Use of Agave durangensis Bagasse Fibers in the Production of Wood-Based Medium Density Fiberboard (MDF)

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Manufacture of MDF Panels

2.3. Physical and Mechanical Properties of MDF Panels

2.4. Statistical Analysis

3. Results and Discussion

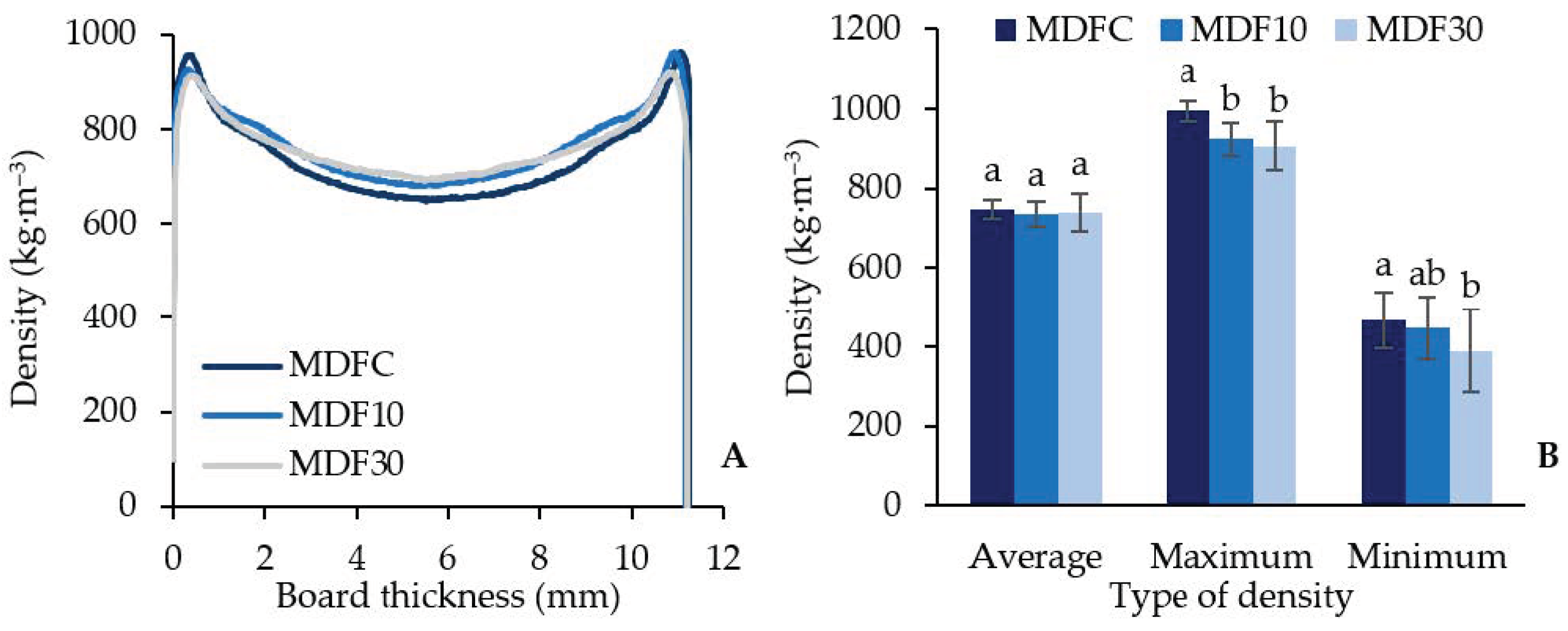

3.1. Panels Density

3.2. Water Absorption and Thickness Swell

3.3. Internal Bond

3.4. Modulus of Elasticity (MOE) and Modulus of Rupture (MOR)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ANSI A208.2. Medium Density Fiberboard (MDF) for Interior Applications; American National Standard Institute: Gaithersburg, MD, USA, 2016. [Google Scholar]

- Indrayani, Y.; Setyawati, D.; Yoshimura, T.; Umemura, K. Termite resistance of medium density fibreboard produced from renewable biomass of agricultural fibre. Procedia Environ. Sci. 2014, 20, 767–771. [Google Scholar] [CrossRef][Green Version]

- Taghiyari, H.R.; Majidi, R.; Arsalan, M.G.; Moradiyan, A.; Militz, H.; Ntalos, G.; Papadopoulos, A.N. Penetration of different liquids in wood-based composites: The effect of adsorption energy. Forests 2021, 12, 63. [Google Scholar] [CrossRef]

- Abdellah, M.Y.; Fahmy, H.S.; Abdel-Jaber, G.T.; Hashem, A.M. Characteristic properties of glass fiber reinforced sugarcane bagasse medium density fiber board. Ciênc. Tecnol. Mater. 2017, 29, 97–105. [Google Scholar] [CrossRef]

- Halvarsson, S.; Edlund, H.; Norgren, M. Manufacture of non-resin wheat straw fiberboards. Ind. Crop. Prod. 2009, 29, 437–445. [Google Scholar] [CrossRef]

- Akgül, M.; Çamlibel, O. Manufacture of medium density fiberboard (MDF) panels from rhododendron (R. ponticum L.) biomass. Build. Environ. 2008, 43, 438–443. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Mohammad-Panah, B.; Morrel, J.J. Effects of wollastonite on the properties of medium-density fiberboard (MDF) made from wood fibers and camel-thorn. Maderas. Cienc. Tecnol. 2016, 18, 157–166. [Google Scholar] [CrossRef]

- Akgül, M.; Uner, B.; Çamlibel, O.; Ayata, U. Manufacture of medium density fiberboard (MDF) panels from agribased lignocellulosic biomass. J. Wood Sci. 2017, 62, 615–624. [Google Scholar]

- Silva, D.W.; Scatolino, M.V.; do Prado, N.R.T.; Mendes, R.F.; Mendes, L.M. Addition of different proportions of castor husk and pine wood in particleboards. Waste Biomass Valor. 2018, 9, 139–145. [Google Scholar] [CrossRef]

- Xing, C.; Deng, J.; Zhang, S.Y.; Riedl, B.; Cloutier, A. Impact of bark content on the properties of medium density fiberboard (MDF) in four species grown in eastern Canada. For. Prod. J. 2006, 56, 64–69. [Google Scholar]

- Yousefi, H. Canola straw as a bio-waste resource for medium density fiberboard (MDF) manufacture. Waste Manag. 2009, 29, 2644–2648. [Google Scholar] [CrossRef]

- Aisyah, H.A.; Paridah, M.T.; Sahri, M.H.; Anwar, U.M.K.; Astimar, A.A. Properties of medium density fibreboard (MDF) from kenaf (Hibiscus cannabinus L.) core as function of refining conditions. Compos. B Eng. 2013, 44, 592–596. [Google Scholar] [CrossRef]

- Ibrahim, Z.; Aziz, A.A.; Ramli, R.; Mokhtar, A.; Lee, S. Effect of refining parameters on medium density fibreboard (MDF) properties from oil palm trunk (Elaeis guineensis). Open J. Compos. Mater. 2013, 3, 127–131. [Google Scholar] [CrossRef]

- Yang, I.; Lee, K.; Oh, S. Manufacture and performance evaluation of medium-density fiberboard made with coffee bean residue-wood fiber. J. Korean Wood Sci. Technol. 2013, 41, 293–301. [Google Scholar] [CrossRef]

- Rashid, M.M.; Das, A.K.; Shams, M.I.; Biswas, S.K. Physical and mechanical properties of medium density fiber board (MDF) fabricated from banana plant (Musa sapientum) stem and midrib. J. Indian Acad. Wood Sci. 2014, 11, 1–4. [Google Scholar] [CrossRef]

- Ashori, A.; Nourbakhsh, A. Bio-based composites from waste agricultural residues. Waste Manag. 2010, 30, 680–684. [Google Scholar] [CrossRef]

- Mihailova, J.; Savov, V.; Grigorov, R. Utilization of mass of industrial hemp in the production of medium-density fibreboards (MDF). J. Anatol. Environ. Anim. Sci. 2019, 4, 679–684. [Google Scholar] [CrossRef]

- Iñiguez-Covarrubias, G.; Lange, S.E.; Rowell, R.M. Utilization of byproducts from the tequila industry: Part 1: Agave bagasse as a raw material for animal feeding and fiberboard production. Bioresour. Technol. 2001, 77, 25–32. [Google Scholar] [CrossRef]

- Ilangovan, K.; Linerio, J.; Álvarez, E.; Briones, M.; Noyola, A. Anaerobic treatment of tequila vinasse. In Environmental Biotechnology and Cleaner Bioprocesses; Olguin, E.J., Sanchez, G., Hernandez, E., Eds.; Taylor & Francis: London, UK, 2010; pp. 101–106. [Google Scholar]

- CRM. Informe Estadístico 2020. Available online: http://www.crm.org.mx/PDF/INF_ACTIVIDADES/INFORME2019.pdf (accessed on 10 September 2020).

- Moreno-Anguiano, O.; Carrilo-Parra, A.; Rutiaga-Quiñones, J.G.; Wehenkel, C.; Pompa-García, M.; Márquez-Montesino, F.; Pintor-Ibarra, L.F. Chemical composition of Luffa aegyptiaca Mill., Agave durangensis Gentry and Pennisetum sp. PeerJ 2021, 9, e10626. [Google Scholar] [CrossRef]

- ASTM D1037. Standard Test Methods for Evaluating Properties of Wood-Based Fiber and Particle Panel Materials; American Society for Testing and Materials: West Conshohocken, PA, USA, 2006. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2020. [Google Scholar]

- Halvarsson, S.; Edlund, H.; Norgren, M. Wheat straw as raw material for manufacture of medium density fiberboard (MDF). Bioresources 2010, 5, 1215–1231. [Google Scholar]

- Wang, S.; Winistorfer, P.M.; Young, T.M.; Helton, C. Step-closing pressing of medium density fiberboard; Part 1. Influences on the vertical density profiles. Holz Roh Werkst. 2001, 59, 19–26. [Google Scholar] [CrossRef]

- Shi, J.L.; Zhang, S.Y.; Riedl, B.; Brunette, G. Flexural properties, internal bond strength, and dimensional stability of medium density fiberboard panels made from hybrid poplar clones. Wood Fiber Sci. 2005, 37, 629–637. [Google Scholar]

- Faria, D.L.; Scatolino, M.V.; Lopes, T.A.; Júnior, L.M.; Mota, G.S.; Júnior, J.B.G.; Mendes, L.M.; Soriano, J. Performance of glulam beams produced with free-formaldehyde adhesive and underexploited rubber wood treated with preservatives solutions of chromated copper borate and pyrethroids. J. Adhes. Sci. Technol. 2019, 112, 1145–1162. [Google Scholar] [CrossRef]

- Hosseinkhani, H.; Euring, M.; Kharazipour, A. Utilization of date palm (Phoenix dactylifera L.) pruning residues as raw material for MDF manufacturing. J. Mater. Sci. Res. 2015, 4, 46. [Google Scholar] [CrossRef][Green Version]

- Akgül, M. Suitability of stinging nettle (Urtica dioica L.) stalks for medium density fiberboards production. Compos. B Eng. 2013, 45, 925–929. [Google Scholar] [CrossRef]

- Akgül, M.; Tozluoğlu, A. Utilizing peanut husk (Arachis hypogaea L.) in the manufacture of medium-density fiberboards. Bioresour. Technol. 2008, 99, 5590–5594. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Shupe, T.F.; Hse, C. Utilization of Chinese tallow tree and bagasse for medium density fiberboard. For. Prod. J. 2004, 54, 71–76. [Google Scholar]

- Akgül, M.; Güler, C.; Çöpür, Y. Certain physical and mechanical properties of medium density fiberboards manufactured from blends of corn (Zea mays indurata Sturt.) stalks and pine (Pinus nigra) wood. Turk. J. Agric. For. 2010, 34, 197–206. [Google Scholar] [CrossRef]

- Akgül, M.; Korkut, S.; Çamlibel, O.; Ayata, Ü. Some chemical properties of Luffa and its suitability for medium density fiberboard (MDF) production. Bioresources 2013, 8, 1709–1717. [Google Scholar] [CrossRef]

- Gilla, P.R.; Irle, M.A.; Amartey, S.A. Development and production of laboratory scale novel MDF panels from composite and nonwoven mattresses of sisal and wood fibre mixtures. Holz Roh Werkst. 2000, 58, 324–330. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Nur Firdaus, M.Y.; Jawaid, M.; Anis, M.; Ridzuan, R.; Mohamed, A.R. Development and material properties of new hybrid medium density fibreboard from empty fruit bunch and rubberwood. Mater. Des. 2010, 31, 4229–4236. [Google Scholar] [CrossRef]

- Belini, U.G.; Filho, M.T.; Louzada, J.L.P.C.; Rodrigues, J.C.C.; Astolphi, J.R.S. Pilot study for MDF manufacture from sugarcane bagasse and eucalyptus fibers. Eur. J. Wood Wood Prod. 2012, 70, 537–539. [Google Scholar] [CrossRef]

- Gadhave, R.V.; Mahanwar, P.A.; Gadekar, P.T. Factor affecting gel time/process-ability of urea formaldehyde resin based wood adhesives. Open J. Polym. Chem. 2017, 7, 33–42. [Google Scholar] [CrossRef]

- Hse, C.Y.; Kuo, M.I. Influence of extractives on wood gluing and finishing—A review. For. Prod. J. 1998, 38, 52–56. [Google Scholar]

- Çöpür, Y.; Güler, C.; Taşçioğlu, C.; Tozluoğlu, A. Incorporation of hazelnut shell and husk in MDF production. Bioresour. Technol. 2008, 99, 7402–7406. [Google Scholar] [CrossRef]

- Akgül, M.; Güler, C.; Üner, B. Opportunities in utilization of agricultural residues in bio-composite production: Corn stalk (Zea mays indurata Sturt) and oak wood (Quercus Robur L.) fiber in medium density fiberboard. Afr. J. Biotechnol. 2010, 9, 5090–5098. [Google Scholar]

- Baharoglu, M.; Nemli, G.; Sarı, B.; Birtürk, T.; Bardak, S. Effects of anatomical and chemical properties of wood on the quality of particleboard. Compos. B Eng. 2013, 52, 282–285. [Google Scholar] [CrossRef]

- Nemli, G.; Yıldız, S.; Gezer, E.D. The potential for using the needle litter of Scotch pine (Pinus sylvestris L.) as a raw material for particleboard manufacturing. Bioresour. Technol. 2008, 99, 6054–6058. [Google Scholar] [CrossRef] [PubMed]

- Xing, C.; Zhang, S.Y.; Deng, J.; Riedl, B.; Cloutier, A. Medium-density fiberboard performance as affected by wood fiber acidity, bulk density, and size distribution. Wood Sci. Technol. 2006, 40, 637–646. [Google Scholar] [CrossRef]

- Poblete, H.; Burgos, R. Eucalyptus nitens como materia prima para tableros de partículas. Maderas. Cienc. Tecnol. 2010, 12, 25–35. [Google Scholar] [CrossRef][Green Version]

- Park, B.D.; Kim, Y.S.; Riedl, B. Effect of wood-fiber characteristics on medium density fiberboard (MDF) performance. Korean Wood Sci. Technol. 2001, 29, 27–35. [Google Scholar]

- Stefke, B.; Dunky, M. Catalytic influence of wood on the hardening behavior of formaldehyde-based resin adhesives used for wood-based panels. J. Adhes. Sci. Technol. 2006, 20, 761–785. [Google Scholar] [CrossRef]

| Properties | Unit | Value |

|---|---|---|

| Appearance | Clear to white liquid | |

| Solids content | (%) | 67.00 ± 1.00 |

| Specific Gravity | (kg·m–3) | 1.305 ± 0.010 |

| Viscosity | cPs | 335 ± 75 |

| pH @ 25 °C | 8.20 ± 0.20 | |

| Buffer capacity | mL | 11.5 ± 3.0 |

| Storage life 25 °C (77 °F) | Days | 21 |

| Type of Panel | Raw Material (%) | |

|---|---|---|

| Wood Fibers (WF) | A. durangensis Bagasse Fibers (ADBF) | |

| MDFC | 100 | 0 |

| MDF10 | 90 | 10 |

| MDF30 | 70 | 30 |

| Test | Symbol | Size (mm) | Samples per Panel | Samples per Type of Panel |

|---|---|---|---|---|

| Water absorption after 2 h | WA2h | 150 × 150 | 4 | 12 |

| Water absorption after 24 h | WA2h | |||

| Thickness swell 2 h | TS2h | |||

| Thickness swell 24 h | TS24h | |||

| Internal bond | IB | 50 × 50 | 6 | 18 |

| Modulus of elasticity | MOE | 75 × 339 | 6 | 18 |

| Modulus of rupture | MOR |

| Type of Density | p Value |

|---|---|

| Average | 0.4565 |

| Maximum | 3.08 × 10−7 * |

| Minimum | 0.0268 * |

| Property | p Value |

|---|---|

| WA2h | 1.29 × 10−6 * |

| WA24h | 0.000269 * |

| TS2h | 0.000162 * |

| TS24h | 1.05 × 10−5 * |

| WA2h | WA24h | TS2h | TS24h | ||

|---|---|---|---|---|---|

| MDFC | Correlation | −0.3007 | −0.1049 | 0.2098 | 0.1049 |

| Significance | 0.34 | 0.75 | 0.51 | 0.75 | |

| MDF10 | Correlation | −0.0403 | 0.2134 | −0.4775 | −0.312 |

| Significance | 0.90 | 0.51 | 0.12 | 0.32 | |

| MDF30 | Correlation | 0.5412 | 0.6124 * | 0.3434 | 0.3272 |

| Significance | 0.07 | 0.03 | 0.27 | 0.30 |

| Test | Average Density | Maximum Density | Minimum Density | |

|---|---|---|---|---|

| MDFC | Correlation | −0.149 | 0.027 | 0.181 |

| Significance | 0.56 | 0.91 | 0.47 | |

| MDF10 | Correlation | 0.425 | 0.290 | 0.286 |

| Significance | 0.08 | 0.24 | 0.25 | |

| MDF30 | Correlation | −0.005 | 0.147 | 0.234 |

| Significance | 0.98 | 0.56 | 0.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreno-Anguiano, O.; Cloutier, A.; Rutiaga-Quiñones, J.G.; Wehenkel, C.; Rosales-Serna, R.; Rebolledo, P.; Hernández-Pacheco, C.E.; Carrillo-Parra, A. Use of Agave durangensis Bagasse Fibers in the Production of Wood-Based Medium Density Fiberboard (MDF). Forests 2022, 13, 271. https://doi.org/10.3390/f13020271

Moreno-Anguiano O, Cloutier A, Rutiaga-Quiñones JG, Wehenkel C, Rosales-Serna R, Rebolledo P, Hernández-Pacheco CE, Carrillo-Parra A. Use of Agave durangensis Bagasse Fibers in the Production of Wood-Based Medium Density Fiberboard (MDF). Forests. 2022; 13(2):271. https://doi.org/10.3390/f13020271

Chicago/Turabian StyleMoreno-Anguiano, Oswaldo, Alain Cloutier, José Guadalupe Rutiaga-Quiñones, Christian Wehenkel, Rigoberto Rosales-Serna, Pamela Rebolledo, Claudia E. Hernández-Pacheco, and Artemio Carrillo-Parra. 2022. "Use of Agave durangensis Bagasse Fibers in the Production of Wood-Based Medium Density Fiberboard (MDF)" Forests 13, no. 2: 271. https://doi.org/10.3390/f13020271

APA StyleMoreno-Anguiano, O., Cloutier, A., Rutiaga-Quiñones, J. G., Wehenkel, C., Rosales-Serna, R., Rebolledo, P., Hernández-Pacheco, C. E., & Carrillo-Parra, A. (2022). Use of Agave durangensis Bagasse Fibers in the Production of Wood-Based Medium Density Fiberboard (MDF). Forests, 13(2), 271. https://doi.org/10.3390/f13020271