Properties of Oak Roundwood with and without Frost Cracks

Abstract

1. Introduction

2. Materials and Methods

2.1. Site and Model Trees’ Selection

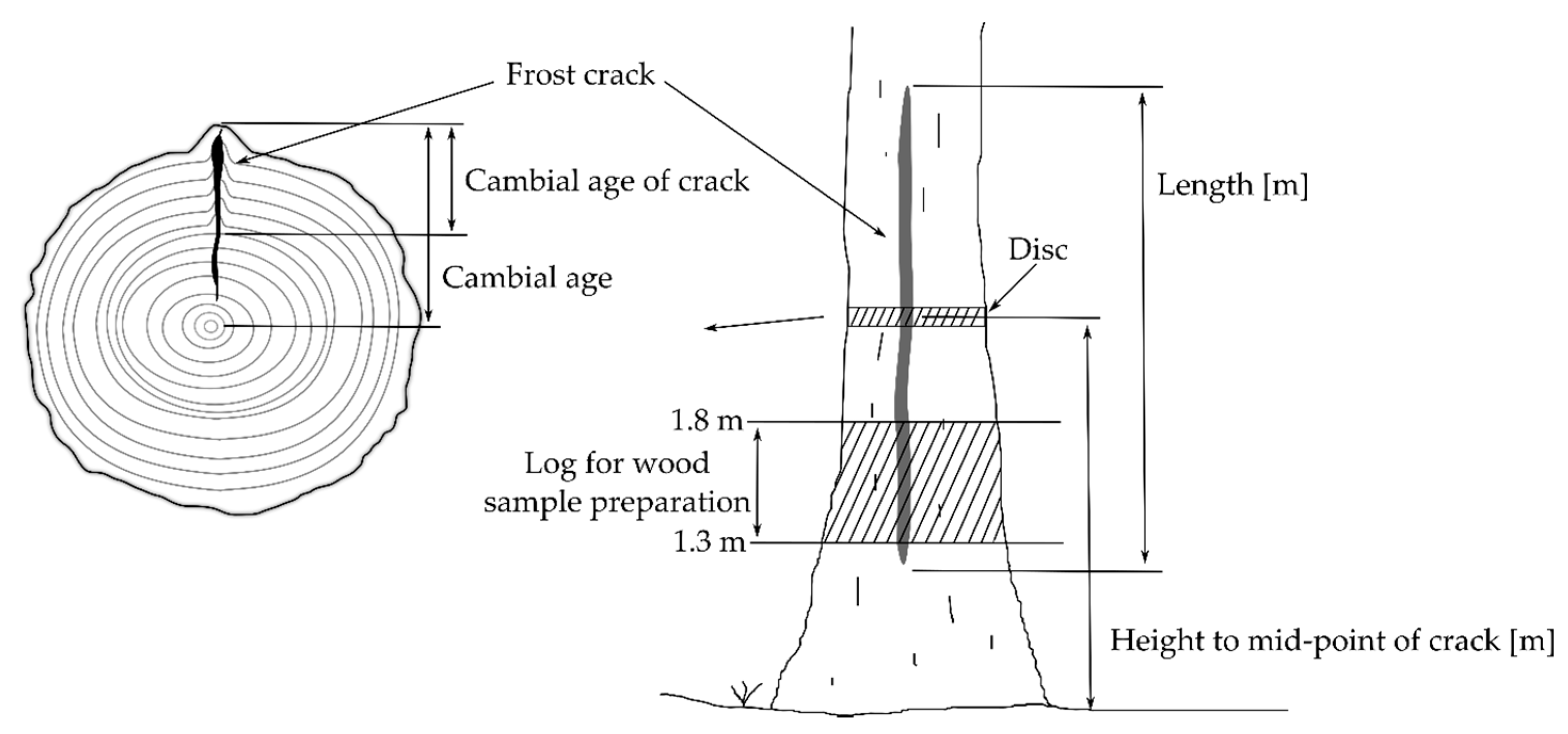

2.2. Frost Crack Measurement

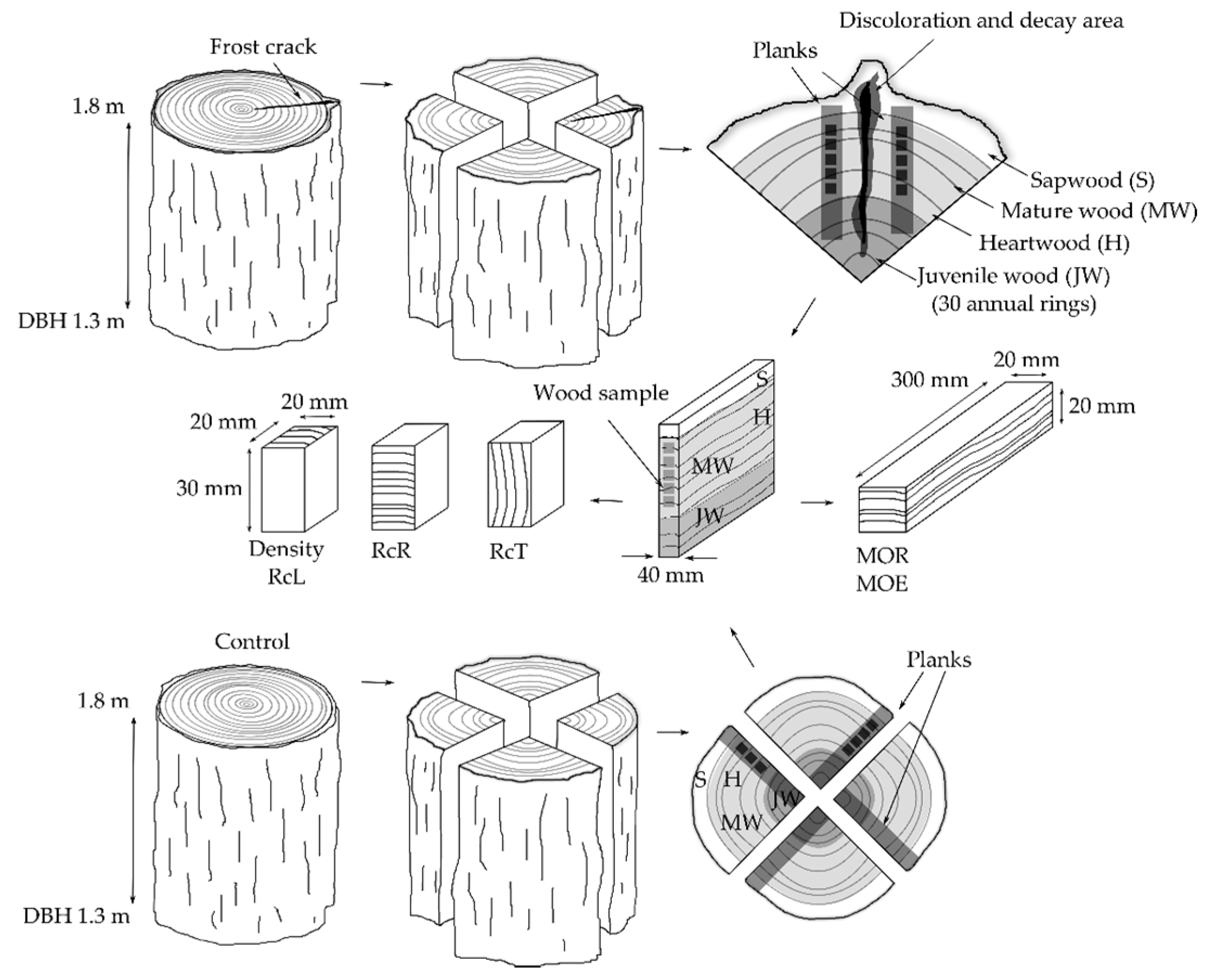

2.3. Sampling Procedure

2.4. Wood Properties’ Measurement

2.5. Statistical Analysis

3. Results

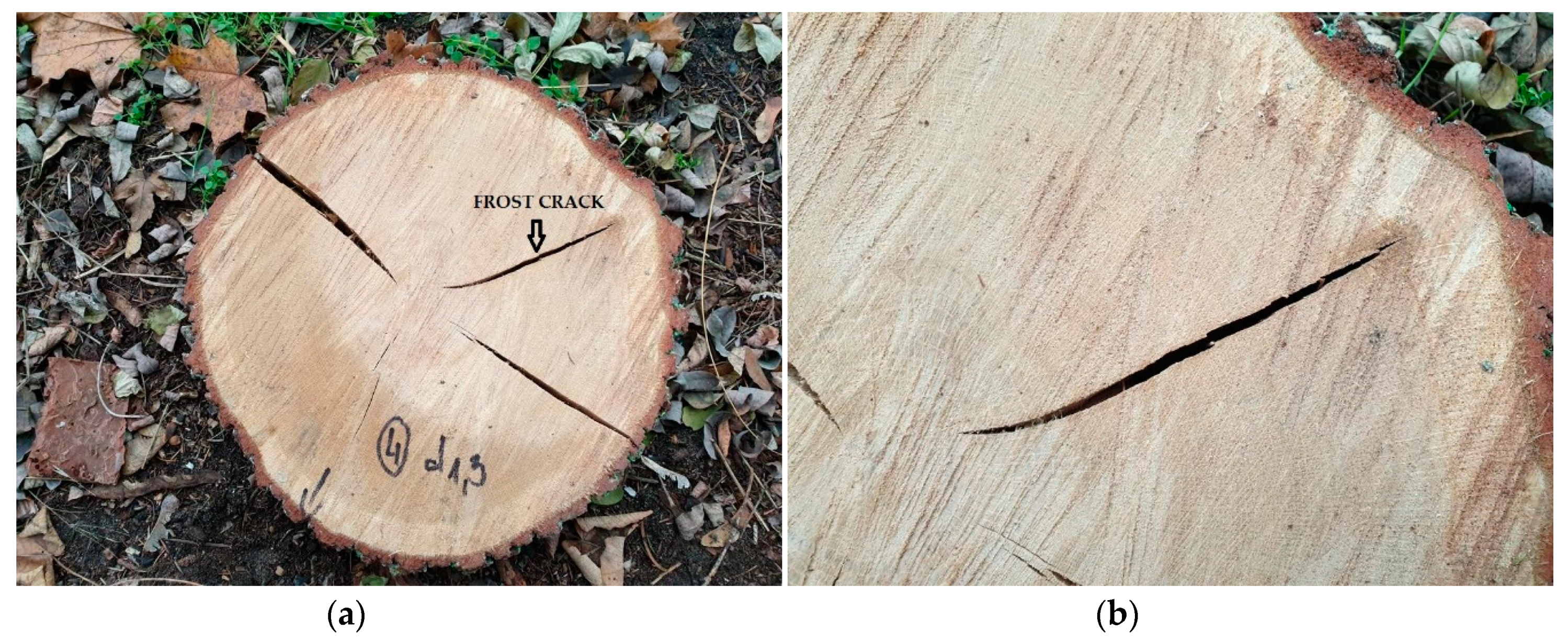

3.1. Frost Cracks’ Characteristic

3.2. Wood Density and Moisture Content

3.3. Mechanical Properties

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pásztory, Z.; Börcsök, Z.; Ronyecz, I.; Mohácsi, K.; Molnár, S.; Kis, S. Oven dry density of sessile oak, turkey oak and hornbeam in different region of Mecsek Mountain. Wood Res. 2014, 59, 683–694. [Google Scholar]

- Longuetaud, F.; Mothe, F.; Santenoise, P.; Diop, N.; Dlouha, J.; Fournier, M.; Deleuze, C. Patterns of within-stem variations in wood specific gravity and water content for five temperate tree species. Ann. For. Sci. 2017, 74, 64. [Google Scholar] [CrossRef]

- Genet, A.; Auty, D.; Achim, A.; Bernier, M.; Pothier, D.; Cogliastro, A. Consequences of faster growth for wood density in northern red oak (Quercus rubra Liebl.). Forestry 2013, 86, 99–110. [Google Scholar] [CrossRef]

- Vavrčík, H.; Gryc, V. Analysis of the annual ring structure and wood density relations in English oak and Sessile oak. Wood Res. 2012, 57, 573–580. [Google Scholar]

- Zhang, S.Y.; Owoundi, R.E.; Nepveu, G.; Mothe, F.; Dhôte, J.F. Modelling wood density in European oak (Quercus petraea and Quercus robur) and simulating the silvicultural influence. Can. J. For. Res. 1993, 23, 2587–2593. [Google Scholar] [CrossRef]

- Lebourgeois, F.; Coussea, G.; Ducos, Y. Climate-tree-growth relationships of Quercus petraea Mill. stand in the Forest of Bercé (“Futaie des Clos”, Sarthe, France). Ann. For. Sci. 2004, 61, 361–372. [Google Scholar] [CrossRef]

- Bergès, L.; Nepveu, G.; Franc, A. Effects of ecological factors on radial growth and wood density components of sessile oak (Quercus petraea Liebl.) in Northern France. For. Ecol. Manag. 2008, 255, 567–579. [Google Scholar] [CrossRef]

- Guada, G.; Vázquez-Ruiz, R.A.; García-González, I. Meteorological conditions control the cessation rather than the beginning of wood formation in a sub-Mediterranean ring-porous oak. Agric. For. Meteorol. 2020, 281, 107833. [Google Scholar] [CrossRef]

- Kubler, H. Origin of frost cracks in stems of trees. J. Arboric. 1987, 13, 93–97. [Google Scholar]

- Kacperska, A. Plant responses to stressful environmental factors. In Fizjologia Roślin; PWN: Warszawa, Poland, 2012; pp. 634–708. [Google Scholar]

- Kollmann, F.; Côté, W.A. Principles of Wood Science and Technology; Springer: Berlin, Germany, 1968. [Google Scholar]

- Cameron, A.; Orr, D.; Clark, J. Variation in the incidence and severity of drought crack in three conifer species in North East Scotland. Scand. J. For. Res. 2017, 32, 658–662. [Google Scholar] [CrossRef]

- Burton, J.I.; Zenner, E.K.; Frelich, L.E. Frost crack incidence in northern hardwood forests of the southern boreal–north temperate transition zone. North. J. Appl. For. 2008, 25, 133–138. [Google Scholar] [CrossRef]

- Hart, J.H.; Dennis, G.K. Effect of tree wrap on the incidence of frost crack in Norway maple. J. Arboric. 1971, 4, 226–227. [Google Scholar]

- Kula, E.; Buchta, I.; Stránský, P. Frost cracks and their effect on the stability of birch stands in the Krušné hory Mts. J. For. Sci. 2006, 52, 348–356. [Google Scholar] [CrossRef]

- Persson, A. Stem cracks in Norway spruce in southern Scandinavia: Causes and consequences. Ann. Sci. For. 1994, 51, 315–327. [Google Scholar] [CrossRef]

- Richter, C. Overview of Cracks/Shake Forms and Causes. In Wood Characteristics; Springer: Cham, Switzerland, 2015; pp. 199–208. [Google Scholar]

- Viherä-Aarnio, A.; Velling, P. Growth, wood density and bark thickness of silver birch originating from the Baltic countries and Finland in two Finnish provenance trials. Silva Fenn. 2017, 51, 18. [Google Scholar]

- Wagener, W.W. Frost Cracks—A Common Defect in White Fir in California; Forest Service, US Dept. of Agriculture, Pacific Southwest Forest and Range Experiment Station: Berkeley, CA, USA, 1970.

- Richter, C. Wood Characteristics: Description, Causes, Prevention, Impact on Use and Technological Adaptation; Springer Internationale Publishing: Basel, Switzerland, 2015. [Google Scholar]

- Sakai, A.; Larcher, W. Frost Survival of Plants: Responses and Adaptation to Freezing Stress; Springer: Berlin, Germany, 2012. [Google Scholar]

- Butin, H.; Shigo, A.L. Radial Shakes and “Frost Cracks” in Living Oak Trees; U.S. Department of Agriculture, Forest Service, Northeastern Forest Experiment Station: Broomall, PA, USA, 1981.

- Danielewicz, W.; Kiciński, P.; Antosz, Ł. Turkey oak (Quercus cerris L.) in Polish forests. Acta Sci. Pol. Silv. Colendar. Rat. Ind. Lignar. 2014, 13, 5–22. [Google Scholar]

- Kovács, I.P.; Czigány, S. The effect of climate and soil moisture on the tree-ring pattern of Turkey oak (Quercus cerris L.) in Central Transdanubia, Hungary. Q. J. Hung. Meteorol. Serv. 2017, 121, 243–263. [Google Scholar]

- Savill, P.S.; Kanowski, P.J. Tree improvement programs for European oaks: Goals and strategies. Ann. Sci. For. 1993, 50, 368–383. [Google Scholar] [CrossRef][Green Version]

- Campu, V.R.; Dumitrache, R. Frost crack impact on European beech (Fagus sylvatica L.) wood quality. Not. Bot. Horti Agrobot. Cluj-Napoca 2015, 43, 272–277. [Google Scholar] [CrossRef]

- Mattheck, C.; Kubler, H. Cracks. In Wood—The Internal Optimization of Trees; Springer Series in Wood Science; Springer: Berlin/Heidelberg, Germany, 1997. [Google Scholar]

- Tomczak, A.; Tomczak, K.; Smarul, N.; Rutkowski, K.; Wenda, M.; Jelonek, T. The gradient of wood moisture within-stem of sessile oak (Quercus petraea (Matt.) Liebl.) in summer. Wood Res. 2018, 63, 809–820. [Google Scholar]

- Sano, Y.; Fukazawa, K. Timing of the occurrence of frost cracks in winter. Trees 1996, 11, 47–53. [Google Scholar] [CrossRef]

- CSN EN 1316-1 Hardwood Round Timber—Qualitative Classification—Part 1: Oak and Beech; European Committee for standardization: Brussels, Belgium, 2012.

- Cinotti, B. Winter moisture content and frost-crack occurrence in oak trees (Quercus petraea Liebl. and Q. robur L.). Ann. Sci. For. 1989, 46, 614–616. [Google Scholar] [CrossRef]

- ISO 13061-2. Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 2: Determination of Density for Physical and Mechanical Tests; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- PN-77/D-04103 Wood. Determination of Static Bending Strength; Polish Committee for Standardization: Warsaw, Poland, 1977. [Google Scholar]

- ISO 13061-1. Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 1: Determination of Moisture Content for Physical and Mechanical Tests; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- ISO 13061-17:2017. Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 17: Determination of Ultimate Stress in Compression Parallel to Grain; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Helińska-Raczkowska, L. Variation of vessel lumen diameter in radial direction as an indication of the juvenile wood growth in oak (Quercus petraea Liebl.). Ann. Sci. For. 1994, 51, 283–290. [Google Scholar] [CrossRef]

- Wangenführ, R. Holzatlas. 6., Bearbeitete und Erweiterte Auflage; Fachbuchverlag: Leipzig, Germany, 2007. [Google Scholar]

- Schwarze, F.W.M.R.; Spycher, M.; Fink, S. Superior wood for violins—Wood decay fungi as a substitute for cold climate. New Phytol. 2008, 179, 1095–1104. [Google Scholar] [CrossRef] [PubMed]

- Winandy, J.; Morrell, J. Relationship between incipient decay, strength, and chemical composition of douglas-fir heartwood. Wood Fiber Sci. 1993, 25, 278–288. [Google Scholar]

- Ibach, R.; Lebow, P. Strength loss in decayed wood. In The McGraw-Hill Encyclopedia of Science & Technology; McGraw-Hill: New York, NY, USA, 2014; pp. 368–371. [Google Scholar]

- Kollmann, F.; Kuenzi, E.; Stamm, A. Principles of wood science and technology. In Wood Based Materials; Springer: Berlin, Germany, 1975; Volume II, pp. 139–149. [Google Scholar]

- Burgert, I.; Eckstein, D. The tensile strength of isolated wood rays of beech (Fagus sylvatica L.) and its significance for the biomechanics of living trees. Trees 2001, 15, 168–170. [Google Scholar] [CrossRef]

| Cracked (n = 5) | Control (n = 5) | |

|---|---|---|

| Height (m) | 27.0 | 27.3 |

| DBH (cm) | 38.2 | 34.0 |

| Canopy depth (m) | 16.8 | 17.2 |

| Canopy depth (%) | 62.5 | 62.2 |

| Tree Number | Total Number of Cracks | Length of Crack (m) | Height to Mid-Point of Crack (m) | Number of Cracks at the Breast Height | Cambial Age * | Cambial Age of the Crack * | Compass Direction |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 3.3 | 1.65 | 1 | 109 | 13 | S |

| 2 | 4 | 5.0 1.9 1.8 2.8 | 2.50 0.95 5.30 6.00 | 2 | 100 114 | 51 12 | SE W SW N |

| 3 | 1 | 3.6 | 1.80 | 1 | 99 | 29 | N |

| 4 | 3 | 1.5 0.8 0.6 | 0.75 0.42 0.30 | 1 | 101 | 55 | SW N N |

| 5 | 5 | 1.6 1.0 0.4 1.8 5.4 | 0.80 0.50 0.20 0.90 4.30 | 2 | 101 100 | 56 42 | SE W NW NE N |

| Properties | Material | Statistical Parameters | ||||

|---|---|---|---|---|---|---|

| min | mean | max | ±SD | CV (%) | ||

| Density (kg × m−3) | Frost crack | 560 | 765 a | 875 | 76 | 9.9 |

| Control | 530 | 650 b | 720 | 47 | 7.2 | |

| Moisture content (%) | Frost crack | 7.9 | 8.4 a | 9.4 | 0.62 | 7.4 |

| Control | 8.1 | 8.8 a | 9.3 | 0.74 | 8.3 | |

| Properties | Material | Statistical Parameters | ||||

|---|---|---|---|---|---|---|

| min | mean | Max | ±SD | CV (%) | ||

| MOE (MPa) | Frost crack | 6526 | 10021 a | 12368 | 1280 | 12.77 |

| Control | 7165 | 10221 a | 12799 | 1334 | 13.05 | |

| MOR (MPa) | Frost crack | 66 | 108 b | 133 | 13.8 | 12.77 |

| Control | 87 | 115 a | 148 | 14.0 | 12.17 | |

| WML (J) | Frost crack | 0.896 | 1.810 b | 2.545 | 0.384 | 21.21 |

| Control | 1.286 | 2.292 a | 5.697 | 0.857 | 37.39 | |

| MOEsp (kN × m × kg−1) | Frost crack | 9.44 | 13.15 b | 17.03 | 1.58 | 12.02 |

| Control | 12.75 | 15.45 a | 18.00 | 1.27 | 8.22 | |

| RcL (MPa) | Frost crack | 43.6 | 52.9 b | 69.6 | 6.4 | 12.09 |

| Control | 57.3 | 66.9 a | 75.8 | 4.9 | 7.32 | |

| RcR (MPa) | Frost crack | 6.76 | 8.37 b | 10.31 | 0.84 | 10.03 |

| Control | 5.69 | 6.92 a | 8.37 | 0.44 | 6.35 | |

| RcT (MPa) | Frost crack | 4.72 | 6.02 b | 7.94 | 0.77 | 12.79 |

| Control | 4.46 | 5.66 a | 6.89 | 0.75 | 13.25 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mania, P.; Tomczak, A. Properties of Oak Roundwood with and without Frost Cracks. Forests 2020, 11, 538. https://doi.org/10.3390/f11050538

Mania P, Tomczak A. Properties of Oak Roundwood with and without Frost Cracks. Forests. 2020; 11(5):538. https://doi.org/10.3390/f11050538

Chicago/Turabian StyleMania, Przemysław, and Arkadiusz Tomczak. 2020. "Properties of Oak Roundwood with and without Frost Cracks" Forests 11, no. 5: 538. https://doi.org/10.3390/f11050538

APA StyleMania, P., & Tomczak, A. (2020). Properties of Oak Roundwood with and without Frost Cracks. Forests, 11(5), 538. https://doi.org/10.3390/f11050538