Abstract

Growing demand for forest machines that cost less to operate than current compared to traditional hydraulic and mechanical ones, along with regulatory pressures for lower emissions, is increasing manufacturers’ interest in developing electric and hybrid drives. While purely electric drives of forest machines meet a lot of bottlenecks (costs of the electric components, battery durability, duration of charging, access to the electrical grid, size of batteries that can ensure enough energy for 8 h working time), electric hybrid drives offer a favorable solution for the propulsion of forestry machinery in terms of lower fuel consumption and improved efficiency. Among all forest vehicles, specialized forest tractors (skidders), so far, have not been considered for forest vehicles with hybrid drive capabilities. A skidder is a forest-articulated self-propelled vehicle for pulling trees or parts of trees. In most countries in southern Europe, the use of skidders equipped with forest winches is the most common technique for timber extraction. The first goal of the research is to develop methods for measuring the energy consumption of skidders at different operating tasks and under different field conditions. Research was performed on the skidder Ecotrac 140V (from Croatian producer Hittner Ltd.) during timber extraction in mountainous terrains in Lika–Senj County. The skidder was equipped with a measuring device WIGO-E (Telematic Data collector) gateway with an integrated GPS system, which ensured data were collected from sensors and motor and stored in a computer via CANBUS and data transfer with GSM to Web platforms. Additionally, a fuel-flow meter was installed on the skidder. Data on fuel consumption (mL), position (traveling route), detection of winch work, engine rpm (min−1), engine torque (% of max), throttle position (%), and engine temperature were measured with a sampling frequency of 5 s. Furthermore, skidder load volumes per cycles and slopes of tractor paths were constantly measured. The paper shows the skidder’s energy consumption per day, work cycle, and individual work procedure with regard to the size of the load, the slope of the tractor path, and the direction of movement based on overlapping and merging all measurement data. Using mathematical and simulation models of the drive with defined operating cycles obtained by measurement, the possibilities of the hybrid drive and the dimensions of the elements of the hybrid drive (internal combustion engine, electric motor, batteries, control unit) were determined and are presented in this paper.

1. Introduction

The use of machines in modern technologies of timber harvesting always involves a certain risk of injury, health of the operator, damages to the forest ecosystem, such as soil treading and compaction, an increase in possibility of erosion processes, damages to trees and their root systems, pollution or contamination of air, soil, water resources, etc. On the other hand, forestry machines must be able to perform hard tasks, fulfilling demands for greater productivity with decreasing operational costs [1]. Primarily the mentioned statement applies to specialized forest vehicles (skidders, forwarders, and harvesters) that move across forest soil. After a period of intensive introduction of forestry machines in timber harvesting works, nowadays, assessing the impact of forest machines on forest environments has become a significant factor in the application of machines and their further development.

The following characteristics play an important role in the development of forestry vehicles, in order to meet the economic, ecological, ergonomic, and energy requirements: production series sizes of different types of forest machines are significantly lower than other specialized machinery (agricultural, construction, material handling machinery); the size of the machines varies due to different types, work tasks, and required power; performance and torque are typical requirements, but the actual speed of moving is typically low [2]. A diesel engine is still the main power source in all types of forest machines, and power transmission is mainly hydrostatic–mechanical [3].

Growing demand for forest machines that cost less to operate, along with regulatory pressures for lower emissions, increases manufacturers’ interest in developing electric and hybrid drives compared to traditional hydraulic and mechanical ones [4,5]. While pure electric drives of forest machines meet a lot of bottlenecks (costs of the electric components, battery durability, duration of charging, access to the electrical grid, and size of batteries that could ensure enough energy for 8 h working time), electric hybrid drives offer a favorable solution for the propulsion of forestry machinery in terms of lower fuel consumption and improved efficiency [6].

The current technical and technological development of hybrid drive systems, as well as their components, has led to significant improvements in drive performance and thus better performance of the new generation of forest vehicles [7]. Improved energy efficiency through the use of hybrid propulsion systems in forest vehicles would result in a significant reduction in greenhouse gas emissions and possibly lower maintenance costs. Variable fuel prices, stricter exhaust emission regulations, and lower prices of electrical components will accelerate the development and application, and the share of different types of hybrid drives in forest vehicles [6].

We need to be aware that such solutions at the beginning will increase the purchase price of machines because it could represent some risk to companies that produce forest machines. Additionally, production series and sales volumes of different types of forest machines are significantly lower than other specialized machines (agricultural, construction, and material handling machines), which poses a risk to manufacturers in terms of return on investment in the development of hybrid drives.

Today, we consider hybrid drive solutions of forest vehicles as an alternative to a purely electric vehicle solution until the time when, through further development, fuel cells or passive energy sources will be sufficient to meet the operating energy requirements of forest vehicles [8].

Till now, only some hybrid pilot projects in forest vehicles have been performed. A positive example should be pointed out in the construction of the El-forest F14 forwarder. The El-forest F14 is a series hybrid forest vehicle involving a smaller diesel engine that drives a generator that, via batteries, provides electric energy to electric motors in the forwarder’s six wheels. It has the possibility of reducing fuel consumption by 20%–50%, which also sharply reduces carbon dioxide emissions [9].

Additionally, the manufacturer Logset Oy developed the first available electro-hybrid harvester. It is a parallel hybrid configuration that utilizes an electric motor connected to the shaft of an internal combustion engine, which is also the generator [10]. In comparison with the same conventional diesel harvester, the Logset hybrid system is 72% more powerful, with a 54% increase in torque, and hydraulic flow is increased by up to 27% [11].

Among all forest vehicles, specialized forest tractors (skidders), so far, have not been considered as forest vehicles with hybrid drive capabilities [12].

The skidder is, according to ISO 6814:2000 standard [13], defined as a self-propelled, articulated forest vehicle for skidding trees or parts of trees. In most countries in southern Europe, the use of skidders equipped with forest winches is the most common technique for timber extraction [14]. The advantage of using a winch on a skidder is reducing damage to forest soil and the remaining trees [15].

The biggest obstacle to the development of a hybrid skidder drive is the lack of knowledge of the total energy consumption of the skidder’s work on skidding wood under different operating conditions [12]. For this purpose, it is necessary to measure the fuel consumption, i.e., to determine the energy of the skidder over a long period of time, because short-term measurements of the work process and fuel consumption can only give an overview of the work for a specific period of time. Seasonal and short-term effects (factors) that can affect energy consumption and the structure of working hours can be covered by long-term measurement during the whole year (or several years).

The research seeks to apply modern methods of determining the energy consumption of the skidder by work components, which include the acquisition of modern measuring devices with the development of remote data transmission. The main demand for the measuring method was to monitor skidder operation, without obstructing the normal work process, based on time and fuel consumption using a semi-automated method over a long period of time.

2. Materials and Methods

The research was conducted in the mountainous area of Lika–Senj County. The data were collected from the work site in Management unit “Jadovno–Jazbine” department 5a, where the skidder was working in the thinning of beech forest on a mountainous terrain. Investigations were carried out on skidder Ecotrac 140V owned by Croatian Forests Ltd., Zagreb, in the real work of timber skidding. Technical characteristics of Ecotrac 140 V are shown in Table 1. For the purpose of collecting telemetry data, skidders were equipped with systems for managing and monitoring the operation of the vehicle, Fleet Management System (FMS) by Mobilisis.

Table 1.

Technical characteristics of skidder Ecotrac 140 V.

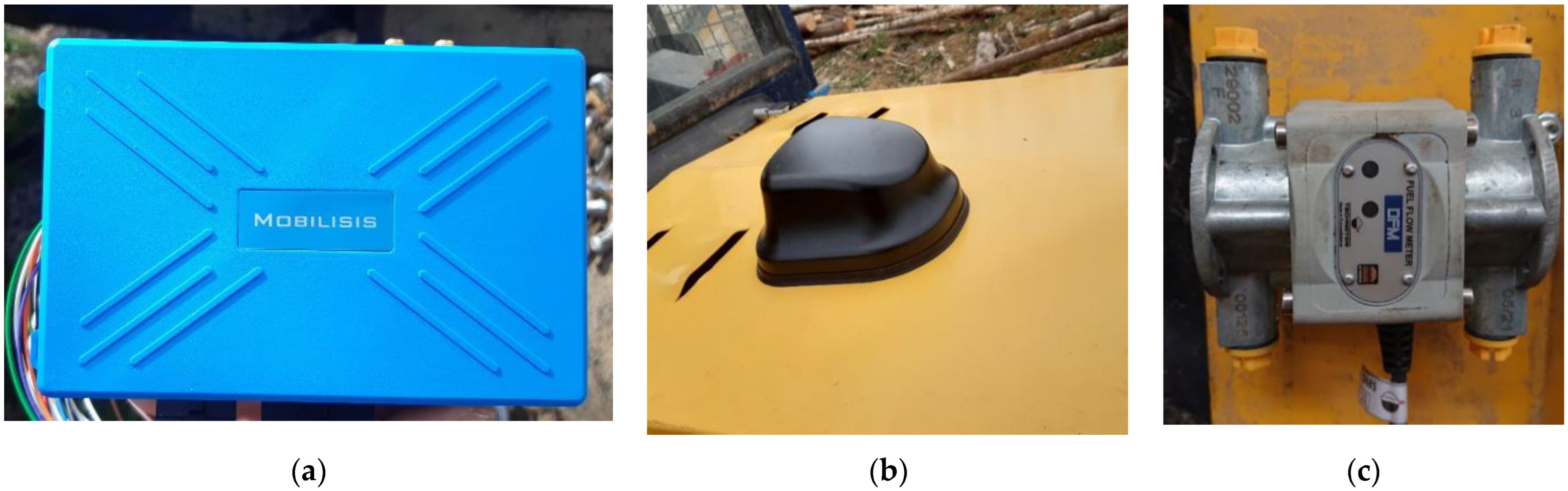

The basic component of the FMS is the mobile unit WIGO-E (Figure 1a). WIGO-E is a professional industrial IoT Gateway that collects and stores data from sensors using different communication protocols, such as WLAN, LAN, and GSM. The data are sent via GSM protocol to the web platform, where they are saved on the cloud. The mobile unit has a useful feature that, in the case of the absence of a GSM signal, which is often the case in forest conditions, it stores the measured data in its internal memory, which are retroactively sent to the server at the moment when the vehicle is in the signal receiving area. An integral part of the FMS is a GPS device that is used to record the position of the vehicle with an associated GPS/GSM antenna that enables the transmission of collected data and the reception of satellite signals for GPS operation (Figure 1b). In order to precisely measure fuel consumption, a differential fuel consumption meter—DFM 100CD—is installed on the skidder, which has the ability to measure current fuel consumption and total fuel consumption. Regarding the measurement range for this model, the minimum flow rate is 10 L/h, and the maximum flow rate is 100 L/h with an accuracy of ± 3% (Figure 1c). The fuel supply line to the drive engine passes through the meter, and the amount of fuel that is not consumed in the engine and returns to the fuel tank passes through the meter, and differential correction of fuel consumption is performed.

Figure 1.

Fleet management components that are installed on the skidder. (a) WIGO-E (Telematic Data Collector), (b) GPS/GSM antenna, (c) differential fuel consumption meter—DFM 100CD.

The data are accessed via the Mobilisis web platform. On the portal, the user can choose which skidder they want to follow, on which day, and during which period. The system offers the possibility of monitoring skidder operation in real time, or it can generate reports for the parameters we monitor in the form of excel tables that are suitable for further processing and analysis. The parameters that are measured are total fuel consumption (mL), skidder position in terms of GPS data (latitude, longitude), time and duration of the winch use, engine rpm (min−1), engine torque (% of maximum), throttle position (%), and engine temperature. In addition to remote data collection, the amount of wood from each skidding cycle is recorded on the field.

The work cycle of the skidder was divided into the following work elements: the unloaded travel from the roadside landing to the felling area in the forest, the operation of the winch (pulling out of winch rope and winching of the load), the travel of the loaded skidder to the roadside landing area, and unloading [16].

From the measurement data, the start and end times of each working cycle, as well as each working element per cycle, were determined. The values of the diesel fuel consumed, measured in milliliters, via the differential flowmeter, were distributed based on measured time to working cycles and working elements.

Energy consumption of the skidder per day, working cycle, and work element is expressed in kWh using the calculation that 1 L of diesel fuel has a specific energy of 38 MJ or 10.56 kWh of energy [17].

3. Results

The data presented in this paper represent part of the database on the basis of which the conceptual model of the skidder hybrid drive was created. Average tree volume in the department where the measurements were conducted was 0.53 m3. Data on load volumes and manufactured wood assortments are presented in Table 2.

Table 2.

Timber extraction structure.

A total of 16 working days were recorded at that worksite, and during that time, the skidder extracted 211.06 m3 of wood mass in 101 skidding cycles. The work site was organized in such a way that the empty skidder drove uphill, and when loaded, it moved downhill.

During all days, the skidder was worked on the same skid trail with a total length of 896 m and a continuous longitudinal slope of 8%. The research was performed during springtime during days without precipitation during rainy periods in a mountainous region. The surface of the skid trail was very wet and muddy with wheel ruts up to 20 cm along the trail length.

During that time, the skidder consumed a total of 485.01 L of diesel fuel or 5121.74 kWh of energy (Table 3). The average consumption per working day was 30.31 ± 8.72 L of fuel or 320.11 ± 92.07 kWh of energy. The minimum fuel consumption per working day was 11.08 L, and the maximum was 42.29 L. The minimum energy consumption per working day was 116.95 kWh, and the maximum was 446.58 kWh. The consumption of fuel and energy per product unit, that is, per m3 of attracted wood assortments, was 2.30 L/m3 and 24.27 kWh/m3.

Table 3.

Skidder energy consumption per day.

Looking at the fuel consumption per skidding cycle, the average fuel consumption per cycle is 4.58 ± 1.18 L, the minimum fuel consumption per cycle is 2.82 L, and the maximum is 7.80 L. The average energy consumption per skidding cycle is 48.32 ± 12.44 kWh, the minimum energy consumption per cycle is 29.73 kWh, and the maximum is 82.32 kWh.

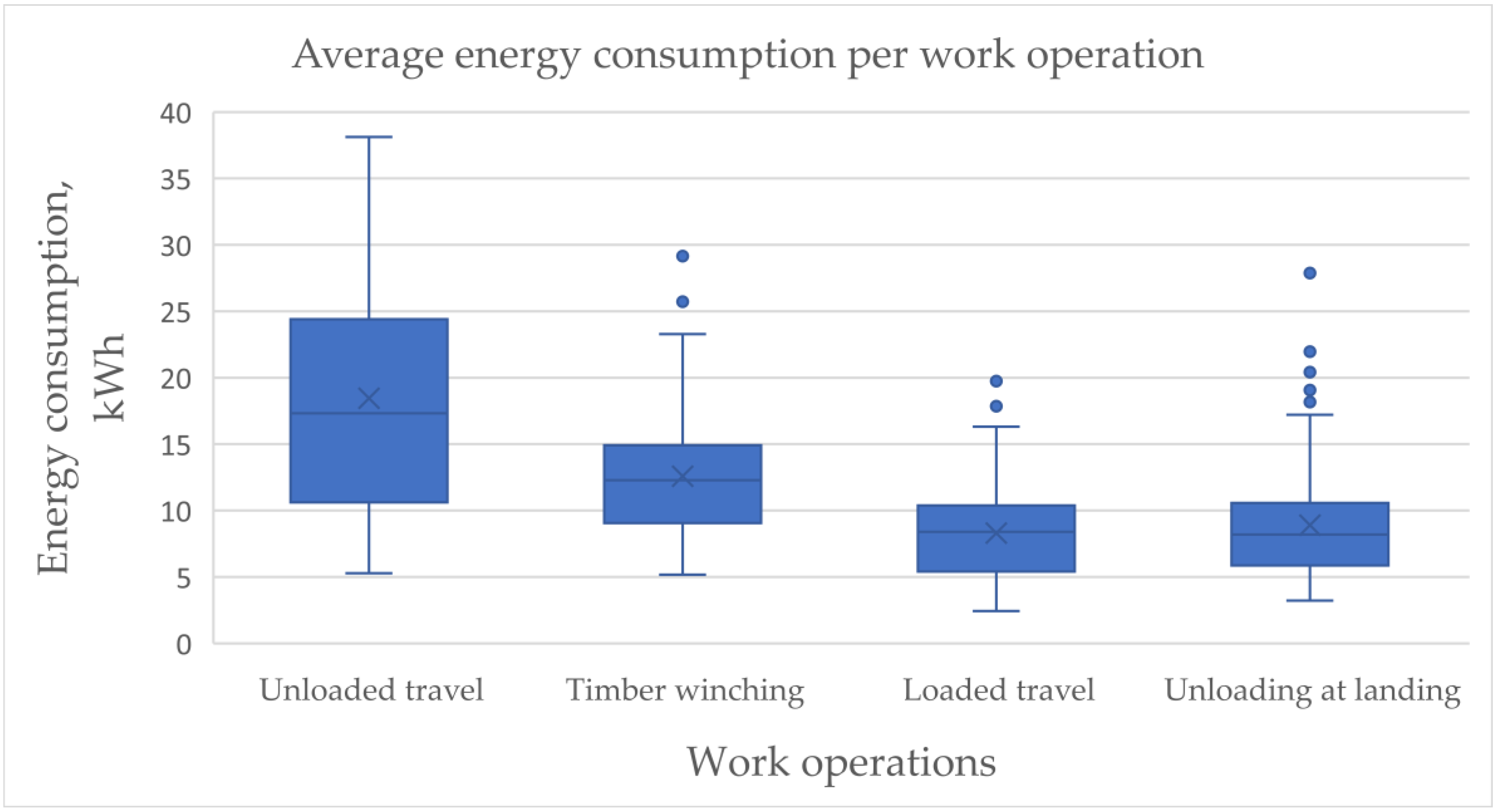

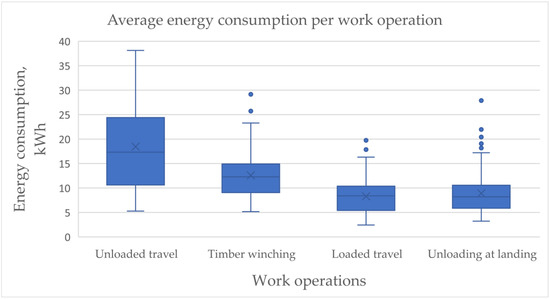

The total fuel consumption per work operation was as follows: driving an unloaded skidder—186.95 L; timber winching—126.27 L; driving a loaded skidder 82.51 L; and working on the landing—89.28 L. The total energy consumption of the skidder per work element for each day is shown in Table 4. The most energy was spent driving an unloaded skidder at 39%. The reason for this is that the energy consumption of driving the skidder is greatly influenced by the skidding distance, the slope of the terrain, and the condition of the soil, and at this work site, the unloaded skidder was moving uphill. The second work operation in terms of energy consumption is timber winching, with 26% of the total energy consumed. For driving a loaded skidder, 17% of the total amount of energy was used, which is more than twice as little as for driving an unloaded skidder. These data show that the slope and length of the terrain have a greater influence on energy consumption than the load size. The average and minimum and maximum values of fuel and energy consumption are shown in Table 5 and Figure 2.

Table 4.

Total energy consumption of skidder per work element.

Table 5.

Average fuel and energy consumption of the skidder by work element.

Figure 2.

Average energy consumption of the skidder by work operations.

4. Discussion

The research is performed to discover possibilities of hybrid powertrain propulsion of the skidder based on the measurements in real terrain conditions with an emphasis on the development of an electric-hybrid winch drive, which could achieve significant fuel savings and reduction in exhaust gases.

Winching is the pulling of wood assortments on the ground from places of production in the forest to the forest vehicle equipped with a forest winch [18]. The skidder is stationary during winching time and the diesel engine is running only for the propulsion of hydraulic-powered winch [19]. The share of forest winch work in the total working time depends on the conditions and slopes of the terrain, the type of felling, and the type of wood, and the method of wood production. In the final fellings on hilly terrains, with the half-stem method of processing beech assortments, it is between 21.8% and 36.0% of the total effective time [20], while in selective feelings on mountain terrains, with the half-stem method of processing beech assortments, it can reach up to 48% of the total effective time [21].

Therefore, the research results provide primarily guidelines for the development of an experimental setup of an electrohydraulic winch in order to produce a precise mathematical model for selecting a suitable winch drive that will fit into a skidder hybrid drive and designing the operation of such a winch.

This method will provide relevant data whose processing and analysis will form the basis for the development of computer models and algorithms for designing the skidder hybrid drive concept.

When analyzing energy consumption for the purpose of modeling a hybrid skidder drive, the key values are the extremes, i.e., the maximum values. Future hybrid drives must satisfy the need for energy in all operating conditions, including the most demanding situations that may occur when the skidder is operating in extreme conditions. This is the reason why long-term monitoring and measurement of energy consumption is necessary to detect extreme situations and measure the highest energy consumption per working day, per skidding cycle, and per individual work operation.

The presented results of the skidder’s energy consumption are based on the analysis of data measured during 16 working days. The total collection of data from the skidder, under real operating conditions, is still in progress to cover a period of more than 250 working days.

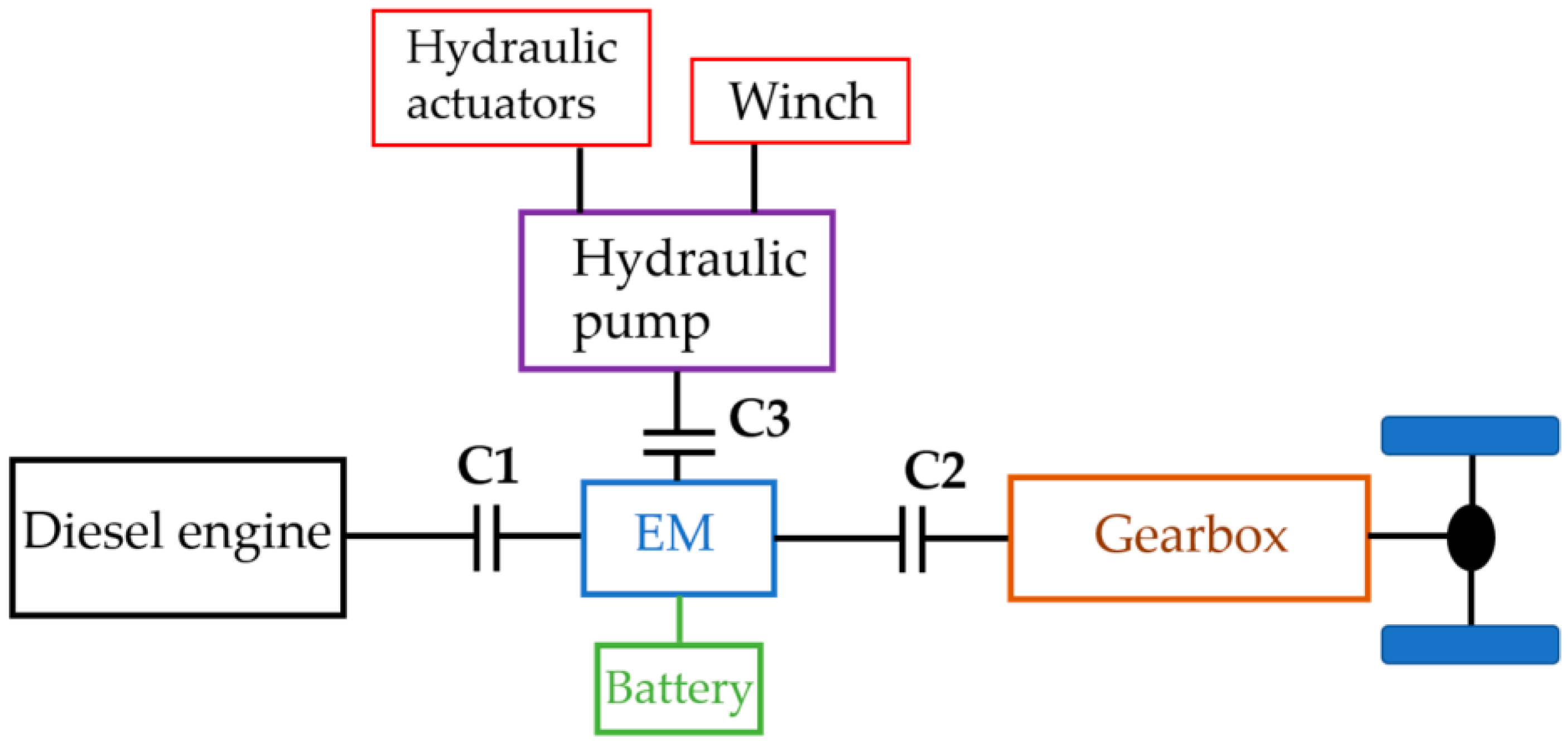

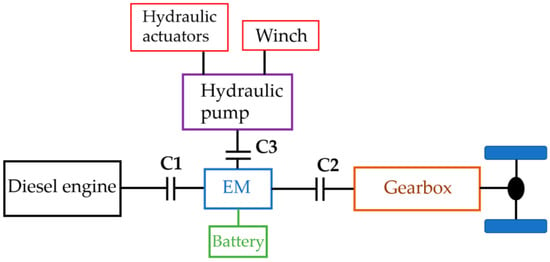

The next step in this research would be to carry out the analysis of accurate real-life recorded terrain data. Using simulation drive models and optimization methods with defined working cycles, energy consumption obtained by measurement, the structure of the hybrid drive, and the dimensions of the hybrid drive elements (internal combustion engine, electric motor, batteries, etc.) can be determined. It can be assumed that a parallel hybrid powertrain configuration of the skidder will be selected as shown in Figure 3.

Figure 3.

Proposed hybrid power-train configuration [12].

The principal requirement of hybridization is maintaining the performance of the hybrid drive equal to the conventional drive while requiring minimal modifications to the overall power train. Performance gains such as improved acceleration, driving comfort, etc., are not crucial for this kind of vehicle. Therefore, the introduction of a hybrid power-train in this type of vehicle is primarily motivated by the reduction in fuel consumption and greenhouse gas emissions [22].

It is important for a hybrid system not to demand substantial modifications to the existing vehicle, while all key functions of the conventional skidder remained unchanged: four-wheel drive, hydraulic drive of additional mechanical components of the vehicle, and independence of the availability of the electrical network. It satisfies all of the listed demands and does not require major modifications of the conventional power train for its installation [23,24].

The hybrid variant includes the addition of an electric motor that is placed between the gearbox and the diesel engine and additional clutches.

The double-drum winch can be driven by an additional electric motor, which is connected to the energy source, i.e., the battery.

The weight of such a battery will not represent a problem regarding the load on the chassis, especially if we take into account that the weight of the vehicle itself exceeds 8 tons. Furthermore, if the additional mass is properly distributed, it is possible to achieve better traction characteristics and improved driving stability on a sloped route.

A detailed description of the hybrid drive components, working regimes, and management strategy will be presented in the following publications.

5. Conclusions

The future development of pure electric forest vehicles, as well as hybrid solutions, is a very important task for forest engineering research activities because forest engineering needs to define the needs for the energy of different types of forest machines performing work in different terrain conditions. Such research results will be a foundation for the future development of electric forest machines. When we will know the energy demands for forest machines, then we will know which capacity of the battery is needed and where and when the application of electric drive is possible according to the recent scientific achievements in battery production. Additionally, it could be considered that some equipment on forest vehicles could be powered by electromotor/hybrid solutions.

The measured and analyzed data regarding the energy consumption of the real work cycle of skidder in different terrains with a newly developed method will be able to be used for the development of hybrid or other alternative drives of different types of vehicles and tools in forestry and in related fields.

Author Contributions

Conceptualization, M.Š. and H.N.; methodology, H.K., Z.P. and M.B.; software, H.K.; validation, M.Š. and H.N.; formal analysis, M.B., H.N. and K.L.; investigation, H.K., Z.P. and M.B.; data, H.K., Z.P. and K.L.; writing—original draft preparation, H.K. and M.Š.; writing—review and editing, M.Š. and K.L.; supervision, M.Š. All authors have read and agreed to the published version of the manuscript.

Funding

The research was co-funded by the European Regional Development Fund, in the scope of the European Union Operational Programme “Competitiveness and Cohesion” under the grant KK. 01.1.1.04.0010 (Development of hybrid drive of skidder—HiSkid).

Data Availability Statement

Raw data were generated at Faculty of Forestry and Wood Technology, University of Zagreb, Svetošimunska Cesta 23, 10000 Zagreb, Croatia. Derived data supporting the findings of this study are available from the main author M.Š. or corresponding author H.K. on request.

Acknowledgments

We acknowledge with deep gratitude that this research was supported by the European Regional Development Fund within the scope of the European Union Operational Programme “Competitiveness and Cohesion” under the grant KK. 01.1.1.04.0010 (“Development of hybrid skidder—HiSkid”) within the scope of the European Union Operational Programme “Competitiveness and Cohesion” 2014–2020 (2014HR16M1OP00-1.2).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Vusić, D.; Šušnjar, M.; Marchi, E.; Spina, R.; Zečić, Ž.; Picchio, R. Skidding operations in thinning and shelterwood cut of mixed stands—Work productivity, energy inputs and emissions. Ecol. Eng. 2013, 61 Pt A, 216–223. [Google Scholar] [CrossRef]

- Anonymous. EV Technologies in Working Machinery–Global View. Finpro, 2010. Available online: http://www.finpro.fi/documents/10304/82c1b231-9f5a-44a0-b2e6-b94fbaf53105 (accessed on 15 September 2022).

- Marenče, J.; Brnić, A.; Šušnjar, M. Wheel Slip During Wood Extraction. Work. Fac. For. Univ. Sarajevo 2017, 47, 36–48. [Google Scholar] [CrossRef]

- Rong-Feng, S.; Xiaozhen, Z.; Chengjun, Z. Study on Drive System of Hybrid Tree Harvester. Sci. World J. 2017, 2017, 8636204. [Google Scholar] [CrossRef] [PubMed]

- Silvaş, E.; Hofman, T.; Steinbuch, M. Review of optimal design strategies for hybrid electric vehicles. IFAC Proc. 2012, 45, 57–64. [Google Scholar] [CrossRef]

- Lajunen, A.; Suomela, J.; Pippuri, J.; Tammi, K.; Lehmuspelto, T.; Sainio, P. Electric and Hybrid Electric Non-Road Mobile Machinery–Present Situation and Future Trends. World Electr. Veh. J. 2016, 8, 172–183. [Google Scholar] [CrossRef]

- Mergl, V.; Pandur, Z.; Klepárník, J.; Kopseak, H.; Bačić, M.; Šušnjar, M. Technical Solutions of Forest Machine Hybridization. Energies 2021, 14, 2793. [Google Scholar] [CrossRef]

- Pandur, Z.; Šušnjar, M.; Bačić, M. Battery Technology—Use in Forestry. Croat. J. For. Eng. 2021, 42, 135–148. [Google Scholar] [CrossRef]

- Stodart, N. El-forest hybrid forwarder. For. J. 2010, 7, 20–21. [Google Scholar]

- Logset Oy. Logset 12H GTE Hybrid. Available online: https://www.logset.com/harvesters/logset-12h-gte-hybrid (accessed on 3 January 2021).

- Anonymous. The Most Productive Hybrid Forest Harvester in the World. Available online: https://www.electrificationstory.com/logset-hybrid-forest-harvester/ (accessed on 22 March 2021).

- Karlušić, J.; Cipek, M.; Pavković, D.; Benić, J.; Šitum, Ž.; Pandur, Z.; Šušnjar, M. Simulation Models of Skidder Conventional and Hybrid Drive. Forests 2020, 11, 921. [Google Scholar] [CrossRef]

- ISO 6814:2000; Machinery for Forestry—Mobile and Self-Propelled Machinery—Terms, Definitions and Classification. International Organization for Standardization: Geneva, Switzerland, 2022; pp. 1–7.

- Spinelli, R.; Magagnotti, N. The effects of introducing modern technology on the financial, labour and energy performance of forest operations in the Italian Alps. For. Pol. Econ. 2011, 13, 520–524. [Google Scholar] [CrossRef]

- Solgi, A.; Naghdi, R.; Tsioras, P.A.; Ilstedt, U.; Salehi, A.; Nikooy, M. Combined Effects of Skidding Direction, Skid Trail Slope and Traffic Frequency on Soil Disturbance in North Mountainous Forest of Iran. Croat. J. For. Eng. 2017, 38, 97–106. [Google Scholar]

- Zečić, Ž.; Krpan, A.P.B.; Poršinsky, T.; Šušnjar, M. Efficiency of tractors Steyr 8090 and 9078 in shelterwood fellings of stands in Požega mountains. Šumarski List. 2004, 128, 245–254. [Google Scholar]

- Giddings, J.; Lake, R.; Matthews, C. Comparing running costs of diesel, LPG and electrical pumpsets. In Primefact 1419 First Edition DPI Agriculture Water and Irrigation Unit; The NSW Department of Primary Industries: Gosford, NSW, Australia, 2016; pp. 1–4. [Google Scholar]

- Proto, A.R.; Macri, G.; Visser, R.; Russo, D.; Zimbalatti, G. Comparison of timber extraction productivity between winch and graplle skidding: A case study in Southern Italian forests. Forests 2018, 9, 61. [Google Scholar] [CrossRef]

- Gužvinec, H.; Zorič, M.; Šušnjar, M.; Horvat, D.; Pandur, Z. Utjecaj načina sidrenja na vrijednosti horizontalne sastavnice vučne sile i faktor prianjanja prilikom privitlavanja drva skiderom i adaptiranim poljoprivrednim traktorom. Nova Meh. Šumarstva 2012, 33, 23–33. [Google Scholar]

- Zečić, Ž.; Benković, Z.; Papa, I.; Marenče, J.; Vusić, D. Productivity of Tractor Ecotrac 120V Timber Skidding in Hilly Area of Central Croatia. Nova Meh. Šumarstva 2019, 40, 1–10. [Google Scholar] [CrossRef]

- Horvat, D.; Zečić, Ž.; Šušnjar, M. Morphological characteristics and productivity of skidder ECOTRAC 120 V. Croat. J. For. Eng. 2007, 28, 11–25. [Google Scholar]

- Karlušić, J.; Cipek, M.; Pavković, D.; Šitum, Ž.; Benić, J.; Šušnjar, M. Benefit Assessment of Skidder Powertrain Hybridization Utilizing a Novel Cascade Optimization Algorithm. Sustainability 2020, 12, 10396. [Google Scholar] [CrossRef]

- Çalışkan, K.; Ünlüsoy, Y.S.; Kiliç, V.; Yildirim, M. Development of a Hybrid Electric Heavy Duty Truck. Int. J. Heavy Veh. Syst. 2018, 25, 203–222. [Google Scholar]

- Dalboni, M.; Santarelli, P.; Patroncini, P.; Soldati, A.; Concari, C.; Lusignani, D. Electrification of a Compact Agricultural Tractor: A Successful Case Study. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 19–21 June 2019; pp. 1–6. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).