Effect of Multi-Directional Forging on Microstructure and Mechanical Properties of Dual-Phase Mg-8Li-3Al-0.3Si Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

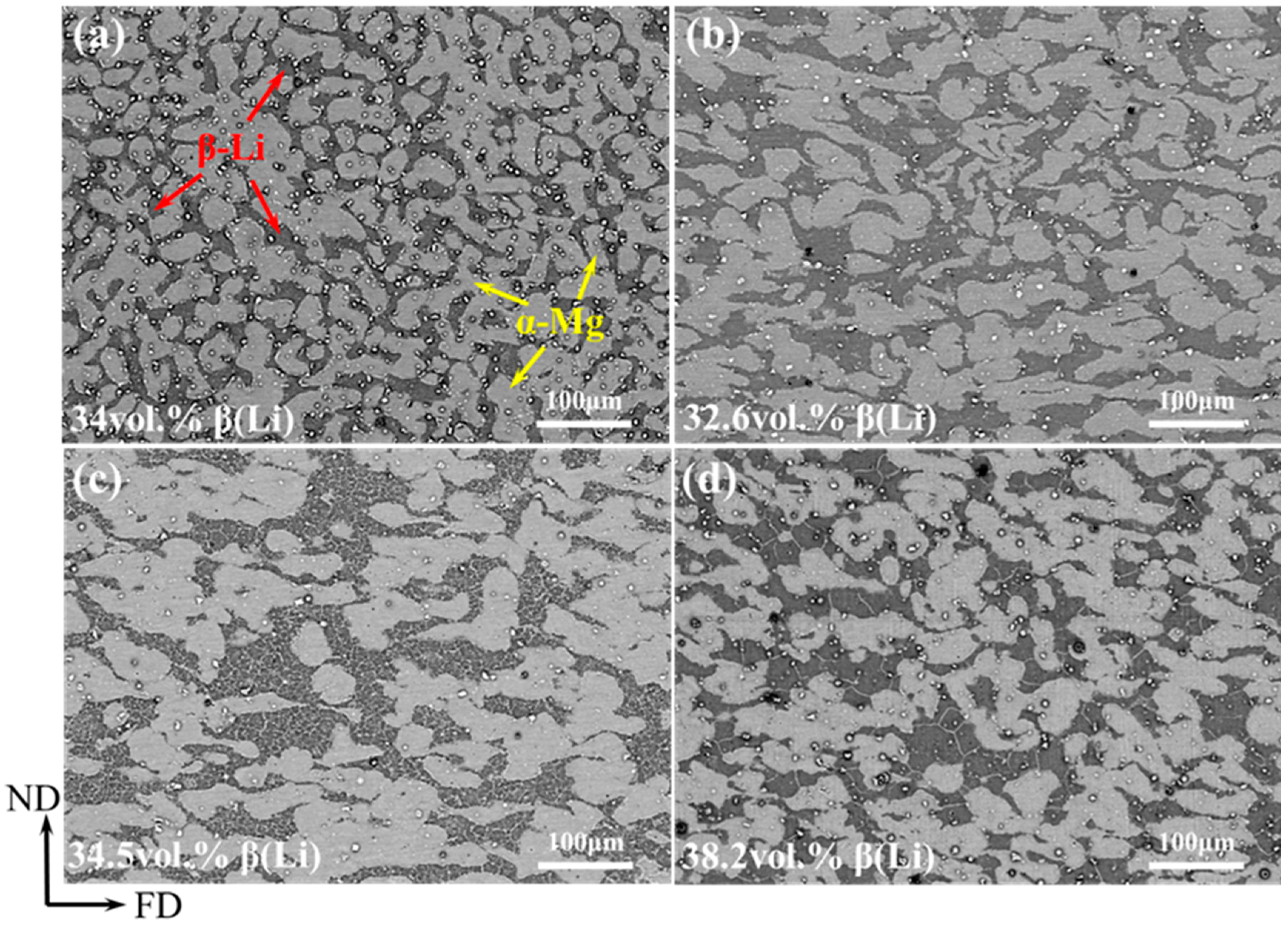

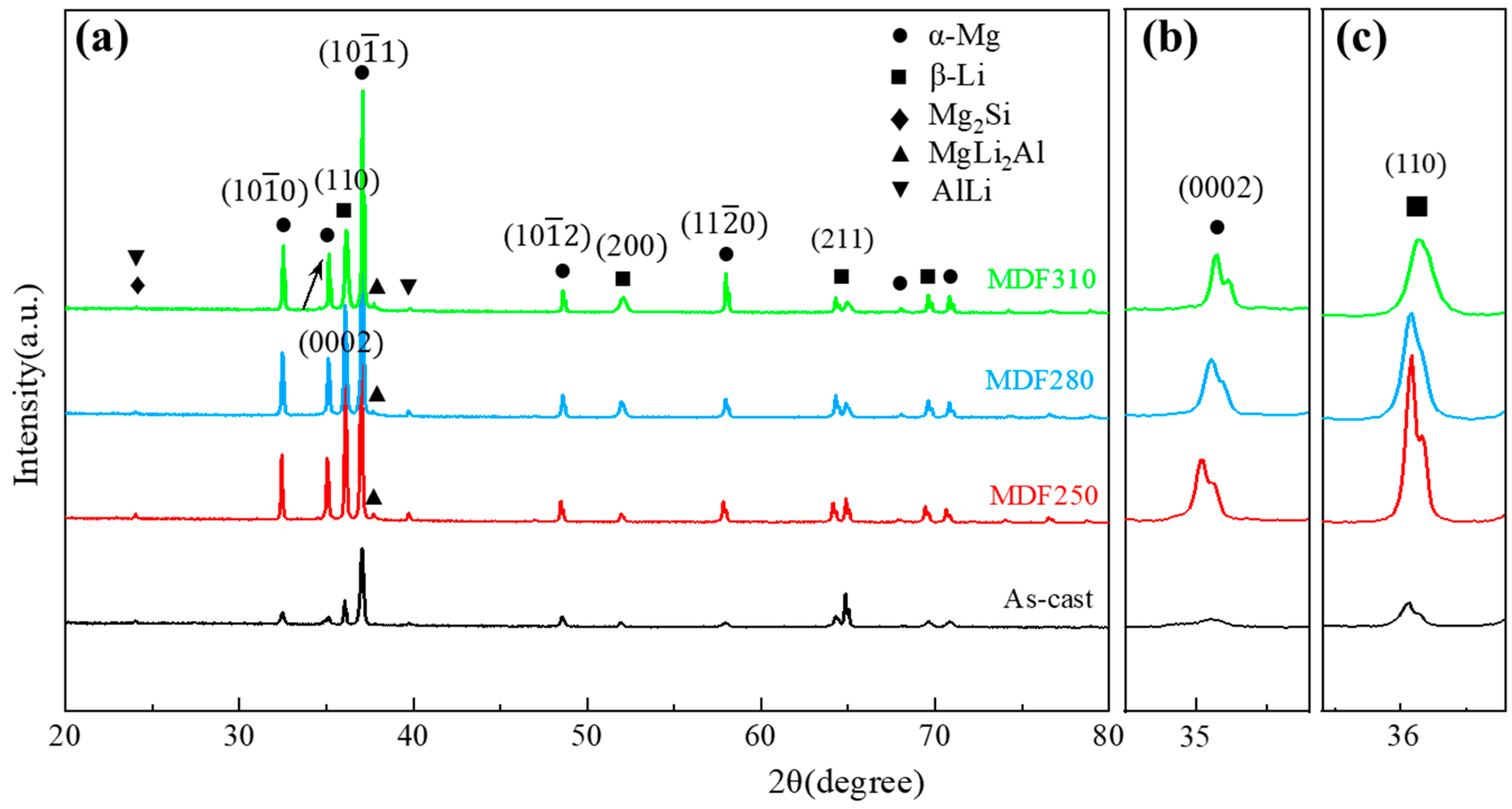

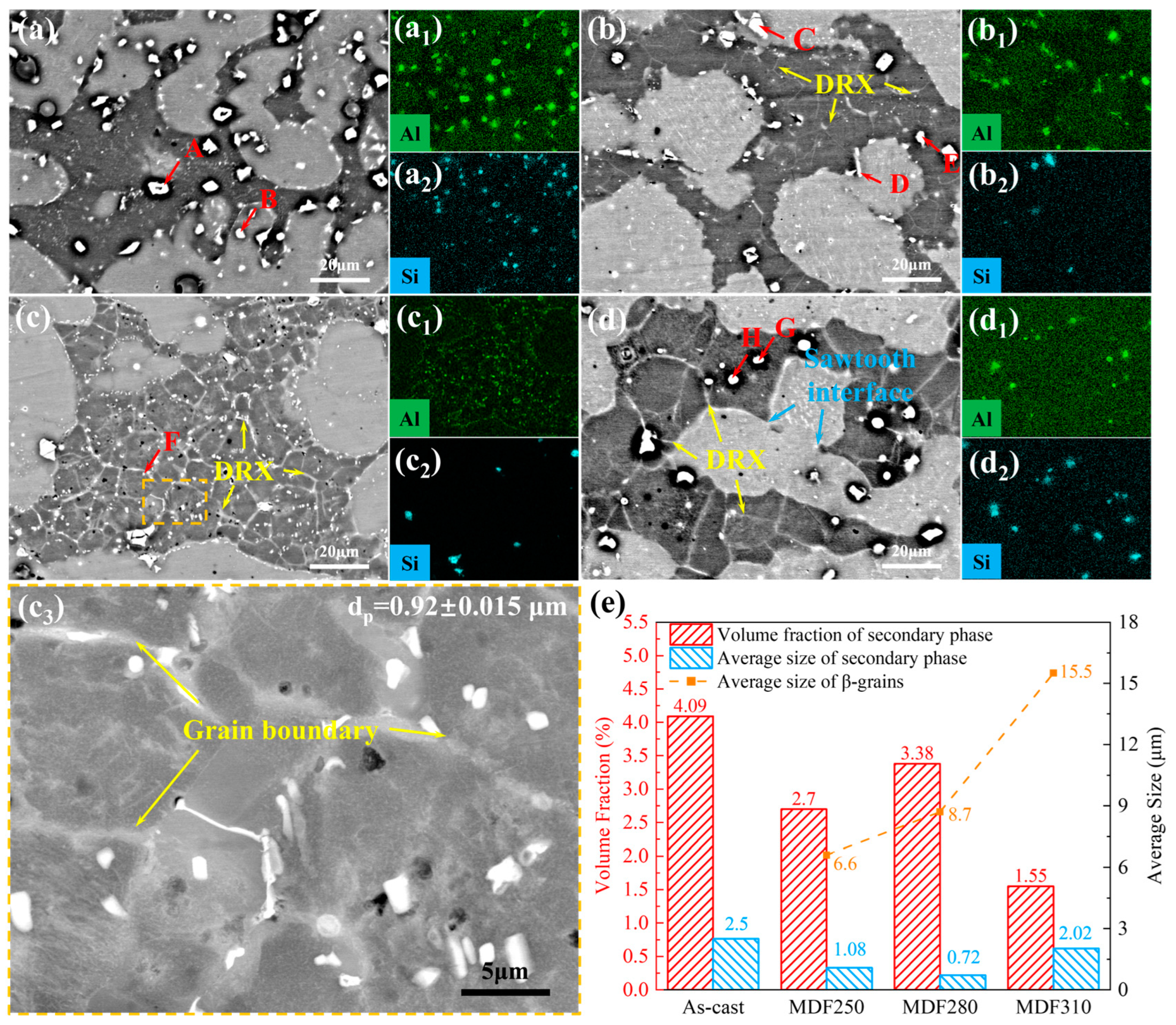

3.1. Microstructure of LA83-0.3Si Alloy

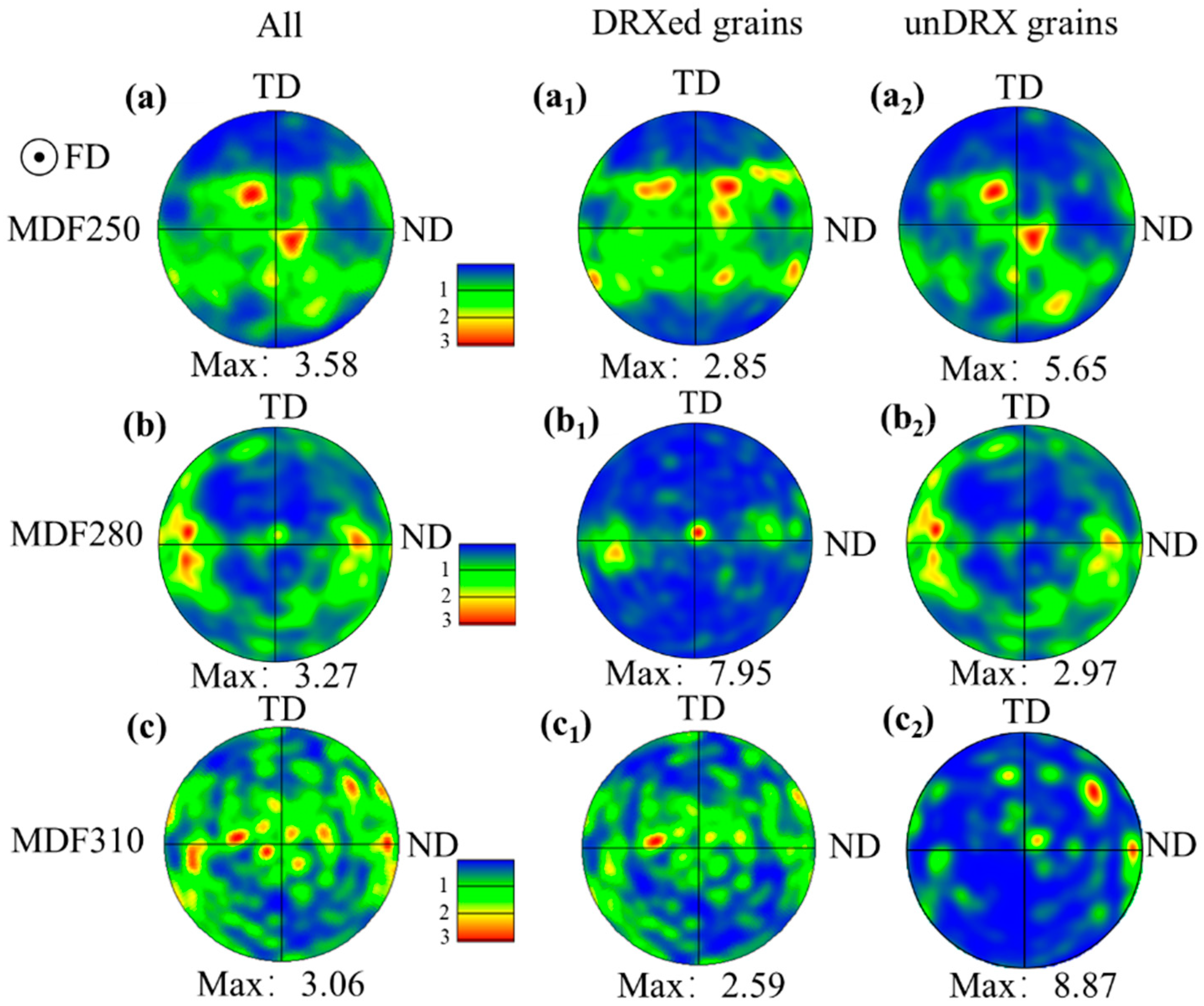

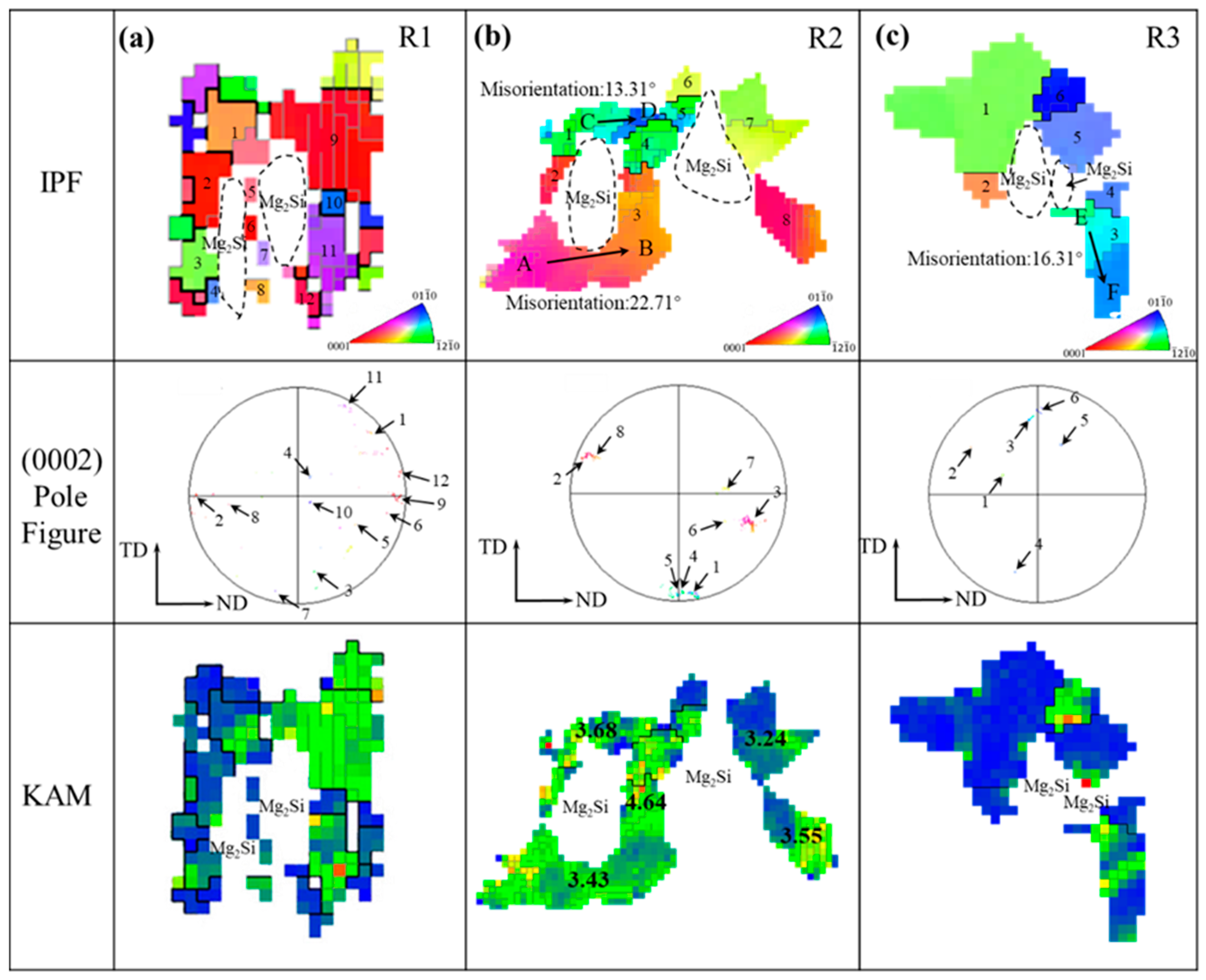

3.2. EBSD Microstructure of LA83-0.3Si Alloy After MDF

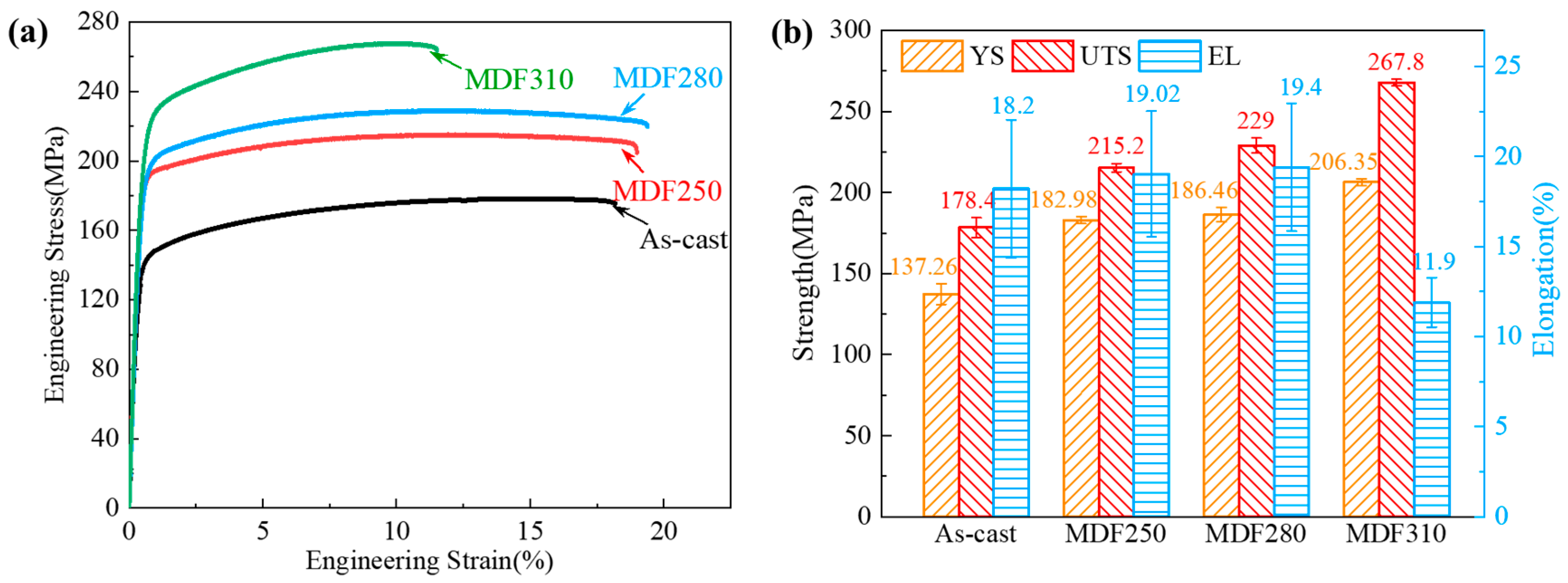

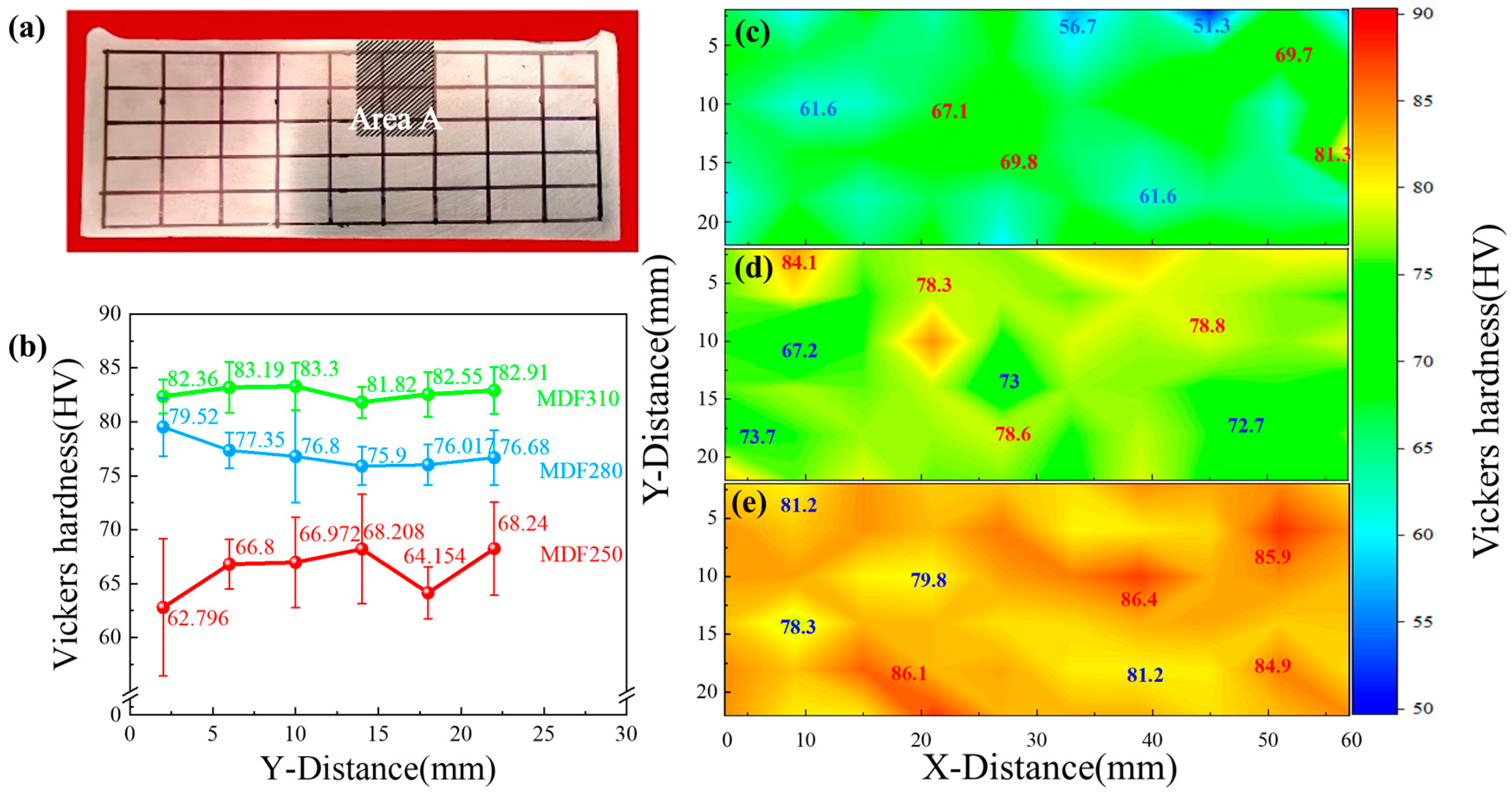

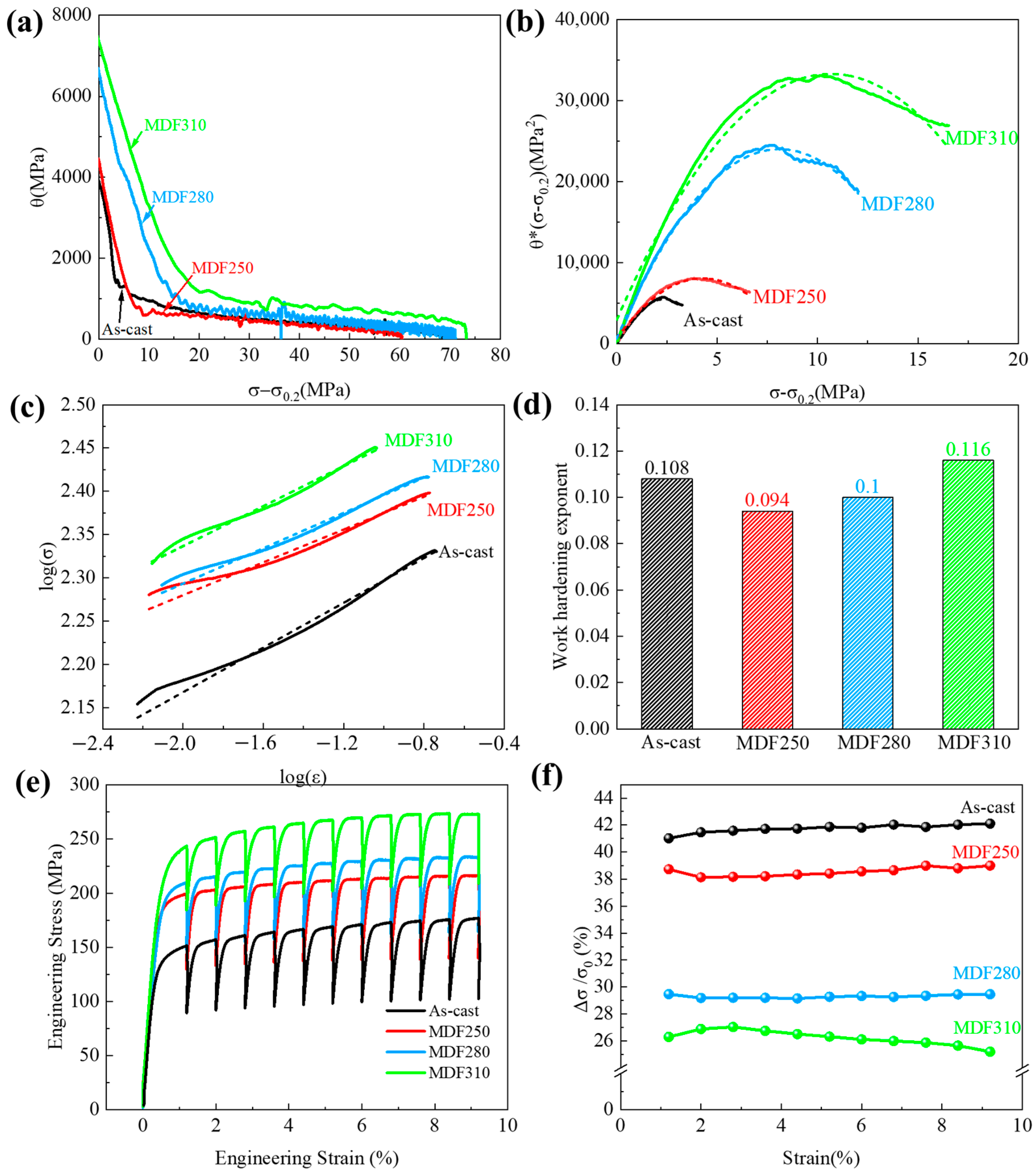

3.3. Mechanical Properties of LA83-0.3Si Alloy Before and After MDF

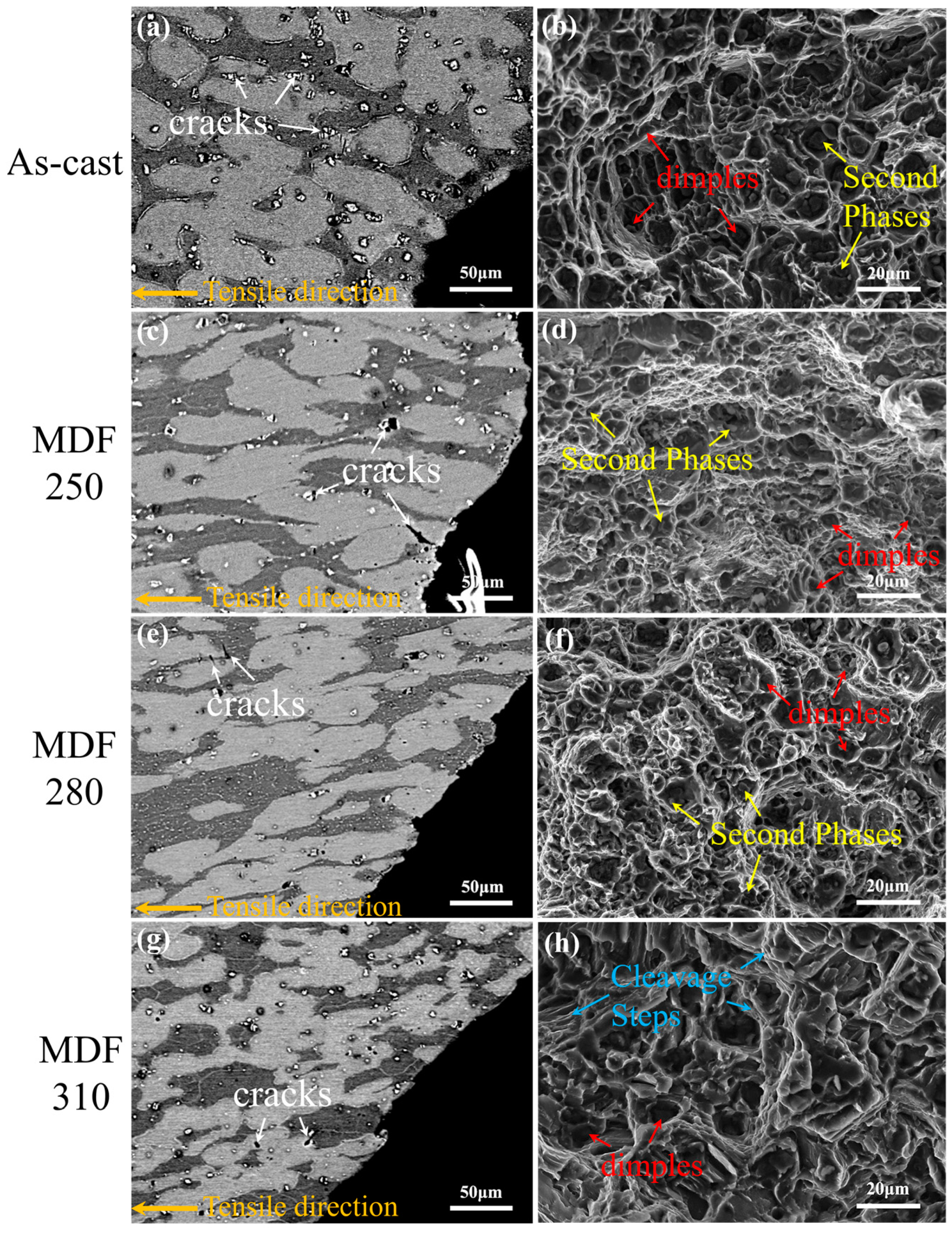

3.4. Fracture Behavior of LA83-0.3Si Alloy Before and After MDF

4. Discussion

4.1. DRX Behavior of LA83-0.3Si Alloy

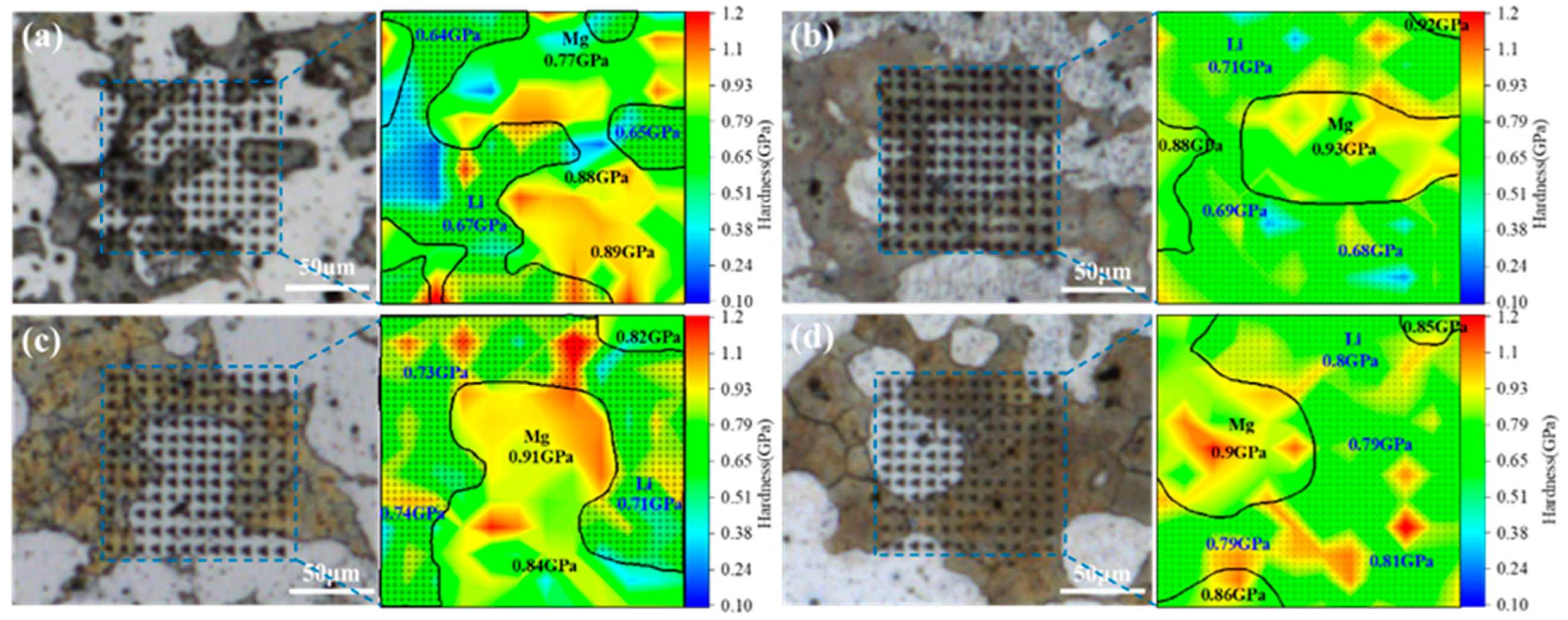

4.2. Work Hardening and Work Softening Behavior Under the Action of α/β Dual Phase

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, X.; Bian, L.; Tian, F.; Han, S.; Wang, T.; Liang, W. Microstructural Evolution and Mechanical Response of Duplex Mg-Li Alloy Containing Particles during ECAP Processing. Mater. Charact. 2022, 188, 111910. [Google Scholar] [CrossRef]

- Ji, Q.; Wang, Y.; Wu, R.; Wei, Z.; Ma, X.; Zhang, J.; Hou, L.; Zhang, M. High Specific Strength Mg-Li-Zn-Er Alloy Processed by Multi Deformation Processes. Mater. Charact. 2020, 160, 110135. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, R.; Ren, J.; Peng, C.; Cai, Z. Microstructure, Texture, and Mechanical Properties of as-Extruded Mg-xLi-3Al-2Zn-0.2Zr Alloys (x = 5, 7, 8, 9, 11 Wt.%). Mater. Sci. Eng. A 2019, 755, 201–210. [Google Scholar] [CrossRef]

- Peng, X.; Liu, W.; Wu, G.; Ji, H.; Ding, W. Plastic Deformation and Heat Treatment of Mg-Li Alloys: A Review. J. Mater. Sci. Technol. 2022, 99, 193–206. [Google Scholar] [CrossRef]

- Wang, J.; Wu, R.; Feng, J.; Zhang, J.; Hou, L.; Zhang, M. Influence of Rolling Strain on Electromagnetic Shielding Property and Mechanical Properties of Dual-Phase Mg-9Li Alloy. Mater. Charact. 2019, 157, 109924. [Google Scholar] [CrossRef]

- Ji, H.; Wu, G.; Liu, W.; Liang, X.; Liao, G.; Ding, D. Microstructure Characterization and Mechanical Properties of the As-Cast and as-Extruded Mg-xLi-5Zn-0.5Er (x = 8, 10 and 12 wt.%) Alloys. Mater. Charact. 2020, 159, 110008. [Google Scholar] [CrossRef]

- Li, C.; Deng, B.; Dong, L.; Liu, X.; Du, K.; Shi, B.; Dong, Y.; Peng, F.; Zhang, Z. Effect of Zn Addition on the Microstructure and Mechanical Properties of As-Cast BCC Mg-11Li Based Alloys. J. Alloys Compd. 2022, 895, 162718. [Google Scholar] [CrossRef]

- Bhagat Singh, P.; Sabat, R.K.; Kumaran, S.; Suwas, S. Effect of Aluminum Addition on the Evolution of Microstructure, Crystallographic Texture and Mechanical Properties of Single Phase Hexagonal Close Packed Mg-Li Alloys. J. Mater. Eng. Perform. 2018, 27, 864–874. [Google Scholar] [CrossRef]

- Zhou, G.; Yang, Y.; Zhang, H.; Hu, F.; Zhang, X.; Wen, C.; Xie, W.; Jiang, B.; Peng, X.; Pan, F. Microstructure and Strengthening Mechanism of Hot-Extruded Ultralight Mg-Li-Al-Sn Alloys with High Strength. J. Mater. Sci. Technol. 2022, 103, 186–196. [Google Scholar] [CrossRef]

- Wu, L.; Cui, C.; Wu, R.; Li, J.; Zhan, H.; Zhang, M. Effects of Ce-Rich RE Additions and Heat Treatment on the Microstructure and Tensile Properties of Mg-Li-Al-Zn-Based Alloy. Mater. Sci. Eng. A 2011, 528, 2174–2179. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, J.; Liu, W.; Wu, G.; Zhang, L. Effect of Y Content on Microstructure and Mechanical Properties of As-Cast Mg-8Li-3Al-2Zn Alloy with Duplex Structure. Mater. Sci. Eng. A 2016, 650, 240–247. [Google Scholar] [CrossRef]

- Lentz, M.; Klaus, M.; Beyerlein, I.J.; Zecevic, M.; Reimers, W.; Knezevic, M. In Situ X-Ray Diffraction and Crystal Plasticity Modeling of the Deformation Behavior of Extruded Mg-Li-(Al) Alloys: An Uncommon Tension–Compression Asymmetry. Acta Mater. 2015, 86, 254–268. [Google Scholar] [CrossRef]

- Ma, L.; Yang, Y.; Wang, X.; Fu, X.; Hu, J.; Shao, H.; Peng, X. Microstructure and Mechanical Properties of Mg-6Li-xAl-0.8Sn Alloys. Mater. Sci. Technol. 2018, 34, 2078–2086. [Google Scholar] [CrossRef]

- Ji, H.; Peng, X.; Zhang, X.; Liu, W.; Wu, G.; Zhang, L.; Ding, W. Balance of Mechanical Properties of Mg-8Li-3Al-2Zn-0.5Y Alloy by Solution and Low-Temperature Aging Treatment. J. Alloys Compd. 2019, 791, 655–664. [Google Scholar] [CrossRef]

- Maurya, R.; Mittal, D.; Balani, K. Effect of Heat-Treatment on Microstructure, Mechanical and Tribological Properties of Mg-Li-Al Based Alloy. J. Mater. Res. Technol. 2020, 9, 4749–4762. [Google Scholar] [CrossRef]

- Xin, T.; Tang, S.; Ji, F.; Cui, L.; He, B.; Lin, X.; Tian, X.; Hou, H.; Zhao, Y.; Ferry, M. Phase Transformations in an Ultralight BCC Mg Alloy during Anisothermal Ageing. Acta Mater. 2022, 239, 118248. [Google Scholar] [CrossRef]

- Shi, Q.; Bian, L.; Liang, W.; Chen, Z.; Yang, F.; Wang, Y. Effects of Adding Al-Si Eutectic Alloy and Hot Rolling on Microstructures and Mechanical Behavior of Mg-8Li Alloys. J. Alloys Compd. 2015, 631, 129–132. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, X.; Li, S.; Mao, Y.; Feng, Z.; Ke, W.; Liu, F. Study on Strengthening and Toughening of Mechanical Properties of Mg-Li Alloy by Adding Non-Rare-Earth Elements Al and Si. JOM 2022, 74, 2554–2565. [Google Scholar] [CrossRef]

- Cao, F.; Zhang, J.; Ding, X.; Xue, G.; Liu, S.; Sun, C.; Su, R.; Teng, X. Mechanical Properties and Microstructural Evolution in a Superlight Mg-6.4Li-3.6Zn-0.37Al-0.36Y Alloy Processed by Multidirectional Forging and Rolling. Mater. Sci. Eng. A 2019, 760, 377–393. [Google Scholar] [CrossRef]

- Zeng, Z.; Zhou, M.; Esmaily, M.; Zhu, Y.; Choudhary, S.; Griffith, J.C.; Ma, J.; Hora, Y.; Chen, Y.; Gullino, A.; et al. Corrosion Resistant and High-Strength Dual-Phase Mg-Li-Al-Zn Alloy by Friction Stir Processing. Commun. Mater. 2022, 3, 18. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, M.; Kong, F.; Li, B.; Cui, X.; Huang, Y.; Hort, N.; Willumeit-Römer, R.; Xie, W.; Wei, G. Effect of Extrusion and Rotary Swaging on the Microstructural Evolution and Properties of Mg-5Li-5.3Al-0.7Si Alloy. Mater. Sci. Eng. A 2023, 885, 145627. [Google Scholar] [CrossRef]

- Mineta, T.; Hasegawa, K.; Sato, H. High Strength and Plastic Deformability of Mg-Li-Al Alloy with Dual BCC Phase Produced by a Combination of Heat Treatment and Multi-Directional Forging in Channel Die. Mater. Sci. Eng. A 2020, 773, 138867. [Google Scholar] [CrossRef]

- Yang, Y.; Su, K.; Zhao, K.; Li, H.; Guo, E.; Chen, Z.; Xin, T.; Kang, H.; Wang, T. Strengthening of Duplex Mg-9Li-3Al-2Zn-1Sn Alloy by Solid Solution and Mixed Rolling-Induced Second Phase Transition. Mater. Sci. Eng. A 2024, 900, 146491. [Google Scholar] [CrossRef]

- Liu, F.; Xin, R.; Zhong, Y.; Liu, Q. Effect of Cold Rolling on Aging Precipitation and Mechanical Properties of Magnesium-Aluminum Alloy. J. Magnes. Alloys 2023. [Google Scholar] [CrossRef]

- Khaleghi, A.A.; Salevati, M.A.; Sabbaghian, M.; Fekete-Horváth, K.; Drozdenko, D.; Máthis, K.; Akbaripanah, F. Comparing the Microstructural and Mechanical Improvements of AZ80/SiC Nanocomposite Using DECLE and MDF Processes. Mater. Sci. Eng. A 2024, 892, 146020. [Google Scholar] [CrossRef]

- Wu, K.; Deng, K.; Nie, K.; Wu, Y.; Wang, X.; Hu, X.; Zheng, M. Microstructure and Mechanical Properties of SiCp/AZ91 Composite Deformed through a Combination of Forging and Extrusion Process. Mater. Des. 2010, 31, 3929–3932. [Google Scholar] [CrossRef]

- Nie, K.; Zhu, Z.; Munroe, P.; Deng, K.; Guo, Y. Microstructure and Mechanical Properties of TiC Nanoparticle-Reinforced Mg-Zn-Ca Matrix Nanocomposites Processed by Combining Multidirectional Forging and Extrusion. Trans. Nonferrous Met. Soc. China 2020, 30, 2394–2412. [Google Scholar] [CrossRef]

- Zhao, J.; Guo, H.; Luo, T.; Zhang, C.; Luo, J. Microstructure Evolution and Grain Refinement Mechanism of Fine-Grained Mg-Gd-Y-Zn-Zr Alloy during Multi-Directional Forging. J. Alloys Compd. 2022, 928, 167199. [Google Scholar] [CrossRef]

- Kang, J.; Wang, C.; Deng, K.; Nie, K.; Bai, Y.; Li, W. Microstructure and Mechanical Properties of Mg-4Zn-0.5Ca Alloy Fabricated by the Combination of Forging, Homogenization and Extrusion Process. J. Alloys Compd. 2017, 720, 196–206. [Google Scholar] [CrossRef]

- Cao, F.; Sun, C.; Shang, H.; Xiang, C.; Liu, R. Microstructure Evolution and Mechanical Properties in an Ultralight Mg-2.76Li–3Al-2.6Zn-0.39Y Alloy. Mater. Sci. Eng. A 2021, 822, 141680. [Google Scholar] [CrossRef]

- Verma, M.; Sugathan, S.; Bhattacharyya, S.; Mukherjee, R. Effect of Concurrent Thermal Grooving and Grain Growth on Morphological and Topological Evolution of a Polycrystalline Thin Film: Insights from a 3D Phase-Field Study. Acta Mater. 2023, 261, 119393. [Google Scholar] [CrossRef]

- Tang, Y.; Jia, W.; Liu, X.; Le, Q.; Zhang, Y. Fabrication of High Strength α, α+β, β Phase Containing Mg-Li Alloys with 0.2%Y by Extruding and Annealing Process. Mater. Sci. Eng. A 2016, 675, 55–64. [Google Scholar] [CrossRef]

- Zhang, Y.; Bourgeois, L.; Chen, Y.; Zeng, Z.; Birbilis, N.; Nakashima, P.N.H. Lithium Mapping in a Mg-9Li-4Al-1Zn Alloy Using Electron Energy-Loss Spectroscopy. J. Magnes. Alloys 2023, 11, 1170–1179. [Google Scholar] [CrossRef]

- Huang, Y.; Sun, J.; Qi, F.; Guo, Y.; Wu, G.; Liu, W. Aging Response and Mechanism of Dual-Phase Mg-Li-Al-Zn Alloy. J. Magnes. Alloys 2024. [CrossRef]

- Tan, Y.; Su, M.; Niu, Y.; Xie, Z.; Chen, Z.; Gong, Y.; Chen, J.; Wu, Z.; Wang, H.; Liaw, P.K.; et al. Probing Temperature Effects on Lattice Distortion and Oxidation Resistance of High-Entropy Alloys by in Situ SR-XRD and XANES. J. Mater. Res. 2021, 36, 4413–4425. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, G.; Wang, L.; Zhang, X.; Knezevic, M.; Zeng, X. Strengthening Mechanisms, Hardening/Softening Behavior, and Microstructure Evolution in an LPSO Magnesium Alloy at Elevated Temperatures. Mater. Charact. 2023, 203, 113066. [Google Scholar] [CrossRef]

- Guo, F.; Liu, L.; Ma, Y.; Jiang, L.; Zhang, D.; Pan, F. Mechanism of Phase Refinement and Its Effect on Mechanical Properties of a Severely Deformed Dual-Phase Mg–Li Alloy during Annealing. Mater. Sci. Eng. A 2020, 772, 138792. [Google Scholar] [CrossRef]

- Thiery, V.; Bou Farhat, H. Lithium-Bearing Minerals under the Scanning Electron Microscope Equipped with Energy Dispersive Spectrometry: Challenges, Recent Advances and Prospects. Chem. Geol. 2023, 633, 121573. [Google Scholar] [CrossRef]

- Österreicher, J.A.; Simson, C.; Großalber, A.; Frank, S.; Gneiger, S. Spatial Lithium Quantification by Backscattered Electron Microscopy Coupled with Energy-Dispersive X-Ray Spectroscopy. Scr. Mater. 2021, 194, 113664. [Google Scholar] [CrossRef]

- Xiong, X.; Yang, Y.; Ma, L.; Li, M.L.; Ren, F.; Hu, J.; Wei, G.; Peng, X. Microstructure and Mechanical Properties of Mg-8Li-xAl-0.5Ca Alloys. Mater. Sci. Technol. 2019, 35, 26–36. [Google Scholar] [CrossRef]

- Tang, S.; Xin, T.; Luo, T.; Ji, F.; Li, C.; Feng, T.; Lan, S. Grain Boundary Decohesion in Body-Centered Cubic Mg-Li-Al Alloys. J. Alloys Compd. 2022, 902, 163732. [Google Scholar] [CrossRef]

- Rajak, M.K.; Mondal, D.P.; Mehta, Y. Effect of Rolling on Microstructure Behaviour, and Mechanical Properties of Mg-Al-Si Alloys. Mater. Today Commun. 2023, 35, 106320. [Google Scholar] [CrossRef]

- Li, X.; Chen, Y.; Wang, X.; Ma, G. Effect of Cooling Rates on As-Cast Microstructures of Mg-9Al-xSi (x=1, 3) Alloys. Trans. Nonferrous Met. Soc. China 2010, 20, s393–s396. [Google Scholar] [CrossRef]

- Dębski, A.; Zakulski, W.; Major, Ł.; Góral, A.; Gąsior, W. Enthalpy of Formation of the Li22Si5 Intermetallic Compound. Thermochim. Acta 2013, 551, 53–56. [Google Scholar] [CrossRef]

- Braga, M.H.; Dębski, A.; Gąsior, W. Li-Si Phase Diagram: Enthalpy of Mixing, Thermodynamic Stability, and Coherent Assessment. J. Alloys Compd. 2014, 616, 581–593. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, L.; Zhang, X.; Huang, X. First-Principles Study of Solute Atoms Segregation in Al Σ5(210) Metastable Grain Boundaries. arXiv 2023, arXiv:2305.16736. [Google Scholar]

- Cao, F.; Deng, K.; Wang, C.; Nie, K.; Shi, Q.; Jia, C.; Zhang, W. The Influence of Tip Aspect Ratio on the Microstructure, Mechanical Properties, and Work Hardening Behavior of the Tip/Mg-Gd-Y-Zn Composites. Mater. Sci. Eng. A 2024, 891, 145981. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, Y.; Deng, L.; Wang, C.; Chen, J.; Zhang, Y. An Investigation on Annealing Process and Strengthening Mechanism of Cold Rolled Mg-10Li-3Al-2.8Zn Alloy. J. Alloys Compd. 2023, 961, 171087. [Google Scholar] [CrossRef]

- Sun, X.; Wang, C.; Deng, K.; Kang, J.; Bai, Y.; Nie, K.; Shang, S. Aging Behavior of AZ91 Matrix Influenced by 5 μm SiCp: Investigation on the Microstructure and Mechanical Properties. J. Alloys Compd. 2017, 727, 1263–1272. [Google Scholar] [CrossRef]

- Wang, X.; Hu, X.; Liu, W.; Du, J.; Wu, K.; Huang, Y.; Zheng, M. Ageing Behavior of As-Cast SiCp/AZ91 Mg Matrix Composites. Mater. Sci. Eng. A 2017, 682, 491–500. [Google Scholar] [CrossRef]

- Jiang, M.; Xu, C.; Yan, H.; Fan, G.; Nakata, T.; Lao, C.; Chen, R.; Kamado, S.; Han, E.; Lu, B. Unveiling the Formation of Basal Texture Variations Based on Twinning and Dynamic Recrystallization in AZ31 Magnesium Alloy during Extrusion. Acta Mater. 2018, 157, 53–71. [Google Scholar] [CrossRef]

- Wang, C.; Li, H.; He, Q.; Wu, J.; Wu, G.; Ding, W. Improvements of Elevated Temperature Tensile Strengths of Mg-Gd-Y-Zr Alloy through Squeeze Cast. Mater. Charact. 2022, 184, 111658. [Google Scholar] [CrossRef]

- Somekawa, H.; Singh, A. Superior Room Temperature Ductility of Magnesium Dilute Binary Alloy via Grain Boundary Sliding. Scr. Mater. 2018, 150, 26–30. [Google Scholar] [CrossRef]

- Li, X.; Ren, L.; Le, Q.; Jin, P.; Cheng, C.; Wang, T.; Wang, P.; Zhou, X.; Chen, X.; Li, D. The Hot Deformation Behavior, Microstructure Evolution and Texture Types of as-cast Mg-Li Alloy. J. Alloys Compd. 2020, 831, 154868. [Google Scholar] [CrossRef]

- Sun, W.; Deng, Y.; Zhan, H.; Zhou, X.; Yao, Y.; Liu, W.; Zeng, G. Interaction of Dynamic Precipitation and Dynamic Recrystallization of a Mg-4Sn-3Al-1Zn Alloy during Hot Compression. J. Alloys Compd. 2024, 970, 172434. [Google Scholar] [CrossRef]

- Zhang, X.; Su, K.; Kang, H.; Liu, L.; Guo, E.; Chen, Z.; Wang, T. Improving the Mechanical Properties of Duplex Mg-Li-Zn Alloy by Mixed Rolling Processing. Mater. Today Commun. 2022, 31, 103538. [Google Scholar] [CrossRef]

- Wu, Z.; Turner, R.; Qi, M.; Shi, L.; Wang, M.; Wang, F.; Gao, Z.; Chiu, Y.; Zhang, Z. Effect of Phase Boundary on the Critical Resolved Shear Stress and Dislocation Behavior of Dual-Phase Titanium Alloy. Acta Mater. 2024, 275, 120051. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, K.; Zhang, K.; Wang, C.; Nie, K.; Gan, W.; Shi, Q. Investigations of PMMCs Laminates with Regulatable Thickness Ratio: Microstructure, Mechanical Behavior and Fractural Mechanism. Mater. Sci. Eng. A 2022, 856, 143997. [Google Scholar] [CrossRef]

- Fan, D.; Deng, K.; Wang, C.; Nie, K.; Shi, Q.; Liang, W. Hot Deformation Behavior and Dynamic Recrystallization Mechanism of an Mg-5wt.%Zn Alloy with Trace SiCp Addition. J. Mater. Res. Technol. 2021, 10, 422–437. [Google Scholar] [CrossRef]

- Chen, R.; Tan, C.; Yu, X.; Hui, S.; Ye, W.; Lee, Y. Effect of TiB Particles on the Beta Recrystallization Behavior of the Ti-2Al-9.2Mo-2Fe-0.1B Metastable Beta Titanium Alloy. Mater. Charact. 2019, 153, 24–33. [Google Scholar] [CrossRef]

- Li, L.; Li, H.; Jiang, W.; Pan, Z.; Wang, Y.; Wang, T. Thermal Deformation Behavior and Processing Maps of As-Homogenized Mg-5.8Zn-0.5Zr-1.0Yb Alloy. JOM 2019, 71, 2033–2039. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, J.; Wang, Y.; Liu, Y.; Huang, M. Hot Deformation Behavior and Microstructure Evolution of Hot-Extruded 6A02 Aluminum Alloy. Mater. Charact. 2022, 188, 111908. [Google Scholar] [CrossRef]

- Chen, K.; Tang, J.; Jiang, F.; Teng, J.; Fu, D.; Zhang, H. The Role of Various Zr Additions in Static Softening Behavior of Al-Zn-Mg-Cu Alloys during Interval Holding of Double-Stage Hot Deformation. J. Alloys Compd. 2019, 792, 1112–1121. [Google Scholar] [CrossRef]

- Shi, Q.; Wang, C.; Deng, K.; Nie, K.; Wu, Y.; Gan, W.; Liang, W. Microstructure and Mechanical Behavior of Mg-5Zn Matrix Influenced by Particle Deformation Zone. J. Mater. Sci. Technol. 2021, 60, 8–20. [Google Scholar] [CrossRef]

- Fan, Y.; Deng, K.; Wang, C.; Nie, K.; Shi, Q. Work Hardening and Softening Behavior of Mg-Zn-Ca Alloy Influenced by Deformable Ti Particles. Mater. Sci. Eng. A 2022, 833, 142336. [Google Scholar] [CrossRef]

- Rollett, A.; Kocks, U. A Review of the Stages of Work Hardening. Solid State Phenom. 1993, 35–36, 1–18. [Google Scholar] [CrossRef]

- Lee, T.; Kim, W. Microstructure and Tensile Properties of Magnesium Nanocomposites Fabricated Using Magnesium Chips and Carbon Black. J. Magnes. Alloys 2020, 8, 860–872. [Google Scholar] [CrossRef]

- Lukáč, P.; Balík, J.; Chmelík, F. Physical Aspects of Plastic Instabilities. Mater. Sci. Eng. A 1997, 234–236, 45–51. [Google Scholar] [CrossRef]

- Zhao, C.; Li, Z.; Shi, J.; Chen, X.; Tu, T.; Luo, Z.; Cheng, R.; Atrens, A.; Pan, F. Strain Hardening Behavior of Mg-Y Alloys after Extrusion Process. J. Magnes. Alloys 2019, 7, 672–680. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, S.; Lu, J.; Wei, J.; Wei, D.; He, F. The Dual Effect of Grain Size on the Strain Hardening Behaviors of Ni-Co-Cr-Fe High Entropy Alloys. J. Mater. Sci. Technol. 2022, 131, 177–184. [Google Scholar] [CrossRef]

- Li, Y.; Deng, K.; Wang, C.; Nie, K.; Shi, Q.; Tian, P.; Zhang, G.-W. Effect of Final Rolling Deformation on Microstructure, Work Hardening and Softening Behavior of Mg-8Li-3Al-0.3Si Alloys. J. Alloys Compd. 2024, 990, 174427. [Google Scholar] [CrossRef]

- Sohrabi, M.J.; Mirzadeh, H.; Sadeghpour, S.; Mahmudi, R. Grain Size Dependent Mechanical Behavior and TRIP Effect in a Metastable Austenitic Stainless Steel. Int. J. Plast. 2023, 160, 103502. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, Y.; Zhou, L.; Zhao, T.; Wang, W.; Liu, F.; Huang, X. Simultaneous Increase of Tensile Strength and Ductility of Al-Si Solid Solution Alloys: The Effect of Solute Si on Work Hardening and Dislocation Behaviors. Mater. Sci. Eng. A 2023, 869, 144792. [Google Scholar] [CrossRef]

- Tang, Y.; Le, Q.; Jia, W.; Liu, X.; Cui, J. Influences of Warm Rolling and Annealing Processes on Microstructure and Mechanical Properties of Three Parent Structures Containing Mg-Li Alloys. Mater. Sci. Eng. A 2018, 711, 1–11. [Google Scholar] [CrossRef]

- Zhang, L.; Deng, K. Microstructures and Mechanical Properties of SiCp/Mg-xAl-2Ca Composites Collectively Influenced by SiCp and Al Content. Mater. Sci. Eng. A 2018, 725, 510–521. [Google Scholar] [CrossRef]

- Sun, X.; Wu, D.; Kang, M.; Ramesh, K.; Kecskes, L. Properties and Hardening Behavior of Equal Channel Angular Extrusion Processed Mg-Al Binary Alloys. Mater. Charact. 2023, 195, 112514. [Google Scholar] [CrossRef]

- Zhao, C.; Chen, X.; Wang, J.; Tu, T.; Dai, Y.; Shin, K.S.; Pan, F. Strain hardening behavior in Mg-Al alloys at room temperature. Adv. Eng. Mater. 2019, 21, 1801062. [Google Scholar] [CrossRef]

- Wang, J.; Chen, Y.; Zhu, Q.; Hong, Z.; Zhang, Z. Grain Boundary Dominated Plasticity in Metallic Materials. Acta Metall. Sin. 2022, 58, 726–745. [Google Scholar] [CrossRef]

- Del Valle, J.A.; Carreño, F.; Ruano, O.A. Influence of Texture and Grain Size on Work Hardening and Ductility in Magnesium-Based Alloys Processed by ECAP and Rolling. Acta Mater. 2006, 54, 4247–4259. [Google Scholar] [CrossRef]

- Xing, Z.; Fan, H.; Xu, C.; Kang, G. Transition from Grain Boundary Migration to Grain Boundary Sliding in Magnesium Bicrystals. Acta Mech. Sin. 2024, 40, 123448. [Google Scholar] [CrossRef]

| Positions | Mg (at.%) | Al (at.%) | Si (at.%) |

|---|---|---|---|

| A | 57.6 | 42.3 | 0.1 |

| B | 84.5 | 1.5 | 14 |

| C | 64.7 | 4.2 | 31.2 |

| D | 80.6 | 19.4 | 0.0 |

| E | 77.2 | 22.8 | 0.0 |

| F | 92.2 | 7.7 | 0.0 |

| G | 77.4 | 13.8 | 8.8 |

| H | 81.0 | 12.5 | 6.4 |

| Materials | k | k1 | k2 | R2 |

|---|---|---|---|---|

| As-cast | 117 | 3182 | 506 | 0.999 |

| MDF250 | 666 | 3437 | 400 | 0.978 |

| MDF280 | 1041 | 5463 | 337 | 0.992 |

| MDF310 | 2932 | 5750 | 271 | 0.976 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, P.; Wang, C.; Nie, K.; Li, Y.; Deng, K. Effect of Multi-Directional Forging on Microstructure and Mechanical Properties of Dual-Phase Mg-8Li-3Al-0.3Si Alloy. Materials 2025, 18, 1829. https://doi.org/10.3390/ma18081829

Tian P, Wang C, Nie K, Li Y, Deng K. Effect of Multi-Directional Forging on Microstructure and Mechanical Properties of Dual-Phase Mg-8Li-3Al-0.3Si Alloy. Materials. 2025; 18(8):1829. https://doi.org/10.3390/ma18081829

Chicago/Turabian StyleTian, Pengcheng, Cuiju Wang, Kaibo Nie, Yaniu Li, and Kunkun Deng. 2025. "Effect of Multi-Directional Forging on Microstructure and Mechanical Properties of Dual-Phase Mg-8Li-3Al-0.3Si Alloy" Materials 18, no. 8: 1829. https://doi.org/10.3390/ma18081829

APA StyleTian, P., Wang, C., Nie, K., Li, Y., & Deng, K. (2025). Effect of Multi-Directional Forging on Microstructure and Mechanical Properties of Dual-Phase Mg-8Li-3Al-0.3Si Alloy. Materials, 18(8), 1829. https://doi.org/10.3390/ma18081829