Resin-Tapping Production in Pinus pinaster Ait. Stands in Galicia (NW Spain): Effects of Location, Number of Faces, Wound Width and Production Year

Abstract

:1. Introduction

2. Material and Methods

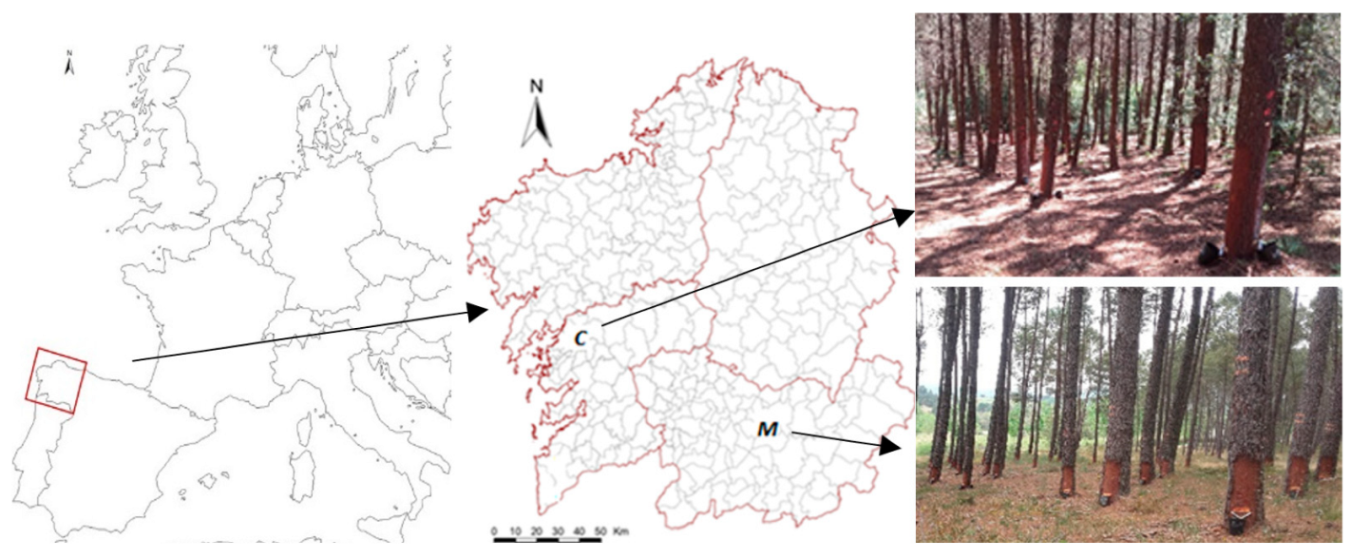

2.1. Study Area

2.2. Statistical Analysis

3. Results and Discussion

3.1. Resin Production in Three Consecutive Years

3.2. Comparative Analysis of Caldas de Reis and Maceda (Coastal and Inland Galicia) for the Same Production Years (2017 and 2018)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alía, R.; Martín, S. EUFORGEN Technical Guidelines for Genetic Conservation and Use for Maritime Pine (Pinus pinaster); International Plant Genetic Resources Institute: Rome, Italy, 2003. [Google Scholar]

- Serrada, R.; Montero, G.; Reque, J.A. Compendio de Selvicultura Aplicada en España; Instituto Nacional de Investigación y Tecnología Agraria y Alimentaria, Ministerio de Educación y Ciencia: Madrid, Spain, 2008. [Google Scholar]

- Coppen, J.J.W.; Hone, G.A. Gum Naval Stores: Turpentine and Rosin from Pine Resin; Natural Resources Institute: Gillingham, UK; FAO: Rome, Italy, 1995. [Google Scholar]

- Rodríguez-García, A.; Martín, J.A.; López, R.; Sanz, A.; Gil, L. Effect of four tapping methods on anatomical traits and resin yield in Maritime pine (Pinus pinaster Ait.). Ind. Crop. Prod. 2016, 86, 143–154. [Google Scholar] [CrossRef]

- Neis, F.A.; de Costa, F.; de Araújo, A.T.; Fett, J.P.; Fett-Neto, A.G. Multiple industrial uses of non-wood pine products. Ind. Crop. Prod. 2019, 130, 248–258. [Google Scholar] [CrossRef]

- Rodrigues-Correa, K.C.d.S.; de Lima, J.C.; Fett-Neto, A.G. Pine oleoresin: Tapping green chemicals, biofuels, food protection, and carbon sequestration from multipurpose trees. Food Energy Sci. 2012, 1, 81–93. [Google Scholar] [CrossRef]

- Cunningham, A. Pine resin tapping techniques used around the world. Pine Resin Biol. Chem. Appl. 2012, 2012, 1–8. [Google Scholar]

- Vázquez-González, C.; Zas, R.; Erbilgin, N.; Ferrenberg, S.; Rozas, V.; Sampedro, L. Resin ducts as resistance traits in conifers: Linking dendrochronology and resin based defences. Tree Physiol. 2020, 40, 1313–1326. [Google Scholar] [CrossRef]

- Rodrigues-Corrêa, K.C.d.S.; de Lima, J.C.; Fett-Neto, A.G. Oleoresins from pine: Production and industrial uses. Nat. Prod. 2013, 4037–4060. [Google Scholar] [CrossRef]

- Michavila, S.; Rodríguez-García, A.; Rubio, F.; Gil, L.; López, R. Salicylic and citric acid as promising new stimulants for resin tapping in maritime pine (Pinus pinaster Ait.). For. Syst. 2020, 29, eSC07. [Google Scholar] [CrossRef]

- Ortuño Perez, S.F.; García-Robredo, F.; Ayuga Tellez, E.; Fullana Belda, C. Effects of the crisis in the resin sector on the demography of rural municipalities in Spain. For. Syst. 2013, 22, 39–46. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-Garcia, A.; Madrigal, J.; González-Sancho, D.; Gil, L.; Guijarro, M.; Hernando, C. Can prescribed burning improve resin yield in a tapped Pinus pinaster stand? Ind. Crop. Prod. 2018, 124, 91–98. [Google Scholar] [CrossRef]

- Hernández Muñoz, L. El Antiguo Oficio de Resinero; Hoja divulgativa nº 2116; Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 2006. [Google Scholar]

- Rodríguez-García, A.; Martín, J.A.; López, R.; Mutke, S.; Pinillos, F.; Gil, L. Influence of climate variables on resin yield and secretory structures in tapped Pinus pinaster Ait. in central Spain. Agr. For. Meteorol. 2015, 202, 83–93. [Google Scholar] [CrossRef] [Green Version]

- Chamorro, E.M. Revisión de las primeras experiencias de resinación en Galicia (1950–1970). Rev. IBADER Recur. Rurais 2016, 12, 13–22. [Google Scholar] [CrossRef]

- MMAMRM (Ministerio de Medio Ambiente, Medio Rural y Marino). Cuarto Inventario Forestal Nacional, Comunidad Autónoma de Galicia; Dirección General de Medio Natural y Política Forestal, Ministerio de Medio Ambiente, Medio Rural y Marino: Madrid, Spain, 2011.

- García-Méijome, A.; Martínez Chamorro, E.; Fernández-Blanco, E.; Gómez-García, E. Análisis de producciones y rendimientos del sistema de resinación de pica de corteza con estimulación química de doble cara ancha en masas de Pinus pinaster Ait. cuyo objetivo principal es la producción de madera. Rev. IBADER Recur. Rurais 2020, 16, 5–10. [Google Scholar] [CrossRef]

- XERA (Axencia Galega da Industria Forestal). La Cadena Forestal—Madera en Galicia 2017; Consellería de Economía e Industria e Universidade de Vigo: Vigo, Spain, 2018.

- Chamorro, E.M.; Rozados Lorenzo, M.J.; García-Méijome, A.; Gómez-García, E. Adaptación del aprovechamiento resinero en masas de Pinus pinaster Ait. destinadas a la producción de madera de sierra en Galicia. Rev. Montes 2019, 137, 32–36. [Google Scholar]

- Harrington, T.A. Production of oleoresin from southern pine trees. For. Prod. J. 1969, 19, 31–36. [Google Scholar]

- García-Iruela, A.; Esteban, L.G.; de Palacios, P.; García-Fernández, F.; de Miguel Torres, A.; Vázquez Iriarte, E.; Simon, C. Resinous wood of Pinus pinaster Ait.: Physico-mechanical properties. Bioresources 2016, 11, 5230–5241. [Google Scholar] [CrossRef] [Green Version]

- Clements, R.W. Modern Gum Naval Stores Methods; Gen. Tech. Rep. SE-7; USDA Forest Service: Asheville, NC, USA, 1974. [Google Scholar]

- Génova, M.; Caminero, L.; Dochao, J. Resin tapping in Pinus pinaster: Effects on growth and response function to climate. Eur. J. For. Res. 2014, 133, 323–333. [Google Scholar] [CrossRef]

- Zas, R.; Touza, R.; Sampedro, L.; Lario, F.J.; Bustingorri, G.; Lema, M. Variation in resin flow among Maritime pine populations: Relationship with growth potential and climatic responses. For. Ecol. Manag. 2020, 474, 118351. [Google Scholar] [CrossRef]

- Pinillos, F.M.; Picardo, A.; Allué-Andrade, M. La Resina: Herramienta de Conservación de Nuestros Pinares; Cesefor, Junta de Castilla y León, Fundación Biodiversidad: Soria, Spain, 2009. [Google Scholar]

- Gómez-García, E.; Rozados Lorenzo, M.J.; Fernández-Blanco, E.; Quintairos Folgoso, A.; Martínez Chamorro, E. Instalación de ensayos para determinar las posibilidades del aprovechamiento resinero en Galicia. In Proceedings of the Actas del 7º Congreso Forestal Español, Plasencia, Extremadura, Spain, 26–30 June 2017. [Google Scholar]

- Gómez-García, E.; Martínez Chamorro, E.; García-Méijome, A.; Rozados Lorenzo, M.J. Modelling resin production distributions for Pinus pinaster Ait. stands in NW Spain. Ind. Crop. Prod. 2022, 176, 114316. [Google Scholar] [CrossRef]

- Rodríguez Soalleiro, R.; Madrigal, A. Selvicultura de Pinus pinaster Ait. subsp. atlantica H. de Vill. In Compendio de Selvicultura Aplicada en España; Serrada, R., Montero, G., Reque, J.A., Eds.; INIA: Madrid, Spain, 2008; pp. 367–398. [Google Scholar]

- Meza-Izquierdo, M. Bioestimulants: An opportunity to increase pine resin yield (Pinus caribeae Morelet, P. tropicalis Morelet, P. cubensis Griseb). Rev. Chapingo Ser. Cienc. For. Ambiente 1998, 4, 300–304. [Google Scholar]

- Kern and Sohn GmbH. Hanging Scale HDB-N/HDB-XL. 2021. Available online: https://www.kern-sohn.com/shop/en/industrial-scales/hanging-scales-crane-scales/HDB-N/HDB-XL/ (accessed on 11 October 2022).

- MeteoGalicia. Consellería de Medio Ambiente, Territorio e Vivenda, Xunta de Galicia. 2022. Available online: www.meteogalicia.gal (accessed on 3 August 2022).

- Lecoutre, B. A correction for the formula approximate test in repeated measures designs with two or more independent groups. J. Educ. Behav. Stat. 1971, 16, 371–372. [Google Scholar]

- The R Project for Statistical Computing 4.1.0; Free Software; 2021. Available online: https://www.r-project.org/ (accessed on 13 November 2022).

- Rodríguez-García, A.; López, R.; Martín, J.A.; Pinillos, F.; Gil, L. Resin yield in Pinus pinaster is related to tree dendrometry, stand density and tapping-induced systemic changes in xylem anatomy. For. Ecol. Manag. 2014, 313, 47–54. [Google Scholar] [CrossRef]

- Zas, R.; Quiroga, R.; Touza, R.; Vázquez-González, C.; Sampedro, L.; Lema, M. Resin tapping potential of Atlantic maritime pine forests depends on tree age and timing of tapping. Ind. Crop. Prod. 2020, 157, 112940. [Google Scholar] [CrossRef]

- Eyles, A.; Bonello, P.; Ganley, R.; Mohammed, C. Induced resistance to pests and pathogens in trees. New. Phytol. 2010, 185, 893–908. [Google Scholar] [CrossRef] [PubMed]

- Franceschi, V.R.; Krokene, P.; Krekling, T.; Christiansen, E. Phloem parenchyma cells are involved in local and distant defense responses to fungal inoculation or bark-beetle attack in Norway spruce (Pinaceae). Am. J. Bot. 2000, 87, 314–326. [Google Scholar] [CrossRef] [PubMed]

- Krokene, P.; Nagy, N.E.; Krekling, T. Traumatic Resin Ducts and Polyphenolic Parenchyma Cells in Conifers. In Induced Plant Resistance to Herbivory; Springer: Dordrecht, The Netherlands, 2008; pp. 147–169. [Google Scholar] [CrossRef]

- Hood, S.; Sala, A.; Heyerdahl, E.K.; Boutin, M. Low severity fire increases tree defense against bark beetle attacks. Ecology 2015, 96, 1846–1855. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lombardero, M.J.; Ayres, M.P.; Lorio, P.L.; Ruel, J.J. Environmental effects on constitutive and inducible resin defences of Pinus taeda. Ecol. Lett. 2000, 3, 329–339. [Google Scholar] [CrossRef] [Green Version]

- Ruel, J.J.; Ayres, M.P.; Lorio, P.L. Loblolly pine responds to mechanical wounding with increased resin flow. Can. J. For. Res. 1998, 28, 596–602. [Google Scholar] [CrossRef]

- Rodrigues, K.C.S.; Azevedo, P.C.N.; Sobreiro, L.E.; Pelissari, P.; Fett-Neto, A.G. Oleoresin yield of Pinus elliottii plantations in a subtropical climate: Effect of tree diameter, wound shape and concentration of active adjuvants in resin stimulating paste. Ind. Crop. Prod. 2008, 27, 322–327. [Google Scholar] [CrossRef]

- Wiedenhoeft, A.C.; Miller, R.B. Structure and function of wood. In Handbook of Wood Chemistry and Wood Composites; Rowell, R.M., Ed.; CRC Press: Boca Raton, FL, USA, 2005; pp. 9–33. [Google Scholar] [CrossRef]

- Hood, S.; Sala, A. Ponderosa pine resin defenses and growth: Metrics matter. Tree Physiol. 2015, 35, 1223–1235. [Google Scholar] [CrossRef] [Green Version]

- Martin, D.M.; Gershenzon, J.; Bohlmann, J. Induction of volatile terpene biosynthesis and diurnal emision by methyl jasmonate in foliage of Norway spruce. Plant Physiol. 2003, 132, 1586–1599. [Google Scholar] [CrossRef] [Green Version]

- Zepner, L.; Karrasch, P.; Wiemann, F.; Bernard, L. ClimateCharts.net—An interactive climate analysis web platform. Int. J. Digit. Earth 2020, 14, 338–356. [Google Scholar] [CrossRef]

- Blanche, C.A.; Lorio, P.L.; Sommers, R.A.; Hodges, J.D.; Nebeker, T.E. Seasonal cambial growth and development of loblolly pine: Xylem formation, inner bark chemistry, resin ducts, and resin flow. For. Ecol. Manag. 1992, 49, 151–165. [Google Scholar] [CrossRef]

- Rodrigues, K.C.S.; Fett-Neto, A.G. Oleoresin yield of Pinus elliottii in a subtropical climate: Seasonal variation and effect of auxin and salicylic acid-based stimulant paste. Ind. Crop. Prod. 2009, 30, 316–320. [Google Scholar] [CrossRef]

- Neis, F.A.; de Costa, F.; Füller, T.N.; de Lima, J.C.; da Silva Rodrigues-Correa, K.C.; Fett, J.P.; Fett-Neto, A.G. Biomass yield of resin in adult Pinus elliottii Engelm. trees is differentially regulated by environmental factors and biochemical effectors. Ind. Crop. Prod. 2018, 118, 20–25. [Google Scholar] [CrossRef]

- Schopmeyer, C.S.; Larson, P.R. Effects of diameter, crown ratio, and growth rate on gum yields of slash and longleaf pine. J. For. 1955, 53, 822–826. [Google Scholar]

- Buschiazzo, E.; Ritland, C.; Bohlmann, J.; Ritland, K. Slow but not low: Genomic comparisons reveal slower evolutionary rate and higher dN/dS in conifers compared to angiosperms. BMC Evol. Biol. 2012, 12, 8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Petit, R.J.; Hampe, A. Some evolutionary consequences of being a tree. Annu. Rev. Ecol. Evol. Syst. 2006, 37, 187–214. [Google Scholar] [CrossRef] [Green Version]

- Sukarno, A.; Hardiyanto, E.B.; Marsoem, S.N.; Na’iem, M. Oleoresin production, turpentine yield and components of Pinus merkusii from various Indonesian provenances. J. Trop. For. Sci. 2015, 27, 136–141. [Google Scholar]

- Zas, R.; Vázquez-Gonzalez, C.; López-Goldar, X.; Alía, R.; Bustingorri, G.; Lario, F.J.; Lema, M.; De La Mata, R.; Quiroga, R.; Sampedro, L.; et al. Producción de resina en los pinares Atlánticos de Pinus pinaster: Factores genéticos, ambientales y ontogenéticos. In Proceedings of the Actas del 8º Congreso Forestal Español, 8CFE-249, Lleida, Spain, 27 June–1 July 2022. [Google Scholar]

- Karsky, D.; Strom, B.; Thistle, H. An Improved Method for Collecting and Monitoring Pine Oleoresin; 0434-2306-MTDC; USDA Forest Service, Missoula Technology and Development Center: Missoula, MT, USA, 2004. [Google Scholar]

- De Oliveira Junkes, C.F.; Vigne Duz, J.V.; Kerber, M.R.; Wieczorek, J.; Galvan, J.L.; Fett, J.P.; Fett-Neto, A.G. Resinosis of young slash pine (Pinus elliottii Engelm.) as a tool for resin stimulant paste development and high yield individual selection. Ind. Crop. Prod. 2019, 135, 179–187. [Google Scholar] [CrossRef]

- Soliño, M.; Yu, T.; Alia, R.; Aunon, F.; Bravo-Oviedo, A.; Regina Chambel, M.; de Miguel, J.; del Rio m Justes, A.; Martinez-Jauregui, M.; Montero, G.; et al. Resin-tapped pine forests in Spain: Ecological diversity and economic valuation. Sci. Total Environ. 2018, 625, 1146–1155. [Google Scholar] [CrossRef] [Green Version]

- Barrio-Anta, M.; Castedo-Dorado, F.; Cámara-Obregón, A.; López-Sánchez, C.A. Predicción del hábitat óptimo y la productividad actual y futura de Pinus pinaster ssp. atlantica en el noroeste de España. In Proceedings of the Actas del 8º Congreso Forestal Español, 8CFE-139, Lleida, Spain, 27 June–1 July 2022. [Google Scholar]

- Chamorro, E.M.; García-Méijome, A.; Gómez García, E.; Fernández Blanco, E. Sistemas de Mecanización de Resinación para Pinus pinaster Ait. en Galicia; Consellería do Medio Rural; Xunta de Galicia: Santiago, Spain, 2021. [Google Scholar]

- Cabaret, T.; Gardere, Y.; Frances, M.; Leroyer, L.; Charrier, B. Measuring interactions between rosin and turpentine during the drying process for a better understanding of exudation in maritime pine wood used as outdoor siding. Ind. Crop. Prod. 2019, 130, 325–331. [Google Scholar] [CrossRef]

| Dasometric Variables | Caldas de Reis | Maceda | ||

|---|---|---|---|---|

| Initial | Final | Initial | Final | |

| Age (years) | 27 | 30 | 56 | 59 |

| Dm (cm) | 33.2 | 34.9 | 41.8 | 43.4 |

| Hm (m) | 19.0 | 20.7 | 24.8 | 26.4 |

| Hc (m) | 10.8 | 13.2 | 17.6 | 18.1 |

| Hcc (m) | 8.3 | 7.4 | 7.5 | 8.3 |

| Meteorological Variables | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|

| Caldas de Reis | ||||

| Mean temperature (°C) | 13.9 | 14.3 | 13.7 | |

| Annual accumulated precipitation (L m−2) | 2183 | 1263 | 1941 | |

| Annual hours of sunshine (h) | 2210 | 2316 | 1985 | |

| Mean relative humidity (%) | 77.3 | 63.7 | 81.6 | |

| Maceda | ||||

| Mean temperature (°C) | 12.8 | 12.1 | 12.0 | |

| Annual accumulated precipitation (L m−2) | 778 | 1266 | 1261 | |

| Annual hours of sunshine (h) | 2515 | 1848 | 2220 | |

| Mean relative humidity (%) | 73.4 | 79.5 | 77.3 |

| Source of between-Subjects Variation | df | F | p > F |

| Location | 1 | 19.16 | <0.0001 ** |

| N° of faces | 1 | 370.37 | <0.0001 ** |

| Wound width | 1 | 11.01 | 0.0009 ** |

| LocationxN° of faces | 1 | 11.22 | 0.0008 ** |

| LocationxWound width | 1 | 0.02 | 0.8763 |

| N° of facesxWound width | 1 | 10.63 | 0.0011 * |

| LocationxN° of facesx Wound width | 1 | 0.11 | 0.7350 |

| Error | 1178 | ||

| Source of within-Subject Variation | df | F | p > F |

| Year | 1 | 2334.60 | <0.0001 ** |

| YearxLocation | 1 | 17.77 | <0.0001 ** |

| YearxN° of faces | 1 | 136.82 | <0.0001 ** |

| YearxWound width | 1 | 3.30 | 0.0696 |

| YearxLocationxN° of faces | 1 | 0.02 | 0.8813 |

| YearxLocationxWound width | 1 | 1.77 | 0.1840 |

| YearxN° of facesxWound width | 1 | 4.66 | 0.0311 * |

| YearxLocationxN° of facesxWound width | 1 | 1.17 | 0.2804 |

| Error (year) | 1178 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Méijome, A.; Rozados Lorenzo, M.J.; Fernández Blanco, E.; Martínez Chamorro, E.; Gómez-García, E. Resin-Tapping Production in Pinus pinaster Ait. Stands in Galicia (NW Spain): Effects of Location, Number of Faces, Wound Width and Production Year. Forests 2023, 14, 128. https://doi.org/10.3390/f14010128

García-Méijome A, Rozados Lorenzo MJ, Fernández Blanco E, Martínez Chamorro E, Gómez-García E. Resin-Tapping Production in Pinus pinaster Ait. Stands in Galicia (NW Spain): Effects of Location, Number of Faces, Wound Width and Production Year. Forests. 2023; 14(1):128. https://doi.org/10.3390/f14010128

Chicago/Turabian StyleGarcía-Méijome, Alberto, María José Rozados Lorenzo, Edgar Fernández Blanco, Enrique Martínez Chamorro, and Esteban Gómez-García. 2023. "Resin-Tapping Production in Pinus pinaster Ait. Stands in Galicia (NW Spain): Effects of Location, Number of Faces, Wound Width and Production Year" Forests 14, no. 1: 128. https://doi.org/10.3390/f14010128