1. Introduction

The use of radiata pine (

Pinus radiata D. Don) in establishing new forests was a very important and sometimes obligatory choice, due to the species’ characteristics as a fast-growing tree that is able to satisfy the growing demand for wood products and forest services. The worldwide diffusion of this forest species exceeds four million hectares, and it is widely present in Australia, Chile, New Zealand, and Spain [

1]. In Italy, radiata pine plantations have been established since the late 1970s, mainly in the southern part of Italy, where the Mediterranean climate conditions, with mild winters and relatively cool and humid summers, are the most suitable for the species [

2]. At the beginning of the 1980s, the surface of pine plantations in Italy was about 25,000 hectares, almost half of which was in Sardinia, the second largest Italian island, with marked Mediterranean environmental conditions [

3]. In the same years, the first studies on the working productivities and costs of thinning operations began on plantations established previously in Central Italy [

4,

5]. In recent decades, the area has been reduced due to exploitation without the replacement of old plantations, and to wildfires, which explains the most recent area estimate by the National Forest Inventory [

6] of about 3000 ha of radiata pine plantations, restricted to Sardinia.

In Sardinia, radiata pine has been planted as a fast-growing species in areas generally little covered by forest and not very affected by grazing. Despite intensive interventions with mechanical equipment for site preparation (ripping and ploughing of the soil), this did not spare the native vegetation, which was present at that time mostly as shrubs or small trees [

7]. Even today, the main problem involves limiting soil degradation by maintaining forest cover as much as possible and controlling fires [

8]. Originally, the plantations were set up with an important public financial contribution, which generally favored local socio-economic developments with a large-scale employment of people.

The main objective of these plantations was to supply raw material to the pulp and paper industry that was developing in Sardinia on the central-eastern coast of the locality of Arbatax (municipality of Tortolì, Nuoro province). The failure of this industrial project at the end of the last century made the destination of plantation timber more uncertain, and now with the planted radiata pines having reached economic maturity, the future of the plantations is an issue of public debate. The Regional Forest Agency for Land and Environment of Sardinia (FoReSTAS) is now looking to the future. This is being achieved by associating traditional forest interventions with innovative actions carried out in the managed public forests to reduce forest degradation and increasing its most significant multiple functions [

9].

More generally, forest plantations should be considered for their potential social benefits, ecosystem effects, and carbon sequestration. The direct and indirect benefits are provided by ecosystem services that originate from the presence of forest plantations in an area. The development of local timber transforming economies, as well as environmental aspects (landscape, biodiversity, carbon sequestration, water quality, and soil erosion) represent new challenges for forest managers [

10]. On the other hand, plantations of introduced (non-native) forest species can have negative impacts, such as a low resilience to biotic and abiotic disturbances, and they have gained a negative public image when these were ignored. Nowadays, foresters are faced with the need to ensure wider benefits from forest plantations, minimizing negative effects, and the management of plantations in order to balance social, cultural, environmental, and economic values [

11].

The main issue behind this study is the sustainability of management in radiata pine plantations of an area in inland Sardinia, by integrating ecological aspects with socio-economic constraints and opportunities. Radiata pine plantations are definitely artificial systems and relatively simplified forest stands, being even-aged and with poor specific and structural diversity. From another perspective, though, older plantations contain large, fast-growing, long-lived trees that interact in different ways with the environment and that can respond to disturbances as resilient ecosystems maintaining stability over time [

1]. Typical radiata pine plantations management provides clearfelling after one or more thinnings, to ensure that only trees of good shape and vigor are left to grow to become more valuable as timber. On the contrary, natural pine regeneration is rarely employed in plantations.

A key management goal for silvicultural decisions in Mediterranean conditions is to maintain a continuous forest cover on the soil surface to limit soil erosion and impoverishment [

12], as well as the economic feasibility of forest interventions. As harvesting operations in intensive plantations and the removal of mature trees cause dramatic changes to soil conditions and the microclimate, the study deals with management practices (thinning and regeneration cuttings) that reduce damage to the soil by fostering a continuous cover forestry (CCF) approach [

13]. The CCF silvicultural system rejects clear-felling by accepting cost penalties and provides more diverse forests for multi-purpose benefits [

14,

15]. Up to now, little experience has been gained on this issue for the Mediterranean parts of Italy. In this research, the costs and incomes of two different thinning methods and an improvement cutting of the type of regeneration cutting following CCF principles, have been analyzed. The evaluation was obtained considering the conditions of most radiata pine plantations, which now allow both thinnings, to concentrate on the growth potential of the site and the natural regeneration of the pines. In Mediterranean countries, the natural regeneration of radiata pine through silvicultural operations might be a more sustainable way to foster the gradual establishment of native forest species by avoiding the negative ecological effects of clearfelling, as long as these operations represent an environmentally, socially, and economically valuable choice.

2. Materials and Methods

The study was carried out in the forest complex of Monte Idòlo (Arzana municipality, province of Nuoro) at the localities “Su Pradu” and “Sa es corriasa” (Lat 39.908576°, Lon 9.514198°), on nearly flat plains (9% slope), at an altitude of 880 m a.s.l., with soils of medium depth and diffuse stoniness. Radiata pine was planted 45 years ago with an original distance between plants of 2 × 2 or 2 × 3 m, which changed to 5 × 5 or 6 × 5 m after thinning at the beginning of this century.

Since the forest cover is characterized by the dominance of the allochthonous radiata pine, and in the undergrowth, only by a sparse layer of other native tree species, the general objective of the management was to enhance the regeneration processes with silvicultural interventions and the assessment of environmental conditions and socio-economic needs, derived also from the local demand for timber. The maximization of timber production depends not only on the management of the site’s resources, but above all, on the intensity of the interventions applied [

16,

17,

18,

19]. The study compares two types of thinning with a regeneration system based on CCF principles [

20], with the aim of not only reducing tree density and improving the quality and growth of the remaining trees [

21], but also to assess their economic impact in terms of salable wood production. Three test areas were established (

Figure S1), each of approximately 0.3 hectare, to compare:

Systematic thinning (SYT), with the felling of one out of three rows in the plantation, which corresponds to a reduction of about 30% of the total wood mass of the stand, without considering the characteristics of the individual trees, aiming to create sufficient light conditions to favor the natural regeneration process;

Selective thinning (SET), with a similar reduction in the overall mass, focusing on the best trees of the stand (assuming as the criteria stem quality, tree vitality, and the effect of removal on the competition of remaining trees); subsequent felling of competitive codominant and suppressed trees, as in the case of crown thinning, which also encourages the natural regeneration process by improving light conditions without interrupting the forest cover;

Regeneration felling (REF), choosing groups of plants to be felled around an existing gap supporting the natural regeneration process to spread centrifugally around the gap under conditions of full light or slight shade on the margins of tree crowns; in this case, the felling started from small groups of existing regeneration of radiata pine, which in the area presents a remarkable capacity of regrowth from seeds dispersed by the wind on the bare soil; as the felling reduced the mass of the stand by about 40%, particular attention was paid to maintain soil protection by limiting open surface extension and shaping margins irregularly according to local site terrain morphology.

An analysis of forest regeneration and the vegetation of the undergrowth was performed using the point-centered quarter (PCQ) method before tree felling, in the test areas and in an area for reference, with the purpose of analyzing the initial conditions of the stand, and with the intention to repeat the analysis after some years after sylvicultural operations. An assessment of the tree layer species (diameter at breast height (DBH) above 3 cm), forest regeneration layer species (tree species with DBH below 3 cm), and shrub layer species was carried out on a transect placed on the midline of the test area, comprising five randomly established sample points (

Figure S2). Tree and shrub species were defined, taking into consideration the habit growth form, and following the national forest inventory list, which includes 263 Italian woody plants [

6]. The PCQ method is widely used to study forest structure and the importance (density) of species in the forest stand [

22,

23].

The forest extraction conditions of the area were favorable for adopting advanced forest mechanization [

24,

25]. A full-tree harvesting method was applied in all observed forest interventions [

26]. In fact, in the late summer of 2019, the fellings were carried out by a crew of four skilled workers using Stihl 260 (3.2 kW) chainsaws, the extraction of whole trees was carried out using a tractor (84 kW) equipped with a DH70 winch, and finally, on the forest landing, processing was performed using a Kamo Euromach 125R processor (125 kW), with a Konrad Woody 50 processor head.

For the economic evaluation, aimed at analyzing the convenience of the three treatments, the hourly cost of all the machines and equipment was considered. For this purpose, the analytical calculation method proposed by Miyata [

27] was applied.

Table S1 shows the main elements considered for the calculation of the machine hourly cost.

For each of the three working operations (felling, wood extraction, and processing) the hourly cost of the forest yard was determined, including the cost of the machines, equipment, and labor.

Table 1 summarizes the composition of work yard for each type of treatment.

On the basis of the dendrometric data of the plantations, of the felled trees, and of the working times recorded directly in the cutting area, it was possible to calculate the work productivity in the three sites, and subsequently, the cost per ton and per hectare.

The productive working time was measured with the aid of a chronometric table in centesimal minutes. The overall times of felling with a chainsaw, extraction of the whole trees, and wood processing in the forest landing were considered. The productive working time also included the unproductive time of each operator and the downtime due to breakdowns, considering delays of up to 15 min [

28,

29,

30,

31,

32].

The observed data were subjected to statistical processing aimed at highlighting the characteristics of the distributions, and the differences between the variables considered. The dataset was used to build general models for estimating the productive working time, working productivity, costs, and profit for each of the three management treatments (SYT, SET, and REF), aimed at the final comparison in terms of economic convenience.

Three types of interpolation equations were considered (power, polynomial and logarithmic), chosen each time based on the criterion of the highest corrected coefficient of determination of the regressions. The final models for the overall evaluation of the three types of treatments were obtained in three steps. The first step involved identifying the most suitable data interpolation model for each treatment and forest operation to estimate the productive working time (PT), working productivity (PH), cost per ton (CT), and cost per hectare (CHA) as a function of the variation in the weight of the felled and processed tree (felling and processing operations), or load of extracted wood (wood extraction operation). The second step involved the determination of a second dataset obtained by adding the values returned by the application of the equations resulting from the first step and applied to the felling, extraction, and processing operations, distinct for each treatment. For estimating the overall productivity of the three forestry yards, it was not possible to proceed in the same way, but in this specific case, the data obtained by applying the following formula were interpolated [

33]:

where:

PH is the working productivity (in tons per hour), W is the weight of the felled and processed tree, or of the load of wood extracted (in tons), PT is the productive working time (in minutes per tree or load) obtained in the first step, and 60 is the conversion factor of the minutes in hours.

Finally, the third step involved the construction of a third dataset obtained by applying the most performing regression models of the second step dataset. The result is represented by the comparison of the three types of treatment in relation to the curves of the variables PT, PH, CT, and CHA, as a function of the respective variation of the weight of the processed wood.

To express a comparative judgment on the economic convenience of the three treatments, a partial economic balance of the three interventions was carried out by considering the revenues deriving from the sale of the wood assortments obtained from the three different treatments. The average prices of EUR 70 t−1 for saw logs, EUR 38 t−1 for firewood, and EUR 26 t−1 for wood chips, taken from a market survey of the local pine timber trade, were considered in the analysis. In addition to the direct costs of felling, wood extraction and processing, calculated from the forecast cost models, indirect costs were also considered, estimating them at approximately 15% of the direct costs, to cover overheads, management, administrative supervision, interest, and taxes.

In relation to the possible obtainable revenues, predictive models were determined considering the dataset of the value of the single tree as a function of the percentage of timber destined for saw logs, firewood, and wood chips. Based on the dataset accounting for differences between revenues from the sale of the assortment and costs, the final predictive models of business profit or loss for the three treatments were built.

Statistical analysis was performed using the SPSS (PASW Statistics 18) and R (version 4.1.1) packages. The characteristics of the experimental data distributions were highlighted by performing the Shapiro–Wilk test for normality and the Levene test for homogeneity of variance. The Kruskal–Wallis non-parametric H test and the subsequent comparison of homogeneous subsets was carried out.

3. Results

The undergrowth of radiata pine plantations analyzed through the PCQ method (

Table 2) shows the highest absolute density for holm oak (

Quercus ilex), with 3351 plantlets/ha in the regeneration layer (tree species with DBH below 3 cm), followed by pine (1139 plantlets ha

−1) and cherry tree (

Prunus avium, 536 plantlets ha

−1). With a relative density of 62.5 and a relative frequency of 50, holm oak occurs homogeneously in the sample points and number of quarters. With lower absolute densities, the other species showed a similar distribution. In the shrub layer, where shrub habit growth form species were recorded, the absolute densities are lower, with

Prunus spinosa having the maximum absolute density of 203 plantlets ha

−1.

Holm oak is a shade-tolerant species that was observed to regenerate under the canopy of pines, and to occur as “advance regeneration” in the area (

Figure S3a), whereas the light-demanding radiata pine requires very light canopies or small gaps for the establishment of seedlings (

Figure S3b). A more detailed analysis on the extent of natural forest regeneration following the sylvicultural operations carried out in the study is expected for the near future.

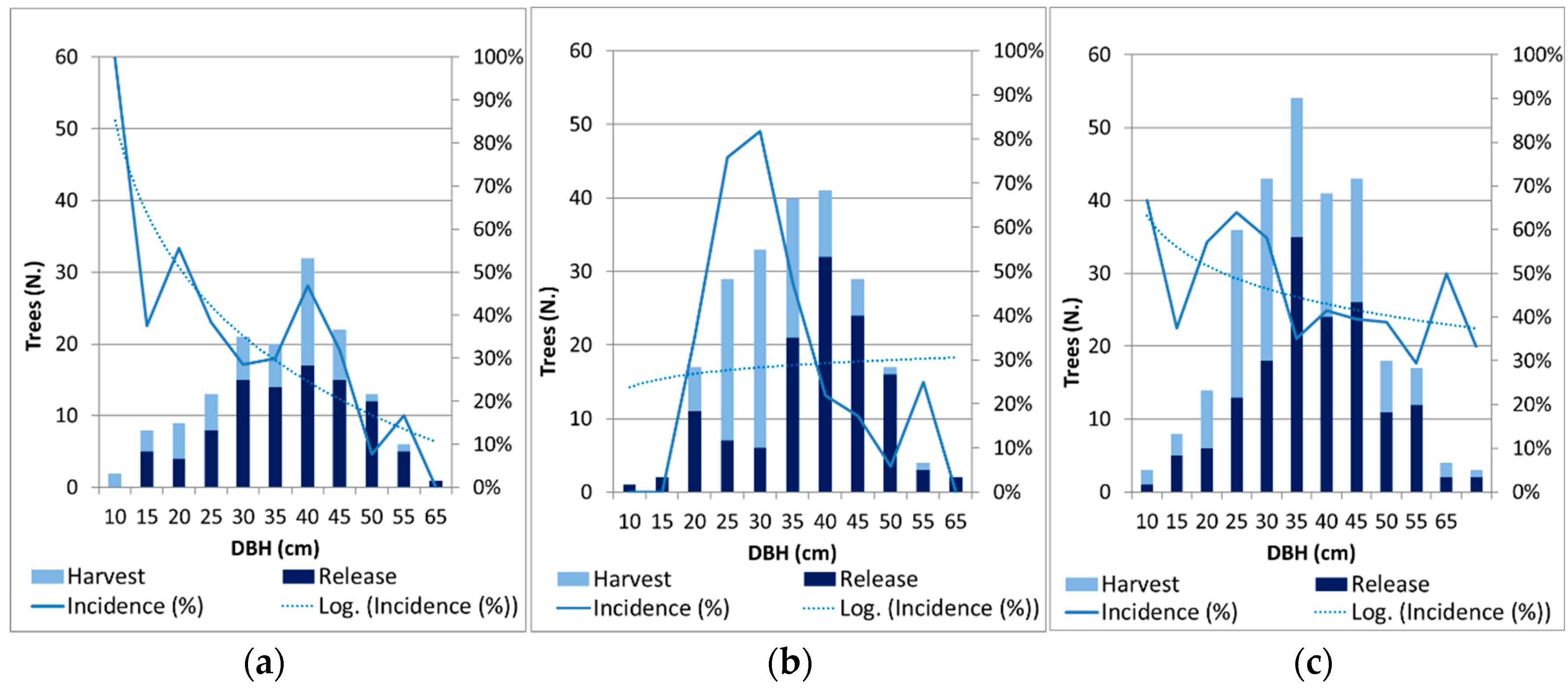

The impact of harvesting operations on the number of trees and diameter distributions varies depending on the silvicultural intervention (

Figure 1). By systematic thinning, trees of mainly small to middle size classes (DBH below 30–40 cm) were felled, maintaining a general distribution of diameter classes in the stand that was similar to the initial conditions. On the contrary, the selective thinning of harvested trees mainly in the middle-diameter classes (DBH 25–35 cm) stand maintained a higher frequency of wider-diameter classes. With the regeneration felling, a similar number of trees were harvested, in relation to their frequency in each diameter class.

Table 3 shows the results of field observations in relation to yield and productivity achieved during the harvesting operations. Felled trees were less than half in systematic thinning compared to those of regeneration felling (50 vs. 128 trees), with consequent lower productive working times (e.g., for felling, 40.66 vs. 83.55 h ha

−1). The yield for thinning operations was about half of that for regeneration felling (220–235 vs. 405 t ha

−1). Working productivity in the felling and extraction phases was highest for systematic thinning, and in the processing phase for regeneration felling.

Statistically significant differences (p < 0.05) between treatments were found in relation to most of the considered variables. In the graphic representations, these differences are highlighted with different letters.

Figure S4 shows the box plots relating to the weight of the trees, the loads transported per wood extraction cycle (

Figure S4a), and the assortments of timber obtained per tree (

Figure S4b). A statistically significant difference between the three treatments was highlighted in the tree weight, but not in the load transported, while the distances were similar for SET and REF, but greater than those for SYT.

There was a statistically significant difference in saw log production per tree between the three treatments, with higher values for SYT, then REF and SET. For firewood, a higher weight per tree was achieved for SET than the other two, which have a similar weight. In the production of wood chips, SYT and REF are similar, while the SET value is lower. The overall sawlogs production was higher for SYT (83%), compared to the intermediate value of REF (81%) and the lowest value of SET (73%). For firewood, the highest percentage was found for SET (20%), compared to REF (12%) and SYT (10%). Wood chips were almost similar in the three treatments (about 7%). In

Figure S5, the box plots relating to the three treatments have been elaborated with reference to the productive working time (in min per tree or per load) (

Figure S5a) and working productivity (in tons per hour) (

Figure S5b). The time consumption was significantly different between SYT, SET, and REF in felling and processing, with times generally being higher for SYT than for the others, while SET was the lowest in felling and intermediate in processing. In the wood extraction, SYT showed the shorter time, while SET has lower productivity than in the others.

As for the cost per ton of wood, SYT showed the lowest cost, together with REF in the felling operation, while it was higher in processing. The extrapolation of the costs per hectare showed the highest felling costs for REF, while SYT had the lowest values in the processing and extraction operations.

Figure S6 shows the distributions of the cost per ton (

Figure S6a) and per hectare (

Figure S6b), taking into account that the hourly cost of the forest yard was equal to EUR 36.96 h

−1 to carry out both felling and processing with a chainsaw, while the cost of processing using the processor was EUR 79.96 h

−1, ending with the cost of EUR 89.30 h

−1 for extracting the wood, referring to the team of workers and a tractor with a winch. For each worker employed, the rate used was EUR 15.00 h

−1.

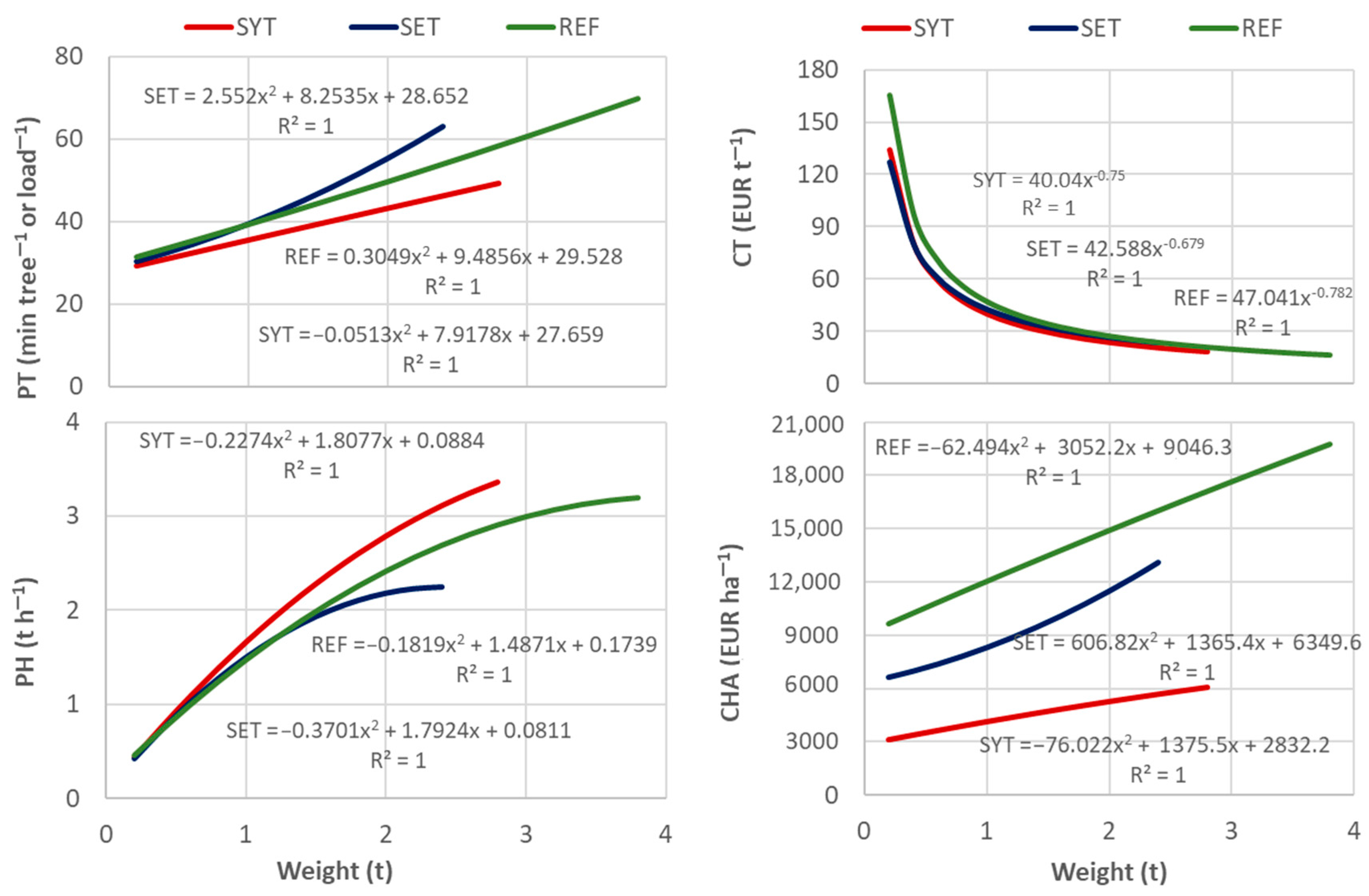

The experimental dataset was used for the elaboration of predictive models for each variable (PT, PH, CT, and CHA) in referring to the three forest operations (felling, extraction, and processing) and to the three treatments (SYT, SET, and REF). The equations for estimating the variables as a function of the weight (per tree or per load), with the relative determination coefficients, are shown in

Table S2 (step 1). A new dataset was built from the sum of the values obtained by the equations referring to the operations (step 2), on which the equations that best fitted the data relating to the three treatments as a function of the weight were determined (step 3).

The graphs resulting from the application of the general equations referring to the total forest logging for the three treatments are shown in

Figure 2.

The developed forecast models show that, with the same amount of processed wood, SYT requires less time than the other two treatments, and this difference is greater as the weight of the processed wood increases. The productive working time (PT) is quite similar for SET and REF up to weights of slightly higher than one ton, while for higher weights, the difference increases with higher values for SET. The trend of the working time curves negatively affects working productivity, which therefore is greater in SYT than in the other two. The productivity of REF becomes greater than that of SET for weights greater than one ton.

The evaluation of the economic sustainability of the interventions is carried out by examining the cost estimation models, represented in all cases by power curves. In general, therefore, the overall cost per ton tends to decrease as the weight of the wood processed increases. The differences between the three treatments are more evident for low weights, with higher costs for REF compared to SYT and SET. These differences tend to reduce as the weight increases. At their respective maximum weights, the lowest costs are estimated for REF (EUR 17 t−1), followed by SYT (EUR 19 t−1) and SET (EUR 24 t−1).

The cost per hectare models return values that increase as the weight increases, with well-spaced and non-overlapping curves. This trend is determined not only by the unit cost trend, but also by the different levels of wood production in the three treatments, which are much higher in REF than in SET and SYT. The range of values estimated by the model range from EUR 9600 to EUR 19,700 ha−1 for REF, and from EUR 6600 to EUR 13,100 ha−1 for SET, whereas the lowest costs were for SYT, ranging from EUR 3100 to EUR 6000 ha−1.

A partial economic balance of the interventions was carried out, considering the difference between the total revenues from the sale of the different wood assortments for the three treatments and the total costs (direct and indirect costs). The models, with relative equations, to estimate the trend of the company’s loss or profit as a function of the tree weight, are shown in

Figure 3.

For all of the treatments, the profit tends to increase with the increase in the weight of the processed trees. This increase is greater for REF than for SET and SYT. For average tree weights of less than 0.56, 0.48, and 0.40 tons, respectively, the profits are transformed into losses so that the three operations become uneconomical.

Table 4 reports the results of the application of the models for estimating the cost per ton of processed wood for each operation (applying the equations of

Table S2), and for the yard (applying the equations of

Figure 2), calculated in correspondence with the average weight of the tree in the three treatments. By entering the respective average weight of each treatment in the predictive models, the highest overall cost per ton is attributed to selective thinning (EUR 48.33 t

−1), followed by the regeneration felling (EUR 43.35 t

−1), while the lowest cost is obtained with systematic thinning (EUR 32.33 t

−1). The imperfect correspondence between the yard cost and the sum of the cost of each operation is precisely due to the fact that these values are obtained by applying two estimation models (respectively, the step 2 and step 1 models).

Table 5, on the other hand, reports the cost, revenue, and profit values per hectare returned by the estimation models in reference to the average weight of the trees for the three treatments.

In terms of total cost per hectare, REF has the highest logging costs (EUR 14,211 ha−1), followed by selective thinning (EUR 9086 ha−1) and systematic thinning (EUR 5206 ha−1). The strong difference (+56% compared to SET and +173% compared to SYT), is largely due to the greater amount of woody biomass removed per hectare in the REF compared to the other two treatments.

Overall, from

Table 5, a maximum economic benefit was found for the regeneration felling, for which the estimation model returns a gain of EUR 11,447 ha

−1, while in the thinning, its gain was reduced by 22% and 55% for systematic (EUR 8891 ha

−1) and selective thinning (EUR 5118 ha

−1), respectively. In any case, the application of the interventions has a positive effect in economic terms, highlighting substantial economic sustainability in carrying out the three types of silvicultural intervention.

4. Discussion

The undergrowth of the examined radiata pine plantations was dominated—in the regeneration layer—by holm oak (Quercus ilex), which represents the principal native component of the forest vegetation in the area, often mixed with other tree species such as Quercus pubescens, Phillyrea latifolia, and Arbutus unedo. The cherry tree (Prunus avium) is a species of the first phase of the ecological succession, which occurs scattered in the woods on soil with more moisture. Given the uniform distribution of holm oak regeneration highlighted by the PCQ analysis, forest management might address silvicultural operations aiming at preserving existing natural regeneration processes and improving the establishment of this species, even if at present it is insufficient to guarantee the growth of a closed forest cover for the near future. Thinning, as well as the regeneration felling that was performed during the study, will improve the microclimatic and soil requirements for holm oak seedlings by assuring the conditions of light and soil moisture for the shade-tolerant Quercus ilex.

On the other hand, holm oak and the other autochthonous tree species grow more slowly than radiata pine, which in that area was observed to regenerate naturally with vigor after the disturbance created by the forest operations. Taking into consideration as a final goal the long-term recovery of the autochthonous forest vegetation, a mixed holm oak forest with some other tree species (e.g.,

Quercus pubescens and Mediterranean sclerophyllous elements) throughout the low-productivity areas [

7], one or more cycles of naturally regenerated radiata pine formations (mixed with the outcoming regeneration of the abovementioned native species) seem to be an affordable and sustainable goal for forest management. A new radiata pine plantation would be unfeasible, due to the changed environmental, economic, and social conditions.

The environmental advantages of the CCF approach in managing radiata pine plantations in Sardinia, besides the increased use of natural regeneration, are the continuity of the forest cover, which leads to an increase in biodiversity, as well as to a greater abundance of deadwood, by releasing stumps and small branches after felling operations, and a more cautious soil protection. This can be of crucial relevance in Mediterranean areas, if compared with the often-used clear-cutting management of radiata pine plantations.

The achievement of economic convenience, due to the numerous factors inherent in silvicultural systems and the imperfections of the product market, is strongly linked to the role of forest management and to the importance of economic, social, and environmental balance. In this sense, even the policies for stimulating the supply of timber should be targeted and combined with measures that are aimed both at the productive aspects and at the conservation of forest values, biodiversity, and the landscape [

34].

In this study, starting from the dendrometric, production, and operational data referring to the three silvicultural treatments observed, the predictive models of times, productivity, and costs and profit as a function of tree weight have been developed, aimed at providing useful operational indications to be applied to silvicultural management interventions.

From an operational point of view, systematic thinning resulted in shorter overall working times for the same weight of the trees processed with a consequent higher working productivity. Regeneration felling and selective thinning result in longer working times. This is due to the greater ease of carrying out work in systematic thinning that does not require the selection of the trees to be cut, an operation that increases operating times [

35].

For a prudent approach to forest management, selective thinning focuses on the quality of the remaining trees, but precisely because a choice of trees is required, this leads to an increase in forest management costs, which translate into higher logging costs per ton of processed wood (about EUR 48 t−1), compared to systematic thinning (about EUR 32 t−1) and regeneration felling (about EUR 43 t−1). The estimation models return logging costs per hectare for the three treatments, which are always increasing as the weight of the tree processed increases, but with well-spaced curves between the different treatments. The costs of regeneration felling are always higher than those of selective and systematic thinning (respectively, by 56% and 173%). This is justified by the difficulty in carrying out the work, but above all, because the quantity of the wood processed is much higher in the regeneration felling than in the other two interventions. However, it is precisely because the production of timber per hectare is much greater in the regeneration felling that the value of the achievable assortments is about 80% higher than for the other two types of thinning. This higher revenue means that the average economic advantage (profit) is on average 124% higher than that of selective thinning, and 29% higher than that of systematic thinning. In any case, the three management options gave a positive economic advantage, which accounts for the convenience of forest operations from an economic point of view.

In the long term, selective crown thinning seeks to favor the crown development of seed trees, while ensuring that site conditions remain optimal for natural regeneration. On the contrary, starting from pre-existent natural regeneration in groups or gaps, regeneration felling focuses on quickly improving the process of establishing a new generation of trees, exploiting the ability of the radiata pine to regenerate naturally in the area. In this case, mainly due to the greater harvested wood mass, even if the costs of the intervention were higher, the value of the timber are also higher, which consequently determines a greater economic gain per hectare (the difference between the value of timber and the costs of forest operations) compared to the other two interventions.

From a social perspective, the implications related to this study deal with mitigation of the problems related to the poor perception of clear-felling, which originated from public debate in previous years in other harvested radiata pine plantation areas of Sardinia, as well as the positive environmental benefits deriving from forest formations in the inner part of the island [

36]. On the other hand, the local value chain starting from the wood produced in these plantations might have a positive impact on employment, although it is of crucial importance to strategically consider the forest management technique to be utilized, as has been highlighted in other contexts [

37]. There is also a rising recognition of the landscape and cultural values of conifer plantations in the area.

5. Conclusions

The sustainability concept is generally understood as meeting the present needs without compromising the needs of future generations. For exploited ecosystems such as forest plantations, the aim is to preserve ecosystem health and productivity by considering ecological processes and functions, and enhancing economic, social, and environmental values. In the case study observed in the internal areas of Sardinia, the high productivity of radiata pine and its natural regeneration ability, compared to the native tree species that slowly appear in the undergrowth of the plantations, facilitate the management of silvicultural systems, with economic, environmental, and social benefits, which over time could be gradually replaced by native tree species.

The effects on natural regeneration and the increase in the biodiversity of sylvicultural operations, which were carried out in the radiata pine plantation considered as a study case, can be evaluated with greater certainty in the coming years, with the ecological conditions being favorable both for the native shade-tolerant Mediterranean species (e.g., Quercus ilex) and for the introduced radiata pine. The study highlighted an economic benefit for the sylviculture operations considered. In particular, regeneration felling obtained the best results, reaching an average profit that was quantified by the proposed model to be about EUR 11,000 ha−1. Economic benefits, albeit lower, were also obtained for thinning operations, with an average profit of about EUR 9000 ha−1 for systematic thinning and about EUR 5000 ha−1 for selective thinning, mainly due to the lower production of wood compared to the regeneration felling.

Climate change and increasing frequency of pests and disturbances (wildfires) represent the main threats to the sustainability of these plantations, whereas the sensibility is higher in even-aged, homogeneous, monospecific artificial tree stands. In the short term, by contrasting these limiting factors with the natural regeneration processes of native and non-native species, continuous cover forest management strategies can help to transform the forest structure and species composition of these plantations into more resilient ecosystems.