Chitosan Shrinking Fibers for Curing-Initiated Stressing to Enhance Concrete Durability †

Abstract

1. Introduction

2. Research Significance

3. Materials and Methods

3.1. Concrete

3.2. Chitosan Fibers

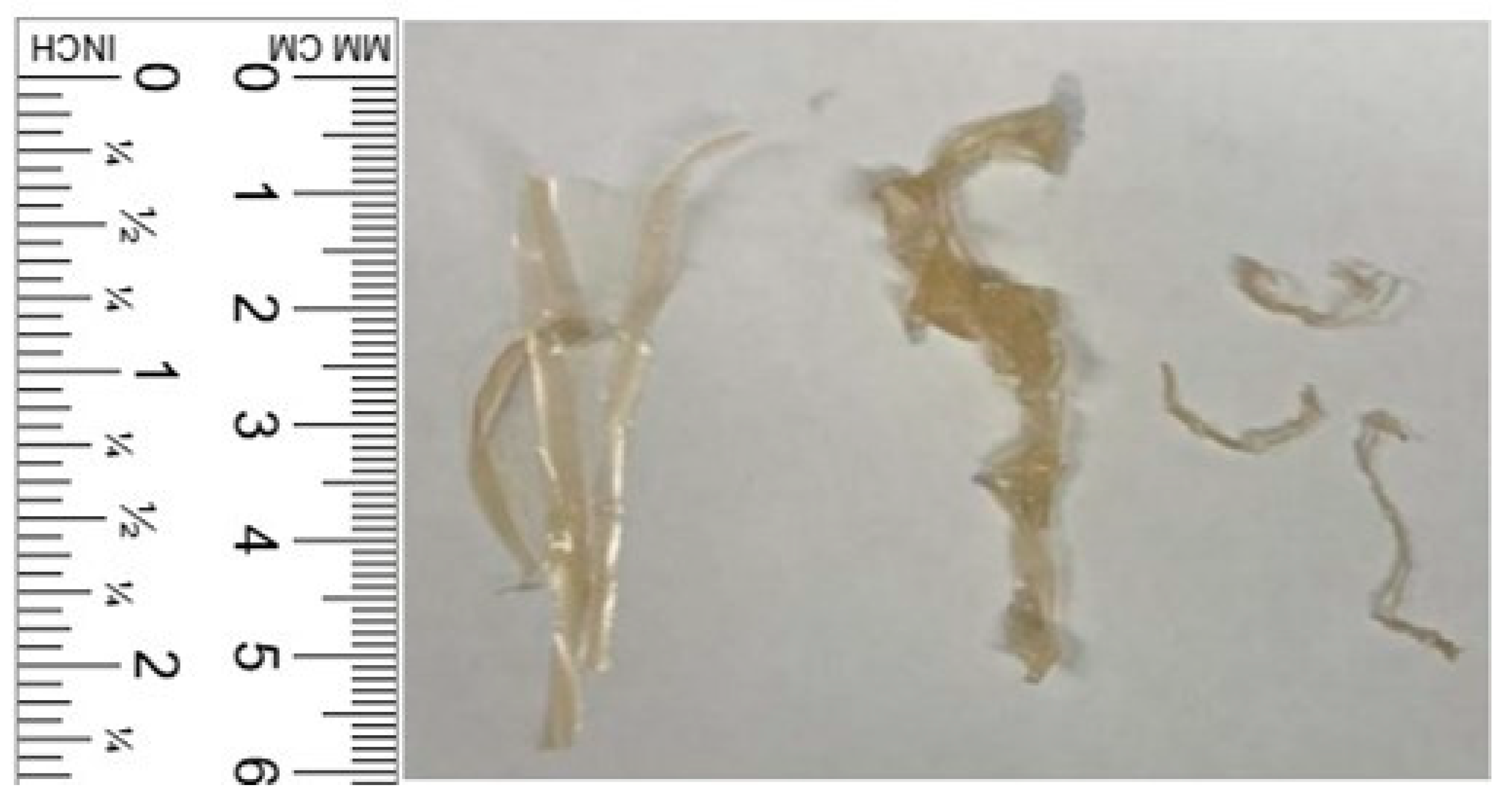

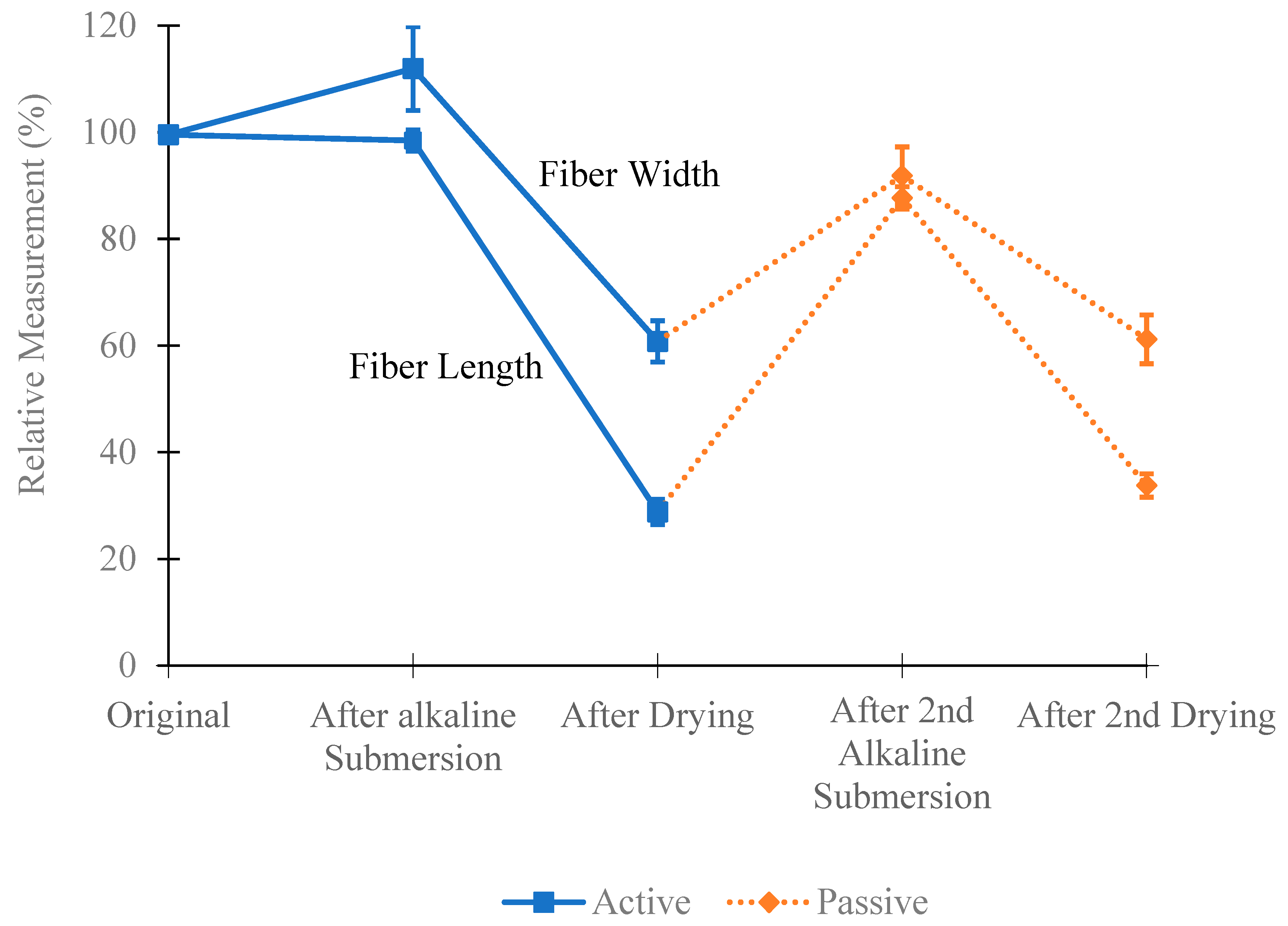

3.3. Initial Testing of Fibers

3.4. Concrete Specimen Preparation for Freeze-Thaw Testing

3.5. Chloride Penetration Testing

3.6. Freeze-Thaw Fatigue and Testing

3.7. Resistivity Testing

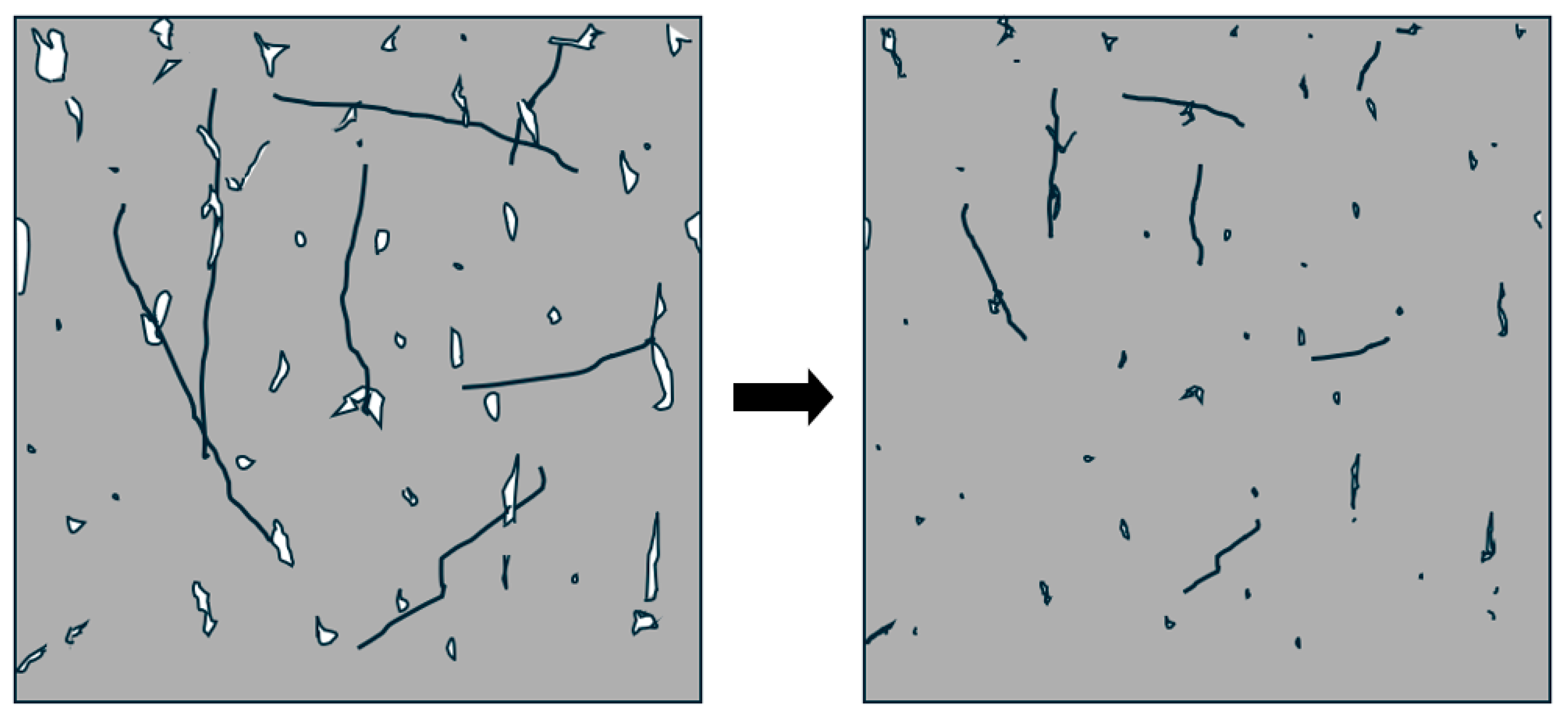

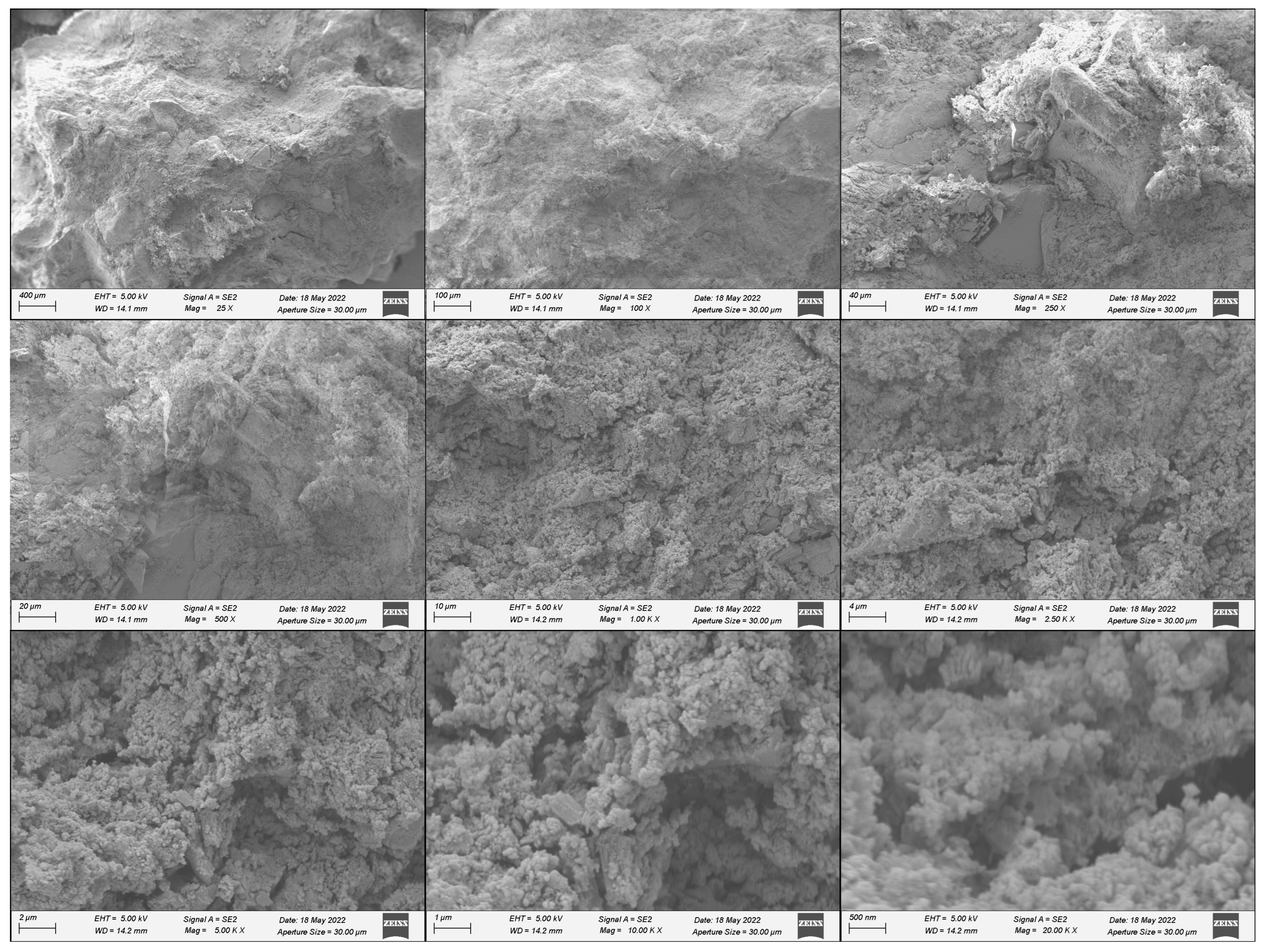

3.8. SEM Images

4. Results and Discussion

4.1. Fiber Shrinking and Alkaline Solution Absorption

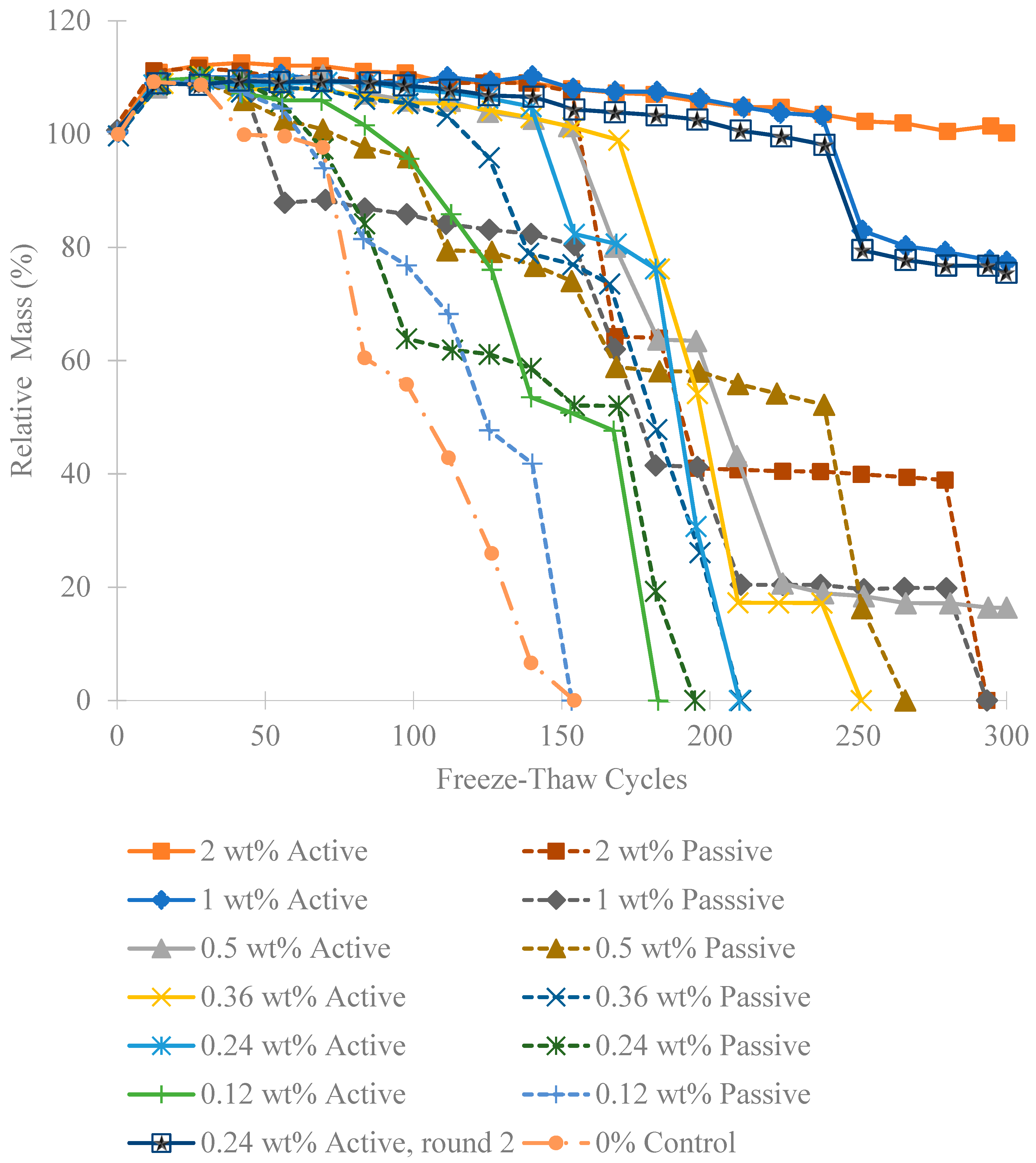

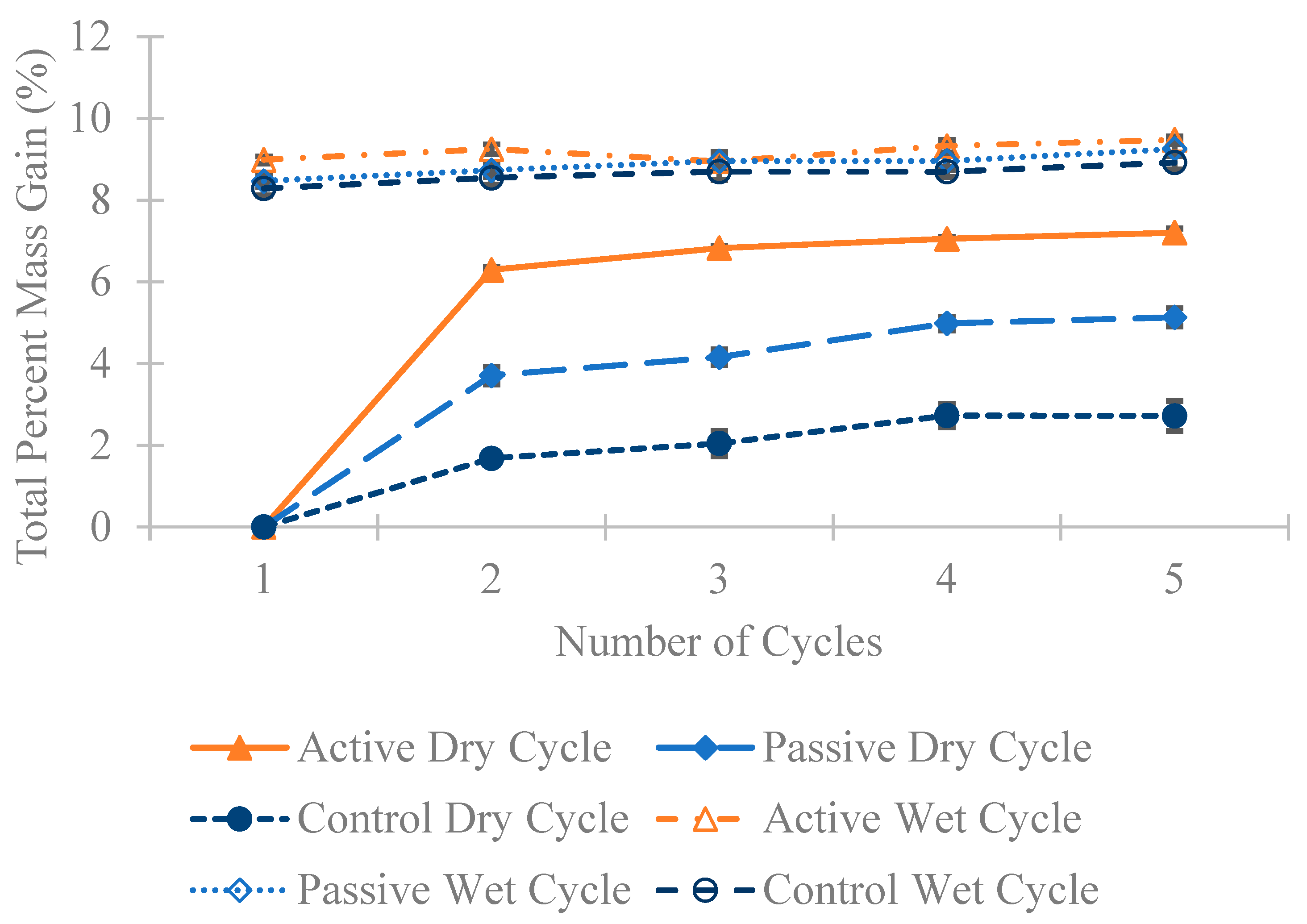

4.2. Mass Results of Freeze-Thaw Testing

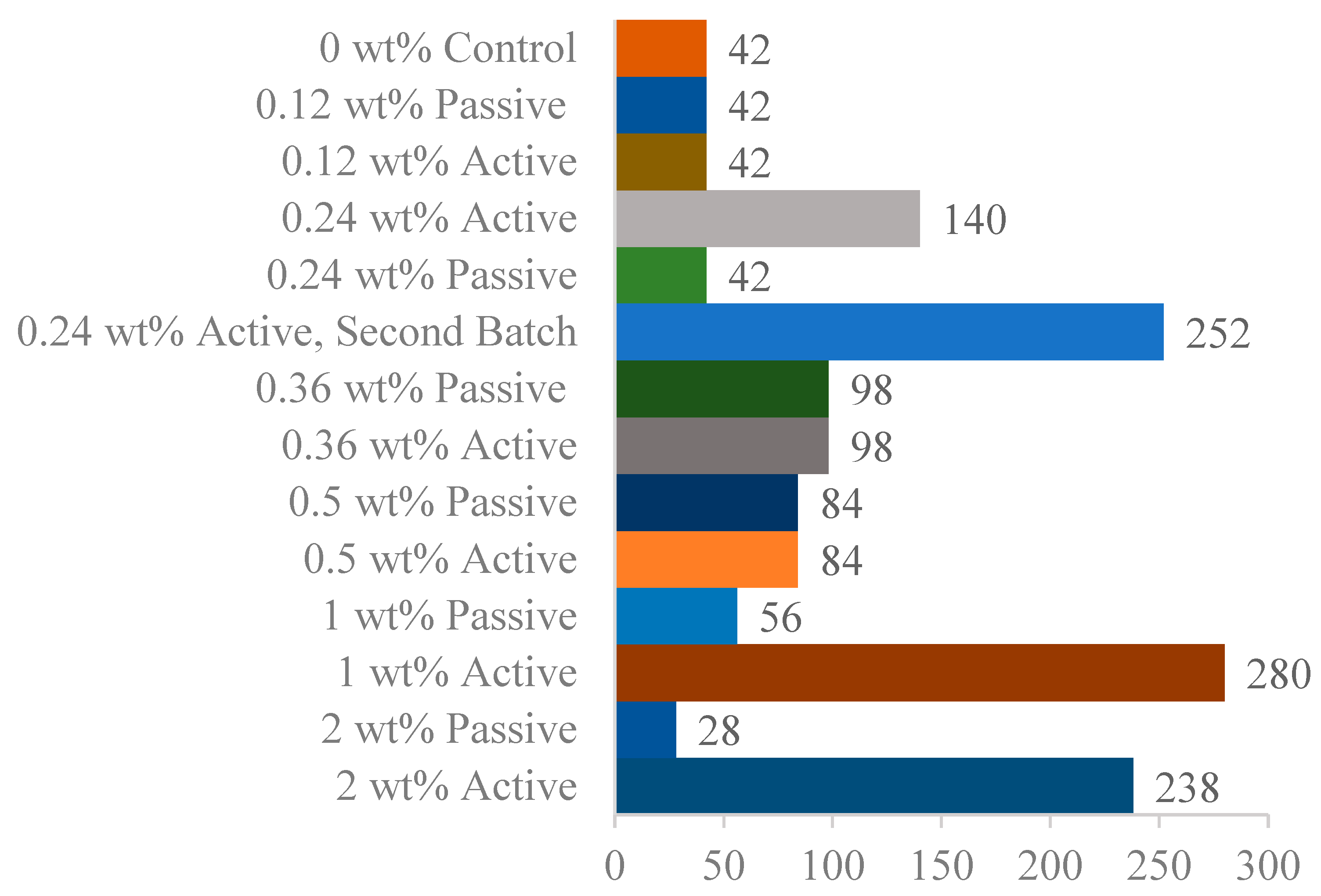

4.3. Relative Dynamic Modulus

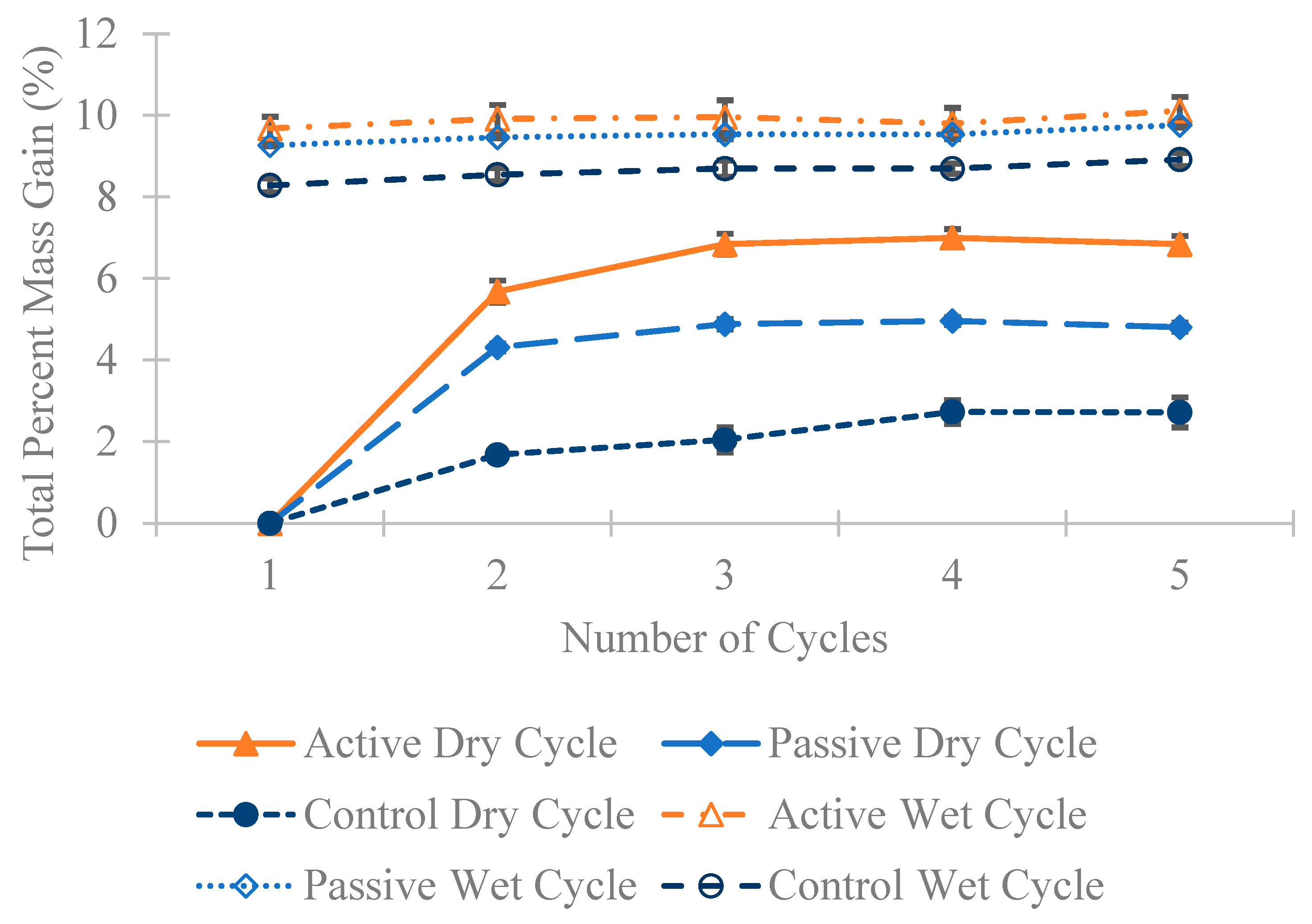

4.4. Mass Results of Chloride Penetration Test

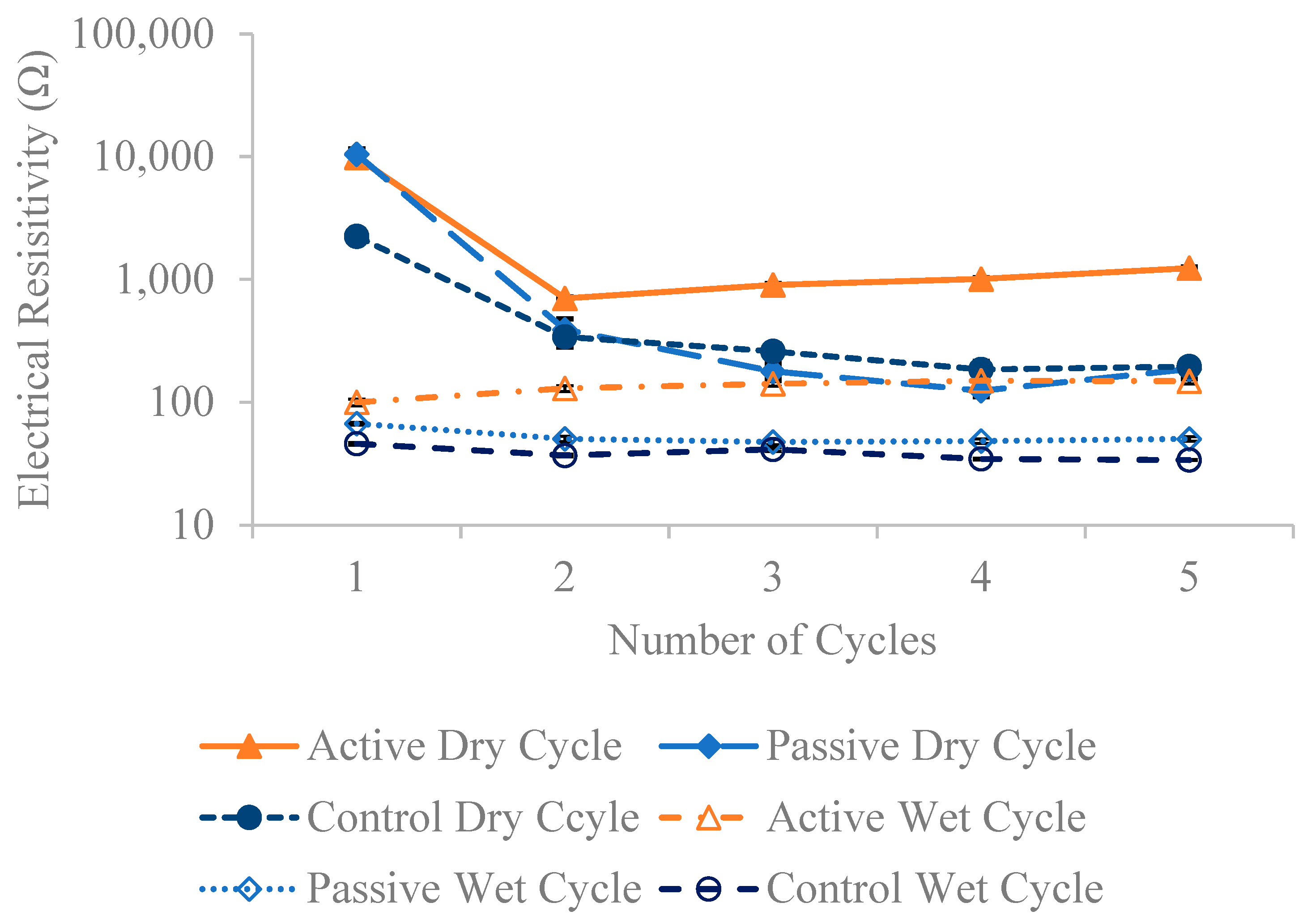

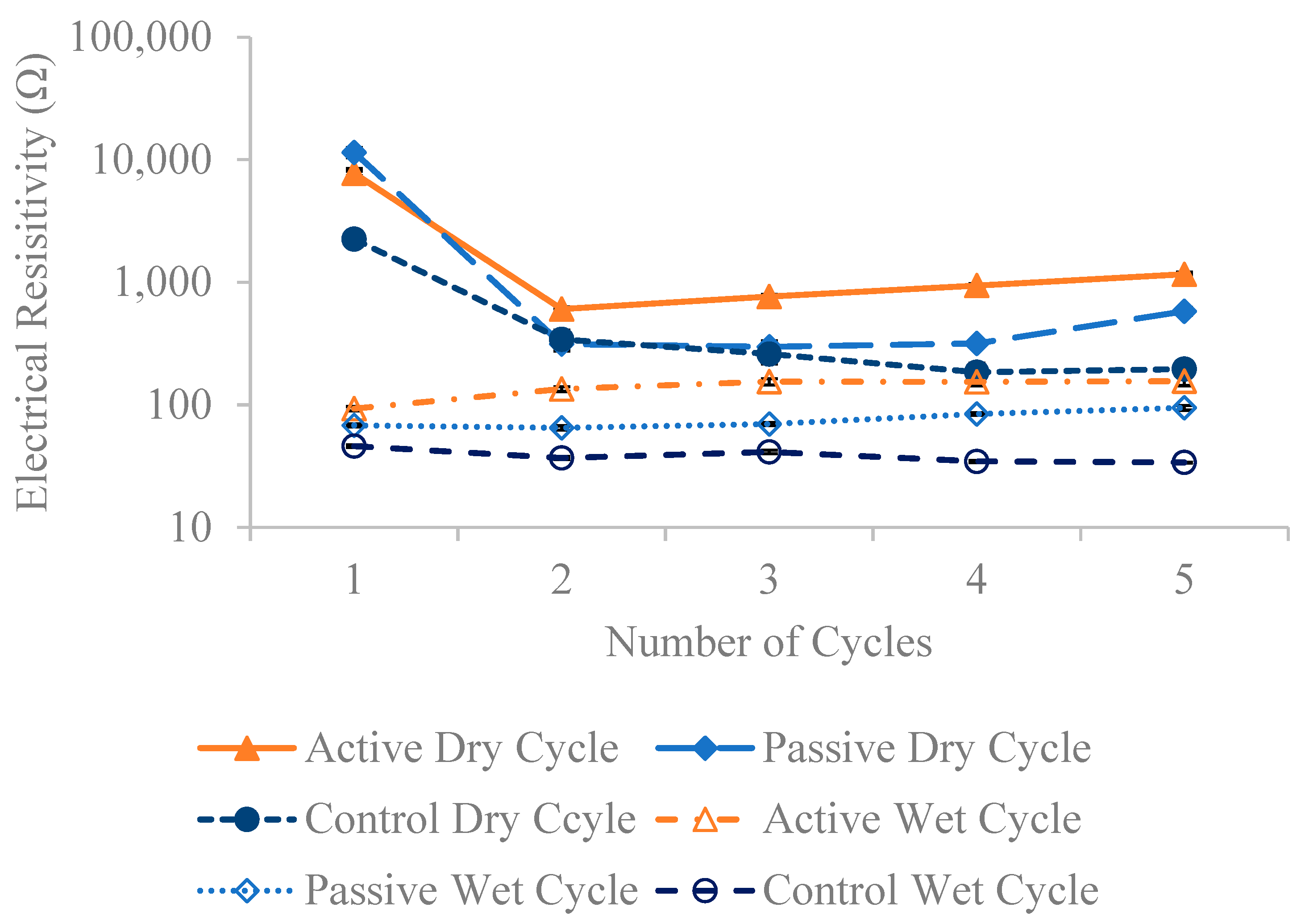

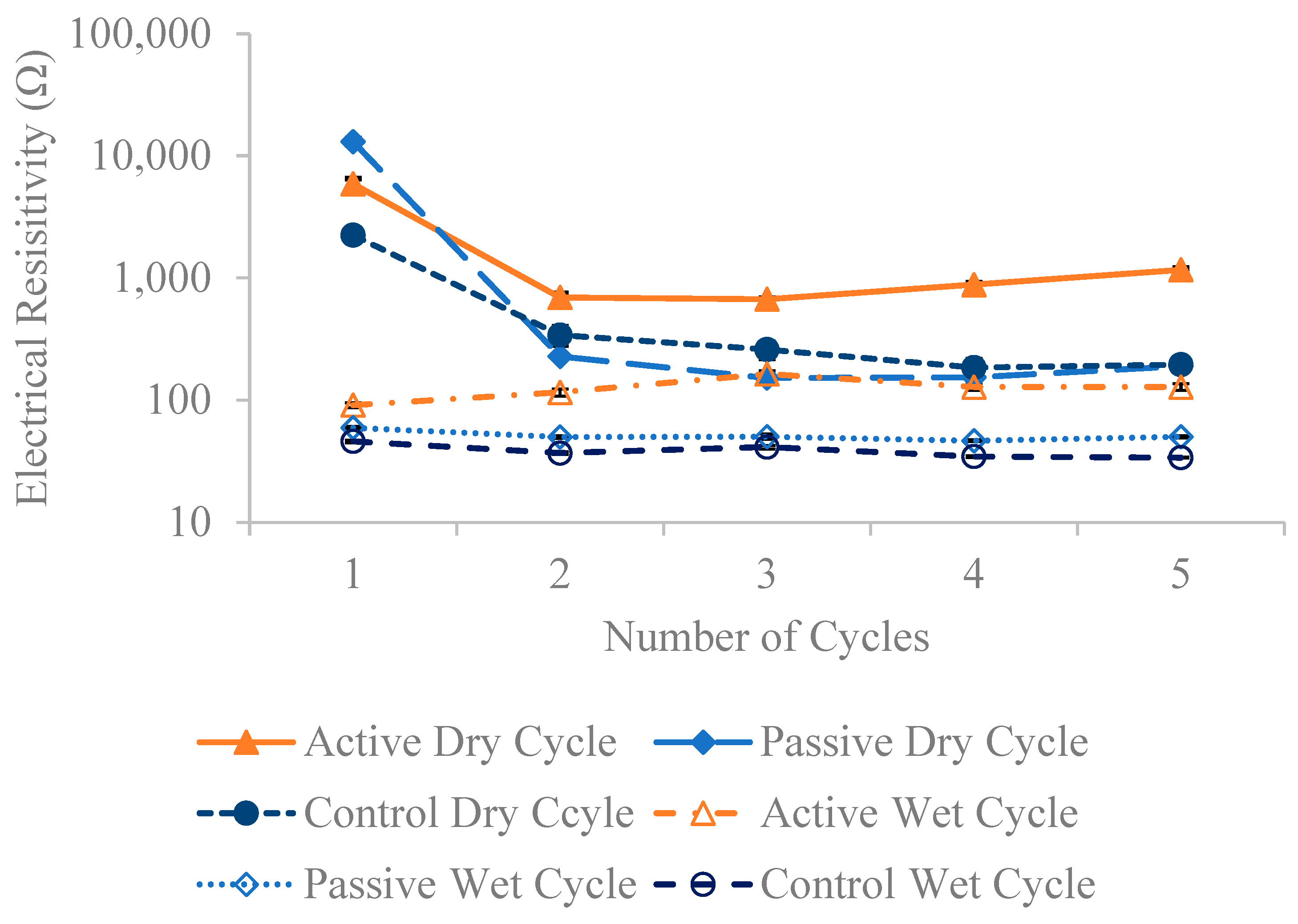

4.5. Electrical Resistivity

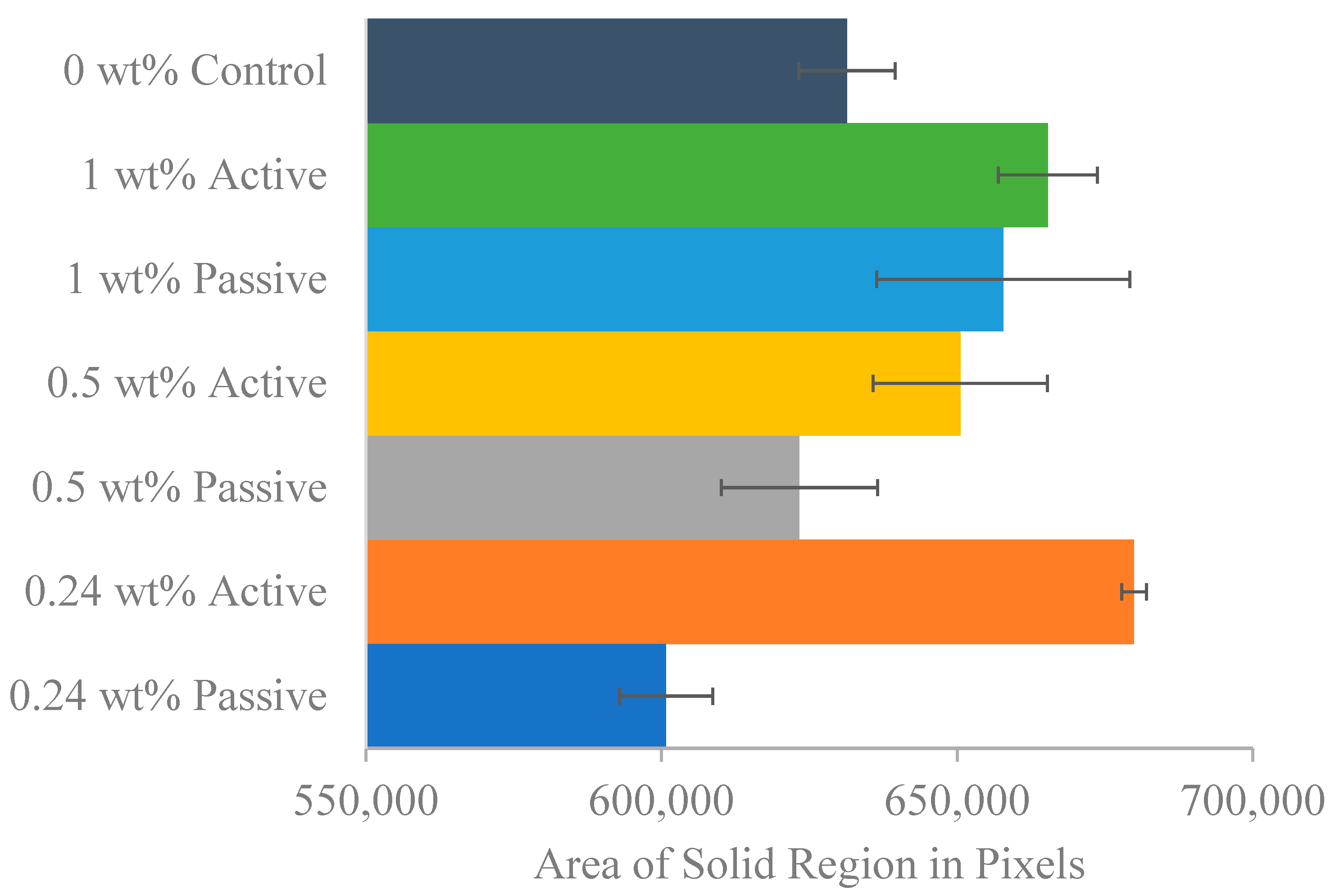

4.6. SEM Image Analysis Results

5. Conclusions

- The mixes with higher fiber ratios, i.e.,1 wt% and 2 wt% active shrinking fiber groups, showed higher durability factors than their respective passive groups in freeze-thaw testing. The 2 wt% active group exhibited a 219% greater durability factor than the 2 wt% passive group. The relatively sparse 0.12 wt% and 0.24 wt% fiber mixes also showed superior durability factors, while the intermediate 0.35 36 wt% and 0.5 wt% exhibited inferior durability.

- After 300 freeze-thaw cycles, only the 2 wt% active group retained all specimens intact, while the 1 wt% and 0.24 wt% active groups-maintained mass well but experienced prism breakage after 250 cycles, in contrast, the 0 wt% control group failed faster (less than 50 cycles) in terms of length and relative dynamic modulus compared to the active and passive fiber.

- Active fiber groups absorbed more mass than passive groups during wet cycles but maintained it after dry cycles, demonstrating higher resistivity despite increased mass gain in resistivity testing. This resilience is attributed to post-stressing applied to the concrete following each wet cycle, which effectively reduces pore size, limits water absorption, and increases electrical resistivity.

- Initial testing on day 0 revealed higher resistance values for passive groups than active groups, except for the 0.24 wt% groups. Over subsequent dry-wet cycles, active fiber groups consistently exhibited improved resistivity, further enhanced by the post-stressing treatment. On average, active fiber groups demonstrated 59% and 249% compared to their respective passive and control groups.

- SEM image analysis of the results aligns with dynamic modulus findings and electrical resistivity results reinforcing the beneficial impact of fiber reinforcement on concrete properties. The higher entropy and solid region area observed in fiber-reinforced groups further support their enhanced performance compared to the control group without fibers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Concrete Needs to Lose Its Colossal Carbon Footprint. Nature News, 28 September 2021. Available online: https://www.nature.com/articles/d41586-021-02612-5#ref-CR2 (accessed on 17 January 2024).

- Rodgers, L. Climate Change: The Massive CO2 Emitter You May Not Know About. BBC News, 17 December 2018. [Google Scholar]

- Sumra, Y.; Payam, S.; Zainah, I. The pH of cement-based materials: A Review. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2020, 35, 908–924. [Google Scholar] [CrossRef]

- Khan, M.S.; Hashmi, A.F.; Shariq, M.; Ibrahim, S.M. Effects of Incorporating Fibres on Mechanical Properties of Fibre-Reinforced Concrete: A Review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Valli, A.; Kumar, S.R. Review on the Mechanism and Mitigation of Cracks in Concrete. Appl. Eng. Sci. 2023, 16, 100154. [Google Scholar] [CrossRef]

- Wong, H.S.; Pappas, A.M.; Zimmerman, R.W.; Buenfeld, N.R. Effect of Entrained Air Voids on the Microstructure and Mass Transport Properties of Concrete. Cem. Concr. Res. 2011, 41, 1067–1077. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, Q.; Ashour, A.; Han, B. Self-healing cement concrete composites for resilient infrastructures: A review. Compos. Part B Eng. 2020, 189, 107892. [Google Scholar] [CrossRef]

- Schlangen, E.; Sangadji, S. Addressing Infrastructure Durability and Sustainability by Self Healing Mechanisms—Recent Advances in Self Healing Concrete and Asphalt. Procedia Eng. 2013, 54, 39–57. [Google Scholar] [CrossRef]

- Lin, Z.; Li, V.C. Crack bridging in fiber reinforced cementitious composites with slip-hardening interfaces. J. Mech. Phys. Solids 1997, 45, 763–787. [Google Scholar] [CrossRef]

- Zheng, X.; Zhang, J.; Wang, Z. Effect of multiple matrix cracking on crack bridging of fiber reinforced engineered cementitious composite. J. Compos. Mater. 2020, 54, 3949–3965. [Google Scholar] [CrossRef]

- Shah, S.P.; Rangan, B.V. Fiber Reinforced Concrete Properties. J. Proc. 1971, 68, 126–137. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S. Mechanical properties of high-strength steel fiber reinforced concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Roque, R.; Kim, N.; Kim, B.; Lopp, G. Durability of Fiber-Reinforced Concrete in Florida Environments; University of Florida: Gainesville, FL, USA, 2009. [Google Scholar]

- Kurita, K. Chitin and Chitosan: Functional Biopolymers from Marine Crustaceans. Mar. Biotechnol. 2006, 8, 203. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Kean, T.; Thanou, M. Biodegradation, biodistribution and toxicity of chitosan. Adv. Drug Deliv. Rev. 2010, 62, 3–11. [Google Scholar] [CrossRef] [PubMed]

- Qasim, S.B.; Zafar, M.S.; Najeeb, S.; Khurshid, Z.; Shah, A.H.; Husain, S.; Rehman, I.U. Electrospinning of Chitosan-Based Solutions for Tissue Engineering and Regenerative Medicine. Int. J. Mol. Sci. 2018, 19, 407. [Google Scholar] [CrossRef] [PubMed]

- Notin, L.; Viton, C.; David, L.; Alcouffe, P.; Rochas, C.; Domard, A. Morphology and mechanical properties of chitosan fibers obtained by gel-spinning: Influence of the dry-jet stretching step and ageing. Acta Biomater. 2006, 2, 387–402. [Google Scholar] [CrossRef] [PubMed]

- Notin, L.; Domard, A.; Viton, C.; Cancel, R.; Wallace, R.; Sassi, G. Chitosan Spinning Method, Device Therefore, and Resulting Chitosan Yarn, and Uses Thereof. EP1670418, 21 June 2006. [Google Scholar]

- Fernandez, J.G.; Ingber, D.E. Manufacturing of Large-Scale Functional Objects Using Biodegradable Chitosan Bioplastic. Macromol. Mater. Eng. 2014, 299, 932–938. [Google Scholar] [CrossRef]

- Baykara, H.; Riofrio, A.; Garcia-Troncoso, N.; Cornejo, M.; Tello-Ayala, K.; Flores Rada, J.; Caceres, J. Chitosan-Cement Composite Mortars: Exploring Interactions, Structural Evolution, Environmental Footprint and Mechanical Performance. ACS Omega 2024, 9, 24978–24986. [Google Scholar] [CrossRef]

- Qin, Y.; Chen, X.; Li, B.; Guo, Y.; Niu, Z.; Xia, T.; Meng, W.; Zhou, M. Study on the mechanical properties and microstructure of chitosan reinforced metakaolin-based geopolymer. Constr. Build. Mater. 2021, 271, 121522. [Google Scholar] [CrossRef]

- Yehia, S.; Ibrahim, A.M.; Ahmed, D.F. The impact of using natural waste biopolymer cement on the properties of traditional/fibrous concrete. Innov. Infrastruct. Solut. 2023, 8, 287. [Google Scholar] [CrossRef]

- Gregory, D.; Worley, R., II; Allen, J.; Kaplita, M.; Huston, D. Chitosan-Based Shrinking Fibers for Post-Cure Stressing to Increase Durability of Concrete. In Proceedings of the SPIE Smart Structures + Nondestructive Evaluation 2022, Long Beach, CA, USA, 6–9 March 2022. Proceedings Volume PC12044, Behavior and Mechanics of Multifunctional Materials XVI. [Google Scholar]

- Winter, G. Design of Concrete Structures, 10th ed; McGraw-Hill: New York, NY, USA, 1986. [Google Scholar]

- Chitosan—High molecular weight Product Specification. Specification Sheet PRD.4.ZQ5.10000004416, Sigma Aldrich. March 2025. Available online: https://www.sigmaaldrich.com/specification-sheets/392/945/419419-BULK_______ALDRICH__.pdf (accessed on 25 February 2025).

- Gowers, K.R.; Millard, S.G. Measurement of Concrete Resistivity for Assessment of Corrosion Severity of Steel Using Wenner Technique. Mater. J. 1999, 96, 536–541. [Google Scholar] [CrossRef]

- Liu, X.; Tang, G. Research on prediction method of concrete freeze-thaw durability under field environments. Chin. J. Rock Mech. Eng. 2007, 26, 2412–2419. [Google Scholar]

- Powers, T.C. A Working Hypothesis for Further Studies of Frost Resistance of Concrete. J. Proc. 1945, 41, 245–272. [Google Scholar] [CrossRef]

- Powers, T.C.; Helmuth, R.A. Theory of volume change in hardened Portland cement paste during freezing. Highw. Res. Board Proc. 1953, 32, 1953. [Google Scholar]

- Zeng, Q.; Fen-Chong, T.; Dangla, P.; Li, K. A study of freezing behavior of cementitious materials by poromechanical approach. Int. J. Solids Struct. 2011, 48, 3267–3273. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, L.; Guo, P.; Yang, P. Fatigue Characteristics of Prestressed Concrete Beam under Freezing and Thawing Cycles. Adv. Civ. Eng. 2020, 2020, e8821132. [Google Scholar] [CrossRef]

- Carl Zeiss AG. ZEISS Sigma Family, EN_40_012_096|CZ2020|Rel. 2.5 Datasheet, August 2021. Revised June 2024. Available online: https://www.google.com.hk/url?sa=t&source=web&rct=j&opi=89978449&url=https://asset-downloads.zeiss.com/catalogs/download/mic/6b4769fe-9397-4301-b662-57d4fd549b8b/EN_product-flyer_Sigma_A4.pdf&ved=2ahUKEwj2gKeqkayMAxU4M9AFHV0TD_sQFnoECBQQAQ&usg=AOvVaw2zbTs_dWB6mxTPDGSVOflA (accessed on 25 February 2025).

| Appearance | Off-White/Beige Powder |

|---|---|

| Color after acidic | Faint yellow bulk |

| Solution density | 0.15–0.3 g/cm3 |

| Deacetylate rate | ≥75% |

| Molecular weight | 387 kg/mol |

| Specimen Number | Test | Fiber Type |

|---|---|---|

| 1–5 | Freeze-thaw | 0.12 wt% passive |

| 6–10 | Freeze-thaw | 0.12 wt% active |

| 11–15 | Freeze-thaw | 0.24 wt% passive |

| 16–20 | Freeze-thaw | 0.24 wt% active |

| 21–25 | Freeze-thaw | 0.36 wt% passive |

| 26–30 | Freeze-thaw | 0.36 wt% active |

| 31–35 | Freeze-thaw | 0 wt% control |

| 36–40 | Freeze-thaw | 0.5 wt% passive |

| 41–45 | Freeze-thaw | 0.5 wt% active |

| 46–50 | Freeze-thaw | 1 wt% passive |

| 51–55 | Freeze-thaw | 1 wt% active |

| 56–60 | Freeze-thaw | 2 wt% passive |

| 61–65 | Freeze-thaw | 2 wt% active |

| 66–70 | Freeze-thaw | 0.24 wt% active round 2 |

| 71–75 | Chloride penetration | 0.24 wt% passive |

| 76–80 | Chloride penetration | 0.24 wt% active |

| 81–85 | Chloride penetration | 0.5 wt% passive |

| 86–90 | Chloride penetration | 0.5 wt% active |

| 91–95 | Chloride penetration | 1 wt% passive |

| 96–100 | Chloride penetration | 1 wt% active |

| 101–105 | Chloride penetration | 0 wt% control |

| 71 | SEM analysis | 0.24 wt% passive |

| 76 | SEM analysis | 0.24 wt% active |

| 81 | SEM analysis | 0.5 wt% passive |

| 86 | SEM analysis | 0.5 wt% active |

| 91 | SEM analysis | 1 wt% passive |

| 96 | SEM analysis | 1 wt% active |

| 101 | SEM analysis | 0 wt% control |

| Passive Absorption (g/g) | Active Absorption (g/g) | |

|---|---|---|

| Average | 3.866 | 3.870 |

| SEM | 0.106 | 0.158 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huston, D.; Dewoolkar, M.M.; Gregory, D.; Abdul Qader, M.; Yeboah, B. Chitosan Shrinking Fibers for Curing-Initiated Stressing to Enhance Concrete Durability. Materials 2025, 18, 1574. https://doi.org/10.3390/ma18071574

Huston D, Dewoolkar MM, Gregory D, Abdul Qader M, Yeboah B. Chitosan Shrinking Fibers for Curing-Initiated Stressing to Enhance Concrete Durability. Materials. 2025; 18(7):1574. https://doi.org/10.3390/ma18071574

Chicago/Turabian StyleHuston, Dryver, Mandar M. Dewoolkar, Diarmuid Gregory, Mohammad Abdul Qader, and Bismark Yeboah. 2025. "Chitosan Shrinking Fibers for Curing-Initiated Stressing to Enhance Concrete Durability" Materials 18, no. 7: 1574. https://doi.org/10.3390/ma18071574

APA StyleHuston, D., Dewoolkar, M. M., Gregory, D., Abdul Qader, M., & Yeboah, B. (2025). Chitosan Shrinking Fibers for Curing-Initiated Stressing to Enhance Concrete Durability. Materials, 18(7), 1574. https://doi.org/10.3390/ma18071574