Characterization and Yield of Eucalyptus regnans F. Muell Logs for Lumber Production

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Description: Site and Stand Details

2.2. Sample Size, Measurement of Cracks, and Estimation of Log Volumes

2.3. Sawing Process and Lumber Grading

2.4. Evaluation of Wood Warping

2.5. Sawing Yield in Eucalyptus regnans Logs

2.6. Statistical Analysis

3. Results and Discussion

3.1. Distribution of Log Diameters

3.2. Assessment of Log Quality

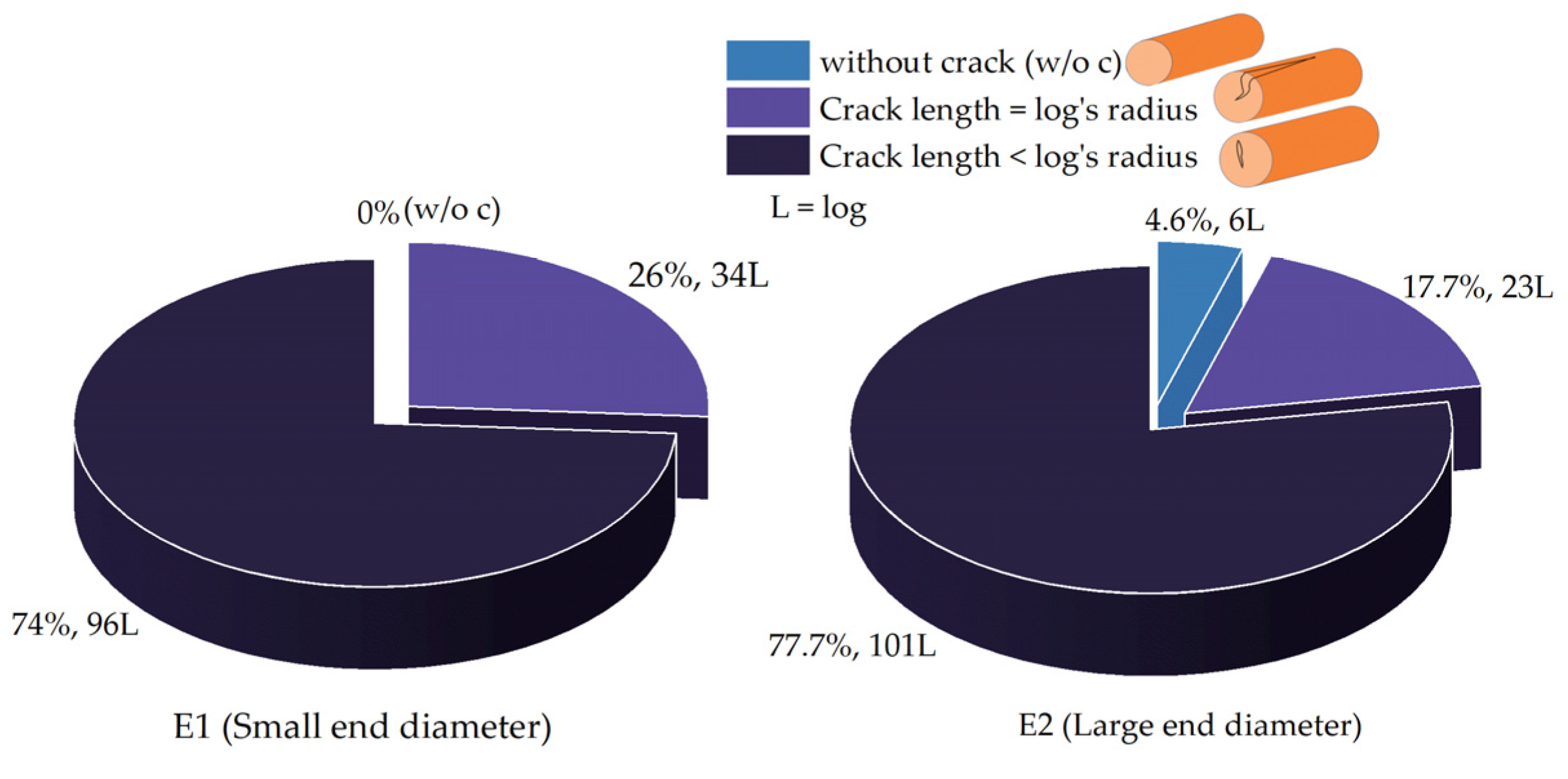

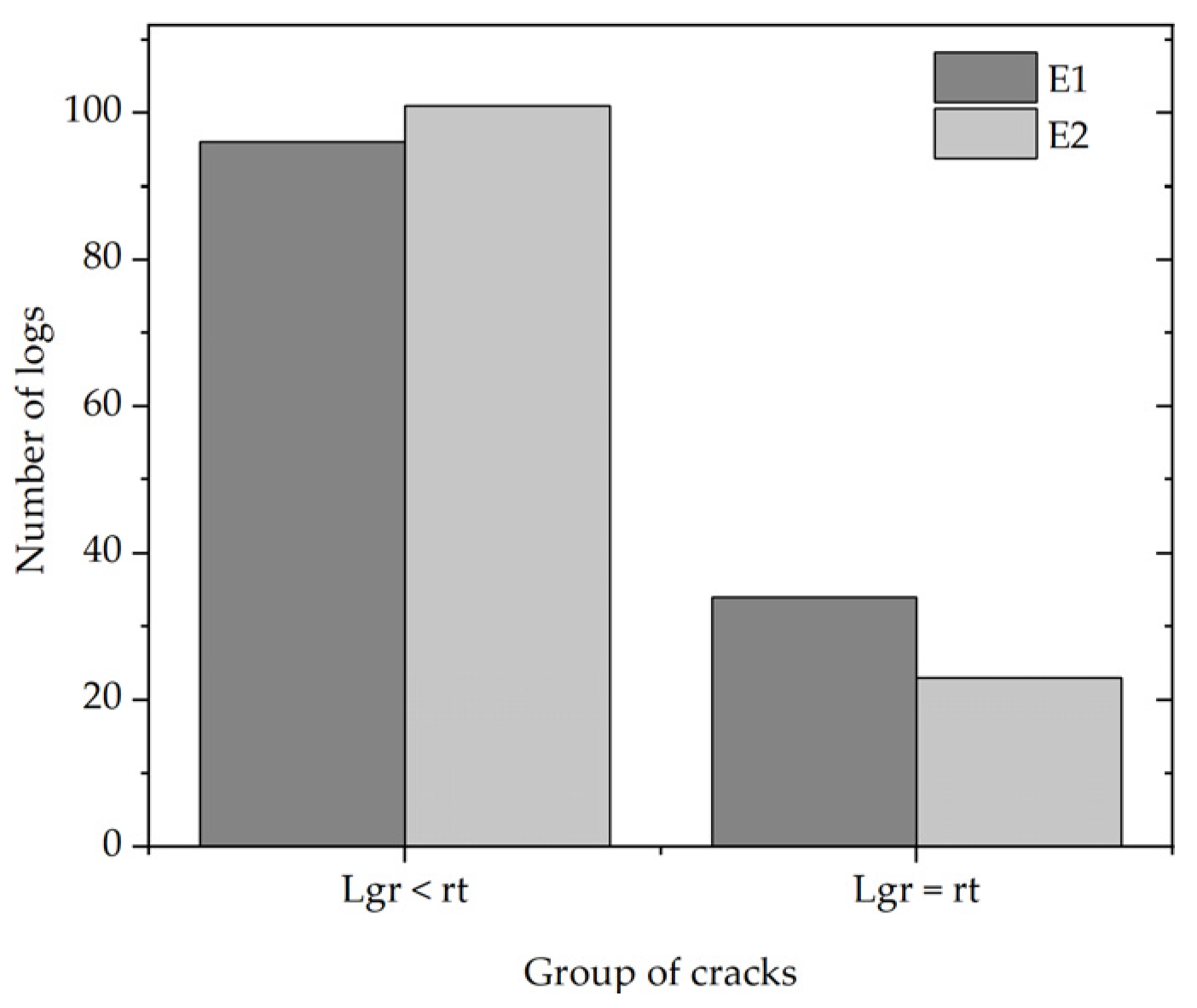

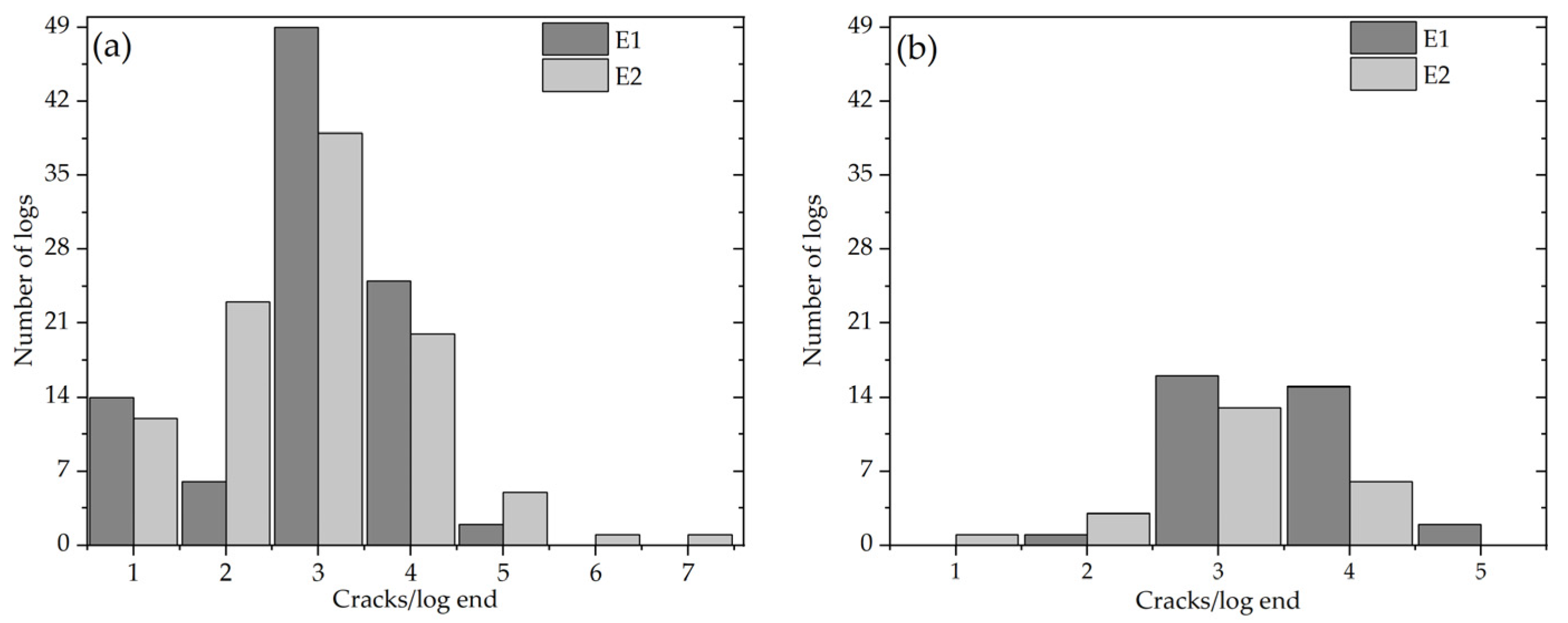

3.2.1. Radial Cracks in Log Ends

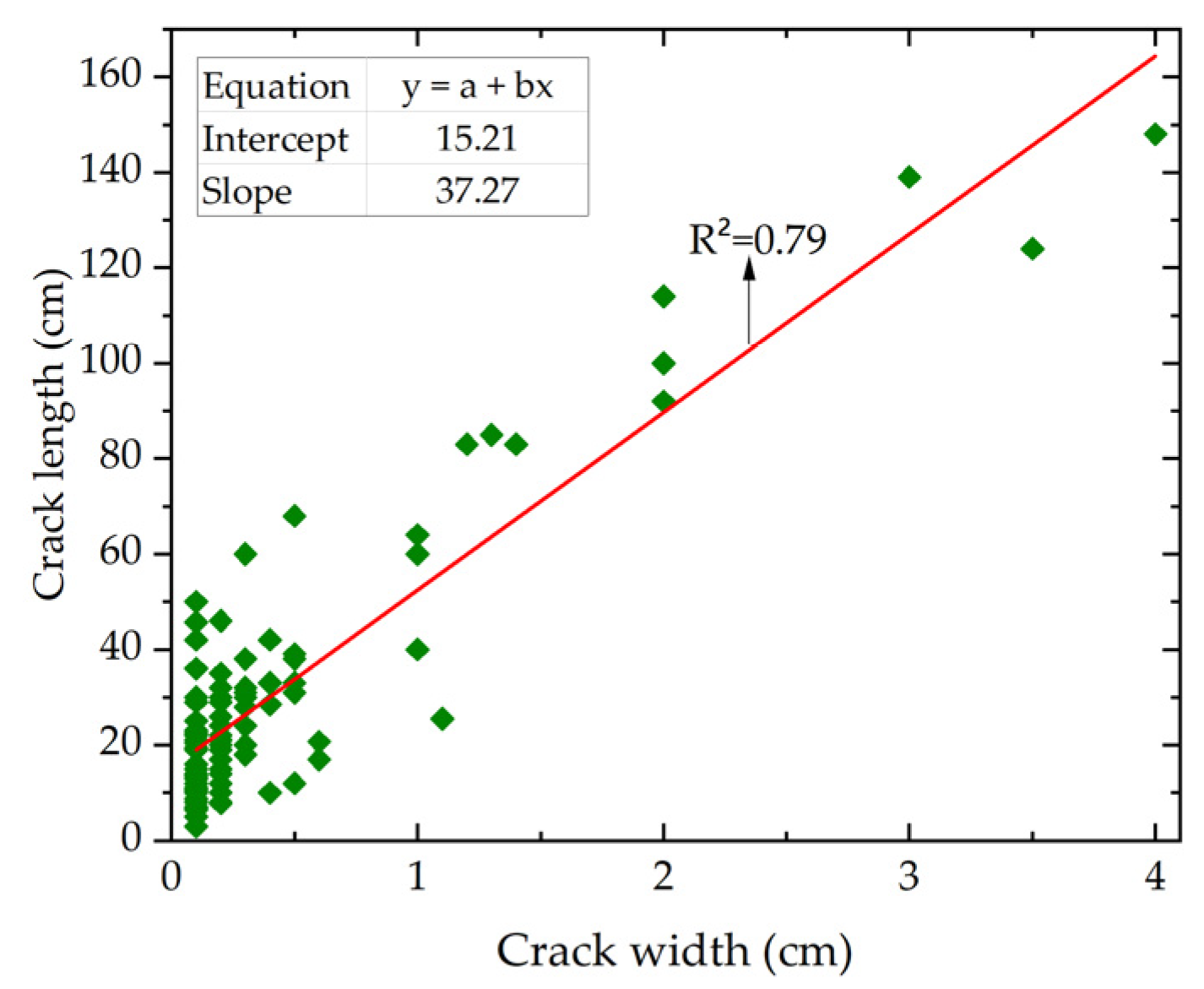

3.2.2. Relationship between the Width and Length of Longitudinal Cracks

3.3. Sorting of Sawn Lumber

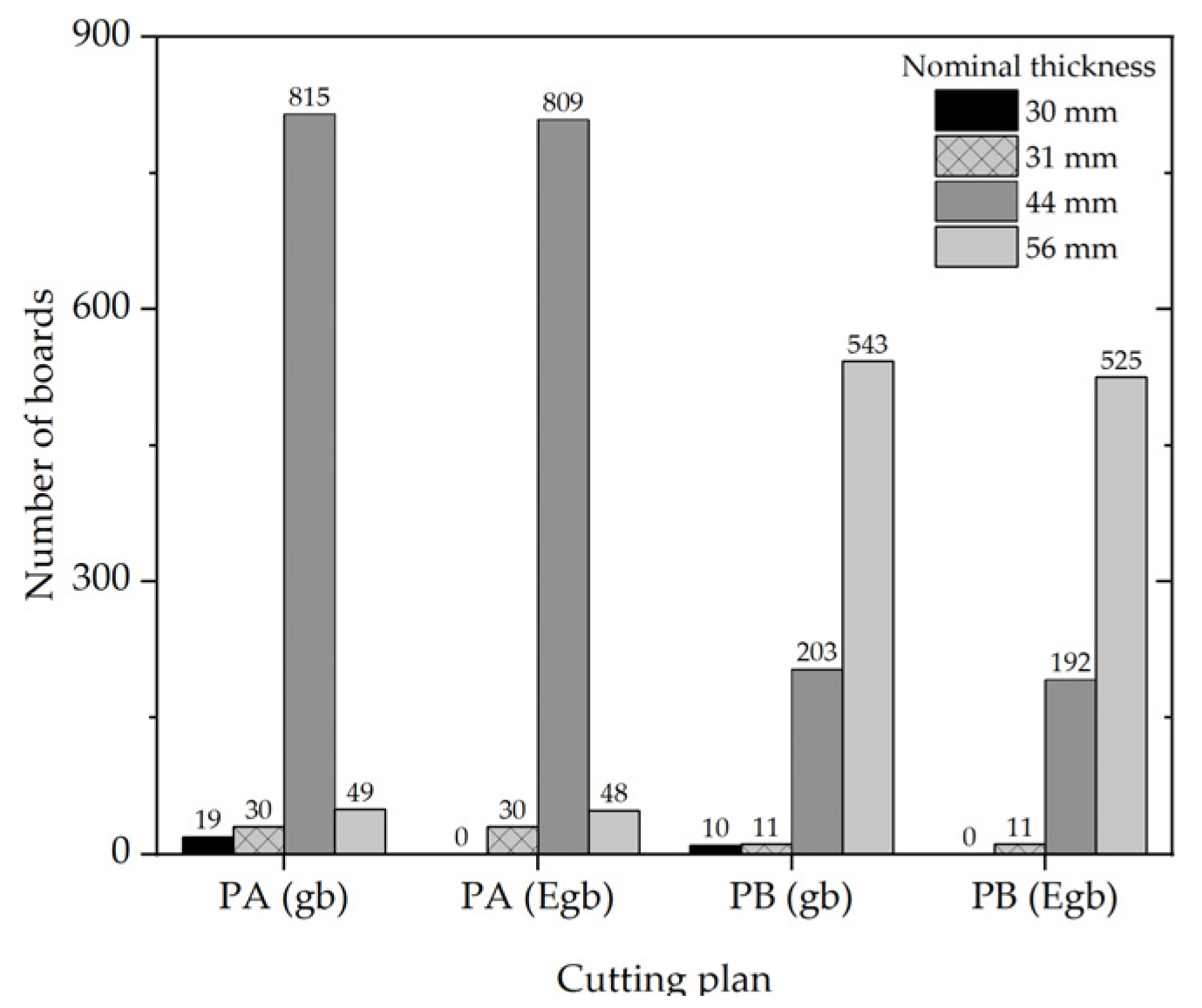

3.3.1. Lumber by Thickness and Cutting Plan

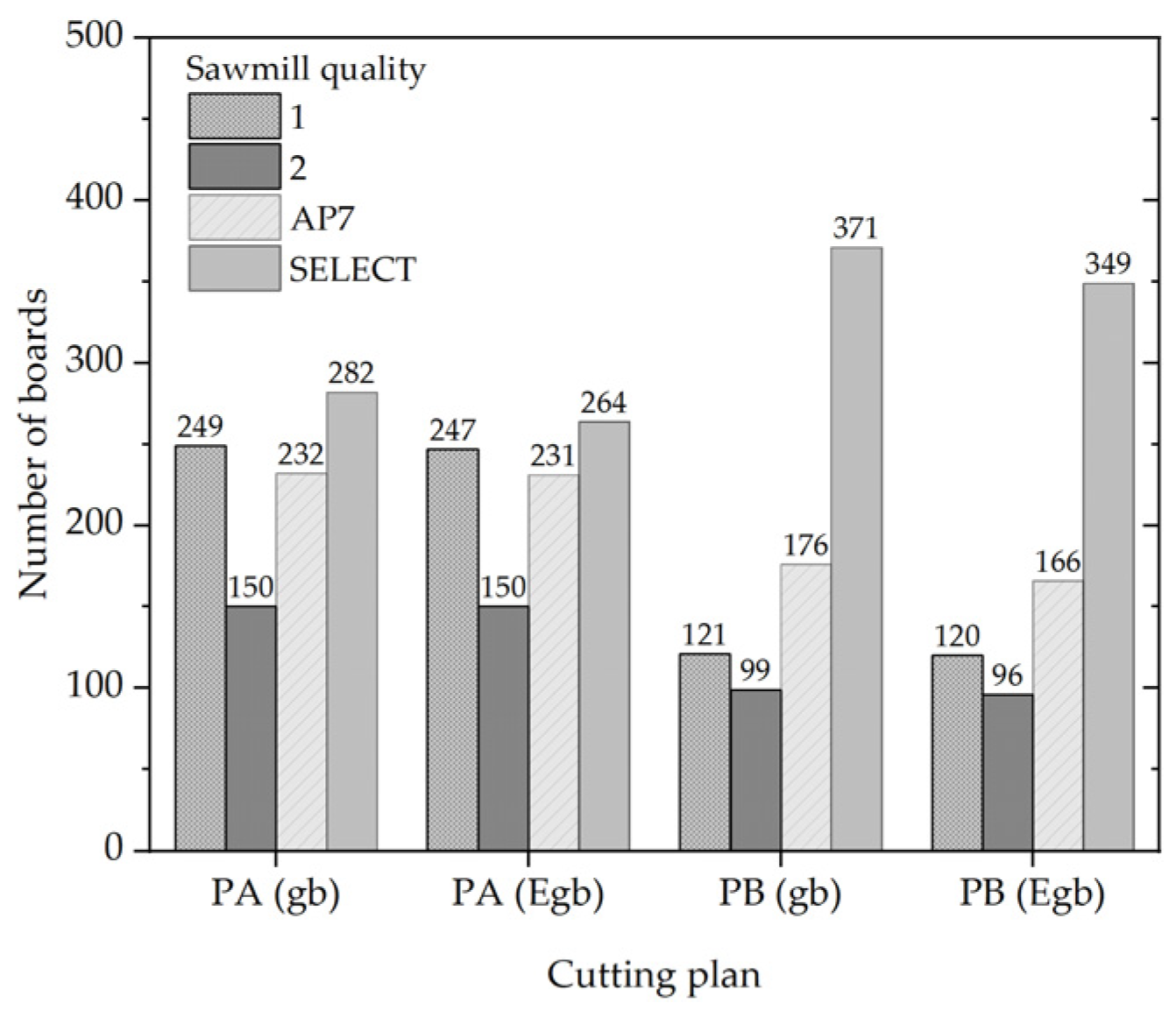

3.3.2. Lumber Grading According to Australian Standards

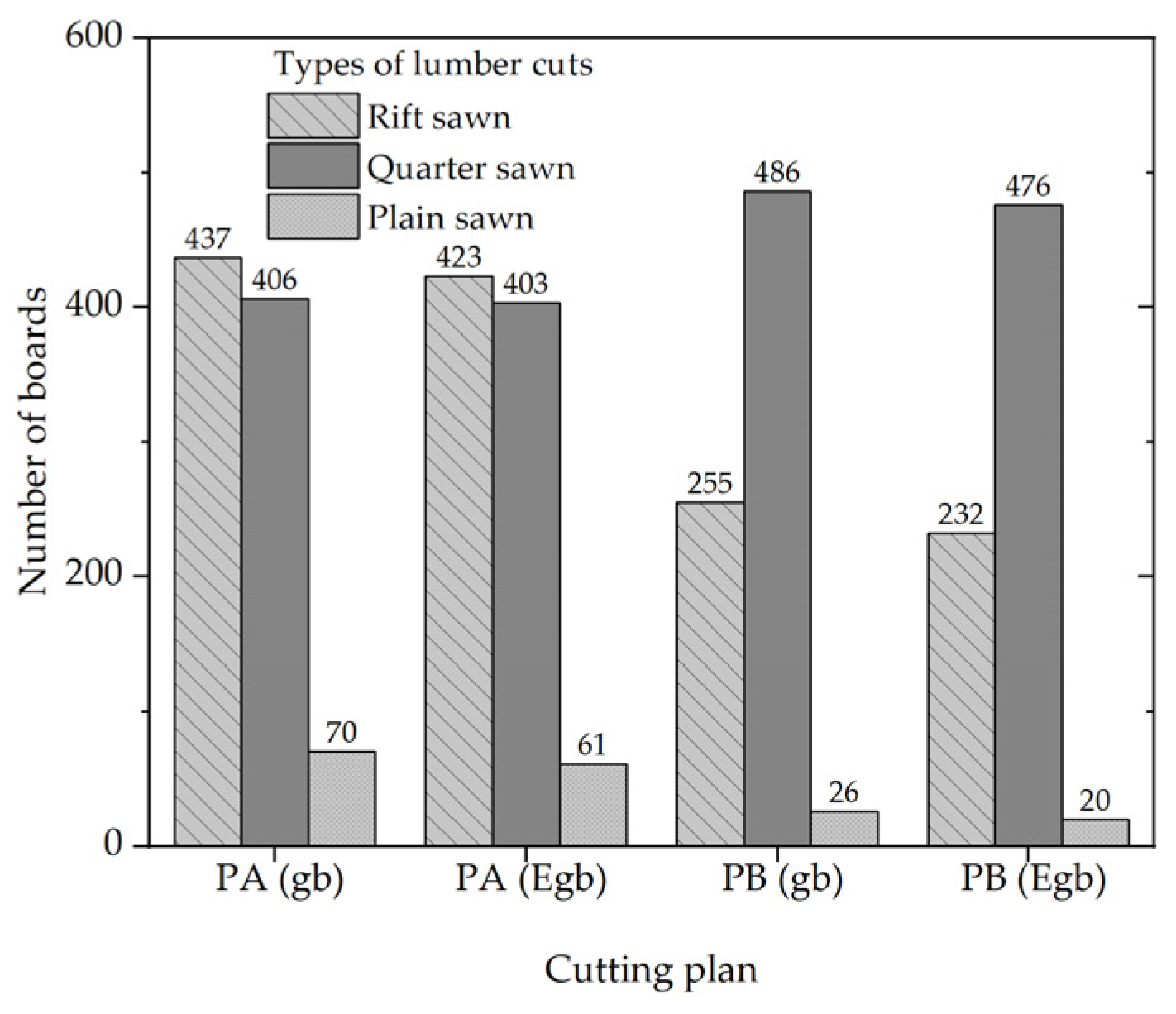

3.3.3. Lumber Grading Based on Customer-Defined Criteria Based on the Types of Wood Cuts: Plain Sawn, Quarter Sawn, and Rift Sawn

3.4. Measurements of Wood Warping

3.4.1. Evaluation of Wood Warping in the Different Cutting Plans

3.4.2. Wood Warping According to the Thickness of Board

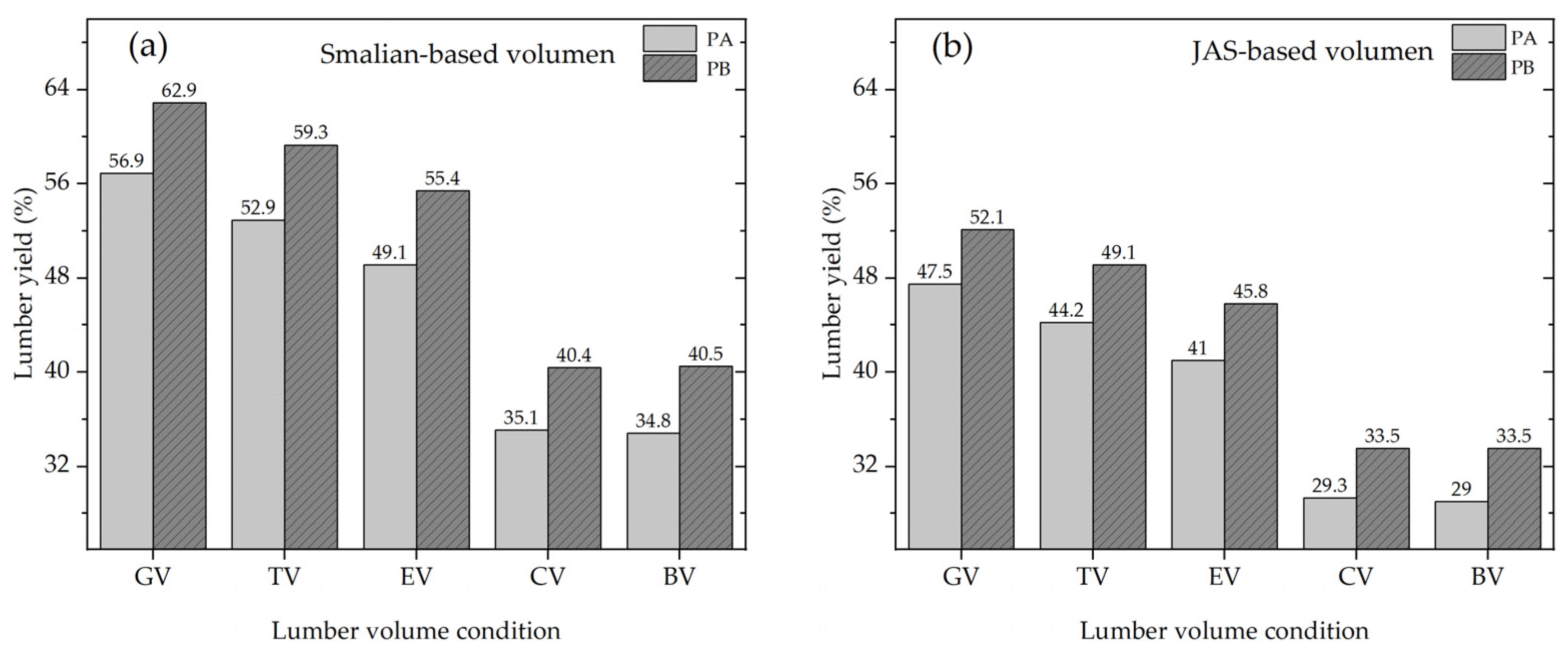

3.5. Lumber Yield

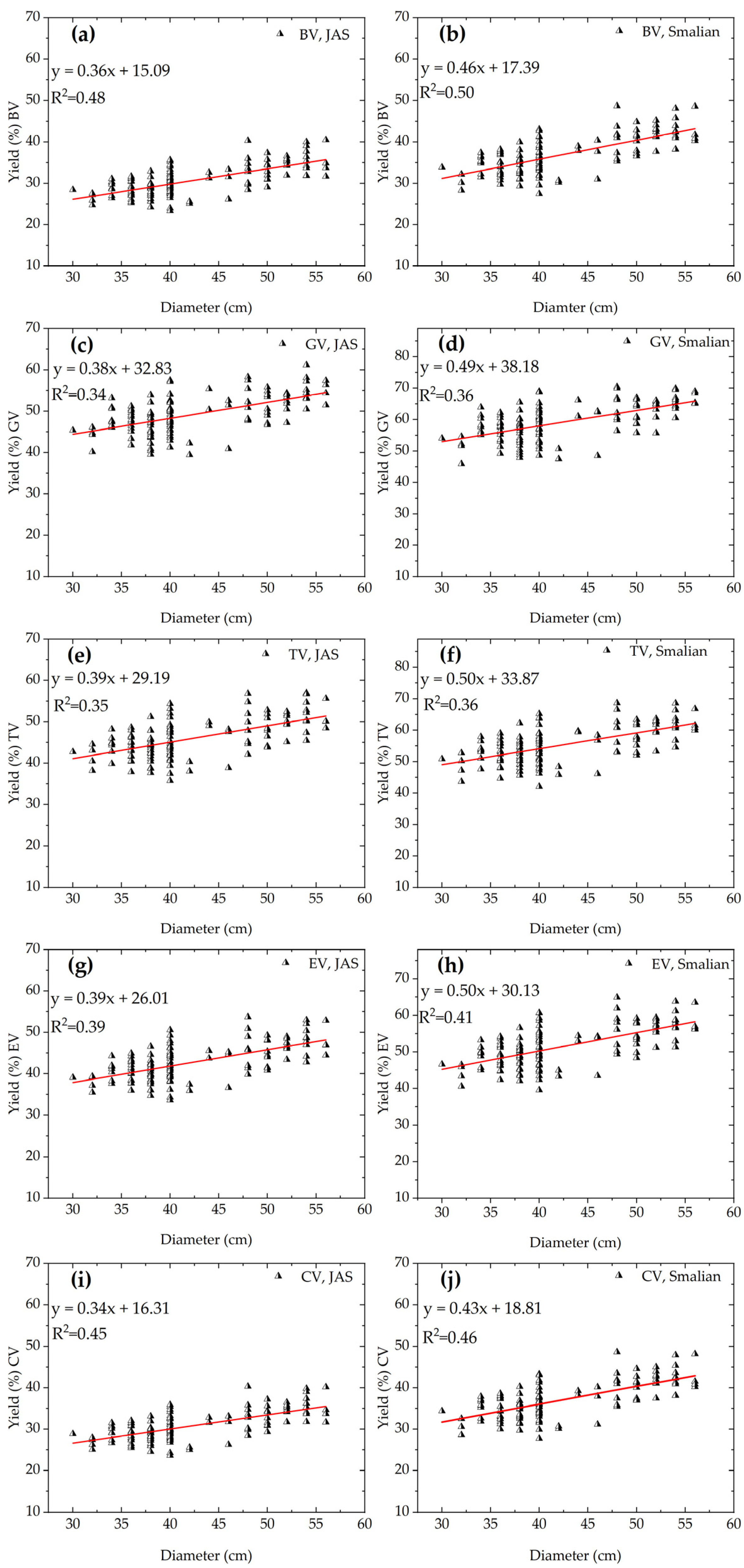

3.6. Relationship between Log Size and Lumber Yield

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Petit, G.; Pfautsch, S.; Anfodillo, T.; Adams, M.A. The Challenge of Tree Height in Eucalyptus Regnans: When Xylem Tapering Overcomes Hydraulic Resistance. New Phytol. 2010, 187, 1146–1153. [Google Scholar] [CrossRef]

- Ilic, J. Woods of Eucalyptus—Part 1. Distinguishing Three Species from the Ash Group. IAWA J. 1997, 18, 27–36. [Google Scholar] [CrossRef]

- Xu, K.; Tu, D.; Peng, P.; Guo, Q.; Yun, H. The Air-Kiln Drying Technology Research on Australian Eucalyptus Regnans Board. Adv. Mater. Res. 2012, 393–395, 507–514. [Google Scholar] [CrossRef]

- Belleville, B.; Ashley, P.; Ozarska, B. Wood Planing Properties of Australian Plantation-Grown Eucalypts. Maderas Cienc. Tecnol. 2016, 18, 425–434. [Google Scholar] [CrossRef]

- Yang, J.L.; Waugh, G. Potential of Plantation-Grown Eucalypts for Structural Sawn Products. II. Eucalyptus nitens (Dean and Maiden) Maiden and E. regnans F. MuelL. Aust. For. 1996, 59, 99–107. [Google Scholar] [CrossRef]

- INFOR. Los Recursos Forestales En Chile 2022. Informe Técnico N°258; INFOR: Santiago, Chile, 2022. [Google Scholar]

- Lisboa, M.; Acuña, E.; Cancino, J.; Muñoz, F.; Rodriguez, R.; Volker, P. Primeros Resultados de Un Ensayo de Severidad de Podas En Eucalyptus Regnans. Efectos En El Crecimiento y Respuesta Fisiológica. Cienc. Investig. For. INFOR 2014, 20, 39–50. [Google Scholar] [CrossRef]

- La Sala, A.V. Long-Term Response of Eucalyptus Regnans F.Muell. to Commercial Thinning in a Regrowth Eucalypt Forest in Tasmania. Aust. For. 2007, 70, 167–172. [Google Scholar] [CrossRef]

- Sillett, S.C.; Van Pelt, R.; Kramer, R.D.; Carroll, A.L.; Koch, G.W. Biomass and Growth Potential of Eucalyptus Regnans up to 100m Tall. For. Ecol. Manag. 2015, 348, 78–91. [Google Scholar] [CrossRef]

- Wood, S.W.; Hua, Q.; Allen, K.J.; Bowman, D.M.J.S. Age and Growth of a Fire Prone Tasmanian Temperate Old-Growth Forest Stand Dominated by Eucalyptus Regnans, the World’s Tallest Angiosperm. For. Ecol. Manag. 2010, 260, 438–447. [Google Scholar] [CrossRef]

- Suontama, M.; Low, C.B.; Stovold, G.T.; Miller, M.A.; Fleet, K.R.; Li, Y.; Dungey, H.S. Genetic Parameters and Genetic Gains across Three Breeding Cycles for Growth and Form Traits of Eucalyptus Regnans in New Zealand. Tree Genet. Genomes 2015, 11, 133. [Google Scholar] [CrossRef]

- Hawthorne, S.N.D.; Lane, P.N.J.; Bren, L.J.; Sims, N.C. The Long Term Effects of Thinning Treatments on Vegetation Structure and Water Yield. For. Ecol. Manag. 2013, 310, 983–993. [Google Scholar] [CrossRef]

- Van Der Meer, P.J.; Dignan, P. Regeneration after 8 Years in Artificial Canopy Gaps in Mountain Ash (Eucalyptus Regnans F. Muell.) Forest in South-Eastern Australia. For. Ecol. Manag. 2007, 244, 102–111. [Google Scholar] [CrossRef]

- INFOR. Eucalyptus Regnans. Antecedentes Silviculturales y Tecnología Para Sus Uso En Chile. Informe Técnico N°181; INFOR: Santiago, Chile, 2011. [Google Scholar]

- Lisboa, M.; Acuña, E.; Cancino, J.; Chao, F.; Muñoz, F.; Rodríguez, R.; Volker, P. Physiological Response to Pruning Severity in Eucalyptus Regnans Plantations. New For. 2014, 45, 753–764. [Google Scholar] [CrossRef]

- INFOR. Anuario Forestal-Chilean Statistical Yearbook of Forestry 2022; INFOR: Santiago, Chile, 2022. [Google Scholar]

- Yang, J.L.; Baillères, H.; Okuyama, T.; Muneri, A.; Downes, G. Measurement Methods for Longitudinal Surface Strain in Trees: A Review. Aust. For. 2005, 68, 34–43. [Google Scholar] [CrossRef]

- Chauhan, S.S.; Walker, J.C.F. Wood Quality in Artificially Inclined 1-Year-Old Trees of Eucalyptus Regnans—Differences in Tension Wood and Opposite Wood Properties. Can. J. For. Res. 2011, 41, 930–937. [Google Scholar] [CrossRef]

- Touza, M. Tensiones de Crecimiento En Eucalyptus Globulus de Galicia (España). Influencia de La Silvicultura y Estrategias de Aserrado. Maderas Cienc. Tecnol. 2001, 3, 68–89. [Google Scholar] [CrossRef]

- Rozas, C.; Burgos, R.; Opazo, A.; Moreno, P.; Erazo, O.; Lasserre, J.P. Distribution of Growth Stresses in Eucalyptus Nitens Maiden Logs Immersed in Water. Forests 2023, 14, 1517. [Google Scholar] [CrossRef]

- Rozas, C.; Sánchez, R.; Pinedo, P. Secado de Eucalyptus Nitens y Globulus y Su Aprovechamiento En Blocks, Pisos y Muebles. Maderas. Cienc. y Tecnol. 2005, 7, 109–120. [Google Scholar] [CrossRef]

- Silva, E.F.F.; de Mendonça Brasil, A.C.; Blanco, C.J.C. Wood Production and Its Correlation with Socioeconomic and Environmental Indicators in the Amazon Region. Sustainability 2023, 15, 11932. [Google Scholar] [CrossRef]

- Rawat, Y.S.; Eba, M.; Nebiyu, M. Lumber Recovery Rate of Cupressus Lusitanica in Arsi Forest Enterprise, Ethiopia. Sustainability 2023, 15, 1046. [Google Scholar] [CrossRef]

- Thomas, R.E.; Bennett, N. An Analysis of the Differences among Log Scaling Methods and Actual Log Volume. For. Prod. J. 2017, 67, 250–257. [Google Scholar] [CrossRef]

- Lin, W.; Wang, J.; Wu, J.; Devallance, D. Log Sawing Practices and Lumber Recovery of Small Hardwood Sawmills in West Virginia. For. Prod. J. 2011, 61, 216–224. [Google Scholar] [CrossRef]

- da Silva Luz, E.; Soares, Á.A.V.; Goulart, S.L.; Carvalho, A.G.; Monteiro, T.C.; de Paula Protásio, T. Challenges of the Lumber Production in the Amazon Region: Relation between Sustainability of Sawmills, Process Yield and Logs Quality. Environ. Dev. Sustain. 2021, 23, 4924–4948. [Google Scholar] [CrossRef]

- Balasso, M.; Hunt, M.; Jacobs, A.; O’Reilly-Wapstra, J. Quality Traits of Plantation Eucalyptus Nitens Logs Impacting Volume and Value Recovery of Structural Sawn Boards. Eur. J. Wood Wood Prod. 2022, 80, 657–668. [Google Scholar] [CrossRef]

- Hittawe, M.M.; Sidibé, D.; Mériaudeau, F. A Machine Vision Based Approach for Timber Knots Detection. In Proceedings of the Twelfth International Conference on Quality Control by Artificial Vision 2015, Le Creusot, France, 3–5 June 2015; Volume 9534, p. 95340L. [Google Scholar]

- Bergman, R.D.; Simpson, W.T.; Turk, C. Evaluating Warp of 2 by 4s Sawn from Panels Produced through Green Gluing Dimension Lumber from Small Ponderosa Pine Logs. For. Prod. J. 2010, 60, 57–63. [Google Scholar] [CrossRef]

- Hittawe, M.M.; Sidibé, D.; Beya, O.; Meriaudeau, F. Machine Vision for Timber Grading Singularities Detection and Applications. J. Electron. Imaging 2017, 26, 063015. [Google Scholar] [CrossRef]

- Keegan, C.E.; Morgan, T.A.; Blatner, K.A.; Daniels, J.M. Trends in Lumber Processing in the Western United States. Part II: Overrun and Lumber Recovery Factors. For. Prod. J. 2010, 60, 140–143. [Google Scholar] [CrossRef]

- Hambisa, M.; Rawat, Y.S.; Nebiyu, M.; Eba, M.; Tekleyohannes, A.T. Assessment of the Rate of Lumber Recovery of Eucalyptus Saligna at Gefere Sawmill in Gimbi Area, Ethiopia. J. Indian Acad. Wood Sci. 2023, 20, 62–72. [Google Scholar] [CrossRef]

- Missanjo, E.; Magodi, F. Impact of Taper and Sawing Methods on Lumber Volume Recovery for Pinus kesiya and Pinus patula Logs in Circular Sawmills. J. For. Prod. Ind. 2015, 4, 12–16. [Google Scholar]

- Wardlaw, T.J.; Plumpton, B.S.; Walsh, A.M.; Hickey, J.E. Comparison of Sawn Timber Recovery and Defect Levels in Eucalyptus Regnans and E. Globulus from Thinned and Unthinned Stands at Balts Road, Tasman Peninsula. Tasforests 2004, 15, 99–109. [Google Scholar]

- Lisboa, M. Efecto de La Poda de Ramas Vivas En La Fisiología, Estructura de Copa, Crecimiento y Densidad de La Madera de Plantaciones de Eucalyptus Regnans Destinadas a La Producción de Madera de Alto Valor. Ph.D. Thesis, Universidad de Concepción, Concepción, Chile, 2014. [Google Scholar]

- NCh44.Of2007; Procedimientos de Muestreo Para Inspección Por Atributos—Planes de Muestreo Indexados Por Nivel de Calidad Aceptable (AQL) Para La Inspección Lote Por Lote. Instituto Nacional de Normalización: Santiago, Chile, 2007.

- Vidaurre, S.; Melo, S.; Pavon, R. Manual 16: Principios de Organizacion y Operación Del Aserradero; INFOR: Santiago, Chile, 1989. [Google Scholar]

- Ministry of Agriculture, Forestry and Fisheries. Japanase Agricultural Standards for Logs; Ministry of Agriculture, Forestry and Fisheries: Tokyo, Japan, 2007. [Google Scholar]

- NCh993:2018; Madera—Procedimiento y Criterios de Evaluación Para Clasificación. Instituto Nacional de Normalización: Santiago, Chile, 2018.

- Rozas, C. Resultados Tecnológicos Proyecto Fondef D9811018: Diversificación y Aprovechamiento de Las Plantaciones de Eucalyptus Globulus y Eucalyptus Nitens Para Su Utilización En La Industria Del Mueble; Univerisad del Bío-Bío: Concepción, Chile, 2002. [Google Scholar]

- Salinas-Lira, C.; Acuña-Alegría, L.; Sepúlveda-Villarroel, V.; Ananías, R.A.; Salvo-Sepúlveda, L.; Torres-Mella, J.; Cancino-Mundaca, F.; Vasco, D.A. Warp Recovery in Radiata Pine Lumber Using Steam Treatment. BioResources 2018, 13, 8421–8431. [Google Scholar] [CrossRef]

- Zhuoting, J.; Hiroyuki, Y.; Miyuki, M.-U.; Yoshida, M.D.M.; Kento, T.; Hirokazu, K. Effect of High Temperature Drying with Load on Reduction of Residual Stress and Correction of Warp of Japanese Cedar Lumber. Dry. Technol. 2023, 41, 3–16. [Google Scholar] [CrossRef]

- Axelsson, A. Effect of Planing on Warp in Scots Pine (Pinus sylvestris). Wood Mater. Sci. Eng. 2012, 7, 154–161. [Google Scholar] [CrossRef]

- Montón, J.; Arriaga, F.; Íñiguez-González, G.; Segués, E. Warp Requirements and Yield Efficiency in the Visual Grading of Sawn Radiata Pine Timber. BioResources 2015, 10, 1115–1126. [Google Scholar] [CrossRef]

- Melo, R.R.; Dacroce, J.M.F.; Junior, F.R.; dos Santos Lisboa, G.; de Jesus França, L.C. Lumber Yield of Four Native Forest Species of the Amazon Region. Floresta e Ambient. 2019, 26, e20160311. [Google Scholar] [CrossRef]

- Ellis, J.C. A Log Volume Formula for Exporters. N. Z. J. For. 2011, 56, 20–26. [Google Scholar]

- de León, G.C.; Uranga-Valencia, L.P. Theoretical Evaluation of Huber and Smalian Methods Applied to Tree Stem Classical Geometries. Bosque 2013, 34, 311–317. [Google Scholar] [CrossRef]

- Li, C.; Barclay, H.; Hans, H.; Sidders, D. Estimation of Log Volumes: A Comparative Study; Information Report FI-X-11; Natural Resources Canada, Canadian Forest Service, Canadian Wood Fibre Centre: Edmonton, AB, Canada, 2015; 20p. [Google Scholar]

- Vilkovský, P.; Klement, I.; Vilkovská, T. The Impact of the Log-Sawing Patterns on the Quantitative and Qualitative Yield of Beech Timber (Fagus sylvatica L.). Appl. Sci. 2023, 13, 8262. [Google Scholar] [CrossRef]

- De Lima, R.B.; Ferreira, R.L.C.; Da Silva, J.A.A.; Guedes, M.C.; Da Silva, D.A.S.; De Oliveira, C.P.; Rabelo, F.G.; Silva, L.F.D.C. Effect of Species and Log Diameter on the Volumetric Yield of Lumber in Northern Brazilian Amazonia: Preliminary Results. J. Sustain. For. 2020, 39, 283–299. [Google Scholar] [CrossRef]

- Matsumura, Y.; Murata, K.; Ikami, Y.; Matsumura, J. Influence of Sawing Patterns on Lumber Quality and Yield in Large Sugi (Cryptomeria japonica) Logs. For. Prod. J. 2012, 62, 25–31. [Google Scholar] [CrossRef]

| Diameter (cm) | Number of Logs | % | Diameter (cm) | Number of Logs | % |

|---|---|---|---|---|---|

| 30 | 1 | 0.8 | 44 | 2 | 1.5 |

| 32 | 4 | 3.1 | 46 | 3 | 2.3 |

| 34 | 8 | 6.2 | 48 | 8 | 6.2 |

| 36 | 16 | 12.3 | 50 | 9 | 6.9 |

| 38 | 24 | 18.5 | 52 | 8 | 6.2 |

| 40 | 32 | 24.6 | 54 | 9 | 6.9 |

| 42 | 2 | 1.5 | 56 | 4 | 3.1 |

| Total | 100 |

| Cutting Plan | Wood Warping Level According to NCh993:2018 [39] | |||||

|---|---|---|---|---|---|---|

| A | B | C | D | Total | ||

| BOW | PA (green board) | 91 | 767 | 51 | 4 | 913 |

| PA (expected green board) | 91 | 742 | 51 | 3 | 887 | |

| PB (green board) | 32 | 716 | 19 | 0 | 767 | |

| PB (expected green board) | 31 | 678 | 19 | 0 | 728 | |

| PA losses | 0 | 25 | 0 | 1 | 26 | |

| PB losses | 1 | 38 | 0 | 0 | 39 | |

| Total losses | 1 | 63 | 0 | 1 | 65 | |

| CROOK | PA (green board) | 26 | 425 | 324 | 138 | 913 |

| PA (expected green board) | 26 | 412 | 319 | 130 | 887 | |

| PB (green board) | 13 | 563 | 154 | 37 | 767 | |

| PB (expected green board) | 12 | 537 | 146 | 33 | 728 | |

| PA losses | 0 | 13 | 5 | 8 | 26 | |

| PB losses | 1 | 26 | 8 | 4 | 39 | |

| Total Losses | 1 | 39 | 13 | 12 | 65 | |

| TWIST | PA (green board) | 454 | 424 | 28 | 7 | 913 |

| PA (expected green board) | 435 | 418 | 27 | 7 | 887 | |

| PB (green board) | 677 | 90 | 0 | 0 | 767 | |

| PB (expected green board) | 644 | 84 | 0 | 0 | 728 | |

| PA losses | 19 | 6 | 1 | 0 | 26 | |

| PB losses | 33 | 6 | 0 | 0 | 39 | |

| Total Losses | 52 | 12 | 1 | 0 | 65 | |

| Nominal Green Thickness (mm) | Wood Warping Grades According to NCh993:2018 [39] | |||||

|---|---|---|---|---|---|---|

| A | B | C | D | Total | ||

| BOW | 30 * | 0 | 29 | 0 | 0 | 29 |

| 31.5 | 0 | 0 | 0 | 0 | 0 | |

| 44 | 0 | 16 | 0 | 1 | 17 | |

| 56 | 1 | 18 | 0 | 0 | 19 | |

| Total loss | 1 | 63 | 0 | 1 | 65 | |

| CROOK | 30 * | 0 | 11 | 7 | 11 | 29 |

| 31.5 | 0 | 0 | 0 | 0 | 0 | |

| 44 | 0 | 13 | 3 | 1 | 17 | |

| 56 | 1 | 15 | 3 | 0 | 19 | |

| Total Loss | 1 | 39 | 13 | 12 | 65 | |

| TWIST | 30 * | 19 | 10 | 0 | 0 | 29 |

| 31.5 | 0 | 0 | 0 | 0 | 0 | |

| 44 | 16 | 0 | 1 | 0 | 17 | |

| 56 | 17 | 2 | 0 | 0 | 19 | |

| Total loss | 52 | 12 | 1 | 0 | 65 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rozas, C.; Zapata, B.; Muñoz, F.; Ortiz-Araya, V.; Erazo, O. Characterization and Yield of Eucalyptus regnans F. Muell Logs for Lumber Production. Forests 2023, 14, 2359. https://doi.org/10.3390/f14122359

Rozas C, Zapata B, Muñoz F, Ortiz-Araya V, Erazo O. Characterization and Yield of Eucalyptus regnans F. Muell Logs for Lumber Production. Forests. 2023; 14(12):2359. https://doi.org/10.3390/f14122359

Chicago/Turabian StyleRozas, Carlos, Barbara Zapata, Fernando Muñoz, Virna Ortiz-Araya, and Oswaldo Erazo. 2023. "Characterization and Yield of Eucalyptus regnans F. Muell Logs for Lumber Production" Forests 14, no. 12: 2359. https://doi.org/10.3390/f14122359

APA StyleRozas, C., Zapata, B., Muñoz, F., Ortiz-Araya, V., & Erazo, O. (2023). Characterization and Yield of Eucalyptus regnans F. Muell Logs for Lumber Production. Forests, 14(12), 2359. https://doi.org/10.3390/f14122359