Preparation of Hydrophobic Optically Transparent Wood via An Efficient UV-Assisted Route

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

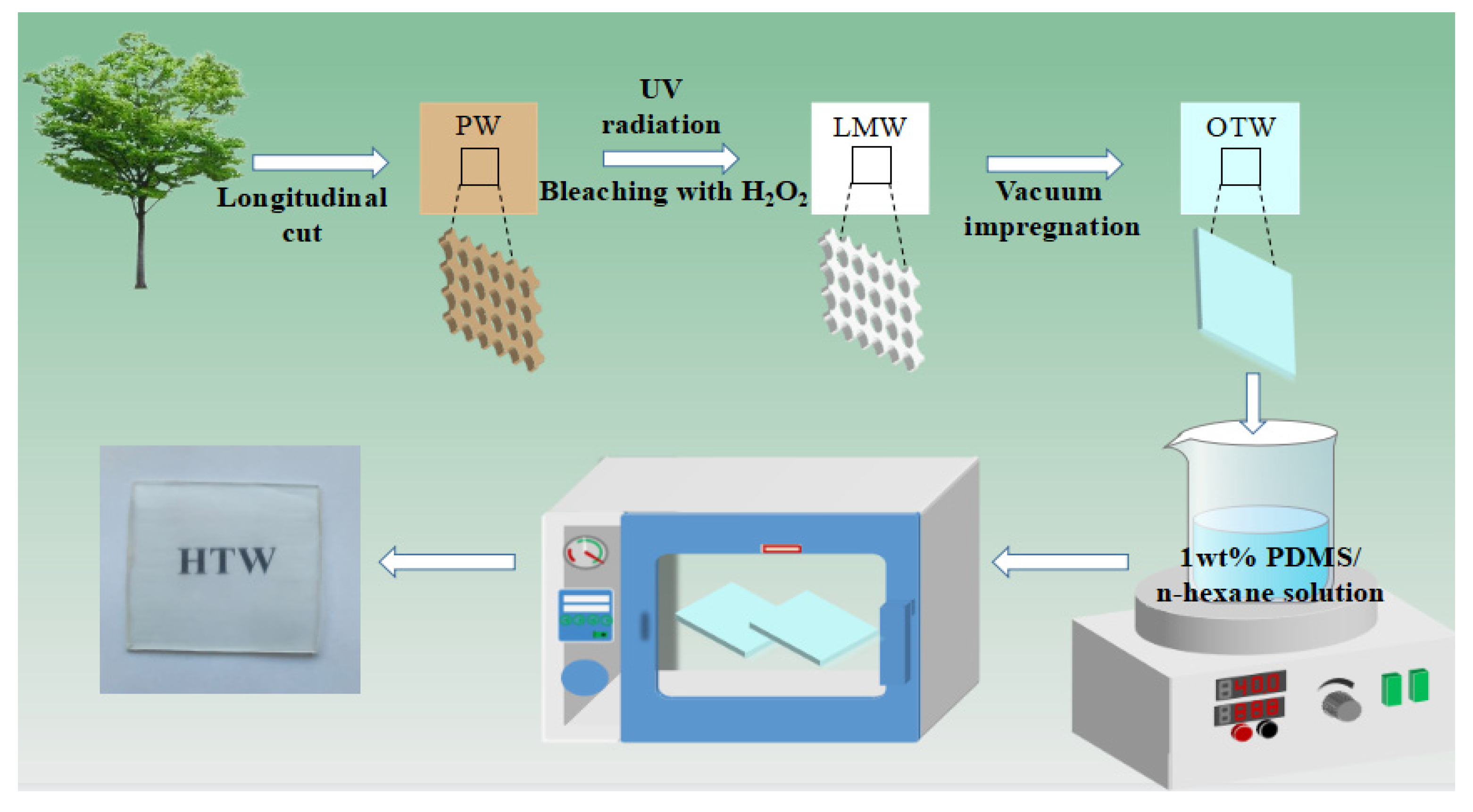

2.2. Preparation of Transparent Wood

2.3. Characterization

2.4. Preparation of Optically Transparent Wood

3. Results and Discussion

Characterization of Transparent Wood

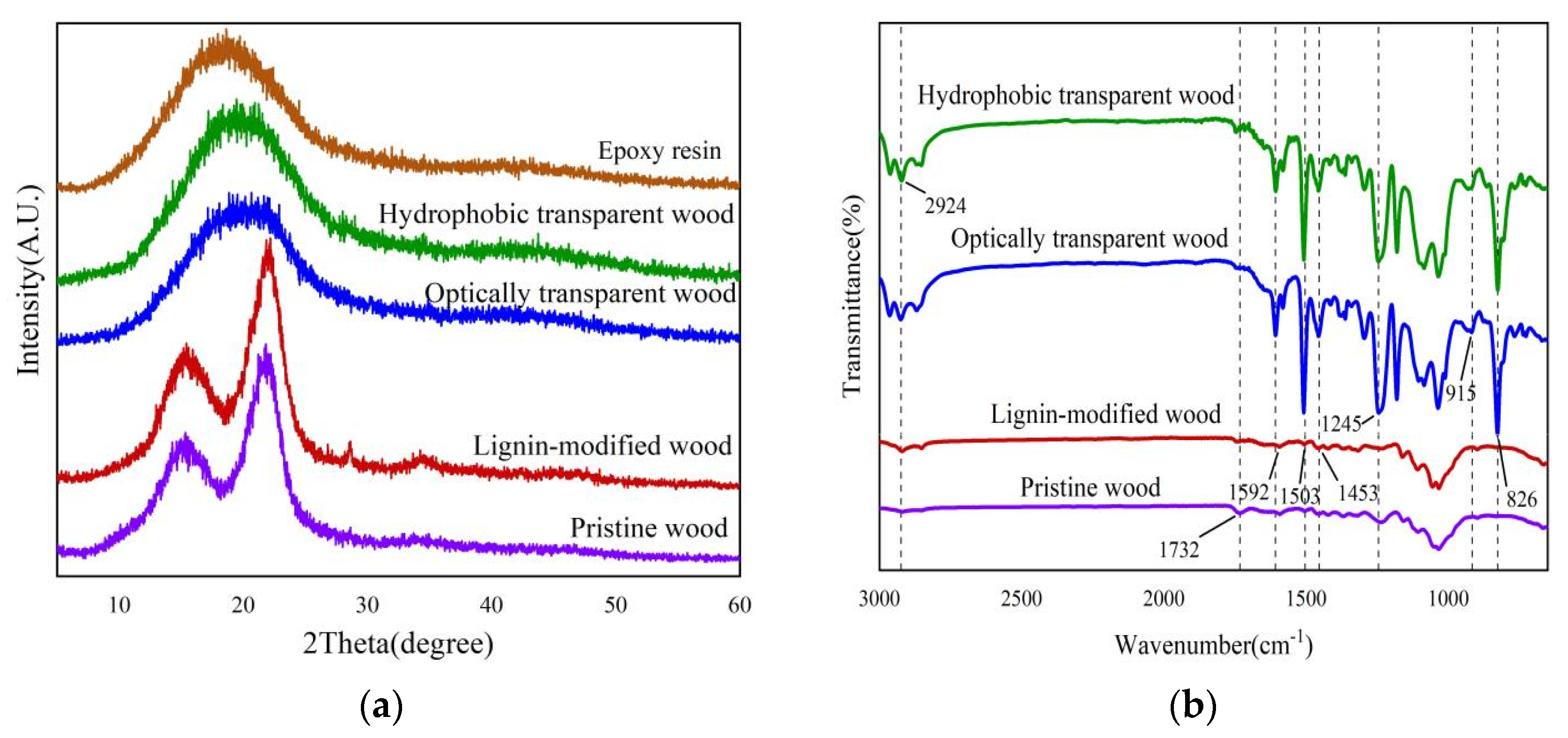

3.1.1. Micromorphology and Microstructure

3.1.2. Chemical Composition

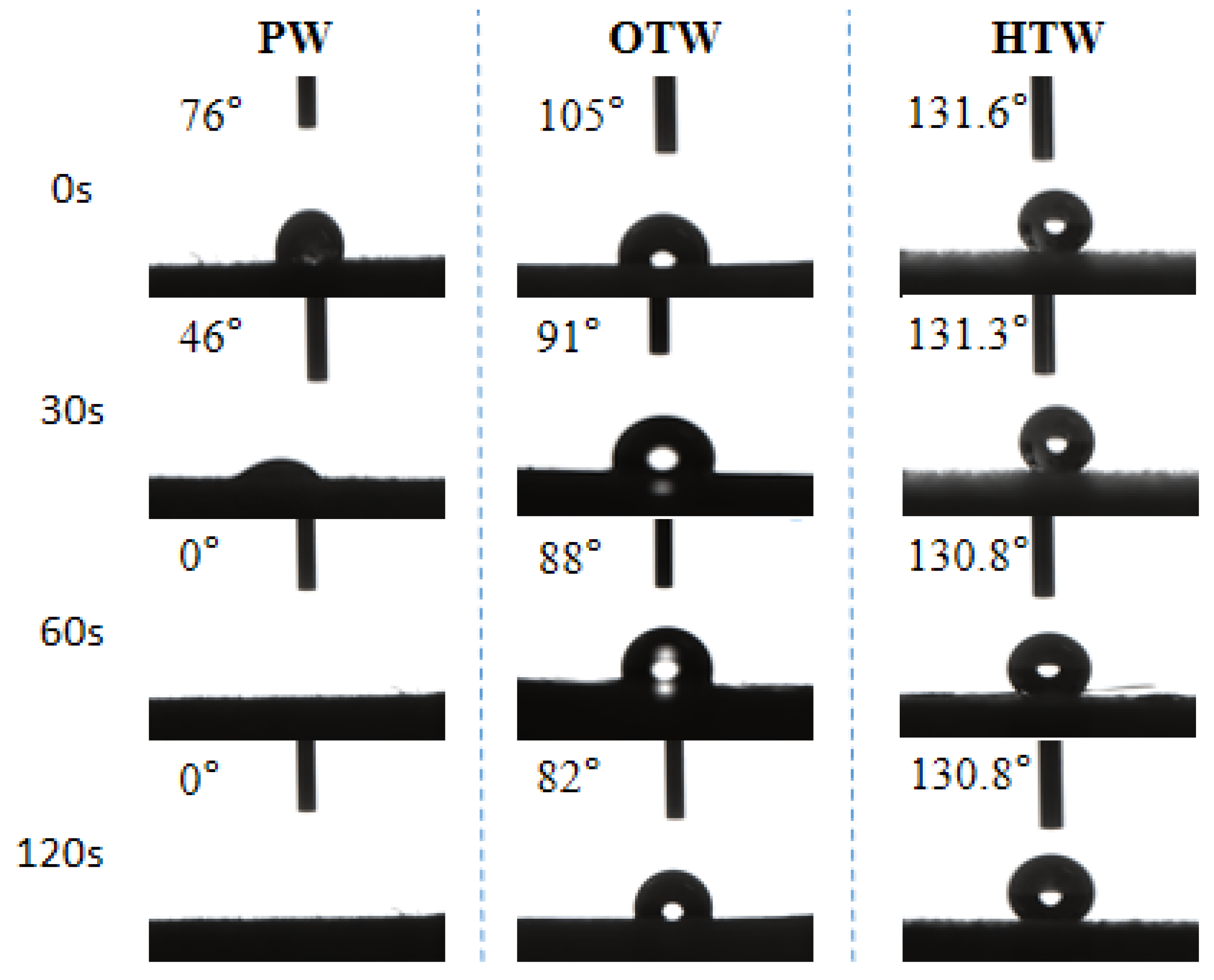

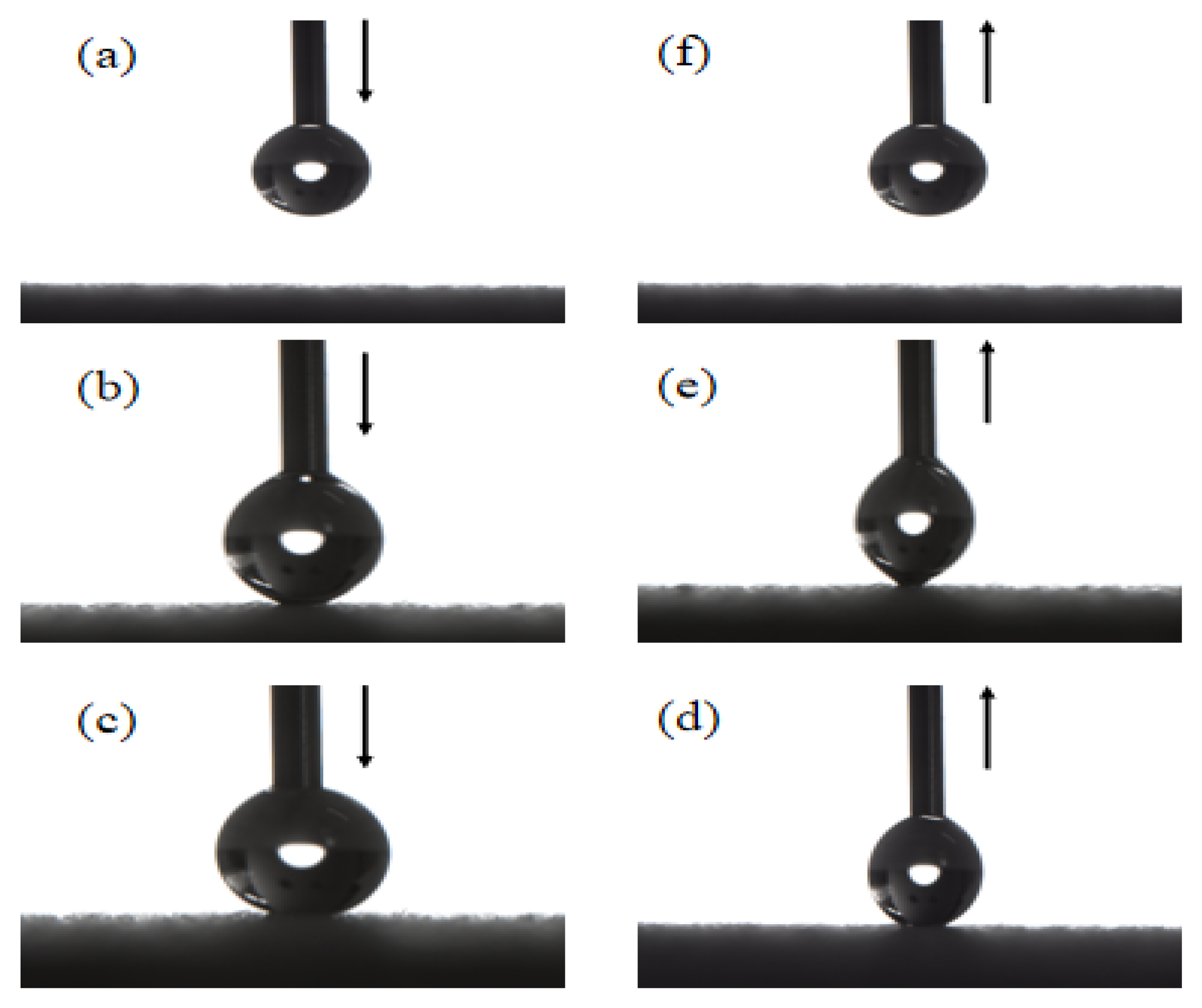

3.1.3. Wettability

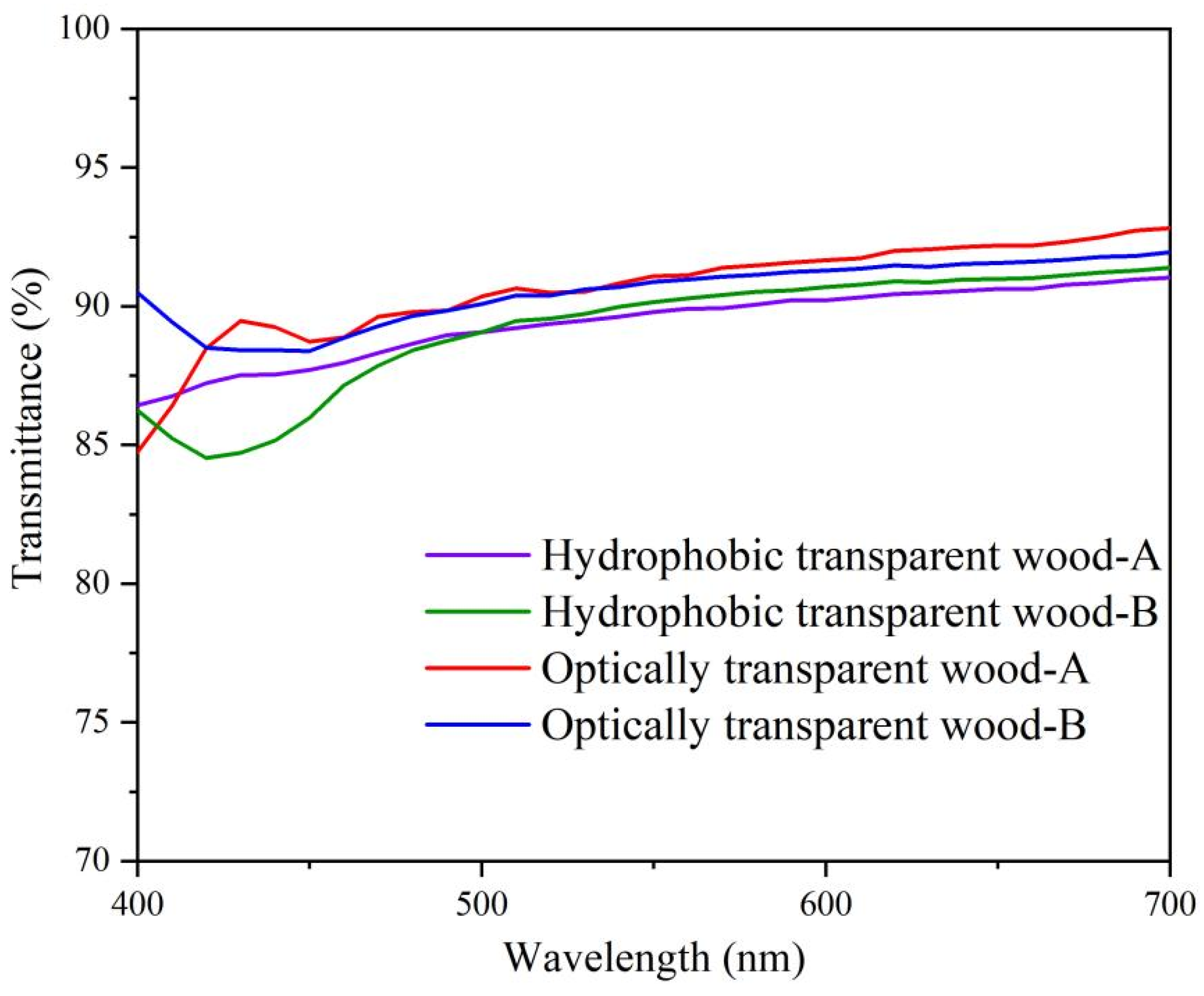

3.1.4. Optical Characteristics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Johnston, C.M.T.; Guo, J.; Prestemon, J.P. U.S. and Global Wood Energy Outlook under Alternative Shared Socioeconomic Pathways. Forests 2022, 13, 786. [Google Scholar] [CrossRef]

- Silva, F.A.G.S.; Dourado, F.; Gama, M.; Poças, F. Nanocellulose Bio-Based Composites for Food Packaging. Nanomaterials 2020, 10, 2041. [Google Scholar] [CrossRef]

- Yang, H.; Gao, M.; Wang, J.; Mu, H.; Qi, D. Fast Preparation of high-performance wood materials assisted by ultrasonic and vacuum impregnation. Forests 2021, 12, 567. [Google Scholar] [CrossRef]

- Vay, O.; De Borst, K.; Hansmann, C.; Teischinger, A.; Müller, U. Thermal conductivity of wood at angles to the principal anatomical directions. Wood Sci. Technol. 2015, 49, 577–589. [Google Scholar] [CrossRef]

- Xia, R.; Liu, Y.; Guo, H. An Overview on Functionalization Modification of Transparent Wood. Mater. Rep. 2021, 35, 5188–5194. (In Chinese) [Google Scholar]

- Liu, X.; Wan, C.; Li, X.; Wei, S.; Zhang, L.; Tian, W.; Yong, K.; Wu, Y.; Li, J. Sustainable wood-based nanotechnologies for photocatalytic degradation of organic contaminants in aquatic environment. Front. Env. Sci. Eng. 2021, 15, 54. [Google Scholar] [CrossRef]

- Chen, C.; Kuang, Y.; Zhu, S.; Burgert, I.; Keplinger, T.; Gong, A.; Li, T.; Berglund, L.; Eichhorn, S.J.; Hu, L. Structure–property–function relationships of natural and engineered wood. Nat. Rev. Mater. 2020, 5, 642–666. [Google Scholar] [CrossRef]

- Koppelhuber, J.; Bauer, B.; Wall, J.; Heck, D. Industrialized timber building systems for an increased market share–a holistic approach targeting construction management and building economics. Procedia Eng. 2017, 171, 333–340. [Google Scholar] [CrossRef]

- Li, J.; Chen, C.; Zhu, J.Y.; Ragauskas, A.J.; Hu, L. In situ wood delignification toward sustainable applications. Acc. Mater. Res. 2021, 2, 606–620. [Google Scholar] [CrossRef]

- Guo, C.F.; Ren, Z. Flexible transparent conductors based on metal nanowire networks. Mater. Today 2015, 18, 143–154. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, P.; Chen, M.; Yang, K.; Cao, Y.; Li, X.; Tang, M.; Chen, W.; Zhou, X. Constructing a novel electroluminescent device with high-temperature and high-humidity resistance based on a flexible transparent wood film. ACS Appl. Mater. Inter. 2019, 11, 36010–36019. [Google Scholar] [CrossRef]

- Mi, R.; Li, T.; Dalgo, D.; Chen, C.; Kuang, Y.; He, S.; Zhao, X.; Xie, W.; Gan, W.; Zhu, J.; et al. A clear, strong, and thermally insulated transparent wood for energy efficient windows. Adv. Funct. Mater. 2020, 30, 1907511. [Google Scholar] [CrossRef]

- Fu, Q.; Yan, M.; Jungstedt, E.; Yang, X.; Li, Y.; Berglund, L.A. Transparent plywood as a load-bearing and luminescent biocomposite. Compos. Sci. Technol. 2018, 164, 296–303. [Google Scholar] [CrossRef]

- Xue, Q.; Xia, R.; Brabec, C.J.; Yip, H. Recent advances in semi-transparent polymer and perovskite solar cells for power generating window applications. Energ. Environ. Sci. 2018, 11, 1688–1709. [Google Scholar] [CrossRef]

- Hui, B.; Li, Y.; Huang, Q.; Li, G.; Li, J.; Cai, L.; Yu, H. Fabrication of smart coatings based on wood substrates with photoresponsive behavior and hydrophobic performance. Mater. Des. 2015, 84, 277–284. [Google Scholar] [CrossRef]

- Li, Y.; Gu, X.; Gao, H.; Li, J. Photoresponsive wood composite for photoluminescence and ultraviolet absorption. Constr. Build. Mater. 2020, 261, 119984. [Google Scholar] [CrossRef]

- Li, Y.; Fu, Q.; Yu, S.; Yan, M.; Berglund, L. Optically transparent wood from a nanoporous cellulosic template: Combining functional and structural performance. Biomacromolecules 2016, 17, 1358–1364. [Google Scholar] [CrossRef] [Green Version]

- Yaddanapudi, H.S.; Hickerson, N.; Saini, S.; Tiwari, A. Fabrication and characterization of transparent wood for next generation smart building applications. Vacuum 2017, 146, 649–654. [Google Scholar] [CrossRef]

- Qiu, Z.; Xiao, Z.; Gao, L.; Li, J.; Wang, H.; Wang, Y.; Xie, Y. Transparent wood bearing a shielding effect to infrared heat and ultraviolet via incorporation of modified antimony-doped tin oxide nanoparticles. Compos. Sci. Technol. 2019, 172, 43–48. [Google Scholar] [CrossRef]

- Rahman, M.R.; Ting, J.S.H.; Hamdan, S.; Hasan, M.; Salleh, S.F.; Rahman, M.M. Impact of delignification on mechanical, morphological, and thermal properties of wood sawdust reinforced unsaturated polyester composites. J. Vinyl Addit. Techn. 2018, 24, 185–191. [Google Scholar] [CrossRef]

- Li, Y.; Fu, Q.; Yang, X.; Berglund, L. Transparent wood for functional and structural applications. Philos. T. R. Soc. A 2018, 376, 20170182. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, A.; Zhu, T.; Chen, Z.; Wu, Y.; Gao, Y. Transparent wood composites fabricated by impregnation of epoxy resin and W-doped VO2 nanoparticles for application in energy-saving windows. ACS Appl. Mater. Inter. 2020, 12, 34777–34783. [Google Scholar] [CrossRef]

- Wood, D.; Vailati, C.; Menges, A.; Rüggeberg, M. Hygroscopically actuated wood elements for weather responsive and self-forming building parts–Facilitating upscaling and complex shape changes. Constr. Build. Mater. 2018, 165, 782–791. [Google Scholar] [CrossRef]

- Li, Y.; Yang, X.; Fu, Q.; Rojas, R.; Yan, M.; Berglund, L. Towards centimeter thick transparent wood through interface manipulation. J. Mater. Chem. A 2018, 6, 1094–1101. [Google Scholar] [CrossRef] [Green Version]

- Makarov, I.S.; Golova, L.K.; Smyslov, A.G.; Vinogradov, M.I.; Palchikova, E.E.; Legkov, S.A. Flax Noils as a Source of Cellulose for the Production of Lyocell Fibers. Fibers 2022, 10, 45. [Google Scholar] [CrossRef]

- El Hage, R.; Brosse, N.; Chrusciel, L.; Sanchez, C.; Sannigrahi, P.; Ragauskas, A. Characterization of milled wood lignin and ethanol organosolv lignin from miscanthus. Polym. Degrad. Stabil. 2009, 94, 1632–1638. [Google Scholar] [CrossRef]

- Herrera, M.; Thitiwutthisakul, K.; Yang, X.; Rujitanaroj, P.; Rojas, R.; Berglund, L. Preparation and evaluation of high-lignin content cellulose nanofibrils from eucalyptus pulp. Cellulose 2018, 25, 3121–3133. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Liu, Y.; Chen, W.; Wang, Q.; Liu, Y.; Li, J.; Yu, H. Facile extraction of cellulose nanocrystals from wood using ethanol and peroxide solvothermal pretreatment followed by ultrasonic nanofibrillation. Green Chem. 2016, 18, 1010–1018. [Google Scholar] [CrossRef]

- González, M.G.; Cabanelas, J.C.; Baselga, J. Applications of FTIR on epoxy resins-identification, monitoring the curing process, phase separation and water uptake. Infrared Spec.-Mater. Sci. Eng. Technol. 2012, 2, 261–284. [Google Scholar]

- Ou, J.; Zhao, G.; Wang, F.; Li, W.; Lei, S.; Fang, X.; Siddiqui, A.R.; Xia, Y.; Amirfazli, A. Durable superhydrophobic wood via one-step immersion in composite silane solution. ACS Omega 2021, 6, 7266–7274. [Google Scholar] [CrossRef]

- JJanesch, J.; Arminger, B.; Gindl-Altmutter, W.; Hansmann, C. Superhydrophobic coatings on wood made of plant oil and natural wax. Prog. Org. Coat. 2020, 148, 105891. [Google Scholar] [CrossRef]

| Optical Properties | OTW-A | OTW-B | HTW-A | HTW-B |

|---|---|---|---|---|

| Transmittance (%) | 91.06 | 90.82 | 89.76 | 90.16 |

| Haze (%) | 72.45 | 73.20 | 80.19 | 79.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Yang, H.; Mu, H. Preparation of Hydrophobic Optically Transparent Wood via An Efficient UV-Assisted Route. Forests 2023, 14, 759. https://doi.org/10.3390/f14040759

Wang H, Yang H, Mu H. Preparation of Hydrophobic Optically Transparent Wood via An Efficient UV-Assisted Route. Forests. 2023; 14(4):759. https://doi.org/10.3390/f14040759

Chicago/Turabian StyleWang, Hang, Hong Yang, and Hongbo Mu. 2023. "Preparation of Hydrophobic Optically Transparent Wood via An Efficient UV-Assisted Route" Forests 14, no. 4: 759. https://doi.org/10.3390/f14040759

APA StyleWang, H., Yang, H., & Mu, H. (2023). Preparation of Hydrophobic Optically Transparent Wood via An Efficient UV-Assisted Route. Forests, 14(4), 759. https://doi.org/10.3390/f14040759