Optimization of Fiber-Reinforced Polymer Bars for Reinforced Concrete Column Using Nonlinear Finite Element Algorithms

Abstract

:1. Introduction

2. Materials and Methods

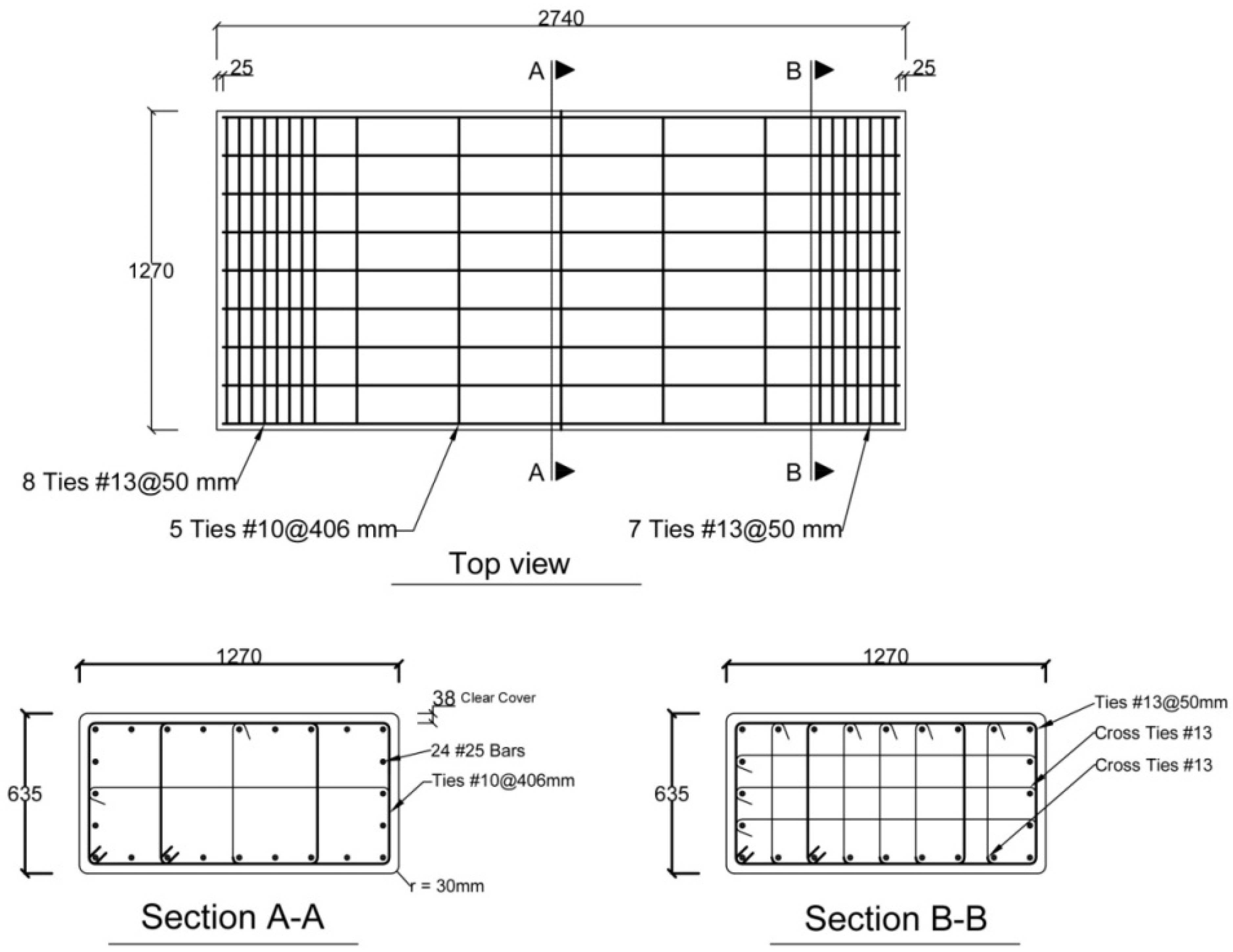

2.1. Finite Element Modeling and Experimental Verification

2.2. Numerical Development of the Models

3. Seismic Parameters Model Development

4. Results (Finite-Element Analysis)

5. Discussion

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xavier, H.F.B. Analysis of Reinforced Concrete Frames Exposed to Fire: Based on Advanced Calculation Methods. Available online: https://repositorio-aberto.up.pt/bitstream/10216/58515/1/000136907.pdf (accessed on 20 December 2021).

- Dilek, U. Assessment of fire damage to a reinforced concrete structure during construction. J. Perform. Constr. Facil. 2007, 21, 257–263. [Google Scholar] [CrossRef]

- Yan, Z.-G.; Shen, Y.; Zhu, H.H.; Li, X.J.; Lu, Y. Experimental investigation of reinforced concrete and hybrid fibre reinforced concrete shield tunnel segments subjected to elevated temperature. Fire Saf. J. 2015, 71, 86–99. [Google Scholar] [CrossRef] [Green Version]

- Soroushnia, S.; Tafreshi, S.T.; Omidinasab, F.; Beheshtian, N.; Soroushnia, S. Seismic performance of RC elevated water tanks with frame staging and exhibition damage pattern. ProcediaEng. 2011, 14, 3076–3087. [Google Scholar] [CrossRef] [Green Version]

- Sezen, H.; Whittaker, A.S.; Elwood, K.J.; Mosalam, K.M. Performance of reinforced concrete buildings during the August 17, 1999 Kocaeli, Turkey earthquake, and seismic design and construction practise in Turkey. Eng. Struct. 2003, 25, 103–114. [Google Scholar] [CrossRef]

- Murat, O. Field reconnaissance of the October 23, 2011, Van, Turkey, earthquake: Lessons from structural damages. J. Perform. Constr. Facil. 2013, 29, 04014125. [Google Scholar] [CrossRef]

- Ramesht, M.H.; Tavasani, M.A.M. A Case Study on Corrosion in Concrete Floating Docks in Qeshm Port. Procedia Eng. 2013, 54, 109–116. [Google Scholar] [CrossRef] [Green Version]

- Nakhostin, E.; Kenny, S.; Sivathayalan, S. Buried Corrugated Steel Culvert Failure Mechanisms Due to Environmental Deteriorations. In Proceedings of the International Conference on Sustainable Infrastructure 2019, Los Angeles, CA, USA, 6–9 November 2019; pp. 29–40. [Google Scholar]

- Nakhostin, E.; Kenny, S.; Sivathayalan, S. Numerical performance assessment of buried corrugated metal culvert subject to service load conditions. Can. J. Civ. Eng. 2021, 48, 99–114. [Google Scholar] [CrossRef]

- Sivakumar, A.; Santhanam, M. A quantitative study on the plastic shrinkage cracking in high strength hybrid fibre reinforced concrete. Cem. Concr. Compos. 2007, 29, 575–581. [Google Scholar] [CrossRef]

- Sarray, A.A. The Deterioration of Concrete in Wastewater Treatment Plants. Available online: http://i-rep.emu.edu.tr:8080/jspui/bitstream/11129/1340/1/SarrayAnmar.pdf (accessed on 15 December 2021).

- Yan, Z.-G.; Zhu, H.-H.; Ju, J.W.; Ding, W.-Q. Full-scale fire tests of RC metro shield TBM tunnel linings. Constr. Build. Mater. 2012, 36, 484–494. [Google Scholar] [CrossRef]

- Xu, H.; Zhao, Y.-X.; Cui, L.; Xu, B. Sulphate attack resistance of high-performance concrete under compressive loading. J. Zhejiang Univ. Sci. A 2013, 14, 459–468. [Google Scholar] [CrossRef] [Green Version]

- Alam, B.; Ashraf, M.; Shahzada, K.; Afzal, S. Sulphate attack in high-performance concrete-a review. J. Adv. Struct. Geotech. Eng. 2012, 1, 15–18. [Google Scholar]

- Freitag, S.A.; Bruce, S.M.; Shayan, A. Concrete Pile Durability in South Island Bridges; Research Report 454; NZ Transport Agency: South Island, New Zealand, 2011. [Google Scholar]

- Folliard, K.J.; Thomas, M.D.A.; Fournier, B.; Kurtis, K.E.; Ideker, J.H. Interim Recommendations for the Use of Lithium to Mitigate or Prevent Alkali-Silica Reaction (ASR); US Department of Transportation: Washington, DC, USA, 2006. [Google Scholar]

- Farny, J.A.; Kosmatka, S.H. Diagnosis and Control of Alkali-Aggregate Reactions in Concrete. Available online: https://www.cement.org/docs/default-source/fc_concrete_technology/is413-diagnosis-and-control-of-alkali-aggregate-reactions-in-concrete.pdf (accessed on 15 December 2021).

- Jana, D. Concrete scaling–a critical review. In Proceedings of the 29th Conference on Cement Microscopy, Quebec, QC, Canada, 20–24 May 2007. [Google Scholar]

- Portland Cement Association. Concrete Slab Surface Defects: Causes, Prevention, Repair; Portland Cement Association: Skokie, IL, USA, 2001. [Google Scholar]

- Song, G.; Shayan, A. Corrosion of Steel in Concrete: Causes, Detection and Prediction: A State-of-the-Art Review; The Australian Road Research Board (ARRB): Melbourne, Australia, 1998. [Google Scholar]

- Jiang, C.; Wu, Y.-F.; Dai, M.-J. Degradation of steel-to-concrete bond due to corrosion. Constr. Build. Mater. 2018, 158, 1073–1080. [Google Scholar] [CrossRef]

- François, R.; Laurens, S.; Deby, F. 1—Steel Corrosion in Reinforced Concrete. In Corrosion and Its Consequences for Reinforced Concrete Structures; François, R., Laurens, S., Deby, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–41. [Google Scholar]

- Song, Y.; Wightman, E.; Tian, Y.; Jack, K.; Li, X.; Zhong, H.; Bond, P.; Yuan, Z.; Jiang, G. Corrosion of reinforcing steel in concrete sewers. Sci. Total Environ. 2019, 649, 739–748. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Poursaee, A. 2—Corrosion of steel in concrete structures. In Corrosion of Steel in Concrete Structures; Poursaee, A., Ed.; Woodhead Publishing: Oxford, UK, 2016; pp. 19–33. [Google Scholar]

- Sen, R.; Mullins, G. Application of FRP composites for underwater piles repair. Compos. Part B Eng. 2007, 38, 751–758. [Google Scholar] [CrossRef]

- Xiao, Y.; Ma, R. Seismic retrofit of RC circular columns using prefabricated composite jacketing. J. Struct. Eng. 1997, 123, 1357–1364. [Google Scholar] [CrossRef]

- Seible, F.; Priestley, M.J.N.; Hegemier, G.A.; Innamorato, D. Seismic retrofit of RC columns with continuous carbon fiber jackets. J. Compos. Constr. 1997, 1, 52–62. [Google Scholar] [CrossRef]

- Wang, Y.-C.; Hsu, K. Design of FRP-wrapped reinforced concrete columns for enhancing axial load carrying capacity. Compos. Struct. 2008, 82, 132–139. [Google Scholar] [CrossRef]

- Colomb, F.; Tobbi, H.; Ferrier, E.; Hamelin, P. Seismic retrofit of reinforced concrete short columns by CFRP materials. Compos. Struct. 2008, 82, 475–487. [Google Scholar] [CrossRef]

- Saadatmanesh, H.; Ehsani, M.R.; Jin, L. Repair of earthquake-damaged RC columns with FRP wraps. ACI Struct. J. 1997, 94, 206–215. [Google Scholar]

- Ma, C.-K.; Apandi, N.M.; Sofrie, C.S.Y.; Ng, J.H.; Lo, W.H.; Awang, A.Z.; Omar, W. Repair and rehabilitation of concrete structures using confinement: A review. Constr. Build. Mater. 2017, 133, 502–515. [Google Scholar] [CrossRef]

- Mullins, G.; Sen, R.; Suh, K.; Winters, D. Underwater FRP repair of prestressed piles in the Allen Creek Bridge in the city of clearwater. ASCE. J. Composites Constr. 2005, 9, 136–146. [Google Scholar] [CrossRef]

- Sen, R.; Mullins, G.; Suh, K.; Winters, D. FRP application in underwater repair of corroded piles. Spec. Publ. 2005, 230, 1139–1156. [Google Scholar]

- Mullins, G.; Sen, R.; Suh, K.S.; Winters, D. A demonstration of underwater FRP repair. Concr. Int. 2006, 28, 70–73. [Google Scholar]

- Yalcin, C.; Kaya, O.; Sinangil, M. Seismic retrofitting of R/C columns having plain rebars using CFRP sheets for improved strength and ductility. Constr. Build. Mater. 2008, 22, 295–307. [Google Scholar] [CrossRef]

- Tu, J.; Gao, K.; He, L.; Li, X. Experimental study on the axial compression performance of GFRP-reinforced concrete square columns. Adv. Struct. Eng. 2019, 22, 1554–1565. [Google Scholar] [CrossRef]

- MugahedAmran, Y.H.; Alyousef, R.; Rashid, R.S.; Alabduljabbar, H.; Hung, C.C. Properties and applications of FRP in strengthening RC structures: A review. Structures 2018, 16, 208–238. [Google Scholar] [CrossRef]

- Antonio De Luca, F.M.; Antonio, N. Behavior of Full-Scale Glass Fiber-Reinforced Polymer Reinforced Concrete Columns under Axial Load. Struct. J. 2010, 107, 589. [Google Scholar]

- HanyTobbi, A.S.F.; Brahim, B. Concrete Columns Reinforced Longitudinally and Transversally with Glass Fiber-Reinforced Polymer Bars. Struct. J. 2012, 109, 551–558. [Google Scholar]

- Pantelides, C.P.; Gibbons, M.E.; Reaveley, L.D. Axial Load Behavior of Concrete Columns Confined with GFRP Spirals. J. Compos. Constr. 2013, 17, 305–313. [Google Scholar] [CrossRef]

- HanyTobbi, A.S.F.; Brahim, B. Behavior of Concentrically Loaded Fiber-Reinforced Polymer Reinforced Concrete Columns with Varying Reinforcement Types and Ratios. Struct. J. 2014, 111, 375–386. [Google Scholar]

- Afifi, M.Z.; Mohamed, H.M.; Benmokrane, B. Strength and Axial Behavior of Circular Concrete Columns Reinforced with CFRP Bars and Spirals. J. Compos. Constr. 2014, 18, 04013035. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Ferrante, L.; Valente, M.; Valente, T.; Lampani, L.; Gaudenzi, P.; Cioffi, S.; Iannace, S.; Sorrentino, L. Drop-weight impact behaviour of woven hybrid basalt–carbon/epoxy composites. Compos. Part B Eng. 2014, 59, 204–220. [Google Scholar] [CrossRef]

- Chen, Y.; Davalos, J.F.; Ray, I. Durability prediction for GFRP reinforcing bars using short-term data of accelerated aging tests. J. Compos. Constr. 2006, 10, 279–286. [Google Scholar] [CrossRef]

- Bakis, C.E.; Bank, L.C.; Brown, V.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Machida, A.; Rizkalla, S.H.; Triantafillou, T.C. Fiber-reinforced polymer composites for construction—State-of-the-art review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef] [Green Version]

- Ou, Y.; Zhu, D.; Zhang, H.; Yao, Y.; Mobasher, B.; Huang, L. Mechanical properties and failure characteristics of CFRP under intermediate strain rates and varying temperatures. Compos. Part B Eng. 2016, 95, 123–136. [Google Scholar] [CrossRef]

- Rocca, S. Experimental and Analytical Evaluation of FRP-Confined Large Size Reinforced Concrete Columns. Ph.D. Thesis, University of Missouri, Rolla, MO, USA, 2007. [Google Scholar]

- SayyarRoudsari, S.; Hamoush, S.A.; Soleimani, S.M.; Madandoust, R. Evaluation of large-size reinforced concrete columns strengthened for axial load using fiber reinforced polymers. Eng. Struct. 2019, 178, 680–693. [Google Scholar] [CrossRef]

- ASTM A370-03a; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM: West Conshohocken, PA, USA, 2003.

- Building Code Requirements for Structural Concrete: 2011. Available online: https://www.usb.ac.ir/FileStaff/5526_2020-1-25-11-12-7.pdf (accessed on 15 December 2021).

- Campbell, F.C. Structural Composite Materials; ASM International: Almere, The Netherlands, 2010. [Google Scholar]

- Standard No. 2800; Iranian Code of Practice for Seismic Resistant Design of Buildings. BHRC: Tehran, Iran, 2005.

- Mahmoudi, M.; Zaree, M. Determination the response modification factors of buckling restrained braced frames. Procedia Eng. 2013, 54, 222–231. [Google Scholar] [CrossRef] [Green Version]

- Fajfar, P. Structural analysis in earthquake engineering–a breakthrough of simplified non-linear methods. In Proceedings of the 12th European Conference on Earthquake Engineering, London, UK, 9–13 September 2002. [Google Scholar]

- Asgarian, B.; Shokrgozar, H. BRBF response modification factor. J. Constr. Steel Res. 2009, 65, 290–298. [Google Scholar] [CrossRef]

- Cican, G.; Deaconu, M.; Mirea, R.; Ceatra, L.; Cretu, M.; Dobre, T. Investigating the Use of Recycled Pork Fat-Based Biodiesel in Aviation Turbo Engines. Processes 2020, 8, 1196. [Google Scholar] [CrossRef]

- Petrescu, F.I.T.; Petrescu, R.V.V. Nuclear hydrogen structure and dimensions. Int. J. Hydrog. Energy 2019, 44, 10833–10837. [Google Scholar] [CrossRef]

- Petrescu, R.V.V.; Machín, A.; Fontánez, K.; Arango, J.C.; Márquez, F.M.; Petrescu, F.I.T. Hydrogen for aircraft power and propulsion. Int. J. Hydrog. Energy 2020, 45, 20740–20764. [Google Scholar] [CrossRef]

- Mirsayar, M.M.; Joneidi, V.A.; Petrescu, R.V.V.; Petrescu, F.I.T.; Berto, F. Extended MTSN criterion for fracture analysis of soda lime glass. Eng. Fract. Mech. 2017, 178, 50–59. [Google Scholar] [CrossRef]

- Petrescu, F.I.T.; Petrescu, R.V.; Mirsayar, M.M. The Computer Algorithm for Machine Equations of Classical Distribution. J. Mater. Eng. Struct. 2017, 4, 193–209. [Google Scholar]

- Petrescu, F.I.T.; Petrescu, R.V.V. An Algorithm to Determining the Gear Efficiency to a Simple Planetary Train. Indep. J. Manag. Prod. 2019, 10, 1392–1404. [Google Scholar] [CrossRef]

| Group | Number of Longitudinal Bars | Number of Stirrups at Ordinary Zones | Number of Stirrups at Specific Zones | ||||

|---|---|---|---|---|---|---|---|

| A1 | N/A * | 1.1 | 31.7 | 6 | 2 | 9 | |

| B1 | 2.0 | 1.4 | 30.2 | 6 | 3 | 9 | |

| C1 | 1.0 | 1.0 | 32.1 | 8 | 3 | 8 | |

| D1 | 1.0 | 1.4 | 30.7 | 12 | 4 | 13 | |

| E1 | 1.0 | 0.7 | 32.3 | 4 | 3 | 7 | |

| F1 | 1.0 | 1.4 | 31.5 | 4 | 5 | 12 | |

| G1 | 1.0 | 2.0 | 31.6 | 26 | 3 | 17 | |

| H1 | 2.0 | 2.7 | 30.3 | 24 | 5 | 15 |

| Laboratory Results | Finite Element Results | Difference (FEM vs. Laboratory) | ||||

|---|---|---|---|---|---|---|

| Specimen | Compressive Strength (MPa) | Maximum Axial Strain (mm/mm) | Compressive Strength (MPa) | Maximum Axial Strain (mm/mm) | Compressive Strength (%) | Maximum Axial Strain (%) |

| A1 | 26 | 2.94 × 10−3. | 29 | 3.00 × 10−3 | 11.9 | 2.5 |

| B1 | 23.94 | 1.60 × 10−3 | 25.1 | 1.50 × 10−3 | 4.9 | −6.6 |

| C1 | 26.6 | 3.25 × 10−3 | 27.3 | 3.30 × 10−3 | 2.5 | 1.6 |

| D1 | 24.5 | 3.16 × 10−3 | 24.7 | 3.12 × 10−3 | 0.6 | −2.0 |

| E1 | 20.4 | 2.20 × 10−3 | 20.55 | 2.13 × 10−3 | 0.4 | 5.3 |

| F1 | 26.2 | 7.70 × 10−3 | 24.7 | 7.40 × 10−3 | −7 | −4 |

| G1 | 28.5 | 6.99 × 10−3 | 30 | 7.11 × 10−3 | 5.2 | 2.5 |

| H1 | - | - | 22.35 | 7.20 × 10−3 | - | - |

| Name | Ultimate Stress (MPa) | Failure Strain | Modulus of Elasticity [1] |

|---|---|---|---|

| CFRP | 3690 | 0.031 | 580 |

| GFRP | 1600 | 0.17 | 51 |

| Group of Specimens | Steel (S) | CFRP Bars (C) | GFRP Bars (G) | Number of Longitudinal Bars #25 | Optimized CFRP with #12 Bars |

|---|---|---|---|---|---|

| A | AS | AC | AG | 6 | AO |

| B | BS | BC | BG | 6 | BO |

| C | CS | CC | CG | 8 | CO |

| D | DS | DC | DG | 12 | DO |

| E | ES | EC | EG | 4 | EO |

| F | FS | FC | FG | 4 | FO |

| G | GS | GC | GG | 26 | GO |

| H | HS | HC | HG | 24 | HO |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roudsari, S.S.; Ungureanu, L.M.; Soroushnia, S.; Abu-Lebdeh, T.; Petrescu, F.I.T. Optimization of Fiber-Reinforced Polymer Bars for Reinforced Concrete Column Using Nonlinear Finite Element Algorithms. Algorithms 2022, 15, 12. https://doi.org/10.3390/a15010012

Roudsari SS, Ungureanu LM, Soroushnia S, Abu-Lebdeh T, Petrescu FIT. Optimization of Fiber-Reinforced Polymer Bars for Reinforced Concrete Column Using Nonlinear Finite Element Algorithms. Algorithms. 2022; 15(1):12. https://doi.org/10.3390/a15010012

Chicago/Turabian StyleRoudsari, Sajjad Sayyar, Liviu Marian Ungureanu, Soheil Soroushnia, Taher Abu-Lebdeh, and Florian Ion Tiberiu Petrescu. 2022. "Optimization of Fiber-Reinforced Polymer Bars for Reinforced Concrete Column Using Nonlinear Finite Element Algorithms" Algorithms 15, no. 1: 12. https://doi.org/10.3390/a15010012

APA StyleRoudsari, S. S., Ungureanu, L. M., Soroushnia, S., Abu-Lebdeh, T., & Petrescu, F. I. T. (2022). Optimization of Fiber-Reinforced Polymer Bars for Reinforced Concrete Column Using Nonlinear Finite Element Algorithms. Algorithms, 15(1), 12. https://doi.org/10.3390/a15010012