Diffusion Mechanism in Running-Water and CFD-DEM Numerical Simulation of Expandable Particulate Grouting Material

Abstract

1. Introduction

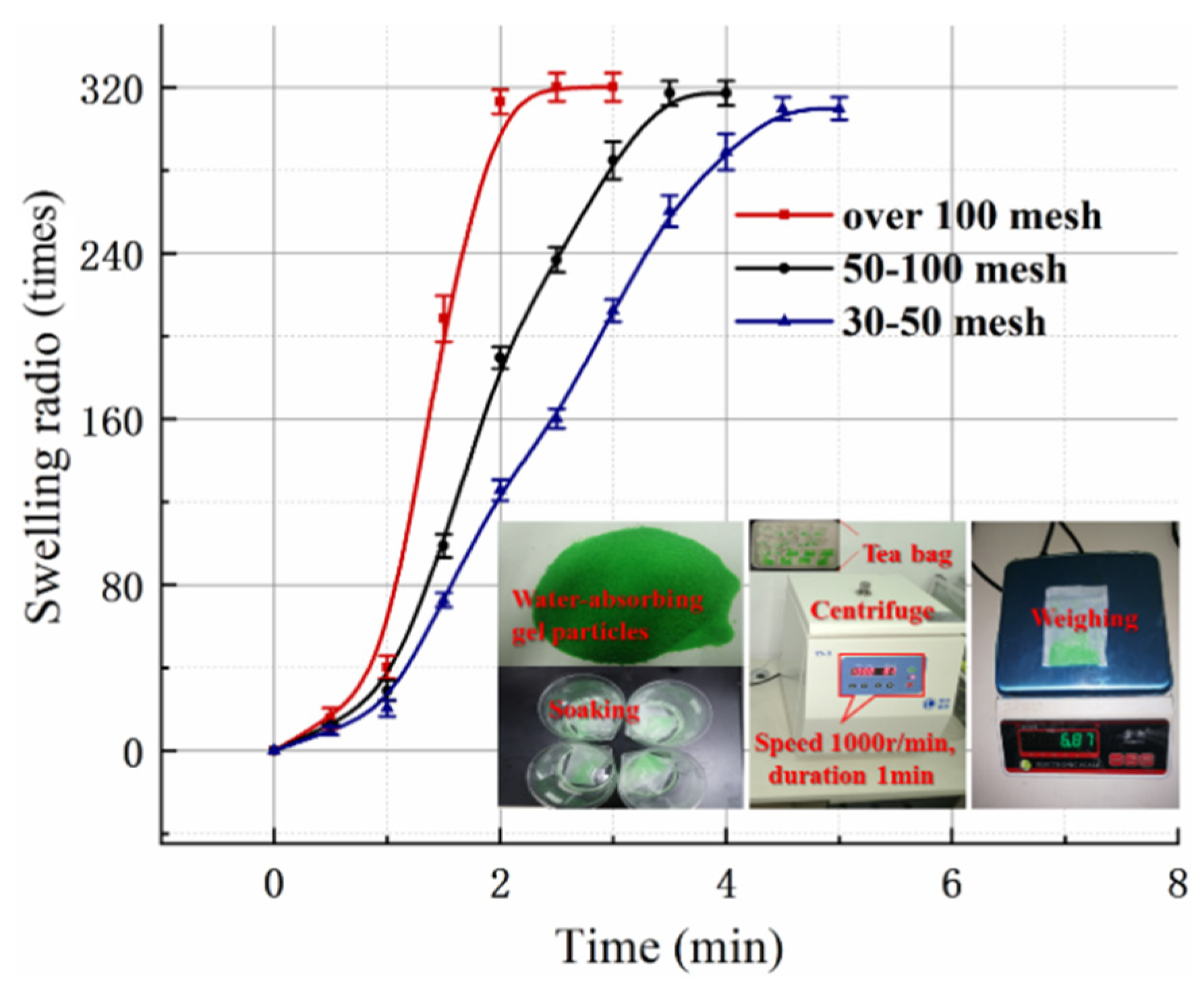

2. Physical and Chemical Properties of Expandable Particles Grouting Material

2.1. Introduction to Expandable Particulate Material

2.2. Material Performance

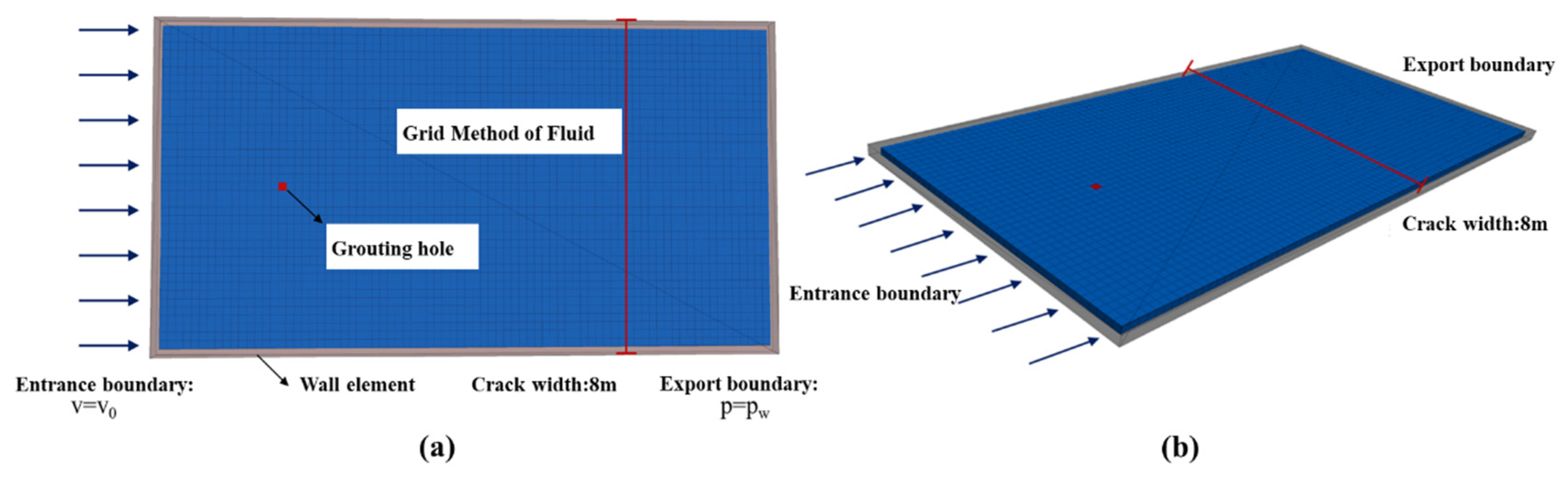

3. CFD-DEM Coupling

3.1. CFD-DEM Coupling Principle

3.1.1. Grid Division and Calculation of Flow Field Information

3.1.2. Calculation Method of Particle-Fluid Interaction

3.2. Calculation Model

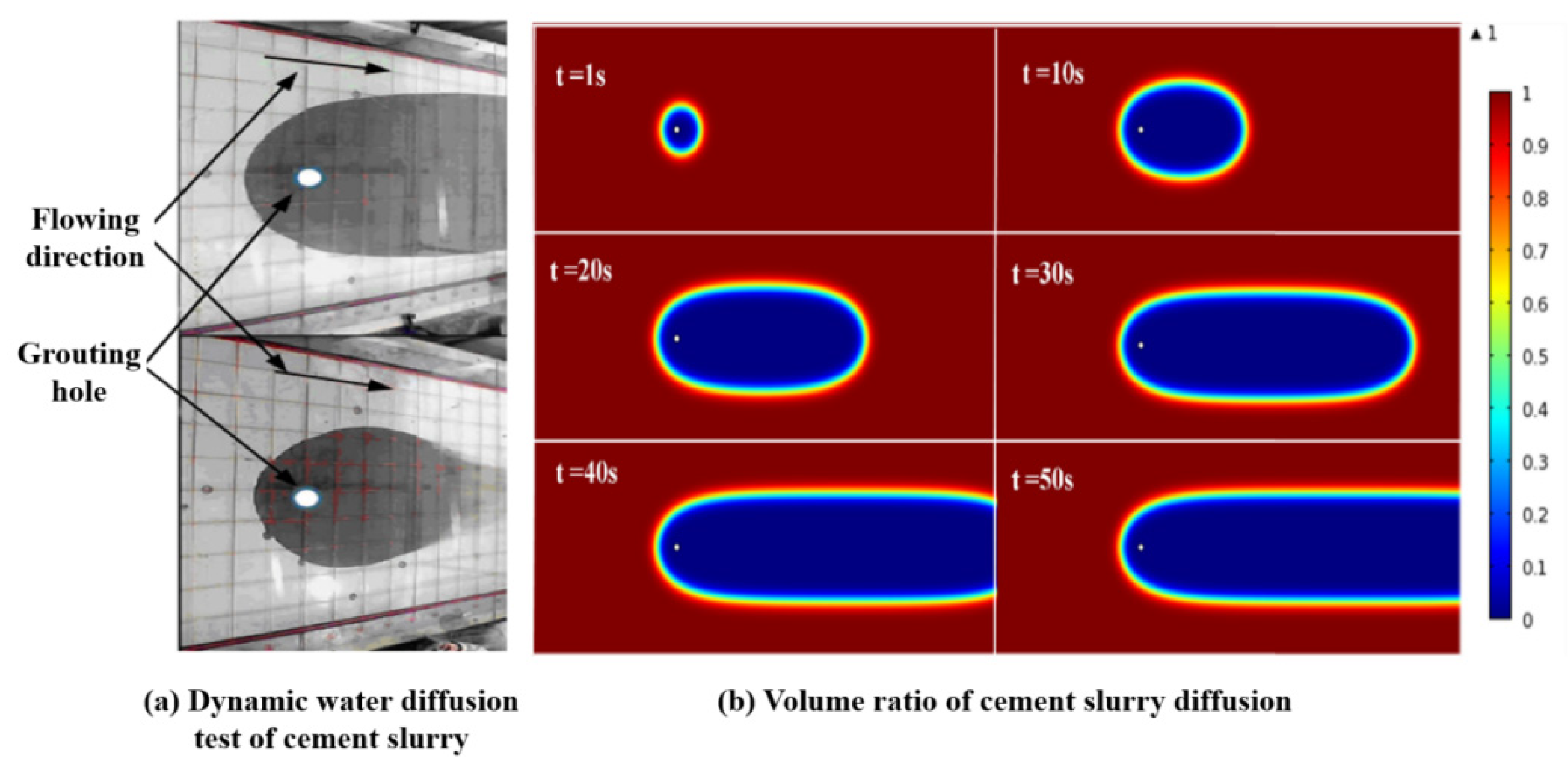

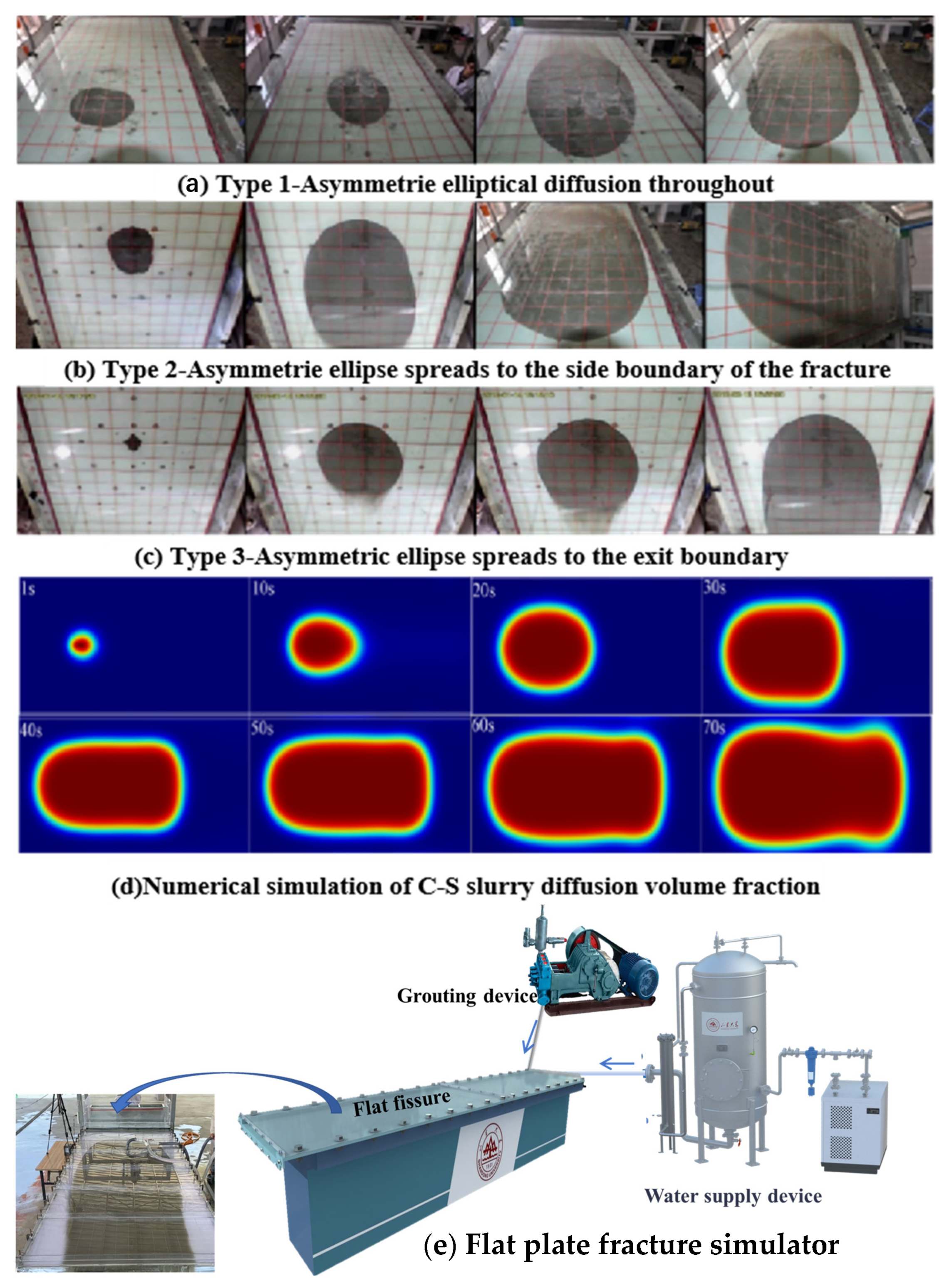

4. Analysis on Slurry Diffusion and Sealing Mechanism of Fracture

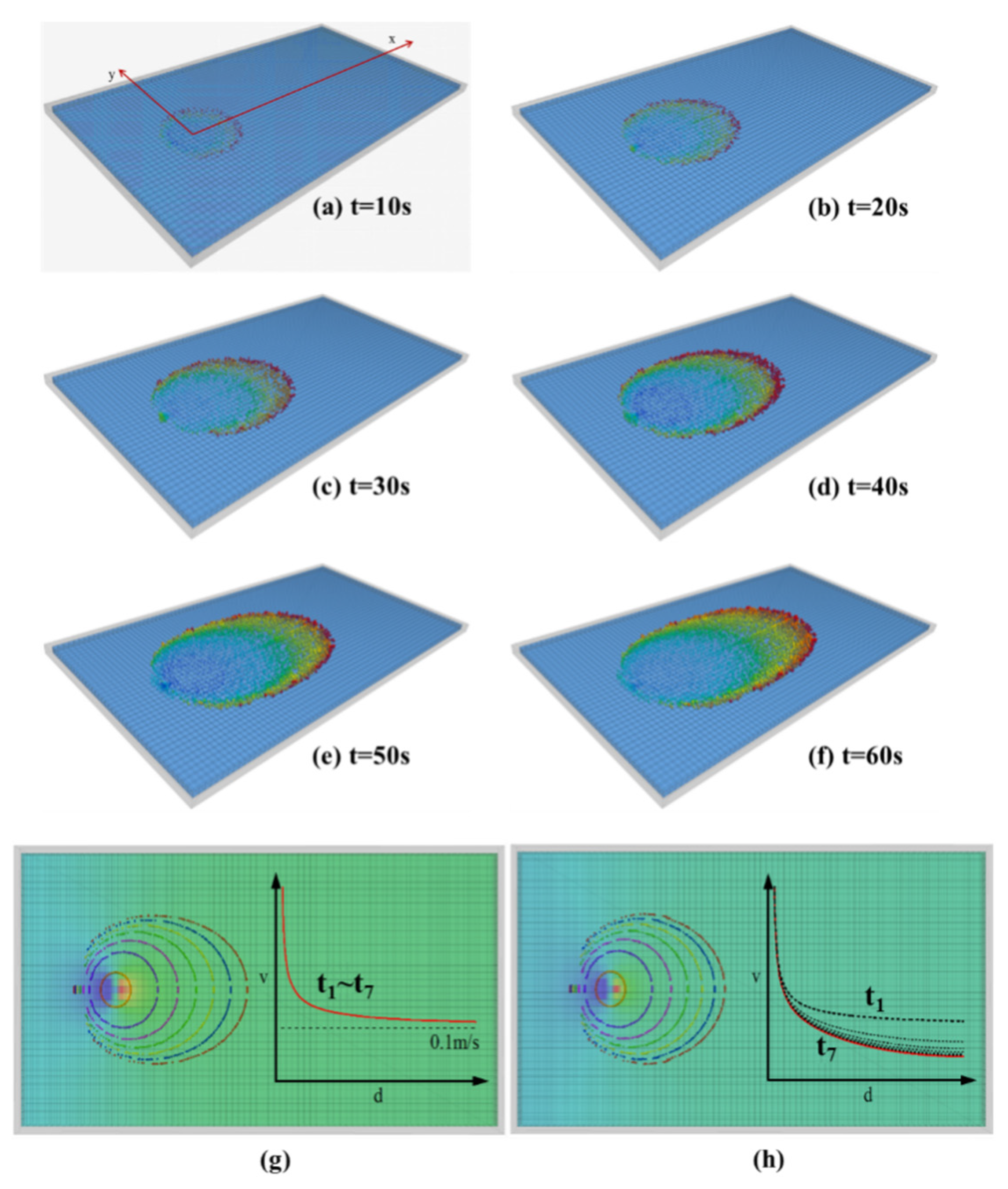

4.1. Diffusion Law of Fissure Grouting in Running Water

4.1.1. Diffusion Morphology of Different Types of Slurry

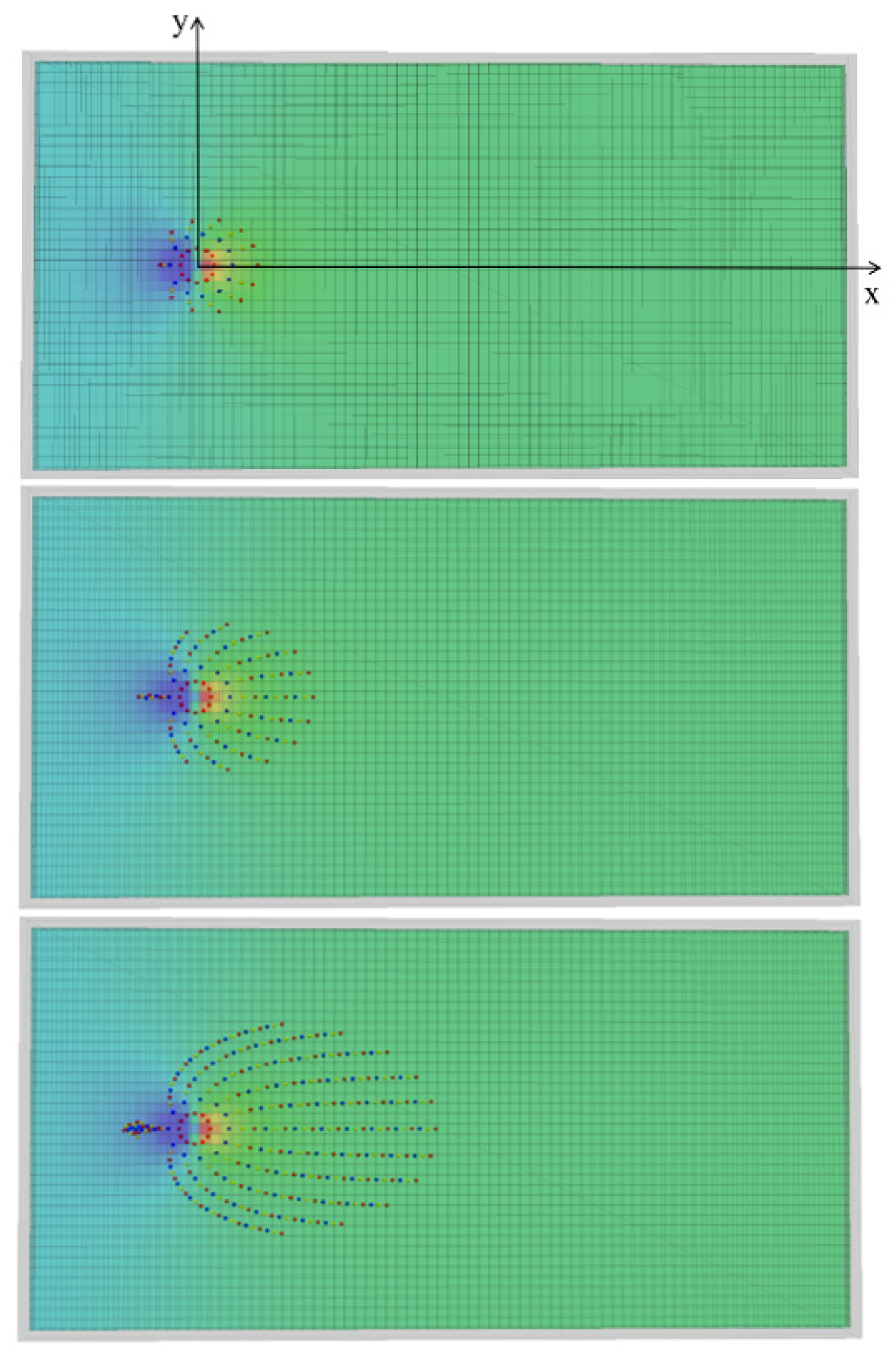

4.1.2. The Effect of Expandable Particles on Fluid Flow Field

4.1.3. The Effect of Expanding Particles on Fluid Drag

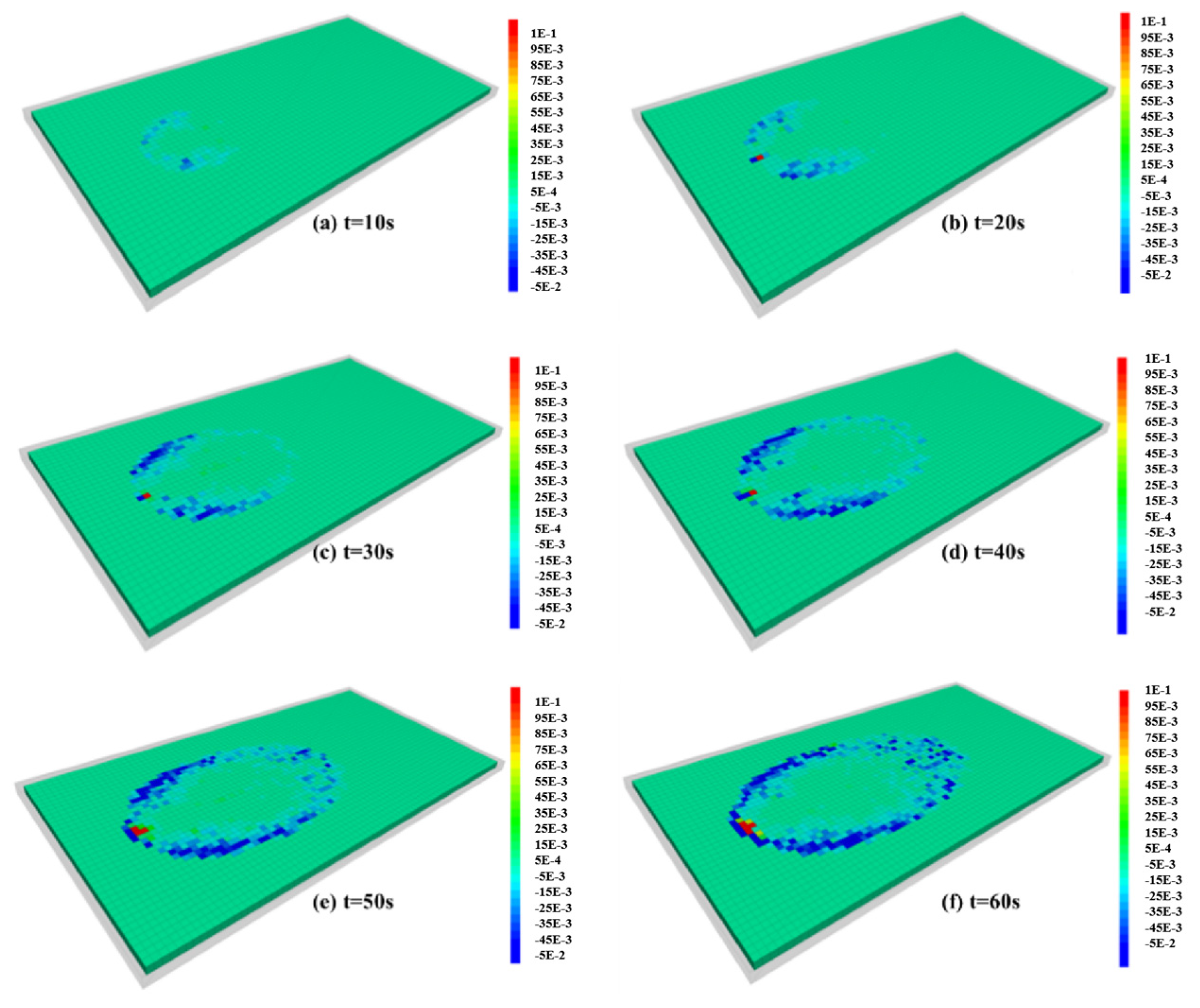

4.2. Plugging Mechanism of Fracture Grouting in Running Water

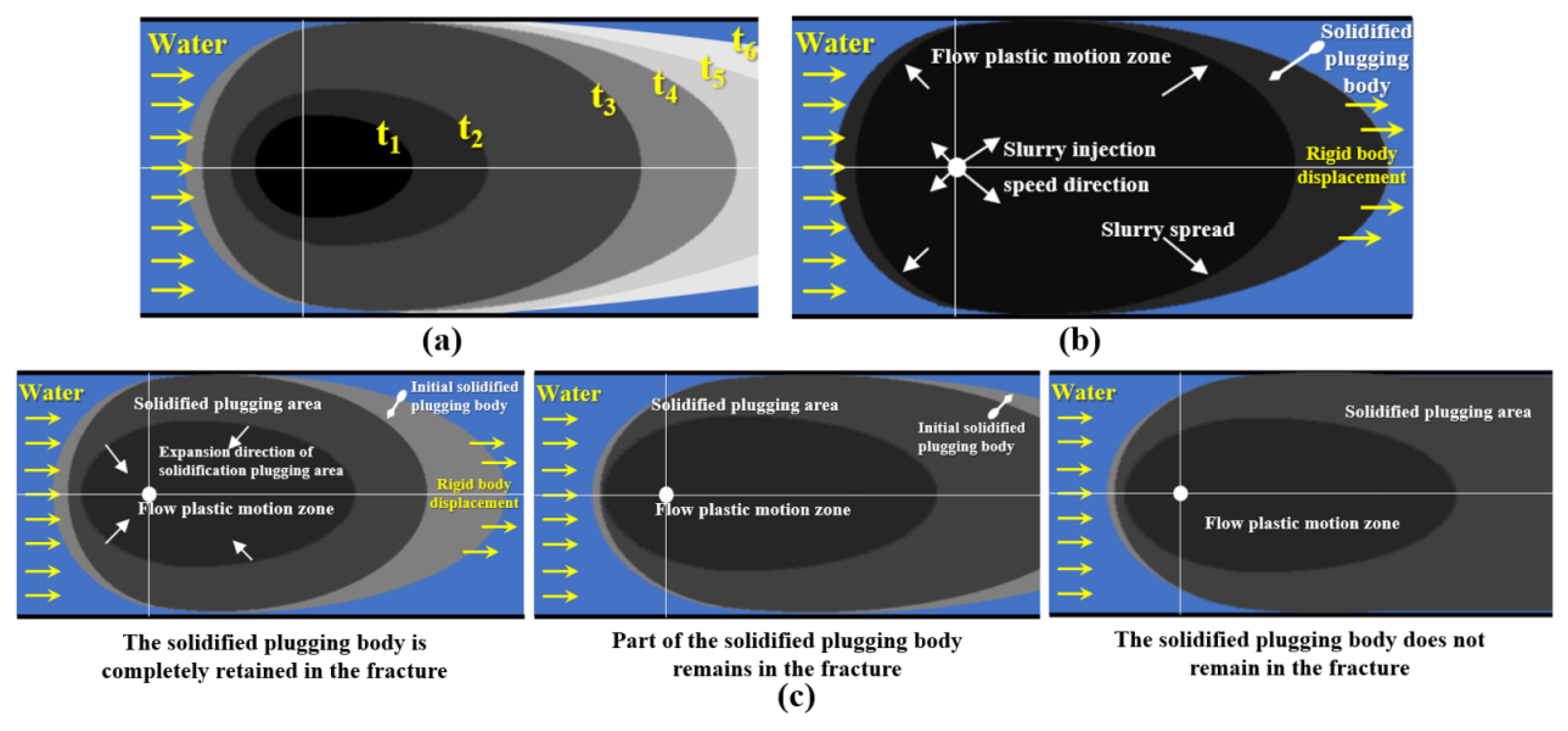

4.2.1. Different Types of Slurry Plugging Mechanisms

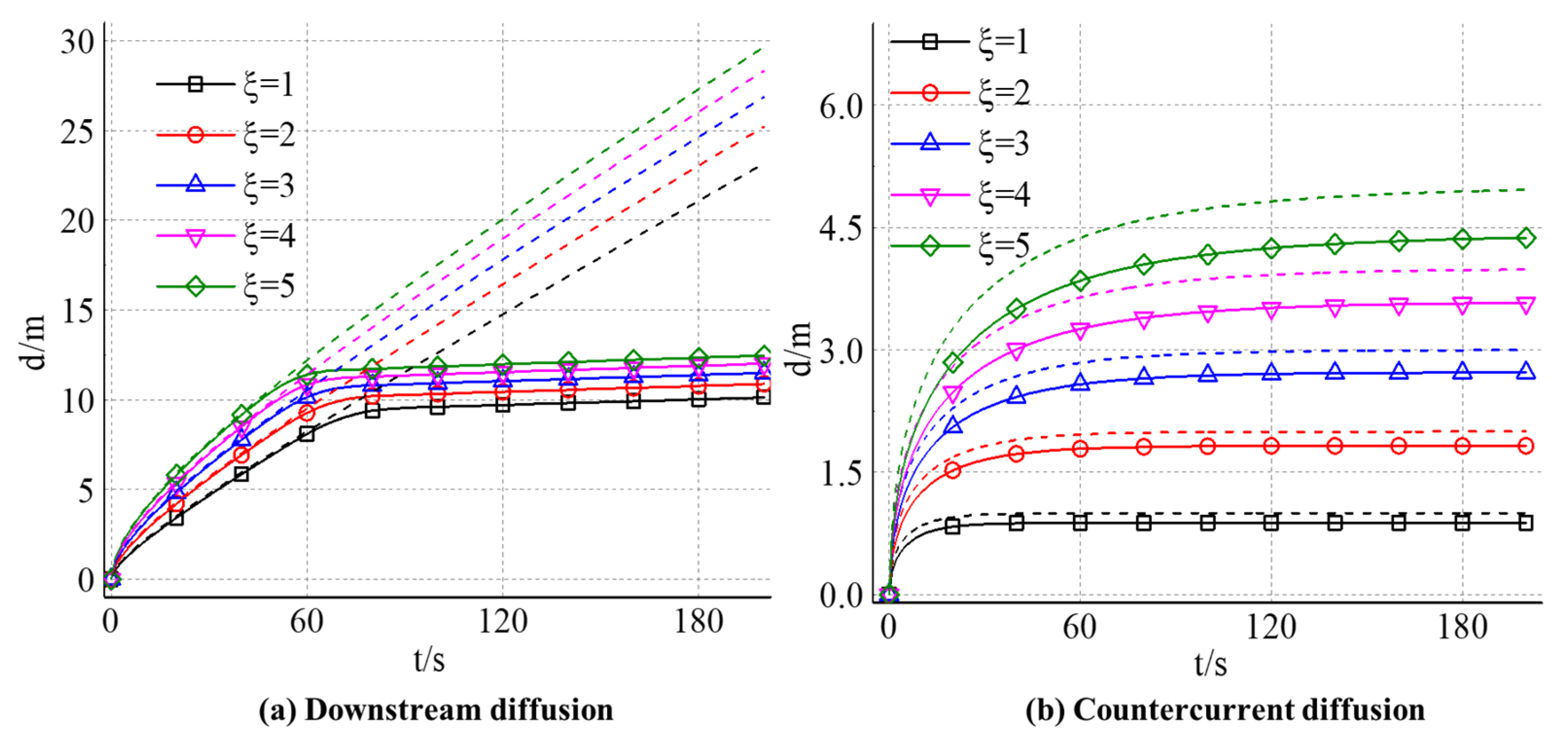

4.2.2. The Effect of Slurry-Water Velocity Ratio on the Diffusion Distance of Expandable Particles

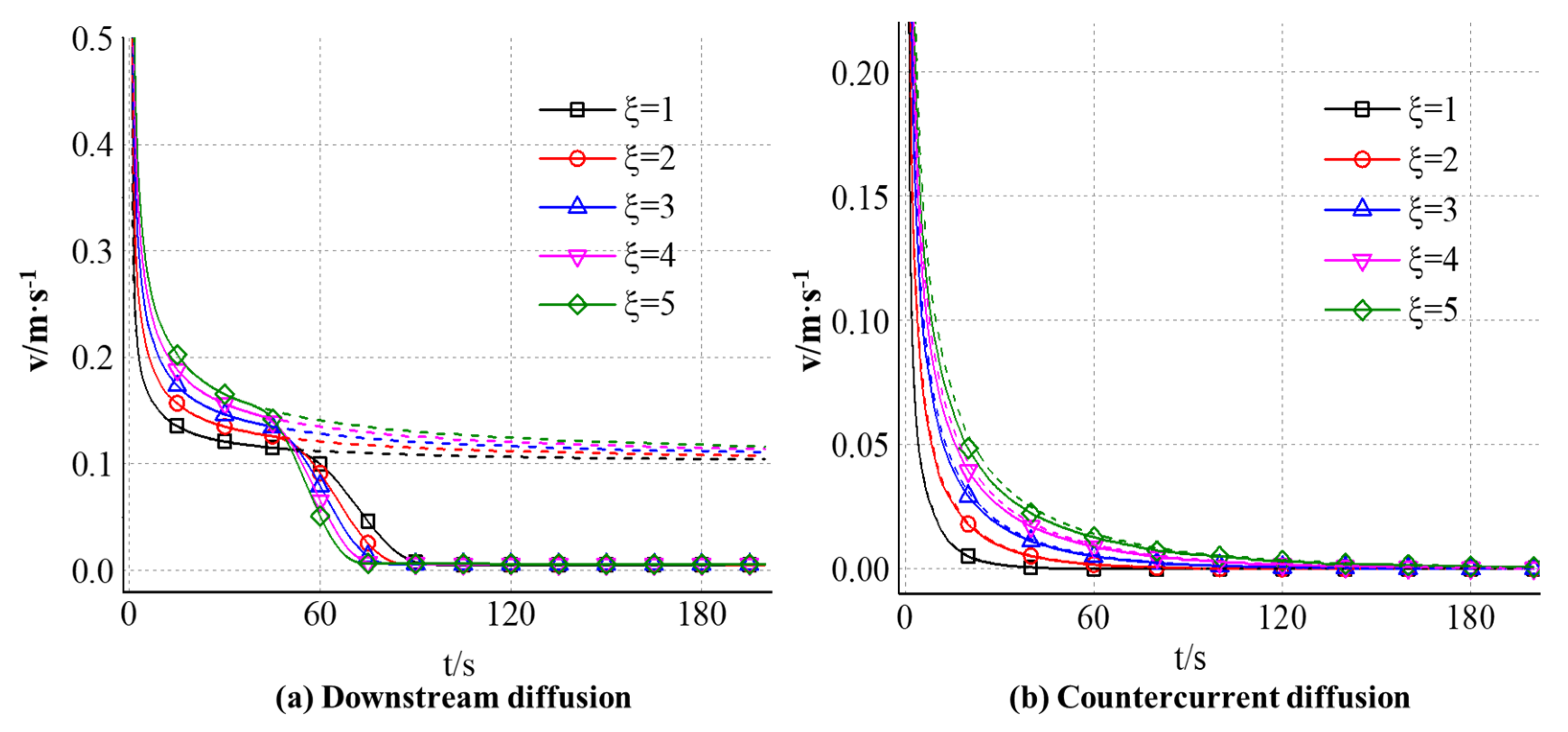

4.2.3. The Effect of Slurry-Water Velocity Ratio on the Diffusion Velocity of Expandable Particles

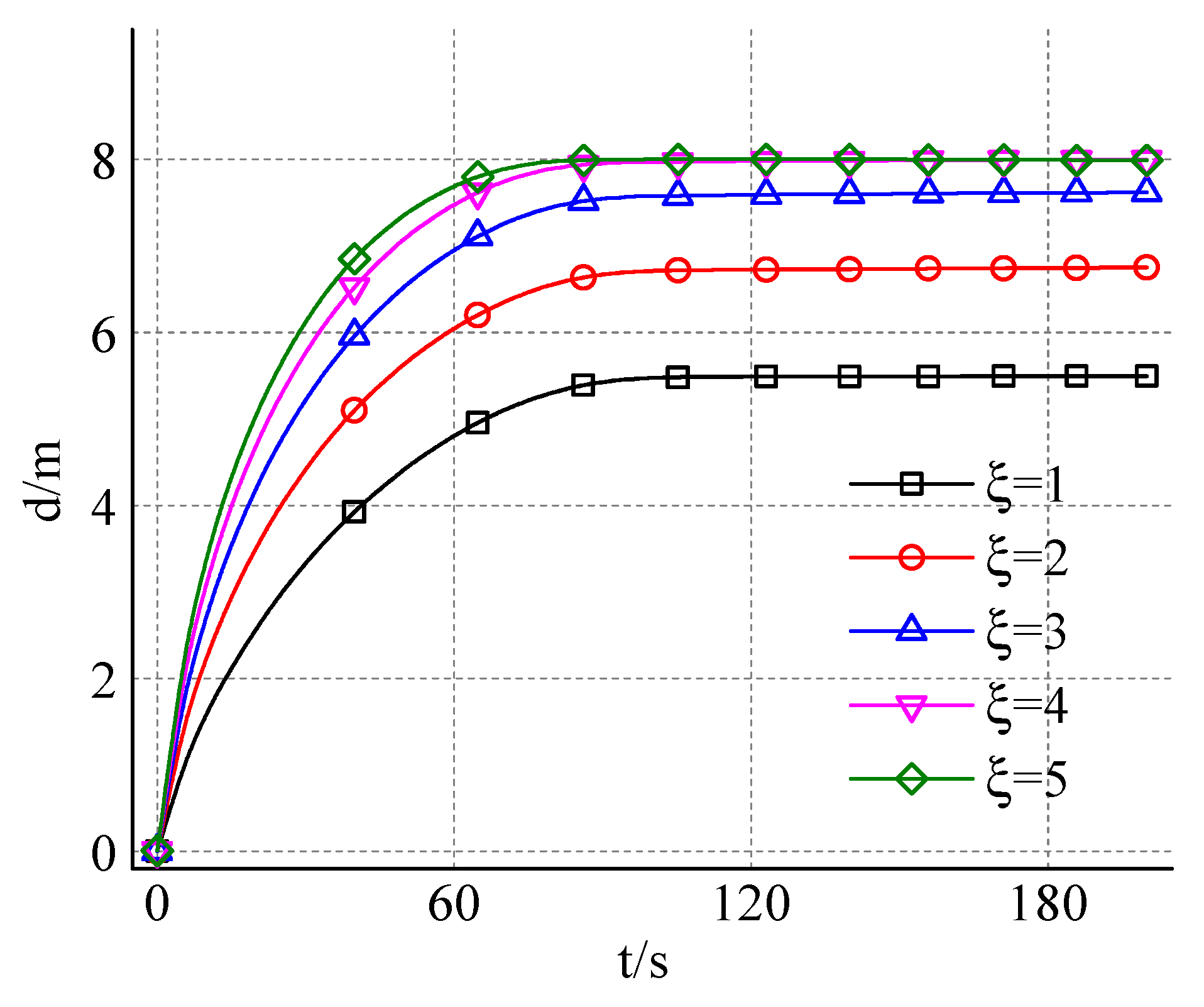

4.2.4. The Effect of Slurry-Water Velocity Ratio on the Opening Degree of Expandable Particles

5. Conclusions

- (1)

- Based on the CFD-DEM method, a numerical model of grouting diffusion in running water of expandable particulate slurry is established. Compared with the calculation method based on continuum theory, the CFD-DEM method can directly reflect the process of gel particle water absorption and expansion and fully consider the interaction between fluid and suspended particles so as to truly reflect the rheological characteristics of expandable particle slurry.

- (2)

- During the grouting process in running water, the cement slurry initially forms an asymmetric ellipse, later becoming elliptical in the counter-water direction. The downstream diffusion range is significantly greater than that of the counter-water diffusion. In the diffusion of cement-sodium silicate slurry, the traces are asymmetric ellipses and different characteristics will be shown by the boundary of the model. For the expandable particulate slurry, the diffusion is approximately elliptical in the fracture with running water. In the counter-water diffusion region, the migration of the gel particles is mainly affected by flow field control, and the attenuation of its speed is mainly caused by a reduction in slurry pressure. In downstream diffusion, the particle is simultaneously influenced by the flow field and its own volume, and its maximum diffusion distance is determined by both. In grouting engineering, adjusting the grout injection rate and the water absorption rate of gel particles can help control the sealing range.

- (3)

- Cement slurry mainly relies on particle deposition to achieve dynamic water sealing, and the work efficiency is relatively low. Cement-sodium silicate slurry has a rapid solidification effect, which is substantially the process of slurry transition from liquid to solid state. The expandable particulate material is mainly based on gel particles that absorb water into the sealing slurry. For expandable particulate materials, if the sealing area is small after grouting, the remaining gel particles will continue to flow and bypass the agglomeration sealing area. At the same time, the original sealing zone expanded particles may also re-flow underwater erosion, eventually resulting in complete loss of the grouting material and not successfully sealing the flow in the fracture. In grouting engineering, the relationship between the diffusion opening degree and the diffusion distance of the slurry is taken, thereby achieving the best grouting sealing effect.

- (4)

- In the actual hydrodynamic grouting process, the water conduction structure in the formation usually has a more complex geometry, which cannot be reduced to a pipeline with a regular contour or a single slab fracture. The diffusion range and plugging effect of the slurry are significantly affected by the spatial morphology of the water conduction structure. Therefore, it is of great significance to construct a more accurate three-dimensional geological model and establish an accurate and efficient grouting diffusion calculation method on this basis for the theory of hydrodynamic grouting plugging.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, X.; Zhong, D.; Ren, B.; Fan, G.; Cui, B. Prediction of curtain grouting efficiency based on ANFIS. Bull. Eng. Geol. Environ. 2019, 78, 281–309. [Google Scholar] [CrossRef]

- Han, C.; Xu, J.; Zhang, W.; Wei, J.; Yang, F.; Yin, H.; Xie, D. Assessment and Grouting of Water Inrush Induced by Shaft-Freezing Holes in the Yingpanhao Coal Mine, Inner Mongolia, China. Mine Water Environ. 2021, 41, 16–29. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhao, J.; Tan, Z.; Zhou, X. Mechanical responses in the construction process of super-large cross-section tunnel: A case study of Gongbei tunnel. Tunn. Undergr. Space Technol. 2021, 115, 104044. [Google Scholar] [CrossRef]

- Li, W.; Yu, L.Y.; Tan, Y.Z.; Wu, L.R.; Qian, J.Y. Mechanical properties and impact behavior of frozen clay: Insights from static mechanical tests, fly-plate tests, and split-Hopkinson pressure bar analysis. Phys. Fluids 2024, 36, 057138. [Google Scholar] [CrossRef]

- Wang, M.; Zhu, Z.; Liu, R.; Li, S.; Zhang, C.; Liu, Y.; Zhang, L.; Bai, J. Influence of extreme high-temperature environment and hydration time on the rheology of cement slurry. Constr. Build. Mater. 2021, 295, 123684. [Google Scholar] [CrossRef]

- Shi, J.; Wang, F.; Zhang, D.; Huang, H. Refined 3D modelling of spatial-temporal distribution of excess pore water pressure induced by large diameter slurry shield tunneling. Comput. Geotech. 2021, 137, 104312. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, B.; Zhong, Y.; Li, X.; Zhang, Y.; Li, S. Damage characteristics and microstructures of low-exothermic polymer grouting materials under F–T cycles. Constr. Build. Mater. 2021, 294, 123390. [Google Scholar] [CrossRef]

- Cui, C.; Guo, C.; Lu, Q.; Wang, F.; Fang, H. Fatigue Performance of Concrete–Polyurethane Composite Materials under Compression. J. Transp. Eng. Part B Pavements 2021, 147, 04021030. [Google Scholar] [CrossRef]

- Li, H.; Liu, J.; Wu, J.; Xu, Z.; Zhang, X.; Zhang, L.; Li, Z. Grouting sealing method of flow-control speed-down in karst pipelines and its engineering application. Tunn. Undergr. Space Technol. 2021, 108, 103695. [Google Scholar] [CrossRef]

- Lu, C.; Zhang, Z.; Shi, C.; Li, N.; Jiao, D.; Yuan, Q. Rheology of alkali-activated materials: A review. Cem. Concr. Compos. 2021, 121, 104061. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Q.; Guo, C.; Xia, Y.; Hao, Y.; Shi, M.; Zhao, P. An Experimental Study on the Reinforcement of Silt with Permeable Polyurethane by Penetration Grouting. Adv. Civ. Eng. 2020, 2020. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, R.; Liu, S.; Zhu, Y.; Wang, S.; Wang, J.; Guan, X. Enhanced toughness of ultra-fine sulphoaluminate cement-based hybrid grouting materials by incorporating in-situ polymerization of acrylamide. Constr. Build. Mater. 2021, 292, 123421. [Google Scholar] [CrossRef]

- Li, Z.Q.; Nie, L.C.; Xue, Y.G.; Li, W.; Fan, K.R. Model Testing on the Processes, Characteristics, and Mechanism of Water Inrush Induced by Karst Caves Ahead and Alongside a Tunnel. Rock Mech. Rock Eng. 2025. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, I.M.; Jang, J.H.; Choi, H. Groutability of cement-based grout with consideration of viscosity and filtration phenomenon. Int. J. Numer. Anal. Methods Geomech. 2009, 33, 1771–1797. [Google Scholar] [CrossRef]

- Pantuso, D.; Jiang, L.; Shankar, S.; Skokov, S. A FEM/VOF hybrid formulation for underfill encapsulation modeling. Comput. Struct. 2003, 81, 879–885. [Google Scholar] [CrossRef]

- Mashayek, F.; Ashgriz, N. A hybrid finite-element–volume-of-fluid method for simulating free surface flows and interfaces. Int. J. Numer. Methods Fluids 1995, 20, 1363–1380. [Google Scholar] [CrossRef]

- Gantois, R.; Cantarel, A.; Dusserre, G.; Félices, J.N.; Schmidt, F. Numerical Simulation of Resin Transfer Molding Using BEM and Level Set Method. Int. J. Mater. Form. 2010, 3, 635–638. [Google Scholar] [CrossRef]

- Chen, T.-l.; Zhang, L.-y.; Zhang, D.-l. An FEM/VOF hybrid formulation for fracture grouting modelling. Comput. Geotech. 2014, 58, 14–27. [Google Scholar] [CrossRef]

- Funehag, J.; Gustafson, G. Design of grouting with silica sol in hard rock—New methods for calculation of penetration length, Part I. Tunn. Undergr. Space Technol. 2008, 23, 1–8. [Google Scholar] [CrossRef]

- Li, S.; Qi, Y.; Li, Z.; Li, H.; Zhang, J. A novel treatment method and construction technology of the pipeline gushing water geohazards in karst region. Tunn. Undergr. Space Technol. 2021, 113, 103939. [Google Scholar] [CrossRef]

- Li, S.; Pan, D.; Xu, Z.; Lin, P.; Zhang, Y. Numerical simulation of dynamic water grouting using quick-setting slurry in rock fracture: The Sequential Diffusion and Solidification (SDS) method. Comput. Geotech. 2020, 122, 103497. [Google Scholar] [CrossRef]

- Chen, H.; Ding, W.; Wei, H.; Saxén, H.; Yu, Y. A Coupled CFD-DEM Study on the Effect of Basset Force Aimed at the Motion of a Single Bubble. Materials 2022, 15, 5461. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.; Dou, Y.; Zhang, N.; Li, Z.; Wang, Z. A New Method for Predicting Erosion Damage of Suddenly Contracted Pipe Impacted by Particle Cluster via CFD-DEM. Materials 2018, 11, 1858. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, Y.; Li, W.; Cao, J.; Huang, J.; Zhu, L.; Guan, Z. Numerical Analysis of the Effect of Retaining Ring Structure on the Chemical Mechanical Polishing Abrasive Motion State. Materials 2023, 16, 62. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Li, S.; Liu, R.; Pei, Y.; Zhang, C.; Liu, Y.; Xu, F.; Feng, X.; Chen, M. Evaluation of a Superabsorbent Polymer for Plugging Karst Pipe Type Water Inrushes. Mine Water Environ. 2021, 41, 252–264. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Q.S.; Wang, X.C.; Yu, L.Y.; Li, Z.Q. Synergistic effect of particle size, carboxymethyl starch and Na2CO3 on rheological and filtration property of bentonite-based material. Case Stud. Constr. Mat. 2024, 21, e03537. [Google Scholar] [CrossRef]

- Zhang, Q.S.; Zhang, L.Z.; Liu, R.T.; Han, W.W.; Zhu, M.T.; Li, X.H.; Zheng, D.Z.; Xu, X.H. Laboratory experimental study of cement-silicate slurry diffusion law of crack grouting with dynamic water. Rock Soil Mech. 2015, 36, 2159–2168. [Google Scholar] [CrossRef]

- Li, S.; Liu, R.; Zhang, Q.; Zhang, X. Protection against water or mud inrush in tunnels by grouting: A review. J. Rock Mech. Geotech. Eng. 2016, 8, 753–766. [Google Scholar] [CrossRef]

- Pal, R. Rheological constitutive equation for bubbly suspensions. Ind. Eng. Chem. Res. 2004, 43, 5372–5379. [Google Scholar] [CrossRef]

- Brouwers, H.J.H. Viscosity of a concentrated suspension of rigid monosized particles. Phys. Rev. E 2010, 81, 051402. [Google Scholar] [CrossRef]

| Fluid Properties | Wall Properties | Particle Properties | |||||

|---|---|---|---|---|---|---|---|

| Name | Density | Viscosity | Stiffness | Stiffness | Density | Particle size | Expansion rate |

| Unit | kg/m3 | Pa·s | Pa | Pa | kg/m3 | mm | s−1 |

| Value | 1000 | 1 × 10−3 | 1 × 109 | 1 × 103 | 1000 | 1 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Ma, C.; Zhao, C.; Zheng, Z.; Li, W.; Liu, R.; Li, X.; Wang, H. Diffusion Mechanism in Running-Water and CFD-DEM Numerical Simulation of Expandable Particulate Grouting Material. Materials 2025, 18, 1681. https://doi.org/10.3390/ma18071681

Zhang Z, Ma C, Zhao C, Zheng Z, Li W, Liu R, Li X, Wang H. Diffusion Mechanism in Running-Water and CFD-DEM Numerical Simulation of Expandable Particulate Grouting Material. Materials. 2025; 18(7):1681. https://doi.org/10.3390/ma18071681

Chicago/Turabian StyleZhang, Zhipeng, Chenyang Ma, Chen Zhao, Zhuo Zheng, Wei Li, Rentai Liu, Xiuhao Li, and Hongyan Wang. 2025. "Diffusion Mechanism in Running-Water and CFD-DEM Numerical Simulation of Expandable Particulate Grouting Material" Materials 18, no. 7: 1681. https://doi.org/10.3390/ma18071681

APA StyleZhang, Z., Ma, C., Zhao, C., Zheng, Z., Li, W., Liu, R., Li, X., & Wang, H. (2025). Diffusion Mechanism in Running-Water and CFD-DEM Numerical Simulation of Expandable Particulate Grouting Material. Materials, 18(7), 1681. https://doi.org/10.3390/ma18071681