Role of Minor Ta Substitution on Thermal Behavior and Soft Magnetic Properties of Co-Fe-Mo-Si-B Metallic Glass Ribbon

Highlights

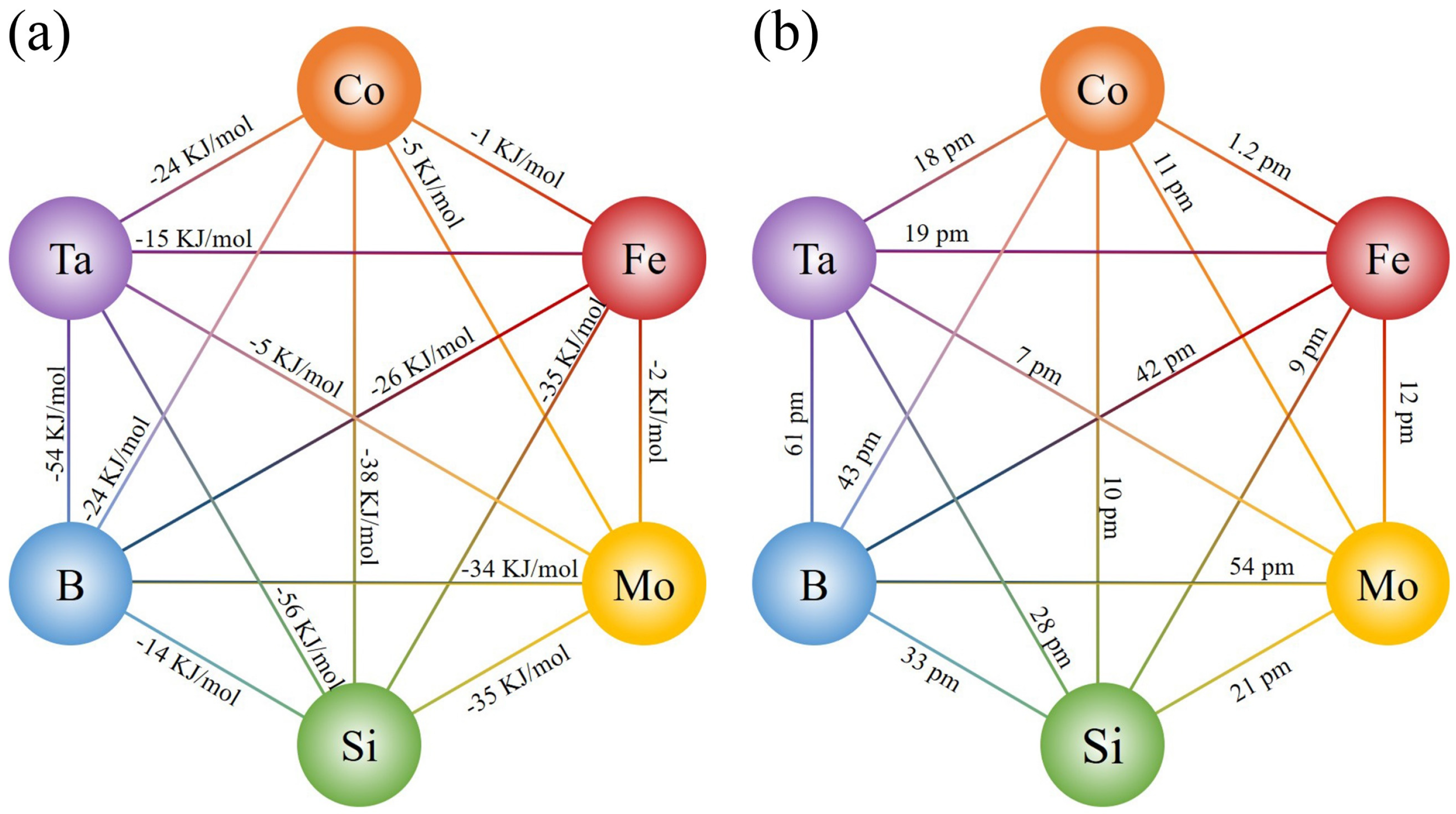

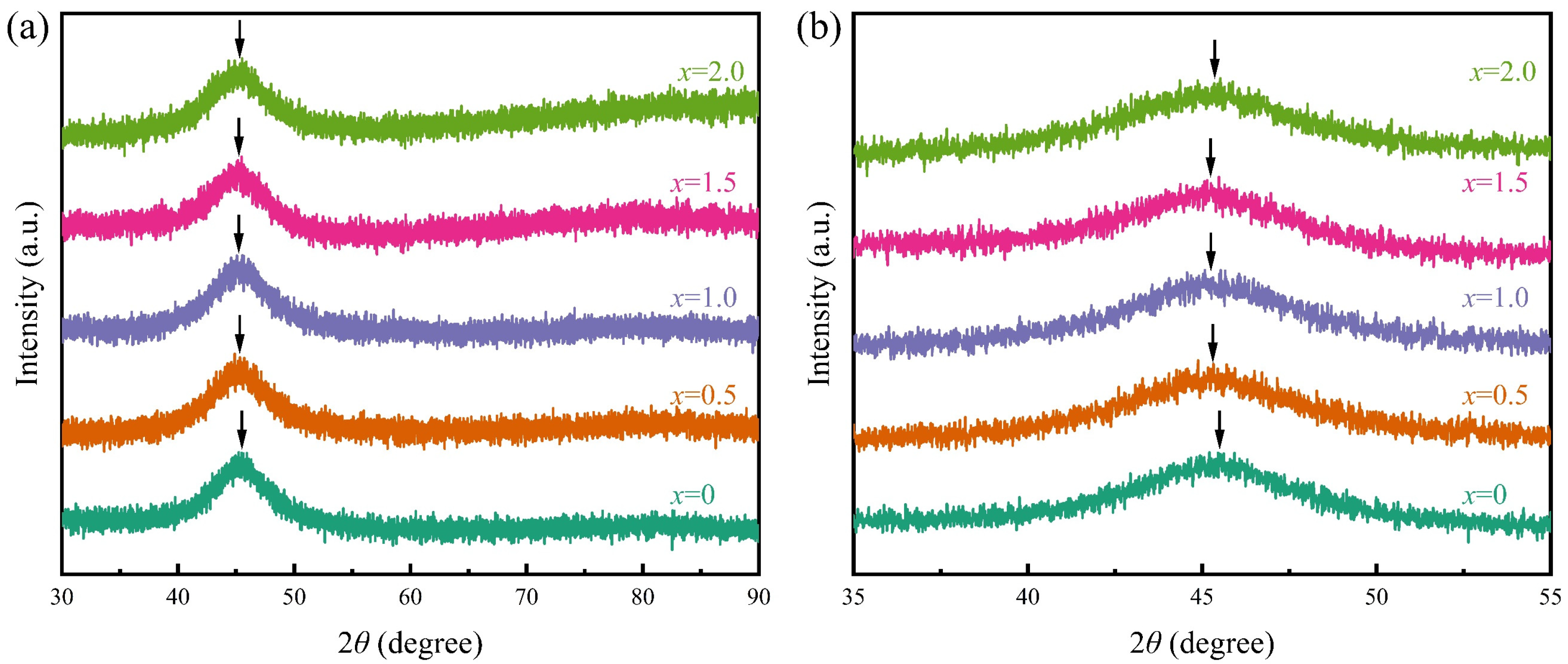

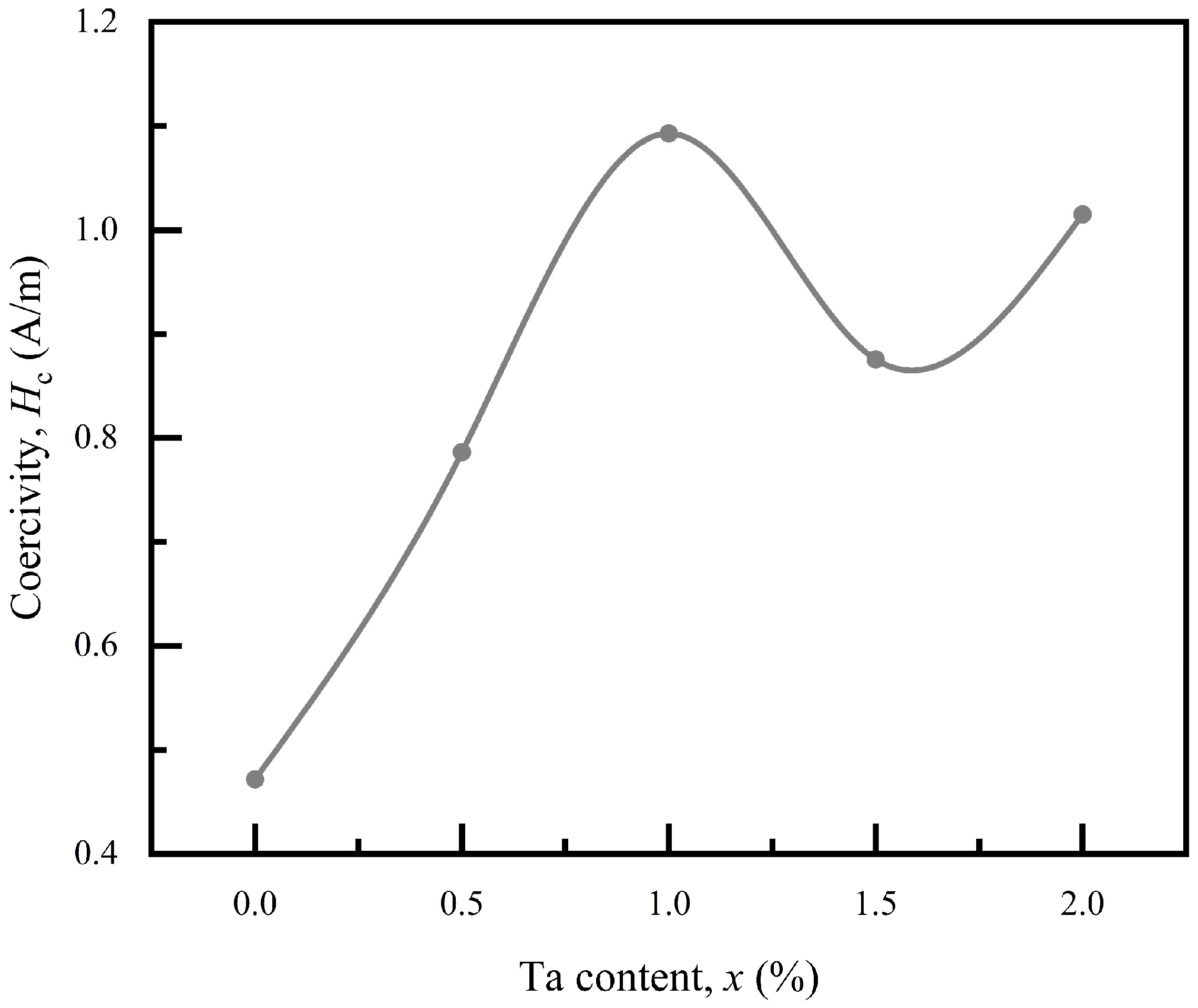

- The impact of Ta replacing Mo on the thermal and magnetic properties of Co-Fe-Mo-Si-B was studied.

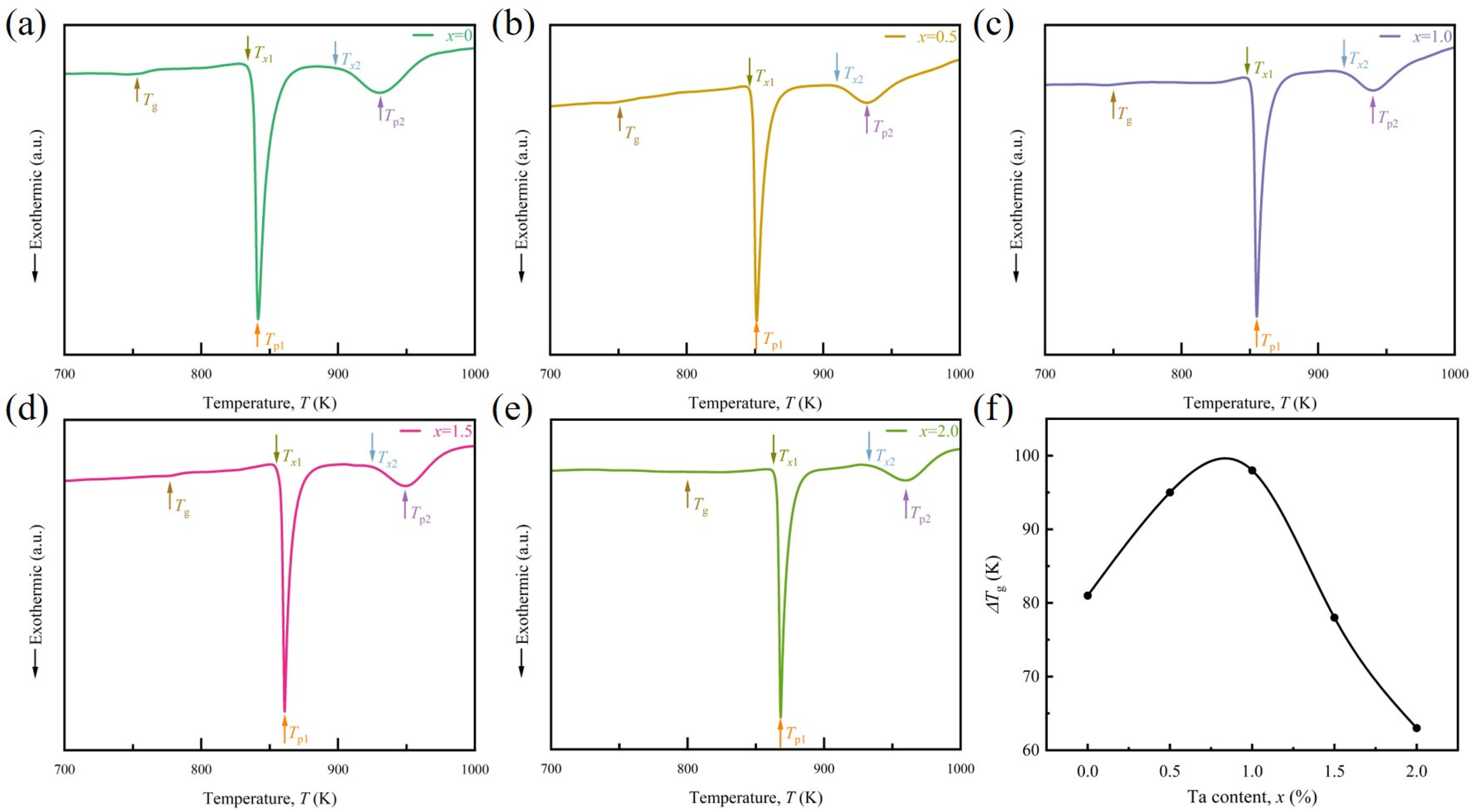

- The Co66Fe4Mo2-xTaxSi16B12 MGs have the best GFA with the ΔTx = 98 K when x = 1.0.

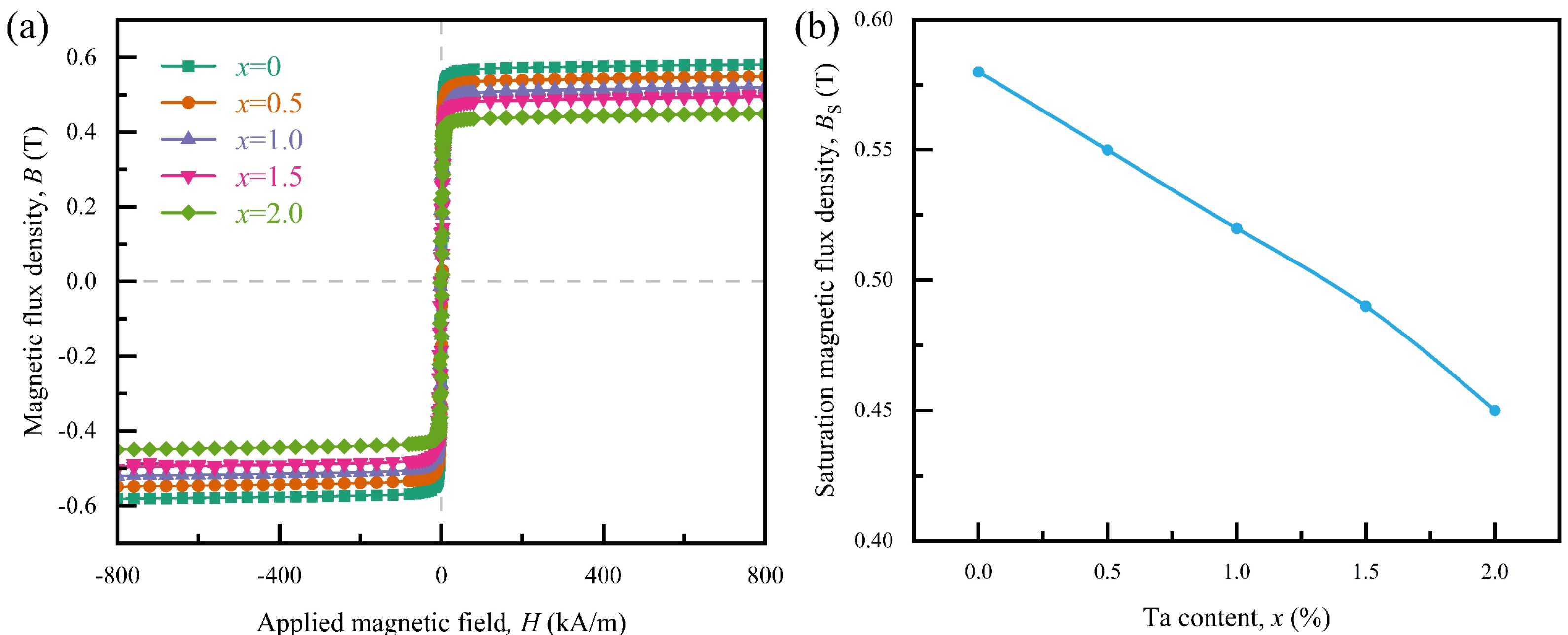

- The Co66Fe4Mo2-xTaxSi16B12 MGs have soft magnetic performance with Hc less than 1.1 A/m.

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Klement, W.; Willens, R.; Duwez, P. Non-crystalline structure in solidified gold–silicon alloys. Nature 1960, 187, 869–870. [Google Scholar] [CrossRef]

- Li, X.X.; Wang, L.Q.; Lu, Y. Three-dimensional disordered alloy metamaterials: A new platform of structure-function integration. Mater. Futures 2025, 4, 012001. [Google Scholar] [CrossRef]

- Cao, M.; Li, W.Y.; Li, T.X.; Zhu, F.L.; Wang, X. Polymetallic amorphous materials: Research progress in synthetic strategies and electrocatalytic applications. J. Mater. Chem. A 2024, 12, 15541–15557. [Google Scholar] [CrossRef]

- Shen, P.P.; Zhang, S.Y.; Ma, D.Y.; Xing, B.Z.; Chen, H.; Zhang, M.S.; Wei, H.Q.; Li, B.; Miao, X.Y.; Xie, M.; et al. High-Shielding Coefficient and Low-Noise of Cobalt-Based Metallic Glass Magnetic Shielding Cylinder. IEEE Trans. Instrum. Meas. 2025, 74, 1004710. [Google Scholar] [CrossRef]

- Taghvaei, A.H.; Eckert, J. Development and characterization of new Co-Fe-Hf-B bulk metallic glass with high thermal stability and superior soft magnetic performance. J. Alloys Compd. 2020, 823, 153890. [Google Scholar] [CrossRef]

- de Lucena, F.A.; Kiminami, C.S.; Afonso CR, M. New compositions of Fe-Co-Nb-B-Y BMG with wide supercooled liquid range, over 100 K. J. Mater. Res. Technol. -JmrT 2020, 9, 9174–9181. [Google Scholar] [CrossRef]

- Wang, F.; Inoue, A.; Kong, F.L.; Zhu, S.L.; Xie, C.X.; Zhao, C.L.; Botta, W.J.; Chang, C.T. Formation and ultrahigh mechanical strength of multicomponent Co-based bulk glassy alloys. J. Mater. Res. Technol. JmrT 2023, 26, 1050–1061. [Google Scholar] [CrossRef]

- Qu, R.T.; Maass, R.; Liu, Z.Q.; Tönnies, D.; Tian, L.; Ritchie, R.O.; Zhang, Z.F.; Volkert, C.A. Flaw-insensitive fracture of a micrometer-sized brittle metallic glass. Acta Mater. 2021, 218, 117219. [Google Scholar] [CrossRef]

- Amiya, K.; Urata, A.; Nishiyama, N.; Inoue, A. Magnetic properties of Co-Fe-B-Si-Nb bulk glassy alloy with zero magnetostriction. J. Appl. Phys. 2007, 101, 09N112. [Google Scholar] [CrossRef]

- Jia, S.K.; Jiang, Y.H.; Chen, S.W.; Han, X.J. Enhancing glass forming ability and magnetic properties of Co-Fe-Si-B metallic glasses by similar element substitution: Experimental and theoretical investigations. Comput. Mater. Sci. 2022, 213, 111639. [Google Scholar] [CrossRef]

- Lin, C.Y.; Tien, H.Y.; Chin, T.S. Soft magnetic ternary iron-boron-based bulk metallic glasses. Appl. Phys. Lett. 2005, 86, 162501. [Google Scholar] [CrossRef]

- Liang, X.Y.; Li, Y.H.; Bao, F.; Zhu, Z.W.; Zhang, H.F.; Zhang, W. Roles of Y and Fe contents on glass-forming ability, thermal stability, and magnetic properties of Co-based Co-Fe-Y-B bulk metallic glasses. Intermetallics 2021, 132, 107135. [Google Scholar] [CrossRef]

- Herzer, G. Modern soft magnets: Amorphous and nanocrystalline materials. Acta Mater. 2013, 61, 718–734. [Google Scholar] [CrossRef]

- Sai, T.; Wang, P.F.; Gu, X.Y.; Xu, X.P.; Sun, J.J.; Ye, J. Low magnetic noise, easy-to-process polystyrene-grafted amorphous alloy composites for extremely-weak magnetic measurement at ultra-low frequency. Mater. Today Adv. 2024, 22, 100487. [Google Scholar] [CrossRef]

- Sharifikolouei, E.; Koziel, T.; Bala, P.; Zywczak, A.; Gondek, L.; Rashidi, R.; Fracasso, M.; Gerbaldo, R.; Ghigo, G.; Gozzelino, L.; et al. Cobalt-Based Metallic Glass Microfibers for Flexible Electromagnetic Shielding and Soft Magnetic Properties. Adv. Electron. Mater. 2024, 10, 2300490. [Google Scholar] [CrossRef]

- Lu, J.; Li, Y.H.; Ma, S.; Li, W.P.; Bao, F.; Zhu, Z.W.; Zeng, Q.S.; Zhang, H.F.; Yao, M.; Zhang, W. Novel Soft Magnetic Co-Based Ternary Co-Er-B Bulk Metallic Glasses. Acta Metall. Sin. Engl. Lett. 2024, 37, 1633–1642. [Google Scholar] [CrossRef]

- Ren, J.P.; Li, Y.H.; Liang, X.Y.; Kato, H.; Zhang, W. Role of Fe substitution for Co on thermal stability and glass-forming ability of soft magnetic Co-based Co-Fe-B-P-C metallic glasses. Intermetallics 2022, 147, 107598. [Google Scholar] [CrossRef]

- Khatun, H.; Nath, S.D.; Sikder, S.S. Kinetics of crystallization and soft magnetic properties of Co72Fe8B10Si10 amorphous alloys. Phys. B Condens. Matter 2024, 691, 416300. [Google Scholar] [CrossRef]

- Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- Lu, Z.P.; Liu, C.T. Role of minor alloying additions in formation of bulk metallic glasses: A review. J. Mater. Sci. 2004, 39, 3965–3974. [Google Scholar] [CrossRef]

- Inoue, A.; Takeuchi, A. Recent development and application products of bulk glassy alloys. Acta Mater. 2011, 59, 2243–2267. [Google Scholar] [CrossRef]

- Wang, W.H. Roles of minor additions in formation and properties of bulk metallic glasses. Prog. Mater. Sci. 2007, 52, 540–596. [Google Scholar] [CrossRef]

- Kim, J.T.; Hong, S.H.; Kim, Y.S.; Park, H.J.; Maity, T.; Chawake, N.M.; Prashanth, K.G.; Park, J.M.; Song, K.K.; Wang, W.M.; et al. Co-Cr-Mo-C-B metallic glasses with wide supercooled liquid region obtained by systematic adjustment of the metalloid ratio. J. Non-Cryst. Solids 2019, 505, 310–319. [Google Scholar] [CrossRef]

- Shen, B.L.; Zhou, Y.J.; Chang, C.T.; Inoue, A. Effect of B to Si concentration ratio on glass-forming ability and soft-magnetic properties in (Co0.705Fe0.045B0.25-xSix)96Nb4 glassy alloys. J. Appl. Phys. 2007, 101, 09N101. [Google Scholar] [CrossRef]

- Fan, X.D.; Li, M.; Zhang, T.; Yuan, C.C.; Shen, B.L. Effect of magnetic field annealing on soft magnetic properties of Co71Fe2Si14-xB9+xMn4 amorphous alloys with low permeability. Aip Adv. 2018, 8, 056105. [Google Scholar] [CrossRef]

- Neamtu, B.V.; Chicinas, H.F.; Marinca, T.F.; Isnard, O.; Chicinas, I. Preparation and characterisation of Co-Fe-Ni-M-Si-B (M = Zr, Ti) amorphous powders by wet mechanical alloying. J. Alloys Compd. 2016, 673, 80–85. [Google Scholar] [CrossRef]

- Inoue, A.; Shen, B.L.; Koshiba, H.; Kato, H.; Yavari, A.R. Ultra-high strength above 5000 MPa and soft magnetic properties of Co-Fe-Ta-B bulk glassy alloys. Acta Mater. 2004, 52, 1631–1637. [Google Scholar] [CrossRef]

- Nickjeh, H.S.; Taghvaei, A.H.; Ramasamy, P.; Eckert, J. Phase transformation, thermal behavior and magnetic study of new Co80-xTaxSi5C15 (x=0, 5) glassy/nanocrystalline alloys prepared by mechanical alloying. J. Alloys Compd. 2020, 843, 155913. [Google Scholar] [CrossRef]

- Taghvaei, A.H.; Bednarcik, J.; Eckert, J. Atomic structure and thermal behavior of (Co0.65,Fe0.35)72Ta8B20 metallic glass with excellent soft magnetic properties. Intermetallics 2016, 69, 21–27. [Google Scholar] [CrossRef]

- Inoue, A. Bulk amorphous alloys with soft and hard magnetic properties. Mater. Sci. Eng. a-Struct. Mater. Prop. Microstruct. Process. 1997, 226, 357–363. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Velasco, M.A.; Almeida, L.; Suárez, R.G.; Zamora, J.; Betancourt, I.; Gil-Monsalve, J.; Arnache, O. Comparative study of the effects of Si and Ge on the magnetic and permeability properties of FeCoNiBM (M = Si, Ge) amorphous ribbons. J. Alloys Compd. 2025, 1020, 179367. [Google Scholar] [CrossRef]

- Taghvaei, A.H.; Farajollahi, R.; Bednarcík, J.; Eckert, J.; Pahlevani, M. Atomic structure, thermal stability and isothermal crystallization kinetics of novel Co-based metallic glasses with excellent soft magnetic properties. J. Alloys Compd. 2023, 963, 171271. [Google Scholar] [CrossRef]

- Li, X.S.; Zhou, J.; Shen, L.Q.; Sun, B.A.; Bai, H.Y.; Wang, W.H. Exceptionally High Saturation Magnetic Flux Density and Ultralow Coercivity via an Amorphous-Nanocrystalline Transitional Microstructure in an FeCo-Based Alloy. Adv. Mater. 2022, 35, 2205863. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Inoue, A.; Han, Y.; Kong, F.L.; Zhu, S.L.; Shalaan, E.; Al-Marzouki, F.; Obaid, A. Excellent soft magnetic Fe-Co-B-based amorphous alloys with extremely high saturation magnetization above 1.85 T and low coercivity below 3 A/m. J. Alloys Compd. 2017, 711, 132–142. [Google Scholar] [CrossRef]

- Fan, Y.Z.; Zhang, S.; Miao, J.K.; Zhang, X.H.; Chen, C.; Zhang, W.W.; Wei, R.; Wang, T.; Li, F.S. Extremely high Bs (Fe1-xCox)86Ni1B13 amorphous soft magnetic alloys with good bending ductility. Intermetallics 2020, 127, 106959. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, R.R.; Zhou, H.T. A comprehensive study of microstructures and soft magnetic properties of amorphous Co66Fe4Mo2Si16B12 tape wound core. J. Magn. Magn. Mater. 2020, 493, 165729. [Google Scholar] [CrossRef]

- Bordin, G.; Buttino, G.; Cecchetti, A.; Poppi, M. Nanocrystallization of ferromagnetic Co-rich amorphous alloys and magnetic softening. J. Phys. D Appl. Phys. 1997, 30, 2163. [Google Scholar] [CrossRef]

- Flohrer, S.; Schäfer, R.; Polak, C.; Herzer, G. Interplay of uniform and random anisotropy in nanocrystalline soft magnetic alloys. Acta Mater. 2005, 53, 2937–2942. [Google Scholar] [CrossRef]

- Sabolek, S.; Babic, E.; Posedel, D.; Susak, M. The influence of surface domains on magnetization of very soft magnetic ribbons. Phys. Status Solidi A Appl. Mater. Sci. 2005, 202, 1161–1165. [Google Scholar] [CrossRef]

- Flohrer, S.; Herzer, G. Random and uniform anisotropy in soft magnetic nanocrystalline alloys (invited). J. Magn. Magn. Mater. 2010, 322, 1511–1514. [Google Scholar] [CrossRef]

- Zheng, H.; Zhu, L.; Jiang, S.S.; Wang, Y.G.; Liu, S.N.; Lan, S.; Chen, F.G. Role of Ni and Co in tailoring magnetic and mechanical properties of Fe84Si2B13P1 metallic glass. J. Alloys Compd. 2020, 816, 152549. [Google Scholar] [CrossRef]

- Sheng, W.W.; Qiu, Z.G.; Zheng, Z.G.; Zeng, D.C. Thermal behavior, microstructure and magnetic properties of (FexNiyCoz)80B10Si2Cu1Zr7 alloys. J. Alloys Compd. 2021, 855, 157436. [Google Scholar] [CrossRef]

| Ta Content x | Tg (K) | Tx1 (K) | Tp1 (K) | Tx2 (K) | Tp2 (K) | ΔTx (K) |

|---|---|---|---|---|---|---|

| 0 | 753 | 834 | 841 | 898 | 931 | 81 |

| 0.5 | 751 | 846 | 851 | 910 | 932 | 95 |

| 1.0 | 750 | 848 | 855 | 919 | 940 | 98 |

| 1.5 | 777 | 855 | 860 | 925 | 949 | 78 |

| 2.0 | 800 | 864 | 868 | 933 | 960 | 63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, P.; Gao, Y.; Zhang, S.; Chen, H.; Wang, P.; Xue, Y.; Zhou, H.; Ma, D.; Lu, J. Role of Minor Ta Substitution on Thermal Behavior and Soft Magnetic Properties of Co-Fe-Mo-Si-B Metallic Glass Ribbon. Materials 2025, 18, 1828. https://doi.org/10.3390/ma18081828

Shen P, Gao Y, Zhang S, Chen H, Wang P, Xue Y, Zhou H, Ma D, Lu J. Role of Minor Ta Substitution on Thermal Behavior and Soft Magnetic Properties of Co-Fe-Mo-Si-B Metallic Glass Ribbon. Materials. 2025; 18(8):1828. https://doi.org/10.3390/ma18081828

Chicago/Turabian StyleShen, Peipei, Yanan Gao, Shuyan Zhang, Hua Chen, Pengfei Wang, Yangzhi Xue, Hongbo Zhou, Danyue Ma, and Jixi Lu. 2025. "Role of Minor Ta Substitution on Thermal Behavior and Soft Magnetic Properties of Co-Fe-Mo-Si-B Metallic Glass Ribbon" Materials 18, no. 8: 1828. https://doi.org/10.3390/ma18081828

APA StyleShen, P., Gao, Y., Zhang, S., Chen, H., Wang, P., Xue, Y., Zhou, H., Ma, D., & Lu, J. (2025). Role of Minor Ta Substitution on Thermal Behavior and Soft Magnetic Properties of Co-Fe-Mo-Si-B Metallic Glass Ribbon. Materials, 18(8), 1828. https://doi.org/10.3390/ma18081828