Effects of Harmless Municipal Solid Waste Incineration Fly Ash on the Macroscopic Properties and Microstructure of Recycled Aggregate Concrete

Abstract

:1. Introduction

2. Materials and Methods

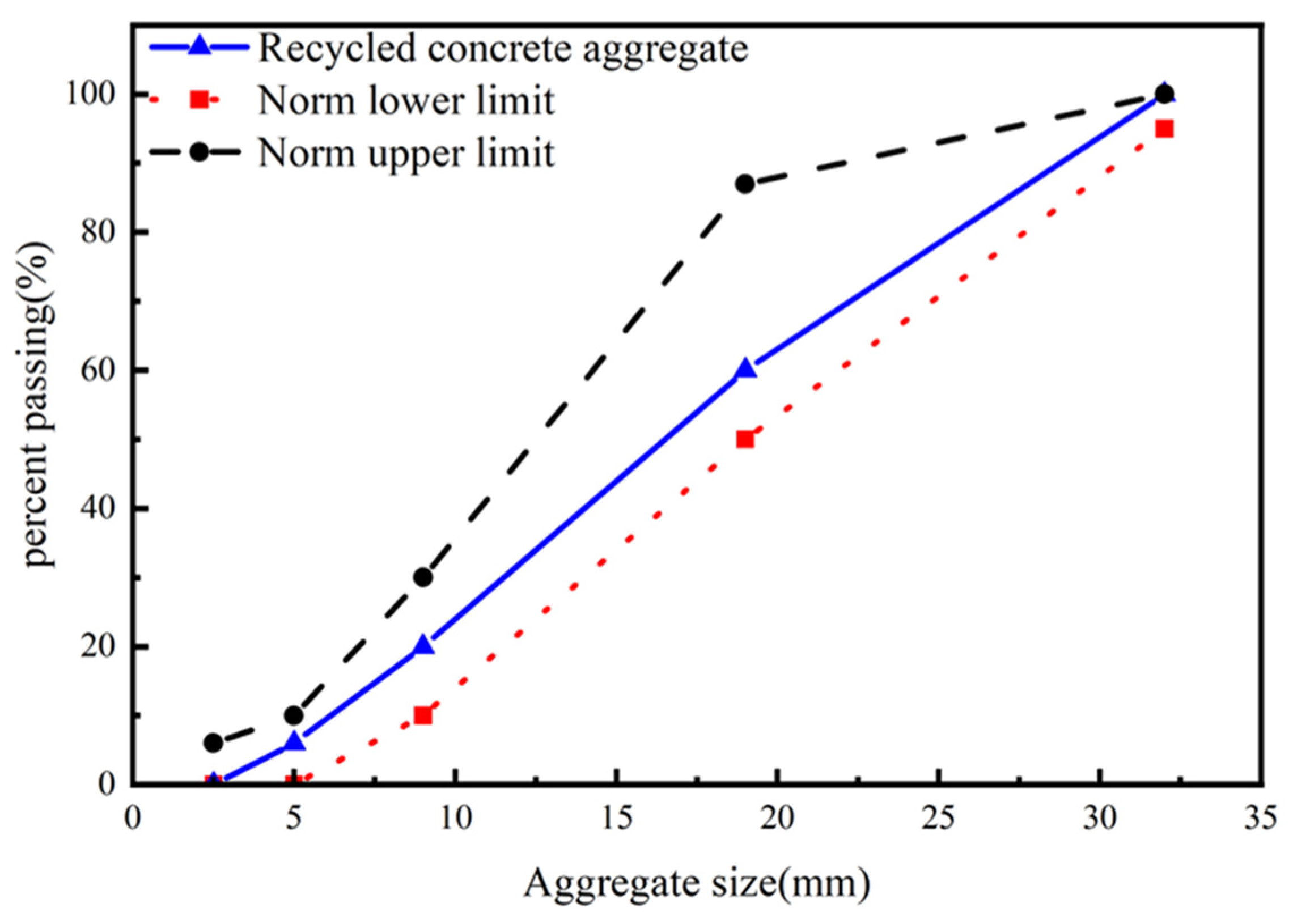

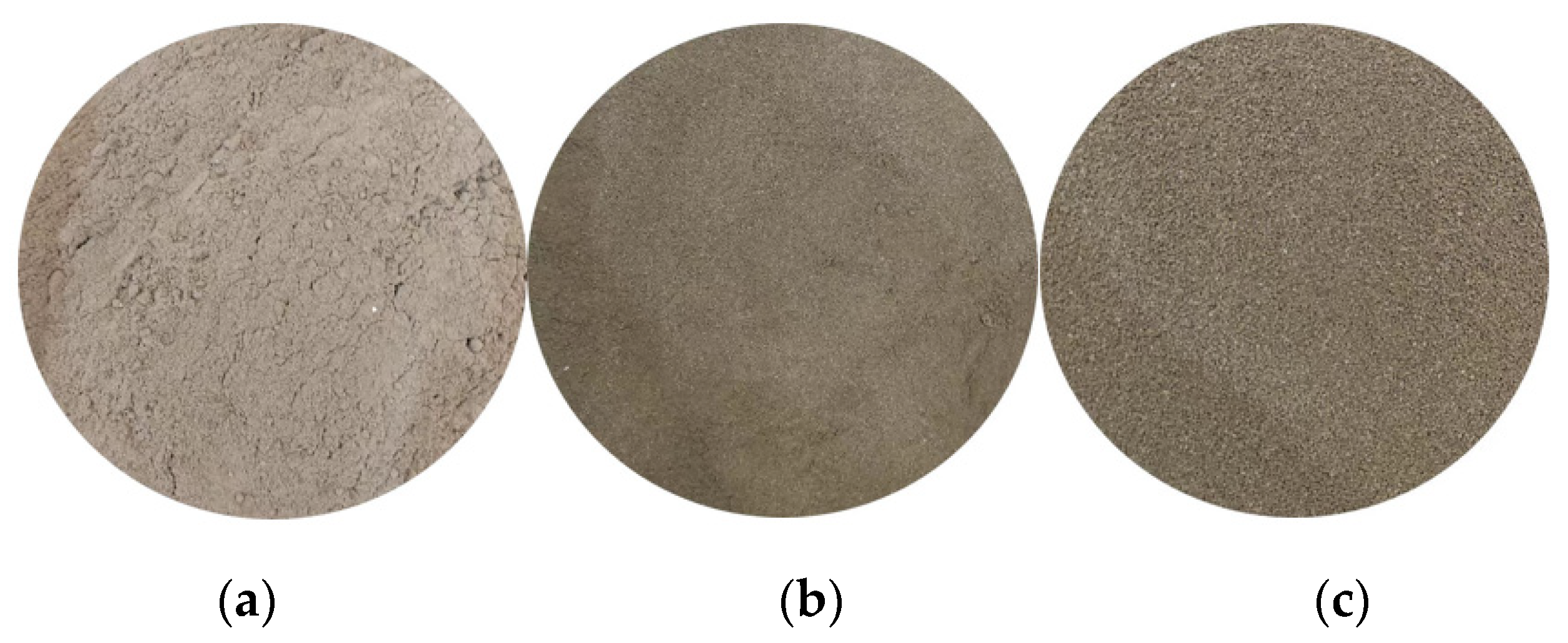

2.1. Raw Materials

2.2. Mix Proportion

2.3. Specimen Preparation

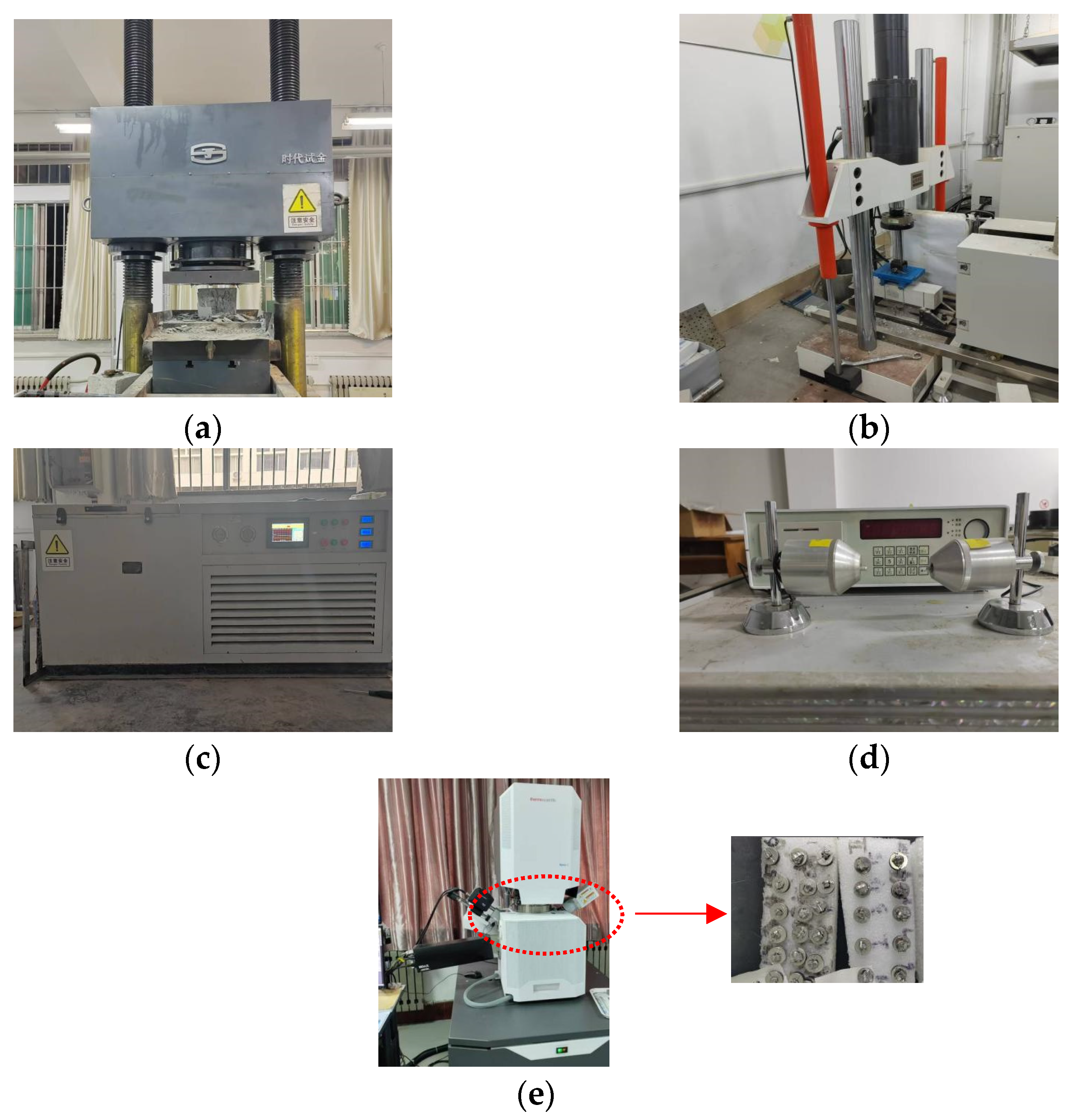

2.4. Test Methods

3. Results and Discussion

3.1. Mechanical Properties Analysis

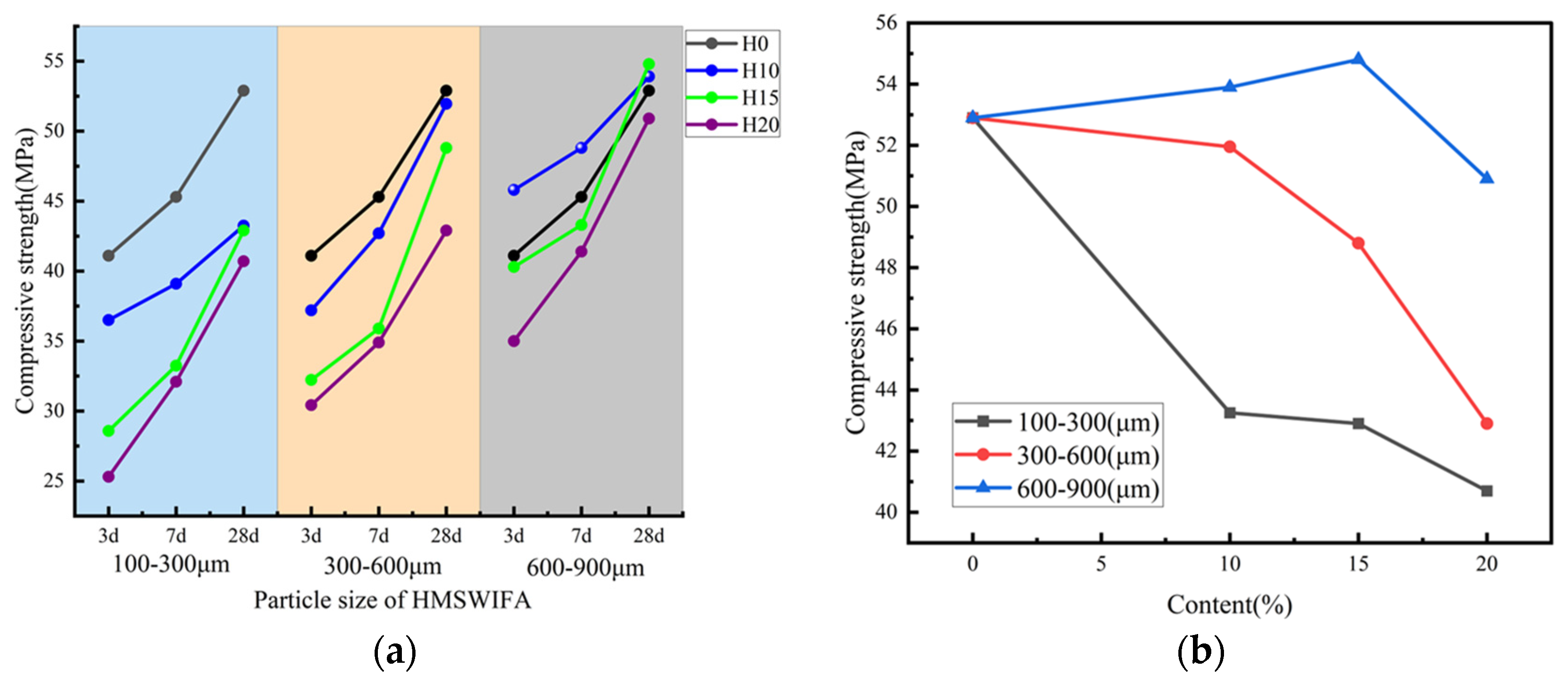

3.1.1. Compressive Strength

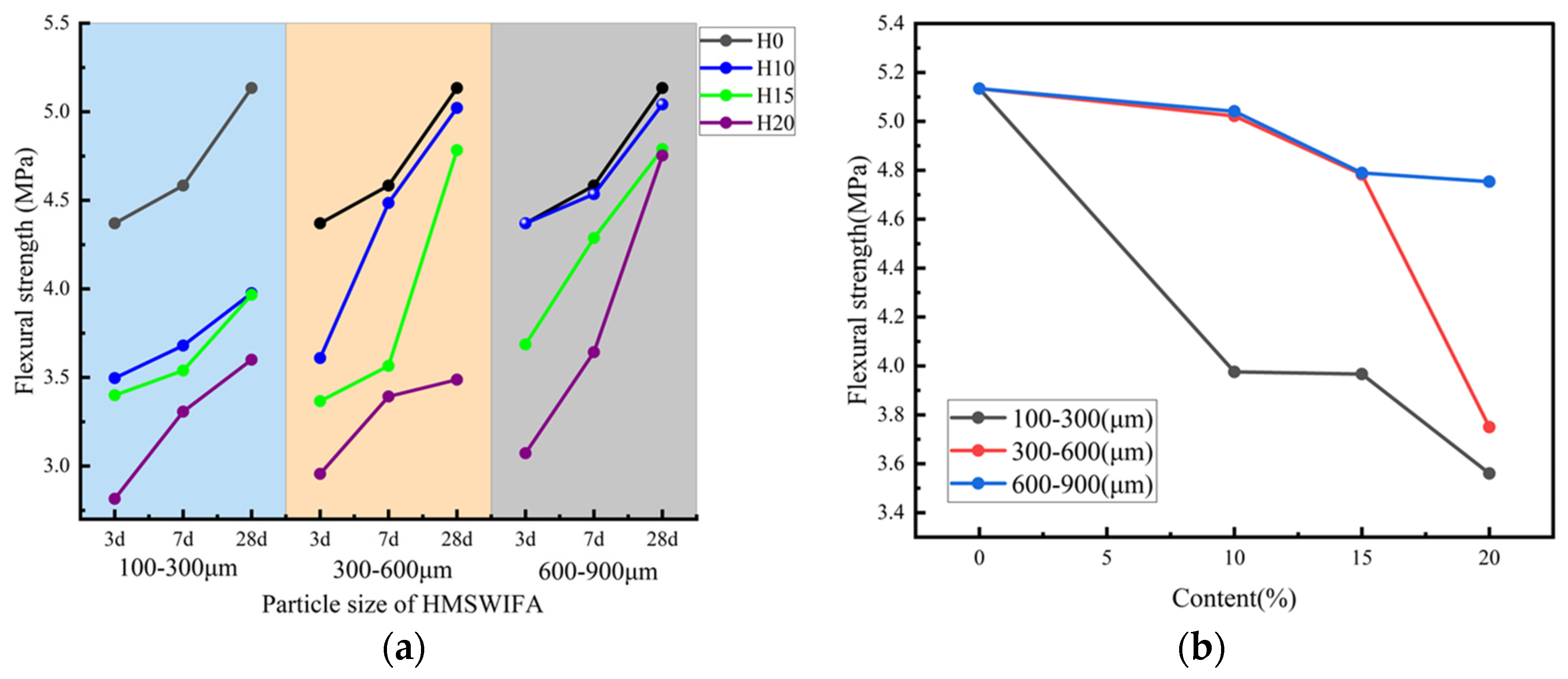

3.1.2. Flexural Strength

3.2. F-T Cycles Test

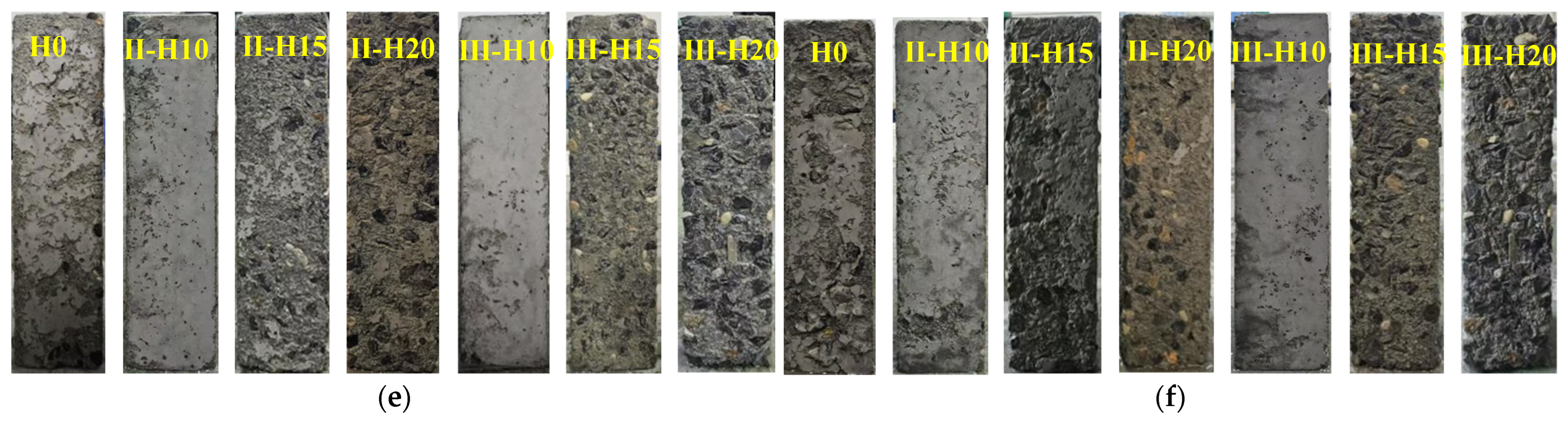

3.2.1. F-T Test Phenomenon

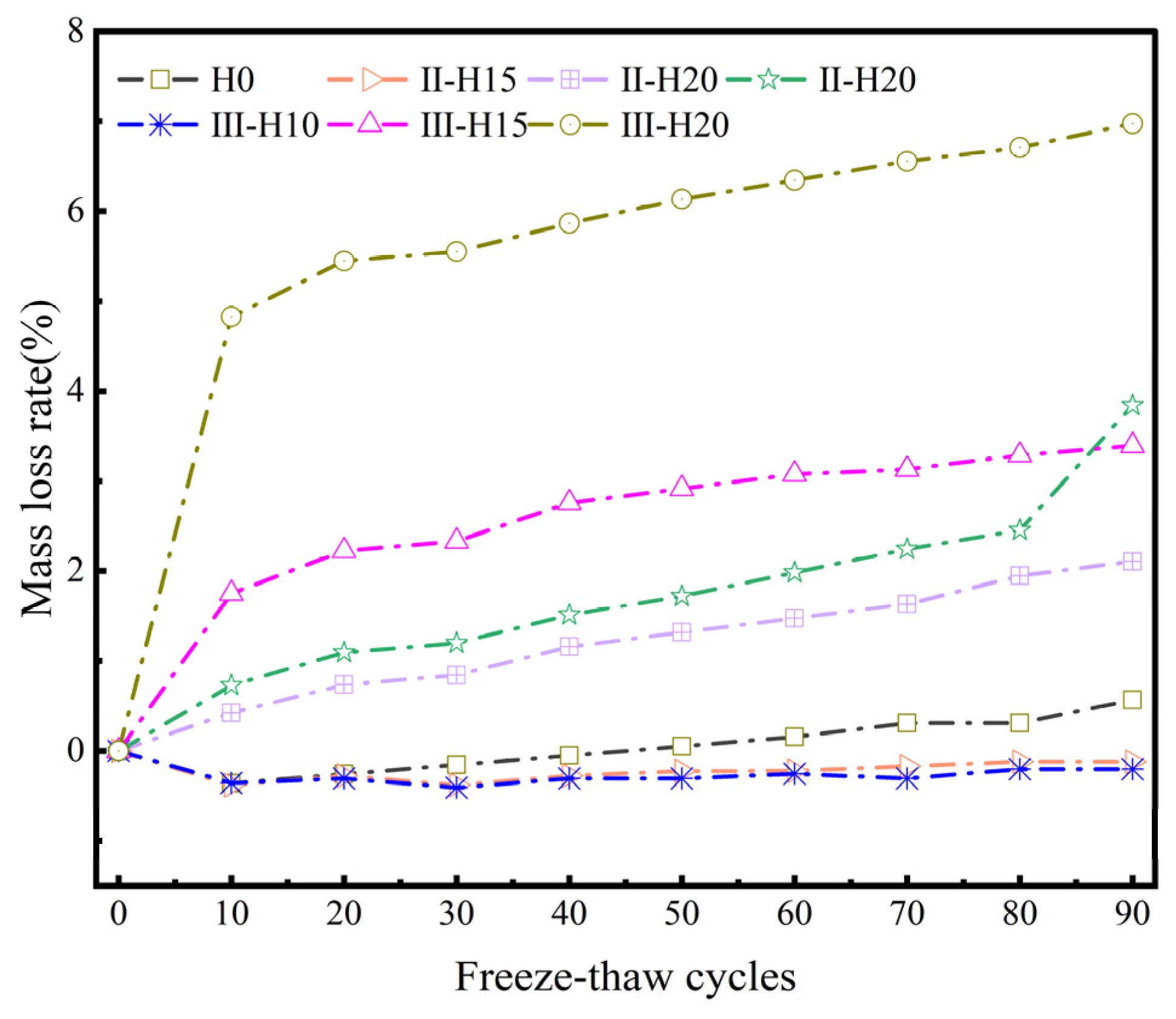

3.2.2. Mass Loss

3.2.3. Relative Dynamic Modulus of Elasticity

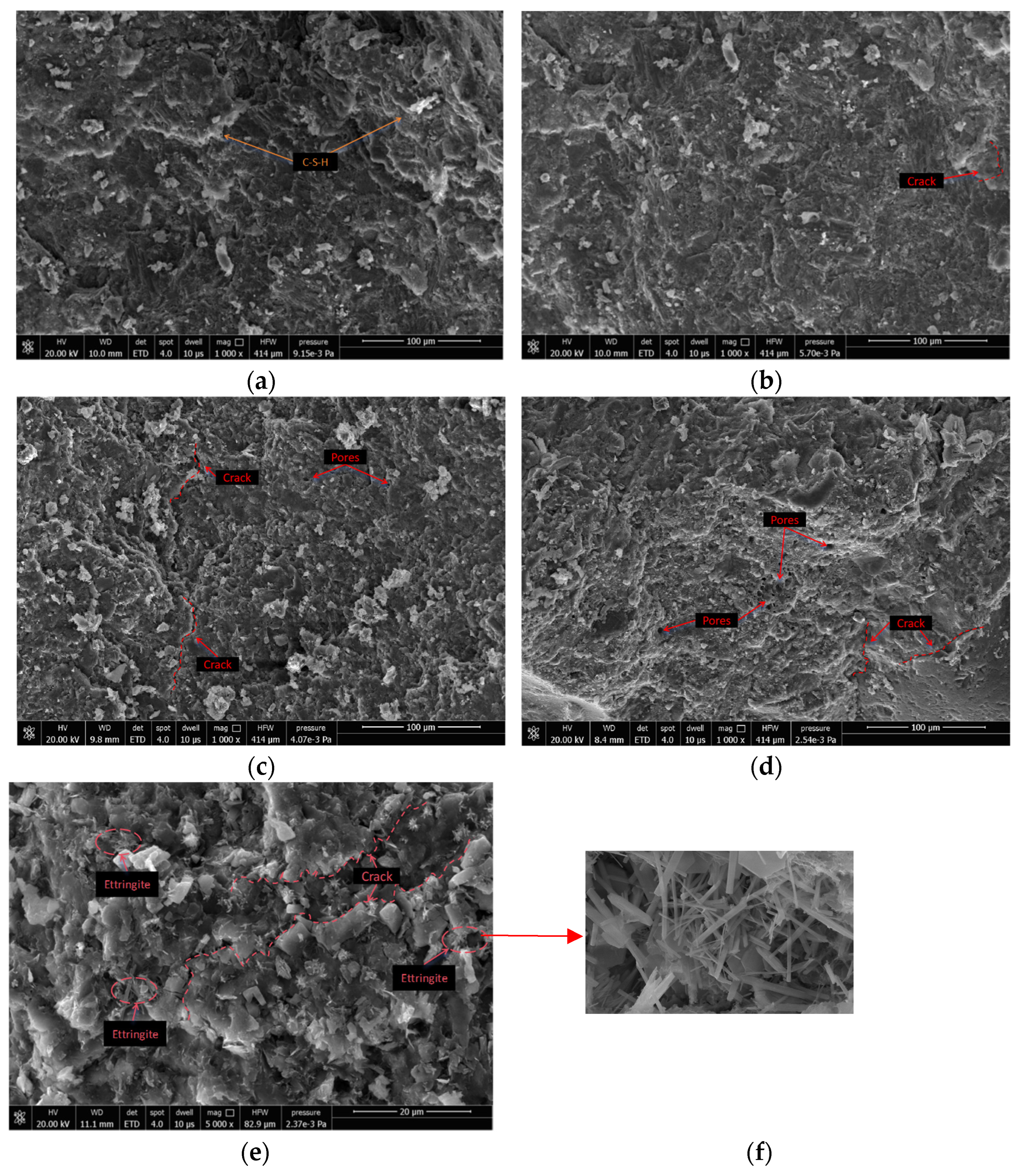

3.3. Micro-Mechanism Analysis

4. Conclusions

- (1)

- HMSWIFA particle size and content significantly influence the mechanical properties of concrete. When the particle size of HMSWIFA ranges from 600 to 900 μm and the content is between 10% and 15%, the 28-day CS of RCA increases by 1.90% to 3.60%. However, the effect on FS is minimal, with a decrease of no more than 1.81%. As the particle size decreases or the mixing amount increases, the aluminum enrichment in HMSWIFA leads to increased porosity, which limits the formation of C-(A)-S-H gel and results in a deterioration of mechanical properties.

- (2)

- A moderate amount of HMSWIFA (10% incorporation) can optimize frost resistance: the mass loss rate is reduced by 0.37% to 0.45% after 90 F-T cycles, and the RDEM is improved by 16.09% to 16.44%. This improvement is attributed to pore refinement and reinforcement of the interfacial transition zone. However, excessive incorporation (≥15%) significantly accelerates F-T damage due to the accumulation of calcite swelling stress and increased pore connectivity.

- (3)

- A small amount of HMSWIFA admixture can effectively refine the pore structure of concrete specimens, enhancing their compactness and integrity, and thereby improving their overall performance. Microstructural analysis revealed that HMSWIFA effectively filled the pores and promoted densification at a content of 10%. However, at contents of 15% or greater, sulfate-induced excessive calcite generation, this phenomenon induces the propagation of microcracks and an escalation in porosity, ultimately leading to a decline in macroscopic properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, B.; Gan, M.; Ji, Z.; Fan, X.; Zhang, D.; Chen, X.; Sun, Z.; Huang, X.; Fan, Y. Recent progress on the thermal treatment and resource utilization technologies of municipal waste incineration fly ash: A review. Process Saf. Environ. Prot. 2022, 159, 547–565. [Google Scholar] [CrossRef]

- Zhang, S.; Ghouleh, Z.; Shao, Y. Green concrete made from MSWI residues derived eco-cement and bottom ash aggregates. Constr. Build. Mater. 2021, 297, 123818. [Google Scholar] [CrossRef]

- Joseph, A.M.; Snellings, R.; Van den Heede, P.; Matthys, S.; De Belie, N. The Use of Municipal Solid Waste Incineration Ash in Various Building Materials: A Belgian Point of View. Materials 2018, 11, 141. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Fan, X.; Li, Z.; Zhang, W.; Jin, H.; Xing, F.; Tang, L. Novel recycling application of high volume municipal solid waste incineration bottom ash (MSWIBA) into sustainable concrete. Sci. Total Environ. 2022, 838, 156124. [Google Scholar] [CrossRef] [PubMed]

- Alderete, N.M.; Joseph, A.M.; Heede, P.V.D.; Matthys, S.; De Belie, N. Effective and sustainable use of municipal solid waste incineration bottom ash in concrete regarding strength and durability. Resour. Conserv. Recycl. 2021, 167, 105356. [Google Scholar] [CrossRef]

- Saikia, N.; Cornells, G.; Mertens, G.; Elsen, J.; Van Balen, K.; Van Gerven, T.; Vandecasteele, C. Assessment of Pb-slag, MSWI bottom ash and boiler and fly ash for using as a fine aggregate in cement mortar. J. Hazard. Mater. 2008, 154, 766–777. [Google Scholar] [CrossRef]

- Tang, P.; Xuan, D.; Cheng, H.W.; Poon, C.S.; Tsang, D.C. Use of CO2 curing to enhance the properties of cold bonded lightweight aggregates (CBLAs) produced with concrete slurry waste (CSW) and fine incineration bottom ash (IBA). J. Hazard. Mater. 2020, 381, 120951. [Google Scholar] [CrossRef]

- Tang, P.; Brouwers, H.J.H. Integral recycling of municipal solid waste incineration (MSWI) bottom ash fines (0–2 mm) and industrial powder wastes by cold-bonding pelletization. Waste Manag. 2017, 62, 125–138. [Google Scholar] [CrossRef]

- Ferraro, A.; Colangelo, F.; Farina, I.; Race, M.; Cioffi, R.; Cheeseman, C.; Fabbricino, M. Cold-bonding process for treatment and reuse of waste materials: Technical designs and applications of pelletized products. Crit. Rev. Environ. Sci. Technol. 2020, 51, 2197–2231. [Google Scholar] [CrossRef]

- Lu, J.; Yang, X.; Lai, Y.; Gao, J.; Wang, Y.; Deng, F.; Zhang, Z. Mechanical and microscopic properties of concretes made with municipal solid waste incinerator bottom ash (MSWIBA) exposed to freeze-thaw cycles. Constr. Build. Mater. 2024, 452, 138864. [Google Scholar] [CrossRef]

- Liu, J.; Hu, L.; Tang, L.; Ren, J. Utilisation of municipal solid waste incinerator (MSWI) fly ash with metakaolin for preparation of alkali-activated cementitious material. J. Hazard. Mater. 2021, 402, 123451.1–123451.12. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Li, Z.; Zhang, W.; Jin, H.; Xing, F.; Tang, L. The impact of cold-bonded artificial lightweight aggregates produced by municipal solid waste incineration bottom ash (MSWIBA) replace natural aggregates on the mechanical, microscopic, and environmental properties and durability of sustainable concrete. J. Clean. Prod. 2022, 337, 130479. [Google Scholar] [CrossRef]

- Chen, Z.; Yang, E.H. Early age hydration of blended cement with different size fractions of municipal solid waste incineration bottom ash. Constr. Build. Mater 2017, 156, 880–890. [Google Scholar] [CrossRef]

- Iino, S.; Tatsuichi, S.; Miyawaki, K. Characterization of metal concentration, heavy metal elution, and desalination behavior of municipal solid waste incineration bottom and grate sifting deposition ash based on particle size. J. Mater. Cycles Waste Manag. 2021, 23, 341–357. [Google Scholar] [CrossRef]

- Beikmohammadi, M.; Yaghmaeian, K.; Nabizadeh, R.; Mahvi, A.H. Analysis of heavy metal, rare, precious, and metallic element content in bottom ash from municipal solid waste incineration in Tehran based on particle size. Sci. Rep. 2023, 13, 16044. [Google Scholar] [CrossRef]

- Weng, M.C.; Wu, M.H.; Lin, C.L.; Syue, D.-K.; Hung, C. Long-term mechanical stability of cemented incineration bottom ash. Constr. Build. Mater. 2015, 93, 551–557. [Google Scholar] [CrossRef]

- Abu Taqa, A.; Ebead, U.A.; Mohsen, M.O.; Aburumman, M.O.; Senouci, A.; Maherzi, W.; Qtiashat, D. Experimental Assessment of the Strength and Microstructural Properties of Fly Ash-Containing Basalt Fiber-Reinforced Self-Compacting Sustainable Concrete. J. Compos. Sci. 2025, 9, 79. [Google Scholar] [CrossRef]

- Golewski, G.L. Determination of fracture mechanic parameters of concretes based on cement matrix enhanced by fly ash and nano-silica. Materials 2024, 17, 4230. [Google Scholar] [CrossRef]

- Li, T.; Wang, B.; Zhang, X.; Han, X.; Xing, Y.; Fan, C.; Liu, Z. Effect of nano silica on solidification/stabilization of heavy metal in alkali-activated MSWI fly ash solidified body. Process Saf. Environ. Prot. 2023, 176, 462–474. [Google Scholar] [CrossRef]

- GB 175-2007; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Standardization Administration of China. Common Portland Cement. Standards Press of China: Beijing, China, 2007. (In Chinese)

- JGJ 55-2011; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Specification for Mix Proportion Design of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2011. (In Chinese)

- Akbas, M.; Iyisan, R.; Dayioglu, A.Y.; Hatipoglu, M. Stiffness properties of recycled concrete aggregates as unbound base and subbase materials under freeze and thaw cycles. Arab. J. Sci. Eng. 2021, 46, 10569–10584. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, J.D.; Xu, S.L.; Hu, Z.J. Experimental Analysis of Relationship between Pore-structure and Frost-resistance of Concrete. Appl. Mech. Mater. 2012, 174, 117–120. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standards for Test Methods of Physical and Mechanical Properties of Concrete. Standards Press of China: Beijing, China, 2019. (In Chinese)

- GB/T 50082-2009; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Standards Press of China: Beijing, China, 2009. (In Chinese)

- Cheng, L.; Jin, H.; Wu, Y.; Ren, Y.; Liu, J.; Xing, F. Influence of municipal solid waste incineration bottom ash particle size on cement hydration and performance. Constr. Build. Mater. 2024, 432, 15. [Google Scholar] [CrossRef]

- Ren, J.; Hu, L.; Dong, Z.; Tang, L.; Xing, F.; Liu, J. Effect of silica fume on the mechanical property and hydration characteristic of alkali-activated municipal solid waste incinerator (MSWI) fly ash. J. Clean. Prod. 2021, 295, 126317. [Google Scholar] [CrossRef]

- Randall, J.P.; Meador, M.A.B.; Jana, S.C. Polymer reinforced silica aerogels: Effects of dimethyldiethoxysilane and bis(trimethoxysilylpropyl)amine as silane precursors. J. Mater. Chem. A 2013, 1, 6642–6652. [Google Scholar] [CrossRef]

- Wang, X.; Shi, C.; He, F.; Yuan, Q.; Wang, D.; Huang, Y.; Li, Q. Chloride Binding and Its Effects on Microstructure of Cement-based Materials. J. Chin. Ceram. Soc. 2013, 41, 187–198. [Google Scholar] [CrossRef]

- Wang, Q.; Li, H.; Ding, Z.; Shan, R.; Zhao, M. Construction of a Molecular Dynamics Model of NASH Geopolymer Based on XRD Analysis. Materials 2024, 17, 6103. [Google Scholar] [CrossRef]

- Powers, T.C. A working hypothesis for further studies of frost resistance of concrete. ACI Mater. J. 1945, 16, 245–272. [Google Scholar] [CrossRef]

- Beaudoin, J.J.; Macinnis, C. The mechanism of frost damage in hardened cement paste. Cem. Concr. Res. 1974, 4, 139–147. [Google Scholar] [CrossRef]

- Wu, J.; Jing, X.; Wang, Z. Uni-axial compressive stress-strain relation of recycled coarse aggregate concrete after freezing and thawing cycles. Constr. Build. Mater. 2017, 134, 210–219. [Google Scholar] [CrossRef]

- Yan, P.; Wu, J.; Lin, D.; Liu, X. Uniaxial compressive stress–strain relationship of mixed recycled aggregate concrete. Constr. Build. Mater. 2022, 350, 128663. [Google Scholar] [CrossRef]

- Xiao, Q.H.; Li, Q.; Cao, Z.Y.; Tian, W.Y. The deterioration law of recycled concrete under the combined effects of freeze-thaw and sulfate attack. Constr. Build Mater. 2019, 200, 344–355. [Google Scholar] [CrossRef]

- Min, D.; Tang, M. Formation and expansion of ettringite crystals. Cem. Concr. Res. 1994, 24, 119–126. [Google Scholar] [CrossRef]

- Niu, H.C.; Fan, Y.H.; Zhang, X.G.; Yin, X. Experimental Study on the Freeze-thaw Resistance of Recycled Concrete with Different Replacement Ratios. J. Mater. Sci. Eng. 2018, 36, 615–620. [Google Scholar]

- Fu, Y.; Cai, L.; Wu, Y. Freeze–thaw cycle test and damage mechanics models of alkali-activated slag concrete. Constr. Build. Mater. 2011, 25, 3144–3148. [Google Scholar] [CrossRef]

- Lin, H.; Takasu, K.; Suyama, H.; Koyamada, H.; Liu, S. A study on properties, static and dynamic elastic modulus of recycled concrete under the influence of modified fly ash. Constr. Build. Mater. 2022, 347, 128585. [Google Scholar] [CrossRef]

- Bizzozero, J.; Gosselin, C.; Scrivener, K.L. Expansion mechanisms in calcium aluminate and sulfoaluminate systems with calcium sulfate. Cem. Concr. Res. 2014, 56, 190–202. [Google Scholar] [CrossRef]

- Mehta, P.K. Mechanism of expansion associated with ettringite formation. Cem. Concr. Res. 1973, 3, 1–6. [Google Scholar] [CrossRef]

| Initial Setting Time (min) | Final Setting Time (min) | CS (MPa) 3 d/28 d | FS (MPa) 3 d/28 d |

|---|---|---|---|

| 183 | 248 | 22.3/47.4 | 4.9/7.8 |

| Chemical Composition | SiO2 | CaO | Al2O | Fe2O3 | MgO | Na2O | K2O |

|---|---|---|---|---|---|---|---|

| Content | 21.65 | 61.88 | 5.35 | 3.21 | 2.52 | 0.21 | 0.16 |

| Aggregate Size (min) | Crushing Index (%) | Density (kg/m3) |

|---|---|---|

| 5–26.5 | 15.2 | 2586.3 |

| Mud Content (min) | Crushing Index (%) | Density (kg/m3) | Water Absorption(%) | Porosity (%) | Particle Size Modulus (mm) |

|---|---|---|---|---|---|

| 0.9 | 8.2 | 2641.2 | 0.7 | 44.3 | 2.9 |

| Specimen Number | Water | Cement | Sand | Natural Stone | RCA | HMSWIFA |

|---|---|---|---|---|---|---|

| H0 | 262.5 | 691.5 | 768 | 1502.4 | 375.6 | 0.00 |

| I/II/III-H5 | 262.5 | 656.93 | 768 | 1502.4 | 375.6 | 34.575 |

| I/II/III-H10 | 262.5 | 622.35 | 768 | 1502.4 | 375.6 | 69.15 |

| I/II/III-H15 | 262.5 | 587.78 | 768 | 1502.4 | 375.6 | 103.73 |

| I/II/III-H20 | 262.5 | 553.20 | 768 | 1502.4 | 375.6 | 138.30 |

| Test Category | Test Age (d) | Specimen Size (mm) | Number of Specimens | Testing Instruments | Test Category |

|---|---|---|---|---|---|

| Cube compressive strength test | 3/7/28 | 100 × 100 × 100 | 3 | YAM-3000A Microcomputer Control Electro-hydraulic Servo Press Machine (NANJING TIMES TESTING EQUIPMENT Co., Ltd., Nanjing, China) | Cube compressive strength test |

| Flexural strength test | 3/7/28 | 100 × 100 × 400 | 3 | PWS-100 Electro-hydraulic servo static universal testing machine (Jinan Limei Electromechanical Technology Co., Ltd., Jinan, China) | Flexural strength test |

| Frost resistance test | 28 | 100 × 100 × 400 | 3 | TDR-9 Concrete Fast Freezing and Thawing Tester (Xinyuan Electromechanical Instrument Factory, Liaoning, China) | Frost resistance test |

| Dynamic modulus of elasticity test | 28 | 100 × 100 × 400 | 6 | DT-10W Dynamic Elastic Modulus Tester (Xin Gao Instrument Co., Ltd., Guizhou, China) | Dynamic modulus of elasticity test |

| Scanning electron microscope test | 28 | / | 3 | Field Emission Environmental Scanning Electron Microscope | Scanning electron microscope test |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, B.; Li, Y.; Zhang, W. Effects of Harmless Municipal Solid Waste Incineration Fly Ash on the Macroscopic Properties and Microstructure of Recycled Aggregate Concrete. Materials 2025, 18, 1866. https://doi.org/10.3390/ma18081866

Song B, Li Y, Zhang W. Effects of Harmless Municipal Solid Waste Incineration Fly Ash on the Macroscopic Properties and Microstructure of Recycled Aggregate Concrete. Materials. 2025; 18(8):1866. https://doi.org/10.3390/ma18081866

Chicago/Turabian StyleSong, Bochen, Yefan Li, and Wengang Zhang. 2025. "Effects of Harmless Municipal Solid Waste Incineration Fly Ash on the Macroscopic Properties and Microstructure of Recycled Aggregate Concrete" Materials 18, no. 8: 1866. https://doi.org/10.3390/ma18081866

APA StyleSong, B., Li, Y., & Zhang, W. (2025). Effects of Harmless Municipal Solid Waste Incineration Fly Ash on the Macroscopic Properties and Microstructure of Recycled Aggregate Concrete. Materials, 18(8), 1866. https://doi.org/10.3390/ma18081866