Comparative Laboratory Tests of Thermal Conductivity of Road Materials Using Two Measurement Methods

Abstract

1. Introduction

2. Materials and Methods

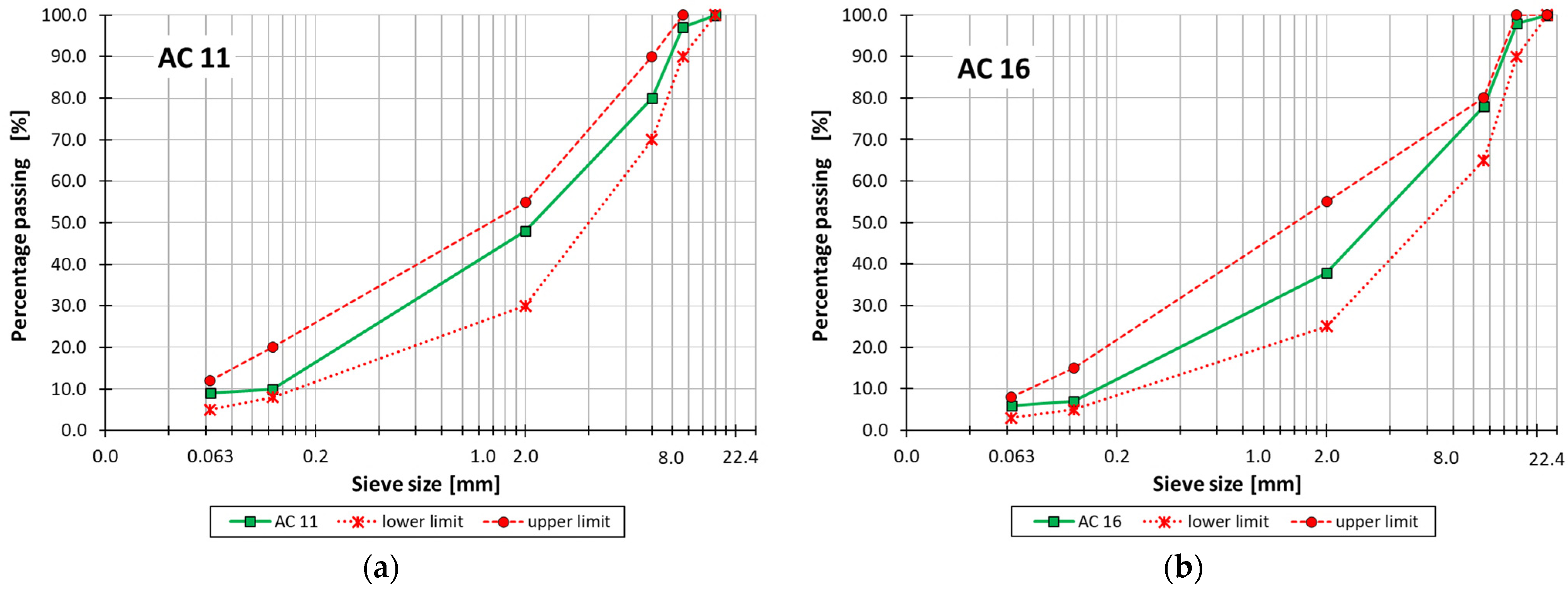

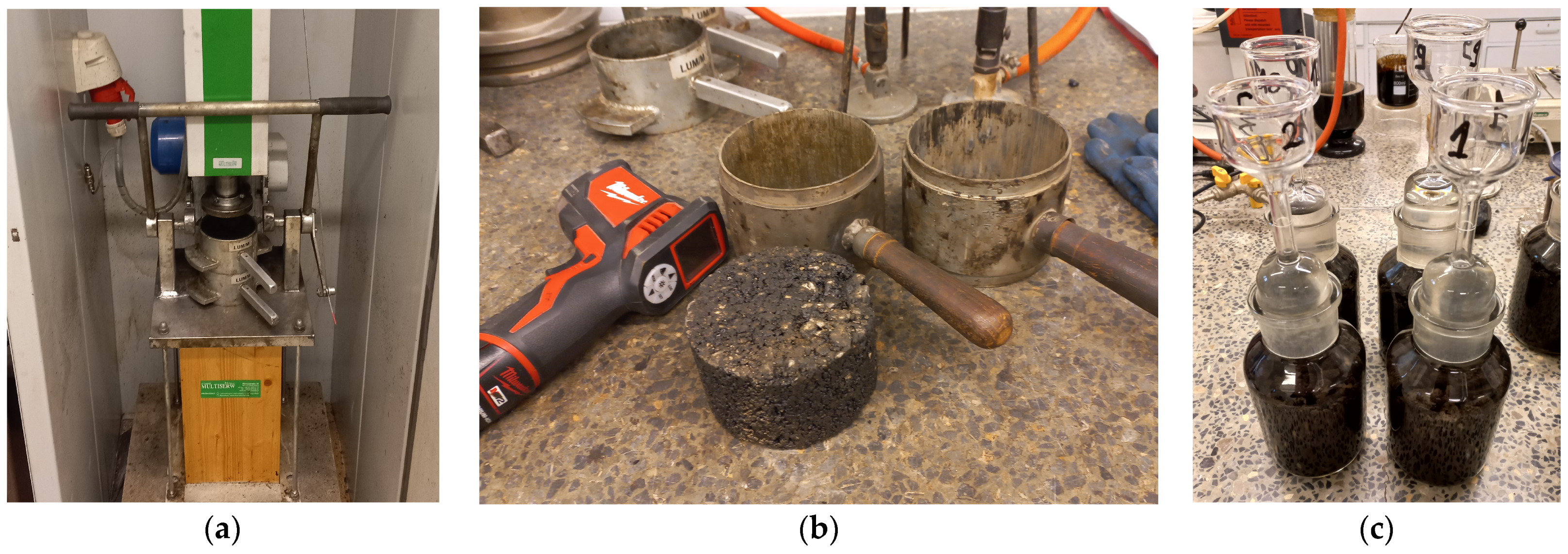

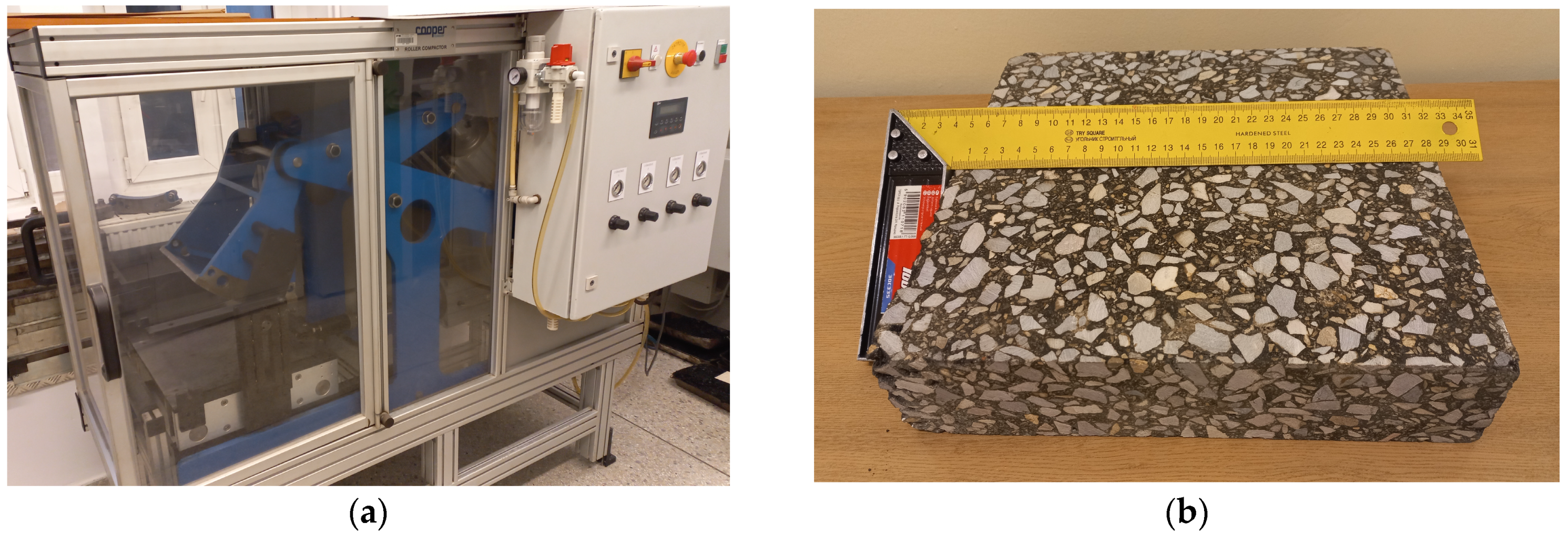

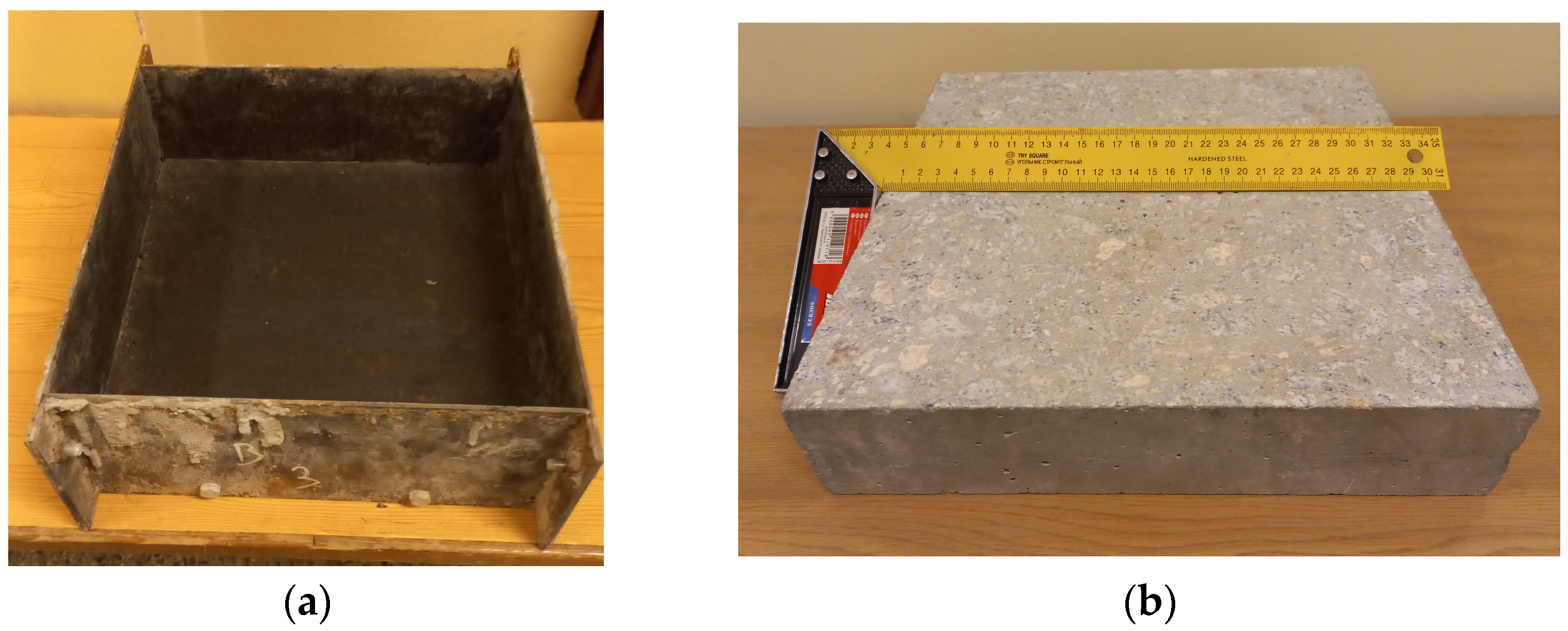

2.1. Tested Asphalt Mixtures

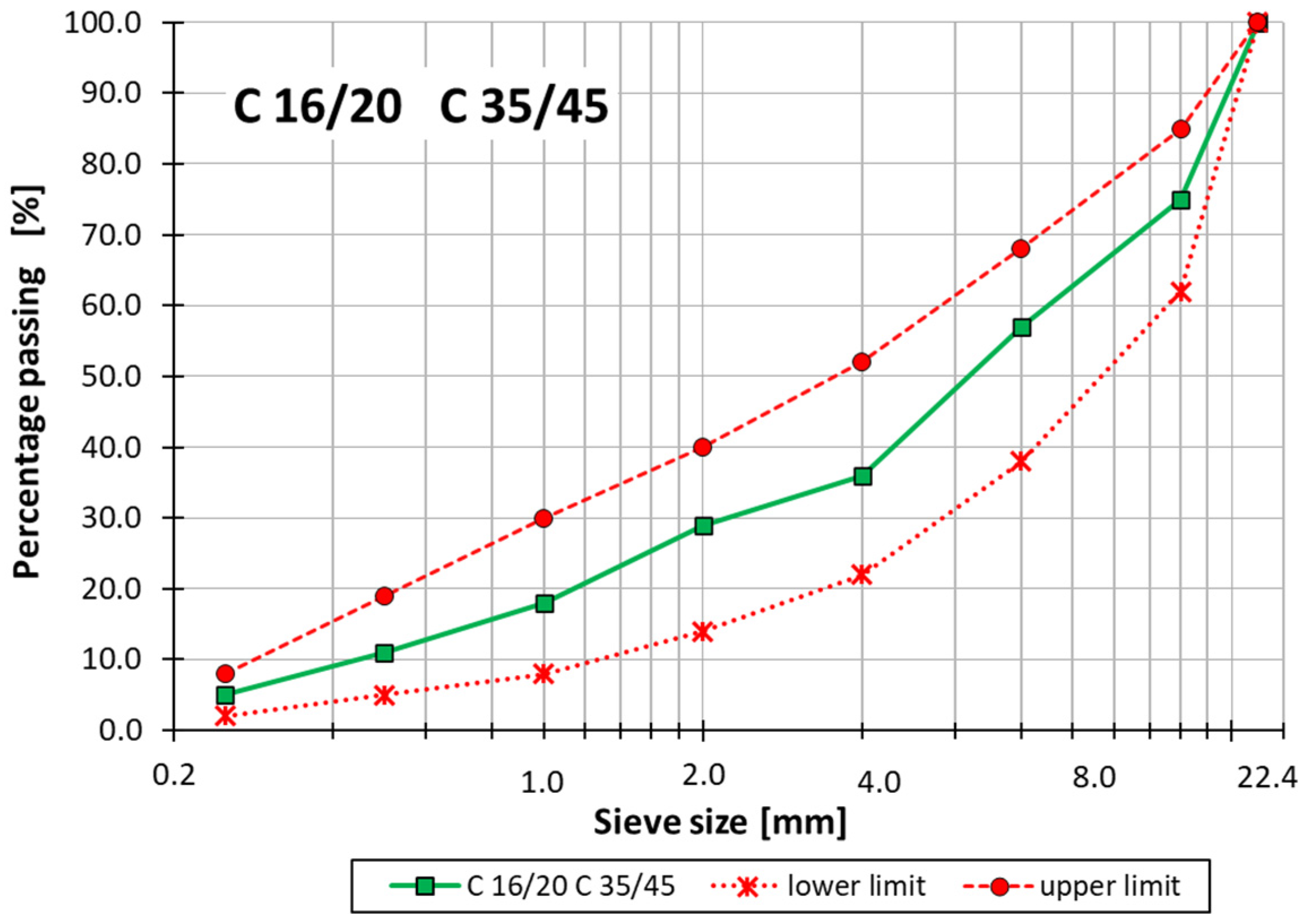

2.2. Tested Cement Concretes

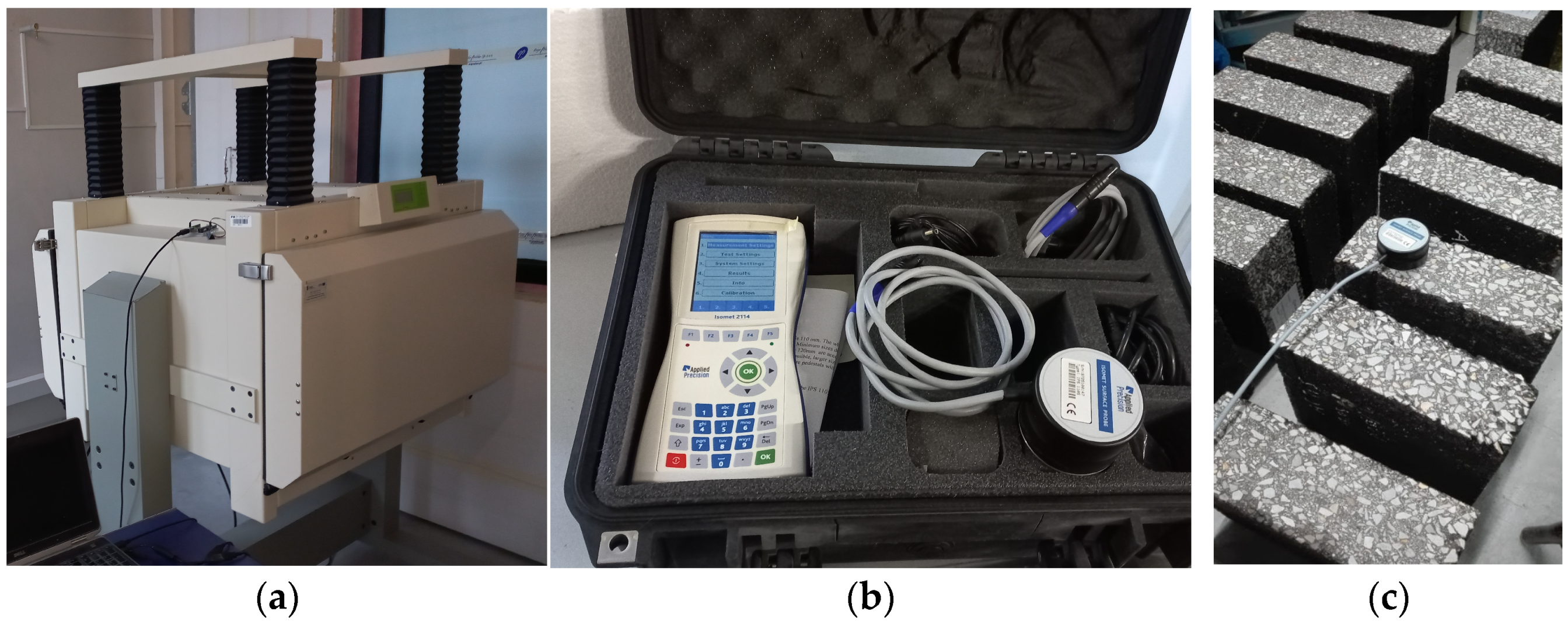

2.3. Test Methods and Parameters

3. Results and Discussion

3.1. Test Results for Individual Materials

3.2. Comparison of the Test Results Obtained by Two Measurement Methods

4. Conclusions

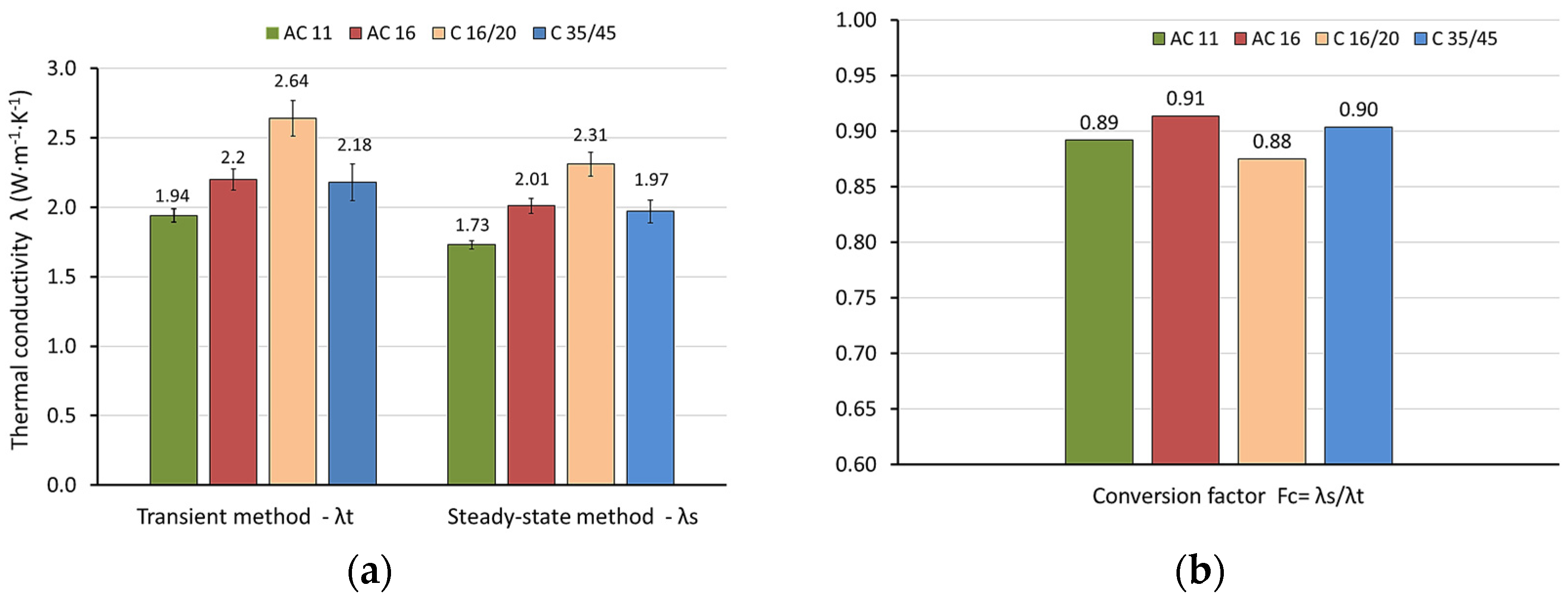

- Both the steady-state and transient methods are suitable for measuring the thermal conductivity of road materials. For the tested specimens, the steady-state method provides thermal conductivity values ranging from 1.73 to 2.31 W·m−1·K−1, while the transient method yields higher values, ranging from 1.94 to 2.64 W·m−1·K−1.

- Statistically significant differences (α = 0.05) were observed between the results obtained using the two methods. The average difference is estimated at 9.7% and 11.1% for asphalt mixtures and cement concretes, respectively.

- Estimating and confirming a statistically significant difference between the test results obtained using the two measurement methods is essential. When performing thermal analysis of road pavement structures, careful consideration should be given to the method used to determine thermal conductivity, as it is a fundamental material parameter. This is particularly important in areas affected by the UHI effect and for road sections used as heat collectors.

- The results of measurements obtained using the transient method show higher variability. The average coefficient of variation is estimated at 4.2% and 3.1% for the transient method and the steady-state method, respectively.

- According to the authors, the transient method can be widely applied due to its simplicity and practicality, especially when testing large and heavy road material specimens. However, a correction should be applied to account for the differences between the results obtained using the standardized steady-state method and the transient method.

- The proposed conversion factor ( = 0.9) can be used to quickly estimate the thermal conductivity values of road materials based on faster and more cost-effective measurements obtained using a non-standardized transient method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pasetto, M.; Pasquini, E.; Giacomello, G.; Baliello, A. Innovative pavement surfaces as urban heat islands mitigation strategy: Chromatic, thermal and mechanical characterisation of clear/coloured mixtures. Road Mater. Pavement Des. 2019, 20 (Suppl. S1), S533–S555. [Google Scholar] [CrossRef]

- Kong, L.; Xu, L.; Du, Y.; Jin, J.; Loprencipe, G.; Moretti, L. Use of Hybrid Mineral Filler with High Emissivity in Asphalt Mixture for Cooling Road Pavements. Materials 2023, 16, 175. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Zou, Z.; Zhou, T.; Zhou, X.; Li, Q. Simulation and Analysis of Influencing Factors of Pavement Thermal Environments in Guangzhou. Sustainability 2022, 14, 7251. [Google Scholar] [CrossRef]

- Marcobal, J.; Lizárraga, J.; Gallego, J. Laboratory Compaction Study and Mechanical Performance Assessment of Half-Warm Mix Recycled Asphalt Mixtures Containing 100% RAP. Materials 2019, 12, 1992. [Google Scholar] [CrossRef] [PubMed]

- Górszczyk, J.; Malicki, K. Comparison of temperature distributions in road pavement obtained in field tests and using transient thermal analysis. MATEC Web Conf. 2019, 262, 05007. [Google Scholar] [CrossRef]

- Shin, A.H.-C.; Kodide, U. Thermal conductivity of ternary mixtures for concrete pavements. Cem. Concr. Compos. 2012, 34, 575–582. [Google Scholar] [CrossRef]

- Górszczyk, J.; Malicki, K. Experimental Investigation of Loading Frequency Influence on a Strength of Asphalt Interlayer Bonding. Arch. Civ. Eng. 2020, 66, 197–208. [Google Scholar] [CrossRef]

- Szydło, A.; Malicki, K. Analysis of the Correlation between the Static and Fatigue Test Results of the Interlayer Bondings of Asphalt Layers. Arch. Civ. Eng. 2016, 62, 83–98. [Google Scholar] [CrossRef]

- Wiśniewski, S.; Wiśniewski, T.S. Heat Transfer; WNT Warsaw: Warszawa, Poland, 1995. (In Polish) [Google Scholar]

- Asadi, I.; Shafigh, P.; Hassan, Z.F.B.A.; Mahyuddin, N.B. Thermal conductivity of concrete—A review. J. Build. Eng. 2018, 20, 81–93. [Google Scholar] [CrossRef]

- Zastawna-Rumin, A.; Nowak, K. Measurement of thermal properties of building materials through the use of different measuring equipment–analysis of results. J. Civ. Eng. Environ. Archit. 2015, XXXII, 603–610. [Google Scholar] [CrossRef]

- Meukam, P.; Jannot, Y.; Noumowe, A.; Kofane, T.C. Thermo physical characteristics of economical building materials. Constr. Build. Mater. 2004, 18, 437–443. [Google Scholar] [CrossRef]

- Chu, L.; He, L.; Fwa, T.F. Determination of thermal conductivity of asphalt paving mixtures using finite element method. Constr. Build. Mater. 2020, 243, 118250. [Google Scholar] [CrossRef]

- Nazki, M.A.; Chopra, T.; Chandrappa, A.K. Rheological properties and thermal conductivity of bitumen binders modified with graphene. Constr. Build. Mater. 2020, 238, 117693. [Google Scholar] [CrossRef]

- Mrawira, D.M.; Luca, J. Effect of aggregate type, gradation, and compaction level on thermal properties of hot-mix asphalts. Can. J. Civ. Eng. 2006, 33, 1410–1417. [Google Scholar] [CrossRef]

- Hassn, A.; Aboufoul, M.; Wu, Y.; Dawson, A.; Garcia, A. Effect of air voids content on thermal properties of asphalt mixtures. Constr. Build. Mater. 2016, 115, 327–335. [Google Scholar] [CrossRef]

- Côté, J.; Grosjean, V.; Konrad, J.-M. Thermal conductivity of bitumen concrete. Can. J. Civ. Eng. 2013, 40, 172–180. [Google Scholar] [CrossRef]

- Dawson, A.R.; Dehdezi, P.K.; Hall, M.R.; Wang, J.; Isola, R. Enhancing thermal properties of asphalt materials for heat storage and transfer applications. Road Mater. Pavement Des. 2012, 13, 784–803. [Google Scholar] [CrossRef]

- Xu, L.; Alae, M.; Du, Y.; Loprencipe, G.; Peluso, P.; Moretti, L. Thermal Characteristics and Temperature Distribution of Asphalt Mixtures Containing Residues from Municipal Solid Waste Incineration. Sustainability 2023, 15, 15612. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete, 5th ed.; Prentice Hall: Harlow, England, New York, NY, USA, 2012. [Google Scholar]

- Asadi, I.; Ji, G.; Baghban, M.H. Evaluating the effective thermal conductivity of cement mortar through x-ray scanning. Case Stud. Therm. Eng. 2023, 41, 102686. [Google Scholar] [CrossRef]

- Bamogo, S.; Zoma, F.; Malbila, E.; Toguyeni, D.Y.K. Thermal Characterization of Concrete and Cement Mortar from Construction Sites and Industrial Production Units in the City of Ouagadougou with a View to Standardization in Energy Certification. Engineering 2023, 15, 396–415. [Google Scholar] [CrossRef]

- Zhang, W.; Min, H.; Gu, X.; Xi, Y.; Xing, Y. Mesoscale model for thermal conductivity of concrete. Constr. Build. Mater. 2015, 98, 8–16. [Google Scholar] [CrossRef]

- Benazzouk, A.; Douzane, O.; Mezreb, K.; Laidoudi, B.; Quéneudec, M. Thermal conductivity of cement composites containing rubber waste particles: Experimental study and modelling. Constr. Build. Mater. 2008, 22, 573–579. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Giacomello, G.; Pasquini, E. Rutting behavior of asphalt surface layers designed for solar harvesting systems. Materials 2023, 16, 277. [Google Scholar] [CrossRef] [PubMed]

- Abbas, F.A.; Alhamdo, M.H. Experimental and numerical analysis of an asphalt solar collector with a conductive asphalt mixture. Energy Rep. 2024, 11, 327–341. [Google Scholar] [CrossRef]

- Górszczyk, J.; Grzybowska, W. The use of fem for thermal analyses of the asphalt pavement. Roads Bridg.–Drog. Mosty 2011, 10, 5–30. [Google Scholar]

- Wu, S.P.; Li, B.; Wang, H.; Qiu, J. Numerical simulation of temperature distribution in conductive asphalt solar collec-tor due to pavement material parameters. Mater. Sci. Forum 2008, 575–578, 1314–1319. [Google Scholar] [CrossRef]

- Han, F.; Lv, Y.; Liang, T.; Zhang, X.; Yu, W.; Fu, X.; Deng, K. Modeling thermal conductivity of aerogel-incorporated concrete: A multi-scale approach. Constr. Build. Mater. 2024, 450, 138605. [Google Scholar] [CrossRef]

- She, W.; Zhao, G.; Cai, D.; Jiang, J.; Cao, X. Numerical study on the effect of pore shapes on the thermal behaviors of cellular concrete. Constr. Build. Mater. 2018, 163, 113–121. [Google Scholar] [CrossRef]

- Poznański, M. Laboratory Tests of Thermal Properities of Selected Hot-Mix Asphalts. Master’s Thesis, Cracow University of Technology, Cracow, Paland, 2018. [Google Scholar]

- Kostecka, K. Laboratory Testing of Thermal Properties of Selected Road Materials in a Stationary and Non-Stationary Heat Flow Test. Master’s Thesis, Cracow University of Technology, Cracow, Poland, 2018. [Google Scholar]

- Asphalt Pavements on National Roads. Technical Requirements WT-2 p. I. Asphalt Mixtures; GDDKiA: Warszawa, Poland, 2014. (In Polish) [Google Scholar]

- EN 12697-5; Bituminous Mixtures–Test Methods for Hot Mix Asphalt–Part 5: Determination of the Maximum Density. European Committee for Standardization: Brussels, Belgium, 2012.

- EN 12697-6; Bituminous Mixtures–Test Methods for Hot Mix Asphalt–Part 6: Determination of Bulk Density of Bituminous Specimens. European Committee for Standardization: Brussels, Belgium, 2012.

- EN 12697-8; Bituminous Mixtures–Test Methods–Part 8: Determination of Void Characteristics of Bituminous Specimens. European Committee for Standardization: Brussels, Belgium, 2012.

- EN 12697-33; Bituminous Mixtures–Test Methods–Part 33: Specimen Prepared by Roller Compactor. European Committee for Standardization: Brussels, Belgium, 2019.

- EN 206; Concrete. Specification, Performance, Production and Conformity. European Committee for Standardization: Brussels, Belgium, 2013.

- EN 1008; Mixing Water for Concrete–Specification for Sampling, Testing and Assessing the Suitability of Water, Including Water Recovered from Processes in the Concrete Industry, as Mixing Water for Concrete. European Committee for Standardization: Brussels, Belgium, 2002.

- EN 12667; Thermal Performance of Building Materials and Products–Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistance. European Committee for Standardization: Brussels, Belgium, 2001.

- ISO 8301; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat flow Meter Apparatus. International Organization for Standardization: Geneve, Switzerland, 1991.

- Thermal Conductivity Instruments. Heat Flow Meter. Brochure; Lasercomp, TA Instruments: New Castle, DE, USA, 2015; Available online: http://www.tainstruments.com/fox-800/ (accessed on 11 October 2024).

- Isomet 2114; Applied Precision Ltd.: Bratislava, Slovakia, 2024; Available online: https://www.appliedp.com/product/isomet/ (accessed on 13 November 2024).

| Steady-State Method | Transient Method |

|---|---|

| Specified standard procedure for laboratory tests | No standard procedure. Tests performed according to the guidelines of the measuring device manufacturers |

| Method used in laboratory conditions | Method can be used both in laboratory and field conditions |

| More expensive testing equipment | Cheaper testing equipment |

| Difficult testing of large and heavy specimens | Relatively easy testing of large and heavy specimens |

| Possibility of testing specimens of limited dimensions | Possibility of testing specimens and elements with different dimensions and geometries |

| Longer measurement time for a single specimen | Shorter measurement time for a single specimen |

| Lower variability of results | Higher variability of results |

| Sieve Size (mm) | AC 11 Mass Passing (%) | AC 16 Mass Passing (%) |

|---|---|---|

| 22.4 | — | 100 |

| 16 | 100 | 98 |

| 11.2 | 97 | 78 |

| 8 | 80 | 63 |

| 2 | 48 | 38 |

| 0.125 | 10 | 7 |

| 0.063 | 9 | 6 |

| Material | Type | Apparent Density (g·cm−3) | Amount in AC 11 (%) | Amount in AC 16 (%) |

|---|---|---|---|---|

| aggregate 8/16 | limestone | 2.71 | — | 39.0 |

| aggregate 8/12 | dolomite | 2.81 | 18.8 | — |

| aggregate 2/8 | limestone | 2.72 | — | 17.1 |

| aggregate 2/8 | dolomite | 2.81 | 24.5 | — |

| aggregate 0/4 | limestone | 2.71 | 33.0 | 18.1 |

| aggregate 0/2 | sandstone | 2.66 | 14.1 | 18.1 |

| mineral filler | limestone | 2.70 | 3.8 | 2.9 |

| road bitumen | 50/70 | 1.023 | 5.78 | 4.78 |

| agent | adhesion | — | 0.02 | 0.02 |

| Parameter | Standard | Results AC 11 | Requirements AC 11 [33] | Results AC 16 | Requirements AC 16 [33] |

|---|---|---|---|---|---|

| Density (g·cm−3) | EN 12697-5 [34] | 2.478 | — | 2.503 | — |

| Bulk density (g·cm−3) | EN 12697-6 [35] | 2.432 | — | 2.395 | — |

| Void ratio VV (%) | EN 12697-8 [36] | 1.9 | 1.0–3.0 | 4.3 | 3.0–6.0 |

| Voids filled with bitumen VFB (%) | EN 12697-8 [36] | 87.9 | 75–93 | 72.3 | 60–80 |

| Voids of mineral aggregate VMA (%) | EN 12697-8 [36] | 15.7 | min. 14 | 15.5 | min. 14 |

| Sieve Size (mm) | Mass Passing (%) |

|---|---|

| 22.4 | 100 |

| 16 | 75 |

| 8 | 57 |

| 4 | 36 |

| 2 | 29 |

| 1 | 18 |

| 0.5 | 11 |

| 0.25 | 5 |

| Material | Coarse Aggregate | Number of Specimens |

|---|---|---|

| AC 11 | granite | 8 |

| AC 16 | limestone | 8 |

| C 16/20 | dolomite | 8 |

| C 35/45 | granite | 8 |

| Specimen Number | AC 11 | AC 16 | C 16/20 | C 35/45 |

|---|---|---|---|---|

| 1 | 1.75 | 2.01 | 2.30 | 2.03 |

| 2 | 1.72 | 1.95 | 2.19 | 1.92 |

| 3 | 1.71 | 2.02 | 2.25 | 1.98 |

| 4 | 1.79 | 1.99 | 2.26 | 1.86 |

| 5 | 1.73 | 2.09 | 2.33 | 2.05 |

| 6 | 1.74 | 1.93 | 2.27 | 1.92 |

| 7 | 1.68 | 2.07 | 2.41 | 2.10 |

| 8 | 1.75 | 2.02 | 2.45 | 1.90 |

| Mean value (W·m−1·K−1) | 1.73 | 2.01 | 2.31 | 1.97 |

| Standard deviation (W·m−1·K−1) | 0.03 | 0.05 | 0.09 | 0.08 |

| Coefficient of variation (%) | 1.8 | 2.7 | 3.8 | 4.2 |

| Specimen Number | Series 1 | Series 2 | Series 3 | Mean Value |

|---|---|---|---|---|

| 1 | 1.95 | 1.94 | 1.99 | 1.96 |

| 2 | 1.94 | 1.86 | 1.88 | 1.90 |

| 3 | 2.01 | 2.03 | 1.98 | 2.00 |

| 4 | 1.93 | 1.93 | 1.88 | 1.91 |

| 5 | 1.92 | 1.92 | 1.91 | 1.92 |

| 6 | 1.90 | 1.91 | 1.84 | 1.88 |

| 7 | 2.07 | 2.01 | 1.96 | 2.01 |

| 8 | 1.91 | 1.99 | 1.91 | 1.93 |

| Mean value (W·m−1·K−1) | 1.94 | |||

| Standard deviation (W·m−1·K−1) | 0.05 | |||

| Coefficient of variation (%) | 2.5 | |||

| Specimen Number | Series 1 | Series 2 | Series 3 | Mean Value |

|---|---|---|---|---|

| 1 | 2.07 | 2.11 | 2.25 | 2.14 |

| 2 | 2.21 | 2.17 | 2.17 | 2.18 |

| 3 | 2.17 | 2.16 | 2.19 | 2.18 |

| 4 | 2.07 | 2.03 | 2.18 | 2.09 |

| 5 | 2.20 | 2.26 | 2.28 | 2.25 |

| 6 | 2.27 | 2.24 | 2.25 | 2.25 |

| 7 | 2.30 | 2.37 | 2.37 | 2.35 |

| 8 | 2.07 | 2.13 | 2.32 | 2.17 |

| Mean value (W·m−1·K−1) | 2.20 | |||

| Standard deviation (W·m−1·K−1) | 0.08 | |||

| Coefficient of variation (%) | 3.5 | |||

| Specimen Number | Series 1 | Series 2 | Series 3 | Mean Value |

|---|---|---|---|---|

| 1 | 2.60 | 2.60 | 2.81 | 2.67 |

| 2 | 2.72 | 2.69 | 2.70 | 2.70 |

| 3 | 2.36 | 2.46 | 2.28 | 2.37 |

| 4 | 2.89 | 2.50 | 2.58 | 2.66 |

| 5 | 2.77 | 2.64 | 2.68 | 2.70 |

| 6 | 2.44 | 2.79 | 2.39 | 2.54 |

| 7 | 2.85 | 2.58 | 2.87 | 2.77 |

| 8 | 2.66 | 2.78 | 2.76 | 2.73 |

| Mean value (W·m−1·K−1) | 2.64 | |||

| Standard deviation (W·m−1·K−1) | 0.13 | |||

| Coefficient of variation (%) | 4.9 | |||

| Specimen Number | Series 1 | Series 2 | Series 3 | Mean Value |

|---|---|---|---|---|

| 1 | 2.13 | 2.11 | 2.16 | 2.13 |

| 2 | 1.95 | 1.92 | 1.99 | 1.95 |

| 3 | 2.23 | 2.19 | 2.22 | 2.22 |

| 4 | 2.17 | 2.16 | 2.16 | 2.16 |

| 5 | 2.36 | 2.33 | 2.38 | 2.36 |

| 6 | 2.21 | 2.19 | 2.21 | 2.21 |

| 7 | 2.10 | 2.09 | 2.07 | 2.09 |

| 8 | 2.35 | 2.31 | 2.32 | 2.33 |

| Mean value (W·m−1·K−1) | 2.18 | |||

| Standard deviation (W·m−1·K−1) | 0.13 | |||

| Coefficient of variation (%) | 6.0 | |||

| Material | Type of Aggregate | Mean Value (W·m−1·K−1) Transient Method | Coefficient of Variation (%) | Mean Value (W·m−1·K−1) Steady-State Method | Coefficient of Variation (%) | Difference in Mean Values (%) |

|---|---|---|---|---|---|---|

| AC 11 | dolomite | 1.94 | 2.5 | 1.73 | 1.8 | 10.8 |

| AC 16 | limestone | 2.20 | 3.5 | 2.01 | 2.7 | 8.6 |

| C 16/20 | dolomite | 2.64 | 4.9 | 2.31 | 3.8 | 12.5 |

| C 35/45 | granite | 2.18 | 6.0 | 1.97 | 4.2 | 9.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Górszczyk, J.; Malicki, K. Comparative Laboratory Tests of Thermal Conductivity of Road Materials Using Two Measurement Methods. Materials 2025, 18, 1970. https://doi.org/10.3390/ma18091970

Górszczyk J, Malicki K. Comparative Laboratory Tests of Thermal Conductivity of Road Materials Using Two Measurement Methods. Materials. 2025; 18(9):1970. https://doi.org/10.3390/ma18091970

Chicago/Turabian StyleGórszczyk, Jarosław, and Konrad Malicki. 2025. "Comparative Laboratory Tests of Thermal Conductivity of Road Materials Using Two Measurement Methods" Materials 18, no. 9: 1970. https://doi.org/10.3390/ma18091970

APA StyleGórszczyk, J., & Malicki, K. (2025). Comparative Laboratory Tests of Thermal Conductivity of Road Materials Using Two Measurement Methods. Materials, 18(9), 1970. https://doi.org/10.3390/ma18091970