Effect of Heat Treatment on the Grain Boundary Character Distribution and Bending Properties of Fine-Grained Phosphorus Bronze

Abstract

1. Introduction

2. Experimental Materials and Methods

3. Results and Discussion

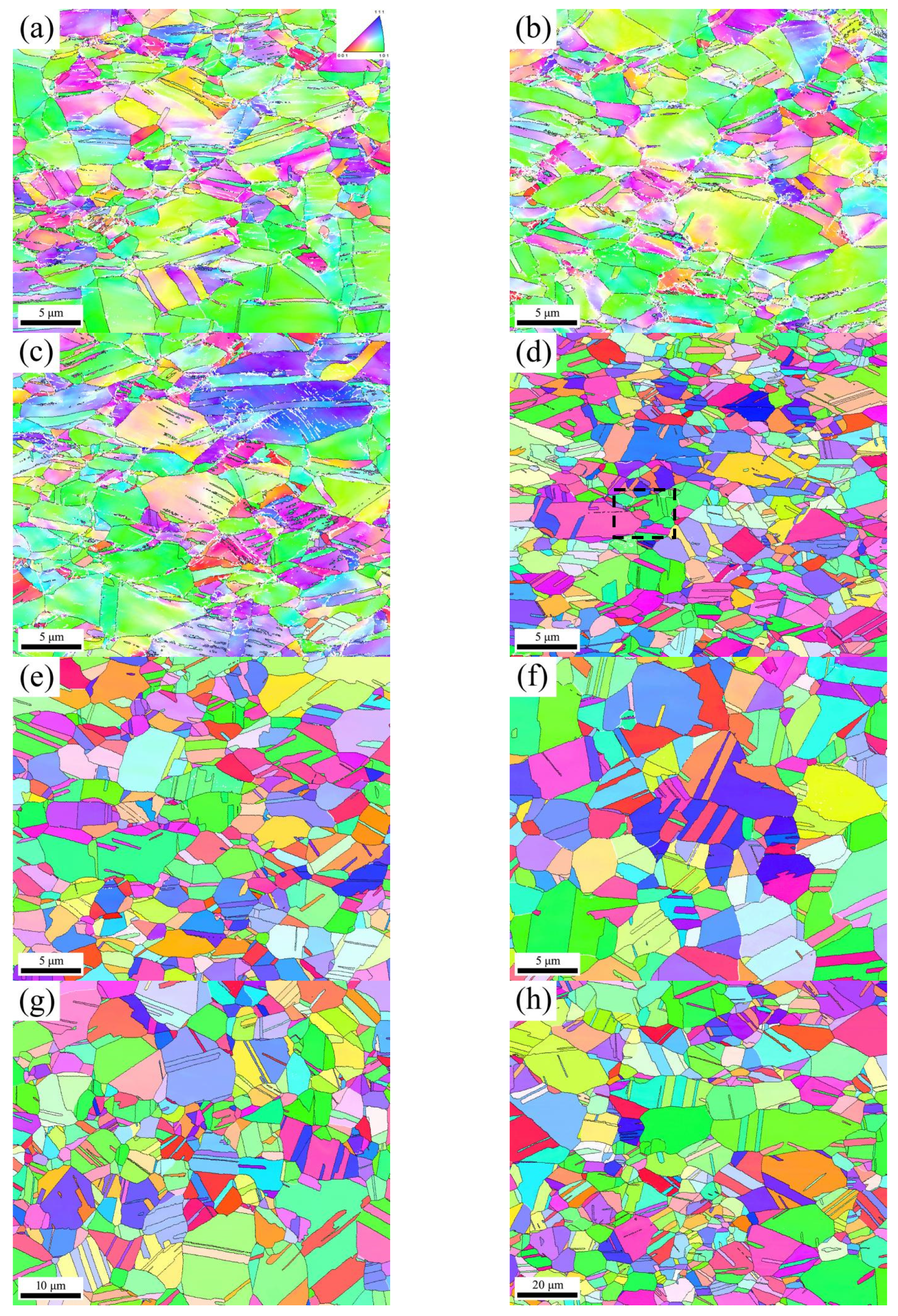

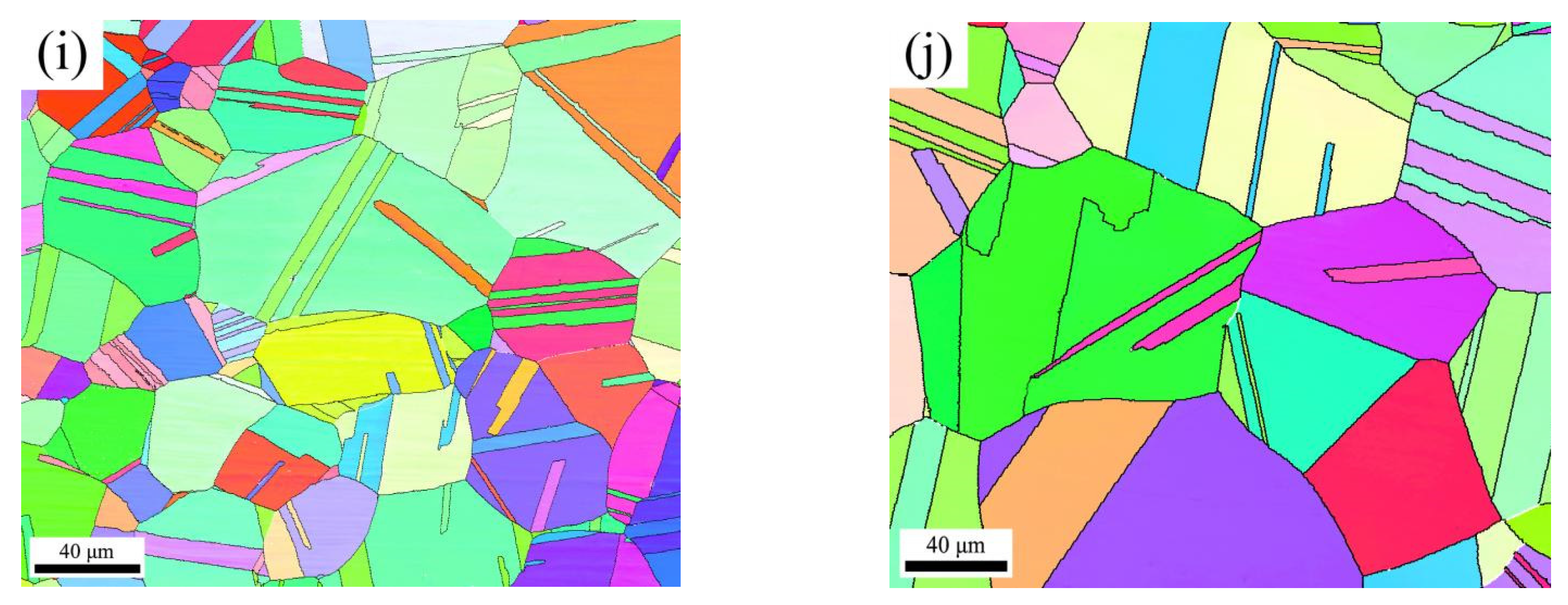

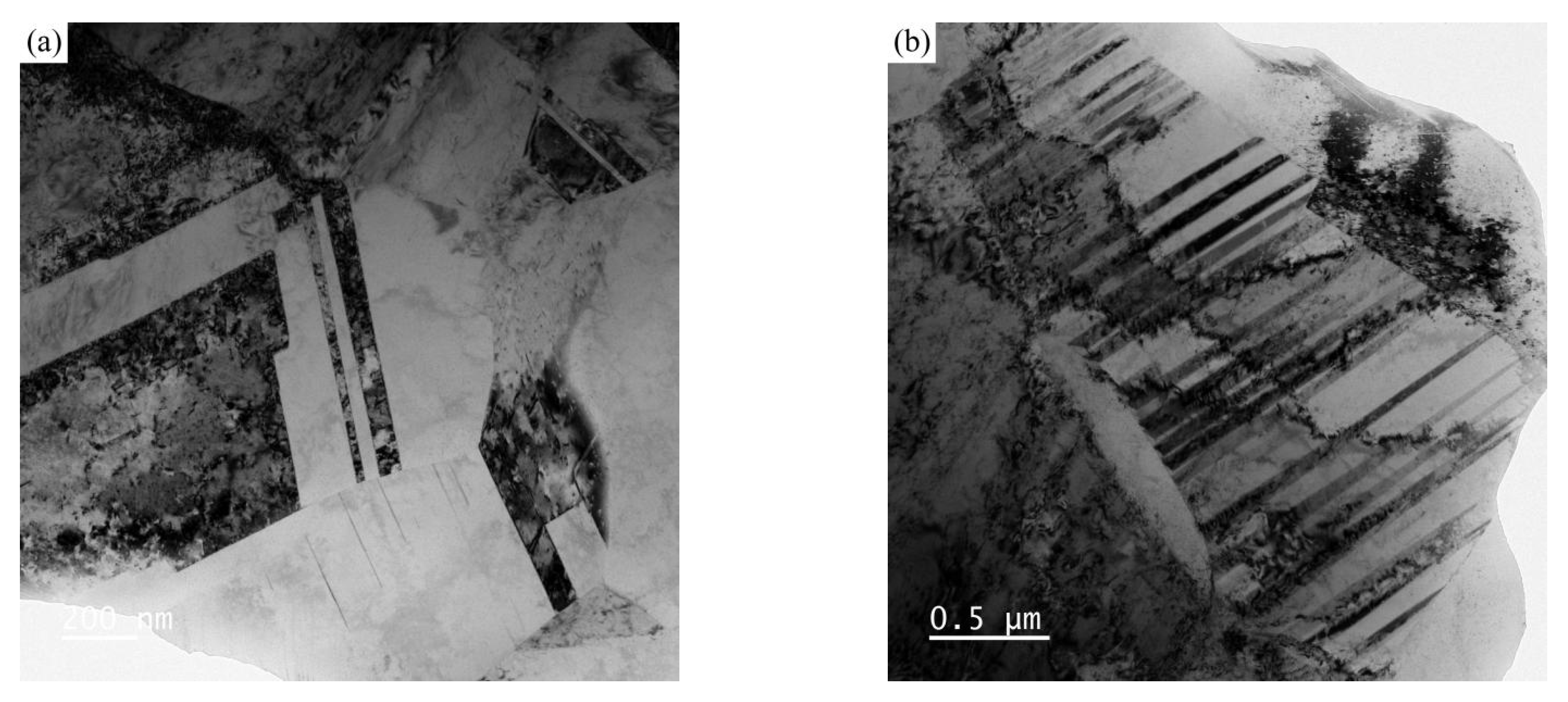

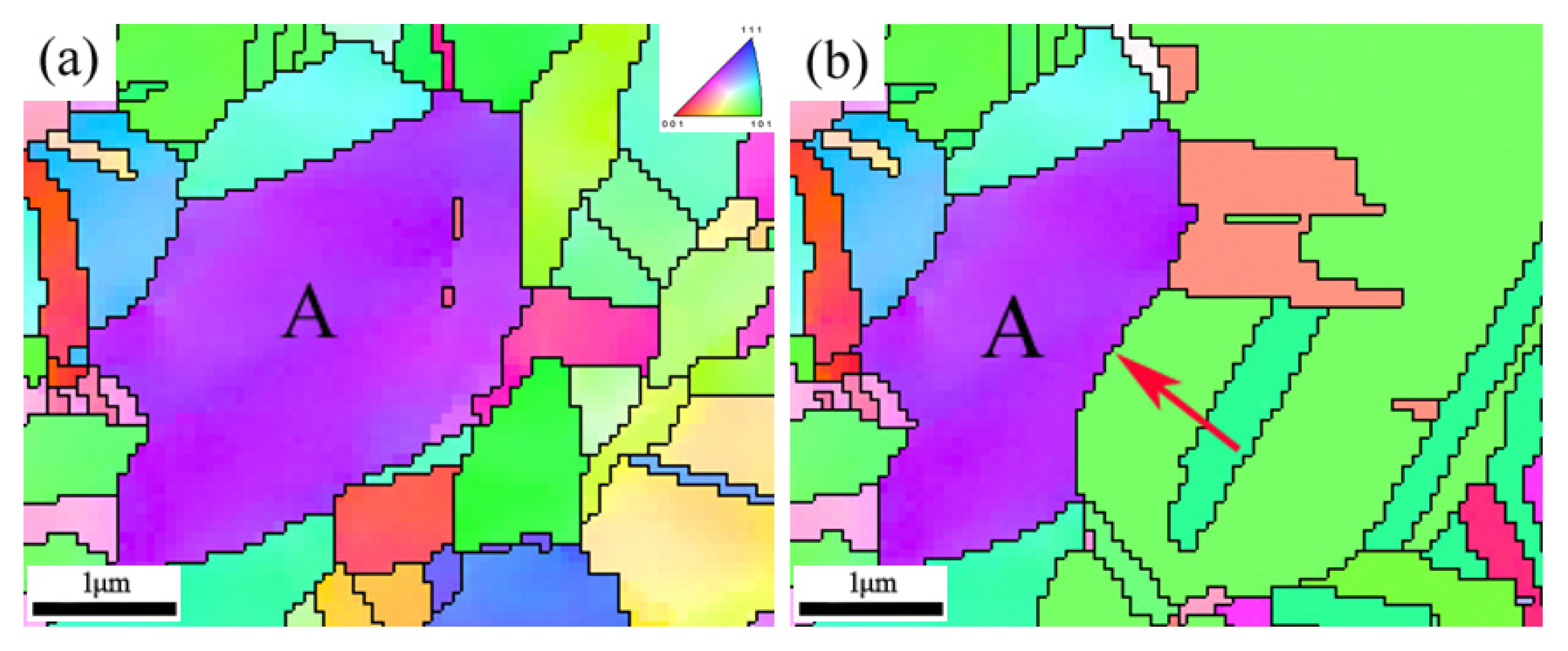

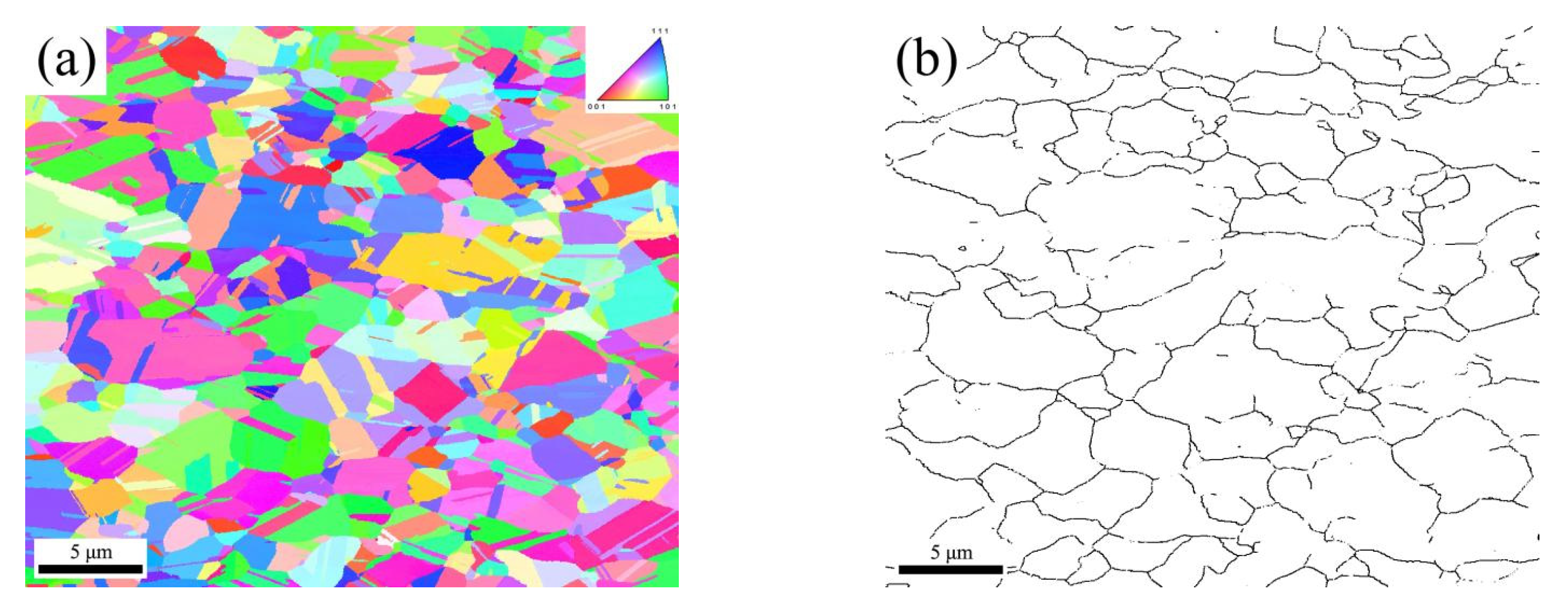

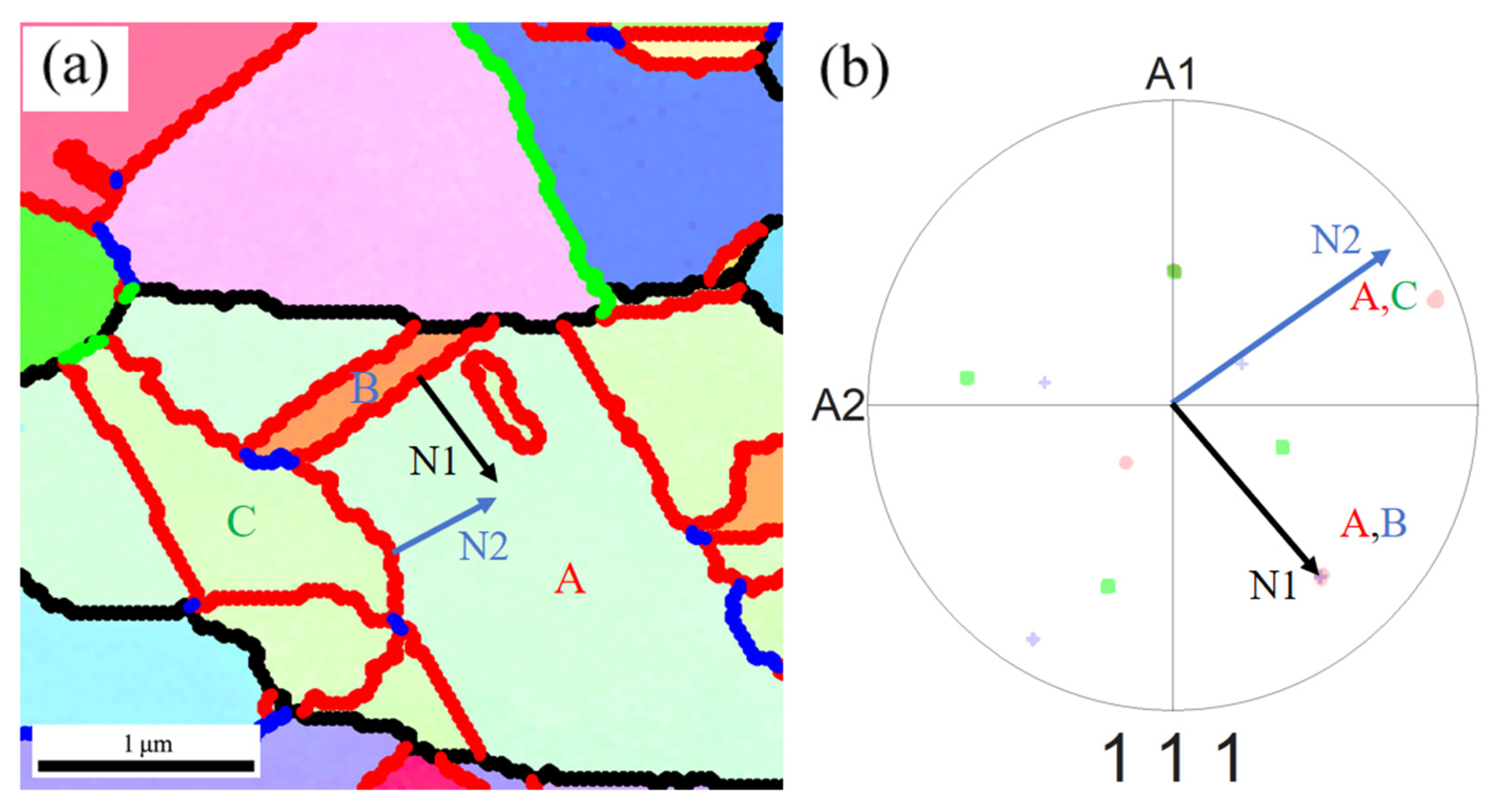

3.1. Effect of Annealing Temperature on Microstructure and the GBCD

3.2. Effect of GBCD Optimization on Bending Properties

4. Conclusions

- (1)

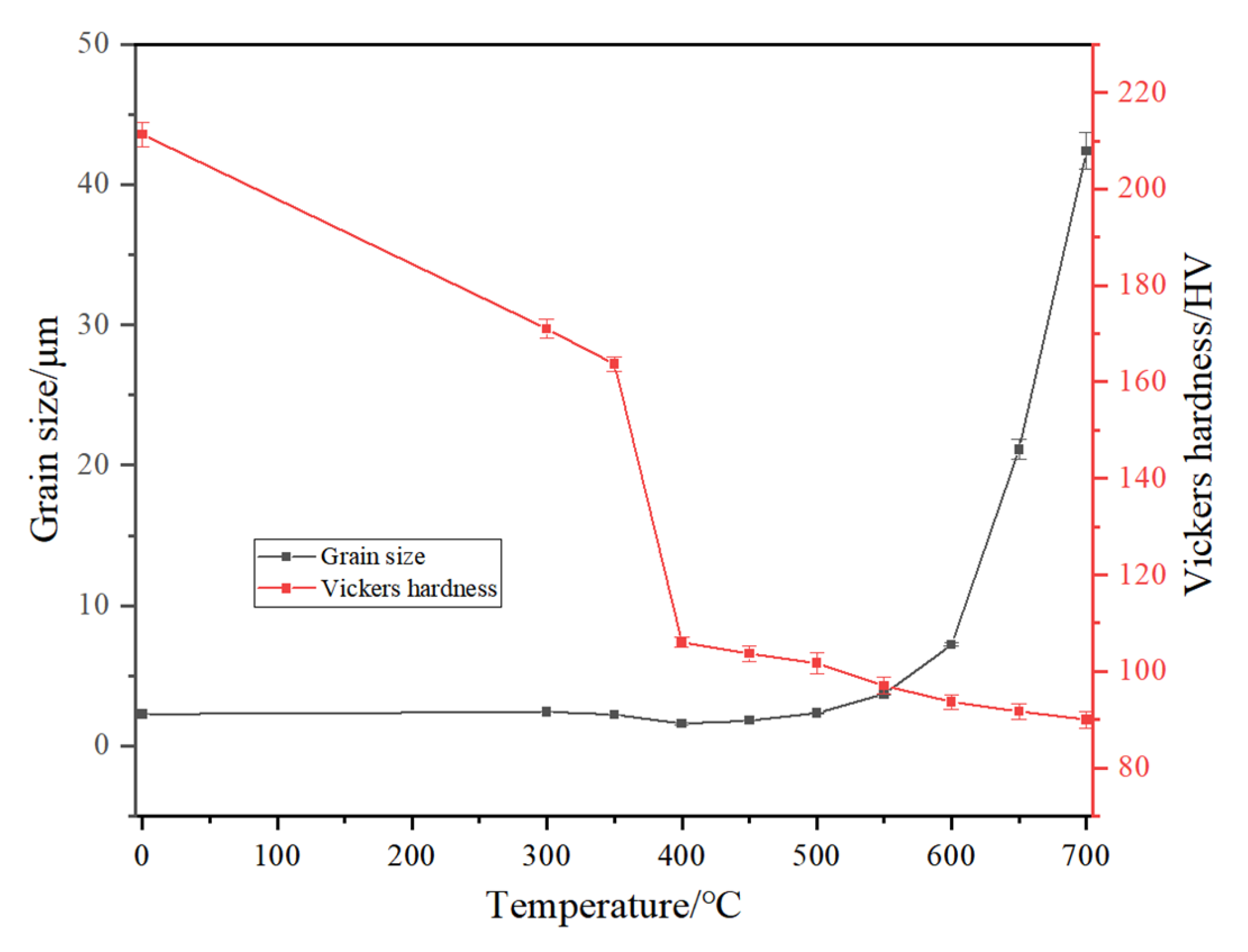

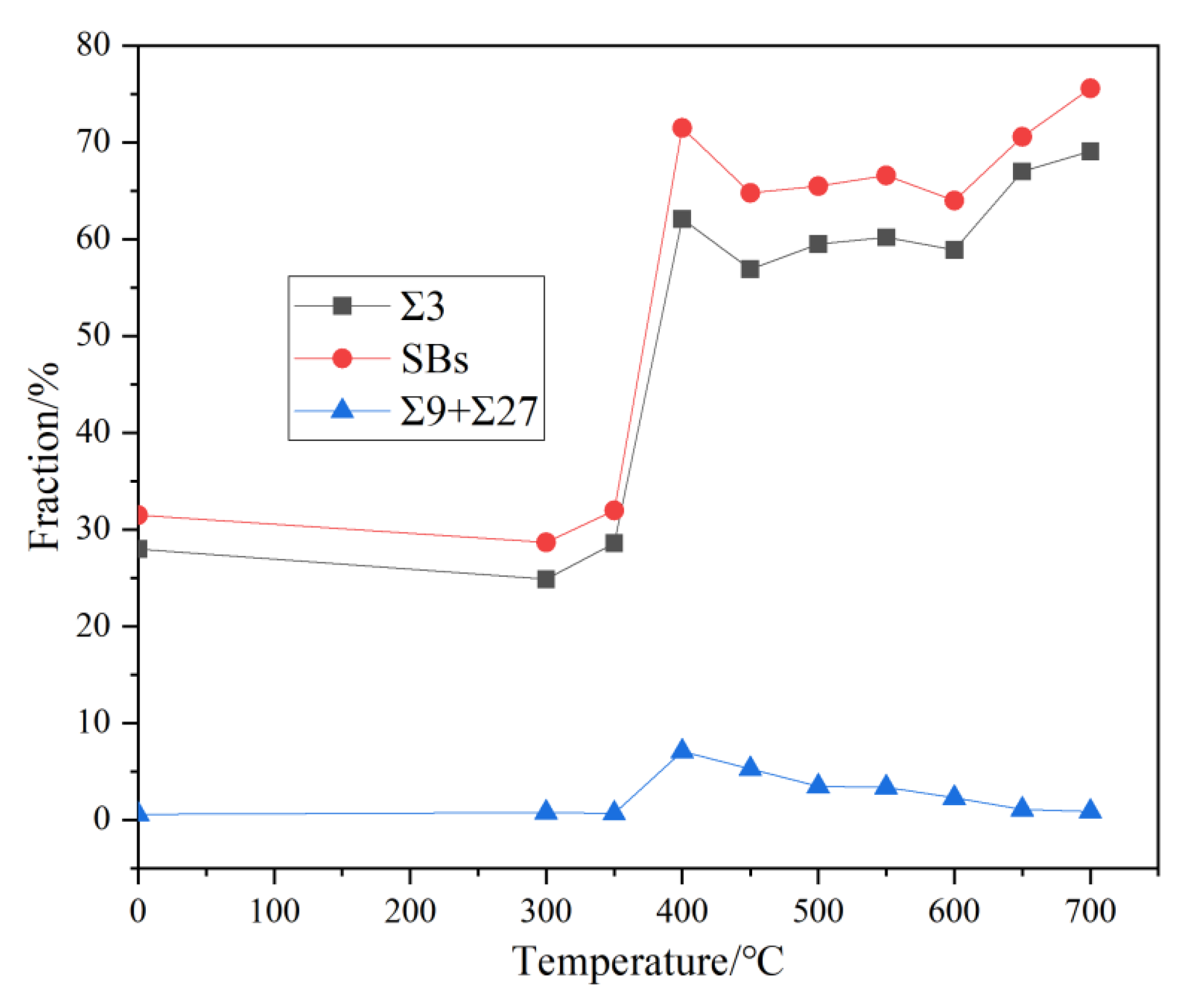

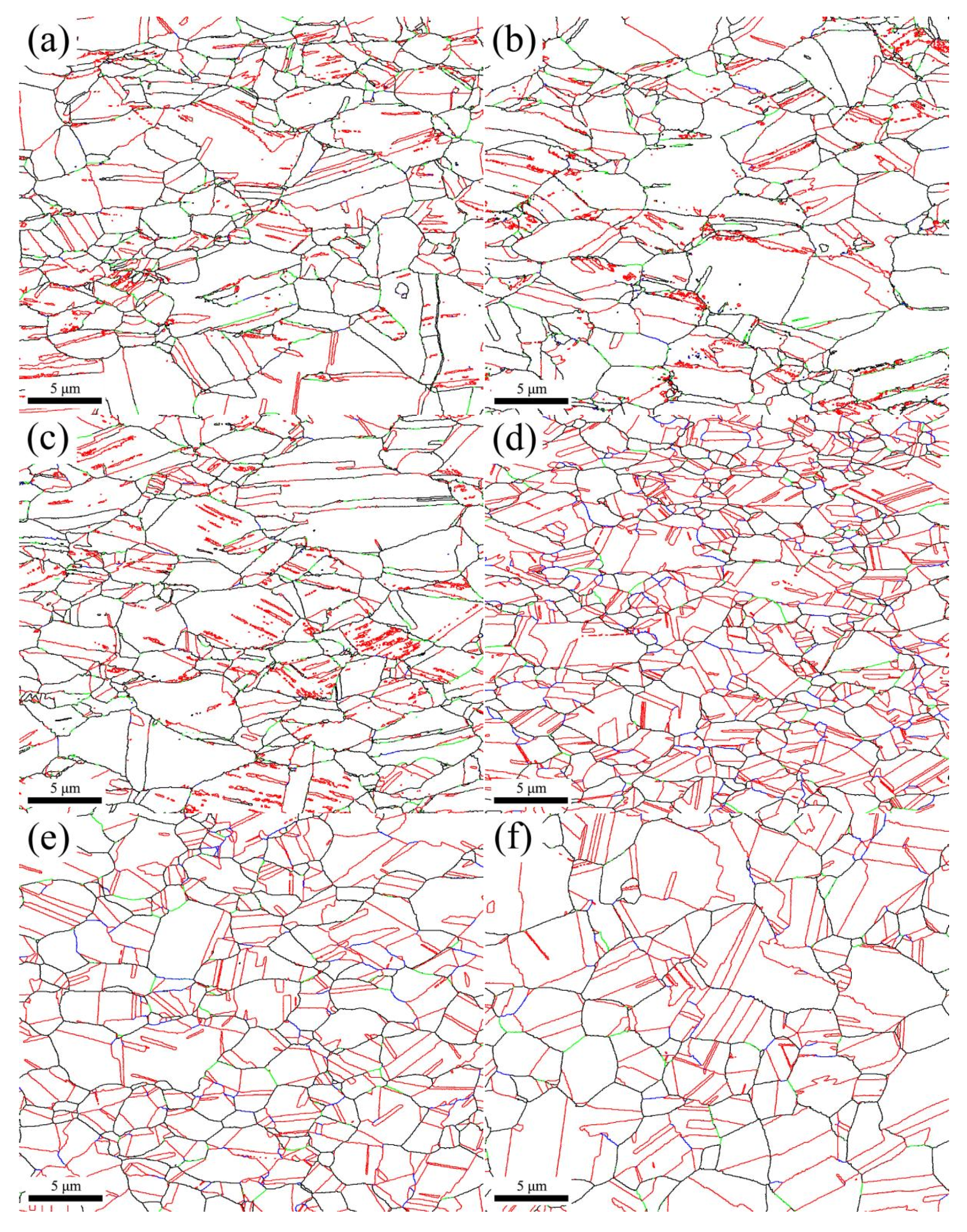

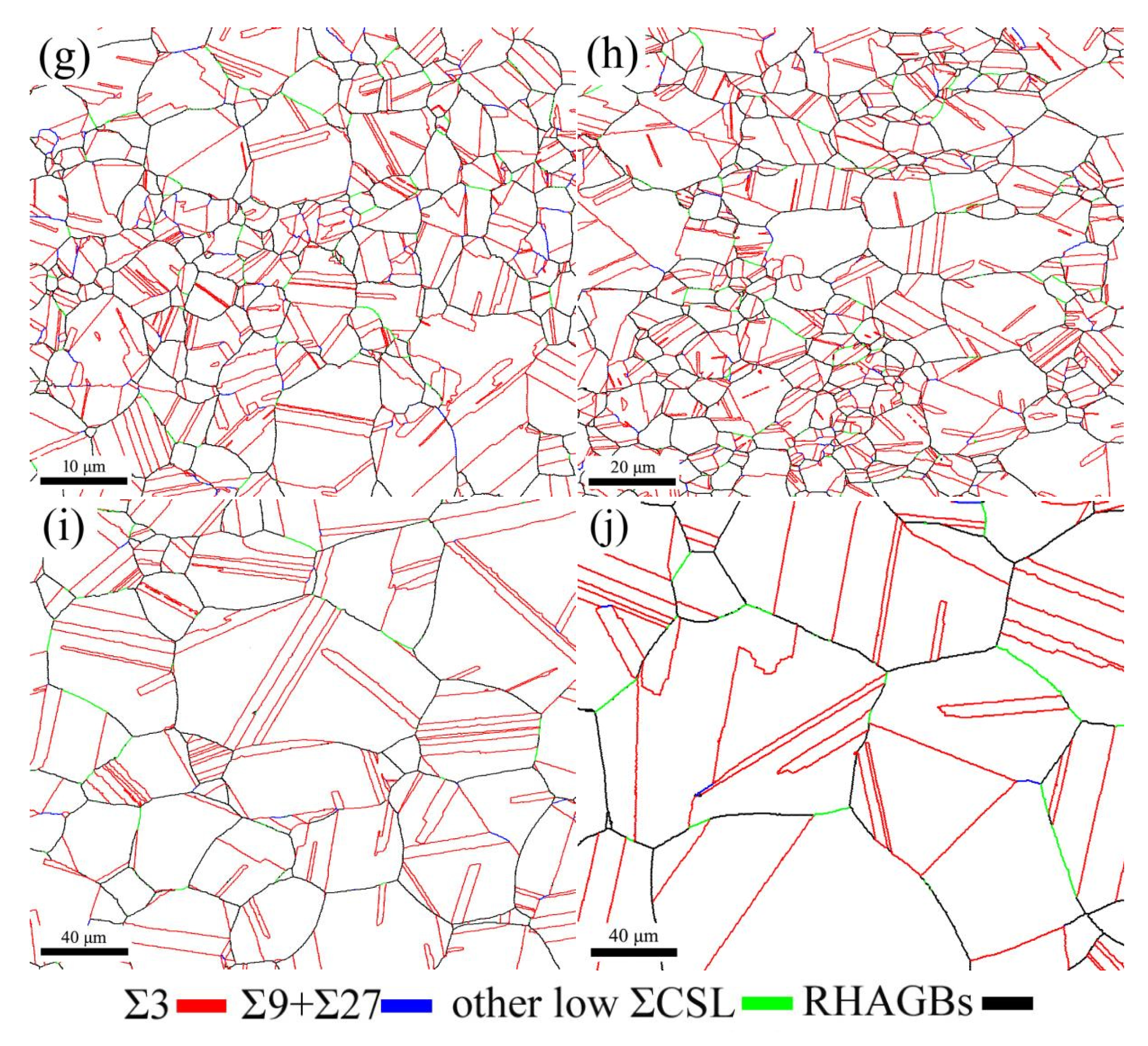

- The deformed phosphorus bronze strip begins to recrystallize when the annealing temperature is increased to 400 °C. Within the range of 400–450 °C, the grain size remains essentially unchanged. The grains grow as the annealing temperature is further increased. The grains grow rapidly when the temperature exceeds 600 °C;

- (2)

- When annealed at 400 °C, phosphorus bronze produces a large number of SBs, with the fSBs value reaching as high as 71.5% and the fΣ9+Σ27 value reaching a maximum of 7.1%. The average grain size is 1.6 μm. At 700 °C, the largest fSBs value of 75.6% is observed, but the Σ9 and Σ27 boundaries are almost nonexistent. Further, the Σ3ic boundaries are replaced to some extent by the Σ3c boundaries, which does not promote the GBCD optimization;

- (3)

- Compared to the unoptimized coarse-grained sample, the GBCD-optimized fine-grained sample exhibits smooth surfaces without orange peel when bent at 90° with R/t = 0 in the BW, demonstrating excellent bending workability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hatakeyama, K.; Hana, Y.; Narieda, H.; Sugawara, A. Evaluation Method of Bend Formability of Copper Alloy Strips for Spring Applications. Trans. Jpn. Soc. Spring Eng. 1999, 44, 17–23. [Google Scholar] [CrossRef]

- Pradhan, S.K.; Bhuyan, P.; Mandal, S. Individual and synergistic influences of microstructural features on intergranular corrosion behavior in extra-low carbon type 304L austenitic stainless steel. Corros. Sci. 2018, 39, 319–332. [Google Scholar] [CrossRef]

- Kobayashi, S.; Kobayashi, R.; Watanabe, T. Control of grain boundary connectivity based on fractal analysis for improvement of intergranular corrosion resistance in SUS316L austenitic stainless steel. Acta Mater. 2016, 102, 397–405. [Google Scholar] [CrossRef]

- Kuang, W.; Was, G.S. The effect of grain boundary structure on the intergranular degradation behavior of solution annealed alloy 690 in high temperature, hydrogenated water. Acta Mater. 2020, 182, 120–130. [Google Scholar] [CrossRef]

- Telang, A.; Gill, A.S.; Kumar, M.; Teysseyre, S.; Qian, D.; Mannava, S.R.; Vasudevan, V.K. Iterative thermomechanical processing of alloy 600 for improved resistance to corrosion and stress corrosion cracking. Acta Mater. 2016, 113, 180–193. [Google Scholar] [CrossRef]

- Wang, Z.; Feng, X.; Zhou, Q.; Wang, H.; Zhang, Y.; Yang, B. Grain boundary characteristics optimization of 90Cu-10Ni copper-nickel alloy for improving corrosion resistance. Corrosion 2018, 74, 819–828. [Google Scholar] [CrossRef]

- Shi, F.; Tian, P.C.; Jia, N.; Ye, Z.H.; Qi, Y.; Liu, C.M.; Li, X.W. Improving intergranular corrosion resistance in a nickel-free and manganese-bearing high-nitrogen austenitic stainless steel through grain boundary character distribution optimization. Corros. Sci. 2016, 107, 49–59. [Google Scholar] [CrossRef]

- Athreya, C.N.; Deepak, K.; Kim, D.I.; De Boer, B.; Mandal, S.; Sarma, V.S. Role of grain boundary engineered microstructure on high temperature steam oxidation behaviour of Ni based superalloy alloy 617. J. Alloy Compd. 2019, 778, 224–233. [Google Scholar] [CrossRef]

- Fu, H.; Chen, X.; Wang, W.; Pia, G.; Zhang, J.; Li, J. Statistical study on the effects of heterogeneous deformation and grain boundary character on hydrogen-induced crack initiation and propagation in twining-induced plasticity steels. Corros. Sci. 2021, 192, 109796. [Google Scholar] [CrossRef]

- Watanabe, T.; Tsurekawa, S. Toughening of brittle materials by grain boundary engineering. Mater. Sci. Eng. A. 2004, 387, 447–455. [Google Scholar] [CrossRef]

- Guan, X.J.; Shi, F.; Ji, H.M.; Li, X.W. Gain boundary character distribution optimization of Cu-16at.% Al alloy by thermomechanical process: Critical role of deformation microstructure. Mater. Sci. Eng. A. 2019, 765, 138299. [Google Scholar] [CrossRef]

- Zhuo, Z.; Xia, S.; Bai, Q.; Zhou, B. The effect of grain boundary character distribution on the mechanical properties at different strain rates of a 316L stainless steel. J. Mater. Sci. 2018, 53, 2844–2858. [Google Scholar] [CrossRef]

- Kumar, B.R.; Ghosh Chowdhury, S.; Narasaiah, N.; Mahato, B.; Das, S.K. Role of grain boundary character distribution on tensile properties of 304L stainless steel. Metall. Mater. Trans. A. 2007, 38, 1136–1143. [Google Scholar] [CrossRef]

- Watanabe, T.; Tsurekawa, S. The control of brittleness and development of desirable mechanical properties in polycrystalline systems by grain boundary engineering. Acta Mater. 1999, 47, 4171–4185. [Google Scholar] [CrossRef]

- Randle, V. Twinning-related grain boundary engineering. Acta Mater. 2004, 52, 4067–4081. [Google Scholar] [CrossRef]

- Randle, V. Grain boundary engineering: An overview after 25 years. Mater. Sci. Tech. 2010, 26, 253–261. [Google Scholar] [CrossRef]

- Detrois, M.; Goetz, R.L.; Helmink, R.C.; Tin, S. The role of texturing and recrystallization during grain boundary engineering of Ni-based superalloy RR1000. J. Mater. Sci. 2016, 51, 5122–5138. [Google Scholar] [CrossRef]

- Schuh, C.A.; Kumar, M.; King, W.E. Analysis of grain boundary networks and their evolution during grain boundary engineering. Acta Mater. 2003, 51, 687–700. [Google Scholar] [CrossRef]

- Watanabe, T. Grain boundary engineering: Historical perspective and future prospects. J. Mater. Sci. 2011, 46, 4095–4115. [Google Scholar] [CrossRef]

- Cayron, C. Quantification of multiple twinning in face centred cubic materials. Acta Mater. 2011, 59, 252–262. [Google Scholar] [CrossRef]

- Li, X.; Guan, X.; Jia, Z.; Chen, P.; Fan, C.; Shi, F. Twin-related grain boundary engineering and its influence on mechanical properties of face-centered cubic metals: A review. Metals 2023, 13, 155. [Google Scholar] [CrossRef]

- Li, J.; Ding, H.; Gao, W.; Wang, L. Microstructure and bending properties of Cu-Cr-Zr alloy subjected to heat treatment and rolling. J. Mater. Eng. Perform. 2021, 30, 5825–5833. [Google Scholar] [CrossRef]

- Gao, H.; Zhang, Y.; Song, K.; Zhou, Y.; Zhou, F.; Liu, A. Effect of Low-Temperature Annealing on the Bending Properties of C19400 Copper Alloy Strips. J. Mater. Eng. Perform. 2024, 33, 5183–5192. [Google Scholar] [CrossRef]

- Oda, S.; Tanaka, S.I. Grain boundaries with high Σ value and strain in grain matrix induce crack initiation in extruded 6000 series aluminium alloys. Mater. Sci. Eng. A 2022, 834, 142630. [Google Scholar] [CrossRef]

- Brandon, D.G. The structure of high-angle grain boundaries. Acta Mater. 1966, 14, 1479–1484. [Google Scholar] [CrossRef]

- Randle, V. Special’boundaries and grain boundary plane engineering. Scr. Mater. 2006, 54, 1011–1015. [Google Scholar] [CrossRef]

- Sharma, N.K.; Shekhar, S. New insights into the evolution of twin boundaries during recrystallization and grain growth of low-SFE FCC alloys. Mater. Charact. 2020, 159, 110015. [Google Scholar] [CrossRef]

- ASTM B820-14; Standard Test Method for Bend Test for Determining the Formability of Copper and Copper Alloy Strip. ASTM: West Conshohocken, PA, USA, 2014.

- Han, W.Z.; Wu, S.D.; Li, S.X.; Zhang, Z.F. Origin of deformation twinning from grain boundary in copper. Appl. Phys. Lett. 2008, 92, 221909. [Google Scholar] [CrossRef]

- Huang, C.X.; Wang, K.; Wu, S.D.; Zhang, Z.F.; Li, G.Y.; Li, S.X. Deformation twinning in polycrystalline copper at room temperature and low strain rate. Acta Mater. 2006, 54, 655–665. [Google Scholar] [CrossRef]

- Lei, L.; Shen, Y.; Chen, X.; Qian, L.; Lu, K. Ultrahigh strength and high electrical conductivity in copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef]

- Kashihara, K.; Inoko, F. Effect of piled-up dislocations on strain induced boundary migration (SIBM) in deformed aluminum bicrystals with originally Σ3 twin boundary. Acta Mater. 2001, 49, 3051–3061. [Google Scholar] [CrossRef]

- Barr, C.M.; Leff, A.C.; Demott, R.W.; Doherty, R.D.; Taheri, M.L. Unraveling the origin of twin related domains and grain boundary evolution during grain boundary engineering. Acta Mater. 2018, 144, 281–291. [Google Scholar] [CrossRef]

- Randle, V.; Coleman, M. A study of low-strain and medium-strain grain boundary engineering. Acta Mater. 2009, 57, 3410–3421. [Google Scholar] [CrossRef]

- Yang, X.; Wang, P.; Huang, M. Grain boundary evolution during low-strain grain boundary engineering achieved by strain-induced boundary migration in pure copper. Mater. Sci. Eng. A. 2022, 833, 142532. [Google Scholar] [CrossRef]

- Chen, Z.P.; Yang, Y.; Lou, H.F.; Xiang, C.J.; Wang, H. Effect of thermomechanical processing on the grain boundary character distribution of phosphorus bronze. Mater. Charact. 2024, 217, 114401. [Google Scholar] [CrossRef]

- Humphreys, J.; Rohrer, G.S.; Rollett, A. Recrystallization and Related Annealing Phenomena, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar] [CrossRef]

- Kumar, M.; Schwartz, A.J.; King, W.E. Microstructural evolution during grain boundary engineering of low to medium stacking fault energy fcc materials. Acta Mater. 2002, 50, 2599–2612. [Google Scholar] [CrossRef]

- Hou, G.; Luo, H.; Lv, J. Grain boundary character distribution and sensitisation behaviour of grain boundary engineered stable austenitic stainless steel (AISI 316L). J. Mater. Sci. Technol. 2014, 30, 1447–1452. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, K.; Guo, H.; Wang, W.; Zhou, B. Twin-induced grain boundary engineering in 304 stainless steel. Mater. Sci. Eng. A. 2008, 487, 7–13. [Google Scholar] [CrossRef]

- Lin, P.; Palumbo, G.; Aust, K.T. Experimental assessment of the contribution of annealing twins to CSL distributions in FCC materials. Scr. Mater. 1997, 36, 1145–1149. [Google Scholar] [CrossRef]

- Pinto, A.L.; da Costa Viana, C.S.; de Almeida, L.H. Micromechanisms involved in grain boundary engineering of α-brass. Mater. Sci. Eng. A. 2007, 445, 14–19. [Google Scholar] [CrossRef]

- Randle, V.; Davies, H. Evolution of microstructure and properties in alpha-brass after iterative processing. Metall. Mater. Trans. A. 2002, 33, 1853–1857. [Google Scholar] [CrossRef]

- Randle, V.; Coleman, M. Grain Growth Control in Grain Boundary Engineered Microstructures. Mater. Sci. Forum. 2012, 715–716, 103–108. [Google Scholar] [CrossRef]

- Randle, V. A methodology for grain boundary plane assessment by single-section trace analysis. Scr. Mater. 2001, 44, 2789–2794. [Google Scholar] [CrossRef]

- Wright, S.I.; Larsen, R.J. Extracting twins from orientation imaging microscopy scan data. J. Microsc. 2002, 205, 245–252. [Google Scholar] [CrossRef] [PubMed]

- Bobylev, S.V.; Ovid’Ko, I.A. Stress-driven migration of deformation-distorted grain boundaries in nanomaterials. Acta Mater. 2015, 88, 260–270. [Google Scholar] [CrossRef]

- Dash, S.; Brown, N. An investigation of the origin and growth of annealing twins. Acta Mater. 1963, 11, 1067–1075. [Google Scholar] [CrossRef]

- Gleiter, H. The formation of annealing twins. Acta Mater. 1969, 17, 1421–1428. [Google Scholar] [CrossRef]

- Lee, G.M.; Lee, J.U.; Park, S.H. Effects of post-heat treatment on microstructure, tensile properties, and bending properties of extruded AZ80 alloy. J. Mater. Red. Technol. 2021, 12, 1039–1050. [Google Scholar] [CrossRef]

- Dillamore, I.L.; Roberts, J.G.; Bush, A.C. Occurrence of shear bands in heavily rolled cubic metals. Met. Sci. 1979, 13, 73–77. [Google Scholar] [CrossRef]

- Kaneko, H.; Morikawa, T.; Tanaka, M.; Inoue, H.; Higashida, K. Recrystallization texture and shear band formation in bending. Mater. Trans. 2017, 58, 218–224. [Google Scholar] [CrossRef]

- Han, D.; Guan, X.J.; Yan, Y.; Shi, F.; Li, X.W. Anomalous recovery of work hardening rate in Cu-Mn alloys with high stacking fault energies under uniaxial compression. Mater. Sci. Eng. A 2019, 743, 745–754. [Google Scholar] [CrossRef]

- Wang, J.; Chen, Y.; Zhu, Q.; Hong, Z.; Zhang, Z. Grain boundary dominated plasticity in metallic materials. Acta Met. Sin. 2022, 58, 726–745. [Google Scholar] [CrossRef]

- Lin, Y.; Han, L.; Wang, G. Relationship between Σ3 boundaries, dislocation slip, and plasticity in pure nickel. Materials 2023, 16, 2853. [Google Scholar] [CrossRef]

- Li, L.L.; Zhang, Z.J.; Zhang, P.; Zhang, Z.F. A review on the fatigue cracking of twin boundaries: Crystallographic orientation and stacking fault energy. Prog. Mater. Sci. 2023, 131, 101011. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Li, L.L.; Zhang, Z.J.; Zhang, P. Twin boundary: Controllable interface to fatigue cracking. J. Mater. Sci. Technol. 2017, 33, 603–606. [Google Scholar] [CrossRef]

- Shen, Z.; Wagoner, R.H.; Clark, W.A.T. Dislocation and grain boundary interactions in metals. Acta Mater. 1988, 36, 3231–3242. [Google Scholar] [CrossRef]

- Lu, K. Stabilizing nanostructures in metals using grain and twin boundary architectures. Nat. Rev. Mater. 2016, 1, 16019. [Google Scholar] [CrossRef]

- Qu, S.; Zhang, P.; Wu, S.D.; Zang, Q.S.; Zhang, Z.F. Twin boundaries: Strong or weak? Scr. Mater. 2008, 59, 1131–1134. [Google Scholar] [CrossRef]

| Element | Sn | P | Zn | Fe | Pb | Cu |

|---|---|---|---|---|---|---|

| Content | 8.0 | 0.14 | 0.01 | 0.01 | 0.001 | Bal. |

| Sample | Σ3 | Σ9 | Σ27 | Low-ΣCSL | Grain Size |

|---|---|---|---|---|---|

| a | 62.1 | 4.7 | 2.4 | 71.5 | 1.60 |

| b | 61.8 | 4.3 | 2.5 | 71.2 | 1.65 |

| c | 63.2 | 4.8 | 2.5 | 72.8 | 1.55 |

| d | 62.9 | 4.6 | 2.3 | 71.9 | 1.68 |

| e | 63.4 | 5.0 | 2.5 | 73.1 | 1.53 |

| Average | 62.7 | 4.7 | 2.4 | 72.1 | 1.60 |

| Standard deviation | 0.57 | 0.21 | 0.07 | 0.67 | 0.05 |

| Sample | As-Received | 300 °C | 350 °C | 400 °C | 450 °C | 500 °C | 550 °C | 600 °C | 650 °C | 700 °C |

|---|---|---|---|---|---|---|---|---|---|---|

| Fraction/% | 47.5 | 41.4 | 41.1 | 4.5 | 4.1 | 1.2 | 1.2 | 1.1 | 0.9 | 0.8 |

| Sample | Σ3/% | Σ9 + Σ27/% | Other ΣCSL/% | Total Low ΣCSL/% | Grain Size/μm | Tensile Strength/MPa |

|---|---|---|---|---|---|---|

| GBCD-optimized fine-grained | 48.0 | 2.7 | 0.6 | 55.2 | 1.5 | 621 |

| Unoptimized coarse-grained | 22.8 | 1.2 | 0.7 | 26.8 | 5.6 | 620 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Yang, Y.; Lou, H.; Wang, H. Effect of Heat Treatment on the Grain Boundary Character Distribution and Bending Properties of Fine-Grained Phosphorus Bronze. Materials 2025, 18, 1941. https://doi.org/10.3390/ma18091941

Chen Z, Yang Y, Lou H, Wang H. Effect of Heat Treatment on the Grain Boundary Character Distribution and Bending Properties of Fine-Grained Phosphorus Bronze. Materials. 2025; 18(9):1941. https://doi.org/10.3390/ma18091941

Chicago/Turabian StyleChen, Zhongping, Yang Yang, Huafen Lou, and Hu Wang. 2025. "Effect of Heat Treatment on the Grain Boundary Character Distribution and Bending Properties of Fine-Grained Phosphorus Bronze" Materials 18, no. 9: 1941. https://doi.org/10.3390/ma18091941

APA StyleChen, Z., Yang, Y., Lou, H., & Wang, H. (2025). Effect of Heat Treatment on the Grain Boundary Character Distribution and Bending Properties of Fine-Grained Phosphorus Bronze. Materials, 18(9), 1941. https://doi.org/10.3390/ma18091941