Bending Performance of Plantation Teakwood and Its Mechanism Based on Radial and Tangential Directions

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Equipment

2.3. Bending Properties and Mechanical Test Methods

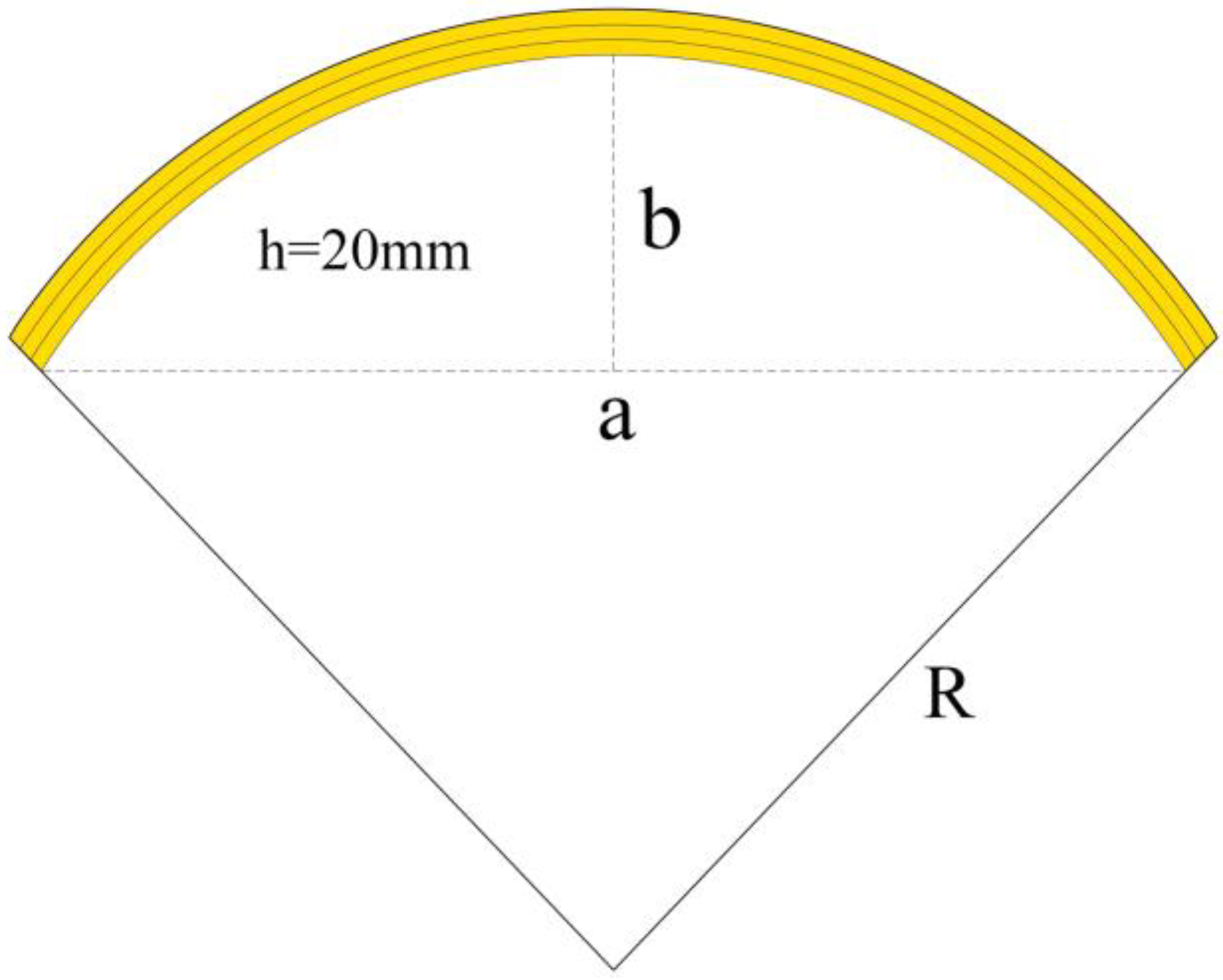

2.3.1. Preparation of Bending Specimens

2.3.2. Evaluation of Bending Performance Test

2.3.3. Bending Mechanics Test Evaluation

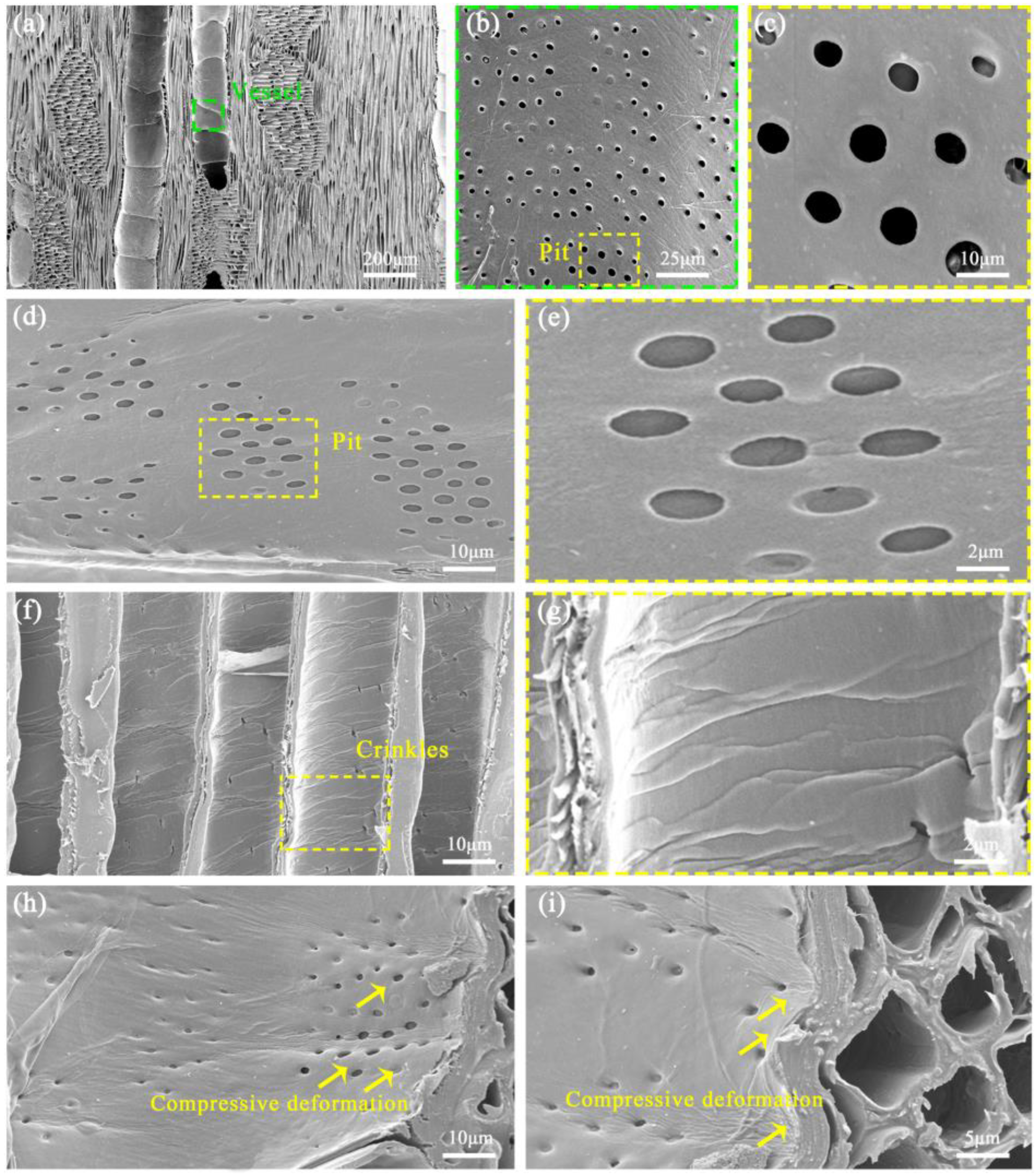

2.4. Microscopic Morphology Analysis

2.4.1. SEM Morphology Analysis

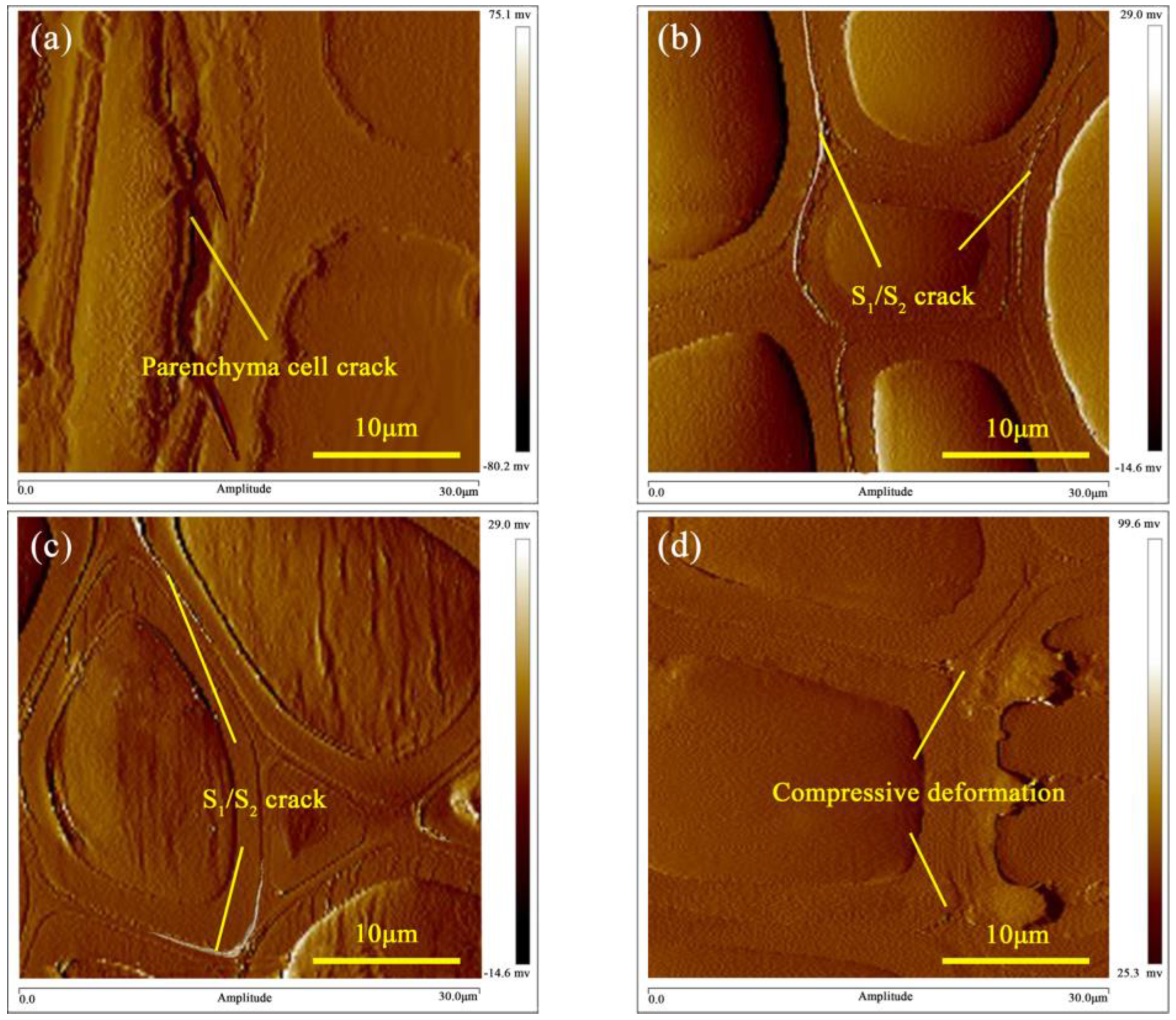

2.4.2. AFM Morphology Analysis

3. Results and Discussion

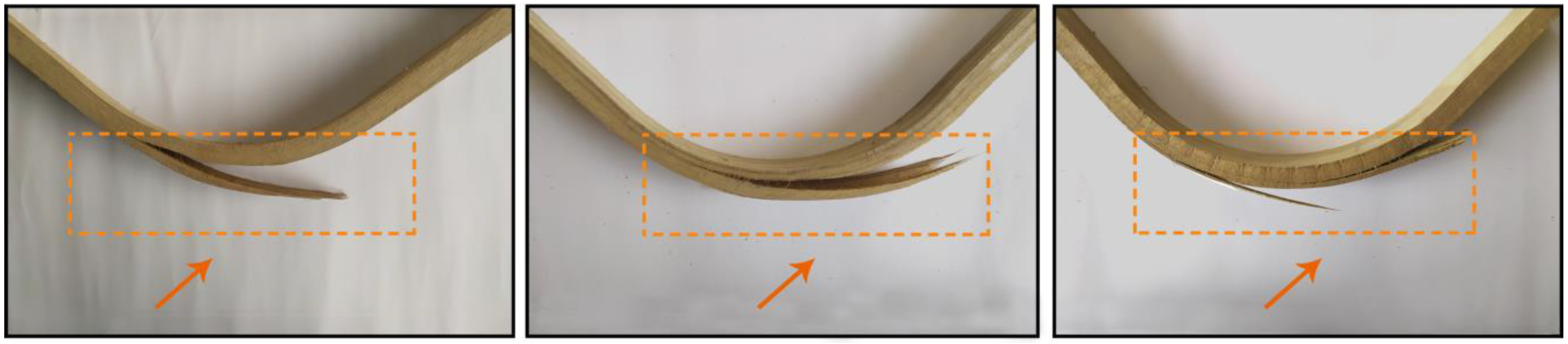

3.1. Analysis of the Change Rule of Bending Radius of Curvature

3.1.1. Radial Bending

3.1.2. Tangential Bending

3.1.3. Analysis of Rule Differences Between Radial and Tangential Bending Modes

3.2. Bending Load–Deformation Relationship Analysis

3.2.1. Radial Bending

3.2.2. Tangential Bending

3.3. Micromorphological Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, X.; Lin, M.; Li, K.; Han, Q.; Pan, D.; Ma, H.; Huang, G. Effects of Intercropping Teak with Alpinia Katsumadai Hayata and Amomum Longiligulare, T.L. Wu on Rhizosphere Soil Nutrients and Bacterial Community Diversity, Structure, and Network. Front. Microbiol. 2024, 15, 1328772. [Google Scholar] [CrossRef]

- Martha, R.; Mubarok, M.; Obounou Akong, F.; George, B.; Rahayu, I.S.; Gérardin, C.; Dumarçay, S.; Darmawan, W.; Gérardin, P. Differences of Technological Properties on Sapwood and Heartwood of Short Rotation Teak Wood. Wood Mater. Sci. Eng. 2024, 19, 6–18. [Google Scholar] [CrossRef]

- Li, Y.; Liang, K.; Huang, G.; Kuang, B.; Hao, J.; Yang, B.; Pan, L.; Huang, R. Growth Performance of 13 Provenances/Families of Tectona Grandis. For. Res. 2024, 37, 1–9. [Google Scholar] [CrossRef]

- De Castro, V.R.; Surdi, P.G.; Fernandes, S.A.; da Silva Berger, M.; Vinha Zanuncio, A.J.; Zanuncio, J.C.; de Oliveira Araujo, S. Chemical Composition of Heartwood and Sapwood of Tectona Grandis Characterized by CG/MS-PY. Sci. Rep. 2022, 12, 18441. [Google Scholar] [CrossRef] [PubMed]

- Yao, L.; Xu, M.; Sun, D.; Wang, Z. Research on Teak Furniture Design and Node Optimization Based on Solid Wood Bending Technology. Furnit. Inter. Des. 2024, 31, 78–85. [Google Scholar] [CrossRef]

- Jun, L. Analysis on the Bending Mechanism and Influencing Factors of Solid Wood Bending. China For. Sci. Technol. 1998, 6, 8–10. [Google Scholar] [CrossRef]

- Luo, H. Study on Fire-Retardant and Bending of the Fast-Growing Chinese Fire. Master’s Thesis, Nanjing Forestry University, Nanjing, China, 2012. [Google Scholar]

- Guo, H.; Zparpucu, O.; Windeisen-Holzhauser, E.; Schlepütz, C.M.; Quadranti, E.; Gaan, S.; Dreimol, C.; Burgert, I. Struvite Mineralized Wood as Sustainable Building Material: Mechanical and Combustion Behavior. ACS Sustain. Chem. Eng. 2020, 8, 10402–10412. [Google Scholar] [CrossRef]

- Báder, M.; Németh, R.; Konnerth, J. Micromechanical Properties of Longitudinally Compressed Wood. Eur. J. Wood Wood Prod. 2019, 77, 341–351. [Google Scholar] [CrossRef]

- Yao, L.; Ji, L.; Sun, D.; Wang, Z.; Ge, H.; Xu, M.; Yu, M. Preparation of Teakwood Bending Components with Excellent Softening Properties by Vacuum Impregnation with Triethanolamine Compounding Solution. Forests 2023, 14, 1773. [Google Scholar] [CrossRef]

- Wang, D.; Lin, L.; Fu, F. Deformation Mechanisms of Wood Cell Walls under Tensile Loading: A Comparative Study of Compression Wood (CW) and Normal Wood (NW). Cellulose 2020, 27, 4161–4172. [Google Scholar] [CrossRef]

- Mania, P.; Kupfernagel, C.; Curling, S. Densification of Delignified Wood: Influence of Chemical Composition on Wood Density, Compressive Strength, and Hardness of Eurasian Aspen and Scots Pine. Forests 2024, 15, 892. [Google Scholar] [CrossRef]

- Gaff, M.; Babiak, M.; Kačík, F.; Sandberg, D.; Turčani, M.; Hanzlík, P.; Vondrová, V. Plasticity Properties of Thermally Modified Timber in Bending–The Effect of Chemical Changes during Modification of European Oak and Norway Spruce. Compos. Part B Eng. 2019, 165, 613–625. [Google Scholar] [CrossRef]

- Wu, Y.; Zhu, J.; Qi, Q.; Cui, L. Research Progress of Solid Wood Bending Softening Technology. Wood Res. 2022, 67, 1056–1073. [Google Scholar] [CrossRef]

- Huang, D.; Shen, H.; Zhang, J.; Zhuo, X.; Dong, L. Effects of Hydrothermal–Microwave Treatment on Bending Properties of Teak in Plantation. Front. Mater. 2024, 11, 1278707. [Google Scholar] [CrossRef]

- Baar, J.; Brabec, M.; Slávik, R.; Čermák, P. Effect of Hemp Oil Impregnation and Thermal Modification on European Beech Wood Properties. Eur. J. Wood Wood Prod. 2021, 79, 161–175. [Google Scholar] [CrossRef]

- Gaff, M.; Vokatý, V.; Babiak, M.; Bal, B.C. Coefficient of Wood Bendability as a Function of Selected Factors. Constr. Build. Mater. 2016, 126, 632–640. [Google Scholar] [CrossRef]

- Wang, D.; Lin, L.; Fu, F.; Fan, M. The Softwood Fracture Mechanisms at the Scales of the Growth Ring and Cell Wall under Bend Loading. Wood Sci. Technol. 2019, 53, 1295–1310. [Google Scholar] [CrossRef]

- Li, J. Wood Science, 3rd ed.; Science Press: Beijing, China, 2014; pp. 210–220. [Google Scholar]

- Ishhara, A.; Imanishi, H.; Mitsui, K. Index for Wood Bending Shapes. Mokuzai Gakkaishi 2019, 65, 235–242. [Google Scholar] [CrossRef]

- Yao, L.; Sun, D.; Wang, Z.; Yu, M. Triethanolamine Impregnation/Steam Synergistic Softening of Teakwood to Improve Bending Properties and Its Mechanism. Wood Mater. Sci. Eng. 2023, 18, 618–629. [Google Scholar] [CrossRef]

- Thybring, E.E.; Fredriksson, M. Wood Modification as a Tool to Understand Moisture in Wood. Forests 2021, 12, 372. [Google Scholar] [CrossRef]

- Varnagirytė-Kabašinskienė, I.; Pukalskienė, M.; Šilinskas, B.; Škėma, M.; Aleinikovas, M. Physical and Chemical Changes in Hydrothermally Modified Wood. Forests 2021, 12, 1771. [Google Scholar] [CrossRef]

- Solanki, R.T. A Technique for High-Density Wood Softening in the Micro-Sectioning Process for Wood Anatomy Studies. IAWA J. 2023, 4, 116–125. [Google Scholar] [CrossRef]

- Hackenberg, H.; Zauer, M.; Dietrich, T.; Hackenberg, K.A.M.; Wagenführ, A. Alteration of Bending Properties of Wood Due to Ammonia Treatment and Additional Densification. Forests 2021, 12, 1110. [Google Scholar] [CrossRef]

- Pelaez-Samaniego, M.R.; Yadama, V.; Lowell, E.; Espinoza-Herrera, R. A Review of Wood Thermal Pretreatments to Improve Wood Composite Properties. Wood Sci. Technol. 2013, 47, 1285–1319. [Google Scholar] [CrossRef]

- Wilkerson, C.G.; Mansfield, S.D.; Lu, F.; Withers, S.; Park, J.Y.; Karlen, S.D.; Gonzales-Vigil, E.; Padmakshan, D.; Unda, F.; Rencoret, J.; et al. Monolignol Ferulate Transferase Introduces Chemically Labile Linkages into the Lignin Backbone. Science 2014, 344, 90–93. [Google Scholar] [CrossRef] [PubMed]

- Oriez, V.; Peydecastaing, J.; Pontalier, P.Y. Lignocellulosic Biomass Mild Alkaline Fractionation and Resulting Extract Purification Processes: Conditions, Yields, and Purities. Clean Technol. 2020, 2, 91–115. [Google Scholar] [CrossRef]

- Börcsök, Z.; Pásztory, Z. The Role of Lignin in Wood Working Processes Using Elevated Temperatures: An Abbreviated Literature Survey. Eur. J. Wood Wood Prod. 2021, 79, 511–526. [Google Scholar] [CrossRef]

- Konukcu, A.C.; Quin, F.; Zhang, J. Effect of Growth Rings on Fracture Toughness of Wood. Eur. J. Wood Wood Prod. 2021, 79, 1495–1506. [Google Scholar] [CrossRef]

- Ren, N.; Liu, Y.; Gong, C. Relationship between wood microstructure and tensile fracture. J. Northeast. For. Unvi. 2008, 36, 33–36. [Google Scholar] [CrossRef]

- Wang, D.; Lin, L.; Fu, F. The Effects of Multiscale Structure Differences on Wood Fracture-A Review. Linye Kexue/Sci. Silvae Sin. 2020, 56, 141–147. [Google Scholar] [CrossRef]

- Borůvka, V.; Novák, D.; Šedivka, P. Comparison and Analysis of Radial and Tangential Bending of Softwood and Hardwood at Static and Dynamic Loading. Forests 2020, 11, 896. [Google Scholar] [CrossRef]

- Mascia, N.T.; Kretschmann, D.E.; Vilela, R. Evaluation of Wood Modulus of Rupture and Modulus of Elasticity in the Radial and Tangential Directions in Bending and Reliability Analysis. Eur. J. Wood Wood Prod. 2022, 80, 597–610. [Google Scholar] [CrossRef]

- Scharf, A.; Lemoine, A.; Neyses, B.; Sandberg, D. The Effect of the Growth Ring Orientation on Spring-Back and Set-Recovery in Surface-Densified Wood. Holzforschung 2023, 77, 394–406. [Google Scholar] [CrossRef]

- Wang, X.; Huang, Y.; Lv, C.; Wang, J.; Wang, S.; Yao, Y. Multi-Scale Investigation of the Mechanical Properties of Loblolly Pine Wood at Elevated Temperature. Wood Mater. Sci. Eng. 2023, 18, 517–524. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, B.; Wang, F. Comparison of Wood Bending Properties and Breaking Features of Masson Pine on Radial and Tangential Direction. China For. Prod. Ind. 2017, 44, 26–29. [Google Scholar] [CrossRef]

- Fu, Z.; Lu, Y.; Wu, G.; Bai, L.; Barker-Rothschild, D.; Lyu, J.; Liu, S.; Rojas, O.J. Wood Elasticity and Compressible Wood-Based Materials: Functional Design and Applications. Prog. Mater. Sci. 2025, 147, 101354. [Google Scholar] [CrossRef]

- Kojima, E.; Yamasaki, M.; Imaeda, K.; Lee, C.G.; Sugimoto, T.; Sasaki, Y. XRD Investigation of Mechanical Properties of Cellulose Microfibrils in S1 and S3 Layers of Thermally Modified Wood under Tensile Loading. Wood Sci. Technol. 2021, 55, 955–969. [Google Scholar] [CrossRef]

- Liu, J.; Bai, Y.; Wang, X.; Xu, G. Research Progress on Nonlinear Constitutive Model for Wood. Chin. J. Wood Sci. Technol. 2023, 37, 18–24. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, S.; Huang, R. A Review of Researches on Wood Bending Techniques. World For. Res. 2010, 23, 40–44. [Google Scholar] [CrossRef]

- Korkut, S. The Effects of Heat Treatment on Some Technological Properties in Uludaǧ Fir (Abies bornmuellerinana Mattf.) Wood. Build. Environ. 2008, 43, 422–428. [Google Scholar] [CrossRef]

- Li, S.; Li, X.; Lin, L.; Zhou, Y.; Fu, F. Effect of High Energy Density Microwave Pretreatment on Bendability of Radiata Pine (Pinus radiata) Wood. China Wood Ind. 2020, 34, 1–6. [Google Scholar] [CrossRef]

- Guo, B.; Lv, H.; Xu, B. Study on the Influence of Wood Ray Morphological Characteristics on the Tensile Strength of Wood Parallel to Grain. Ind. Crops Prod. 2024, 221, 119258. [Google Scholar] [CrossRef]

- Maaß, M.C.; Saleh, S.; Militz, H.; Volkert, C.A. Radial Microfibril Arrangements in Wood Cell Walls. Planta 2022, 256, 75. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhao, Y. Bending Performance of Water Saturated White Birch and Ash Wood at 20–100 °C. Forests 2024, 15, 1077. [Google Scholar] [CrossRef]

- Xing, X.; Li, S.; Jin, W.; Lin, L.; Zhou, Y.; Fu, F. Bending Properties and Damage Evolution Characteristics of High-intensity Microwave Treated Radiata Pine Lumber. J. Beijing For. Univ. 2022, 44, 107–116. [Google Scholar] [CrossRef]

| Parameters | The Mean Value of the Radius of Curvature (mm) | The Standard Deviation of the Radius of Curvature (mm) | The Variation Coefficient of the Radius of Curvature (%) | Bending Coefficient (Kb) | |

|---|---|---|---|---|---|

| Specimens | |||||

| Unimpregnated | 232.4 | 16.31 | 7.01 | 1/11.62 | |

| Impregnated (15%) | 185.2 | 13.12 | 7.09 | 1/9.26 | |

| Parameters | The Mean Value of the Radius of Curvature (mm) | The Standard Deviation of the Radius of Curvature (mm) | The Variation Coefficient of the Radius of Curvature (%) | Bending Coefficient (Kb) | |

|---|---|---|---|---|---|

| Specimens | |||||

| Unimpregnated | 371.7 | 18.15 | 4.99 | 1/18.58 | |

| Impregnated (15%) | 316.0 | 14.57 | 4.61 | 1/15.80 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, L.; Ji, L.; Wang, Z.; Liu, J. Bending Performance of Plantation Teakwood and Its Mechanism Based on Radial and Tangential Directions. Forests 2024, 15, 2203. https://doi.org/10.3390/f15122203

Yao L, Ji L, Wang Z, Liu J. Bending Performance of Plantation Teakwood and Its Mechanism Based on Radial and Tangential Directions. Forests. 2024; 15(12):2203. https://doi.org/10.3390/f15122203

Chicago/Turabian StyleYao, Linghua, Lina Ji, Zhangheng Wang, and Junnan Liu. 2024. "Bending Performance of Plantation Teakwood and Its Mechanism Based on Radial and Tangential Directions" Forests 15, no. 12: 2203. https://doi.org/10.3390/f15122203

APA StyleYao, L., Ji, L., Wang, Z., & Liu, J. (2024). Bending Performance of Plantation Teakwood and Its Mechanism Based on Radial and Tangential Directions. Forests, 15(12), 2203. https://doi.org/10.3390/f15122203