1. Introduction

Burning wood as an energy source, for heating, cooking, lighting, and pottery, is an ancient and primitive practice. The practice declined in most developed nations when fossil fuel was discovered in the 1900s [

1]. Today, burning fuelwood (firewood and charcoal) for heating and cooking is a cheap necessity and widely applied in developing countries [

2]. For instance, 85% of the population of Papua New Guinea (PNG) depends on fuelwood [

3]. About 90% of fuelwood is used in tropical countries [

4], while a 60 to 80% share of wood consumption is fuelwood in the developing world [

2]. Furthermore, about 53% of wood was consumed worldwide for energy over the past 17 years [

5]. A recent report [

6] highlights that 21% of energy consumption was derived from renewable sources in 2020 in the U.S. Globally, the total energy generation from renewable sources (biomass) increased in 2020 (7%) and 2021 (8.3%) [

7]. In addition, another article [

8] reported a 9.7% rise in renewable energy (including biofuels) worldwide in 2020. It is projected that 18% of the world’s energy consumption will be sourced from wood by 2050 [

9]. Moreover, more than half the world’s population relies on forest biomass for energy [

10]. Furthermore, a population of 2.7 billion will rely on biomass energy by 2030 [

11]. Apart from household needs (heating and cooking), a substantial share of fuelwood is consumed by agri-industries for curing their products [

1].

Presently, global demand for fossil fuel-derived energy is increasing due to the growing population and industrialization. By 2040, energy demand will rise by 30% [

12]. However, the issue with burning fossil fuels for energy is that it is linked with the emission of greenhouse gas (GHG) and environmental degradation. Environmental issues, as well as limited natural oil reserves and high costs of petroleum products, have triggered interest in ‘green energy’ [

13,

14,

15]. The focus is on renewable energy, and forest biomass is identified as a potential bio-energy source [

16]. Biomass, the fourth largest contributor of bio-energy [

12], has the advantages of being renewable and sustainable, abundantly available, and environmentally benign [

17]. Furthermore, biomass has low embodied energy and is cost effective [

1], technically feasible, and economically viable [

18]. Currently, the industrial bio-energy market is increasing in Europe and the U.S., and Eastern Europe biomass industries are manufacturing millions of tons of wood pellets to supply the market [

19]. Additionally, South Korea is subsidizing forest biomass for renewable energy [

19]. Meanwhile, Australia intends to supply the European energy market with 15,000 tons of charcoal briquettes made from eucalyptus [

20]. In PNG, industrial conversion of forest biomass into energy products is non-existent although there is a potential to utilize the vast forest resource and tap into international renewable energy markets. As far as GHG is concerned, biomass combustion releases carbon which has a similar effect as carbon emitted from fossil fuels [

21,

22]. Comparatively, the carbon released from burning biomass is lower than fossil fuels [

23,

24]. For example, burning 1.0 t of biomass generates 1.5 t of CO

2, on average [

18]. Furthermore, IRENA [

25] reported that 36.9 Gt of CO

2 was released in 2017. Additionally, Yoshida et al. [

26] compared the CO

2 emitted from burning biomass with conventional fuels, such as biomass (10 g C MJ

−1), gasoline (150 g C MJ

−1), and diesel (140 g C MJ

−1). Moreover, bio-energy advocators assert that carbon emission from biomass combustion is absorbed by growing trees and the process is ‘carbon neutral’ with zero-net carbon emission [

22]. However, many environmental scientists argue that the carbon neutrality concept is erroneous, misleading, and could destabilize the climate [

22,

27,

28,

29,

30].

Combustion characteristics vary significantly within and between timber species. These are attributed to the heterogeneous physical nature and chemical composition of wood. For instance, wood density and chemical constituents, e.g., high carbon content, lignin content, and extractives, affect heating values [

31,

32,

33,

34,

35]. In addition, high density woods with long fibers and thick cell walls, low holocellulose, and high extractive and lignin contents, have high heating values and, thus, are potential materials for bioenergy [

36]. Comparatively, resinous softwoods yield higher heating values than hardwoods [

33,

37,

38]. Furthermore, wood’s hygroscopic nature, moisture content, temperature, and structural features influence combustion and flammability [

37,

39]. After the combustion of biomass, the remains are ash content. Ash content, the mass of the biomass material that remains after high temperature burning in the presence of oxygen, is expressed as a percentage of the moisture-free weight of the wood [

1]. It is expressed that ash content is an important parameter that determines calorific value [

40]. High ash content reduces the effect of fuel quality and affects the efficiency of the combustion process. Furthermore, the properties of biomass to consider during the processing of energy are calorific value, proportions of carbon and volatiles, ash content, alkali metal content, and cellulose/lignin ratio [

41].

Globally, combustion characteristics of various forest species are studied extensively for their fuelwood potential. For the categorizing of a species for its potentiality as fuelwood, Johnathan et al. [

40] stated a 20.0 kJ/g heat calorific value as a standard. The authors [

40] reported 21.7 kJ/g (as average heating values) for 31 PNG species, and recommended potential fuelwoods. In addition, species with fuelwood potentials have been selectively cultivated in woodlots and plantations to provide feedstocks for the biofuel industry around the world. For instance, in Poland, three species are managed on a short rotation plantation for bio-energy [

42]. Brazil has the world’s largest Eucalyptus plantation devoted to bio-energy [

11]; India launched 600,000 ha of biofuel plantations on wastelands from 2004–2005 [

43]; and in Sri Lanka, a plantation (101.6 ha) was tried with 12 different species for fuelwood [

44]. Meanwhile, in PNG, a bio-energy project has established a 2400 ha plantation (as of 2018) of

Eucalyptus pellita and

Acacia spp. for electricity generation [

45] and is anticipated to secure 22,000 ha on a long-term basis [

46]. Additionally, small business opportunities were identified in charcoal production from short-rotation agroforestry practices in PNG [

47].

Technologies are available to convert biomass residues/wastes from primary industries for biofuel products [

48]. Agroforestry residues include shavings, slabs, sawdust, and off-cuts from forest industries [

49]. Meanwhile, rice and wheat husks, kernels, and palm oil wastes from agricultural industries [

50,

51,

52,

53] are prime raw materials for biofuels. These feedstocks are converted into biofuel products (charcoal, briquettes, pellets, and biogas) using modern technological processes, e.g., combustion, carbonization, pyrolysis, gasification, fermentation, biochemical, and transesterification [

34,

54]. Prior to their conversion into biofuels, pre-treatments (defiberization, densification, pelletizing, and torrefaction) are carried out to improve biomass characteristics and, hence, increase heat energy output [

34,

54]. In this case, solid materials are reduced to fine particles, dried, solidified into pellets, and torrified [

54,

55,

56,

57]. Furthermore, advanced technologies are adopted for the production of biofuel liquids on industrial scales, e.g., the fermentation of sugarcane wastes for bioethanol [

58]. Globally, Brazil is the largest bioethanol producer after the U.S. [

59]. Additionally, vegetable oils derived from plant seed kernels [

60,

61] are converted into biodiesel through transesterification for energy source [

62,

63,

64,

65,

66,

67].

This case study examines the combustion characteristics of a plantation-grown Araucaria cunninghamii Ait., and the natural hardwoods Intsia bijuga Kuntze. and Pometia pinnata Forst. The specific objectives were to:

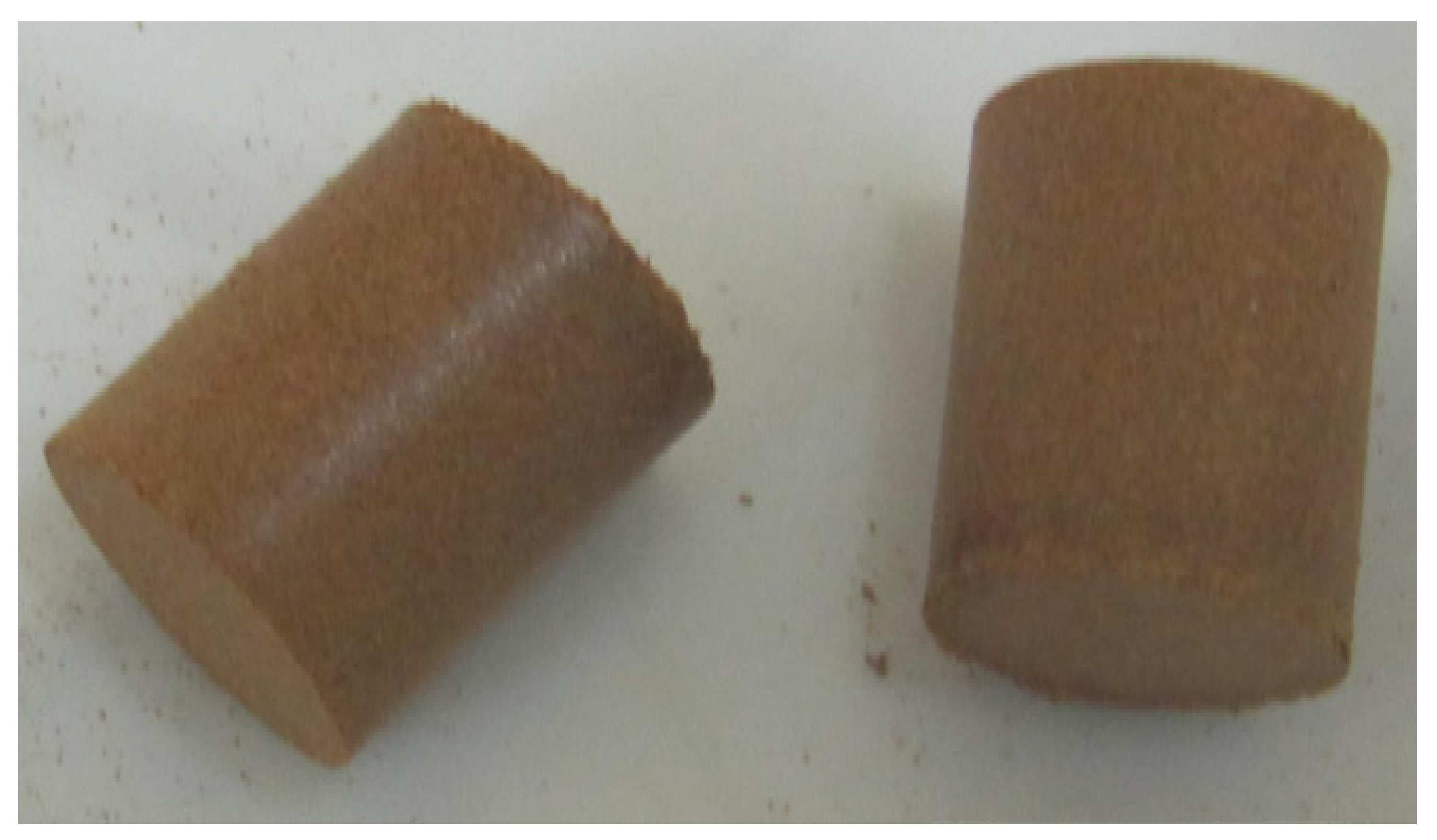

make a comparative assessment of the heat energy outputs between the sawdust pellets and solid woods, and analyze the ash contents of the sawdust pellets.

make recommendations on the potential of the species for fuelwood.

The three test species selected for the combustion experiment were based on their commercial importance and local end uses. Presently, the state (PNG Forest Authority) manages 12,000 ha of Araucaria cunninghamii plantation that provides an important feedstock for the plywood-making industry. Alternatively, Intsia bijuga and Pometia pinnata are valuable species found in lowland forest and are sought by processing industries (sawmills) for sawn timber production. The sawn boards are then seasoned and processed for decorative and structural constructions. In many rural communities of PNG, these species are extracted and utilized for traditional constructions as well as fuelwood for energy.

4. Conclusions and Recommendations

The combustion characteristics, in terms of heat energy outputs and ash contents, varied markedly between the sawdust pellets (treatment) and solid woods (control) of the three test species (Araucaria cunninghamii, Intsia bijuga, and Pometia piñata). Comparatively, the treatment specimens of A. cunninghamii generated a higher heat calorific value than the control specimens. On the other hand, the treatment specimens of I. bijuga and P. pinnata yielded lower heat energies than their control specimens. In this case, the solid woods (control) of I. bijuga and P. pinnata produced higher heat energies than the sawdust pellets (treatment). According to the ash content analysis, high ash remains were observed for A. cunninghamii, followed by P. pinnata and I. bijuga. The variations in combustion characteristics were attributed to physical (specimen dimensions, volumes, and oven-dry densities) and chemical (extractives) properties, as well as the hand-held pelletizing device used for solidifying the test specimens.

As far as fuelwood potentiality is concerned, the treatment specimens of the three species could not meet the standard heat energy requirement (20.0 kJ/g) and, therefore, were unsuitable as fuelwoods. An exception was the control specimens of P. pinnata that produced an equivalent heat calorific value and, thus, this species could hold potential for fuelwood.

For similar studies that include other native species in future, this work recommends the use of test specimens (sawdust and solid wood) with uniform dimensions and mass (uniform volume and density), for assessing the combustion characteristics. In addition, the use of an advanced mechanized (standard) device, for pelletizing the sawdust particles for solidifying (densification), is highly desirable.