Construction of Wood-Based Lamella for Increased Load on Seating Furniture

Abstract

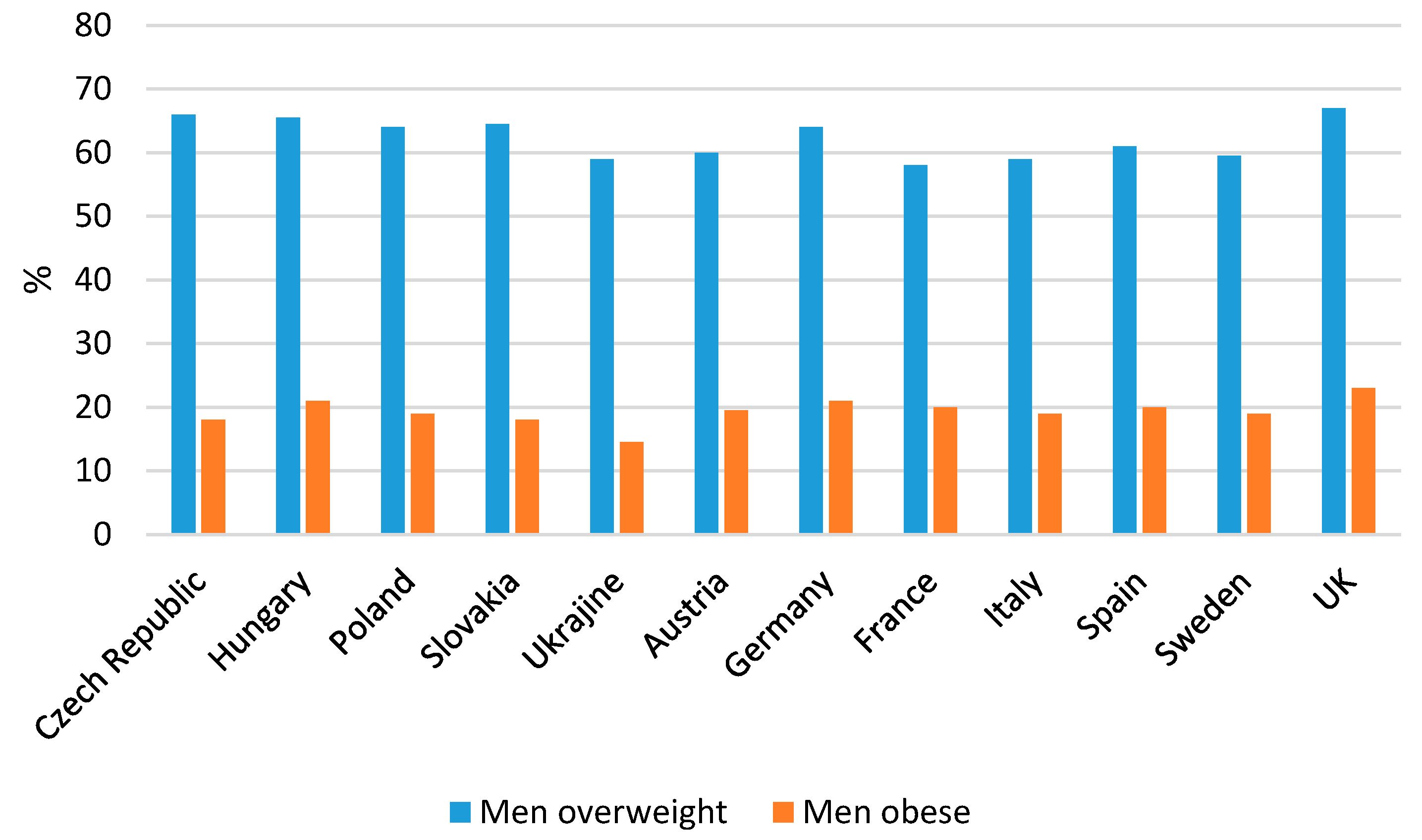

1. Introduction

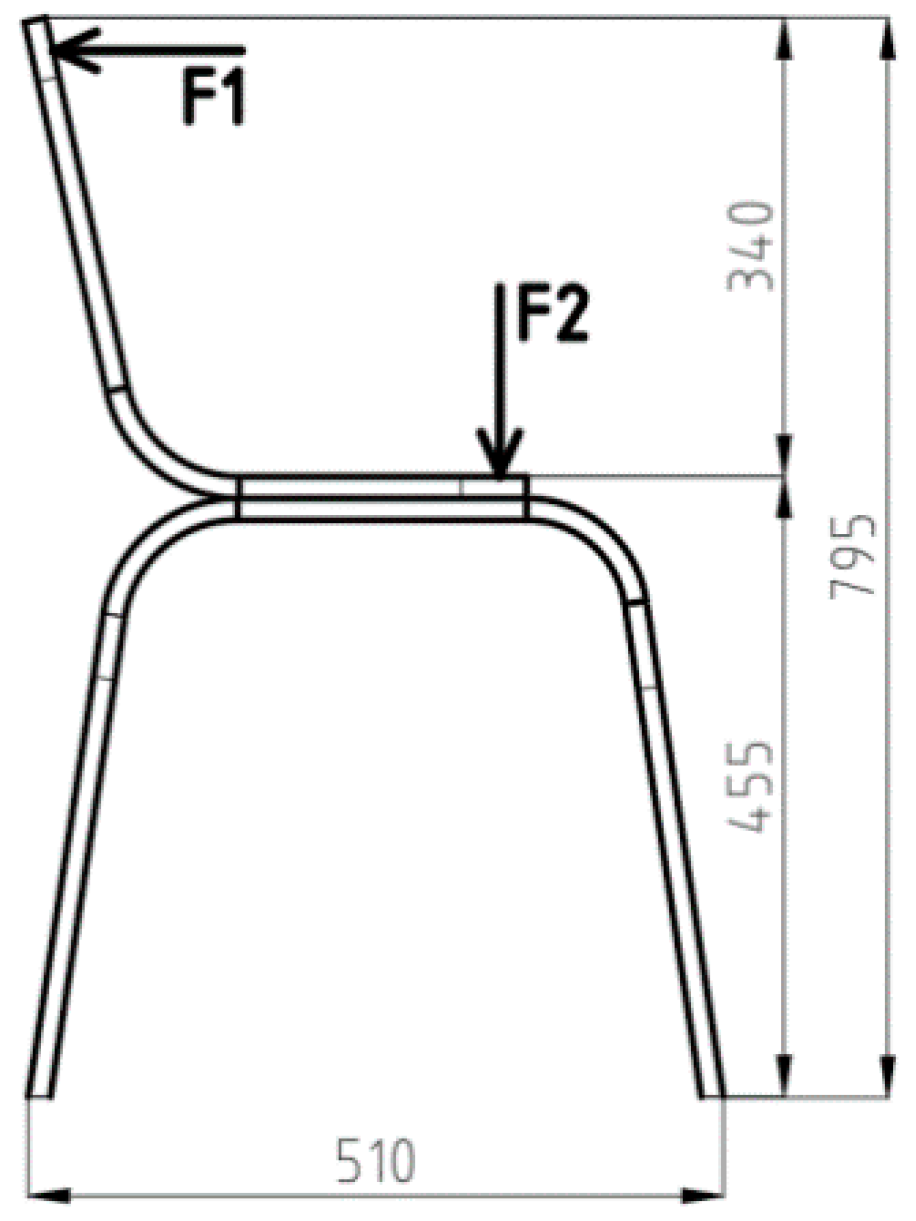

2. Materials and Methods

| where: | σ0,d—design stress in the beech lamella mold (MPa), | |

| fb,0,d—design strength in the beech lamella mold (MPa). |

| where: | —characteristic bending strength of glued lamella (MPa), | |

| —mean value of bending strength (MPa), | ||

| —quantile of Student’s t-distribution (one-side test), when t95 = 1.64, | ||

| —coefficient of variation (absolute value) (MPa). |

| where: | —characteristic strength of beech lamella in mold (MPa), | |

| —partial safety factor (-), for wood-based materials γM = 1.3, | ||

| —modification coefficient (-) (takes into account the effect of loading time and moisture content on the characteristic strength of material) for the action/load with the shortest design situation kmod = 1.10. |

3. Results and Discussion

3.1. Ultimate Limit State Assessment

3.2. Serviceability Limit State Assessment

3.3. Lamella construction meeting the requirements of ultimate states

4. Conclusions

- The research presented was focused on the assessment of two ultimate states of flexible chair construction. Minimum thickness requirements for lamellae needed for chairs for users with weight up to 110 kg and 150 kg resulted from the research.

- Following the mechanical properties of laminated veneer lamellae and the assessment of ultimate limit state and serviceability limit state, as well as the use of lamella in flexible chairs, four thicknesses of lamellae were examined.

- Requirements for the strength of structural elements were evaluated by the ultimate limit state and allowable deformation of chair construction and the position of the centre of gravity during the loading were evaluated by the serviceability limit state. Following the results of the research, the fact that three types of tested lamellae (thickness 11 mm, 13.5 mm and 16 mm) did not meet the requirements of the both ultimate states. Lamella with thickness of 21 mm met the requirements for both ultimate states in the case of loading of 110 kg and 150 kg.

- The methodology to evaluate the serviceability limit state of flexible chairs based on ergonomy and chair safety can be considered as another contribution of the research.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Joščák, P.; Dudas, J.; Gáborík, J.; Gaff, M.; Langová, N.; Navrátil, V.; Slabejová, G. Wood and Wood-Based Furniture Constructions; Technická univerzita vo Zvolene: Zvolen, Slovakia, 2014. [Google Scholar]

- Wang, Y.; Beydoun, M.A. The obesity epidemic in the United States—Gender, age, socioeconomic, racial/ethnic, and geographic characteristics: A systematic review and meta-regression analysis. Epidemiol. Rev. 2007, 29, 6–28. [Google Scholar] [CrossRef] [PubMed]

- Stevens, G.A.; Singh, G.M.; Lu, Y.; Danaei, G.; Lin, J.K.; Finucane, M.M.; Bahalim, A.N.; McIntire, R.K.; Gutierrez, H.R.; Cowman, M.; et al. National, regional, and global trends in adult overweight and obesity prevalences. Popul. Health Metr. 2012, 10, 22. [Google Scholar] [CrossRef] [PubMed]

- Tremmel, M.; Gerdtham, U.G.; Nilsson, P.M.; Saha, S. Economic Burden of Obesity: A Systematic Literature Review. Int. J. Environ. Res. Public Health 2017, 14, 435. [Google Scholar] [CrossRef] [PubMed]

- González-Rodríguez, L.G.; Perea Sánchez, J.M.; Aranceta-Bartrina, J.; Gil, Á.; González-Gross, M.; Serra-Majem, L.; Varela-Moreiras, G.; Ortega, R.M. Intake and Dietary Food Sources of Fibre in Spain: Differences with Regard to the Prevalence of Excess Body Weight and Abdominal Obesity in Adults of the ANIBES Study. Nutrients 2017, 9, 326. [Google Scholar] [CrossRef] [PubMed]

- Burke, N.L.; Shomaker, L.B.; Brady, S.; Reynolds, J.C.; Young, J.F.; Wilfley, D.E.; Sbrocco, T.; Stephens, M.; Olsen, C.H.; Yanovski, J.A.; et al. Impact of Age and Race on Outcomes of a Program to Prevent Excess Weight Gain and Disordered Eating in Adolescent Girls. Nutrients 2017, 9, 947. [Google Scholar] [CrossRef] [PubMed]

- Chan, R.S.; Woo, J. Prevention of Overweight and Obesity: How Effective is the Current Public Health Approach. Int. J. Environ. Res. Public Health 2010, 7, 765–783. [Google Scholar] [CrossRef]

- Peltzer, K.; Pengpid, S.; Samuels, T.A.; Özcan, N.K.; Mantilla, C.; Rahamefy, O.H.; Wong, M.L.; Gasparishvili, A. Prevalence of Overweight/Obesity and Its Associated Factors among University Students from 22 Countries. Int. J. Environ. Res. Public Health 2014, 11, 7425–7441. [Google Scholar] [CrossRef]

- Finucane, M.M.; Stevens, G.A.; Cowan, M.J.; Danaei, G.; Lin, J.K.; Paciorek, C.J.; Singh, G.M.; Gutierrey, H.R.; Lu, Y.; Bahalim, A.N. Global burden of metabolic risk factors of chronic diseases collaborating group body mass index. Lancet 2011, 377, 557–567. [Google Scholar] [CrossRef]

- De Onis, M.; Blössner, M.; Borghi, E. Global prevalence and trends of overweight and obesity among preschool children. Am. J. Clin. Nutr. 2010, 92, 1257–1264. [Google Scholar] [CrossRef]

- Rockholm, B.; Baker, J.L.; Sorensen, T.I.A. The levelling off of the obesity epidemic since the year 1999- A review of evidence and perspectives. Obes. Rev. 2010, 11, 835–846. [Google Scholar] [CrossRef]

- Odunitan-Wayas, F.; Okop, K.; Dover, R.; Alaba, O.; Micklesfield, L.; Puoane, T.; Uys, M.; Tsolekile, L.; Levitt, N.; Battersby, J.; et al. Food Purchasing Characteristics and Perceptions of Neighborhood Food Environment of South Africans Living in Low-, Middle- and High-Socioeconomic Neighborhoods. Sustainability 2018, 10, 4801. [Google Scholar] [CrossRef]

- Manzano, S.; Doblaré, M.; Hamdy Doweidar, M. Altered Mechano-Electrochemical Behavior of Articular Cartilage in Populations with Obesity. Appl. Sci. 2016, 6, 186. [Google Scholar] [CrossRef]

- Ng, M.; Fleming, T.; Robinson, M.; Tomson, B.; Graetz, N.; Margono, C.; Mullany, E.C.; Biryukov, S.; Abbafati, C.; Abera, S.F.; et al. Global, regional, and national prevalence of overweight and obesity in children and adults during 1980-2013: A systematic analysis for the Global Burden of Disease Study 2013. Lancet 2014, 384, 766–781. [Google Scholar] [CrossRef]

- Di Cesare, M.; Bentham, J.; Stevens, G.A.; Zhou, B.; Danaei, G.; Lu, Y.; Bixby, H.; Cowan, M.J.; Riley, L.M.R.; Hajifathalian, K.; et al. Trends in adult body-mass index in 200 countries from 1975 to 2014: A pooled analysis of 1698 population-based measurement studies with 19.2 million participants. Lancet 2016, 387, 1377–1396. [Google Scholar]

- Hitka, M.; Hajduková, A. Antropometrická optimalizácia rozmerov lôžkového nábytku. Acta Facultatis Xylologiae Zvolen 2013, 55, 101–109. [Google Scholar]

- Čuta, M.; Kukla, L.; Novák, L. Modelling the development of body height (length) in children using parental height data. Československá Pediatrie 2010, 65, 159–166. [Google Scholar]

- Harrison, C.R.; Robinette, K.M. CAESAR > Summarz Statistics for the Adult Population (Ages 18–65) of the United States of America; United States Air Force Research Laboratorz: Wright-Patterson AFB, OH, USA, 2002.

- Réh, R.; Krišťák, Ľ.; Hitka, M.; Langová, N.; Joščák, P.; Čambál, M. Analysis to Improve the Strength of Beds Due to the Excess Weight of Users in Slovakia. Sustainability 2019, 11, 624. [Google Scholar] [CrossRef]

- Ministry of Health of the Slovak Republic. Report on Health Status in Slovakia. Health 2016. Available online: http://health.gov.sk (accessed on 31 September 2018).

- Public Health Authority of the Slovak Republic. Annual Report on the Activities of the Public Health Office for 2017. Available online: http://uvzsr.sk/docs/vs/vyrocna_sprava_2017.pdf (accessed on 31 September 2018).

- Statistical Office of the Slovak Republic. View of Health Status of the Slovak Population and Its Determinants (Results of EHIS 2016). Available online: http://slovak.statistics.sk (accessed on 31 September 2018).

- World Health Organization Regional Office for Europe. The Health Systems in Transition (HiT). Available online: http://euro.whoint/en/countries/slovakia (accessed on 31 September 2018).

- Porta, J.; Saco-Ledo, G.; Cabanas, M.D. The ergonomics of airplane seats: The problem with economy class. Int. J. Ind. Ergon. 2019, 69, 90–95. [Google Scholar] [CrossRef]

- Quigley, C.; Southall, D.; Freer, M.; Moody, A.; Porter, M. Anthropometric Study to Update Minimum Aircraft Seating Standards. Available online: https://dspace.lboro.ac.uk/2134/701 (accessed on 18 January 2019).

- Roggla, G.; Moser, B.; Roggla, M. Seat space on airlines. Lancet 1999, 353, 1532. [Google Scholar] [CrossRef]

- BIFMA X6.1. Educational Seating. American National Standard for Office Furnishings (Revised in 2018); BIFMA: Grand Rapids, MI, USA, 2018. [Google Scholar]

- Bellingar, T.A.; Benden, M.E. New ANSI/BIFMA standard for testing of educational seating. Ergon. Des. Q. Hum. Factors Appl. 2015, 23, 23–27. [Google Scholar] [CrossRef]

- Parcells, C.; Stommel, M.; Hubbard, R.P. Mischmatch of classroom furniture and student body dimensions: Empirical findings and health implications. J. Adolesc. Health 1999, 24, 265–273. [Google Scholar] [CrossRef]

- Panagiotopoulou, G.; Christoulas, K.; Papanckolaou, A.; Mandroukas, K. Classroom furniture dimensions and anthropometric measures in primary school. Appl. Ergon. 2004, 35, 121–128. [Google Scholar] [CrossRef] [PubMed]

- Mohamed-Thariq, M.G.; Munasinghe, H.P.; Abeysekara, J.D. Designing chairs with mounted desktop for university students Ergonomics and comfort. Int. J. Ind. Ergon. 2010, 40, 8–18. [Google Scholar] [CrossRef]

- Oyewole, S.A.; Haight, J.M.; Freivalds, A. The ergonomic design of classroom furniture/computer work station for first graders in the elementary school. Int. J. Ind. Ergon. 2010, 40, 437–447. [Google Scholar] [CrossRef]

- Agha, S.R.; Alnahhal, M.J. Neural network and multiple linear regression to predict school children dimensions for ergonomic school furniture design. Appl. Ergon. 2012, 43, 979–984. [Google Scholar] [CrossRef] [PubMed]

- BIFMA X5.11. Large Occupant Office Chair Standard. American National Standard for Office Furnishings; BIFMA: Grand Rapids, MI, USA, 2015. [Google Scholar]

- AFRDI 142. Certification for Heavy Duty Office Chairs; Australian Furnishings Research and Development Institute: Launceston, Australia, 2012. [Google Scholar]

- AFRDI 151. Rated Load Standard for Fixed Height Chairs; Australian Furnishings Research and Development Institute: Launceston, Australia, 2014. [Google Scholar]

- BS 5459-2:2000 and A2:2008. Specification for Performance Requirements and Tests for Office Furniture; British Standards Institutions: London, UK, 2000. [Google Scholar]

- ISO 17025. General Requirements for the Competence of Testing and Calibration Laboratories; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- SATRA. Satra Technology—International Product Research, Testing and Supply Chain Quality. Available online: http://satra.com (accessed on 31 September 2018).

- Bonenberg, A.; Branowski, B.; Kurcyewski, P.; Lewandowska, A.; Sydor, M.; Torzynski, D.; Zablocki, M. Designing for human use: Examples of kitchen interiors for person with disability and elderly people. Hum. Factors Ergon. Manuf. 2019, 29, 177–186. [Google Scholar] [CrossRef]

- Mehrparvar, A.H.; Mirmohammadi, S.J.; Hafezi, R.; Mostaghaci, M.; Davari, M.H. Static anthropometric dimensions in a population of Iranian high school students: Considering ethnic differences. Hum. Factors J. Hum. Factors Ergon. Soc. 2015, 57, 447–460. [Google Scholar] [CrossRef]

- Qutubuddin, S.M.; Hebbal, S.S.; Kumar, C.S. Anthropometric consideration for designing students desks in engineering colleges. Int. J. Curr. Eng. Technol. 2013, 3, 1179–1185. [Google Scholar]

- Shin, D.; Kim, J.Y.; Hallbeck, M.S.; Haight, J.M.; Jung, M.C. Ergonomic hand tool and desk and chair development process. Int. J. Occup. Saf. Ergon. 2008, 14, 247–252. [Google Scholar] [CrossRef][Green Version]

- Masson, A.E.; Hignett, S.; Gyi, D.E. Anthropometric Study to Understand Body Size and Shape for Plus Size People at Work. Procedia Manuf. 2015, 3, 5647–5654. [Google Scholar] [CrossRef]

- Smardzewski, J. Furniture Design; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar]

- Hitka, M.; Joščák, P.; Langová, N.; Krišťák, L.; Blašková, S. Load-Carrying Capacity and the Size of Chair Joints D etermined for Users with a Higher Body Weight. Bioresources 2018, 13, 6428–6443. [Google Scholar]

- Hitka, M.; Sedmák, R.; Joščák, P.; Ližbetinová, L. Positive Secular Trend in Slovak Population Urges on Updates of Functional Dimensions of Furniture. Sustainability 2018, 10, 3474. [Google Scholar] [CrossRef]

- Dvouletá, K.; Káňová, D. Utilization of anthropometry in the sphere of sitting and bed furniture. Acta Univ. Agric. Silvic. Mendel. Brun. 2014, 62, 81–90. [Google Scholar] [CrossRef]

- Muir, M.; Archer-Heese, G. Essentials of a bariatric patient handling program. OJIN Online J. Issues Nurs. 2009, 14, 5. [Google Scholar]

- Gourash, W.; Rogula, T.; Schauer, P.R. Essential Bariatric Equipment: Making Your Facility More Accommodating to Bariatric Surgical Patients; Springer: New York, NY, USA, 2007. [Google Scholar]

- Wiggermann, N.; Smith, K.; Kumpar, D. What bed size does a patient need? The relationship between body mass index and space required to turn in bed. Nurs. Res. 2017, 66, 483–489. [Google Scholar] [CrossRef] [PubMed]

- Ko, Y.C.; Lo, C.H.; Chen, C.C. Influence of Personality Traits on Consumer Preferences: The Case of Office Chair Selection by Attractiveness. Sustainability 2018, 10, 4183. [Google Scholar] [CrossRef]

- Nüesch, C.; Kreppke, J.N.; Mündermann, A.; Donath, L. Effects of a Dynamic Chair on Chair Seat Motion and Trunk Muscle Activity during Office Tasks and Task Transitions. Int. J. Environ. Res. Public Health 2018, 15, 2723. [Google Scholar] [CrossRef]

- Borůvka, V.; Dudík, R.; Zeidler, A.; Holeček, T. Influence of Site Conditions and Quality of Birch Wood on Its Properties and Utilization after Heat Treatment. Part I—Elastic and Strength Properties, Relationship to Water and Dimensional Stability. Forests 2019, 10, 189. [Google Scholar] [CrossRef]

- Wei, P.; Rao, X.; Yang, J.; Guo, Y.; Chen, H.; Zhang, Y.; Chen, S.; Deng, X.; Wang, Z. Hot pressing of wood-based composites: A review. For. Prod. J. 2016, 66, 419–427. [Google Scholar] [CrossRef]

- Derikvand, M.; Kotlarewski, N.; Lee, M.; Jiao, H.; Nolan, G. Characterisation of Physical and Mechanical Properties of Unthinned and Unpruned Plantation-Grown Eucalyptus nitens H. Deane & Maiden Lumber. Forests 2019, 10, 194. [Google Scholar]

- Šubic, B.; Fajdiga, G.; Lopatič, J. Bending Stiffness, Load-Bearing Capacity and Flexural Rigidity of Slender Hybrid Wood-Based Beams. Forests 2018, 9, 703. [Google Scholar] [CrossRef]

- Réh, R.; Igaz, R.; Krišťák, Ľ.; Ružiak, I.; Gajtanska, M.; Božíková, M.; Kučerka, M. Functionality of beech bark in adhesive mixtures used in plywood and its effect on the stability associated with material systems. Materials 2019, 12, 1298. [Google Scholar] [CrossRef] [PubMed]

- Morales, G.A. Potential of Gmelina arborea for solid wood products. New For. 2004, 28, 331–337. [Google Scholar] [CrossRef]

- Sikora, A.; Svoboda, T.; Záborský, V.; Gaffová, Z. Effect of selected factors on the bending deflection at the limit of proportionality and at the modulus of rupture in laminated veneer lumber. Forests 2019, 10, 401. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, Y.; Yu, Y.; Song, J. Improve Performance of Soy Flour-Based Adhesive with a Lignin-Based Resin. Polymers 2017, 9, 261. [Google Scholar] [CrossRef] [PubMed]

- Gejdoš, M.; Tončíková, Z.; Němec, M.; Chovan, M.; Gergeľ, T. Balcony cultivator: New biomimicry design approach in the sustainable device. Futures 2018, 98, 32–40. [Google Scholar] [CrossRef]

- Bekhta, P.; Hiziroglu, S.; Potapova, O.; Sedliačik, J. Shear Strength of Exterior Plywood Panels Pressed at Low Temperature. Materials 2009, 2, 876–882. [Google Scholar] [CrossRef]

- Erdil, Y.Z.; Zhang, J.; Eckelman, C.A. Withdrawal and bending strength of dowel-nuts in plywood and oriented strandboard. For. Prod. J. 2003, 53, 54–57. [Google Scholar]

- Prekrat, S.; Smardzewski, J. Effect of gluline shape on strength of mortise and tenon joint. Drv. Ind. 2010, 61, 223–228. [Google Scholar]

- Kilic, H.; Kasal, A.; Kuskun, T.; Acar, M.; Erdil, Y.Z. Effect of Tenon Size on Static Front to Back Loading Performance of Wooden Chairs in Comparison with Acceptable Design Loads. Bioresources 2018, 13, 256–271. [Google Scholar]

- Kuskun, T.; Kasal, A.; Haviarova, E.; Kilic, H.; Uysal, M.; Erdil, Y.Z. Relationship between static and cyclic front to back load capacity of wooden chairs, and evaluation of the strength values according to acceptable design values. Wood Fiber Sci. 2018, 50, 1–9. [Google Scholar] [CrossRef]

- Oktaee, J.; Ebrahimi, G.; Layeghi, M.; Ghofrani, M.; Eckelman, C.A. Bending moment capacity of simple and haunched mortise and tenon furniture joints under tension and compression loads. Turk. J. Agric. For. 2014, 38, 291–297. [Google Scholar] [CrossRef]

- Likos, E.; Haviarova, E.; Eckelmna, C.A.; Erdil, Y.Z.; Ozcifci, A. Technical note: Static versus cyclic load capacity of side chairs constructed with mortise and tenon joints. Wood Fiber Sci. 2013, 45, 223–227. [Google Scholar]

- Gaff, M.; Gašparík, M.; Boruvka, V.; Haviarová, E. Stress simulation in layered wood-based materials under mechanical loading. Mater. Des. 2015, 87, 1065–1071. [Google Scholar] [CrossRef]

- Grič, M.; Joščák, P.; Tarvainen, I.; Ryonankoski, H.; Lagaňa, R.; Langová, N.; Andor, T. Mechanical properties of furniture self-locking frame joints. Bioresources 2017, 12, 5525–5538. [Google Scholar] [CrossRef][Green Version]

- Branowski, B.; Zablocki, M.; Sydor, M. Experimental analysis of new furniture joints. Bioresources 2018, 13, 370–382. [Google Scholar] [CrossRef]

- Hajdarevič, S.; Busuladžič, I. Stiffness Analysis of Wood Chair Frame. Procedia Eng. 2015, 100, 746–755. [Google Scholar] [CrossRef]

- Staneva, N.; Genchev, Y.; Hristodorova, D. Approach to designing an upolstered furniture frame by the finite element method. Acta Fac. Xylologiae 2018, 60, 61–70. [Google Scholar]

- Hu, W.G.; Guan, H.Y. Research on withdrawal strength of mortise and tenon joint by numerical and analytic methods. Wood Res. 2017, 62, 575–586. [Google Scholar]

- Derikvand, M.; Ebrahimi, G. Finite element analysis of stress and strain distributions in mortise and loose tenon furniture joints. J. For. Res. 2014, 25, 677–681. [Google Scholar] [CrossRef]

- Hu, W.G. Study of finite element analysis of node in solid wood structure furniture based on ANSYS. Furnit. Inter. Des. 2015, 46, 65–67. [Google Scholar]

- Kasal, A.; Eckelman, C.A.; Haviarova, E.; Yalcin, I. Bending moment capacities of L-shaped mortise and tenon joints under compression and tension loadings. Bioresources 2016, 1, 6836–6853. [Google Scholar] [CrossRef]

- Diler, H.; Efe, H.; Erdil, Y.Z.; Kuskun, T.; Kasal, A. Determination of allowable design loads for wood chairs. In Proceedings of the XXVIII International Conference Research for Furniture Industry, Poznan, Poland, 21–22 September 2017. [Google Scholar]

- Laemlaksakul, V. Innovative Design of Laminated Bamboo Furniture Using Finite Element Method. Int. J. Math. Comput. Simul. 2008, 3, 274–284. [Google Scholar]

- EN 1728. Furniture. Seating. Test Methods for the Determination of Strength and Durability; BSI: London, UK, 2012. [Google Scholar]

- EN 12520. Furniture—Strength, Durability and Safety—Requirements for Domestic Seating; BSI: London, UK, 2015. [Google Scholar]

- EN 1022. Domestic Furniture. Seating. Determination of Stability; BSI: London, UK, 2018. [Google Scholar]

- Sydor, M.; Wieloch, G. Construction properties of wood taken into consideration in engenering practice. Drewno 2009, 52, 63–73. [Google Scholar]

- Požgaj, A.; Chovanec, D.; Kurjatko, S.; Babiak, M. Štruktúra a Vlastnosti Dreva; Príroda a.s.: Bratislava, Slovakia, 1993. [Google Scholar]

- Sedlecký, M.; Kvietková, M.S.; Kminiak, R. Medium-density fiberboard (MDF) and Edge-glued Panels (EGP) after edge milling—Surface roughness after machining with different parameters. Bioresources 2018, 13, 2005–2021. [Google Scholar] [CrossRef]

- Němec, M.; Kminiak, R.; Danihelová, A.; Gergel, T.; Ondrejka, V. Vibrations and workpiece surface quality at changing feed speed of CNC machine. Akustika 2017, 28, 117–124. [Google Scholar]

- Ke, Q.; Zhang, F.; Zhang, Y. Optimisation design of pine backrest chair based on Taguchi method. Int. Wood Prod. J. 2017, 8, 18–25. [Google Scholar] [CrossRef]

- Szalai, J. Festigkeitstheorien von anisotropen Stoffen mit sprodem bruchverhalten. Acta Silv. Lign. Hung. 2008, 4, 61–79. [Google Scholar]

| Young’s Modulus (MPa) | Poisson’s Ratio (-) | Shear Modulus (MPa) | ||||||

|---|---|---|---|---|---|---|---|---|

| Ex | Ey | Ez | µxy | µyz | µxz | Gxy | Gyz | Gxz |

| 1130.0 | 16670.0 | 630.0 | 0.044 | 0.33 | 0.027 | 1200.0 | 190.0 | 930.0 |

| Type of Lamella | Mean Value (MPa) | Coefficient of Variation ϑ (%) | Characteristic Bending Strength fb,0,k (MPa) | Design Bending Strength fb,0,d (MPa) |

|---|---|---|---|---|

| A | 111.85 | 4.96 | 102.76 | 86.86 |

| B | 104.64 | 6.57 | 93.37 | 79.01 |

| C | 93.80 | 6.11 | 84.41 | 71.42 |

| Type of Lamella | Mean Value (MPa) | Coefficient of Variation ϑ (%) | Characteristic Bending Strength fb,0,k (MPa) | Design Bending Strength fb,0,d (MPa) |

|---|---|---|---|---|

| A | 123.85 | 4.55 | 114.61 | 96.98 |

| B | 98.13 | 3.59 | 92.35 | 78.15 |

| C | 89.48 | 5.97 | 80.70 | 68.28 |

| Type of Lamella | Loading of 110 kg | Loading of 150 kg | ||

|---|---|---|---|---|

| Design Stress FEM (MPa) | Design Stress FEM (MPa) | |||

| In Tension σt,0,d | In Compression σc,0,d | In Tension σt,0,d | In Compression σc,0,d | |

| A | 85.90 | 122.55 | 117.06 | 167.38 |

| B | 69.04 | 104.52 | 82.55 | 142.77 |

| C | 47.18 | 65.14 | 64.25 | 88.98 |

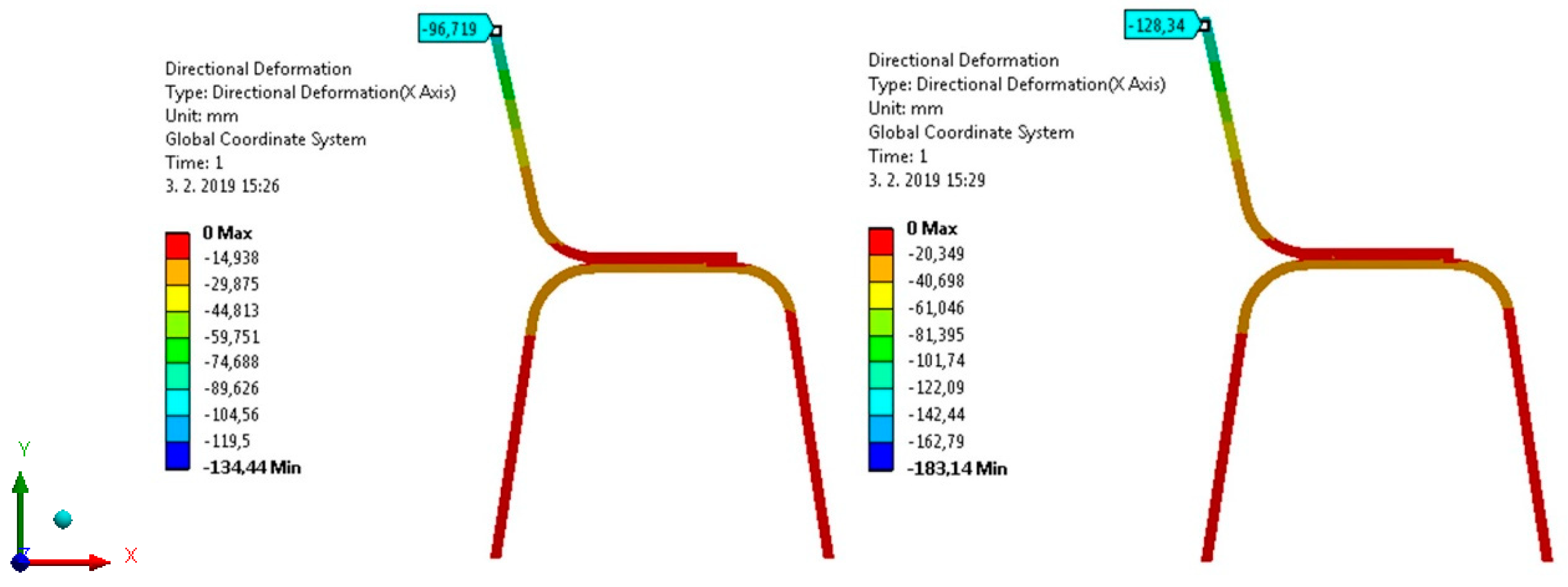

| Type of Lamella. | Loading of 110 kg | Loading of 150 kg | ||

|---|---|---|---|---|

| u (mm) | b (mm) | u (mm) | b (mm) | |

| A | 289.15 | −63.5 | 343.15 | −140.1 |

| B | 189.13 | +33.7 | 256.16 | −54.6 |

| C | 96.72 | +157.4 | 128.34 | +74.2 |

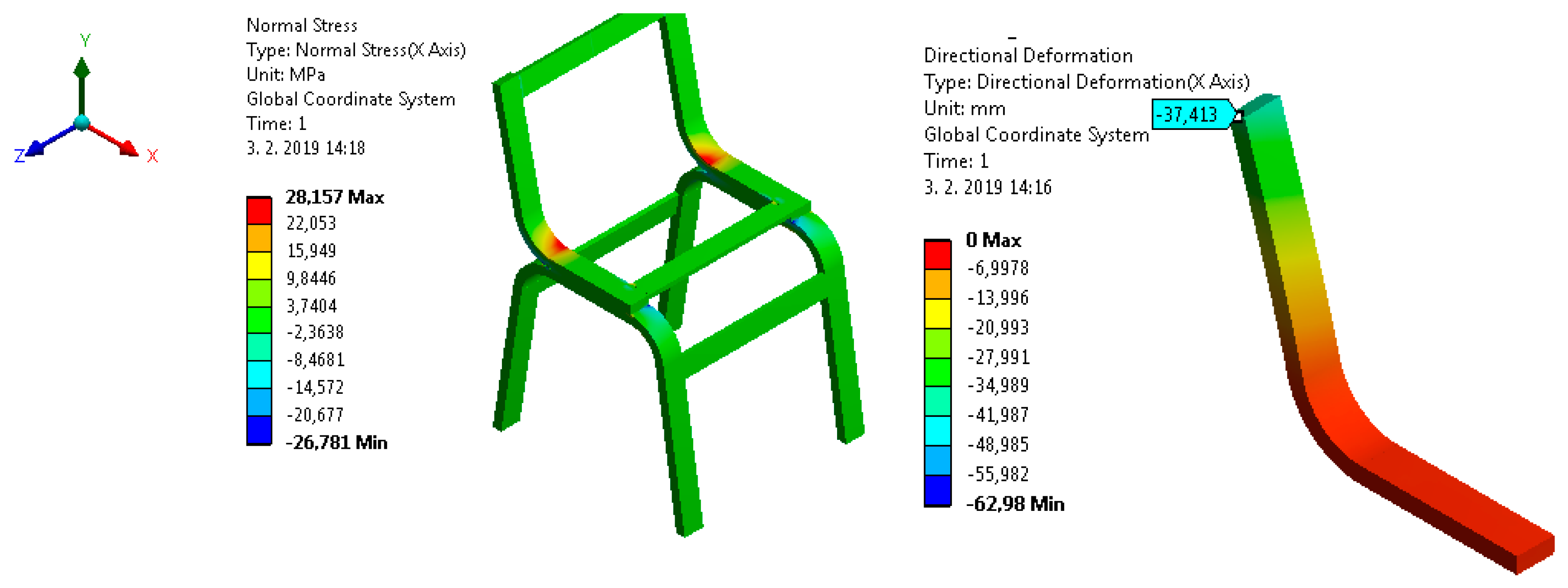

| Type of Lamella | Design Stress-FEM (MPa) | Displacement of the Chair Back | |

|---|---|---|---|

| in Tension | in Compression | u (mm) | |

| D | 28.16 | 26.78 | 37.41 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Langová, N.; Réh, R.; Igaz, R.; Krišťák, Ľ.; Hitka, M.; Joščák, P. Construction of Wood-Based Lamella for Increased Load on Seating Furniture. Forests 2019, 10, 525. https://doi.org/10.3390/f10060525

Langová N, Réh R, Igaz R, Krišťák Ľ, Hitka M, Joščák P. Construction of Wood-Based Lamella for Increased Load on Seating Furniture. Forests. 2019; 10(6):525. https://doi.org/10.3390/f10060525

Chicago/Turabian StyleLangová, Nadežda, Roman Réh, Rastislav Igaz, Ľuboš Krišťák, Miloš Hitka, and Pavol Joščák. 2019. "Construction of Wood-Based Lamella for Increased Load on Seating Furniture" Forests 10, no. 6: 525. https://doi.org/10.3390/f10060525

APA StyleLangová, N., Réh, R., Igaz, R., Krišťák, Ľ., Hitka, M., & Joščák, P. (2019). Construction of Wood-Based Lamella for Increased Load on Seating Furniture. Forests, 10(6), 525. https://doi.org/10.3390/f10060525