Vibration and Noise Exposure during Pre-Commercial Thinning Operations: What Are the Ergonomic Benefits of the Latest Generation Professional-Grade Battery-Powered Chainsaws?

Abstract

1. Introduction

2. Materials and Methods

2.1. Setting

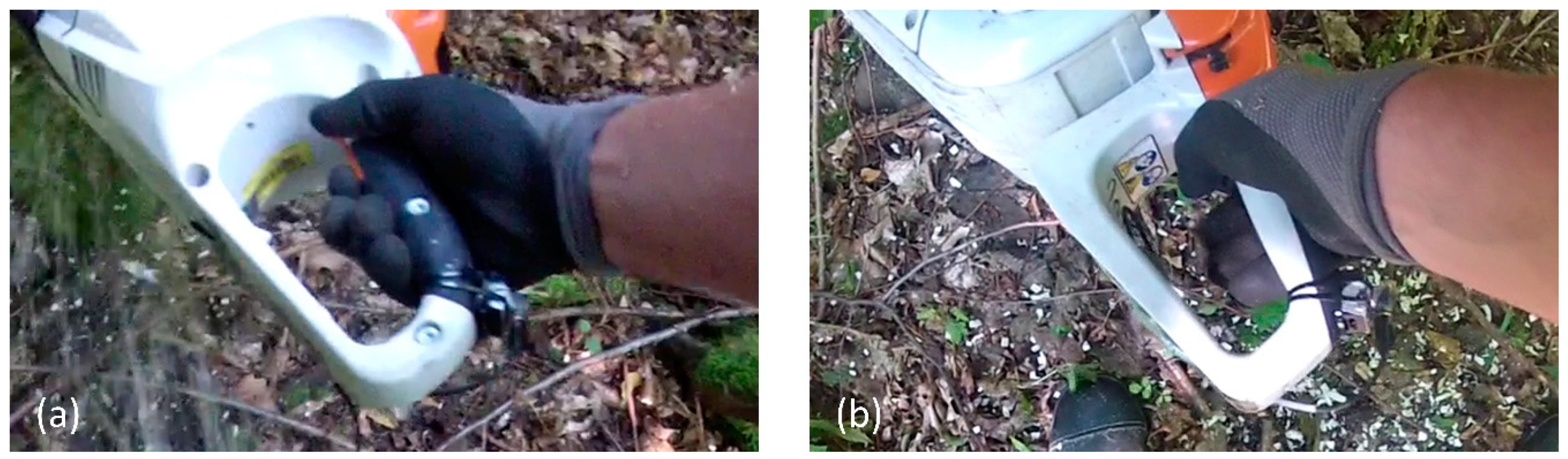

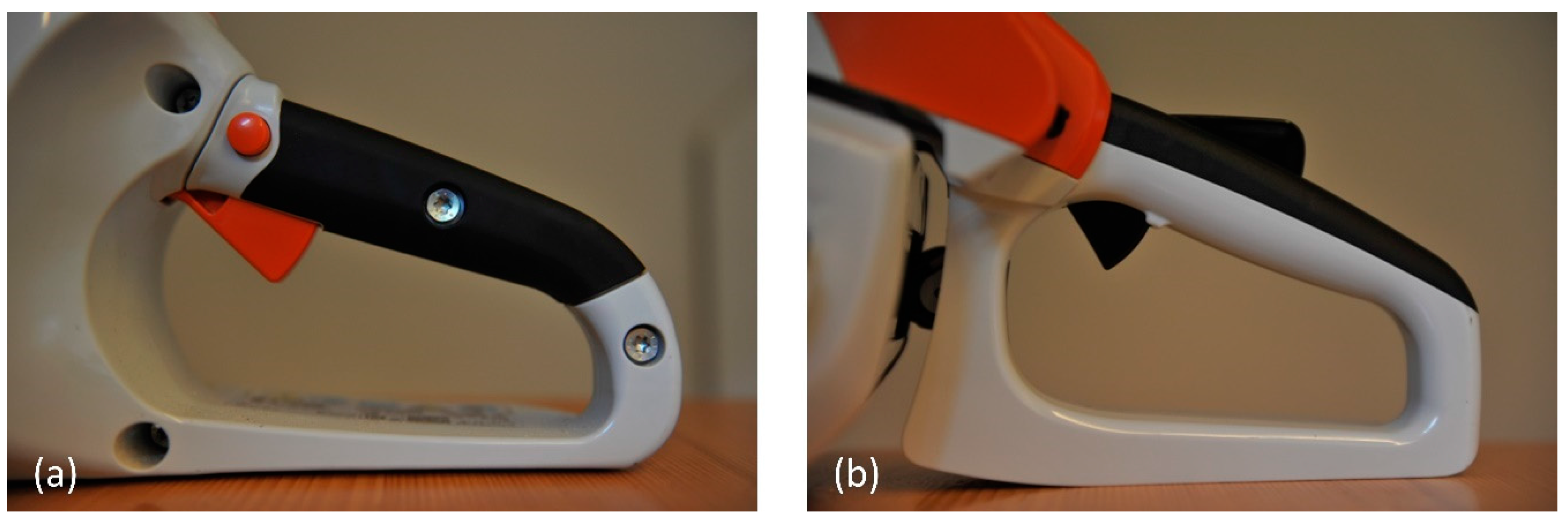

2.2. Vibration Exposure

- Sawing: The period from pulling the throttle trigger of the chainsaw under load up to releasing it.

- Actions related to sawing: All actions that were directly related to the sawing process, such as pressing the throttle trigger in mid-air before sawing or repositioning the chainsaw between two consecutive cuts.

- Walking and orientation: All periods when the operator oriented himself in the stand, walked from one tree to another or walked to perform the next cut. During walking the chainsaw was held by both hands.

- Saw held on one handle: All periods when, due to the experimental set-up, the chainsaw was held on only one handle. These periods mainly included actions, such as, for example, pushing down sawn-off trees or laying them aside.

- Interruptions of the productive work time and faulty measurements: All periods during which the productive work time was interrupted, for example due to the experiment or due to technical issues, e.g., when the saw chain had to be reattached after jumping off. Additionally, all faulty measurements, such as, for example, when a small branch hit the sensor.

2.3. Noise Exposure

2.4. Analysis Tools

3. Results

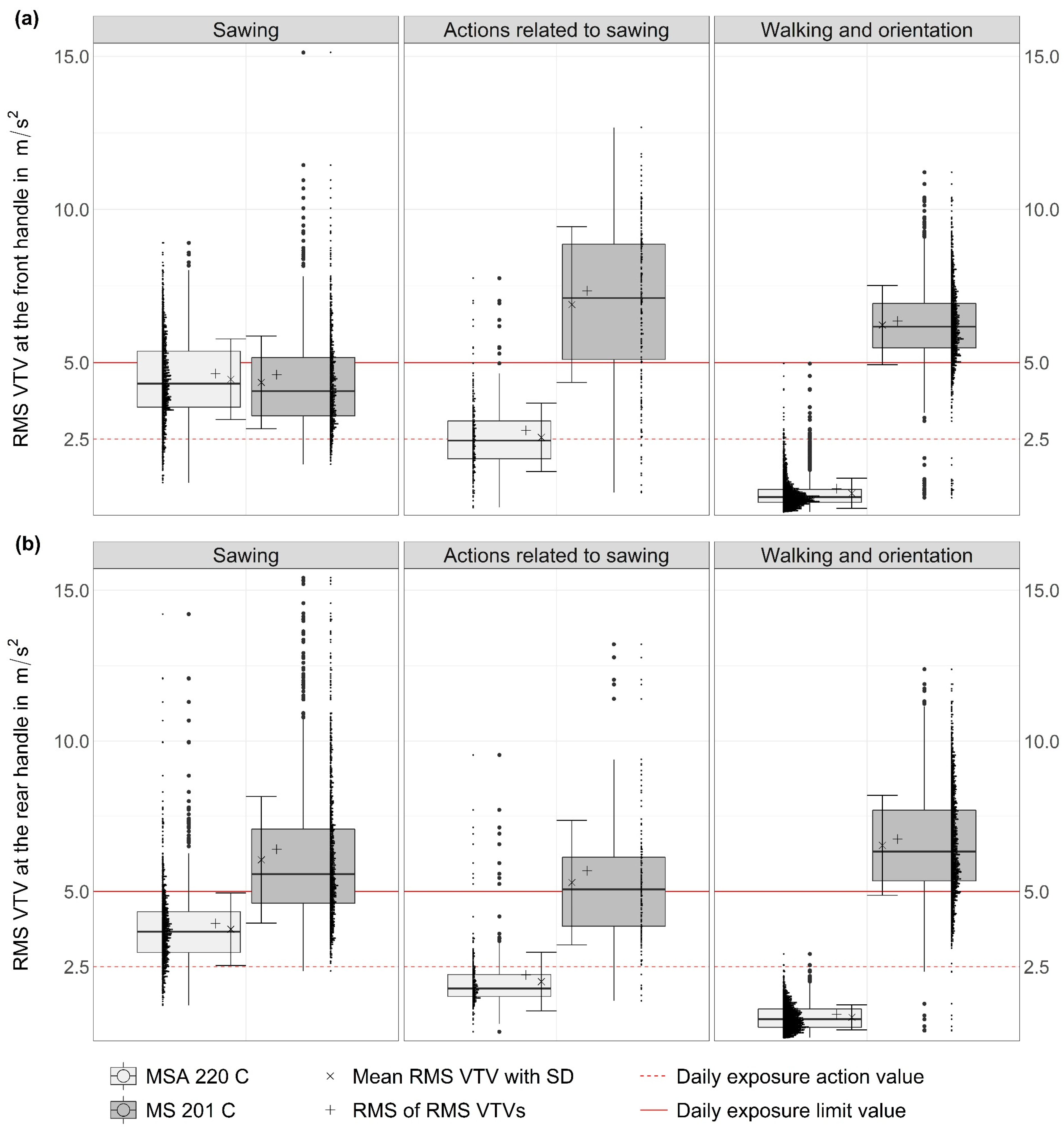

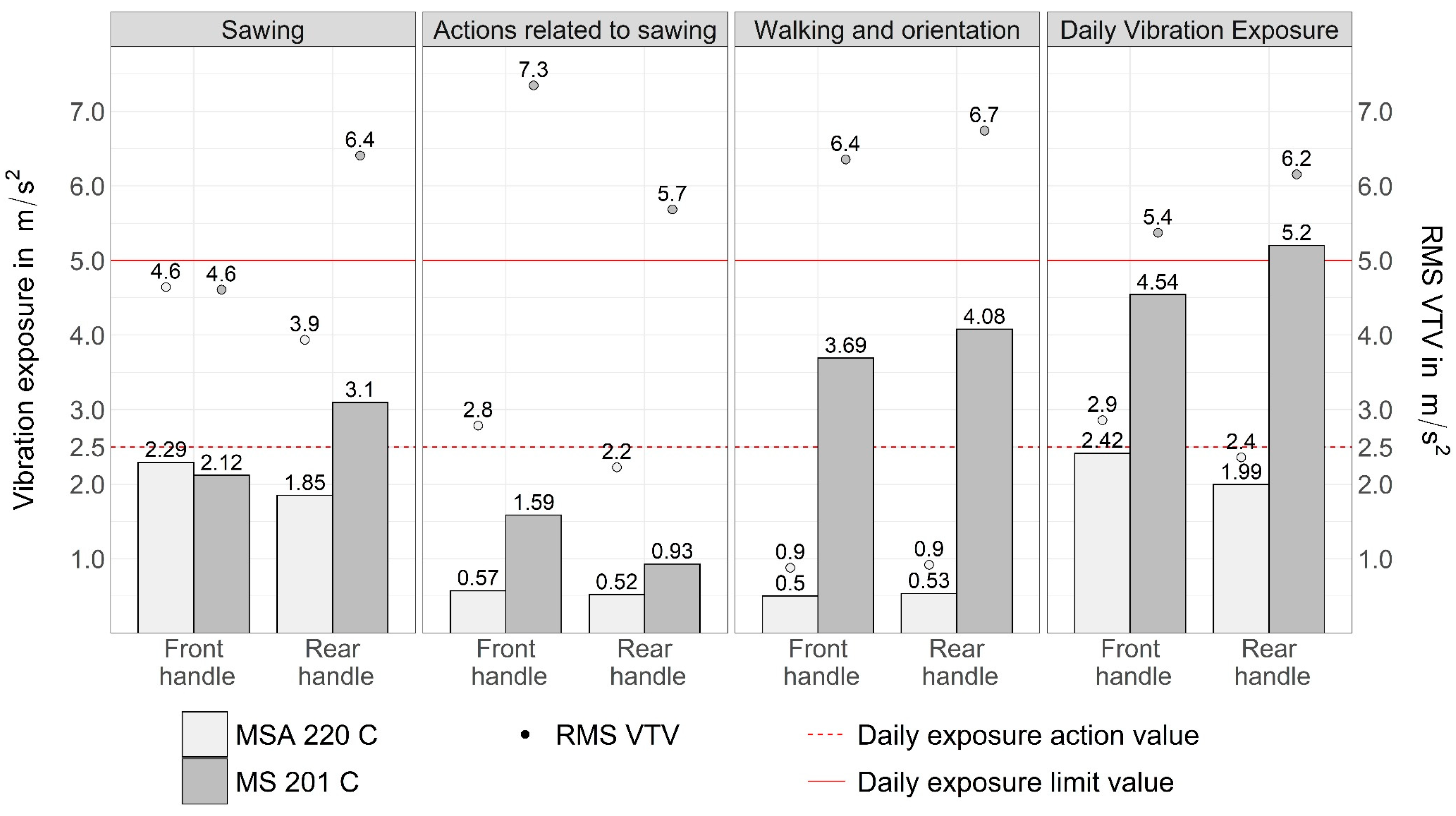

3.1. Vibration Exposure

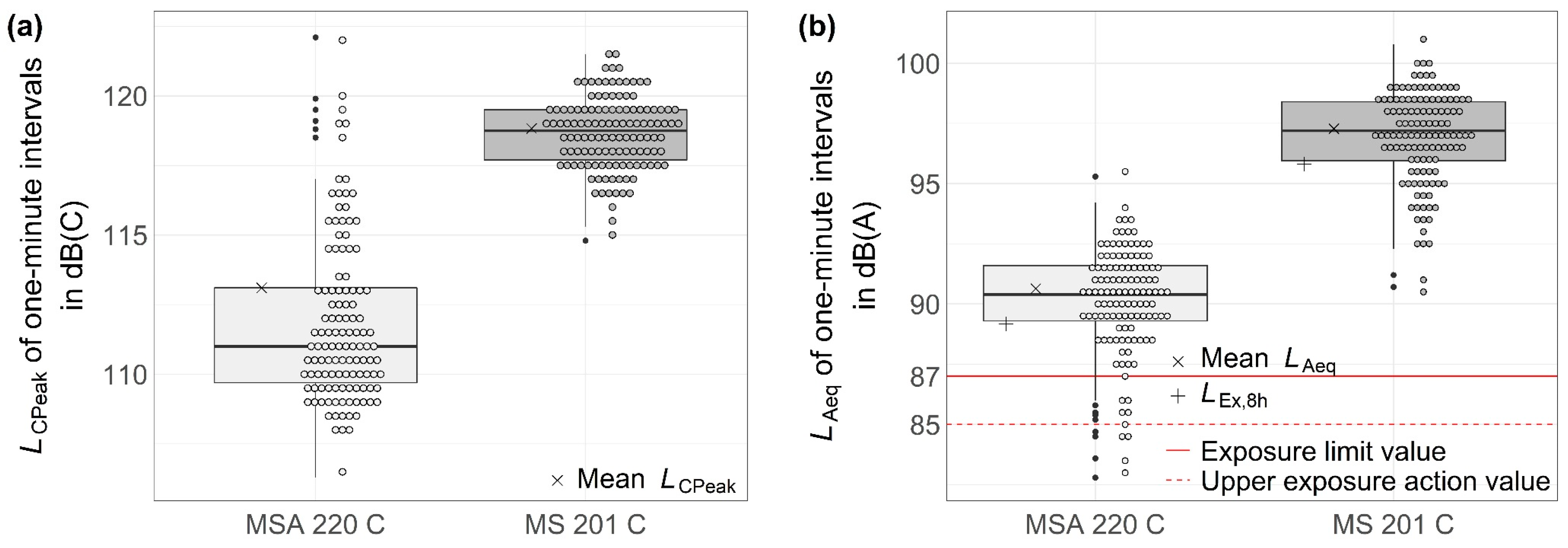

3.2. Noise Exposure

4. Discussion

4.1. Vibration Exposure

4.2. Noise Exposure

4.3. Operational Remarks

5. Conclusions

- Battery-powered chainsaws can lead to a considerable reduction in vibration and noise exposure;

- The vibration and noise exposure of battery-powered chainsaws might often be underestimated;

- Hearing protection and glove use is recommended during all operating times.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Slappendel, C.; Laird, I.; Kawachi, I.; Marshall, S.; Cryer, C. Factors affecting work-related injury among forestry workers: A review. J. Saf. Res. 1993, 24, 19–32. [Google Scholar] [CrossRef]

- Tsioras, P.A.; Rottensteiner, C.; Stampfer, K. Wood harvesting accidents in the Austrian State Forest Enterprise 2000–2009. Saf. Sci. 2014, 62, 400–408. [Google Scholar] [CrossRef]

- Axelsson, S.-Ă. The mechanization of logging operations in Sweden and its effect on occupational safety and health. J. For. Eng. 1998, 9, 25–31. [Google Scholar]

- Labelle, E.R.; Lemmer, K.J. Selected Environmental Impacts of Forest Harvesting Operations with Varying Degree of Mechanization. Croat. J. For. Eng. J. Theory Appl. For. Eng. 2019, 40, 239–257. [Google Scholar] [CrossRef]

- Müller, F.; Jaeger, D.; Hanewinkel, M. Digitization in wood supply—A review on how Industry 4.0 will change the forest value chain. Comput. Electron. Agric. 2019, 162, 206–218. [Google Scholar] [CrossRef]

- Berendt, F.; Hoffmann, S.; Jaeger, D.; Prettin, S.; Schweier, J. Application of spiroergometry to determine work metabolism related strain in the course of cable work with a mini forestry crawler. Int. J. For. Eng. 2020, 31, 114–125. [Google Scholar] [CrossRef]

- Potočnik, I.; Poje, A. Forestry ergonomics and occupational safety in high ranking scientific journals from 2005–2016. Croat. J. For. Eng. J. Theory Appl. For. Eng. 2017, 38, 291–310. [Google Scholar]

- Dimou, V.; Kantartzis, A.; Malesios, C.; Kasampalis, E. Research of exhaust emissions by chainsaws with the use of a portable emission measurement system. Int. J. For. Eng. 2019, 30, 228–239. [Google Scholar] [CrossRef]

- Magnusson, R.; Nilsson, C. The influence of oxygenated fuels on emissions of aldehydes and ketones from a two-stroke spark ignition engine. Fuel 2011, 90, 1145–1154. [Google Scholar] [CrossRef]

- Poje, A.; Potočnik, I.; Mihelič, M. Comparison of Electric and Petrol Chainsaws in Terms of Efficiency and Safety When Used in Young Spruce Stands in Small-Scale Private Forests. Small Scale For. 2018, 17, 411–422. [Google Scholar] [CrossRef]

- Rottensteiner, C.; Stampfer, K. Evaluation of operator vibration exposure to chainsaws equipped with a Kesper safety bar. Scand. J. For. Res. 2013, 28, 193–200. [Google Scholar] [CrossRef]

- Griffin, M.J. Minimum health and safety requirements for workers exposed to hand-transmitted vibration and whole-body vibration in the European Union; a review. Occup. Environ. Med. 2004, 61, 387–397. [Google Scholar] [CrossRef] [PubMed]

- Malinowska-Borowska, J.; Harazin, B.; Zieliński, G. The influence of wood hardness and logging operation on coupling forces exerted by lumberjacks during wood harvesting. Int. J. Ind. Ergon. 2011, 41, 546–550. [Google Scholar] [CrossRef]

- Malinowska-Borowska, J.; Zieliński, G. Coupling forces exerted on chain saws by inexperienced tree fellers. Int. J. Ind. Ergon. 2013, 43, 283–287. [Google Scholar] [CrossRef]

- Kováč, J.; Krilek, J.; Dado, M.; Beňo, P. Investigating the influence of design factors on noise and vibrations in the case of chainsaws for forestry work. FME Trans. 2018, 46, 513–519. [Google Scholar] [CrossRef]

- Fonseca, A.; Aghazadeh, F.; de Hoop, C.; Ikuma, L.; Al-Qaisi, S. Effect of noise emitted by forestry equipment on workers’ hearing capacity. Int. J. Ind. Ergon. 2015, 46, 105–112. [Google Scholar] [CrossRef]

- Neri, F.; Foderi, C.; Laschi, A.; Fabiano, F.; Cambi, M.; Sciarra, G.; Aprea, M.C.; Cenni, A.; Marchi, E. Determining exhaust fumes exposure in chainsaw operations. Environ. Pollut. 2016, 218, 1162–1169. [Google Scholar] [CrossRef] [PubMed]

- Neri, F.; Laschi, A.; Foderi, C.; Fabiano, F.; Bertuzzi, L.; Marchi, E. Determining noise and vibration exposure in conifer cross-cutting operations by using li-ion batteries and electric chainsaws. Forests 2018, 9, 501. [Google Scholar] [CrossRef]

- Andreas Stihl AG & Co KG. STIHL MSA 220 C Gebrauchsanleitung; Andreas Stihl AG & Co KG: Waiblingen, Germany, 2018. [Google Scholar]

- Brieger, F.; Fei, J.; Sauter, F.; Sauter, U.H. Vorstudie zum Einsatz von Akku-Motorsägen in der Jungbestandspflege; Projektbericht, FVA—Waldnutzung; Unpublished; 2021. [Google Scholar]

- Marchi, E.; Chung, W.; Visser, R.; Abbas, D.; Nordfjell, T.; Mederski, P.S.; McEwan, A.; Brink, M.; Laschi, A. Sustainable Forest Operations (SFO): A new paradigm in a changing world and climate. Sci. Total Environ. 2018, 634, 1385–1397. [Google Scholar] [CrossRef]

- Andreas Stihl AG & Co KG. STIHL MS 201 C-M Gebrauchsanleitung; Andreas Stihl AG & Co KG: Waiblingen, Germany, 2019. [Google Scholar]

- Stihl Vertriebszentrale AG & Co. KG. Akku AP 300 S. Available online: https://www.stihl.de/de/ap/akku-ap-300-s-88828 (accessed on 12 March 2021).

- Stihl Vertriebszentrale AG & Co. KG. Kettensägen/Motorsägen: MS 201. Available online: https://www.stihl.de/de/p/kettensaegen-motorsaegen-ms-201-43584 (accessed on 12 March 2021).

- Stihl Vertriebszentrale AG & Co. KG. Kettensägen/Motorsägen: MSA 220—AP-System. Available online: https://www.stihl.de/de/p/kettensaegen-motorsaegen-msa-220-ap-system-102688#c-b-ohne-akku-ohne-ladegeraet-102688 (accessed on 15 December 2020).

- Marenče, J.; Mihelic, M.; Poje, A. Influence of Chain Filing, Tree Species and Chain Type on Cross Cutting Efficiency and Health Risk. Forests 2017, 8, 464. [Google Scholar] [CrossRef]

- Stempski, W.; Jabłoński, K.; Wegner, J. Relations between top-plate filling angle values of cutting chains and chainsaw vibration levels. Acta Sci. Pol. 2010, 9, 31–39. [Google Scholar]

- Deutsches Institut für Normung e.V. DIN EN ISO 5349-1:2001-12; Mechanische Schwingungen—Messung und Bewertung der Einwirkung von Schwingungen auf das Hand-Arm-System des Menschen—Teil 1: Allgemeine Anforderungen (ISO 5349-1:2001); Beuth: Berlin, Germany, 2001. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung e.V. DIN EN ISO 5349-2:2015-12; Mechanische Schwingungen—Messung und Bewertung der Einwirkung von Schwingungen auf das Hand-Arm-System des Menschen—Teil 2: Praxisgerechte Anleitung zur Messung am Arbeitsplatz (ISO 5349-2:2001 + Amd 1:2015); Beuth: Berlin, Germany, 2015. [Google Scholar] [CrossRef]

- Brüel & Kjær Sound & Vibration Measurement A/S. Daten und Fakten: Humanschwingungsanalysator—Typ 4447; Brüel & Kjær Sound & Vibration Measurement A/S: Nærum, Denmark, 2009. [Google Scholar]

- Brüel & Kjær Sound & Vibration Measurement A/S. Catalogue—Transducers and Conditioning; Brüel & Kjær Sound & Vibration Measurement A/S: Nærum, Denmark, 2016. [Google Scholar]

- Brüel & Kjær Sound & Vibration Measurement A/S. Technische Dokumentation: Humanschwingungsanalysator Typ 4447; Brüel & Kjær Sound & Vibration Measurement A/S: Nærum, Denmark, 2009. [Google Scholar]

- European Parliament; Council of the European Union. Directive 2002/44/EC of the European Parliament and of the Council of 25 June 2002 on the minimum health and safety re-quirements regarding the exposure of workers to the risks arising from physical agents (vibration) (sixteenth individual Di-rective within the meaning of Article 16(1) of Directive 89/391/EEC). Off. J. Eur. Commun. 2002, 45, 13–20. [Google Scholar]

- Deutsches Institut für Normung e.V. DIN EN ISO 22867:2012-04; Forst- und Gartenmaschinen—Schwingungsmessnorm für Handgehaltene Maschinen mit Verbrennungsmotor—Schwingungen an den Handgriffen; Beuth: Berlin, Germany, 2012. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung e.V. DIN EN 60745-2-13:2011-07; Handgeführte Motorbetriebene Elektrowerkzeuge—Sicherheit—Teil 2-13: Besondere Anforderungen für Kettensägen (IEC 60745-2-13:2006, Modifiziert + A1:2009); Beuth: Berlin, Germany, 2011. [Google Scholar]

- Goglia, V.; Suchomel, J.; Žgela, J.; Đukić, I. The effectiveness of forest pre-commercial thinning in the context of Directive 2002/44/EC. Sumar. List 2012, 136, 471–478. [Google Scholar]

- Kaulbars, U. Gefährdungsbeurteilung der Hand-Arm-Vibration bei der Waldarbeit mit Motorkettensägen, 2nd ed.; IFA Report, 5/2015; Deutsche Gesetzliche Unfallversicherung e.V. (DGUV): Sankt Augustin, Germany, 2015. [Google Scholar]

- Forstliche Bildungsstätten der Bundesrepublik Deutschland. Der Forstwirt, 6th ed; Eugen Ulmer KG: Stuttgart, Germany, 2015; ISBN 978-3-8001-8448-4. [Google Scholar]

- Casella UK Office. CEL-35x dBadge Users Handbook; Casella UK Office: Bedford, UK, 2015. [Google Scholar]

- Maue, J.H. Lärmmessung im Betrieb: Anleitung zur Normgerechten Ermittlung der Lärmexposition am Arbeitsplatz und der Geräuschemission von Maschinen; Erich Schmidt Verlag GmbH & Co. KG: Berlin, Germany, 2011; ISBN 978-3-503-13007-8. [Google Scholar]

- Deutsches Institut für Normung e.V. DIN EN ISO 9612:2009-09; Akustik—Bestimmung der Lärmexposition am Arbeitsplatz—Verfahren der Genauigkeitsklasse 2 (Ingenieurverfahren) (ISO 9612:2009); Beuth: Berlin, Germany, 2009. [Google Scholar] [CrossRef]

- European Parliament, Council of the European Union. Directive 2003/10/EC of the European Parliament and of the Council of 6 February 2003 on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (noise) (seventeenth individual Directive within the meaning of Article 16(1) of Directive 89/391/EEC). Off. J. Eur. Commun. 2003, 46, 38–44. [Google Scholar]

- Bundesministerium der Justiz und für Verbraucherschutz. Lärm- und Vibrations-Arbeitsschutzverordnung—LärmVibrationsArbSchV; BGBl. I S. 261, last edited by Art. 5 Abs. 5 of the regulation on 18 October 2017, BGBl. I S. 3584; Bundesministerium der Justiz und für Verbraucherschutz: Berlin, Germany, 2007. [Google Scholar]

- Casella. Casella dBadge Lärmdosimeter—Datenblatt; Casella: Bedford, UK, 2013. [Google Scholar]

- Crocker, M.J.; Arenas, J.P. Engineering Acoustics: Noise and Vibration Control; Wiley: Hoboken, NJ, USA, 2021; ISBN 978-1-1184-9642-8. [Google Scholar]

- TSI Incorporated. The Impact of Threshold, Criterion Level and Exchange Rate on Noise Exposure Data Results; Application Note Quest-001; TSI Incorporated: Shoreview, MN, USA, 2020. [Google Scholar]

- Feldmann, R. Vibrations- und Schallemissionen von Akkumotorsägen in der Jungbestandspflege. Master’s Thesis, Albert-Ludwigs-Universität Freiburg, Freiburg, Germany, 2019. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2020; Available online: https://www.R-project.org/ (accessed on 17 June 2021).

- RStudio Team. RStudio: Integrated Development Environment for R; RStudio, PBC: Boston, MA, USA, 2020; Available online: http://www.rstudio.com/ (accessed on 17 June 2021).

- Kassambara, A. ggpubr: ‘ggplot2’ Based Publication Ready Plots, R Package Version 0.4.0. 2020. Available online: https://cran.r-project.org/package=ggpubr (accessed on 17 June 2021).

- Schauberger, P.; Walker, A. Openxlsx: Read, Write and Edit xlsx Files, R Package Version 4.1.5. 2020. Available online: https://cran.r-project.org/package=openxlsx (accessed on 17 June 2021).

- Wickham, H. ggplot2: Elegant Graphics for Data Analysis; Springer: New York, NY, USA, 2016; ISBN 978-3-319-24277-4. Available online: https://ggplot2.tidyverse.org (accessed on 17 June 2021).

- Deutsches Institut für Normung e.V. Kalkulationsprogramm zur DIN EN ISO 9612:2009-09 (Unsicherheiten). 2015. Available online: https://www.din.de/de/mitwirken/normenausschuesse/nals/kalkulationsprogramm-zur-din-en-iso-9612-2009-09-unsicherheiten--90316 (accessed on 25 November 2020).

- Jäger, M. Stihl MSA 220 C-B im Test: Akku-Kettensäge für Professionelle Ansprüche. Available online: https://www.chip.de/test/Stihl-MSA-220-C-B-im-Test_182903473.html (accessed on 15 December 2020).

- Malchaire, J.; Piette, A.; Moens, G.; Boodts, S.; Cornillie, F.; Delaruelle, D.; de Cooman, G.; Timmerman, I.; Carlier, P.; Mathy, F.; et al. Vibrations Mains-Bras: Serie Strategie Sobane—Gestion des Risques Professionnels; SPF Emploi, Travail et Concertation sociale: Brussels, Belgium, 2020. [Google Scholar]

- Kaulbars, U.; Scheffer, M. Forschungsbericht Hand-Arm-Schwingungen III Wirkung von Greif- und Andruckkraft unter Schwingungsbelastung; Hauptverband der Gewerblichen Berufsgenossenschaften: Sankt Augustin, Germany, 1992; ISBN 3-88383-309-6. [Google Scholar]

- Bundesanstalt für Arbeitsschutz und Arbeitsmedizin. Technische Regeln zur Lärm- und Vibrations-Arbeitsschutzverordnung: TRLV Vibrationen—Teil 1: Beurteilung der Gefährdung durch Vibrationen; GMBl 2015 Nr. 25/26 2015, Ausgabe März; Bundesministerium des Innern, für Bau und Heimat: Berlin, Germany, 2015. [Google Scholar]

- Deutsches Institut für Normung e.V. DIN 45679:2013-02; Mechanische Schwingungen—Messung und Bewertung der Ankopplungskräfte zur Beurteilung der Schwingungsbelastung des Hand-Arm-Systems; Beuth: Berlin, Germany, 2013. [Google Scholar]

- Malinowska-Borowska, J.; Harazin, B.; Zieliński, G. Measuring Coupling Forces Woodcutters Exert on Saws in Real Working Conditions. Int. J. Occup. Saf. Ergon. 2012, 18, 77–83. [Google Scholar] [CrossRef]

- Hewitt, S.; Dong, R.; McDowell, T.; Welcome, D. The efficacy of anti-vibration gloves. Acoust. Aust. 2016, 44, 121–127. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Shibata, N. Effect of shelf aging on vibration transmissibility of anti-vibration gloves. Ind. Health 2017, 55, 575–579. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Hewitt, S.; Dong, R.G.; Welcome, D.E.; McDowell, T.W. Anti-vibration gloves? Ann. Occup. Hyg. 2014, 59, 127–141. [Google Scholar]

- McDowell, T.W.; Dong, R.G.; Welcome, D.E.; Xu, X.S.; Warren, C. Vibration-reducing gloves: Transmissibility at the palm of the hand in three orthogonal directions. Ergonomics 2013, 56, 1823–1840. [Google Scholar] [CrossRef] [PubMed]

- Welcome, D.E.; Dong, R.G.; Xu, X.S.; Warren, C.; McDowell, T.W. Tool-specific performance of vibration-reducing gloves for attenuating fingers-transmitted vibration. Occup. Ergon. 2016, 13, 23–44. [Google Scholar] [CrossRef]

- Kaulbars, U.; Walther, C. Certified anti-vibration gloves: Test methods and the limits to their effectiveness. In Proceedings of the 20th Japan Conference on Human Response to Vibration, Osaka, Japan, 4–6 September 2012. [Google Scholar]

- Kaulbars, U. Vibrations-Schutzhandschuhe haben begrenzte Wirkung. MM Masch. 2010, 19, 30–32. [Google Scholar]

- Health and Safety Executive. Hand Arm Vibration in Forestry and Arboriculture. Available online: https://www.hse.gov.uk/treework/health/hand-arm-vibration.htm (accessed on 26 March 2021).

- Kuratorium für Waldarbeit und Forsttechnik e.V. Prüfbericht: Stihl MS 201/MS 201 C E Stihl MS 201 C-M/MS 201 C-EM; Kuratorium für Waldarbeit und Forsttechnik e.V: Groß-Umstadt, Germany, 2019. [Google Scholar]

- Deutsche Gesetzliche Unfallversicherung e.V. DGUV Regel 112-194: Benutzung von Gehörschutz; Deutsche Gesetzliche Unfallversicherung e.V: Berlin, Germany, 2015. [Google Scholar]

- Höllerl, H. Akkupower. ForstTech 2020, 3.2020, 15–17. [Google Scholar]

- Pandur, Z.; Šušnjar, M.; Bačić, M. Battery Technology. Croat. J. For. Eng. J. Theory Appl. For. Eng. 2021, 42, 135–148. [Google Scholar] [CrossRef]

- STIHL Vertriebszentrale AG & Co. KG. AR 3000 L Backpack Battery, Set with Connecting Cable and AP Adapter. Available online: https://www.stihl.de/de/ap/rueckentragbarer-akku-ar-3000-l-95347 (accessed on 15 December 2020).

- Makita Corporation. Portable Power Pack PDC01. Available online: https://www.makita.com.sg/product/pdc01-portable-power-pack/ (accessed on 15 December 2020).

| STIHL MSA 220 C | STIHL MS 201 C | |

|---|---|---|

| Type | Battery-powered chainsaw with lithium-ion battery AP 300 S | Petrol chainsaw with single-cylinder two-stroke engine |

| Weight | 3.6 kg (with guide bar and saw chain, without battery and saw chain adhesion oil) | 4.54 kg (with guide bar and saw chain, without fuel and saw chain adhesion oil) |

| Oil tank capacity | 0.21 L | 0.22 L |

| Fuel tank capacity | - | 0.31 L |

| Battery Weight | 1.8 kg | - |

| Voltage/Energy content/Capacity according to IEC 61960 | 36 V/281 Wh/7.2 Ah | - |

| Engine power | - | 1.8 kW/2.4 hp |

| Guide bar length | 35 cm | 35 cm |

| Maximum chain speed (6-tooth for 3/8” P) according to ISO 11681 | 23.3 m/s | 26.0 m/s |

| Total gross mass | 5.64 kg | 4.98 kg |

| Accelerometer Position | Front Handle | Rear Handle | ||

|---|---|---|---|---|

| Chainsaw | MSA 220 C | MS 201 C | MSA 220 C | MS 201 C |

| Area [ha] | 0.37 | 0.35 | 0.35 | 0.24 |

| Real productive work time [min] | 75.58 | 61.90 | 73.55 | 77.55 |

| Productive work time for vibration exposure [min] | 75.58 | 56.48 | 73.55 | 70.27 |

| Productive work time for noise exposure [min] | 61 | 54 | 58 | 70 |

| Workplace time [min] (28.6% delay and service times) | 105.8 | 86.7 | 103.0 | 108.6 |

| Number of trees felled | 80 | 93 | 90 | 97 |

| Mean diameter at base height [cm] | 13.8 | 12.0 | 14.1 | 13.9 |

| Number of cuts | 237 | 239 | 236 | 264 |

| Work Element | Total | Sawing | Actions Related to Sawing | Walking and Orientation | Saw Held On One Handle | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Handle Chainsaw | Front Handle | Rear Handle | Front Handle | Rear Handle | Front Handle | Rear Handle | Front Handle | Rear Handle | Front Handle | Rear Handle | |

| Productive work time [min] | MSA 220 C | 75.58 | 73.55 | 25.80 | 27.73 | 4.45 | 5.58 | 34.10 | 34.75 | 11.23 | 10.48 |

| MS 201 C | 56.48 | 70.27 | 16.72 | 22.95 | 3.68 | 2.63 | 26.65 | 35.98 | 9.43 | 8.70 | |

| Time share (productive work time) [%] | MSA 220 C | 100 | 100 | 34.1 | 30.9 | 5.9 | 7.6 | 45.1 | 47.3 | 14.9 | 14.3 |

| MS 201 C | 100 | 100 | 29.6 | 32.7 | 6.5 | 3.8 | 47.2 | 51.2 | 16.7 | 12.4 | |

| RMS VTV productive work time [m/s2] | MSA 220 C | 2.86 | 2.36 | 4.64 | 3.94 | 2.79 | 2.23 | 0.88 | 0.92 | ||

| MS 201 C | 5.37 | 6.16 | 4.61 | 6.41 | 7.35 | 5.69 | 6.36 | 6.74 | |||

| Difference of RMS VTVs during productive work time [%] | MS 201 C compared to MSA 220 C | +87.8 | +161.0 | −0.6 | +62.7 | +163.4 | +155.2 | +622.7 | +632.6 | ||

| Partial/Daily Vibration Exposure [m/s2] | MSA 220 C | 2.42 | 1.99 | 2.29 | 1.85 | 0.57 | 0.52 | 0.50 | 0.53 | ||

| MS 201 C | 4.54 | 5.20 | 2.12 | 3.10 | 1.59 | 0.93 | 3.69 | 4.08 | |||

| Difference in partial vibration exposure [%] | MS 201 C compared to MSA 220 C | +87.6 | +161.3 | −7.4 | +67.6 | +178.9 | +78.8 | +638.0 | +669.8 | ||

| MSA 220 C | MS 201 C | Difference (MS 201 C Compared to MSA 220 C) | |

|---|---|---|---|

| Productive work time [min] | 119 | 124 | +5 min |

| productive work time [dB(A)] | 90.64 | 97.28 | +6.64 dB(A) |

| Mean [dB(C)] | 113.10 | 118.83 | +5.73 dB(C) |

| Maximum [dB(C)] | 122.1 | 121.5 | −0.6 dB(C) |

| [dB(A)] (28.6% delay and service time with an of 65.43 dB(A)) | 89.18 | 95.81 | +6.63 dB(A) |

| Dose full working day [%] | 165.5 | 767.4 | +363.7% (relative difference) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huber, M.; Hoffmann, S.; Brieger, F.; Hartsch, F.; Jaeger, D.; Sauter, U.H. Vibration and Noise Exposure during Pre-Commercial Thinning Operations: What Are the Ergonomic Benefits of the Latest Generation Professional-Grade Battery-Powered Chainsaws? Forests 2021, 12, 1120. https://doi.org/10.3390/f12081120

Huber M, Hoffmann S, Brieger F, Hartsch F, Jaeger D, Sauter UH. Vibration and Noise Exposure during Pre-Commercial Thinning Operations: What Are the Ergonomic Benefits of the Latest Generation Professional-Grade Battery-Powered Chainsaws? Forests. 2021; 12(8):1120. https://doi.org/10.3390/f12081120

Chicago/Turabian StyleHuber, Martin, Stephan Hoffmann, Frauke Brieger, Florian Hartsch, Dirk Jaeger, and Udo Hans Sauter. 2021. "Vibration and Noise Exposure during Pre-Commercial Thinning Operations: What Are the Ergonomic Benefits of the Latest Generation Professional-Grade Battery-Powered Chainsaws?" Forests 12, no. 8: 1120. https://doi.org/10.3390/f12081120

APA StyleHuber, M., Hoffmann, S., Brieger, F., Hartsch, F., Jaeger, D., & Sauter, U. H. (2021). Vibration and Noise Exposure during Pre-Commercial Thinning Operations: What Are the Ergonomic Benefits of the Latest Generation Professional-Grade Battery-Powered Chainsaws? Forests, 12(8), 1120. https://doi.org/10.3390/f12081120