Termite Resistance of a Fast-Growing Pine Wood Treated by In Situ Polymerization of Three Different Precursors

Abstract

1. Introduction

2. Materials and Methods

2.1. WPC Production

2.2. Termite Tests

2.3. WPC Characterization

2.3.1. ATR-FTIR

2.3.2. Scanning Electron Microscopy (SEM)

2.4. Statistical Analyses

3. Results

3.1. ATR-FTIR Spectra

3.2. SEM Images

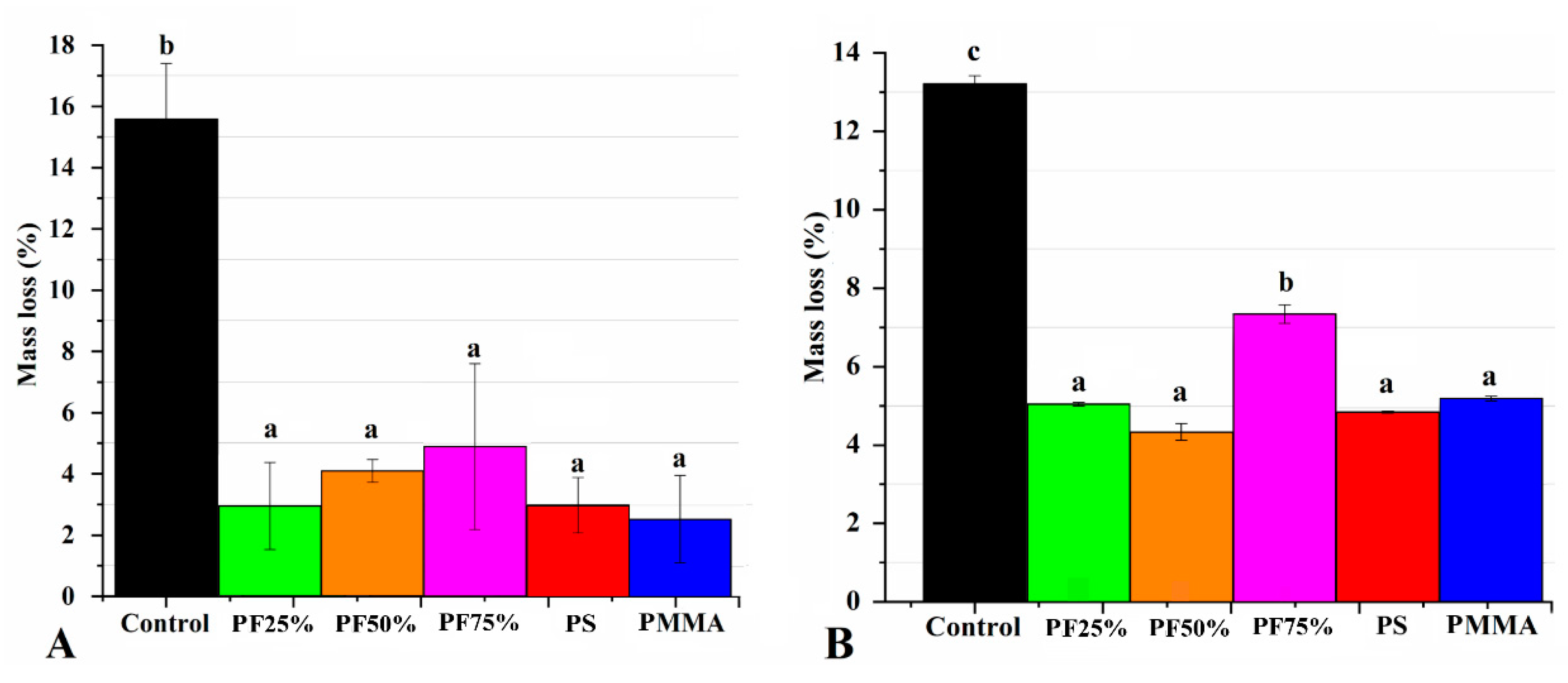

3.3. Termite Tests

4. Discussion

4.1. ATR-FTIR Spectra

4.2. SEM Images

4.3. Termite Tests

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bremer, L.L.; Farley, K.A. Does plantation forestry restore biodiversity or create green deserts? A synthesis of the effects of land-use transitions on plant species richness. Biodivers. Conserv. 2010, 19, 3893–3915. [Google Scholar] [CrossRef]

- Delucis, R.D.; Beltrame, R.; Gatto, D.A. Discolouration of heat-treated fast-growing eucalyptus wood exposed to natural weathering. Cellul. Chem. Technol. 2019, 53, 635–641. [Google Scholar] [CrossRef]

- Aguiar, A.; Gavioli, D.; Ferraz, A. Extracellular activities and wood component losses during Pinus taeda biodegradation by the brown-rot fungus Gloeophyllum trabeum. Int. Biodeterior. Biodegrad. 2013, 82, 187–191. [Google Scholar] [CrossRef]

- de Avila Delucis, R.; Magalhães, W.L.; Petzhold, C.L.; Amico, S.C. Forest-based resources as fillers in biobased polyurethane foams. J. Appl. Polym. Sci. 2018, 135, 1–7. [Google Scholar] [CrossRef]

- Heräjärvi, H.; Jouhiaho, A.; Tammiruusu, V.; Verkasalo, E. Small-Diameter Scots Pine and Birch Timber as Raw Materials for Engineered Wood Products. Int. J. For. Eng. 2004, 15, 23–34. [Google Scholar] [CrossRef]

- Hadi, Y.S.; Massijaya, M.Y.; Hermawan, D.; Arinana, A. Feeding rate of termites in wood treated with borax, acetylation, polystyrene, and smoke. J. Indian Acad. Wood Sci. 2015, 12, 74–80. [Google Scholar] [CrossRef]

- de Moura Palermo, G.P.; de Figueiredo Latorraca, J.V.; Severo, E.T.; do Nascimento, A.M.; de Rezende, M.A. Delimitação entre os lenhos juvenil e adulto de pinus elliottii engelm. Rev. Arvore 2013, 37, 191–200. [Google Scholar] [CrossRef]

- Gascón-Garrido, P.; Thévenon, M.F.; Mainusch, N.; Militz, H.; Viöl, W.; Mai, C. Siloxane-treated and copper-plasma-coated wood: Resistance to the blue stain fungus Aureobasidium pullulans and the termite Reticulitermes flavipes. Int. Biodeterior. Biodegrad. 2017, 120, 84–90. [Google Scholar] [CrossRef]

- Afzal, I.; Shinwari, Z.K.; Sikandar, S.; Shahzad, S. Plant beneficial endophytic bacteria: Mechanisms, diversity, host range and genetic determinants. Microbiol. Res. 2019, 221, 36–49. [Google Scholar] [CrossRef]

- Forschler, B.T.; Henderson, G. Subterranean termite behavioral reaction to water and survival of inundation: Implications for field populations. Environ. Entomol. 1995, 24, 1592–1597. [Google Scholar] [CrossRef]

- Hadi, S.Y.; Massijaya, M.Y.; Arinana, A. Subterranean Termite Resistance of Polystyrene-TreatedWood from Three TropicalWood Species. Insects 2016, 7, 37. [Google Scholar] [CrossRef] [PubMed]

- Shelton, T.G.; Grace, J.K. Effects of Exposure Duration on Transfer of Nonrepellent Termiticides among Workers of Coptotermes formosanus Shiraki (Isoptera: Rhinotermitidae). J. Econ. Entomol. 2003, 96, 456–460. [Google Scholar] [CrossRef] [PubMed]

- Gérardin, P. New alternatives for wood preservation based on thermal and chemical modification of wood—A review. Ann. For. Sci. 2016, 73, 559–570. [Google Scholar] [CrossRef]

- Cornelius, M.L.; Osbrink, W.L.A. Natural resistance of exotic wood species to the Formosan subterranean termite (Isoptera: Rhinotermitidae). Int. Biodeterior. Biodegrad. 2015, 101, 8–11. [Google Scholar] [CrossRef]

- Liew, F.J.; Schilling, J.S. Choice tests and neighbor effects during fungal brown rot of copper-and non-treated wood. Int. Biodeterior. Biodegrad. 2012, 74, 7–10. [Google Scholar] [CrossRef]

- Karami-Mohajeri, S.; Abdollahi, M. Toxic influence of organophosphate, carbamate, and organochlorine pesticides on cellular metabolism of lipids, proteins, and carbohydrates: A systematic review. Hum. Exp. Toxicol. 2011, 30, 1119–1140. [Google Scholar] [CrossRef]

- Mattos, B.D.; de Cademartori, P.H.; Missio, A.L.; Gatto, D.A.; Magalhães, W.L. Wood-polymer composites prepared by free radical in situ polymerization of methacrylate monomers into fast-growing pinewood. Wood Sci. Technol. 2015, 49, 1281–1294. [Google Scholar] [CrossRef]

- Magalhaes, W.L.E.; da Silva, R.R. Treatment of caribbean pine by in situ polymerization of styrene and furfuryl alcohol. J. Appl. Polym. Sci. 2004, 91, 1763–1769. [Google Scholar] [CrossRef]

- Zabel, R.A.; Morrell, J.J. Wood deterioration agents. In Wood Microbiology, 2nd ed.; Zabel, R.A., Morrell, J.J., Eds.; Academic Press: San Diego, CA, USA, 2020; pp. 19–54. [Google Scholar]

- Mai, C.; Militz, H. Modification of wood with silicon compounds. Treatment systems based on organic silicon compounds—A review. Wood Sci. Technol. 2004, 37, 453–461. [Google Scholar] [CrossRef]

- Kartal, S.N.; Yoshimura, T.; Imamura, Y. Decay and termite resistance of boron-treated and chemically modified wood by in situ co-polymerization of allyl glycidyl ether (AGE) with methyl methacrylate (MMA). Int. Biodeterior. Biodegrad. 2004, 53, 111–117. [Google Scholar] [CrossRef]

- Keplinger, T.; Cabane, E.; Chanana, M.; Hass, P.; Merk, V.; Gierlinger, N.; Burgert, I. A versatile strategy for grafting polymers to wood cell walls. Acta Biomater. 2015, 11, 256–263. [Google Scholar] [CrossRef] [PubMed]

- Mantanis, G.I. Chemical modification of wood by acetylation or furfurylation: A review of the present scaled-up technologies. BioResources 2017, 12, 4478–4489. [Google Scholar] [CrossRef]

- Che, W.; Xiao, Z.; Han, G.; Zheng, Z.; Xie, Y. Radiata pine wood treatment with a dispersion of aqueous styrene/acrylic acid copolymer. Holzforschung 2018, 72, 387–396. [Google Scholar] [CrossRef]

- Olaniran, S.O.; Michen, B.; Mendez, D.F.; Wittel, F.K.; Bachtiar, E.V.; Burgert, I.; Rüggeberg, M. Mechanical behaviour of chemically modified Norway spruce (Picea abies L. Karst.): Experimental mechanical studies on spruce wood after methacrylation and in situ polymerization of styrene. Wood Sci. Technol. 2019, 53, 425–445. [Google Scholar] [CrossRef]

- Hadi, Y.S.; Nurhayati, T.; Yamamoto, H.; Kamiya, N. Resistance of smoked wood to subterranean and dry-wood termite attack. Int. Biodeterior. Biodegrad. 2012, 70, 79–81. [Google Scholar] [CrossRef]

- Hadi, Y.S.; Massijaya, M.Y.; Zaini, L.H.; Abdillah, I.B.; Arsyad, W.O. Resistance of methyl methacrylate-impregnated wood to subterranean termite attack. J. Korean Wood Sci. Technol. 2018, 46, 748–755. [Google Scholar] [CrossRef]

- Mattos, B.D.; de Cademartori, P.H.; Magalhães, W.L.; Lazzarotto, M.; Gatto, D.A. Thermal tools in the evaluation of decayed and weathered wood polymer composites prepared by in situ polymerization. J. Therm. Anal. Calorim. 2015, 121, 1263–1271. [Google Scholar] [CrossRef]

- Zeng, W.R.; Li, S.F.; Chow, W.K. Preliminary studies on burning behavior of polymethylmethacrylate (PMMA). J. Fire Sci. 2002, 20, 297–317. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, Y.F.; Fan, S.Z.; Abbod, M.F.; Shieh, J.S. EEG Signals Analysis Using Multiscale Entropy for Depth of Anesthesia Monitoring during Surgery through Artificial Neural Networks. Comput. Math. Methods Med. 2015, 2015, 232381. [Google Scholar] [CrossRef]

- Li, Y.; Dong, X.; Liu, Y.; Li, J.; Wang, F. Improvement of decay resistance of wood via combination treatment on wood cell wall: Swell-bonding with maleic anhydride and graft copolymerization with glycidyl methacrylate and methyl methacrylate. Int. Biodeterior. Biodegrad. 2011, 65, 1087–1094. [Google Scholar] [CrossRef]

- Indrayani, Y.; Yoshimura, T.; Yanase, Y.; Imamura, Y. Feeding responses of the western dry-wood termite Incisitermes minor (Hagen) (Isoptera: Kalotermitidae) against ten commercial timbers. J. Wood Sci. 2007, 53, 239–248. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Laboratory Evaluation of Solid Wood for Resistance to Termites; ASTM D3345-17; ASTM International: West Conshohocken, PA, USA, 2017; Available online: www.astm.org (accessed on 5 February 2020).

- Oliveira, A.M.; Lelis, A.D.; Lepage, E.S.; Lopez, G.C.; Oliveira, L.D.; Cañedo, M.D.; Milano, S. Manual de preservação de madeiras. In Agentes Destruidores da Madeira; Instituto de Pesquisas Tecnológicas do Estado de São Paulo: São Paulo, Brazil, 1986; Volume 1. [Google Scholar]

- Gascón-Garrido, P.; Oliver-Villanueva, J.V.; Ibiza-Palacios, M.S.; Militz, H.; Mai, C.; Adamopoulos, S. Resistance of wood modified with different technologies against Mediterranean termites (Reticulitermes spp.). Int. Biodeterior. Biodegrad. 2013, 82, 13–16. [Google Scholar] [CrossRef]

- Barsberg, S.; Thygesen, L.G. Poly(furfuryl alcohol) formation in neat furfuryl alcohol and in cymene studied by ATR-IR spectroscopy and density functional theory (B3LYP) prediction of vibrational bands. Vib. Spectrosc. 2009, 49, 52–63. [Google Scholar] [CrossRef]

- Pilgård, A.; De Vetter, L.; Van Acker, J.; Westin, M. Toxic hazard of leachates from furfurylated wood: Comparison between two different aquatic organisms. Environ. Toxicol. Chem. 2010, 29, 1067–1071. [Google Scholar] [CrossRef]

- Merlatti, C.; Perrin, F.X.; Aragon, E.; Margaillan, A. Natural and artificial weathering characteristics of stabilized acrylic-urethane paints. Polym. Degrad. Stab. 2008, 93, 896–903. [Google Scholar] [CrossRef]

- Doroudiani, S.; Omidian, H. Environmental, health and safety concerns of decorative mouldings made of expanded polystyrene in buildings. Build. Environ. 2010, 45, 647–654. [Google Scholar] [CrossRef]

- Ahmad, S.; Ahmad, S.; Agnihotry, S.A. Synthesis and characterization of in situ prepared poly (methyl methacrylate) nanocomposites. Bull. Mater. Sci. 2007, 30, 31–35. [Google Scholar] [CrossRef]

- Islam, M.S.; Hamdan, S.; Hassan, A.; Talib, Z.A.; Sobuz, H.R. The chemical modification of tropical wood polymer composites. J. Compos. Mater. 2014, 48, 783–789. [Google Scholar] [CrossRef]

- Yang, X.; Yu, I.K.; Cho, D.W.; Chen, S.S.; Tsang, D.C.; Shang, J.; Yip, A.C.; Wang, L.; Ok, Y.S. Tin-Functionalized Wood Biochar as a Sustainable Solid Catalyst for Glucose Isomerization in Biorefinery. ACS Sustain. Chem. Eng. 2019, 7, 4851–4860. [Google Scholar] [CrossRef]

- Georgieva, M.; Harata, M.; Miloshev, G. The nuclear actin-related protein Act3p/Arp4 influences yeast cell shape and bulk chromatin organization. J. Cell. Biochem. 2008, 104, 59–67. [Google Scholar] [CrossRef]

- Ghorbani, M.; Aghmashadi, Z.A.; Amininasab, S.M.; Abedini, R. Effect of different coupling agents on chemical structure and physical properties of vinyl acetate/wood polymer composites. J. Appl. Polym. Sci. 2019, 136, 1–6. [Google Scholar] [CrossRef]

- Dong, Y.; Yan, Y.; Zhang, S.; Li, J. Wood/polymer nanocomposites prepared by impregnation with furfuryl alcohol and Nano-SiO2. BioResources 2014, 9, 6028–6040. [Google Scholar] [CrossRef]

- Venäläinen, M.; Partanen, H.; Harju, A. The strength loss of Scots pine timber in an accelerated soil contact test. Int. Biodeterior. Biodegrad. 2014, 86, 150–152. [Google Scholar] [CrossRef]

- Myer, A.; Forschler, B.T. Evidence for the Role of Subterranean Termites (Reticulitermes spp.) in Temperate Forest Soil Nutrient Cycling. Ecosystems 2019, 22, 602–618. [Google Scholar] [CrossRef]

- Köhler, T.; Dietrich, C.; Scheffrahn, R.H.; Brune, A. High-resolution analysis of gut environment and bacterial microbiota reveals functional compartmentation of the gut in wood-feeding higher termites (Nasutitermes spp.). Appl. Environ. Microbiol. 2012, 78, 4691–4701. [Google Scholar] [CrossRef] [PubMed]

- Sivrikaya, H.; Tesařová, D.; Jeřábková, E.; Can, A. Color change and emission of volatile organic compounds from Scots pine exposed to heat and vacuum-heat treatment. J. Build. Eng. 2019, 26, 100918. [Google Scholar] [CrossRef]

- Sivrikaya, H.; Can, A.; de Troya, T.; Conde, M. Comparative biological resistance of differently thermal modified wood species against decay fungi, Reticulitermes grassei and Hylotrupes bajulus. Maderas Cienc. Tecnol. 2015, 17, 559–570. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acosta, A.P.; Labidi, J.; Barbosa, K.T.; Cruz, N.; Delucis, R.d.A.; Gatto, D.A. Termite Resistance of a Fast-Growing Pine Wood Treated by In Situ Polymerization of Three Different Precursors. Forests 2020, 11, 865. https://doi.org/10.3390/f11080865

Acosta AP, Labidi J, Barbosa KT, Cruz N, Delucis RdA, Gatto DA. Termite Resistance of a Fast-Growing Pine Wood Treated by In Situ Polymerization of Three Different Precursors. Forests. 2020; 11(8):865. https://doi.org/10.3390/f11080865

Chicago/Turabian StyleAcosta, Andrey Pereira, Jalel Labidi, Kelvin Techera Barbosa, Nidria Cruz, Rafael de Avila Delucis, and Darci Alberto Gatto. 2020. "Termite Resistance of a Fast-Growing Pine Wood Treated by In Situ Polymerization of Three Different Precursors" Forests 11, no. 8: 865. https://doi.org/10.3390/f11080865

APA StyleAcosta, A. P., Labidi, J., Barbosa, K. T., Cruz, N., Delucis, R. d. A., & Gatto, D. A. (2020). Termite Resistance of a Fast-Growing Pine Wood Treated by In Situ Polymerization of Three Different Precursors. Forests, 11(8), 865. https://doi.org/10.3390/f11080865