Evaluating Profitability of Individual Timber Deliveries in the US South

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brandeis, C.; Hodges, D.G. Forest sector and primary forest products industry contributions to the economies of the southern states: 2011 update. J. For. 2015, 113, 205–209. [Google Scholar] [CrossRef]

- Butler, B.J.; Hewes, J.H.; Dickinson, B.J.; Andrejczyk, K.; Butler, S.M.; Markowski-Lindsay, M. Family forest ownerships of the United States, 2013: Findings from the USDA Forest Service’s national woodland owner survey. J. For. 2016, 114, 638–647. [Google Scholar] [CrossRef]

- Zhang, D.; Butler, B.J.; Nagubadi, R.V. Institutional timberland ownership in the US South: Magnitude, location, dynamics, and management. J. For. 2012, 110, 355–361. [Google Scholar] [CrossRef]

- Grove, P.M.; Conrad, J.L., IV; Harris, T.G., Jr.; Dahlen, J. Consulting forester timber sale practices in the US South. For. Sci. 2020, 66, 221–229. [Google Scholar] [CrossRef]

- Flick, W.A. The wood dealer system in Mississippi: An essay on regional economics and culture. J. For. Hist. 1985, 29, 131–138. [Google Scholar] [CrossRef]

- Conrad, J.L., IV; Greene, W.D.; Hiesl, P. The evolution of logging businesses in Georgia 1987–2017 and South Carolina 2012–2017. For. Sci. 2018, 64, 671–681. [Google Scholar] [CrossRef]

- TimberMart-South. Delivered Timber Summary 1st Quarter 2020; Norris Foundation, University of Georgia: Athens, GA, USA, 2020; Volume 45. [Google Scholar]

- TimberMart-South. Logging Rates Report 1st Quarter 2020; Norris Foundation, University of Georgia: Athens, GA, USA, 2020. [Google Scholar]

- Koirala, A.; Kizha, A.R.; De Urioste-Stone, S.M. Policy recommendations from stakeholders to improve forest products transportation: A qualitative study. Forests 2017, 8, 434. [Google Scholar] [CrossRef] [Green Version]

- Koirala, A.; Kizha, A.R.; Roth, B.E. Perceiving major problems in forest products transportation by trucks and trailers: A cross-sectional survey. Eur. J. For. Eng. 2017, 3, 23–34. [Google Scholar]

- Conrad, J.L., IV. Costs and challenges of log truck transportation in Georgia, USA. Forests 2018, 9, 650. [Google Scholar] [CrossRef] [Green Version]

- Cole, N.B.; Barrett, S.M.; Bolding, M.C.; Aust, W.M. An analysis of fatal log truck crashes in the United States from 2011 through 2015. Int. J. For. Eng. 2019, 30, 121–131. [Google Scholar] [CrossRef]

- Conrad, J.L., IV. Forest Logistics Summit Identifies Opportunities to Address Log Trucking Challenges; Forest Resources Association: Rockville, MD, USA, 2019. [Google Scholar]

- Gallagher, T.; McDonald, T.; Smidt, M.; Tufts, R. Let’s Talk Trucking: Weights and Loading Methods; Forest Resources Association: Rockville, MD, USA, 2005. [Google Scholar]

- Hamsley, A.K.; Greene, W.D.; Siry, J.P.; Mendell, B.C. Improving timber trucking performance by reducing variability of log truck weights. S. J. Appl. For. 2007, 31, 12–16. [Google Scholar] [CrossRef] [Green Version]

- Reddish, R.P.; Baker, S.A.; Greene, W.D. Improving log trucking efficiency by using in-woods scales. S. J. Appl. For. 2011, 35, 178–183. [Google Scholar] [CrossRef] [Green Version]

- Dowling, T.N. An Analysis of Log Truck Turn Times at Harvest Sites and Mill Facilities. Master’s Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2010. [Google Scholar]

- Baker, S.; Lowe, R., III; Greene, D. Follow that Tractor: What Truck-Mounted GPS Tells Us About Log Truck Performance. In Proceedings of the 39th Council on Forest Engineering Annual Meeting, Vancouver, BC, Canada, 22–24 September 2016. [Google Scholar]

- Daniel, M.; Gallagher, T.; McDonald, T.; Mitchell, D. Utilization of Phone Application Technology to Record Log Truck Movement in the Southeastern US. In Proceedings of the 40th Council on Forest Engineering Annual Meeting, Bangor, ME, USA, 30 July–2 August 2017. [Google Scholar]

- Deckard, D.L.; Newbold, R.A.; Vidrine, C.G. Benchmark roundwood delivery cycle-times and potential efficiency gains in the southern United States. For. Prod. J. 2003, 53, 61–69. [Google Scholar]

- Siry, J.P.; Greene, W.D.; Harris, T.G., Jr.; Izlar, R.L.; Hamsley, A.K.; Eason, K.; Tye, T.; Baldwin, S.S.; Hyldahl, C. Wood supply chain efficiency and fiber cost: What can we do better? For. Prod. J. 2006, 56, 4–10. [Google Scholar]

- Greene, W.D.; Marchman, S.C.; Baker, S.A. Changes in Logging Firm Demographics and Logging Capacity in the US. South. In Proceedings of the 36th Council on Forest Engineering Annual Meeting, Missoula, MT, USA, 7–10 July 2013. [Google Scholar]

- Conrad, J.L., IV. Production Up, Transportation Challenging: Georgia Logger Survey Results 2017; Forest Resources Association: Rockville, MD, USA, 2018. [Google Scholar]

- Väätäinen, K.; Laitila, J.; Anttila, P.; Pilpeläinen, A.; Asikainen, A. The influence of gross vehicle weight (GVW) and transport distance on timber trucking performance indicators–Discrete event simulation case study in Central Finland. Int. J. For. Eng. 2020, 31, 156–170. [Google Scholar] [CrossRef]

- McDonald, T.; Taylor, S.; Valenzuela, J. Potential of Shared Log Transport Services. In Proceedings of the 24th Council on Forest Engineering Annual Meeting, Snowshoe, WV, USA, 15–18 July 2001. [Google Scholar]

- Mendell, B.C.; Haber, J.A.; Sydor, T. Evaluating the potential for shared log truck resources in middle Georgia. S. J. Appl. For. 2006, 30, 86–91. [Google Scholar] [CrossRef] [Green Version]

- US Endowment for Forestry and Communities. 2019. The Timber Logistics Improvement Project. Available online: https://www.usendowment.org/wp-content/uploads/2019/05/the-timber-logistics-improvement-project-.pdf (accessed on 3 December 2020).

- Grebner, D.L.; Grace, L.A.; Stuart, W.; Gilliland, D.P. A practical framework for evaluating hauling costs. Int. J. For. Eng. 2005, 16, 115–128. [Google Scholar] [CrossRef]

- Germain, R.; Bick, S.; Kelly, M.; Benjamin, J.; Farrand, W. Case study of three high-performing contract loggers with distinct harvest systems: Are they thriving, striving, or just surviving? For. Prod. J. 2016, 66, 97–105. [Google Scholar] [CrossRef]

- Regula, J.; Germain, R.; Bick, S.; Zhang, L. Assessing the economic viability of loggers operating tree-length harvest systems in the Northeast. J. For. 2018, 116, 347–356. [Google Scholar] [CrossRef] [Green Version]

- Rissman, A.R.; Geisler, E.; Gorby, T.; Rickenbach, M.G. “Maxed out on efficiency”: Logger perceptions of financial challenges facing timber operations. J. Sustain. For. 2020. [Google Scholar] [CrossRef]

- Murray, D.; Glidewell, S. An Analysis of the Operational Costs of Trucking: 2019 Update; American Transportation Research Institute: Arlington, VA, USA, 2019. [Google Scholar]

- Esri. ArcGIS Online. Available online: http://usg.maps.arcgis.com/ (accessed on 4 December 2020).

- Conrad, J.L., IV. Would weight parity on interstate highways improve safety and efficiency of timber transportation in the US South? Int. J. For. Eng. 2020, 31, 242–252. [Google Scholar] [CrossRef]

- Cassens, D.L.; Gibson, H.; Friday, J.S. Modeling lumber manufacturing processes using Monte Carlo computer simulation. For. Prod. J. 1993, 43, 41–48. [Google Scholar]

- Elustondo, D.M.; Avramidis, S. Comparative analysis of three methods for stochastic lumber drying simulation. Dry. Technol. 2005, 23, 131–142. [Google Scholar] [CrossRef]

- Moore, T.Y.; Ruel, J.-C.; Lapointe, M.-A.; Lussier, J.-M. Evaluating the profitability of selection cuts in irregular boreal forests: An approach based on Monte Carlo simulations. Forestry 2012, 85, 63–77. [Google Scholar] [CrossRef] [Green Version]

- Mei, B.; Clutter, M.L.; Harris, T.G. Timberland return drivers and timberland returns and risks: A simulation approach. South. J. Appl. For. 2013, 37, 18–25. [Google Scholar] [CrossRef]

- Petrasek, S.; Perez-Garcia, J.M. Valuation of timber harvest contracts as American call options with modified least-squares Monte Carlo algorithm. For. Sci. 2010, 56, 494–504. [Google Scholar]

- McConnell, T.E. Unit costs and trends within Louisiana’s logging contract rate. For. Prod. J. 2020, 70, 50–59. [Google Scholar]

- Energy Information Administration. Gasoline and Diesel Fuel Update. Available online: https://www.eia.gov/petroleum/gasdiesel/ (accessed on 3 December 2020).

- Rizet, C.; Cruz, C.; Mbacke, M. Reducing freight transport CO2 emissions by increasing the load factor. Procedia–Soc Behav Sci. 2012, 48, 184–195. [Google Scholar] [CrossRef] [Green Version]

- JMP. JMP Pro 14.3.0; SAS Institute Inc.: Cary, NC, USA, 2018. [Google Scholar]

- Conrad, J.L., IV. Analysis of timber transportation accident frequency, location, and contributing factors in Georgia, USA 2006–2016. Int. J. For. Eng. 2019, 30, 109–120. [Google Scholar] [CrossRef]

- Williams, E. SC Forest Industry Margins Chopped by Rising Transportation Costs. Available online: https://www.postandcourier.com/ (accessed on 11 February 2021).

- Hooper, A.; Murray, D. E-Commerce Impacts on the Trucking Industry; American Transportation Research Institute: Arlington, VA, USA, 2019. [Google Scholar]

- Baker, S.; Mendell, B. Compensation Indices for Logging and Trucking Occupations; Wood Supply Research Institute: Valley Head, WV, USA, 2016. [Google Scholar]

- Murphy, G. Reducing trucks on the road through optimal route scheduling and shared log transport services. S. J. Appl. For. 2003, 27, 198–205. [Google Scholar] [CrossRef] [Green Version]

- Lautala, P.; Pouryousef, H.; Stewart, R.; Ogard, L.; Vartiainen, J. Analyzing Log and Chip Truck Performances in the Upper Peninsula of Michigan with GPS Tracking Devices; National Center for Freight & Infrastructure Research & Education, University of Wisconsin-Superior: Superior, WI, USA, 2011. [Google Scholar]

- Federal Motor Carrier Safety Administration. Hours of Service. Available online: https://www.fmcsa.dot.gov/regulations/hours-of-service (accessed on 20 November 2020).

- Conrad, J.L., IV. Safety and Efficiency of State-Legal Log Trucks on Interstate Highways in Eight Wood Baskets in the US South; Georgia Forestry Foundation Center for Forest Competitiveness and Forest Resources Association: Forsyth, GA, USA; Rockville, MD, USA, 2020. [Google Scholar]

- Bolding, M.C.; Dowling, T.N.; Barrett, S.M. Safe and Efficient Practices for Trucking Unmanufactured Forest Products; Virginia Cooperative Extension: Blacksburg, VA, USA, 2009. [Google Scholar]

- Huynh, N. Reducing truck turn times at marine terminals with appointment scheduling. Transp. Res. Rec. 2009, 2100, 47–57. [Google Scholar] [CrossRef]

- Malladi, K.T.; Sowlati, T. Optimization of operational level transportation planning in forestry: A review. Int. J. For. Eng. 2017, 28, 198–210. [Google Scholar] [CrossRef]

| Variable | Mean | Standard Deviation |

|---|---|---|

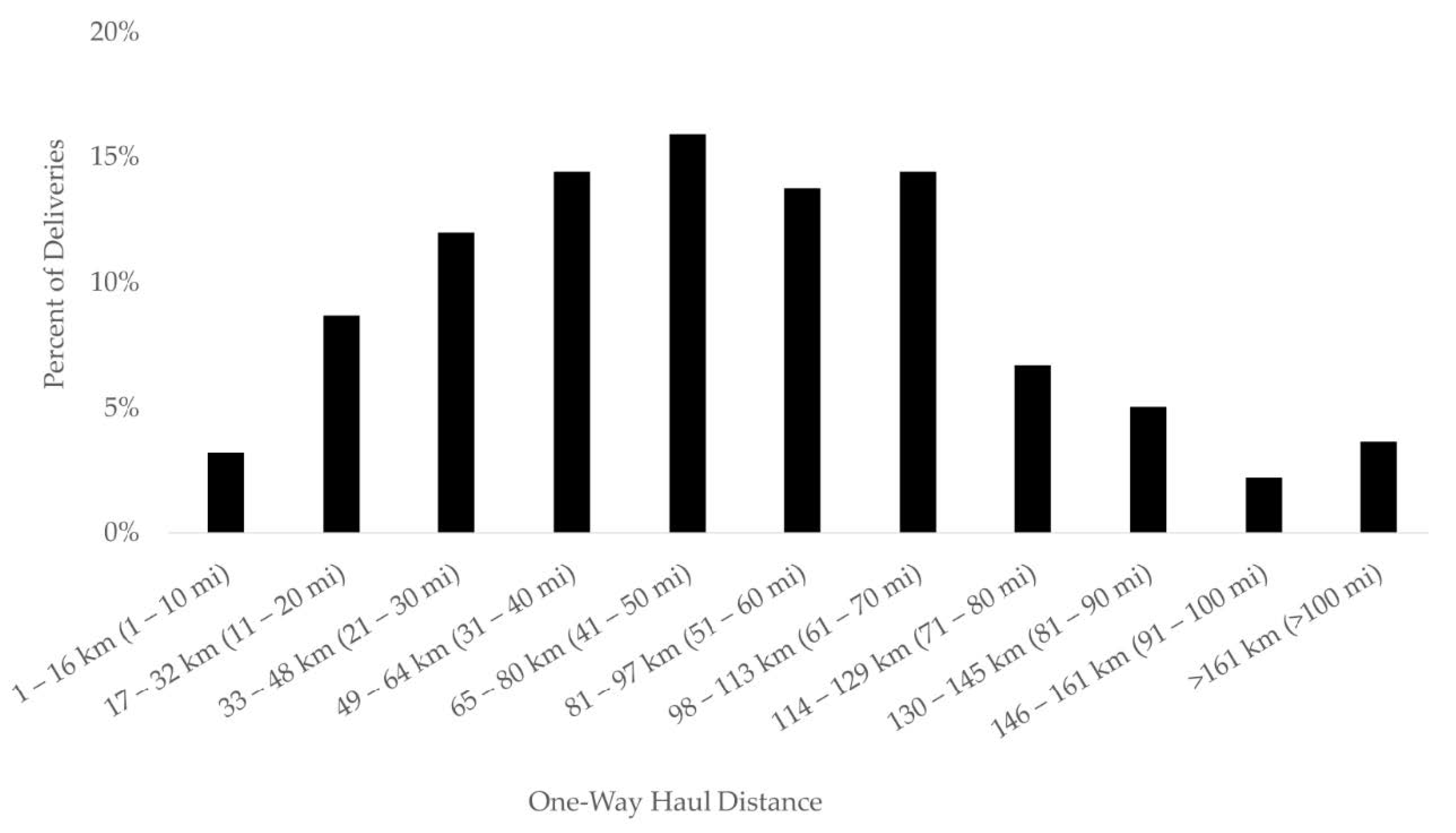

| Haul distance (one-way, km [mi]) | 79.6 (49.5) | 40.0 (24.9) |

| Average travel speed (km h−1 [mi h−1]) | 74.8 (46.5) | 7.8 (4.9) |

| Average one-way travel time (min) | 63.4 | 30.6 |

| Percent-loaded km | 44.3% | 1.1% |

| Percent of total time traveling loaded | 27.0% | 8.2% |

| Payload (t [US tons]) | 25.4 (28.0) | 1.5 (1.7) |

| Mill turn time (min) | 28.3 | 20.7 |

| Harvest site turn time (min) | 63.4 | 52.3 |

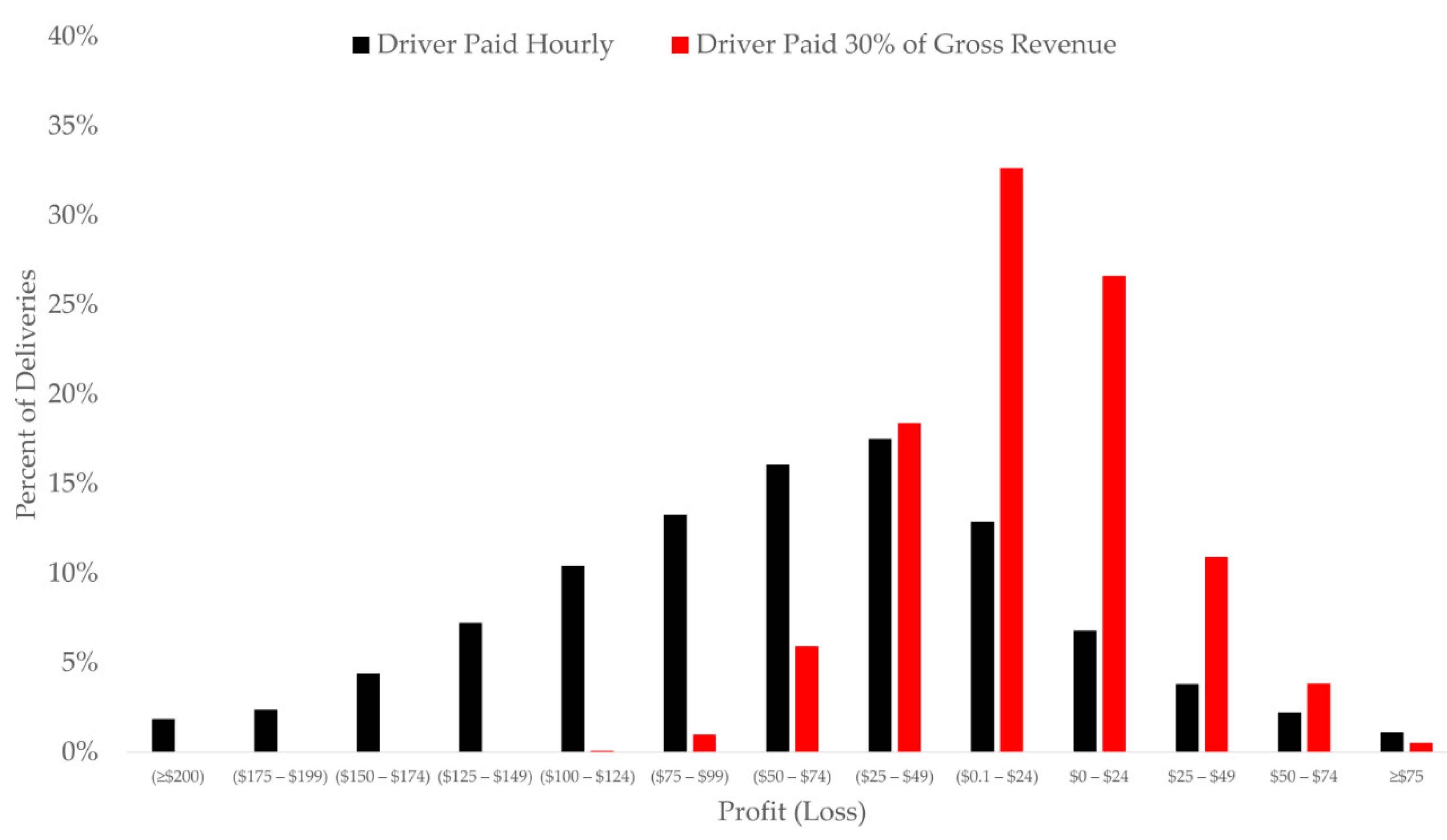

| Profit per delivery when driver paid hourly | −$62.65 | $61.90 |

| Profit per delivery when driver paid 30% of gross revenue | −$5.37 | $30.60 |

| Variable | Estimate (Std Error) | p-Value |

|---|---|---|

| Intercept | −79.972 (0.434) | <0.0001 |

| Haul distance 1 | ||

| 1–16 km (1–10 mi) | 23.882 (0.107) | <0.0001 |

| 17–32 km (11–20 mi) | 17.880 (0.082) | <0.0001 |

| 33–48 km (21–30 mi) | 10.276 (0.059) | <0.0001 |

| 49–64 km (31–40 mi) | 3.554 (0.052) | <0.0001 |

| 81–97 km (51–60 mi) | 1.927 (0.053) | <0.0001 |

| 98–113 km (61–70 mi) | 2.913 (0.052) | <0.0001 |

| 114–129 km (71–80 mi) | 4.167 (0.054) | <0.0001 |

| 130–145 km (81–90 mi) | 4.925 (0.055) | <0.0001 |

| 146–161 km (91–100 mi) | 5.636 (0.063) | <0.0001 |

| >161 km (>100 mi) | 7.915 (0.058) | <0.0001 |

| Mill turn-time (min) | −0.150 (0.001) | <0.0001 |

| Harvest site turn-time (min) | −0.156 (0.001) | <0.0001 |

| Percent-loaded km | 64.548 (0.664) | <0.0001 |

| Payload (t) | 1.359 (0.007) | <0.0001 |

| Average travel speed (km h−1) | 0.193 (0.001) | <0.0001 |

| Variable | Estimate (Std Error) | p-Value |

|---|---|---|

| Intercept | −101.274 (0.359) | <0.0001 |

| Haul distance 1 | ||

| 1–16 km (1–10 mi) | 26.200 (0.106) | <0.0001 |

| 17–32 km (11–20 mi) | 19.430 (0.061) | <0.0001 |

| 33–48 km (21–30 mi) | 10.510 (0.035) | <0.0001 |

| 49–64 km (31–40 mi) | 3.084 (0.020) | <0.0001 |

| 81–97 km (51–60 mi) | 2.256 (0.020) | <0.0001 |

| 98–113 km (61–70 mi) | 4.157 (0.021) | <0.0001 |

| 114–129 km (71–80 mi) | 5.834 (0.027) | <0.0001 |

| 130–145 km (81–90 mi) | 7.628 (0.032) | <0.0001 |

| 146–161 km (91–100 mi) | 8.587 (0.042) | <0.0001 |

| >161 km (>100 mi) | 12.318 (0.047) | <0.0001 |

| Mill turn-time (min) | −0.116 (0.000) | <0.0001 |

| Harvest site turn-time (min) | −0.114 (0.000) | <0.0001 |

| Percent-loaded km | 89.811 (0.508) | <0.0001 |

| Payload (t) | 1.867 (0.006) | <0.0001 |

| Average travel speed (km h−1) | 0.217 (0.001) | <0.0001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Conrad, J.L., IV. Evaluating Profitability of Individual Timber Deliveries in the US South. Forests 2021, 12, 437. https://doi.org/10.3390/f12040437

Conrad JL IV. Evaluating Profitability of Individual Timber Deliveries in the US South. Forests. 2021; 12(4):437. https://doi.org/10.3390/f12040437

Chicago/Turabian StyleConrad, Joseph L., IV. 2021. "Evaluating Profitability of Individual Timber Deliveries in the US South" Forests 12, no. 4: 437. https://doi.org/10.3390/f12040437