Admixtures in Cement-Matrix Composites for Mechanical Reinforcement, Sustainability, and Smart Features

Abstract

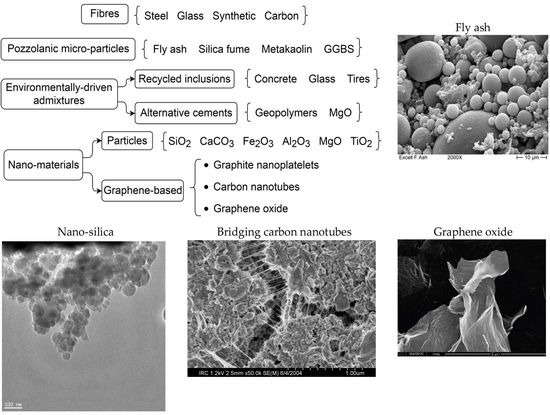

:1. Introduction

2. Fibers

2.1. Steel Fibers

2.2. Glass Fibers

2.3. Synthetic Fibers

2.4. Carbon Fibers

3. Pozzolanic Admixtures: High Performance Concrete

3.1. Fly Ash

3.2. Silica Fume

3.3. Metakaolin

3.4. Ground Granulated Blast-Furnace Slag

4. Environmentally-Driven Admixtures

5. Nanoinclusions

5.1. Nanoparticles

5.2. Carbon-Based Nanoinclusions

6. Discussion of Results

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mahasenan, N.; Smith, S.; Humphreys, K. The cement industry and global climate change: Current and potential future cement industry CO2 emissions. In Proceedings of the 6th International Conference on Greenhouse Gas Control Technologies, Kyoto, Japan, 1–4 October 2002; Gale, J., Kaya, Y., Eds.; Pergamon: Oxford, UK, 2003; pp. 995–1000. [Google Scholar]

- The Freedonia Group. World Cement: Industry Study with Forecasts for 2015 & 2020. Available online: http://www.freedoniagroup.com/brochure/28xx/2805smwe.pdf (accessed on 25 November 2016).

- Portland Cement Association. World Cement Consumption. Available online: http://www.betonabq.org/images/imguser/WorldReport_Aug_2013final__01__cement.pdf (accessed on 25 November 2016).

- Chung, D.D.L. Cement reinforced with short carbon fibers: A multifunctional material. Compos. Part B Eng. 2000, 31, 511–526. [Google Scholar] [CrossRef]

- Hewlett, P. Lea’s Chemistry of Cement and Concrete, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2004. [Google Scholar]

- Brandt, A. Cement-Based Composites: Materials, Mechanical Properties and Performance, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Ahmed, S.F.U.; Maalej, M. Tensile strain hardening behaviour of hybrid steel-polyethylene fibre reinforced cementitious composites. Constr. Build. Mater. 2009, 23, 96–106. [Google Scholar] [CrossRef]

- Liu, G.R. A step-by-step method of rule-of-mixture of fiber- and particle-reinforced composite materials. Compos. Struct. 1997, 40, 313–322. [Google Scholar] [CrossRef]

- Kim, H.S. On the rule of mixtures for the hardness of particle reinforced composites. Mater. Sci. Eng. A 2000, 289, 30–33. [Google Scholar] [CrossRef]

- Aziz, M.A.; Paramasivam, P.; Lee, S.L. Prospects for natural fibre reinforced concretes in construction. Int. J. Cem. Compos. Lightweight Concr. 1981, 3, 123–132. [Google Scholar] [CrossRef]

- Majumdar, A.J.; Ryder, J.F. Glass fibre reinforcement of cement products. Glass Technol. 1968, 9, 78–84. [Google Scholar]

- Romualdi, J.; Batson, G. Mechanics of crack arrest in concrete. J. Eng. Mech. Division 1963, 89, 147–168. [Google Scholar]

- Romualdi, J.; Mandel, J. Tensile strength of concrete affected by uniformly distributed and closely spaced short lengths of wire reinforcement. J. Proc. 1964, 61, 657–672. [Google Scholar]

- Brandt, A.M. Fibre reinforced cement-based (FRC) composites after over 40 years of development in building and civil engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Goldfein, S. Fibrous reinforcement for portland cement. Mod. Plast. 1965, 42, 156–160. [Google Scholar]

- Markets and Markets. Global Concrete Fibers Market. Global Trends & Forecasts to 2020; Research and Markets: Dublin, Ireland, 2015. [Google Scholar]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete—A review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Chuah, S.; Pan, Z.; Sanjayan, J.G.; Wang, C.M.; Duan, W.H. Nano reinforced cement and concrete composites and new perspective from graphene oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Birgisson, B.; Taylor, P.; Attoh-Okine, N.O. (Eds.) Nanotechnology in Civil Infrastructure; Springer: Berlin, Germany, 2011.

- Birgisson, B.; Mukhopadhyay, A.K.; Geary, G.; Khan, M.; Sobolev, K. Nanotechnology in Concrete Materials: A Synopsis—Transportation Research Circular E-C170; Transportation Research Board: Washington, DC, USA, 2012. [Google Scholar]

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef]

- Salas, D.; Ramirez, A.; Rodríguez, C.; Petroche, D.; Boero, A.; Duque-Rivera, J. Environmental impacts, life cycle assessment and potential improvement measures for cement production: A literature review. J. Clean. Prod. 2016, 113, 114–122. [Google Scholar] [CrossRef]

- Paris, J.; Roessler, J.; Ferraro, C.; DeFord, H.; Townsend, T. A review of waste products utilized as supplements to Portland cement in concrete. J. Clean. Prod. 2016, 121, 1–18. [Google Scholar] [CrossRef]

- Nautiyal, H.; Shree, V.; Khurana, S.; Kumar, N.; Varun. Recycling potential of building materials: A review. In Environmental Implications of Recycling and Recycled Products; Muthu, S.S., Ed.; Springer: Singapore, 2015; pp. 31–50. [Google Scholar]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K. Geopolymer concrete: A review of some recent developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef]

- Silvestre, J.; Silvestre, N.; Brito, J. Review on concrete nanotechnology. Eur. J. Environ. Civ. Eng. 2016, 20, 455–485. [Google Scholar] [CrossRef]

- Hossain, M.M.; Karim, M.R.; Hasan, M.; Hossain, M.K.; Zain, M.F.M. Durability of mortar and concrete made up of pozzolans as a partial replacement of cement: A review. Constr. Build. Mater. 2016, 116, 128–140. [Google Scholar] [CrossRef]

- Literature Review on Macro Synthetic Fibres in Concrete. Available online: http://www.sun.ac.za/english/faculty/eng/ucm/Documents/Report%20ISI2013-15%20Literature%20Review%20on%20Macro%20Synthetic%20Fibres%20in%20Concrete.pdf (accessed on 28 September 2016).

- TR63 Guidance for the Design of Steel-Fibre-Reinforced Concrete; The Concrete Society: Camberley, UK, 2007.

- Qian, C.X.; Stroeven, P. Development of hybrid polypropylene-steel fibre-reinforced concrete. Cem. Concr. Res. 2000, 30, 63–69. [Google Scholar] [CrossRef]

- Rossi, P.; Parant, E. Damage mechanisms analysis of a multi-scale fibre reinforced cement-based composite subjected to impact and fatigue loading conditions. Cem. Concr. Res. 2008, 38, 413–421. [Google Scholar] [CrossRef]

- Silva, E.R.; Coelho, J.F.J.; Bordado, J.C. Strength improvement of mortar composites reinforced with newly hybrid-blended fibres: Influence of fibres geometry and morphology. Constr. Build. Mater. 2013, 40, 473–480. [Google Scholar] [CrossRef]

- Li, V.C.; Wu, H.C. Conditions for pseudo strain-hardening in fiber reinforced brittle matrix composites. Appl. Mech. Rev. 1992, 45, 390–398. [Google Scholar] [CrossRef]

- Li, V.C.; Leung, C.K.Y. Theory of steady state and multiple cracking of random discontinuous fiber-reinforced brittle matrix composites. ASCE J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef]

- Naaman, A.E. Tensile strain-hardening FRC composites: Historical evolution since the 1960. In Advances in Construction Materials 2007; Grosse, C.U., Ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 181–202. [Google Scholar]

- Fantilli, A.P.; Mihashi, H.; Vallini, P. Multiple cracking and strain hardening in fiber-reinforced concrete under uniaxial tension. Cem. Concr. Res. 2009, 39, 1217–1229. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.; Wu, C. Tensile strain-hardening behaviour of polyvinyl alcohol engineered cementitious composite (PVA-ECC). ACI Mater. J. 2001, 98, 483–492. [Google Scholar]

- Gencturk, B.; Elnashai, A.S. Multi-Objective Optimal Seismic Design of Buildings Using Advanced Engineered Materials. MAE Center Report No. 11-01. 2011. Available online: https://www.ideals.illinois.edu/bitstream/handle/2142/25523/Report11-01.pdf?sequence=2 (accessed on 14 November 2016).

- Grubb, J.A.; Blunt, J.; Ostertag, C.P.; Devine, T.M. Effect of steel microfibers on corrosion of steel reinforcing bars. Cem. Concr. Res. 2007, 37, 1115–1126. [Google Scholar] [CrossRef]

- McCormac, J.; Brown, R. Design of Reinforced Concrete, 9th ed.; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

- Yao, W.; Li, J.; Wu, K. Mechanical properties of hybrid fiber-reinforced concrete at low fiber volume fraction. Cem. Concr. Res. 2003, 33, 27–30. [Google Scholar] [CrossRef]

- Benmokrane, B.; Chaallal, O.; Masmoudi, R. Glass fibre reinforced plastic (GFRP) rebars for concrete structures. Constr. Build. Mater. 1995, 9, 353–364. [Google Scholar] [CrossRef]

- Trens, P.; Denoyel, R.; Guilloteau, E. Evolution of surface composition, porosity, and surface area of glass fibers in a moist atmosphere. Langmuir 1996, 12, 1245–1250. [Google Scholar] [CrossRef]

- Krasnikovs, A.; Lapsa, V.; Eiduks, M. Non-traditional reinforcement for concrete composites. State of the art. Transp. Eng. Mech. 2007, 24, 191–200. [Google Scholar]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites, 2nd ed.; Taylor & Francis: Abingdon, UK, 2007. [Google Scholar]

- Noushini, A.; Samali, B.; Vessalas, K. Effect of polyvinyl alcohol (PVA) fibre on dynamic and material properties of fibre reinforced concrete. Constr. Build. Mater. 2013, 49, 374–383. [Google Scholar] [CrossRef]

- Rangan, V.B. Advances in Design of Concrete Structural Members. In Recent Advances in Structural Engineering; Jagadish, K.S., Iyengar, R.N., Eds.; Universities Press: Hyderabad, India, 2005; pp. 1–38. [Google Scholar]

- Katzer, J. Steel fibers and steel fiber reinforced concrete in civil engineering. Pac. J. Sci. Technol. 2006, 7, 53–58. [Google Scholar]

- Sarbini, N.; Ibrahim, I.; Saim, A. Assessment on the mechanical performance of steel fibre reinforced concrete using fibres geometrical factor. In Proceedings of 8th RILEM International Symposium on Fibre Reinforced Concrete: Challenges and Opportunities (BEFIB 2012), Guimarães, Portugal, 19–21 September 2012.

- State-of-the-Art Report on Fiber Reinforced Concrete; ACI 544.1R-96; American Concrete Institute: Farmington Hills, MI, USA, 2002; pp. 2–66.

- Wafa, F. Properties and applications of fiber reinforced concrete. JKAU Eng. Sci. 1990, 2, 49–63. [Google Scholar] [CrossRef]

- Deshmukh, S.; Bhusari, J.; Zende, A. Effect of glass fibres on ordinary portland cement concrete. IOSR J. Eng. 2012, 2, 1318–1322. [Google Scholar]

- Yao, W. Flexural strength and behavior of polypropylene fiber reinforced concrete beams. J. Wuhan Univ. Technol. 2002, 17, 54–57. [Google Scholar]

- Mishra, C.B.; Desai, P.; Ghodasara, I. Efficacy appraisal of polypropylene fibers in pavement quality concrete. Int. J. Curr. Eng. Technol. 2016, 6, 204–208. [Google Scholar]

- Noushini, A.; Vessalas, K.; Samali, B. Flexural and tensile characteristics of polyvinyl alcohol fibre reinforced concrete (PVA-FRC). In Proceedings of the 13th East Asia-Pacific Conference on Structural Engineering and Construction (EASEC-13), Sapporo, Japan, 11–13 September 2013.

- Park, S.-J.; Seo, M.-K.; Shim, H.-B.; Rhee, K.-Y. Effect of different cross-section types on mechanical propertiesof carbon fibers-reinforced cement composites. Mater. Sci. Eng. A 2003, 366, 348–355. [Google Scholar] [CrossRef]

- Han, B.; Zhang, L.; Zhang, C.; Wang, Y.; Yu, X.; Ou, J. Reinforcement effect and mechanism of carbon fibers to mechanical and electrically conductive properties of cement-based materials. Constr. Build. Mater. 2016, 125, 479–489. [Google Scholar] [CrossRef]

- Biryukovich, K.L.; Yu, D.L. Glass Fiber Reinforced Cement; Civil Eng. Res. Assoc.: London, UK, 1965; p. 41. [Google Scholar]

- Enfedaque, A.; Alberti, M.; Galvez, J. The influence of additions in the use of glass fibre reinforced cement as a construction material. Mater. Sci. Appl. 2016, 7, 89–100. [Google Scholar] [CrossRef]

- Majumdar, A.; Laws, V. Glass Fiber Reinforced Cement; BSP Professional Books: Oxford, UK, 1991. [Google Scholar]

- Cascone, S.; Sapienza, V.; Lionti, I.; Porto, S. Fiber-reinforced polymer nets for strengthening lava stone masonries in historical buildings. Sustainability 2016, 8, 394. [Google Scholar] [CrossRef]

- Shakor, P.; Pimplikar, S. Glass fibre reinforced concrete use in construction. Int. J. Technol. Eng. Syst. 2011, 2, 2. [Google Scholar]

- Brookes, A. Cladding of Buildings, 3rd ed.; Taylor & Francis: Abingdon, UK, 2002. [Google Scholar]

- Iucolano, F.; Liguori, B.; Colella, C. Fibre-reinforced lime-based mortars: A possible resource for ancient masonry restoration. Constr. Build. Mater. 2013, 38, 785–789. [Google Scholar] [CrossRef]

- Ramamurthi, D.; Sophia, M. A review on modified lime based mortars—An alternative to cement mortar. Int. J. Innov. Res. Sci. Technol. 2016, 2, 350–356. [Google Scholar]

- MacDonald, C.; Michael, M.; Ballou, L.; Biddle, D. Case histories using synthetic fiber reinforced concrete. In Proceedings of the Shotcrete for underground support XI. Engineering Conferences International, Davos, Switzerland, 7–10 June 2009.

- Richardson, A.; Coventry, K.; Landless, S. Synthetic and steel fibres in concrete with regard to equal toughness. Struct. Surv. 2010, 28, 355–369. [Google Scholar] [CrossRef]

- Madhavi, T.C.; Raju, L.S.; Mathur, D. Polypropylene fiber reinforced concrete—A review. Int. J. Emerg. Technol. Adv. Eng. 2014, 4, 114–119. [Google Scholar]

- Alsadey, S. Effect of polypropylene fiber on properties of mortar. Int. J. Energy Sci. Eng. 2016, 2, 8–12. [Google Scholar]

- Venkatesan, R.C.S.; Patnaikuni, I. Review on hybrid fiber reinforced high performance high volume flyash concrete. Int. J. Struct. Civ. Eng. Res. 2016, 5, 39–43. [Google Scholar]

- Sarangi, S.; Sinha, A.K. Mechanical properties of hybrid fiber reinforced concrete. Ind. J. Sci. Technol. 2016, 9. [Google Scholar] [CrossRef]

- Hesami, S.; Hikouei, I.S.; Emadi, S.A.A. Mechanical behaviour of self-compacting concrete pavements incorporating recycled tire rubber crumb and reinforced with polypropylene fiber. J. Clean. Prod. 2016, 133, 228–234. [Google Scholar] [CrossRef]

- Mohseni, E.; Khotbehsara, M.M.; Naseri, F.; Monazami, M.; Sarker, P. Polypropylene fiber reinforced cement mortars containing rice husk ash and nano-alumina. Constr. Build. Mater. 2016, 111, 429–439. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Bodnárová, L.; Macháňová, P.; Kopkáně, D.; Herka, P.; Sťahel, P. Application of polypropylene fibre with various surface treatments in concrete. Adv. Mater. Res. 2014, 75–79. [Google Scholar] [CrossRef]

- Tosun-Felekoglu, K.; Felekoglu, B. Effects of fiber-matrix interaction on multiple cracking performance of polymeric fiber reinforced cementitious composites. Compos. Part B 2013, 52, 62–71. [Google Scholar] [CrossRef]

- Pakravan, H.R.; Latifi, M.; Jamshidi, M. Ductility improvement of cementitious composites reinforced with polyvinyl alcohol-polypropylene hybrid fibers. J. Ind. Text. 2014. [Google Scholar] [CrossRef]

- Yang, Y.; Lepech, M.D.; Yang, E.-H.; Li, V.C. Autogenous healing of engineered cementitious composites under wet-dry cycles. Cem. Concr. Res. 2009, 39, 382–390. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, E.-H.; Li, V.C. Autogenous healing of engineered cementitious composites at early age. Cem. Concr. Res. 2011, 41, 176–183. [Google Scholar] [CrossRef]

- Edvardsen, C. Water permeability and autogenous healing of cracks in concrete. ACI Mater. J. 1999, 96, 448–454. [Google Scholar]

- Lv, Z.; Chen, D. Overview of recent work on self-healing in cementitious materials. Mater. Constr. 2014, 64. [Google Scholar] [CrossRef]

- Mihashi, H.; Nishiwaki, T. Development of engineered self-healing and self-repairing concrete. J. Adv. Concr. Technol. 2012, 10, 170–184. [Google Scholar] [CrossRef]

- Nam, J.; Kim, G.; Lee, B.; Hasegawa, R.; Hama, Y. Frost resistance of polyvinyl alcohol fiber and polypropylene fiber reinforced cementitious composites under freeze thaw cycling. Compos. Part B 2016, 90, 241–250. [Google Scholar] [CrossRef]

- Homma, D.; Mihashi, H.; Nishiwaki, T. Self-healing capability of fibre reinforced cementitious composites. J. Adv. Concr. Technol. 2009, 7, 217–228. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G.; Qian, C.; Schlangen, E. Self-healing in cementitious materials: Materials, methods and service conditions. Mater. Des. 2016, 92, 499–511. [Google Scholar] [CrossRef]

- Choi, H.; Inoue, M.; Kwon, S.; Choi, H.; Lim, M. Effective crack control of concrete by self-healing of cementitious composites using synthetic fiber. Materials 2016, 9, 248. [Google Scholar] [CrossRef]

- Snoeck, D.; Schaubroeck, D.; Dubruel, P.; Belie, N.D. Effect of high amounts of superabsorbent polymers and additional water on the workability, microstructure and strength of mortars with a water-to-cement ratio of 0.50. Constr. Build. Mater. 2014, 72, 148–157. [Google Scholar] [CrossRef]

- Snoeck, D.; Tittelboom, K.V.; Steuperaert, S.; Dubruel, P.; Belie, N.D. Self-healing cementitious materials by the combination of microfibers and superabsorbent polymers. J. Intell. Mater. Syst. Struct. 2014, 25, 13–24. [Google Scholar] [CrossRef] [Green Version]

- Snoeck, D.; Steuperaert, S.; Tittelboom, K.V.; Dubruel, P.; Belie, N.D. Visualization of water penetration in cementitious materials with superabsorbent polymers by means of neutron radiography. Cem. Concr. Res. 2012, 42, 1113–1121. [Google Scholar] [CrossRef]

- Ahn, K.-L.; Jang, S.-J.; Kang, D.-H.; Yun, H.-D. Effect of superabsorbent polymer (SAP) on the performance of polyvinyl alcohol (PVA) fiber-reinforced strain-hardening cement composites. Contemp. Eng. Sci. 2015, 8, 1361–1369. [Google Scholar]

- Yeh, F.-Y.; Chang, K.-H.; Liao, W.-C. Experimental investigation of self-sensing carbon fiber reinforced cementitious composite for strain measurement of an RC portal frame. Int. J. Distrib. Sens. Netw. 2015, 2015, 531069. [Google Scholar] [CrossRef]

- Liu, X.; Nie, Z.; Wu, S.; Wang, C. Self-monitoring application of conductive asphalt concrete under indirect tensile deformation. Case Stud. Constr. Mater. 2015, 3, 70–77. [Google Scholar] [CrossRef]

- Shetty, M. Concrete Technology: Theory and Practice; S. Chand Publishing: New Delhi, India, 1982. [Google Scholar]

- Jo, B.-W.; Kim, C.-H.; Tae, G.; Park, J.-B. Characteristics of cement mortar with nano-SiO2 particles. Constr. Build. Mater. 2007, 21, 1351–1355. [Google Scholar] [CrossRef]

- Neville, A.; Aïtcin, P.-C. High performance concrete—An overview. Mater. Struct. 1998, 31, 111–117. [Google Scholar] [CrossRef]

- Caldarone, M. High-Strength Concrete: A Practical Guide; Taylor & Francis: Abingdon, UK, 2009. [Google Scholar]

- Russell, H. Mineral admixtures for High Performance Concrete. Concr. Prod. 2002, 105, 60. [Google Scholar]

- Aïtcin, P.-C. High Performance Concrete (HPC) (revisited in 2011). In Proceedings of the 36th Conference on Our World in Concrete & Structures, Singapore, 14–16 August 2011.

- Safiuddin, M.; Zain, M. Supplementary cementing materials for high performance concrete. BRAC Univ. J. 2006, 3, 47–57. [Google Scholar]

- Kosmatka, S.; Kerhoff, B.; Panarese, W.; MacLeod, N.; McGrath, R. Design and Control of Concrete Mixtures, 7th ed.; Cement Association of Canada: Ottawa, ON, Canada, 2002. [Google Scholar]

- Petra Buildcare Products. Hollow Spheres. Available online: http://www.indiacenosphere.com/hollowSphere.html (accessed on 13 October 2016).

- Hake, M.; Kayali, O. Properties of high-strength concrete using a fine fly ash. Cem. Concr. Res. 1998, 28, 1445–1452. [Google Scholar]

- Bentz, D.; Peltz, M.; Durán-Herrera, A.; Valdez, P.; Juárez, C. Thermal properties of high-volume fly ash mortars and concretes. J. Build. Phys. 2011, 34, 263–275. [Google Scholar] [CrossRef]

- Fly Ash in Production of High Performance Concrete in Denmark; COWI, A/S: Kongens Lyngby, Denmark, 2009.

- Wong, H.; Razak, H. Efficiency of calcined kaolin and silica fume as cement replacement material for strength performance. Cem. Concr. Res. 2004, 35, 696–702. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P. Effect of fly ash on the durability properties of high strength concrete. Procedia Eng. 2011, 14, 1149–1156. [Google Scholar] [CrossRef]

- Yeau, K.; Kim, E. An experimental study on corrosion resistance of concrete with ground granulate blast-furnace slag. Cem. Concr. Res. 2005, 35, 1391–1399. [Google Scholar] [CrossRef]

- Khan, M.I.; Siddique, R. Utilization of silica fume in concrete: Review of durability properties. Resour. Conserv. Recycl. 2011, 57, 30–35. [Google Scholar] [CrossRef]

- Siddique, R.; Klaus, J. Influence of metakaolin on the properties of mortar and concrete: A review. Appl. Clay Sci. 2009, 43, 392–400. [Google Scholar] [CrossRef]

- Neville, A. Properties of Concrete, 4th ed.; John Wiley & Sons: New York, NY, USA, 1996. [Google Scholar]

- ACI Committee 226.1R: Ground Granulated Blast-Furnace Slag as a Cementitiuous Constituent in Concrete; Amercian Concrete Institute: Detroit, MI, USA, 1992.

- Meyer, C. Concrete as a green building material. In Proceedings of the 3rd International Conference on Construction Materials (ConMat’05), Vancouver, BC, Canada, 22–24 August 2005; Available online: http://www.columbia.edu/cu/civileng/meyer/publications/publications/87%20Concrete%20as%20a%20Green%20Building%20Material.pdf (accessed on 28 September 2016).

- Huntzinger, D.; Eatmon, T. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Shi, X.; Xiao, Z.; Wu, J. The use of nanotechnology to improve the bulk and surface properties of steel for structural applications. In Nanotechnology in Eco-Efficient Construction; Woodhead Publishing: Cambridge, UK, 2013; pp. 75–107. [Google Scholar]

- Supino, S.; Malandrino, O.; Testa, M.; Sica, D. Sustainability in the EU cement industry: The Italian and German experiences. J. Clean. Prod. 2016, 112, 430–442. [Google Scholar] [CrossRef]

- Mehta, P.K. Global concrete industry sustainability. Concr. Int. 2009, 31, 45–48. [Google Scholar]

- McNeil, K.; Kang, T.-K. Recycled concrete aggregates: A review. Int. J. Concr. Struct. Mater. 2013, 7, 61–69. [Google Scholar] [CrossRef]

- Correia, J.; Brito, J.; Pereira, A. Effects on concrete durability of using recycled ceramic aggregates. Mater. Struct. 2006, 39, 169–177. [Google Scholar] [CrossRef]

- Phonphuak, N.; Kanyakam, S.; Chindrapasirt, P. Utilization of waste glass to enhance physical–mechanical properties of fired clay brick. J. Clean. Prod. 2016, 112, 3057–3062. [Google Scholar] [CrossRef]

- US Environmental Protection Agency. Wastes—Resource Conservation—Common Wastes & Materials—Glass; US Environmental Protection Agency: Washington, DC, USA, 2014.

- Aliabdo, A.; Elmoaty, M.; Aboshama, A. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Harbec, D.; Bahri, H.; Tagnit-Hamou, A.; Gitzhofer, F. New silica fume from recycled glass. In Proceedings of the Fifth international Symposium on Nanotechnology in Construction (NICOM5), Chicago, IL, USA, 24–26 May 2015.

- Thomas, B.; Gupta, R. A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energy Rev. 2016, 54, 1323–1333. [Google Scholar] [CrossRef]

- Frolova, O.; Salaiová, B.; Olexa, T.; Mandula, J. Using crumb rubber from waste tires to reduce road traffic noise. In Proceedings of the XV International Conference Topical Problems of Architecture, Civil Engineering, Energy Efficiency and Ecology (TPACEE-2016), Tyumen, Russia, 27–29 April 2016.

- Aiello, M.; Leuzzi, F.; Centonze, G.; Maffezzoli, A. Use of steel fibres recovered from waste tyres as reinforcement in concrete: Pull-out behaviour, compressive and flexural strength. Waste Manag. 2009, 29, 1960–1970. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Ding, Z.; Zhang, Y. Developments of sustainable cementitious materials. In Proceedings of the International Workshop on Sustainable Development & Concrete Technology, Beijing, China, 20–21 May 2004.

- Wilkinson, A.; Woodward, D.; Magee, B.; Tretsiakova-McNally, S. A state of the art review into the use of geopolymer cement for road applications. In Bituminous Mixtures and Pavements VI; Nikolaides, A., Ed.; CRC Press: London, UK, 2015; pp. 147–152. [Google Scholar]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef] [Green Version]

- Heidrich, C.; Sanjayan, J.; Berndt, M.L.; Foster, S.; Sagoe-Crentsil, K. Pathways and barriers for acceptance and usage of geopolymer concrete in mainstream construction. In Proceedings of the 2015 World of Coal Ash (WOCA), Nashville, TN, USA, May 2015; Available online: http://www.flyash.info/2015/189-heidrich-2015.pdf (accessed on 10 October 2016).

- Nuruddin, M.F.; Malkawi, A.B.; Fauzi, A.; Mohammed, B.S.; Almattarneh, H.M. Geopolymer concrete for structural use: Recent findings and limitations. IOP Conf. Ser. Mater. Sci. Eng. 2016, 133, 012021. [Google Scholar] [CrossRef]

- Dewald, U.; Achternbosch, M. Why more sustainable cements failed so far? Disruptive innovations and their barriers in a basic industry. Environ. Innov. Soc. Transit. 2016, 19, 15–30. [Google Scholar] [CrossRef]

- Huang, C.-F.; Chen, J.-L. The promotion strategy of green construction materials: A path analysis approach. Materials 2015, 8, 6999–7005. [Google Scholar] [CrossRef]

- Patil, J.; Pendharkar, U. Study of effect of nanomaterials as cement replacement on physical properties of concrete. Int. Res. J. Eng. Technol. 2013, 3, 300–308. [Google Scholar]

- Raki, L.; Beaudoin, J.; Alizadeh, R.; Makar, J.; Sato, T. Cement and concrete nanoscience and nanotechnology. Materials 2010, 3, 918–942. [Google Scholar] [CrossRef]

- Hakamy, A.; Shaikh, F.U.A.; Low, I.M. Characteristics of nanoclay and calcined nanoclay-cement nanocomposites. Compos. Part B 2015, 78, 174–184. [Google Scholar] [CrossRef]

- Shaikh, F.; Supit, S. Effects of superplasticizer types and mixing methods of nanoparticles on compressive strengths of cement pastes. J. Mater. Civ. Eng. 2016, 28, 06015008. [Google Scholar] [CrossRef]

- Zhang, L.; Ma, N.; Wang, Y.; Han, B.; Cui, X.; Yu, X.; Ou, J. Study on the reinforcing mechanisms of nano silica to cement-based materials with theoretical calculation and experimental evidence. J. Compos. Mater. 2016. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Asaad, D.S.; Muhyaddin, G.F. Properties of low binder ultra-high performance cementitious composites: Comparison of nanosilica and microsilica. Constr. Build. Mater. 2016, 102, 706–713. [Google Scholar] [CrossRef]

- Sonebi, M.; García-Taengua, E.; Hossain, K.; Khatib, J.; Lachemi, M. Effect of nanosilica addition on the fresh properties and shrinkage of mortars with fly ash and superplasticizer. Constr. Build. Mater. 2015, 84, 269–276. [Google Scholar] [CrossRef]

- Nili, M.; Ehsani, A. Investigating the effect of the cement paste and transition zone on strength development of concrete containing nanosilica and silica fume. Mater. Des. 2015, 75, 174–183. [Google Scholar] [CrossRef]

- Beigi, M.; Berenjian, J.; Omran, O.; Nik, A.; Nikbin, I. An experimental survey on combined effects of fibers and nanosilica on the mechanical, rheological, and durability properties of self-compacting concrete. Mater. Des. 2013, 50, 1019–1029. [Google Scholar] [CrossRef]

- Sikora, P.; Augustyniak, A.; Cendrowski, K.; Horszczaruk, E.; Rucinska, T.; Nawrotek, P.; Mijowska, E. Characterization of mechanical and bactericidal properties of cement mortars containing waste glass aggregate and nanomaterials. Materials 2016, 9, 701. [Google Scholar] [CrossRef]

- Jalal, M.; Mansouri, E.; Sharifipour, M.; Pouladkhan, A. Mechanical, rheological, durability and microstructural properties of high performance self-compacting concrete containing SiO2 micro and nanoparticles. Mater. Des. 2012, 34, 389–400. [Google Scholar] [CrossRef]

- Jinchang, P.; Ronggui, L. Improvement of performance of ultra-high performance concrete based composite material added with nano materials. Fratt. Integr. Strutt. 2016, 36, 130–138. [Google Scholar]

- Wu, Z.; Shi, C.; Khayat, K.; Wan, S. Effects of different nanomaterials on hardening and performance of ultra-high strength concrete (UHSC). Cem. Concr. Compos. 2016, 70, 24–34. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.-G.; Yuan, J.; Ou, J. Microstructure of cement mortar with nano-particles. Compos. Part B Eng. 35, 185–189. [CrossRef]

- Ismael, R.; Silva, J.; Carmo, R.; Soldado, E.; Lourenço, C.; Costa, H.; Júlio, E. Influence of nano-SiO2 and nano-Al2O3 additions on steel-to-concrete bonding. Constr. Build. Mater. 2016, 125, 1080–1092. [Google Scholar] [CrossRef]

- Shah, S.; Hou, P.; Konsta-Gdoutos, M. Nano-modification of cementitious material: Toward a stronger and durable concrete. J. Sustain. Cem.-Based Mater. 2015, 5, 1–22. [Google Scholar] [CrossRef]

- Cai, Y.; Hou, P.; Zhou, Z.; Cheng, X. Effects of nano-CaCO3 on the properties of cement paste: Hardening process and shrinkage at different humidity levels. In Proceedings of the 5th International Conference on Durability of Concrete Structures, Shenzhen, China, 30 June–1 July 2016.

- Land, G.; Stephan, D. Controlling cement hydration with nanoparticles. Cem. Concr. Comp. 2014, 57, 64–67. [Google Scholar] [CrossRef]

- Mendes, T.; Hotza, D.; Repette, W. Nanoparticles in cement based materials: A review. Rev. Adv. Master. Sci. 2015, 40, 89–96. [Google Scholar]

- Mohseni, E.; Naseri, F.; Amjadi, R.; Khotbehsara, M.M.; Ranjbar, M.M. Microstructure and durability properties of cement mortars containing nano-TiO2 and rice husk ash. Constr. Build. Mater. 2016, 114, 656–664. [Google Scholar] [CrossRef]

- Cerro-Prada, E.; Manso, M.; Torres, V.; Soriano, J. Microstructural and photocatalytic characterization of cement-paste sol-gel synthesized titanium dioxide. Front. Struct. Civ. Eng. 2016, 10, 189–197. [Google Scholar] [CrossRef]

- Mendoza, C.; Valle, A.; Castellote, M.; Bahamonde, A.; Faraldos, M. TiO2 and TiO2–SiO2 coated cement: Comparison of mechanic and photocatalytic properties. Appl. Catal. B Environ. 2015, 178, 155–164. [Google Scholar] [CrossRef]

- Jafari, H.; Afshar, S. Improved photodegradation of organic contaminants using nano-TiO2 and TiO2-SiO2 deposited on portland cement concrete blocks. Photochem. Photobiol. 2016, 92, 87–101. [Google Scholar] [CrossRef] [PubMed]

- Li, Z. Cement-based 0–3 piezoelectric composites. J. Am. Ceram. Soc. 2002, 85, 305–313. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Wang, S.; Chung, D.D.L. Cement-based piezoelectret. Mater. Struct. 2009, 42, 541–557. [Google Scholar] [CrossRef]

- Dong, B.; Liu, Y.; Qin, L.; Wang, Y.; Fang, Y.; Xing, F.; Chen, X. In-situ structural health monitoring of a reinforced concrete frame embedded with cement-based piezoelectric smart composites. Res. Nondestruct. Eval. 2016, 27, 216–229. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, Y.; Lu, Y.; Dong, P.; Guo, B.; Ding, W.; Xing, F.; Liu, T.; Dong, B. In-situ crack propagation monitoring in mortar embedded with cement-based piezoelectric ceramic sensors. Constr. Build. Mater. 2016, 126, 361–368. [Google Scholar] [CrossRef]

- Chaipanich, A. Dielectric and piezoelectric properties of PZT-silica fume cement composites. Curr. Appl. Phys. 2007, 7, 532–536. [Google Scholar] [CrossRef]

- Pan, H.H.; Chiang, C.K.; Yang, R.H.; Wu, Y.H.; Chang, C.S. Age effect on piezoelectric properties of cement-based piezoelectric composites containing slag. In Proceedings of the 13th East Asia-Pacific Conference on Structural Engineering and Construction (EASEC-13), Sapporo, Japan, 11–13 September 2013.

- Li, Z.; Gong, H.; Zhang, Y. Fabrication and piezoelectricity of 0–3 cement based composite with nano-PZT powder. Curr. Appl. Phys. 2009, 9, 588–591. [Google Scholar] [CrossRef]

- Gong, H.; Li, Z.; Zhang, Y.; Fan, R. Piezoelectric and dielectric behavior of 0–3 cement-based composites mixed with carbon black. J. Eur. Ceram. Soc. 2009, 29, 2013–2019. [Google Scholar] [CrossRef]

- Wang, H.-Y.; Wang, C.-C.; Chang, S.-C.; Lin, J.-C. A study of engineering and electricity properties of cement mortar added with recycled materials and piezoelectric powders. Constr. Build. Mater. 2016, 113, 297–305. [Google Scholar] [CrossRef]

- Geim, A.; Novoselov, K. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Dreyer, D.; Ruoff, R.; Bielawski, C. From conception to realization: An historial account of graphene and some perspectives for its future. Angew. Chem. 2010, 49, 9336–9344. [Google Scholar] [CrossRef] [PubMed]

- Iijima, S. Carbon nanotubes: Past, present, and future. Phys. B Condens. Matter 2002, 323, 1–5. [Google Scholar] [CrossRef]

- Palermo, V.; Kinloch, I.; Ligi, S.; Pugno, N. Nanoscale mechanics of graphene and graphene oxide in composites: A scientific and technological perspective. Adv. Mater. 2016, 28, 6232–6238. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Cote, L.; Kim, F.; Yuan, W.; Shull, K.; Huang, J. Graphene oxide sheets at interfaces. J. Am. Chem. Soc. 2010, 132, 8180–8186. [Google Scholar] [CrossRef] [PubMed]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.B.; Kohlhass, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef] [PubMed]

- Khitab, A.; Arshad, M. Nano construction materials: Review. Rev. Adv. Mater. Sci. 2014, 38, 181–189. [Google Scholar]

- Zohhadi, N.; Aich, N.; Matta, F.; Saleh, N.B.; Ziehl, P. Graphene nanoreinforcement for cement composites. In Proceedings of the 5th International Symposium on Nanotechnology in Construction (NICOM5), Chicago, IL, USA, May 2015; pp. 265–270.

- Meng, W.; Khayat, K. Mechanical properties of ultra-high-performance concrete enhanced with graphite nanoplatelets and carbon nanofibers. Compos. Part B 2016, 107, 113–122. [Google Scholar] [CrossRef]

- Kumar, N.; Kumbhat, S. Essentials in Nanoscience and Nanotechnology; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- Vera-Agullo, J.; Chozas-Ligero, V.; Portillo-Rico, D.; García-Casas, M.J.; Gutiérrez-Martínez, A.; Mieres-Royo, J.M.; Grávalos-Moreno, J. Mortar and concrete reinforced with nanomaterials. In Proceedings of the 3rd International Symposium on Nanotechnology in Construction (NICOM 3), Bilbao, Spain, 2009; pp. 383–388.

- Alrekabi, S.; Cundy, A.; Lampropoulos, A.; Savina, I. Experimental investigation on the effect of ultrasonication on dispersion and mechanical performance of multi-wall carbon nanotube-cement mortar composites. Int. J. Civ. Environ. Struct. Constr. Archit. Eng. 2016, 10, 268–274. [Google Scholar]

- Parveen, S.; Rana, S.; Fangueiro, R. A Review on nanomaterial dispersion, microstructure, and mechanical properties of carbon nanotube and nanofiber reinforced cementitious composites. J. Nanomater. 2013, 2013, 710175. [Google Scholar] [CrossRef]

- Aza, C.A.; Danoglidis, P.A.; Konsta-Gdoutos, M.S. Self sensing capability of multifunctional cementitious nanocomposites. In Proceedings of the Fifth International Symposium on Nanotechnology in Construction (NICOM5), Chicago, IL, USA, 2015; pp. 363–369.

- D’Alessandro, A.; Rallini, M.; Ubertini, F.; Materazzi, A.L.; Kenny, J.M. Investigations on scalable fabrication procedures for self-sensing carbon nanotube cement-matrix composites for SHM applications. Cem. Concr. Compd. 2016, 65, 200–213. [Google Scholar] [CrossRef]

- Zuo, J.; Yao, W.; Liu, X.; Qin, J. Sensing properties of carbon nanotube–carbon fiber/cement nanocomposites. J. Test. Eval. 2012, 40, 1–6. [Google Scholar] [CrossRef]

- Babak, F.; Abolfazl, H.; Alimorad, R.; Parviz, G. Preparation and Mechanical Properties of Graphene Oxide: Cement Nanocomposites. Sci. World J. 2014, 2014, 276323. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Pan, Z.; He, L.; Qiu, L.; Korayem, A.; Li, G.; Zhu, J.; Collins, F.; Li, D.; Duan, W.; Wang, M. Mechanical properties and microstructure of a graphene oxide–cement composite. Cem. Concr. Compos. 2015, 58, 140–147. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.; Lu, C.-X.; Liu, B.-W.; Zhang, K.; Li, C.-Z. Influence of graphene oxide additions on the microstructure and mechanical strength of cement. New Carbon Mater. 2015, 30, 349–356. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, Z.-R.; Fu, X.; Xu, Y.-J. TiO2–graphene nanocomposites for gas-phase photocatalytic degradation of volatile aromatic pollutant: Is TiO2𠄲graphene truly different from other TiO2–carbon composite materials? ACS Nano 2010, 4, 7303–7314. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wei, W.; Qin, H.; Hu, Y. Co-effects of graphene oxide sheets and single wall carbon nanotubes on mechanical properties of cement. J. Phys. Chem. Sol. 2015, 85, 39–43. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Tam, C.M.; Tam, V.W.Y.; Ng, K.M. Assessing drying shrinkage and water permeability of reactive powder concrete produced in Hong Kong. Constr. Build. Mater. 2012, 26, 79–89. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H. Effect of mineral admixtures on the properties of a sustainable Ultra-High Performance Concrete (UHPC). In Proceedings of the High Performance Fiber Reinforced Cement Composites (HPFRCC7), Stuttgart, Germany, 1–3 June 2015.

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Yoon, Y.-S. A review on structural behaviour, design, and application of Ultra-High-Performance Fiber-Reinforced Concrete. Int. J. Concr. Struct. Mater. 2016, 10, 125–142. [Google Scholar] [CrossRef]

- Shah, A.; Ribakov, Y. Recent trends in steel fibered high-strength concrete. Mater. Des. 2011, 32, 4122–4151. [Google Scholar] [CrossRef]

- Suhendro, B. Toward green concrete for better sustainable environment. In Proceedings of the Second International Conference on Sustainable Civil Engineering Structures and Construction Materials (SCESCM ’14), Yogyakarta, Indonesia, 23–25 September 2014.

- Patz, J.; Frumkin, H. Environmental health: From global to local. In Climate Change and Human Health, 3rd ed.; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- Farid, M.; Keen, M.; Papaioannou, M.; Parry, I.; Patillo, C.; Ter-Martirosyan, A. After Paris: Fiscal, Macroeconomic, and Financial Implications of Climate Change; IMF Stuff Discussion Note, SDN/16/01; International Monetary Fund: Washington, DC, USA, 2016. [Google Scholar]

- Banerjee, S.; Dionysiou, D.; Pillai, S. Self-cleaning applications of TiO2 by photo-induced hydrophilicity and photocatalysis. Appl. Catal. B Environ. 2015, 176, 396–428. [Google Scholar] [CrossRef]

| Fiber Type | Elastic Modulus (GPa) | Tensile Strength (Gpa) | Elongation at Break (%) | Diameter (µm) | Aspect Ratio | Source |

|---|---|---|---|---|---|---|

| Steel | 200 | 1.5 | 3.2 | 500 | 20 | [42] |

| Glass (E-glass) | 72 | 3.45 | 4.8 | 5–10 | 600–1500 | [18,43,44] |

| Glass (AR-glass) | 70–76 | 1.8–3.5 | 2 | 12 | 600–1500 | [18,45] |

| Polypropylene | 8 | 0.1–0.8 | 8.1 | 100 | 150 | [42,46] |

| Polyvinyl alcohol | 29–36 | 0.8 | 5.7 | 14–650 | 430–860 | [46,47] |

| Carbon | 240 | 2.5 | 1.4 | 7 | 710 | [42] |

| Volume Fraction of Fibers | Properties of Fiber | Type of Cement-based Mixture 1 | Increase in Performance 2 | Ref. |

|---|---|---|---|---|

| 1.5% Steel fibers | Hooked type; 33 mm length; 0.55 mm diameter; 1.25 GPa tensile str. | Concrete; superplasticiser | 87% split tensile str.; 72% flexural str. | [50] |

| 1.0% Steel fibers | Hooked type; 60 mm length; 0.80 mm diameter; 0.66 GPa tensile str. | Concrete; superplasticiser | 59.0% split tensile str. 68.7% flexural str. | [52] |

| 0.1% Glass fibers | 12 mm length; 14 µm diameter; 72 GPa elastic modulus; | Concrete; OPC 53 grade | 42.23% split tensile str.; 19.31% flexural str. | [53] |

| 1.5% Polypropylene fibers | 15 mm length; 100 µm diameter; 0.4 GPa tensile str. | Concrete; superplasticiser | −35.6% 1st crack str. −33.3% flexural str.; 27.3% toughness (I5) | [54] |

| 0.75% Polypropylene fibers | 12 mm length; | Pavement concrete; OPC 53 grade | 11.9% compressive str.; 9.7% flexural str. | [55] |

| 0.25% PVA fibers | 6 mm length; 14 µm diameter; 1.5 GPa tensile str. | Concrete; Shrinkage limited PC; Fly ash | 11.7% compressive str.; 32.4% split tensile str.; 21.4% flexural str. | [56] |

| 2% Carbon fibers | 3 mm length; 26.8 µm diameter; 0.86 GPa tensile str. | Mortar | 140% tensile str.; 187% flexural str. | [57] |

| 0.8% Carbon fibers | 3 mm length; 7 µm diameter; 3.45 GPa tensile str. | Mortar; Superplasticiser; Carbon fibers with hydrophilic surface modification; Dispersed through ultrasonication | 17.9% flexural str. | [58] |

| Pozzolanic Admixture and Weight of Cement | Water-to-Cement Ratio/Water-to-Binder Ratio | Compressive Str. at the 28th Day (MPa) | Compressive Str. at the 56th Day (MPa) | Source |

|---|---|---|---|---|

| 15% SF | 0.27 w/c | 101.0 | 103.5 | [106] |

| 5% MK | 0.3 w/c | 89.0 | 94.0 | [106] |

| 30% FA | 0.41 w/b | 72.5 | 90.3 | [107] |

| 33% GGBS | 0.42 w/b | 40.7 | 52.3 | [108] |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bastos, G.; Patiño-Barbeito, F.; Patiño-Cambeiro, F.; Armesto, J. Admixtures in Cement-Matrix Composites for Mechanical Reinforcement, Sustainability, and Smart Features. Materials 2016, 9, 972. https://doi.org/10.3390/ma9120972

Bastos G, Patiño-Barbeito F, Patiño-Cambeiro F, Armesto J. Admixtures in Cement-Matrix Composites for Mechanical Reinforcement, Sustainability, and Smart Features. Materials. 2016; 9(12):972. https://doi.org/10.3390/ma9120972

Chicago/Turabian StyleBastos, Guillermo, Faustino Patiño-Barbeito, Faustino Patiño-Cambeiro, and Julia Armesto. 2016. "Admixtures in Cement-Matrix Composites for Mechanical Reinforcement, Sustainability, and Smart Features" Materials 9, no. 12: 972. https://doi.org/10.3390/ma9120972

APA StyleBastos, G., Patiño-Barbeito, F., Patiño-Cambeiro, F., & Armesto, J. (2016). Admixtures in Cement-Matrix Composites for Mechanical Reinforcement, Sustainability, and Smart Features. Materials, 9(12), 972. https://doi.org/10.3390/ma9120972