Full Scale Evaluation of GFRP Confined Softwood after Long-Term Exposure to High Humidity Environment

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials

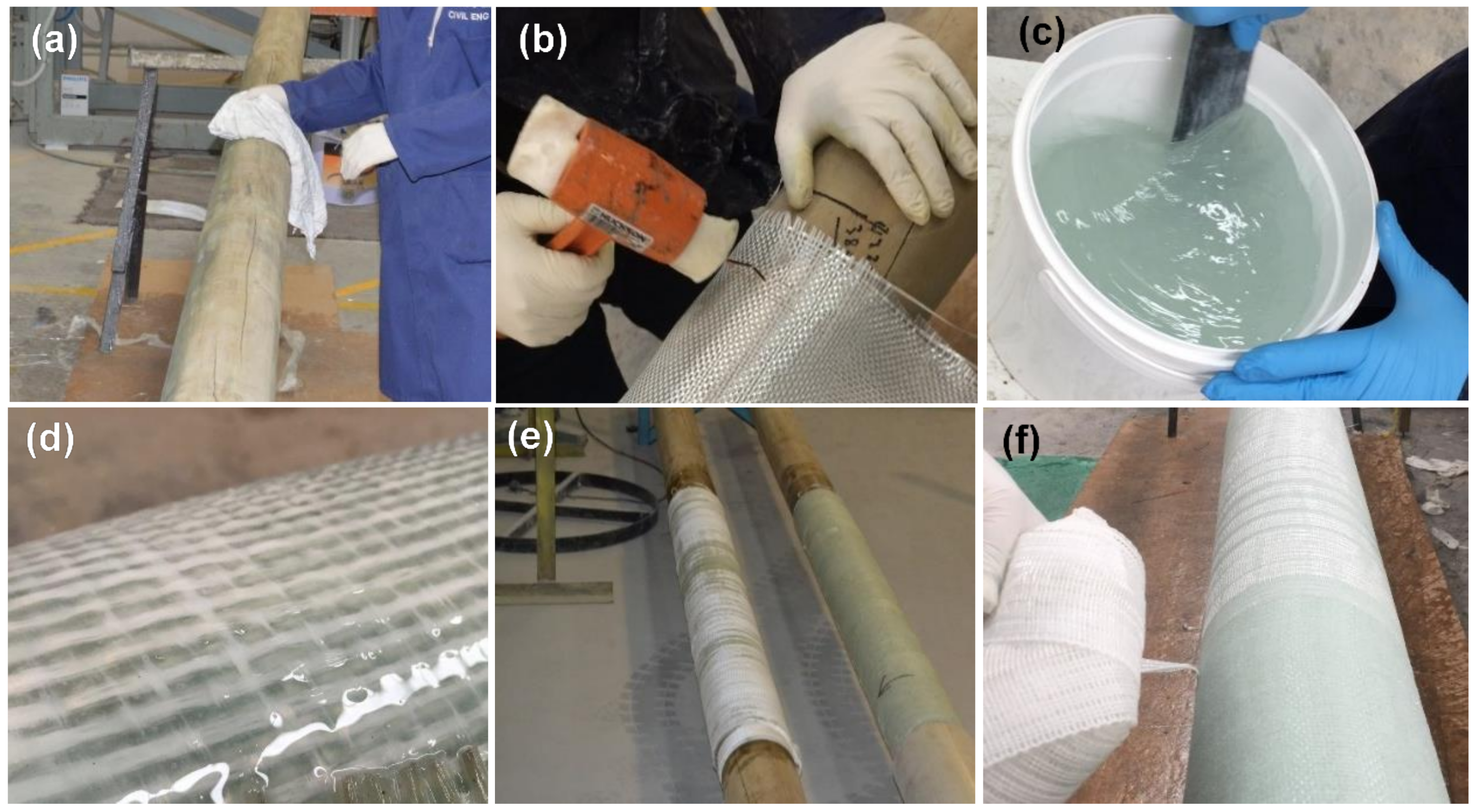

2.2. Specimens Preparation and Configurations

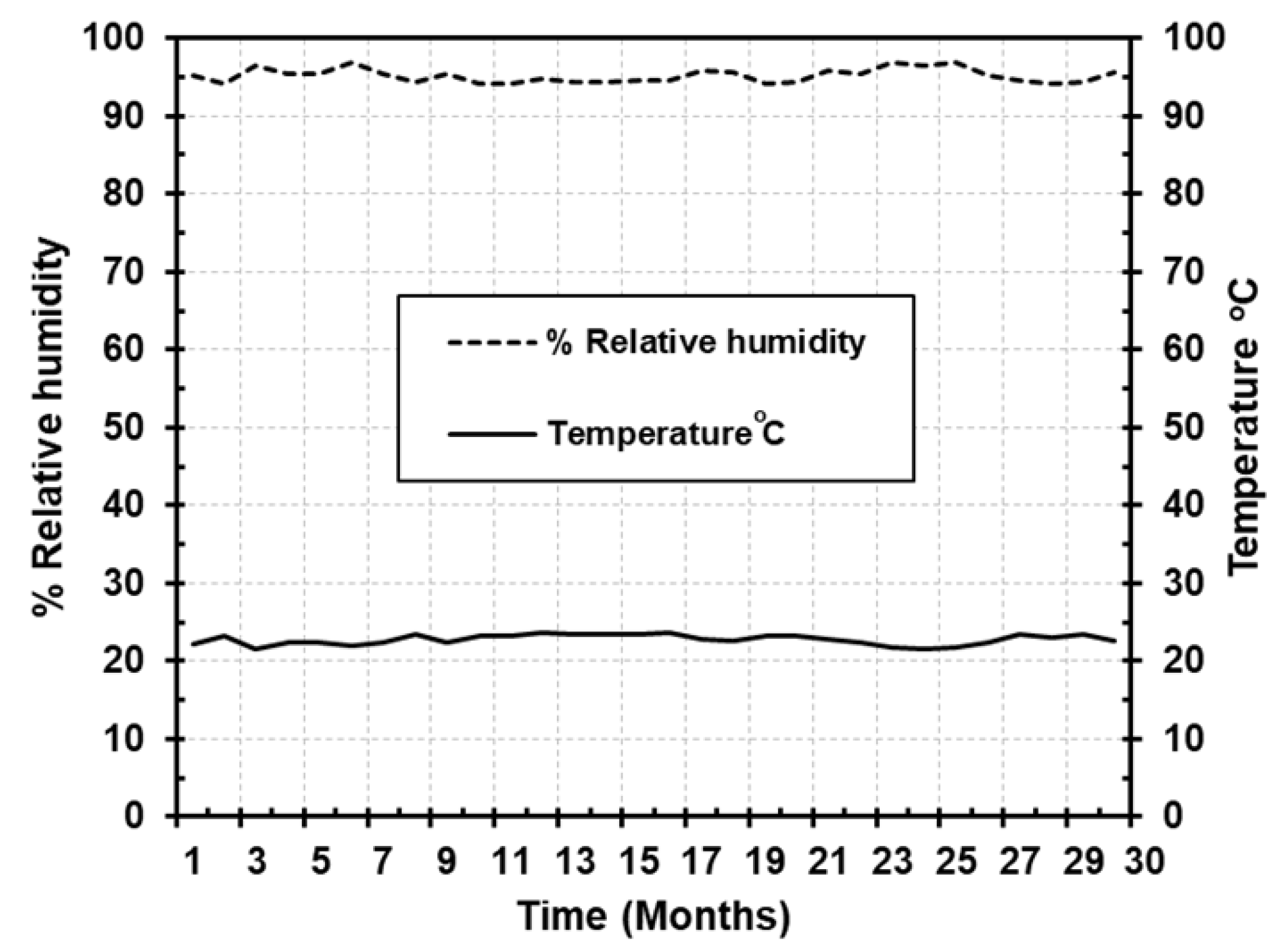

2.3. Moisture Exposure

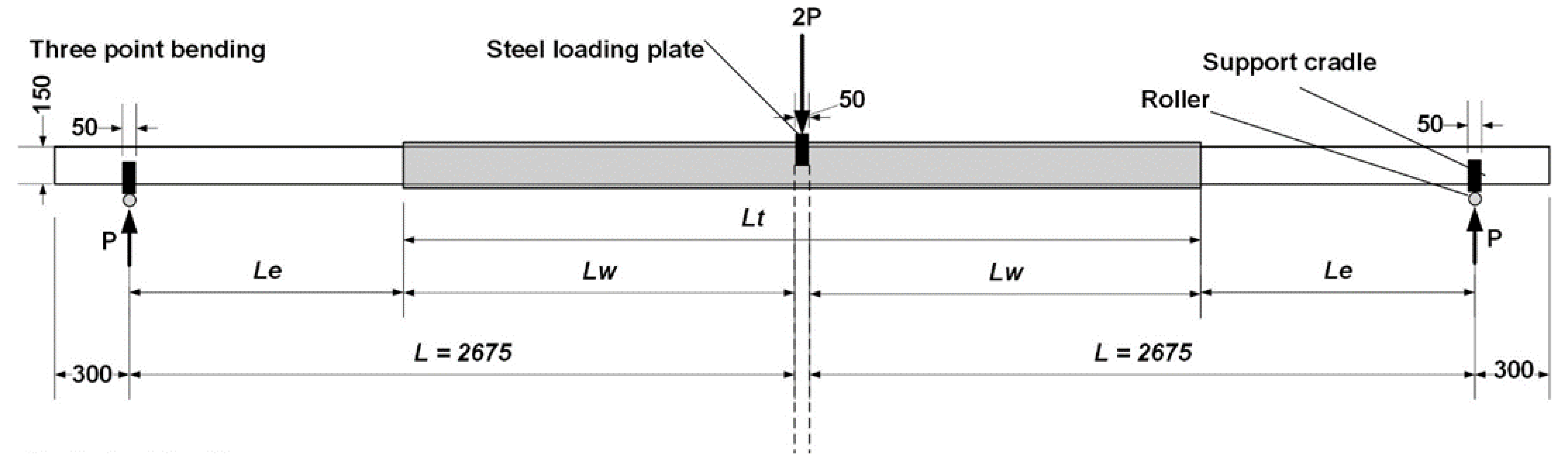

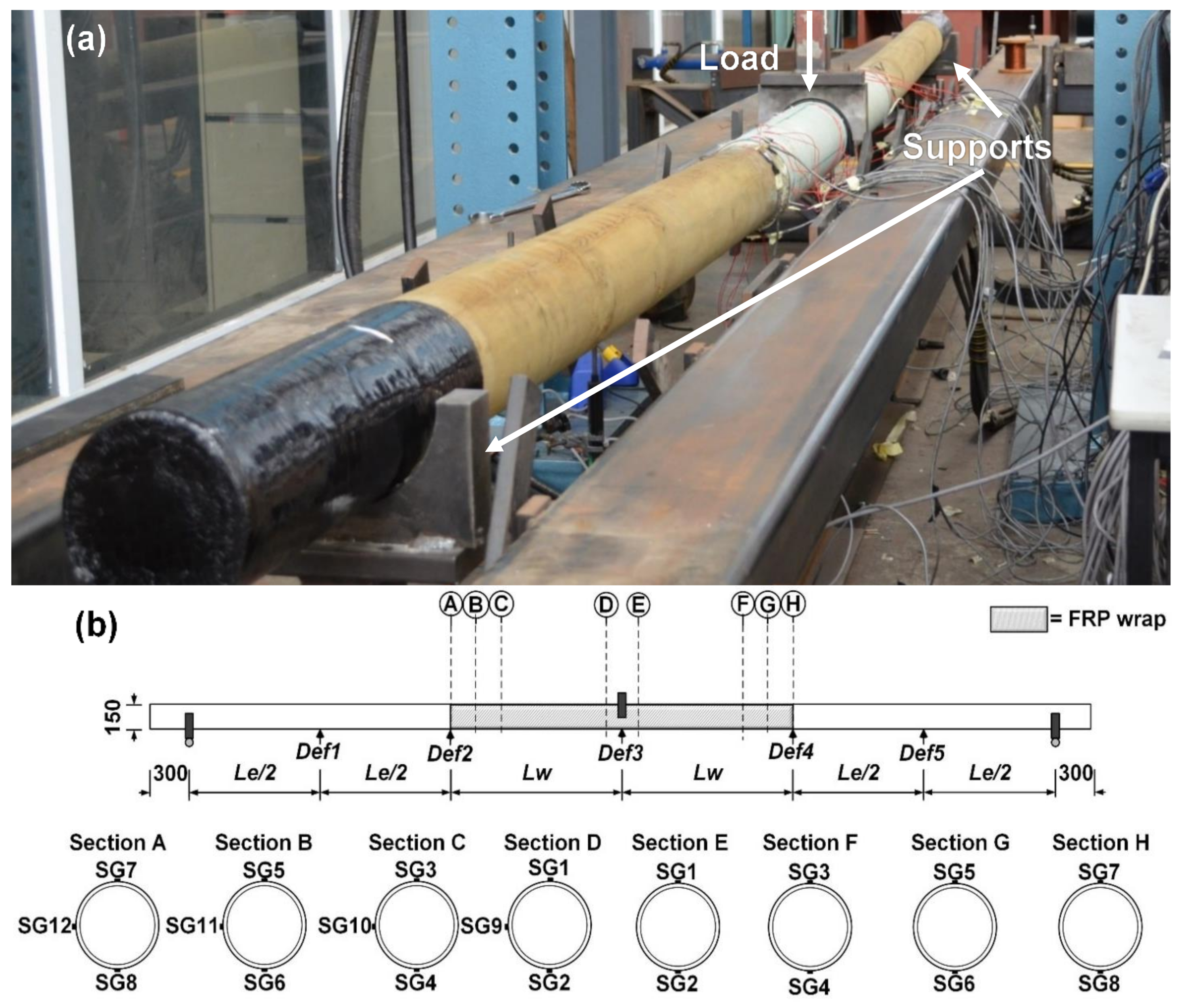

2.4. Mechanical Experimental Setup and Instrumentation

3. Experimental Results and Discussion

3.1. Failure Modes

3.2. Load–Displacement Behavior

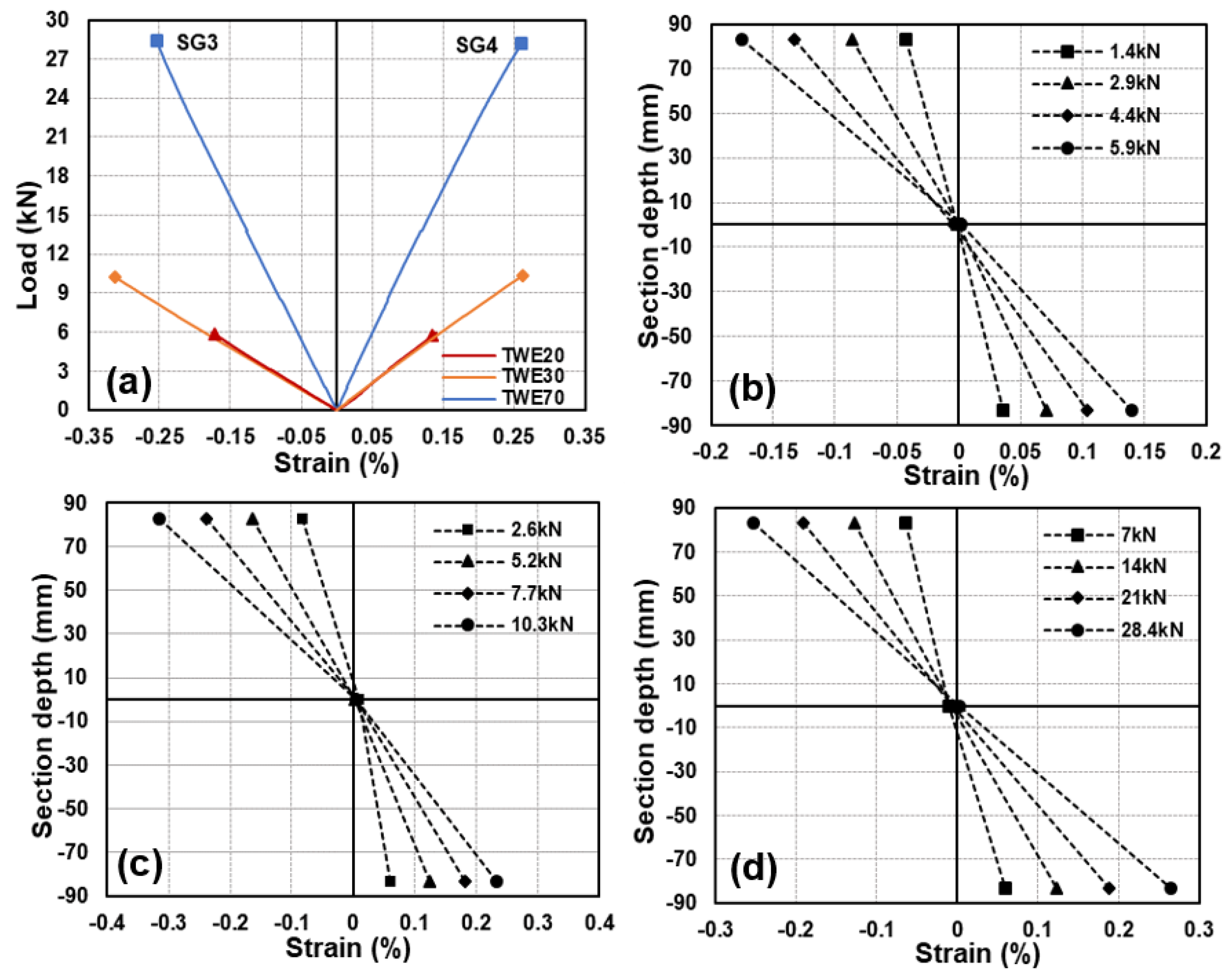

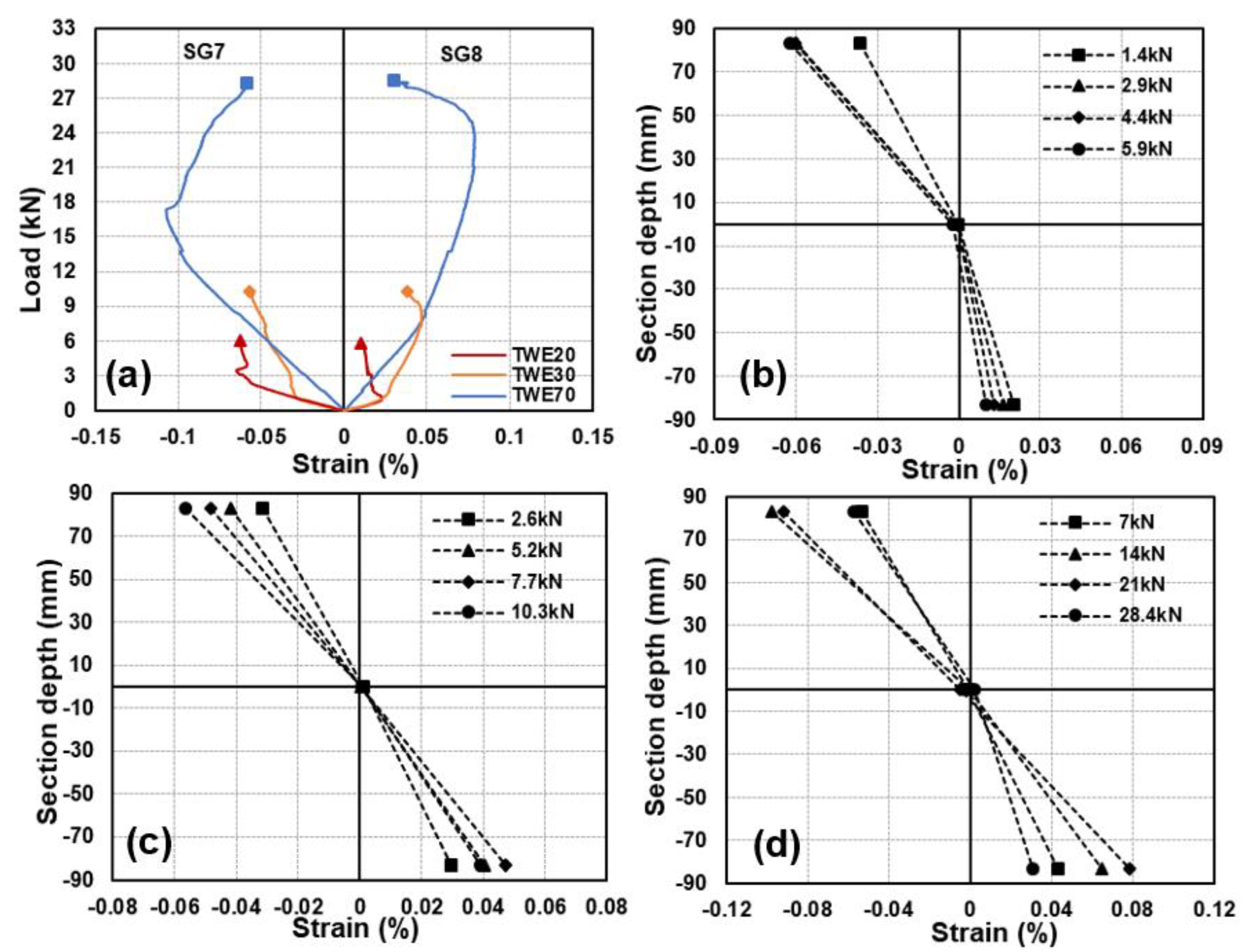

3.3. Load–Strain Behavior and Composite Action

3.4. Bending Stiffness

4. Moment Capacity Comparisons

5. Recommendations

6. Conclusions

- (1)

- The ultimate load capacities for specimens with 0% to 70% GFRP confinement of the span length (i.e., TWE0 to TWE70) after exposure to high humidity environment for 30 months were found to be close to the specimens without environmental exposure and the maximum difference in the ultimate load capacity was about 18% for the specimen that has 20% GFRP confinement length of the span (i.e., TWE20).

- (2)

- All the specimens with GFRP confinement after environmental exposure showed a similar failure mode as a sudden flexural tensile failure of timber at the ultimate loads. For the TWE0 specimen without GFRP wrapping the failure happened on the midspan, while the specimens with 20% to 70% GFRP wrapping, failed on the timber at one portion close to the rim of the GFRP confinement. However, the depths of timber failure inside the GFRP wrapping were different, namely, 11 mm, 17 mm, and 58 mm for specimens with 20%, 30%, and 70% GFRP wrapping, respectively.

- (3)

- GFRP-softwood composite specimens showed different performances, in terms of the moisture content after exposure and subsequent load-displacement responses, with the GFRP confinement length. The load-deflection responses started to change from linear to nonlinear when ultimate loads of about 50% were reached for the specimens with 20% and 30% GFRP confinement. The nonlinear response started for the TWE70 specimen ultimate load of at about 70%. The moisture content for the specimens decreased when the GFRP confinement length increased.

- (4)

- After exposure to high humidity for 30 months, full composite action between the GFRP and softwood was maintained for most of the bonded area in the softwood and GFRP composite specimens. For specimen TWE20 with 20% GFRP confinement, the first sign of debonding was 100 mm away from the rim of the GFRP confinement and the degradation in bonding was estimated to be 35.7% of the confinement length based on the strain responses at various sections along the span. For the specimens with 30% and 70% GFRP confinement span length, the degradation in bonding was estimated to be 12.1% and 5.7% of the overall confinement length, respectively.

- (5)

- The high humidity exposure of 30 months causes a reduction in bending stiffness for all the specimens. For the specimen without GFRP wrapping the bending stiffness decreased slightly by 6.1% compared to the unexposed one. The role of degradation in composite action caused more reduction in bending stiffness of 16.4% for specimen TWE20 with 20% confinement, and of 11.7% for the specimen with 30% GFRP confinement. For specimen TWE70 with 70% GFRP confinement, the environmental effect was minor with only 3.3% reduction in bending stiffness.

- (6)

- The capacity of the moment from the experimental results of the GFRP-softwood composite system after 30 months of exposure can be classified into several strength groups in accordance with the relevant standard (AS/NZS 2878. Timber-classification into strength groups, Standards Australia). Where specimens with 0% and 20% confinement with moment capacities of 8.8 kN·m and 8 kN·m correspond to the lowest strength groups—S6 and S7. Specimen TWE30 with 30% confinement presents the capacity of the moment of 13.4 kN·m and is located between strength groups S5 and S4. TWE70 showed 16.1% higher moment capacity compared to the highest strength group, S1, and it is also 45% higher than the hardwood pole species such as Corymbia (spotted gum) and Eucalyptus pilularis (blackbutt) currently in use.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Francis, L.; Norton, J. Australian Timber Pole Resources for Energy Networks. A Review; Technical Report; Department of Primary Industries and Fisheries: Queensland, QLD, Australia, 2006. [Google Scholar]

- Deegan, C. Environmental costing in capital investment decisions: Electricity distributors and the choice of power poles. Aust. Account. Rev. 2008, 18, 2–15. [Google Scholar] [CrossRef]

- Saafi, M.; Asa, E. Extending the service life of electric distribution and transmission wooden poles using a wet layup FRP composite strengthening system. J. Perform. Constr. Facil. 2010, 24, 409–416. [Google Scholar] [CrossRef]

- Bolin, C.A.; Smith, S.T. Life cycle assessment of pentachlorophenol-treated wooden utility poles with comparisons to steel and concrete utility poles. Renew. Sustain. Energy Rev. 2011, 15, 2475–2486. [Google Scholar] [CrossRef]

- Lu, H.R.; El Hanandeh, A. Environmental and economic assessment of utility poles using life cycle approach. Clean Technol. Environ. Policy 2017, 19, 1047. [Google Scholar] [CrossRef]

- Lu, H.R.; El Hanandeh, A. Soil Factors Behind Inground Decay of Timber Poles: Testing and Interpretation of Results. IEEE Trans. Power Deliv. 2007, 22, 1897–1903. [Google Scholar]

- Ibrahim, S.; Polyzois, D.; Hassan, S.K. Development of glass fiber reinforced plastic poles for transmission and distribution lines. Can. J. Civ. Eng. 2000, 27, 850–858. [Google Scholar] [CrossRef]

- Yu, Y.; Li, J.; Yan, N.; Dackermann, U.; Samali, B. Load capacity prediction of in-service timber utility poles considering wind load. J. Civ. Struct. Health Monit. 2016, 6, 385–394. [Google Scholar] [CrossRef]

- Lopez-Anido, R.; Michael, A.P.; Sandford, T.C.; Goodell, B. Repair of Wood Piles Using Prefabricated Fiber-Reinforced Polymer Composite Shells. J. Perform. Constr. Facil. 2005, 19, 78–87. [Google Scholar] [CrossRef]

- Horwood, M.A.; Westlake, T.; Kathuria, A. Control of Subterranean Termites (Isoptera: Rhinotermitidae) Infesting Power Poles. J. Econ. Entomol. 2010, 103, 2140–2146. [Google Scholar] [CrossRef]

- Bradshaw, C.J.A. Little left to lose: Deforestation and forest degradation in Australia since European colonization. J. Plant Ecol. 2012, 5, 109–120. [Google Scholar] [CrossRef]

- Bakis, C.E.; Bank, L.C.; Brown, V.L.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Machida, A.; Rizkalla, S.H.; Triantafillou, T.C. Fiber-Reinforced Polymer Composites for Construction-State-of-the-Art Review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef] [Green Version]

- Ferdous, W.; Almutairi, A.D.; Huang, Y.; Bai, Y. Short-term flexural behaviour of concrete filled pultruded GFRP cellular and tubular sections with pin-eye connections for modular retaining wall construction. Compos. Struct. 2018, 206, 1–10. [Google Scholar] [CrossRef]

- Qiu, C.; Bai, Y.; Cai, Z.; Zhang, Z. Cyclic performance of splice connections for hollow section fibre reinforced polymer members. Compos. Struct. 2020, 243, 112222. [Google Scholar] [CrossRef]

- Bai, Y.; Qiu, C. Load-Dependent Composite Action for Beam Nonlinear and Ductile Behavior. J. Struct. Eng. 2020, 146, 04020028. [Google Scholar] [CrossRef]

- Farinha, C.B.; de Brito, J.; Veiga, R. Assessment of glass fibre reinforced polymer waste reuse as filler in mortars. J. Clean. Prod. 2019, 210, 1579–1594. [Google Scholar] [CrossRef]

- Manalo, A.C.; Mendis, P.; Bai, Y.; Jachmann, B.; Sorbello, C.D. Fiber-reinforced polymer bars for concrete structures: State-of-the-practice in Australia. J. Compos. Constr. 2021, 25, 05020007. [Google Scholar] [CrossRef]

- Zuo, P.; Srinivasan, D.V.; Vassilopoulos, A.P. Review of hybrid composites fatigue. Compos. Struct. 2021, 274, 114358. [Google Scholar] [CrossRef]

- Amorim, L.; Santos, A.; Nunes, J.; Viana, J. Bioinspired approaches for toughening of fibre reinforced polymer composites. Mater. Des. 2021, 199, 109336. [Google Scholar] [CrossRef]

- Delzendehrooy, F.; Akhavan-Safar, A.; Barbosa, A.; Beygi, R.; Cardoso, D.; Carbas, R.; Marques, E.; da Silva, L. A comprehensive review on structural joining techniques in the marine industry. Compos. Struct. 2022, 289, 115490. [Google Scholar] [CrossRef]

- Saeedifar, M.; Zarouchas, D. Damage characterization of laminated composites using acoustic emission: A review. Compos. Part B Eng. 2020, 195, 108039. [Google Scholar] [CrossRef]

- Wang, W.; De Freitas, S.T.; Poulis, J.A.; Zarouchas, D. A review of experimental and theoretical fracture characterization of bi-material bonded joints. Compos. Part B Eng. 2021, 206, 108537. [Google Scholar] [CrossRef]

- Chen, C.; Yang, Y.; Zhou, Y.; Xue, C.; Chen, X.; Wu, H.; Sui, L.; Li, X. Comparative analysis of natural fiber reinforced polymer and carbon fiber reinforced polymer in strengthening of reinforced concrete beams. J. Clean. Prod. 2020, 263, 121572. [Google Scholar] [CrossRef]

- Xie, L.; Bai, Y.; Qi, Y.; Wang, H. Pultruded GFRP square hollow columns with bolted sleeve joints under eccentric compression. Compos. Part B Eng. 2019, 162, 274–282. [Google Scholar] [CrossRef]

- Qi, Y.; Xie, L.; Bai, Y.; Liu, W.; Fang, H. Axial compression behaviours of pultruded GFRP–wood composite columns. Sensors 2019, 19, 755. [Google Scholar] [CrossRef]

- Lei, X.; Yujun, Q.; Yu, B.; Chengyu, Q.; Hao, W.; Hai, F.; Xiao-Ling, Z. Sandwich assemblies of composites square hollow sections and thin-walled panels in compression. Thin-Walled Struct. 2019, 145, 106412. [Google Scholar] [CrossRef]

- Zhu, Y.M.; Yuan, S.C.; Hou, M.; Wang, Q.Y. Square Short Wood Columns Strengthened with FRP Sheets under Compressive Load. Appl. Mech. Mater. 2013, 256–259, 1008–1011. [Google Scholar] [CrossRef]

- Fang, H.; Bai, Y.; Liu, W.; Qi, Y.; Wang, J. Connections and structural applications of fibre reinforced polymer composites for civil infrastructure in aggressive environments. Compos. Part B 2019, 164, 129–143. [Google Scholar] [CrossRef]

- Manalo, A.; Aravinthan, T. Behaviour of glued fibre composite sandwich structure in flexure: Experiment and Fibre Model Analysis. Mater. Des. 2012, 39, 458–468. [Google Scholar] [CrossRef]

- Li, W.-Q.; Zhu, J.-H.; Chen, P.-Y.; Xing, F.; Li, D.; Su, M. Evaluation of carbon fiber reinforced cementitious matrix as a recyclable strengthening material. J. Clean. Prod. 2019, 217, 234–243. [Google Scholar] [CrossRef]

- Yang, Q.; Hong, B.; Lin, J.; Wang, D.; Zhong, J.; Oeser, M. Study on the reinforcement effect and the underlying mechanisms of a bitumen reinforced with recycled glass fiber chips. J. Clean. Prod. 2020, 251, 119768. [Google Scholar] [CrossRef]

- Azwa, Z.; Yousif, B.; Manalo, A.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef] [Green Version]

- Bajracharya, R.M.; Manalo, A.C.; Karunasena, W.; Lau, K.-T. An overview of mechanical properties and durability of glass-fibre reinforced recycled mixed plastic waste composites. Mater. Des. 2014, 62, 98–112. [Google Scholar] [CrossRef]

- Shamsuddoha; Islam, M.; Aravinthan, T.; Manalo, A.; Lau, K.T. Characterisation of mechanical and thermal properties of epoxy grouts for composite repair of steel pipelines. Mater. Des. 2013, 52, 315–327. [Google Scholar] [CrossRef]

- Keller, T.; Gürtler, H. Composite Action and Adhesive Bond between Fiber-Reinforced Polymer Bridge Decks and Main Girders. J. Compos. Constr. 2005, 9, 360–368. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Almutairi, A.D.; Satasivam, S.; Jeske, J. Modular assembly of water-retaining walls using GFRP hollow profiles: Components and connection performance. Compos. Struct. 2018, 194, 1–11. [Google Scholar] [CrossRef]

- Correia, J.R. Pultrusion of advanced fibre-reinforced polymer (FRP) composites. In Advanced Fibre-Reinforced Polymer (FRP) Composites for Structural Applications; Elsevier: Amsterdam, The Netherlands, 2013; pp. 207–251. [Google Scholar]

- Satasivam, S.; Bai, Y. Mechanical performance of bolted modular GFRP composite sandwich structures using standard and blind bolts. Compos. Struct. 2014, 117, 59–70. [Google Scholar] [CrossRef]

- Shi, H.; Liu, W.; Fang, H.; Bai, Y.; Hui, D. Flexural responses and pseudo-ductile performance of lattice-web reinforced GFRP-wood sandwich beams. Compos. Part B Eng. 2017, 108, 364–376. [Google Scholar] [CrossRef]

- Zhu, D.; Shi, H.; Fang, H.; Liu, W.; Qi, Y.; Bai, Y. Fiber reinforced composites sandwich panels with web reinforced wood core for building floor applications. Compos. Part B Eng. 2018, 150, 196–211. [Google Scholar] [CrossRef]

- Keller, T.; Rothe, J.; de Castro, J.; Osei-Antwi, M. GFRP-Balsa Sandwich Bridge Deck: Concept, Design, and Experimental Validation. J. Compos. Constr. 2014, 18, 04013043. [Google Scholar] [CrossRef]

- Li, L.; Yuan, S.L.; Dong, J.F.; Wang, Q.Y. An experimental study on the axial compressive behavior of timber columns strengthened by FRP sheets with different wrapping methods. Appl. Mech. Mater. 2013, 351–352, 1419–1422. [Google Scholar] [CrossRef]

- Hagos, M. Repair of Heavily Decayed Timber Piles Using Glass Fiber-Reinforced Polymers (GFRP) and Cementitious Grout. Master’s Thesis, University of Manitoba, Winnipeg, MB, Canada, July 2001. [Google Scholar]

- Caiza, P.; Shin, M.; Andrawes, B. Flexure-Compression Testing of Bridge Timber Piles Retrofitted with Fiber Reinforced Polymers. Open J. Civ. Eng. 2012, 2, 115–124. [Google Scholar] [CrossRef] [Green Version]

- Almutairi, A.D.; Bai, Y.; Wang, Y.; Jeske, J. Mechanical performance of fibre reinforced polymer confined softwood timber for pole applications. Compos. Struct. 2020, 235, 111807. [Google Scholar] [CrossRef]

- Bank, L.C. Composites for Construction: Structural Design with FRP Materials; John Wiley & Sons: New York, NY, USA, 2006. [Google Scholar]

- Vahedian, A.; Shrestha, R.; Crews, K. Effective bond length and bond behaviour of FRP externally bonded to timber. Constr. Build. Mater. 2017, 151, 742–754. [Google Scholar] [CrossRef]

- Boothby, T.E.; Bakis, C.E. Durability of Externally Bonded Fiber-Reinforced Polymer (FRP) Composite Systems; Woodhead Publishing: Sawston, UK, 2008. [Google Scholar]

- Ellyin, F.; Rohrbacher, C. Effect of Aqueous Environment and Temperature on Glass-Fibre Epoxy Resin Composites. J. Reinf. Plast. Compos. 2000, 19, 1405–1427. [Google Scholar] [CrossRef]

- Ribeiro, M.C.S.; Fiúza, A.; Ferreira, A.; Dinis, M.D.L.; Castro, A.C.M.; Meixedo, J.P.; Alvim, M.R. Recycling approach towards sustainability advance of composite materials’ industry. Recycling 2016, 1, 178–193. [Google Scholar] [CrossRef]

- Correia, J.R.; Almeida, N.M.; Figueira, J.R. Recycling of FRP composites: Reusing fine GFRP waste in concrete mixtures. J. Clean. Prod. 2011, 19, 1745–1753. [Google Scholar] [CrossRef]

- Yu, T.; Wong, Y.L.; Teng, J.G.; Dong, S.L.; Lam, E.S. Flexural Behavior of Hybrid FRP-Concrete-Steel Double-Skin Tubular Members. J. Compos. Constr. 2006, 10, 443–452. [Google Scholar] [CrossRef] [Green Version]

- Clarke, J.L. Structural Design of Polymer Composites: EUROCOMP Design Code and Handbook; E. & FN Spon Publisher: London, UK, 1996. [Google Scholar]

- ASTM D143-94; Standard Test Methods for Small Clear Specimens of Timber. ASTM: West Conshohocken, PA, USA, 2000.

- AS/NZS 1080.1; Timber—Methods of Test—Moisture Content. Standards Australia: Sydney, NSW, Australia, 1997.

- Gomez Casanova, S.M. Performance of Timber Stringers Reinforced with GFRP Wraps; ProQuest Dissertations Publishing: Ann Arbor, MI, USA, 2006. [Google Scholar]

- Climate Statistics for Australian Locations. Available online: http://www.bom.gov.au/climate/averages/tables/cw_086071.shtml (accessed on 4 January 2021).

- Pang, S.; Orchard, R.; McConchie, D. Tangential shrinkage of Pinus radiata earlywood and latewood, and its implication for within-ring internal checking. N. Z. J. For. Sci. 1999, 29, 484–491. [Google Scholar]

- Herritsch, A. Investigations on Wood Stability and Related Properties of Radiata Pine. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, October 2007. [Google Scholar]

- Gerhards, C.C. Effect of moisture content and temperature on the mechanical properties of wood: An analysis of immediate effects. Wood Fiber Sci. 2007, 14, 4–36. [Google Scholar]

- Wilson, T.R.C. Strength-Moisture Relations for Wood; U.S. Department of Agriculture: Washington, DC, USA, 1932. [Google Scholar]

- Forest Products Laboratory Corporate A. Wood Handbook Wood as an Engineering Material; U.S. Department of Agriculture: Washington, DC, USA, 1999. [Google Scholar]

- Zoghi, M. The International Handbook of FRP Composites in Civil Engineering; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Bai, J. Advanced Fibre-Reinforced Polymer (FRP) Composites for Structural Applications; Woodhead Publishing: Philadelphia, PA, USA, 2013. [Google Scholar]

- Bauchau, O.; Craig, J. Euler-Bernoulli Beam Theory. Structural Analysis; Springer: Dordrecht, The Netherlands, 2009; pp. 173–221. [Google Scholar]

- AS/NZS 2878; Timber—Classification into Strength Groups. Standards Australia: Sydney, NSW, Australia, 2000.

- AS/NZS 4676; Structural Design Requirements for Utility Services Poles. Standards Australia: Sydney, NSW, Australia, 2000.

| Grade of Glass Fiber | Density (g/cm3) | Tensile Modulus (GPa) | Tensile Strength (MPa) |

|---|---|---|---|

| E | 2.57 | 72.5 | 3400 |

| A | 2.46 | 73 | 2760 |

| C | 2.46 | 74 | 2350 |

| S | 2.47 | 88 | 4600 |

| Parameters | Magnitude | Unit |

|---|---|---|

| Tensile strength parallel to wood grain direction | 30.6 | MPa |

| Compressive strength parallel to wood grain direction | 34.2 | MPa |

| Tensile modulus of elasticity parallel to wood grain direction | 6.6 | GPa |

| Compressive modulus of elasticity parallel to wood grain direction | 4.2 | GPa |

| Flexural modulus of elasticity of softwood | 5.9 | GPa |

| Density of softwood | 400 | kg/m3 |

| GFRP longitudinal in-plane modulus | 23.2 | GPa |

| GFRP transverse in-plane modulus | 23.2 | GPa |

| GFRP shear in-plane modulus | 3.89 | GPa |

| GFRP major in-plane Poisson ratio | 0.15 | |

| GFRP minor in-plane Poisson ratio | 0.15 |

| Specimen Name | FRP Confinement (%) | Confinement Length Lw (mm) a | Exposed Length Le (mm) | Total Confined Length Lt (mm) |

|---|---|---|---|---|

| TWE0 | 0 | 0 | 2675 | 0 |

| TWE20 | 20 | 535 | 2140 | 1120 |

| TWE30 | 30 | 803 | 1873 | 1655 |

| TWE70 | 70 | 1873 | 803 | 3795 |

| Confinement | Failure Load (kN) | Bending Stiffness EIexp (kN·mm2) × 108 | Maximum Compression Strain at Midspan | Maximum Tension Strain at Midspan | Maximum Stress in Tension at Midspan σt (MPa) | Maximum Stress in Compression at Midspan σc (MPa) | Degradation in Bonding a (%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TW | TWE | % D | TW | TWE | % D | TWE | TWE | TWE | TWE | TWE | |

| 20% | 7.0 | 5.9 | 18.3 | 1.9 | 1.7 | 16.4 | −0.2 | 0.2 | 44.1 | 55.7 | 35.7 |

| 30% | 9.6 | 10.3 | −7.1 | 2.8 | 2.5 | 11.7 | −0.4 | 0.3 | 69.6 | 83.5 | 12.1 |

| 70% | 31.6 | 28.5 | 10.9 | 5.3 | 5.1 | 3.4 | −0.7 | 0.7 | 153.1 | 155.4 | 5.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almutairi, A.D.; Bai, Y.; Zhao, X.-L.; Ferdous, W. Full Scale Evaluation of GFRP Confined Softwood after Long-Term Exposure to High Humidity Environment. Forests 2023, 14, 343. https://doi.org/10.3390/f14020343

Almutairi AD, Bai Y, Zhao X-L, Ferdous W. Full Scale Evaluation of GFRP Confined Softwood after Long-Term Exposure to High Humidity Environment. Forests. 2023; 14(2):343. https://doi.org/10.3390/f14020343

Chicago/Turabian StyleAlmutairi, Ahmed D., Yu Bai, Xiao-Ling Zhao, and Wahid Ferdous. 2023. "Full Scale Evaluation of GFRP Confined Softwood after Long-Term Exposure to High Humidity Environment" Forests 14, no. 2: 343. https://doi.org/10.3390/f14020343