Thermal and Moisture Management Properties of Knitted Fabrics for Skin-Contact Workwear

Abstract

1. Introduction

2. Materials and Methods

2.1. Garment Selection

2.2. Knitted Fabric Characterization

2.2.1. Physical Properties

2.2.2. Thermal and Moisture Management Properties

3. Results

3.1. Physical Properties

3.2. Thermoregulation Properties

4. Discussions

4.1. Fabric Mass

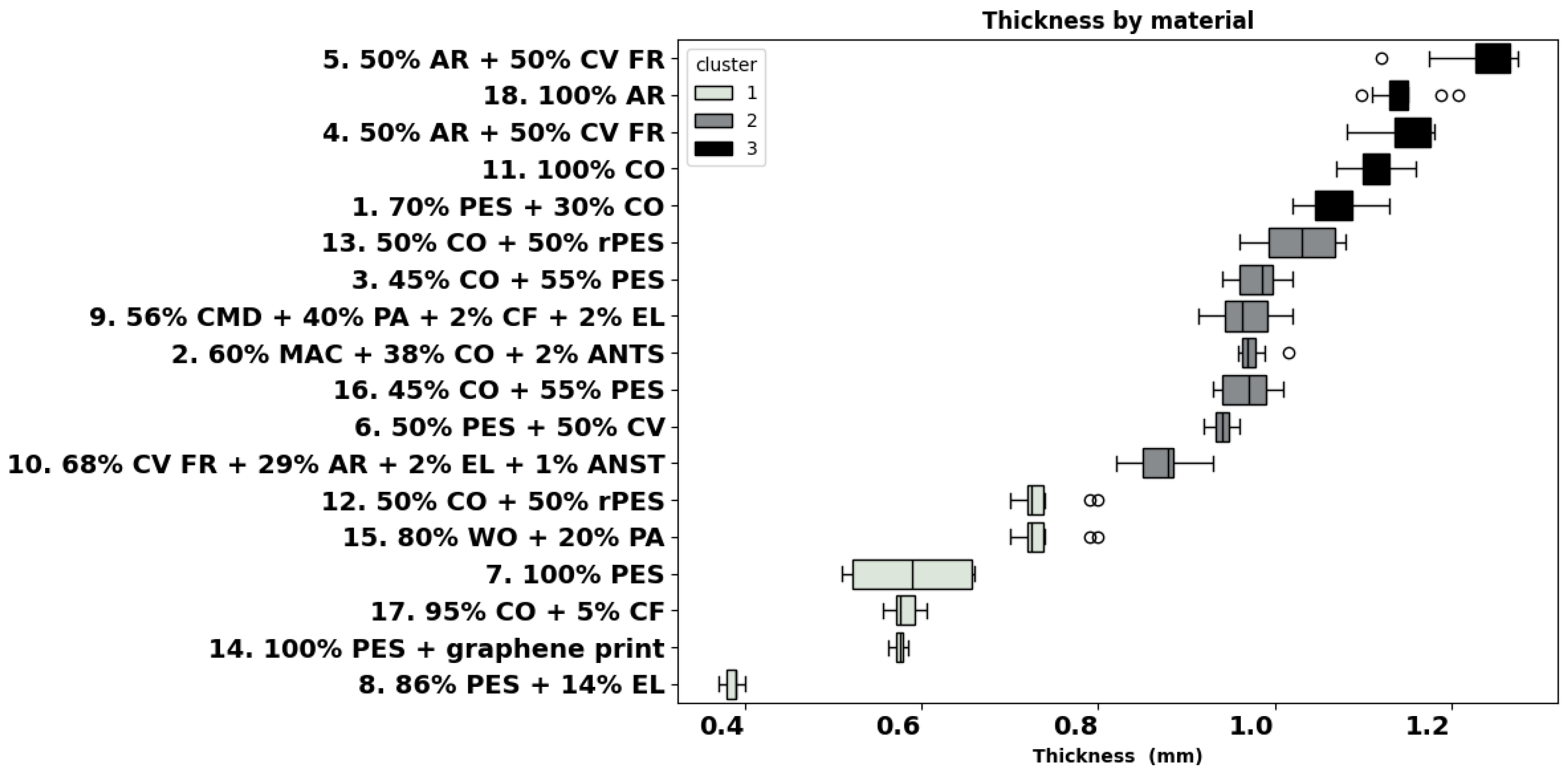

4.2. Fabric Thickness

4.3. Air Permeability

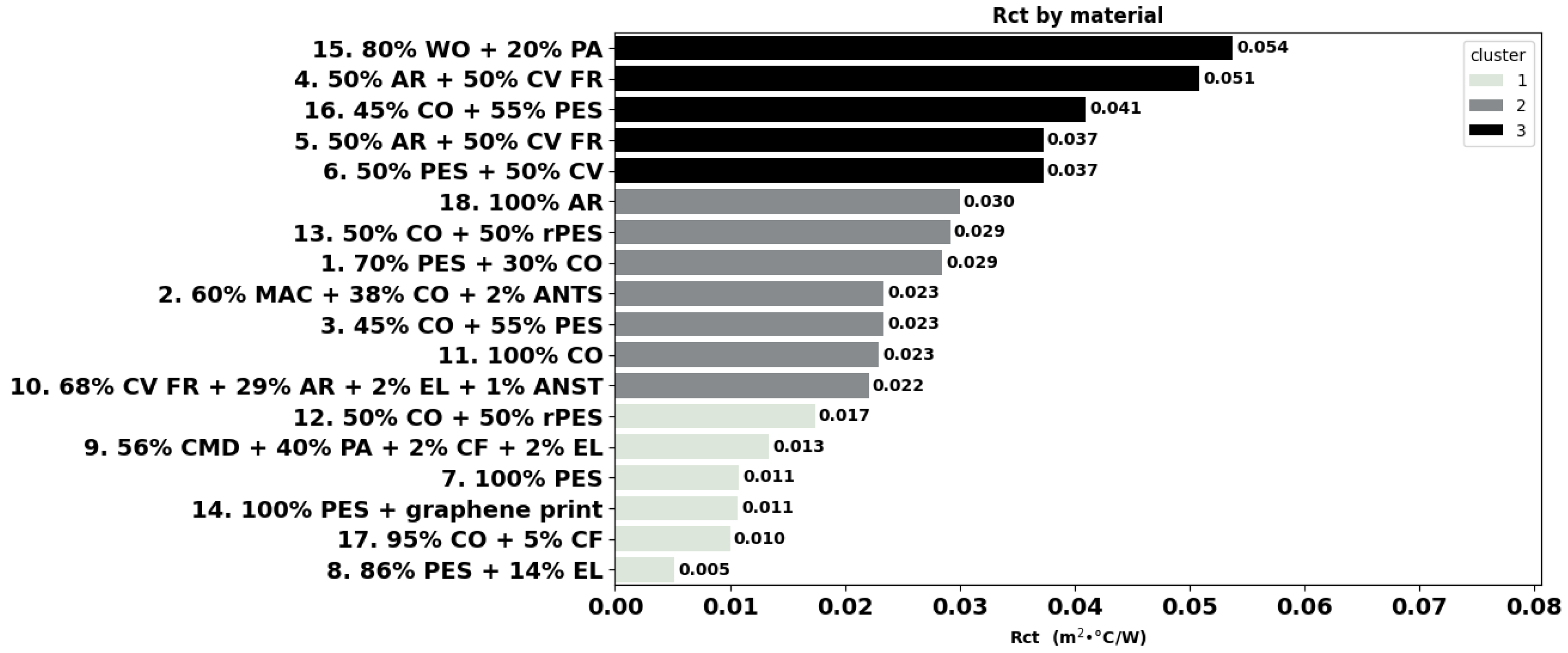

4.4. Thermal Properties

4.5. Water Vapour Permeability

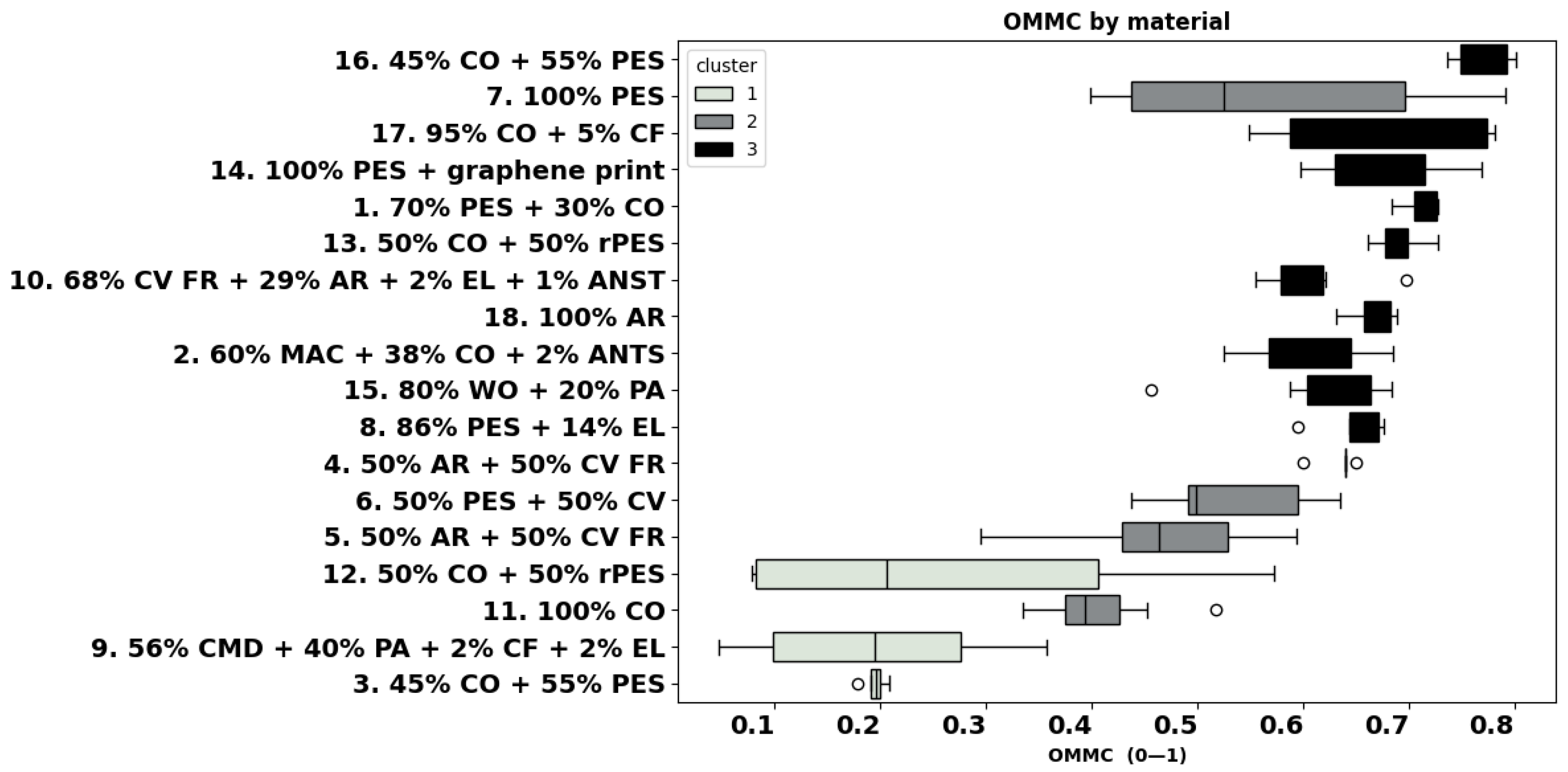

4.6. Liquid Moisture Properties

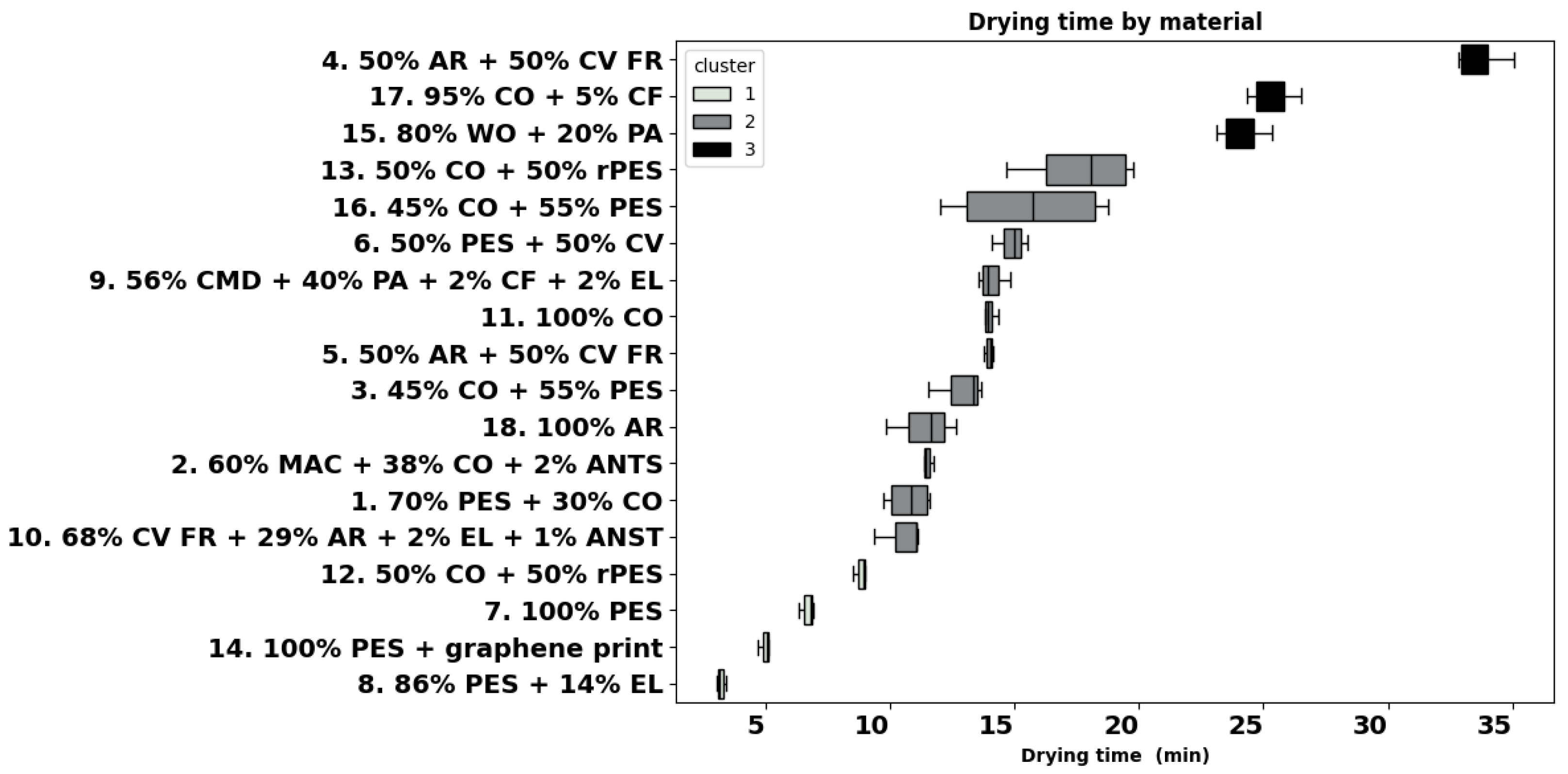

4.7. Drying Time

4.8. Thermal Comfort Performance

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dorman, L.E.; Havenith, G. The effects of protective clothing on energy consumption during different activities. Eur. J. Appl. Physiol. 2009, 105, 463–470. [Google Scholar] [CrossRef] [PubMed]

- Watson, C.; Nawaz, N.; Wardiningsih, W.; Troynikov, O. Materials used in industrial workwear for hot workplace environments: Thermal and moisture management attributes. J. Ind. Text. 2022, 52, 15280837221141716. [Google Scholar] [CrossRef]

- Havenith, G. Individualized model of human thermoregulation for the simulation of heat stress response. J. Appl. Physiol. 2001, 90, 1943–1954. [Google Scholar] [CrossRef]

- Ramezanifar, S.; Shakiba, Z.; Pirposhteh, E.A.; Poursadeghiyan, M.; Sahlabadi, A.S. The effects of personal protective equipment on heart rate, oxygen consumption and body temperature of firefighters: A systematic review. Work 2023, 76, 95–107. [Google Scholar] [CrossRef] [PubMed]

- Dorman, L.E.; Havenith, G.; Broede, P.; Candas, V.; Hartog, E.A.d.; Holmer, I.; Meinander, H.; Nocker, W.; Richards, M. Modelling the Metabolic Effects of Protective Clothing; Technical Report; Loughborough University: Loughborough, UK, 2006. [Google Scholar]

- Renberg, J.; Christiansen, M.T.; Wiggen, ∅.N.; Roeleveld, K.; Bardal, E.M.; Reinertsen, R.E. Metabolic rate and muscle activation level when wearing state-of-the-art cold-weather protective clothing during level and inclined walking. Appl. Ergon. 2020, 82, 102956. [Google Scholar] [CrossRef] [PubMed]

- Goldman, R.F.; Kampmann, B. Handbook on Clothing. Available online: https://www.sciencedirect.com/science/article/pii/B9780750670494500126 (accessed on 12 January 2025).

- Holmér, I. Protective Clothing in Hot Environments. Ind. Health 2006, 44, 404–413. [Google Scholar] [CrossRef]

- Crown, E.M.; Batcheller, J.C. Technical textiles for personal thermal protection. In Handbook of Technical Textiles, 2nd ed.; Horrocks, A.R., Anand, S.C., Eds.; Woodhead Publishing: Cambridge, UK, 2016; pp. 271–285. [Google Scholar] [CrossRef]

- Yoo, S.; Barker, R.L. Comfort Properties of Heat-Resistant Protective Workwear in Varying Conditions of Physical Activity and Environment. Part I: Thermophysical and Sensorial Properties of Fabrics. Text. Res. J. 2005, 75, 523–530. [Google Scholar] [CrossRef]

- Watson, C.; Troynikov, O.; Lingard, H. Design considerations for low-level risk personal protective clothing: A review. Ind. Health 2019, 57, 306–325. [Google Scholar] [CrossRef]

- Nayak, R.; Houshyar, S.; Padhye, R. Recent trends and future scope in the protection and comfort of fire-fighters’ personal protective clothing. Fire Sci. Rev. 2014, 3, 4. [Google Scholar] [CrossRef]

- Rathour, R.; Das, A.; Alagirusamy, R. Performance analysis of fire protective clothing: A review. Int. J. Occup. Saf. Ergon. Jose 2024, 4, 1–19. [Google Scholar] [CrossRef]

- Mandal, S.; Annaheim, S.; Capt, A.; Greve, J.; Camenzind, M.; Rossi, R. A categorization tool for fabric systems used in firefighters’ clothing based on their thermal protective and thermo-physiological comfort performances. Text. Res. J. 2018, 89, 3244–3259. [Google Scholar] [CrossRef]

- Watson, C.; Troynikov, O.; Wardiningsih, W.; Nawaz, N. Novel materials for low-risk category personal protective clothing for industrial workwear used in hot workplace environments: Improved thermal and moisture management attributes. Text. Res. J. 2023, 93, 2242–2256. [Google Scholar] [CrossRef]

- Watson, C.; Troynikov, O.; Kuklane, K.; Nawaz, N. Industrial workwear for hot workplace environments: Thermal management attributes. Int. J. Biometeorol. 2021, 65, 1751–1765. [Google Scholar] [CrossRef] [PubMed]

- Vasile, S.; Malengier, B.; De Raeve, A.; Louwagie, J.; Vanderhoeven, M.; Van Langenhove, L. Assessment of sensorial comfort of fabrics for protective clothing. In Proceedings of the 7th European Conference on Protective Clothing, Izmir, Turkey, 23–25 May 2016; pp. 111–113. [Google Scholar]

- Śledzińska, K.; Napieralska, L.; Jasińska, I.; Witczak, E.; Jarzyna, V. Fibres & Textiles in Eastern Europe. Sciendo 2022, 30, 47–54. [Google Scholar] [CrossRef]

- Mandal, S.; Mazumder, N.U.S.; Agnew, R.J.; Song, G.; Li, R. Characterization and Modeling of Thermal Protective and Thermo-Physiological Comfort Performance of Polymeric Textile Materials—A Review. Materials 2021, 14, 2397. [Google Scholar] [CrossRef]

- Islam, M.R.; Golovin, K.; Dolez, P.I. Clothing Thermophysiological Comfort: A Textile Science Perspective. Textiles 2023, 3, 353–407. [Google Scholar] [CrossRef]

- Mishra, R.; Jamshaid, H.; Yosfani, S.H.S.; Hussain, U.; Nadeem, M.; Petru, M.; Tichy, M.; Muller, M. Thermo physiological comfort of single jersey knitted fabric derivatives. Fash. Text. 2021, 8, 40. [Google Scholar] [CrossRef]

- Mölders, N. Inventory of the Thermo-Physiological Behavior of Fabrics—A Review. J. Text. Sci. Technol. 2023, 9, 127–150. [Google Scholar] [CrossRef]

- Öner, E.; Okur, A. Thermophysiological comfort properties of selected knitted fabrics and design of T-shirts. J. Text. Inst. 2015, 106, 1403–1414. [Google Scholar] [CrossRef]

- Chen, Q.; Tang, K.P.M.; Ma, P.; Jiang, G.; Xu, C. Thermophysiological comfort properties of polyester weft-knitted fabrics for sports T-shirt. J. Text. Inst. 2017, 108, 1421–1429. [Google Scholar] [CrossRef]

- Rajendrakumar, G.; Vivekanandan, M.; Arputharaj, A.; Saxena, S.; Chattopadhyay, S. Development of cotton-rich/polylactic acid fiber blend knitted fabrics for sports textiles. J. Ind. Text. 2015, 45, 405–415. [Google Scholar] [CrossRef]

- Manshahia, M.; Das, A. Thermophysiological comfort characteristics of plated knitted fabrics. J. Text. Inst. 2014, 105, 509–519. [Google Scholar] [CrossRef]

- Yang, Y.; Yu, X.; Chen, L.; Zhang, P. Effect of knitting structure and yarn composition on thermal comfort properties of bi-layer knitted fabrics. Text. Res. J. 2020, 91, 004051752093255. [Google Scholar] [CrossRef]

- Matusiak, M.; Sukhbat, O. Moisture transport in relaxed and stretched knitted fabrics. Technol. I Jakość Wyr. 2022, 67, 117–128. [Google Scholar]

- Demiryürek, O.; Uysaltürk, D. Thermal comfort properties of Viloft/cotton and Viloft/polyester blended knitted fabrics. Text. Res. J. 2013, 83, 1740–1753. [Google Scholar] [CrossRef]

- Karthikeyan, G.; Nalankilli, G.; Shanmugasundaram, O.L.; Prakash, C. Thermal comfort properties of bamboo tencel knitted fabrics. Int. J. Cloth. Sci. Technol. 2016, 28, 420–428. [Google Scholar] [CrossRef]

- Prakash, C.; Ramakrishnan, G.; Koushik, C.V. Effect of blend proportion on moisture management characteristics of bamboo/cotton knitted fabrics. J. Text. Inst. 2013, 104, 1320–1326. [Google Scholar] [CrossRef]

- Masood, R.; Jamshaid, H.; Khubaib, M.A. Development of knitted vest fabrics for human body thermoregulation. J. Therm. Anal. Calorim. 2020, 139, 159–167. [Google Scholar] [CrossRef]

- Thangavelu, V.; C, P.; Babu, R.; Rajwin, A.; Shah, A.; Roy, R. Thermal properties of different kinds of polyester knitted fabrics. Indian J. Fibre Text. Res. 2023, 48, 295–301. [Google Scholar] [CrossRef]

- Dolanbay Dogan, S.; Kılınc, N. Thermal Comfort Properties of 100% Cashmere Knitted Fabrics. Fibers Polym. 2024, 25, 1137–1147. [Google Scholar] [CrossRef]

- Majumdar, A.; Mukhopadhyay, S.; Yadav, R. Thermal properties of knitted fabrics made from cotton and regenerated bamboo cellulosic fibres. Int. J. Therm. Sci. 2010, 49, 2042–2048. [Google Scholar] [CrossRef]

- Ibrahim, N.A.; Khalifa, T.F.; El-Hossamy, M.B.; Tawfik, T.M. Effect of Knit Structure and Finishing Treatments on Functional and Comfort Properties of Cotton Knitted Fabrics. J. Ind. Text. 2010, 40, 49–64. [Google Scholar] [CrossRef]

- Sampath, M.B.; Prakash, C.; Senthil Kumar, M. Influence of Laundering on Comfort Characteristics of Moisture Management Finished Microdenier Polyester Knitted Fabrics. Fibers Polym. 2019, 20, 668–674. [Google Scholar] [CrossRef]

- Debebe, E.; Yilma, B.B. Thermo-physiological comfort properties of structurally and enzymatically modified knitted fabric for sportswear. J. Ind. Text. 2025, 55, 15280837251328299. [Google Scholar] [CrossRef]

- Kaplan, S. Thermal Comfort Performance of Sports Garments with Objective and Subjective Measurements. 2012. Available online: https://www.academia.edu/77343476/Thermal_comfort_performance_of_sports_garments_with_objective_and_subjective_measurements (accessed on 12 January 2025).

- Fayala, F.; Alibi, H.; Jemni, A.; Zeng, X. A new hybrid artificial intelligence approach to predicting global thermal comfort of stretch knitted fabrics. Fibers Polym. 2015, 16, 1417–1429. [Google Scholar] [CrossRef]

- Bedek, G.; Salaün, F.; Martinkovska, Z.; Devaux, E.; Dupont, D. Evaluation of thermal and moisture management properties on knitted fabrics and comparison with a physiological model in warm conditions. Appl. Ergon. 2011, 42, 792. [Google Scholar] [CrossRef]

- Xiao, Y.Q.; Kan, C.W. Review on the Development and Application of Directional Water Transport Textile Materials. Coatings 2022, 12, 301. [Google Scholar] [CrossRef]

- Pamuk, G.; Cüreklibatır Encan, B.; Yıldız, E.Z. Thermal Characteristics, Mechanical and Comfort Properties of Heat-Protective Textiles. Fibers Polym. 2023, 24, 4457–4468. [Google Scholar] [CrossRef]

- Mäkinen, H.; Smolander, J.; Vuorinen, H. Simulation of the Effect of Moisture Content in Underwear and on the Skin Surface on Steam Burns of Fire Fighters. In Performance of Protective Clothing: Second Symposium; ASTM International: West Conshohocken, PA, USA, 1988. [Google Scholar] [CrossRef]

- Keiser, C.; Becker, C.; Rossi, R.M. Moisture Transport and Absorption in Multilayer Protective Clothing Fabrics. Text. Res. J. 2008, 78, 604–613. [Google Scholar] [CrossRef]

- Eryuruk, S.; Gidik, H.; Koncar, V.; Kalaoglu, F.; Tao, X.; Saglam, Y. Heat and moisture transfer properties of a firefighter clothing with a new fire-resistant underwear. J. Ind. Text. 2022, 51, 4480S–4513S. [Google Scholar] [CrossRef]

- Zupin, Z.; KniFiC, K.; Pavko Cuden, A. Comfort Properties of Functional Double Bed Knitted Fabric for Firefighters Underwear. Tekst. Konfeksiyon 2022, 33, 249–261. [Google Scholar] [CrossRef]

- Stygienė, L.; Krauledas, S.; Abraitienė, A.; Varnaitė-Žuravliova, S.; Dubinskaitė, K. Flammability and Thermoregulation Properties of Knitted Fabrics as a Potential Candidate for Protective Undergarments. Materials 2022, 15, 2647. [Google Scholar] [CrossRef]

- Kofler, P.; Herten, A.; Heinrich, D.; Bottoni, G.; Hasler, M.; Faulhaber, M.; Bechtold, T.; Nachbauer, W.; Burtscher, M. Viscose as an alternative to aramid in workwear: Influence on endurance performance, cooling, and comfort. Text. Res. J. 2013, 83, 2085–2092. [Google Scholar] [CrossRef]

- Santhanam, S.; Bogale, M.; Selvaraj, S.K. Moisture and Thermal Comfort Properties of Heat Resistance Protective Work Wear Using Cotton and Cotton/Polyester Blended Weft Knitted Fabrics. J. Text. Apparel Technol. Manag. 2022, 12, 1. [Google Scholar]

- Nawaz, N.; Troynikov, O.; Watson, C. Thermal Comfort Properties of Knitted Fabrics Suitable for Skin Layer of Protective Clothing Worn in Extreme Hot Conditions. Adv. Mater. Res. 2011, 331, 184–187. [Google Scholar] [CrossRef]

- Mishra, R.; Jamshaid, H.; Basra, S.A.; Jiang, G.; Gao, Z.; Ma, P.; Petru, M.; Raza, A.; Muller, M. Effect of Stitch Characteristics on Flammability and Thermo-Physiological Comfort Properties of Knitted Fabrics. Fibers Polym. 2020, 21, 2652–2663. [Google Scholar] [CrossRef]

- Horrocks, A.R. Technical fibres for heat and flame protection. In Handbook of Technical Textiles, 2nd ed.; Horrocks, A.R., Anand, S.C., Eds.; Woodhead Publishing: Cambridge, UK, 2016; pp. 237–270. [Google Scholar] [CrossRef]

- ISO 2076:2021; Textiles—Man-Made Fibres—Generic Names. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 6938:2012; Textiles—Natural Fibres—Generic Names and Definitions. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 11612:2015; Protective Clothing—Clothing to Protect Against Heat and Flame—Minimum Performance Requirements. International Organization for Standardization: Geneva, Switzerland, 2015.

- EN 1149-5; Protective Clothing-Electrostatic Properties—Part 5: Material Performance and Design Requirements. European Committee for Standardization: Brussels, Belgium, 2018.

- ASTM D6413/D6413M-15; Standard Test Method for Flame Resistance of Textiles (Vertical Test). ASTM International: West Conshohocken, PA, USA, 2022.

- ISO 14116:2015; Protective Clothing—Protection Against Flame—Limited Flame Spread Materials, Material Assemblies and Clothing. International Organization for Standardization: Geneva, Switzerland, 2015.

- EN 61340-5-1-2016EDS; Electrostatics—Part 5-1: Protection of Electronic Devices from Electrostatic Phenomena—General Requirements. European Committee for Standardization: Brussels, Belgium, 2016.

- ISO 139:2005; Textiles—Standard Atmospheres for Conditioning and Testing. International Organization for Standardization: Geneva, Switzerland, 2005.

- ISO 3801:1977; Textiles—Woven Fabrics—Determination of Mass per Unit Length and Mass per Unit Area. International Organization for Standardization: Geneva, Switzerland, 1977. Available online: https://www.iso.org/standard/9335.html (accessed on 31 March 2025).

- EN ISO 5084:1996; Textiles—Determination of Thickness of Textiles and Textile Products. European Committee for Standardization: Brussels, Belgium, 1996. Available online: https://standards.iteh.ai/catalog/standards/cen/060c0de0-db3b-43c2-ae4a-7b5077ddbceb/en-iso-5084-1996 (accessed on 31 March 2025).

- Hearle, J.W.S.; Morton, W.E. Physical Properties of Textile Fibres, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- ISO 9237:1995; Textiles—Determination of the Permeability of Fabrics to Air. International Organization for Standardization: Geneva, Switzerland, 1995. Available online: https://www.iso.org/standard/16869.html (accessed on 16 December 2024).

- ISO 11092:2014; Textiles—Physiological Effects—Measurement of Thermal and Water-Vapour Resistance Under Steady-State Conditions (Sweating Guarded-Hotplate Test). International Organization for Standardization: Geneva, Switzerland, 2014. Available online: https://www.iso.org/standard/65962.html (accessed on 31 March 2025).

- AATCC TM195; Standard Test Method for Measuring the Resistance of Materials to the Passage of Air. AATCC: Durham, NC, USA, 2011. Available online: https://members.aatcc.org/store/tm195/591/ (accessed on 16 December 2024).

- AATCC TM201; Standard Test Method for Measuring the Absorbency of Fabrics. AATCC: Durham, NC, USA, 2012. Available online: https://members.aatcc.org/store/tm201/955/ (accessed on 16 December 2024).

- Mandal, S.; Annaheim, S.; Greve, J.; Camenzind, M.; Rossi, R.M. Modeling for predicting the thermal protective and thermo-physiological comfort performance of fabrics used in firefighters’ clothing. Text. Res. J. 2019, 89, 2836–2849. [Google Scholar] [CrossRef]

- Golalipour, K.; Akbari, E.; Hamidi, S.S.; Lee, M.; Enayatifar, R. From clustering to clustering ensemble selection: A review. Eng. Appl. Artif. Intell. 2021, 104, 104388. [Google Scholar] [CrossRef]

- Marolleau, A.; Salaün, F.; Dupont, D.; Gidik, H.; Ducept, S. Influence of textile properties on thermal comfort. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 254, p. 182007. [Google Scholar] [CrossRef]

- Jerkovic, I.; Ebrahimi, S.; Baumann, J.; Stämpfli, R.; Camenzind, M.; Annaheim, S.; Rossi, R.M. Relevant fabric parameters to be considered for optimizing combined drying and support properties of sports bras. J. Ind. Text. 2025, 55, 15280837251321854. [Google Scholar] [CrossRef]

- Wei, B.; Yang, N.; Tian, M.; Qu, L.; Zhu, S. Effect of coating methods on thermal conductivity of graphene-coated fabrics for welding protective clothing. Mater. Lett. 2022, 314, 131787. [Google Scholar] [CrossRef]

- Colombo, B. Graphene and Workwear: A Winning Combination. 2021. Available online: https://www.grassi.it/en/graphene-and-workwear-a-winning-combination/ (accessed on 14 January 2025).

- Vasile, S.; Georgievska, M.; Copot, C.; De Raeve, A. Comparative Analysis of Elastic Polyester Sportswear Fabrics with Printed Graphene Patterns. Materials 2023, 16, 2028. [Google Scholar] [CrossRef] [PubMed]

- Havenith, G. Heat balance when wearing protective clothing. Ann. Occup. Hyg. 1999, 43, 289–296. [Google Scholar] [CrossRef] [PubMed]

- Bączek, M. Thermophysiological Properties of Dry and Wet Functional Sportswear Made of Synthetic Fibres. Tekstilec 2017, 60, 331–338. [Google Scholar] [CrossRef]

- Li, Y. Perceptions of temperature, moisture and comfort in clothing during environmental transients. Ergonomics 2005, 48, 234–248. [Google Scholar] [CrossRef]

- Raccuglia, M.; Hodder, S.; Havenith, G. Human moisture perception of textile materials under static skin contact. 2016. Available online: https://www.researchgate.net/publication/301593094_Human_moisture_perception_of_textile_materials_under_static_skin_contact (accessed on 14 January 2025).

- Fukazawa, T.; Havenith, G. Differences in comfort perception in relation to local and whole body skin wettedness. Eur. J. Appl. Physiol. 2009, 106, 15–24. [Google Scholar] [CrossRef]

- ASTM D1909-13 (2020); Standard Tables of Commercial Moisture Regains and Commercial Allowances for Textile Fibers. ASTM International: West Conshohocken, PA, USA, 2020.

| Garment Description and Destination | Fabric Composition | Fabric Structure | ||

|---|---|---|---|---|

| Outer | Inner | |||

| 1 | Short-sleeved polo; police shooting monitors | 70% PES + 30% CO |  |  |

| 2 | Short-sleeved polo; maritime police; compliant with ISO 11612 [56] (A1B1C1) and EN 1149-5 [57] | 60% MAC + 38% CO + 2% ANST |  |  |

| 3 | Short-sleeved polo; basic clothing, police | 45% CO + 55% PES |  |  |

| 4 | Long-sleeved T-shirt; winter undergarment compliant with ISO 11612, police | 50% AR + 50% CV FR |  |  |

| 5 | Long-sleeved T-shirt; summer undergarment compliant with ISO 11612, police | 50% AR + 50% CV FR |  |  |

| 6 | Long-sleeved T-shirt; Thermal underwear, police | 50% PES + 50% CV |  |  |

| 7 | T-shirt; standard sportswear, police | 100% PES |  |  |

| 8 | T-shirt; standard sportswear | 86% PES + 14% EL |  |  |

| 9 | Long-sleeved seamless T-shirt compliant with ASTM D6413/D6413M-15 [58]; military | 56% CMD + 40% PA + 2% CF+ 2% EL |  |  |

| 10 | Long-sleeved seamless T-shirt compliant with ISO 14116 [59] (FR index 3); military, firefighters | 68% CV FR + 29% AR + 2% EL + 1% ANST |  |  |

| 11 | Short-sleeved polo, compliant with the ASTM D6413/D6413M-15; military | 100% CO |  |  |

| 12 | Short-sleeved T-shirt; base layer in industrial and healthcare sector | 50% CO + 50% rPES |  |  |

| 13 | Short-sleeved polo; industrial and healthcare sector | 50% CO + 50% rPES |  |  |

| 14 | Long-sleeved T-shirt with thermoregulation properties; industrial and healthcare sector | 100% PES graphene print inside |  |  |

| 15 | Long-sleeved T-shirt; winter thermal underwear worn under the combat uniform, military | 80% WO + 20% PA |  |  |

| 16 | Long-sleeved T-shirt; undershirt, cold protection, and industrial applications, i.e., cool chain logistics, food industry, etc. | 55% PES + 45% CO |  |  |

| 17 | Long-sleeved polo; compliant with EN 61340-5-1-2016EDS [60] protection, automotive, electronics, etc. | 95% CO + 5% CF |  |  |

| 18 | Long-sleeved turtleneck; military | 100% AR |  |  |

| Rct | Ret | imt | OMMC | SST | SSB | WTT | WTB | MWRT | MWRB | Drying Time | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (m2·°C/W) | (m2·Pa/W) | (0–1) | (0–1) | (mm/s) | (mm/s) | (s) | (s) | (mm) | (mm) | (min) | |

| Mass (g/m2) | 0.42 | 0.61 * | 0.21 | −0.40 * | 0.44 * | −0.22 * | −0.3 * | 0.36 * | 0.36 * | −0.1 | 0.35 * |

| Thickness (mm) | 0.63 * | 0.68 * | 0.54 * | −0.07 | 0.09 | −0.21 * | −0.04 | −0.06 | −0.03 | −0.24 * | 0.41 * |

| Bulk density (g/cm3) | −0.56 * | −0.4 | −0.69 * | −0.33 * | 0.45 * | 0.2 * | −0.38 * | 0.17 | 0.42 * | 0.29 * | −0.2 |

| Air permeability (mm/s) | 0.31 | 0.25 | 0.35 | 0.5 * | −0.32 * | 0.04 | 0.25 * | −0.23 * | −0.25 * | 0.03 | 0.03 |

| Porosity (%) | 0.23 | 0.17 | 0.34 | 0.42 | −0.55 * | −0.22 | 0.47 * | −0.21 | −0.55 * | −0.42 | 0.3 |

| Fabric ID | WTT | WTB | ART | ARB | MWRT | MWRB | SST | SSB | R |

|---|---|---|---|---|---|---|---|---|---|

| (s) | (s) | (%/s) | (%/s) | (mm) | (mm) | (mm/s) | (mm/s) | (%) | |

| 1. 70% PES + 30% CO | 14.3 | 3.8 | 5.9 | 33 | 0 | 15.0 | 0.0 | 2.8 | 406.7 |

| (3) | (0.6) | (1.2) | (2.8) | (0.0) | (0.0) | (0.0) | (0.2) | (24.6) | |

| 2. 60% MAC + 38% CO + 2% ANTS | 13.8 | 9.1 | 48.6 | 101.1 | 15.7 | 15.7 | 1.2 | 1.5 | 269.8 |

| (6.5) | (3.9) | (9.1) | (26.3) | (3.5) | (1.9) | (0.6) | (0.5) | (104.2) | |

| 3. 45% CO + 55% PES | 3.2 | 5.6 | 44.0 | 48.5 | 20.0 | 15.0 | 3.6 | 2.1 | −156.6 |

| (0.2) | (0.3) | (1.4) | (2.3) | (0.0) | (0.0) | (0.1) | (0.1) | (6.8) | |

| 4. 50% AR + 50% CV FR | 120.0 | 5.1 | 0.0 | 55.0 | 0.0 | 5.0 | 0.0 | 1.0 | 926.2 |

| (0.0) | (1.4) | (0.0) | (7.4) | (0.0) | (0.0) | (0.0) | (0.2) | (74.7) | |

| 5. 50% AR + 50% CV FR | 5.2 | 5.5 | 26.3 | 45.1 | 17.0 | 18.0 | 2.5 | 2.4 | 172.5 |

| (0.7) | (0.8) | (5.2) | (10.1) | (2.7) | (2.7) | (0.4) | (0.4) | (62.5) | |

| 6. 50% PES + 50% CV | 15.4 | 10.7 | 56.2 | 72.6 | 13.9 | 14.4 | 0.8 | 0.9 | 270.6 |

| (4.5) | (3.2) | (18.6) | (23.7) | (4.2) | (3.0) | (0.4) | (0.3) | (63.5) | |

| 7. 100% PES | 13.3 | 6.4 | 12.2 | 45.2 | 2.9 | 18.6 | 0.4 | 2.5 | 291.4 |

| (7.9) | (2.4) | (9.4) | (21.8) | (7.6) | (6.3) | (1.1) | (1.1) | (146.2) | |

| 8. 86% PES + 14% EL | 2.6 | 2.6 | 51.1 | 64.0 | 25.0 | 24.0 | 5.4 | 5.4 | 174.9 |

| (0.1) | (0.1) | (4.8) | (2.5) | (0.0) | (2.2) | (0.2) | (0.3) | (33.8) | |

| 9. 56% CMD + 40% PA + 2% CF + 2% EL | 4.1 | 10.3 | 34.4 | 39.5 | 21.5 | 15.0 | 4.6 | 2.4 | −75.8 |

| (1.3) | (3.1) | (11.1) | (13.5) | (2.4) | (3.3) | (0.6) | (1.2) | (27.1) | |

| 10. 68% CV FR + 29% AR + 2% EL + 1% ANST | 5.2 | 5.1 | 35.5 | 59.5 | 20.0 | 19.3 | 2.8 | 2.6 | 253.1 |

| (1.1) | (0.6) | (12.3) | (4.8) | (0.0) | (1.9) | (0.2) | (0.3) | (48.4) | |

| 11. 100% CO | 7.3 | 4.8 | 12.7 | 29.3 | 14.4 | 15.0 | 1.9 | 2.3 | 175.8 |

| (4.2) | (0.5) | (11.0) | (9.8) | (1.8) | (0.0) | (0.7) | (0.1) | (25.0) | |

| 12. 50% CO + 50% rPES | 64 | 6.7 | 8.9 | 17.5 | 6.0 | 12.0 | 0.9 | 1.8 | 77.4 |

| (59.1) | (2.2) | (12.5) | (15.9) | (9.7) | (7.5) | (1.5) | (1.4) | (60.5) | |

| 13. 50% CO + 50% rPES | 120 | 8.7 | 0.0 | 78.0 | 0.0 | 5.0 | 0.0 | 0.6 | 1010.0 |

| (0.0) | (1.4) | (0.0) | (9.2) | (0.0) | (0.0) | (0.0) | (0.1) | (20.9) | |

| 14. 100% PES + graphene print | 11.0 | 4.9 | 7.0 | 31.1 | 5.6 | 20.6 | 0.6 | 3.8 | 300.5 |

| (4.1) | (2.0) | (2.9) | (3.1) | (10.5) | (1.8) | (1.4) | (0.5) | (41.8) | |

| 15. 80% WO + 20% PA | 27.5 | 7.1 | 28.0 | 66.6 | 15.0 | 15.0 | 0.7 | 1.1 | 474.4 |

| (20.5) | (1.2) | (15.7) | (3.6) | (4.5) | (4.5) | (0.4) | (0.4) | (208.1) | |

| 16. 45% CO + 55% PES | 85.9 | 1.9 | 7.9 | 61.9 | 3.0 | 6.0 | 0.1 | 2.5 | 1188.2 |

| (41.8) | (0.4) | (8.2) | (5.1) | (2.7) | (2.2) | (0.1) | (0.5) | (109) | |

| 17. 95% CO + 5% CF | 120 | 3.2 | 0.0 | 40.3 | 0.0 | 5.0 | 0.0 | 2.1 | 1180.7 |

| (0.0) | (3.0) | (0.0) | (23.9) | (0.0) | (0.0) | (0.0) | (1.0) | (110.3) | |

| 18. 100% AR | 3.6 | 4.0 | 39.8 | 63.3 | 21.0 | 21.0 | 3.8 | 3.6 | 230.6 |

| (0.9) | (1.1) | (5.0) | (7.1) | (2.2) | (2.2) | (0.7) | (0.6) | (24.9) |

| Ret | Rct | SST | SSB | WTT | WTB | MWRT | MWRB | |

|---|---|---|---|---|---|---|---|---|

| (m2·Pa/W) | (m2·°C/W) | (mm/s) | (mm/s) | (s) | (s) | (mm) | (mm) | |

| Drying time (min) | 0.63 * | 0.58 * | −0.14 | −0.59 * | 0.47 * | 0.17 | −0.14 | −0.65 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasile, S.; Vega Arellano, J.P.; Copot, C.; Osman, A.; De Raeve, A. Thermal and Moisture Management Properties of Knitted Fabrics for Skin-Contact Workwear. Materials 2025, 18, 1859. https://doi.org/10.3390/ma18081859

Vasile S, Vega Arellano JP, Copot C, Osman A, De Raeve A. Thermal and Moisture Management Properties of Knitted Fabrics for Skin-Contact Workwear. Materials. 2025; 18(8):1859. https://doi.org/10.3390/ma18081859

Chicago/Turabian StyleVasile, Simona, Jaime Paolo Vega Arellano, Cosmin Copot, Ahmad Osman, and Alexandra De Raeve. 2025. "Thermal and Moisture Management Properties of Knitted Fabrics for Skin-Contact Workwear" Materials 18, no. 8: 1859. https://doi.org/10.3390/ma18081859

APA StyleVasile, S., Vega Arellano, J. P., Copot, C., Osman, A., & De Raeve, A. (2025). Thermal and Moisture Management Properties of Knitted Fabrics for Skin-Contact Workwear. Materials, 18(8), 1859. https://doi.org/10.3390/ma18081859