Investigation of the Process Optimization for L-PBF Hastelloy X Alloy on Microstructure and Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. L-PBF Process

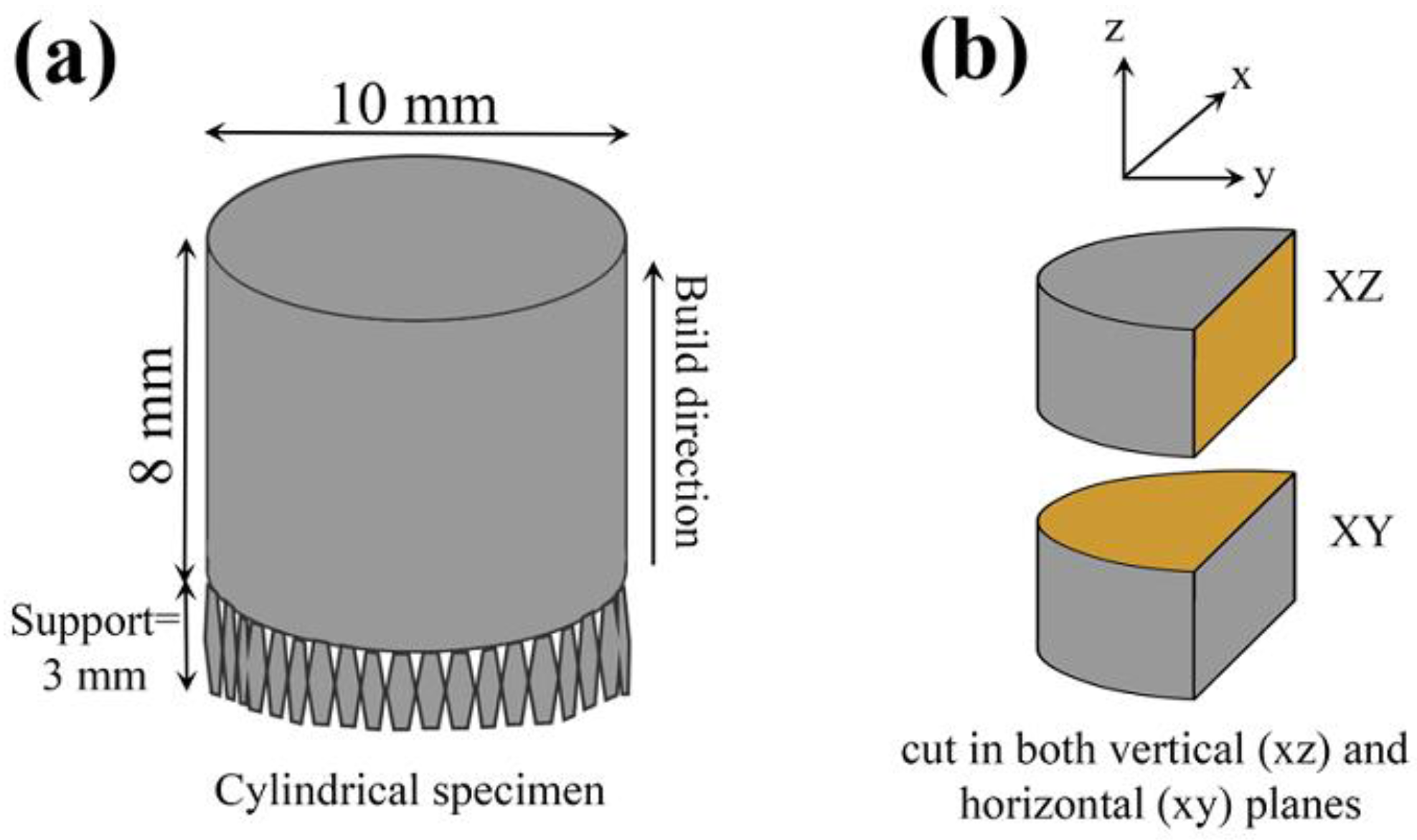

2.2. Material Characterization Techniques

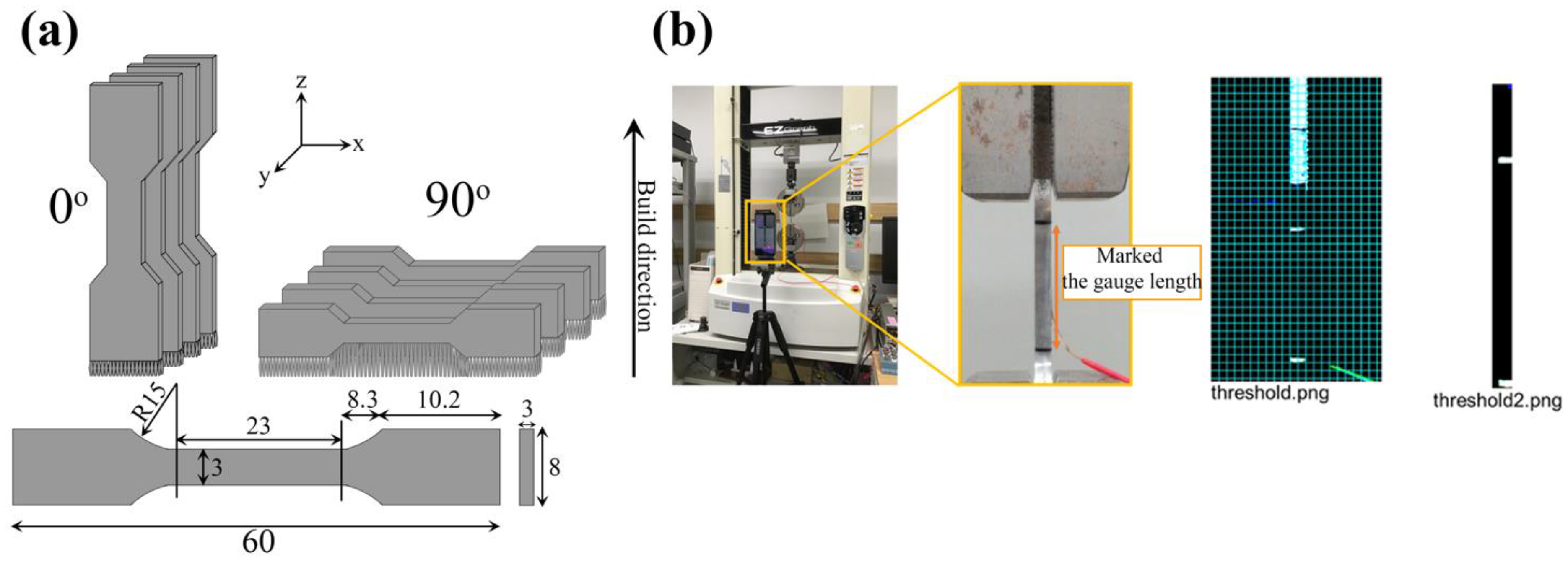

2.3. Tests for Mechanical Properties

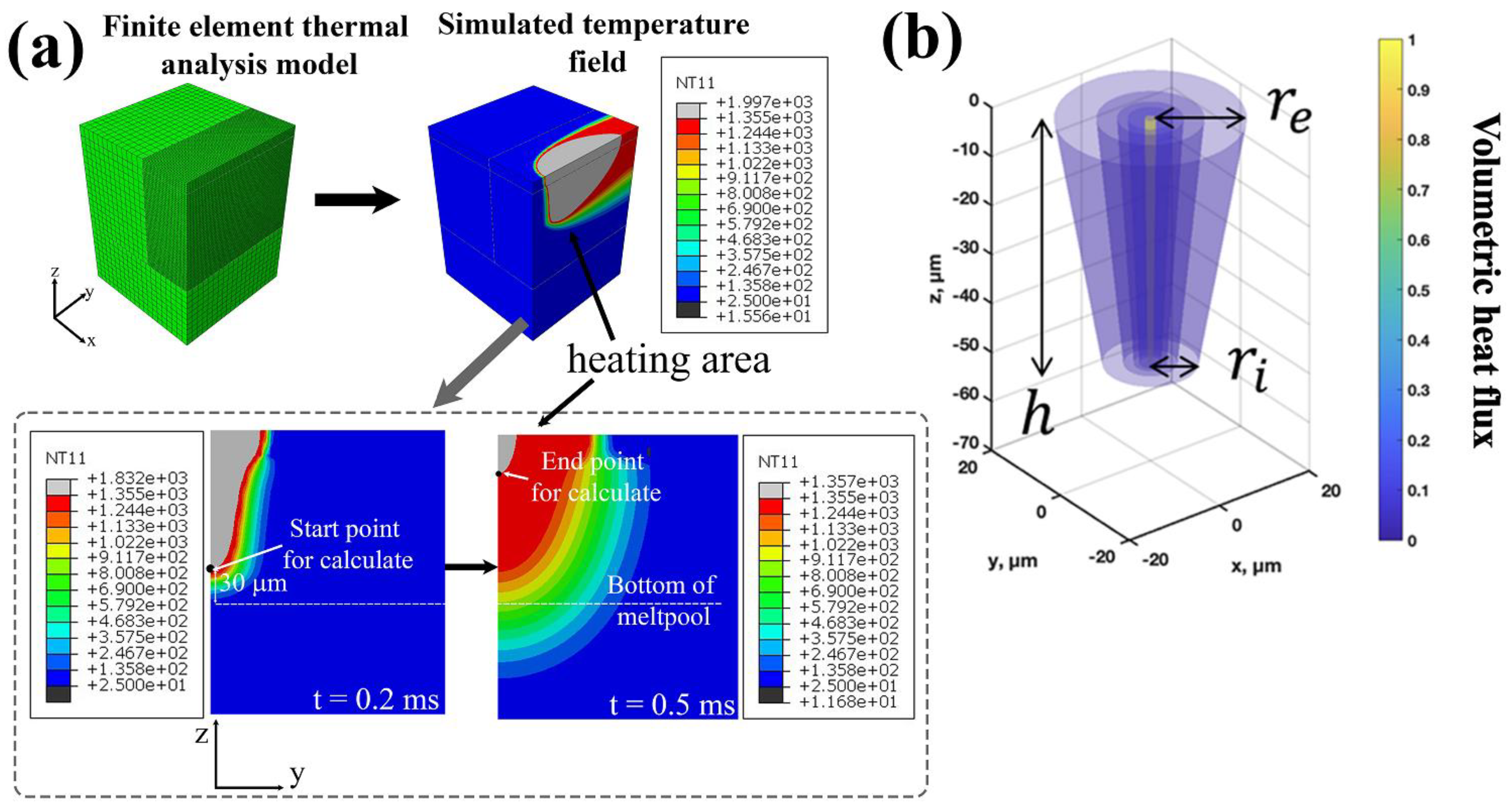

2.4. FEM Analysis

3. Results

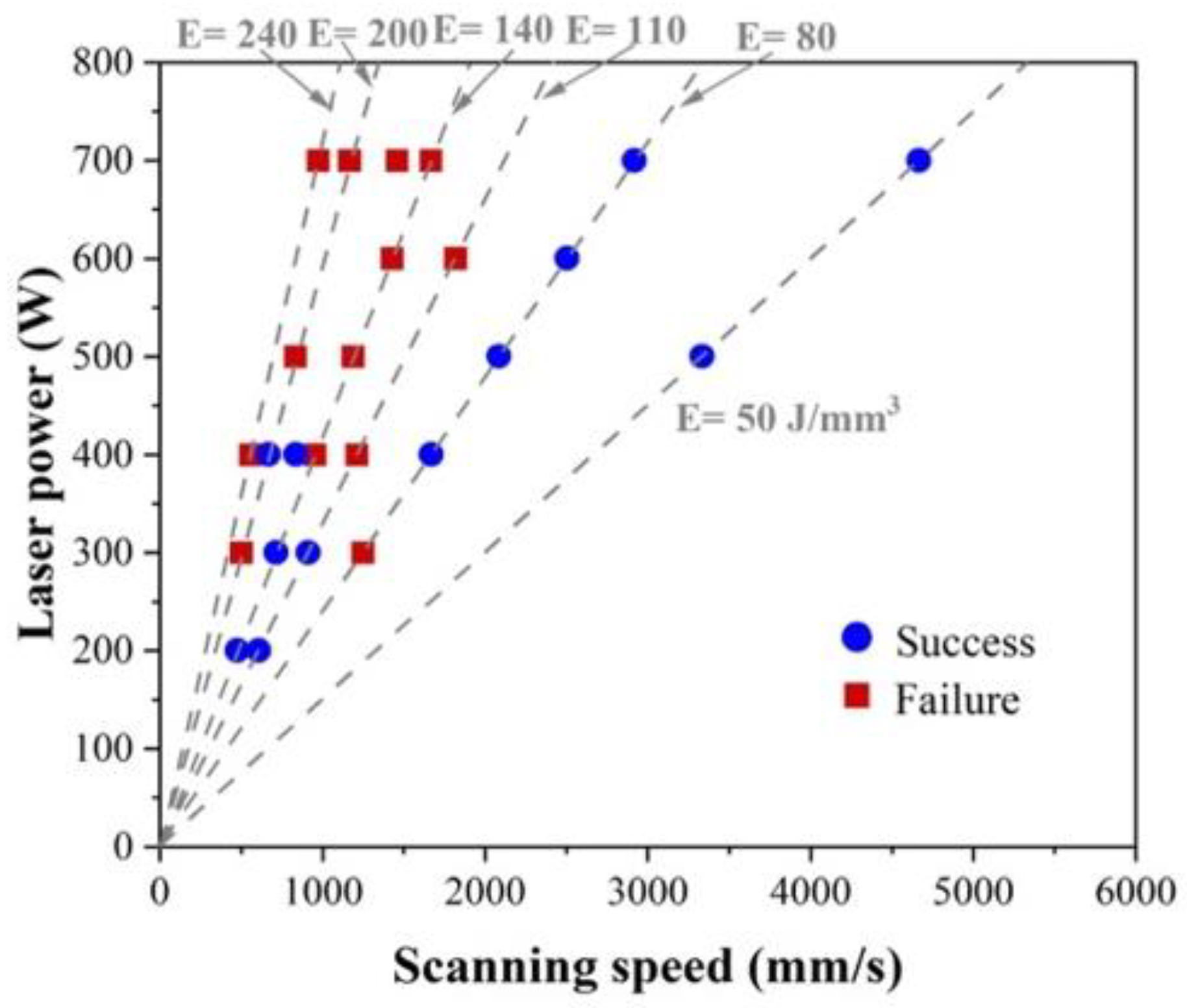

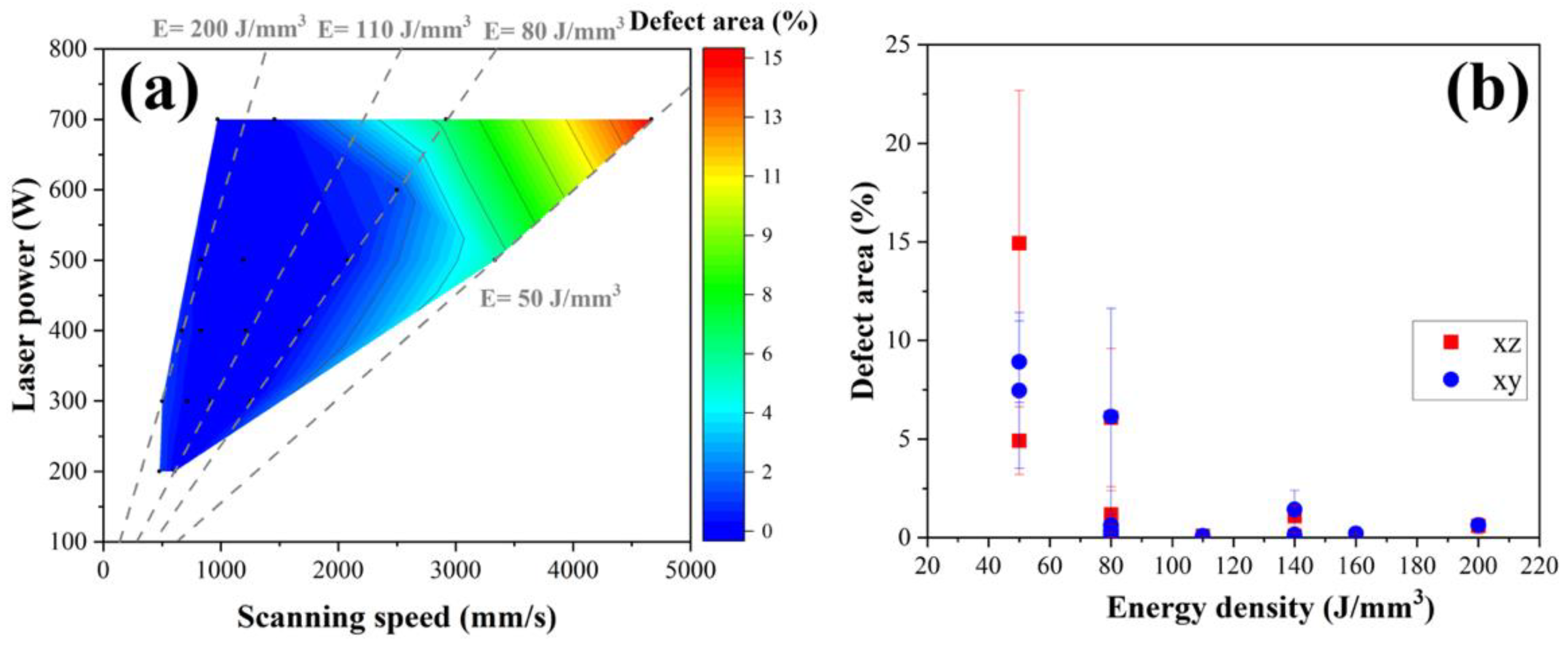

3.1. Optimization of L-PBF Parameters

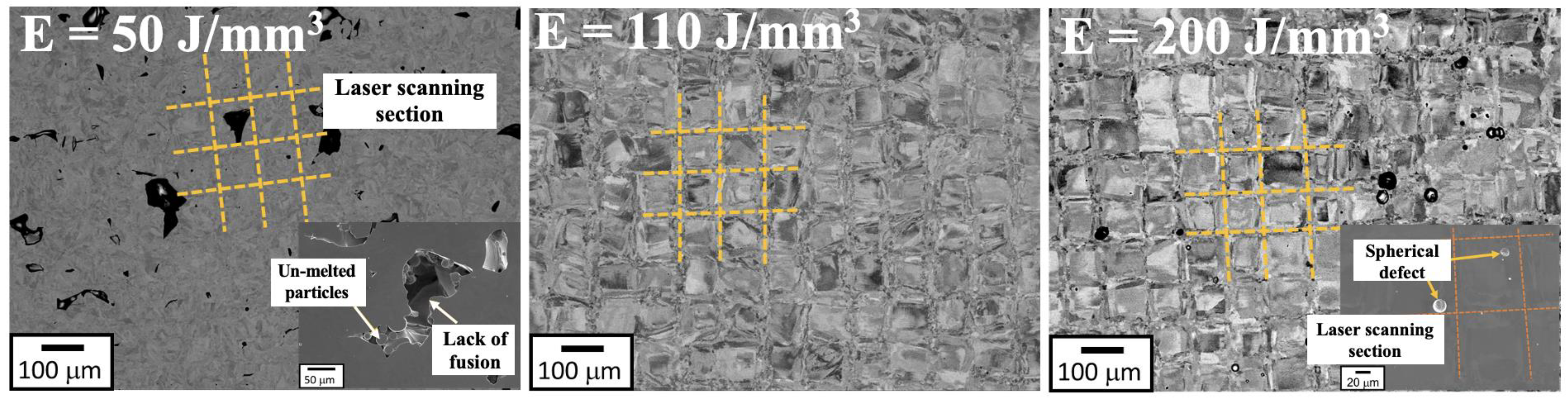

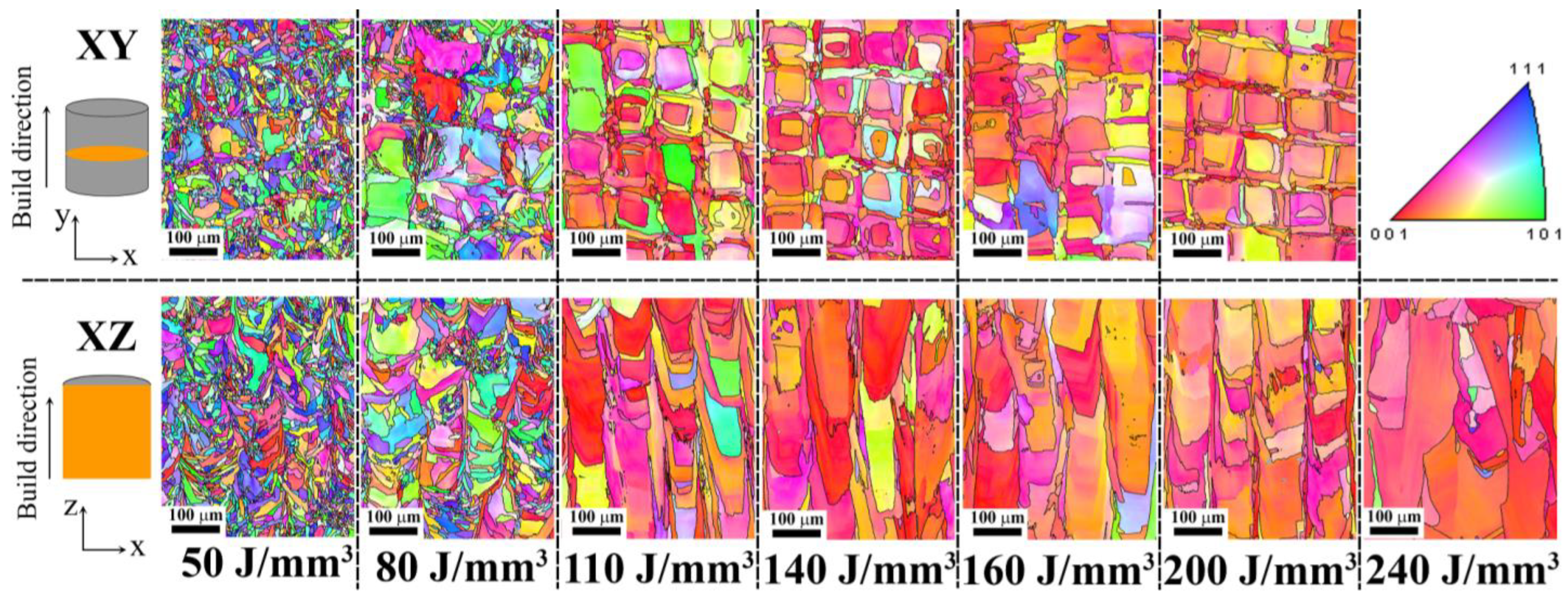

3.2. Effects of the Process Parameters on the Defects and Microstructure

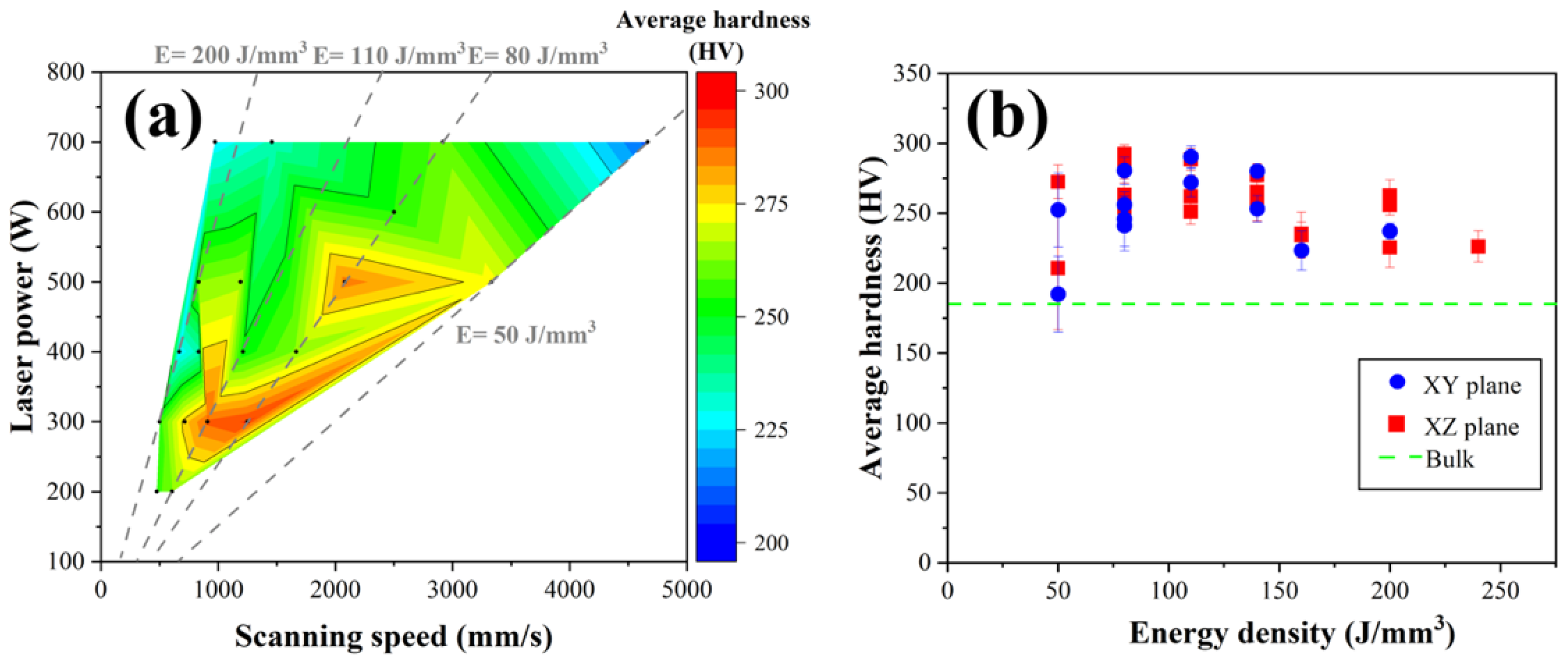

3.3. Effects of the Process Parameters on the Mechanical Properties

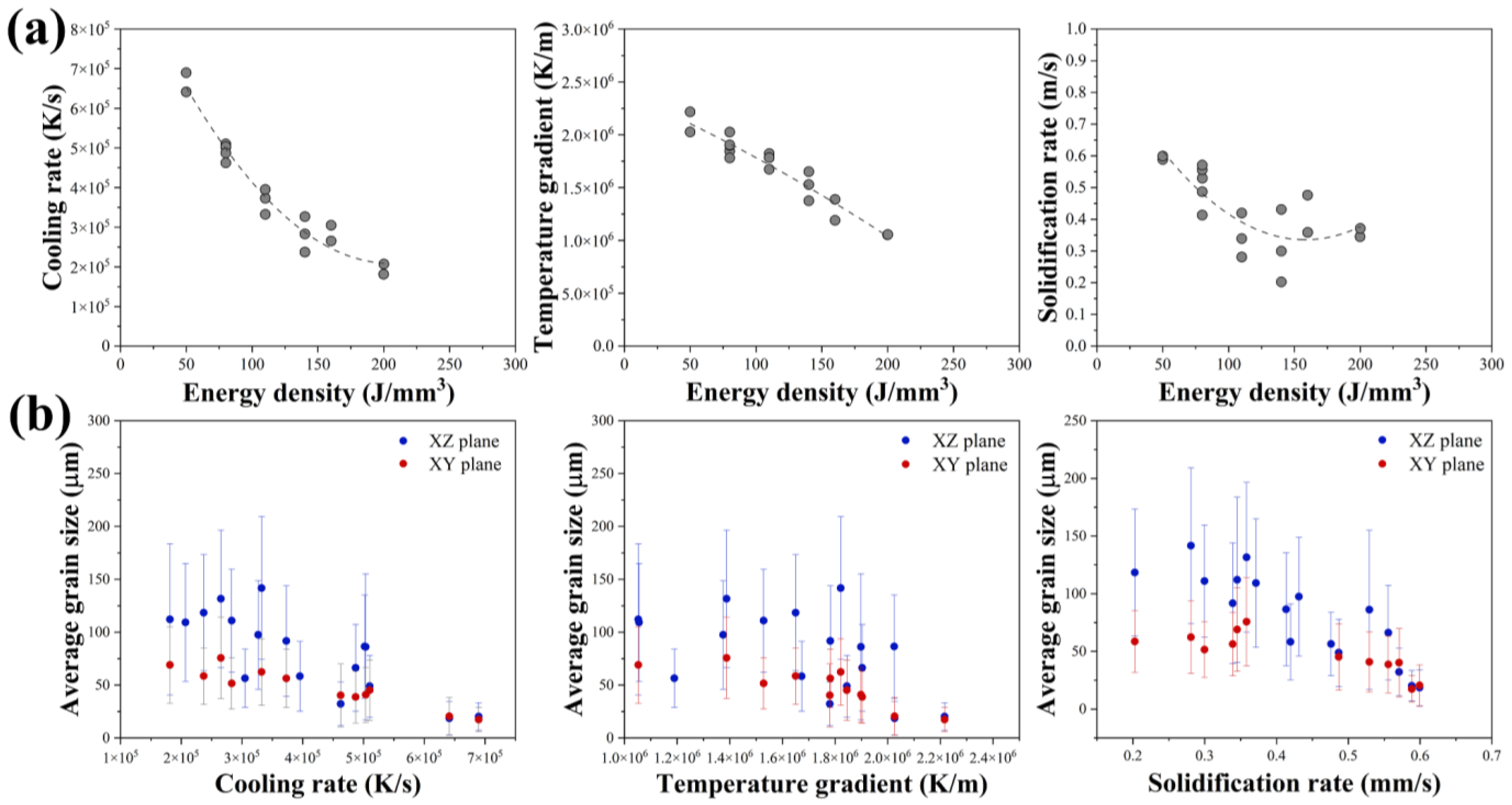

3.4. FEM Simulation Results

4. Discussion

5. Conclusions

- Insufficient energy input resulted in porous structures with the a of fusion defects, while excessive energy input led to some spherical pores by metal evaporation.

- When a high energy input is used, the cooling rate during L-PBF is reduced, thereby increasing the cell and grain size. The lowest thermal gradient promotes the epitaxial growth and columnar grain, resulting in the formation of both a morphological and crystallographic texture along the building direction.

- The finer grain with a high dislocation density caused by the high cooling rate in the low-energy-input L-PBF process was responsible for the high hardness values together with the tensile strength. The heterogeneous structure with fine grains in various L-PBF processing parameters of the HX alloy is responsible for the higher mechanical properties when compared to that produced by the traditional process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, Q.; Mertens, R.; Montero-Sistiaga, M.L.; Yang, S.; Setchi, R.; Vanmeensel, K.; Hooreweder, B.V.; Evans, S.L.; Fan, H. Laser Powder Bed Fusion of Hastelloy X: Effects of Hot Isostatic Pressing and the Hot Cracking Mechanism. Mater. Sci. Eng. A 2018, 732, 228–239. [Google Scholar] [CrossRef]

- Esmaeilizadeh, R.; Keshavarzkermani, A.; Ali, U.; Mahmoodkhani, Y.; Behravesh, B.; Jahed, H.; Bonakdar, A.; Toyserkani, E. Customizing Mechanical Properties of Additively Manufactured Hastelloy X Parts by Adjusting Laser Scanning Speed. J. Alloys Compd. 2020, 812, 152097. [Google Scholar] [CrossRef]

- Hibino, S.; Todo, T.; Ishimoto, T.; Gokcekaya, O.; Koizumi, Y.; Igashira, K.; Nakano, T. Control of Crystallographic Texture and Mechanical Properties of Hastelloy-X via Laser Powder Bed Fusion. Crystals 2021, 11, 1064. [Google Scholar] [CrossRef]

- Huang, Z.; Zhai, Z.; Lin, W.; Chang, H.; Wu, Y.; Yang, R.; Zhang, Z. On the Orientation Dependent Microstructure and Mechanical Behavior of Hastelloy X Superalloy Fabricated by Laser Powder Bed Fusion. Mater. Sci. Eng. A 2022, 844, 143208. [Google Scholar] [CrossRef]

- Abd-Elaziem, W.; Elkatatny, S.; Abd-Elaziem, A.-E.; Khedr, M.; Abd El-baky, M.A.; Hassan, M.A.; Abu-Okail, M.; Mohammed, M.; Järvenpää, A.; Allam, T.; et al. On the Current Research Progress of Metallic Materials Fabricated by Laser Powder Bed Fusion Process: A Review. J. Mater. Res. Technol. 2022, 20, 681–707. [Google Scholar] [CrossRef]

- Harrison, N.J.; Todd, I.; Mumtaz, K. Reduction of Micro-Cracking in Nickel Superalloys Processed by Selective Laser Melting: A Fundamental Alloy Design Approach. Acta Mater. 2015, 94, 59–68. [Google Scholar] [CrossRef]

- Kitano, H.; Kusano, M.; Tsujii, M.; Yumoto, A.; Watanabe, M. Process Parameter Optimization Framework for the Selective Laser Melting of Hastelloy X Alloy Considering Defects and Solidification Crack Occurrence. Crystals 2021, 11, 578. [Google Scholar] [CrossRef]

- Kitano, H.; Tsujii, M.; Kusano, M.; Yumoto, A.; Watanabe, M. Effect of Plastic Strain on the Solidification Cracking of Hastelloy-X in the Selective Laser Melting Process. Addit. Manuf. 2021, 37, 101742. [Google Scholar] [CrossRef]

- Esmaeilizadeh, R.; Keshavarzkermani, A.; Ali, U.; Behravesh, B.; Bonakdar, A.; Jahed, H.; Toyserkani, E. On the Effect of Laser Powder-Bed Fusion Process Parameters on Quasi-Static and Fatigue Behaviour of Hastelloy X: A Microstructure/Defect Interaction Study. Addit. Manuf. 2021, 38, 101805. [Google Scholar] [CrossRef]

- Tomus, D.; Tian, Y.; Rometsch, P.A.; Heilmaier, M.; Wu, X. Influence of Post Heat Treatments on Anisotropy of Mechanical Behaviour and Microstructure of Hastelloy-X Parts Produced by Selective Laser Melting. Mater. Sci. Eng. A 2016, 667, 42–53. [Google Scholar] [CrossRef]

- Montero-Sistiaga, M.L.; Pourbabak, S.; Van Humbeeck, J.; Schryvers, D.; Vanmeensel, K. Microstructure and Mechanical Properties of Hastelloy X Produced by HP-SLM (High Power Selective Laser Melting). Mater. Des. 2019, 165, 107598. [Google Scholar] [CrossRef]

- Promoppatum, P.; Yao, S.-C.; Pistorius, P.C.; Rollett, A.D. A Comprehensive Comparison of the Analytical and Numerical Prediction of the Thermal History and Solidification Microstructure of Inconel 718 Products made by Laser Powder-Bed Fusion. Engineering 2017, 3, 685–694. [Google Scholar] [CrossRef]

- Kusano, M.; Watanabe, M. Heat Source Model Development for Thermal Analysis of Laser Powder Bed Fusion using Bayesian Optimization and Machine Learning. Integr. Mater. Manuf. Innov. 2024, 13, 288–304. [Google Scholar] [CrossRef]

- Roberts, I.A.; Wang, C.J.; Esterlein, R.; Stanford, M.; Mynors, D.J. A Three-Dimensional Finite Element Analysis of the Temperature Field during Laser Melting of Metal Powders in Additive Layer Manufacturing. Int. J. Mach. Tools Manuf. 2009, 49, 916–923. [Google Scholar] [CrossRef]

- Kusano, M.; Watanabe, M. Microstructure Control of Hastelloy X by Geometry-Induced Elevation of Sample Temperature during a Laser Powder Bed Fusion Process. Mater. Des. 2022, 222, 111016. [Google Scholar] [CrossRef]

- Yang, T.; Liu, T.; Liao, W.; MacDonald, E.; Wei, H.; Zhang, C.; Chen, X.; Zhang, K. Laser Powder Bed Fusion of AlSi10Mg: Influence of Energy Intensities on Spatter and Porosity Evolution, Microstructure and Mechanical Properties. J. Alloys Compd. 2020, 849, 156300. [Google Scholar] [CrossRef]

- Haynes International. HASTELLOY® X Alloy. Available online: https://haynesintl.com/en/alloys/alloy-portfolio/high-temperature-alloys/hastelloy-x/ (accessed on 18 March 2025).

- Li, X.; Liu, Y. Effect of Laser Remelting on Printability, Microstructure and Mechanical Performance of Al-Mg-Sc-Zr Alloy produced by Laser Powder Bed Fusion. J. Alloys Compd. 2023, 963, 171287. [Google Scholar] [CrossRef]

- Prasad, K.; Obana, M.; Ishii, Y.; Ito, A.; Torizuka, S. The Effect of Laser Scanning Strategies on the Microstructure, Texture and Crystallography of Grains exhibiting Hot Cracks in Additively Manufactured Hastelloy X. Mech. Mater. 2021, 157, 103816. [Google Scholar] [CrossRef]

- Andreau, O.; Koutiri, I.; Peyre, P.; Penot, J.-D.; Saintier, N.; Pessard, E.; Terris, T.D.; Dupuy, C.; Baudin, T. Texture Control of 316L Parts by Modulation of the Melt Pool Morphology in Selective Laser Melting. J. Mater. Process. Technol. 2019, 264, 21–31. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel: III Discussion of Results. Proc. Phys. Soc. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Petch, N.J. The Cleavage Strength of Polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Wilson-Heid, A.E.; Novak, T.C.; Beese, A.M. Characterization of the Effects of Internal Pores on Tensile Properties of Additively Manufactured Austenitic Stainless Steel 316L. Exp. Mech. 2018, 59, 793–804. [Google Scholar] [CrossRef]

- Gorny, B.; Niendorf, T.; Lackmann, J.; Thoene, M.; Troester, T.; Maier, H.J. In Situ Characterization of the Deformation and Failure Behavior of Non-Stochastic Porous Structures processed by Selective Laser Melting. Mater. Sci. Eng. A 2011, 528, 7962–7967. [Google Scholar] [CrossRef]

- Marattukalam, J.J.; Karlsson, D.; Pacheco, V.; Beran, P.; Winklund, U.; Jansson, U.; Hjorvarsson, B.; Sahlberg, M. The Effect of Laser Scanning Strategies on Texture, Mechanicl Properties, and Site-Specific Grain Orientation in Selective Laser Melted 216L SS. Mater. Des. 2020, 193, 108852. [Google Scholar] [CrossRef]

- Deev, A.A.; Kuznetcov, P.A.; Petrov, S.N. Anisotropy of Mechanical Properties and Its Correlation with the Structure of the Stainless Steel 316L produced by SLM Method. Phys. Procedia 2016, 83, 789–796. [Google Scholar] [CrossRef]

- Etter, T.; Kunze, K.; Geiger, F.; Meidani, H. Reduction in Mechanical Anisotropy through High Temperature Heat Treatment of Hastelloy X processed by Selective Laser Melting (SLM). IOP Conf. Ser. Mater. Sci. Eng. 2015, 82, 012097. [Google Scholar] [CrossRef]

- Xiong, Z.H.; Liu, S.L.; Li, S.F.; Shi, Y.; Yang, Y.F.; Misra, R.D.K. Role of Melt Pool Boundary Condition in Determining the Mechanical Properties of Selective Laser Melting AlSi10Mg Alloy. Mater. Sci. Eng. A 2019, 740–741, 148–156. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, W.; Li, H.; Xie, Y.; Shi, J.; Liang, Z.; Han, P.; Li, S.; Zhang, H. Nano-Scale Microstructural Evolution and Mechanical Property Enhancement Mechanism during Crack Inhibition in Nickel-Based Superalloys Fabricated by Laser Powder Bed Fusion. Addit. Manuf. 2025, 100, 104685. [Google Scholar] [CrossRef]

| Ni | Fe | Cr | Co | Mo | W | C |

|---|---|---|---|---|---|---|

| Bal. | 18.1 | 22.1 | 1.6 | 9.0 | 0.7 | 0.06 |

| Parameters | |

|---|---|

| Laser type | Gaussian beam |

| Laser power (W) | 200–700 |

| Scanning speed (mm/s) | 476–4667 |

| Hatch spacing (μm) | 100 |

| Layer thickness (μm) | 30 |

| Laser diameter (μm) | 70 |

| Scanning strategy | 90° rotation |

| Conditions | Energy Density (J/mm3) | Laser Power (W) | Scanning Speed (mm/s) | Hatch Spacing (μm) | Layer Thickness (μm) | Laser Type |

|---|---|---|---|---|---|---|

| 0°, 90° 3 samples/ condition | 50 | 500 | 3333 | 100 | 30 | Gaussian beam |

| 80 | 700 | 2917 | ||||

| 80 | 500 | 2083 | ||||

| 110 | 300 | 909 | ||||

| 140 | 200 | 476 | ||||

| 140 | 300 | 714 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Daram, P.; Kusano, M.; Watanabe, M. Investigation of the Process Optimization for L-PBF Hastelloy X Alloy on Microstructure and Mechanical Properties. Materials 2025, 18, 1890. https://doi.org/10.3390/ma18081890

Daram P, Kusano M, Watanabe M. Investigation of the Process Optimization for L-PBF Hastelloy X Alloy on Microstructure and Mechanical Properties. Materials. 2025; 18(8):1890. https://doi.org/10.3390/ma18081890

Chicago/Turabian StyleDaram, Phuangphaga, Masahiro Kusano, and Makoto Watanabe. 2025. "Investigation of the Process Optimization for L-PBF Hastelloy X Alloy on Microstructure and Mechanical Properties" Materials 18, no. 8: 1890. https://doi.org/10.3390/ma18081890

APA StyleDaram, P., Kusano, M., & Watanabe, M. (2025). Investigation of the Process Optimization for L-PBF Hastelloy X Alloy on Microstructure and Mechanical Properties. Materials, 18(8), 1890. https://doi.org/10.3390/ma18081890