recrystallization in the Isothermal Double Compression of CP800 Steel. Materials 2025, 18, 1549. https://doi.org/10.3390/ma18071549

Yang X, Mi Z, Mu W. Metadynamic Recrystallization in the Isothermal Double Compression of CP800 Steel. Materials. 2025; 18(7):1549. https://doi.org/10.3390/ma18071549

Chicago/Turabian StyleYang, Xiaoyu, Zhenli Mi, and Wangzhong Mu. 2025. "Metadynamic Recrystallization in the Isothermal Double Compression of CP800 Steel" Materials 18, no. 7: 1549. https://doi.org/10.3390/ma18071549

APA StyleYang, X., Mi, Z., & Mu, W. (2025). Metadynamic Recrystallization in the Isothermal Double Compression of CP800 Steel. Materials, 18(7), 1549. https://doi.org/10.3390/ma18071549