Research on the End-Milling Surface Quality of Paulownia Based on Response Surface Model in Terms of Force and Chip Morphology

Abstract

:1. Introduction

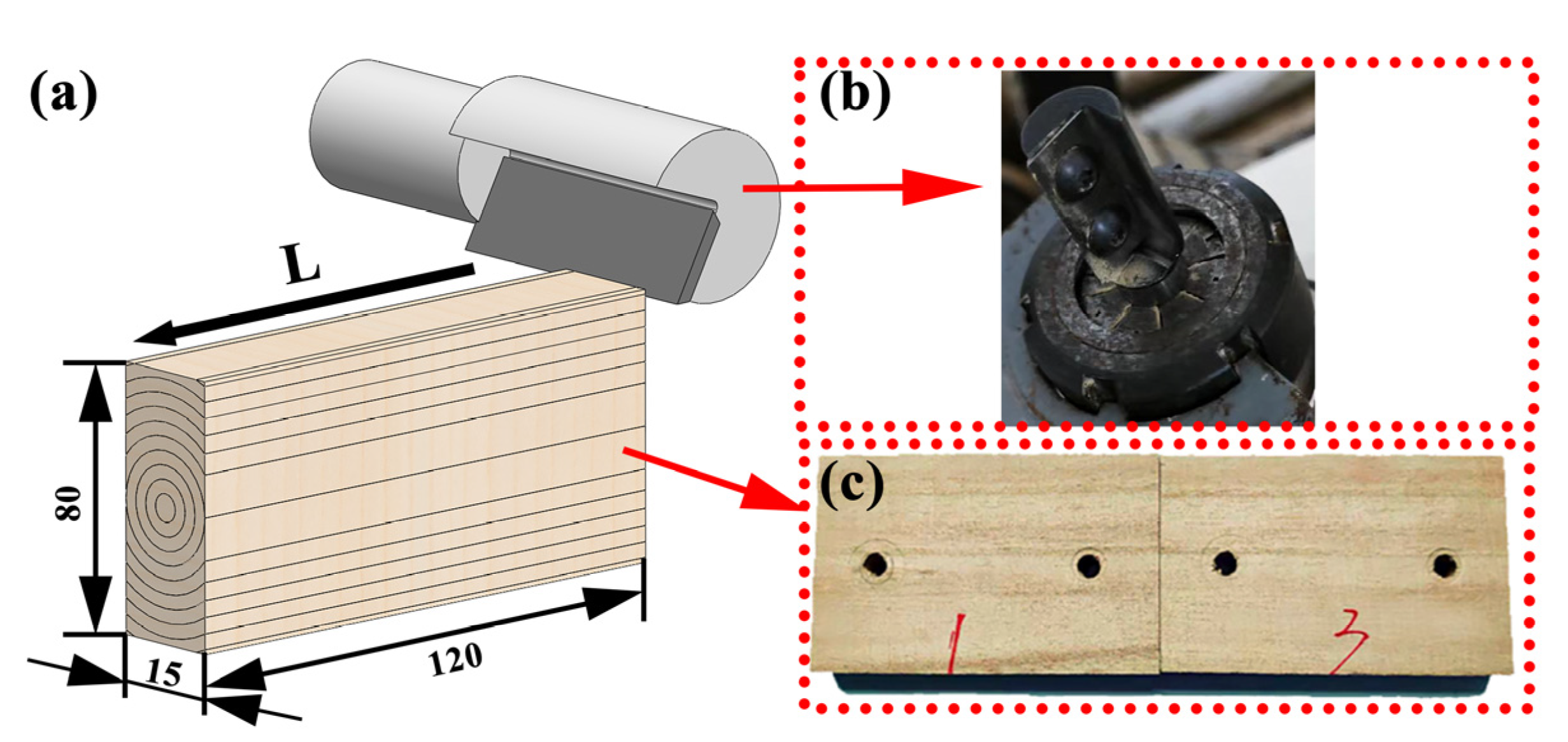

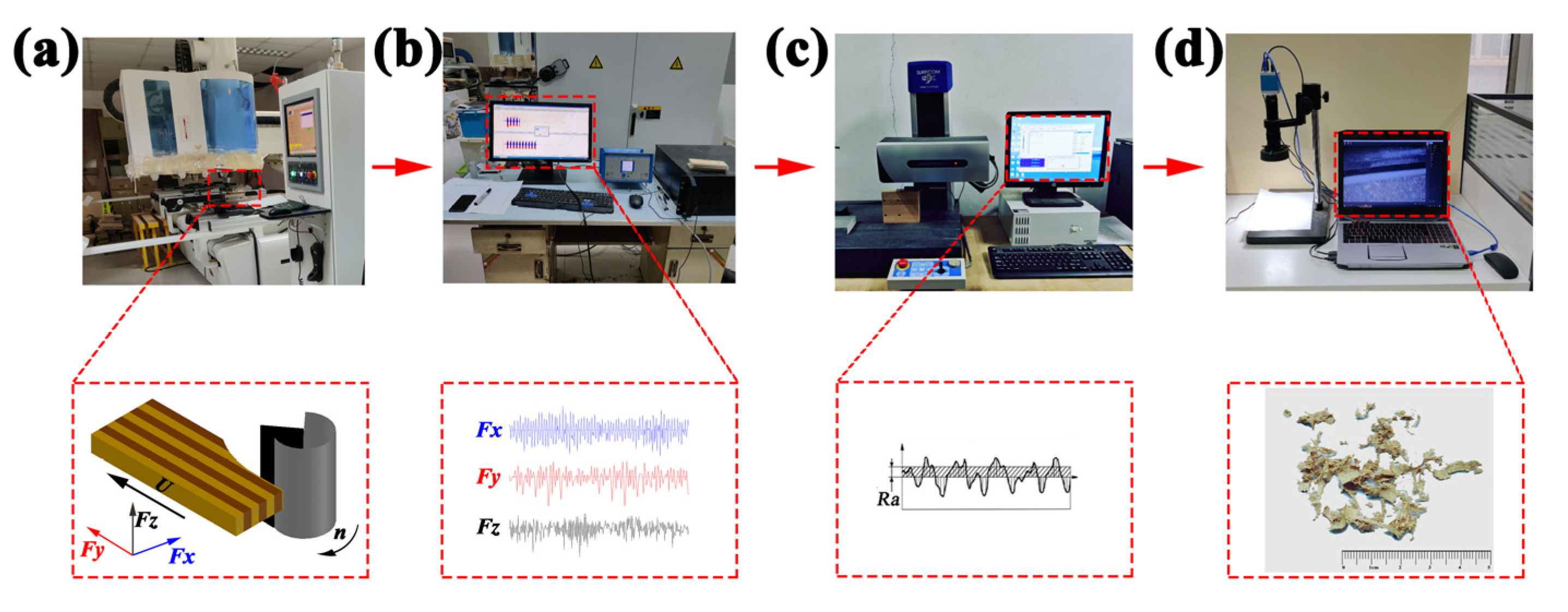

2. Materials and Methods

2.1. Materials

2.2. Experiment Design

3. Results and Discussion

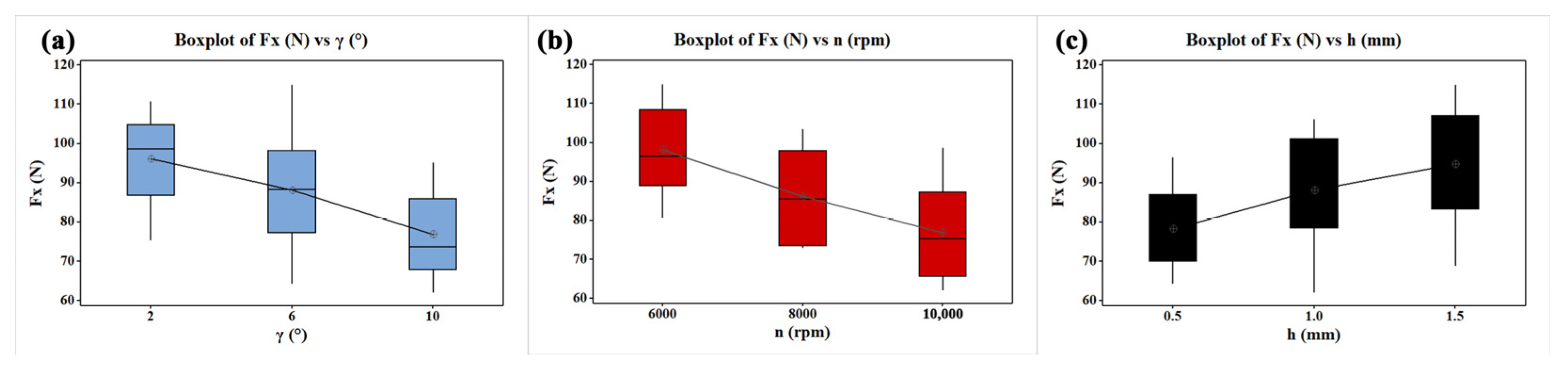

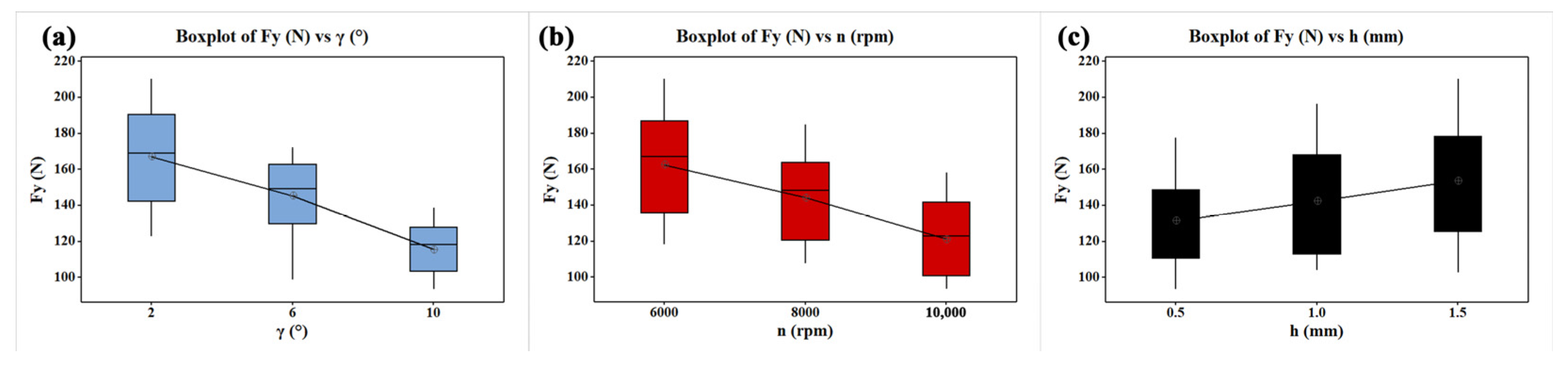

3.1. Milling Force

3.1.1. The Influence of Milling Parameters on Fx

3.1.2. The Influence of Milling Parameters on Fy

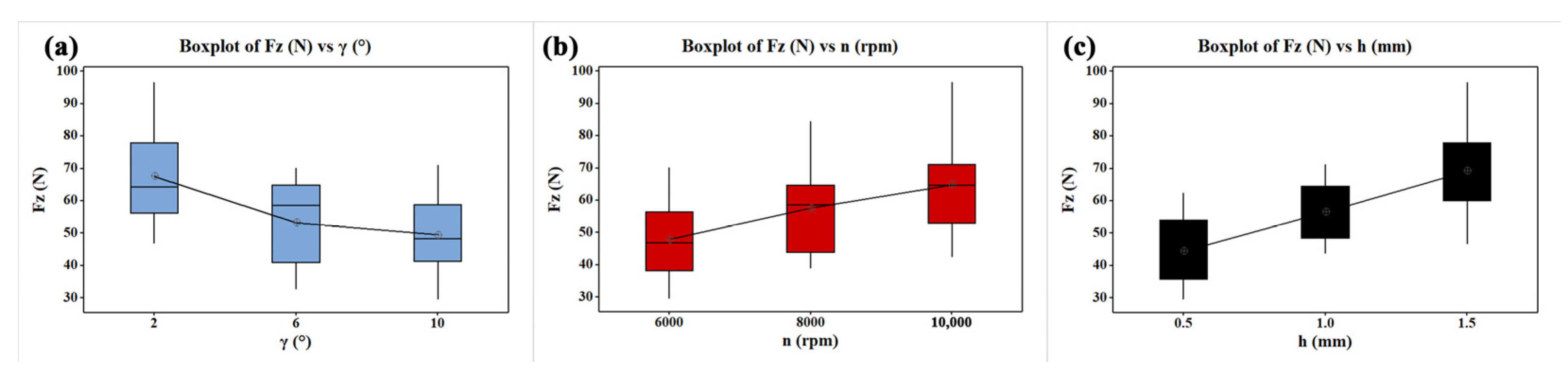

3.1.3. The Influence of Milling Parameters on Fz

3.2. Chip Morphology

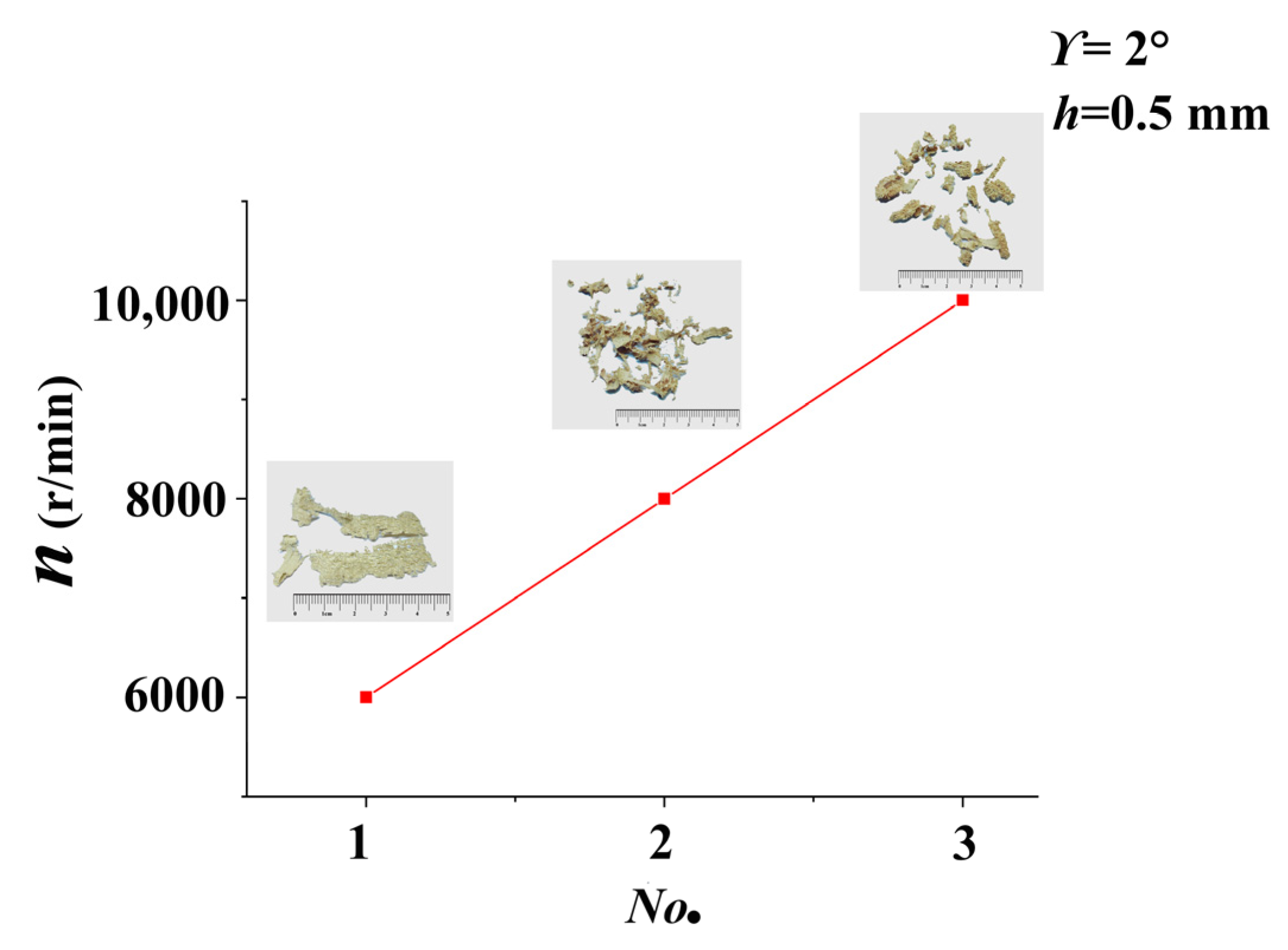

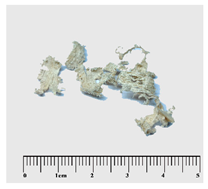

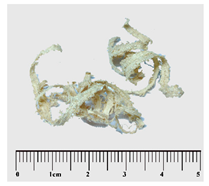

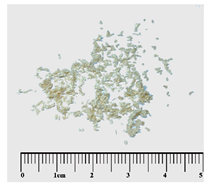

3.2.1. The Influence of Spindle’s rotational frequency on Chip Morphology

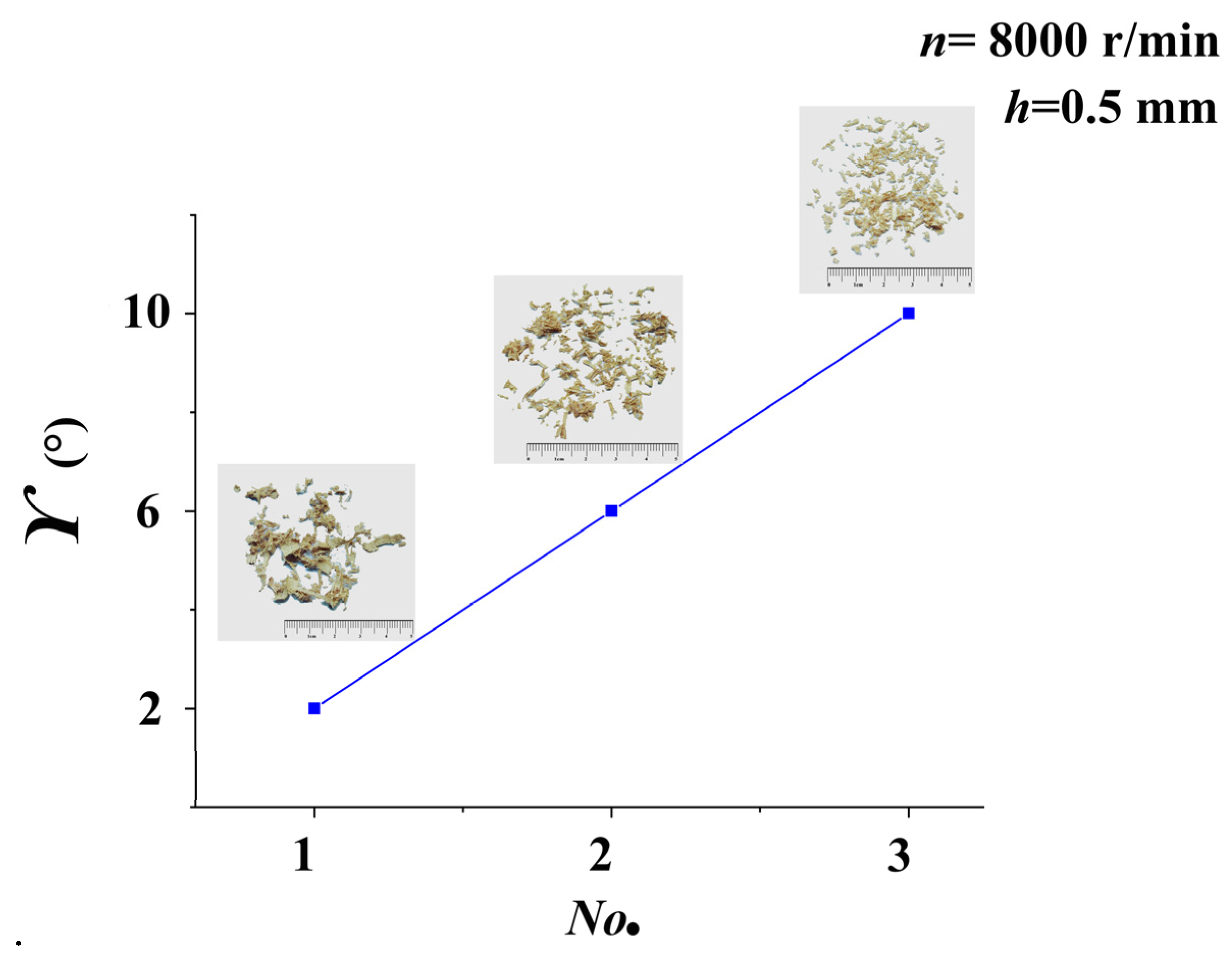

3.2.2. The Influence of Rake Angle on Chip Morphology

3.2.3. The Influence of Milling Width on Chip Morphology

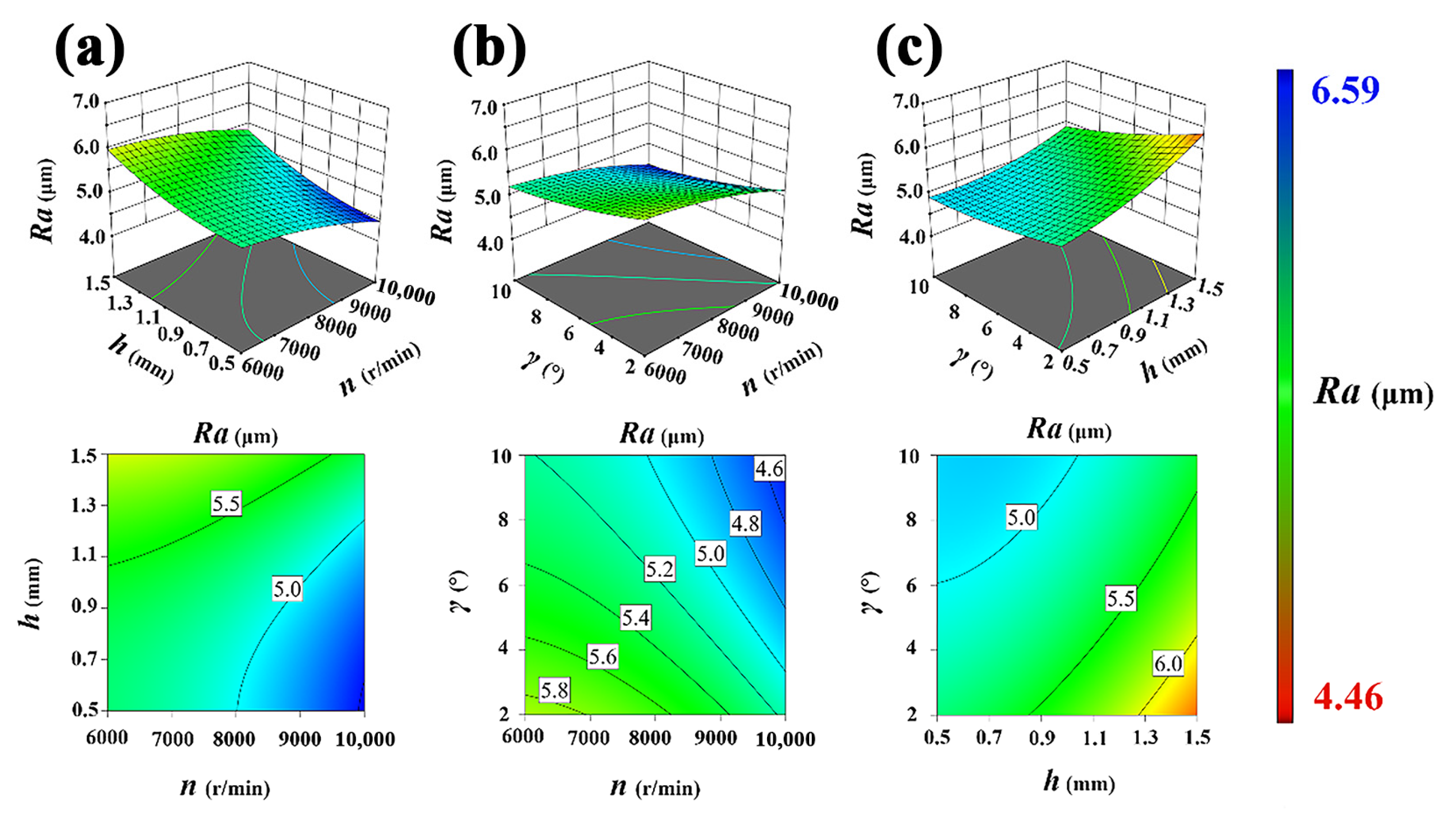

3.3. Surface Quality

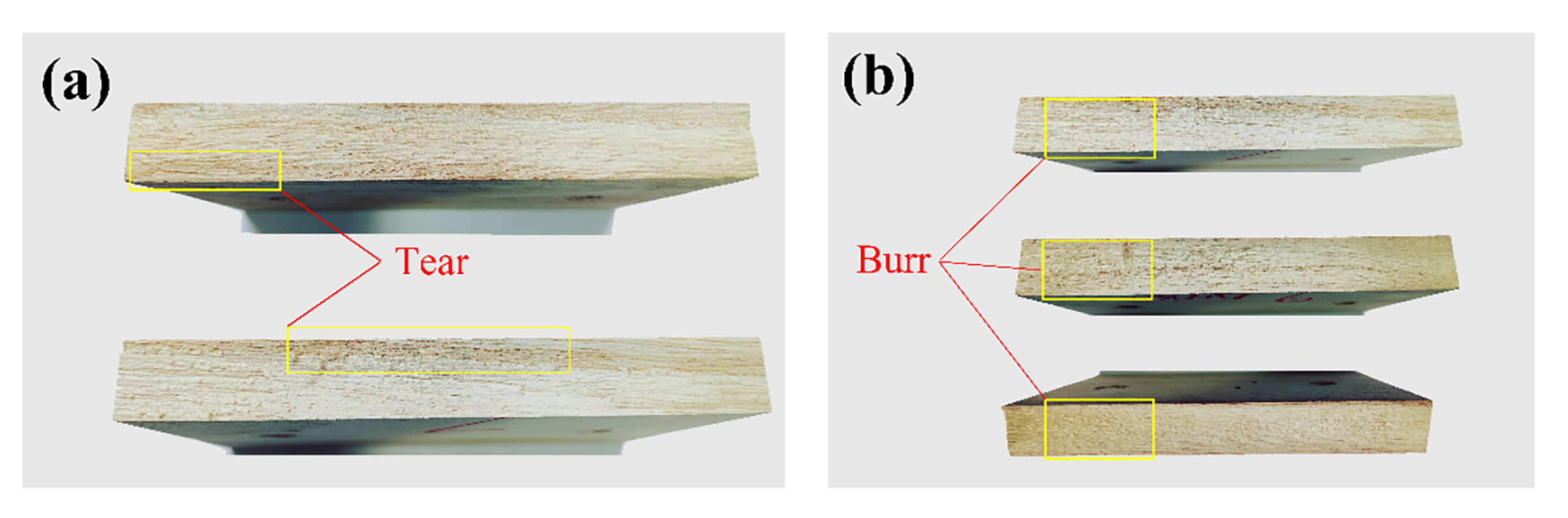

3.3.1. Machined Surface Damage

3.3.2. The RSM Model of Ra

4. Conclusions

- (1)

- Increasing the tool rake angle and the spindle’s rotational frequency leads to a decrease in milling forces along the parallel and tangential axes. However, milling forces increase with the milling depth. The spindle’s rotational frequency has a unique impact on milling forces along the lateral axis due to the complex fiber characteristics of Paulownia.

- (2)

- Higher spindle rotational frequency and rake angle result in Paulownia chips developing in a more fragmented direction. Despite the fragmented chip morphology, the machined quality improves with increased spindle rotational frequency and rake angle. Under specific conditions, a striped chip formation significantly enhances the quality of the machined surface compared to similar milling parameters.

- (3)

- The response surface methodology (RSM) for Paulownia milling surface roughness is considered to be more credible. This established RSM has a reference value for research on reducing damage to the Paulownia milling surface.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Akyildiz, M.H.; Kol, H.S. Some technological properties and uses of paulownia (Paulownia tomentosa Steud.) wood. J. Environ. Biol. 2010, 31, 351–355. [Google Scholar]

- Jakubowski, M. Cultivation Potential and Uses of Paulownia Wood: A Review. Forests 2022, 13, 668. [Google Scholar] [CrossRef]

- Kaygin, B.; Gunduz, G.; Aydemir, D. Some physical properties of heat-treated paulownia (Paulownia elongata) wood. Dry. Technol. 2009, 27, 89–93. [Google Scholar] [CrossRef]

- Rencoret, J.; Marques, G.; Gutiérrez, A.; Nieto, L.; Jiménez-Barbero, J.; Martínez, Á.T.; del Río, J.C. Isolation and structural characterization of the milled-wood lignin from Paulownia fortunei wood. Ind. Crops Prod. 2009, 30, 137–143. [Google Scholar] [CrossRef]

- Gochev, Z. Examination the process of longitudinal solid wood profile milling. Part II: Influence of the revolution frequency and feed rate on the roughness of the treated surfaces. Innov. Woodwork. Eng. Des. 2014, 1, 48–54. [Google Scholar]

- Isleyan, Ü.K.; Karamanoglu, M. The Influence of Machining Parameters on Surface Roughness of MDF in Milling Operation. Bioresources 2019, 14, 3266–3277. [Google Scholar] [CrossRef]

- Wei, W.H.; Cong, R.; Xue, T.M.; Abraham, A.D.; Yang, C.Y. Surface Roughness and Chip Morphology of Wood-plastic Composites Manufactured via High-speed Milling. Bioresources 2021, 16, 5733–5745. [Google Scholar] [CrossRef]

- Eriksen, E. The influence of surface roughness on the mechanical strength properties of machined short-fibre-reinforced thermoplastics. Compos. Sci. Technol. 2000, 60, 107–113. [Google Scholar] [CrossRef]

- Curti, R.; Marcon, B.; Denaud, L.; Togni, M.; Furferi, R.; Goli, G. Generalized cutting force model for peripheral milling of wood, based on the effect of density, uncut chip cross section, grain orientation and tool helix angle. Eur. J. Wood Wood Prod. 2021, 79, 667–678. [Google Scholar] [CrossRef]

- Ibrisevic, A.; Obucina, M.; Hajdarevic, S.; Mihulja, G.; Kuzman, M.K.; Busuladzic, I. Effects of Cutting Parameters and Grain Direction on Surface Quality of Three Wood Species Obtained by CNC Milling. In Bulletin of the Transilvania University of Brasov; Series II: Forestry, Wood Industry, Agricultural Food Engineering; Transilvania University Press: Lexington, KY, USA, 2023; pp. 127–140. [Google Scholar]

- Darmawan, W.; Azhari, M.; Rahayu, I.S.; Nandika, D.; Nishio, S. The chips generated during up-milling and down-milling of pine wood by helical router bits. J. Indian Acad. Wood Sci. 2018, 15, 172–180. [Google Scholar] [CrossRef]

- Li, B.; Wang, X.; Hu, Y.; Li, C. Analytical prediction of cutting forces in orthogonal cutting using unequal division shear-zone model. Int. J. Adv. Manuf. Technol. 2011, 54, 431–443. [Google Scholar] [CrossRef]

- Marchal, R.; Mothe, F.; Denaud, L.E.; Thibaut, B.; Bleron, L. Cutting forces in wood machining—Basics and applications in industrial processes. A review COST Action E35 2004–2008: Wood machining—Micromechanics and fracture. Holzforschung 2009, 63, 157–167. [Google Scholar] [CrossRef]

- Cyra, G.; Tanaka, C. The effects of wood-fiber directions on acoustic emission in routing. Wood Sci. Technol. 2000, 34, 237–252. [Google Scholar] [CrossRef]

- Liu, C.; Wang, G.; Dargusch, M.S. Modelling, simulation and experimental investigation of cutting forces during helical milling operations. Int. J. Adv. Manuf. Technol. 2012, 63, 839–850. [Google Scholar] [CrossRef]

- Caceres, C.B.; Uliana, L.; Hernandez, R.E. Orthogonal cutting study of wood and knots of white spruce. Wood Fiber Sci. 2018, 50, 55–65. [Google Scholar] [CrossRef]

- Cao, P.X.; Zhu, Z.L.; Buck, D.; Guo, X.L.; Ekevad, M.; Wang, X. Effect of rake angle on cutting performance during machining of stone-plastic composite material with polycrystalline diamond cutters. J. Mech. Sci. Technol. 2019, 33, 351–356. [Google Scholar] [CrossRef]

- Xu, W.Y.; Wu, Z.W.; Lu, W.; Yu, Y.Y.; Wang, J.X.; Zhu, Z.L.; Wang, X.D. Investigation on Cutting Power of Wood-Plastic Composite Using Response Surface Methodology. Forests 2022, 13, 1397. [Google Scholar] [CrossRef]

- Zhu, Z.L.; Buck, D.; Wang, J.X.; Wu, Z.W.; Xu, W.; Guo, X.L. Machinability of Different Wood-Plastic Composites during Peripheral Milling. Materials 2022, 15, 1303. [Google Scholar] [CrossRef]

- Guo, X.L.; Wang, J.X.; Buck, D.; Zhu, Z.L.; Ekevad, M. Cutting forces and cutting quality in the up-milling of solid wood using ceramic cutting tools. Int. J. Adv. Manuf. Technol. 2021, 114, 1575–1584. [Google Scholar] [CrossRef]

- Box, G.E.P.; Wilson, K.B. On the experimental attainment of optimum conditions. In Breakthroughs in Statistics: Methodology and Distribution; Springer: New York, NY, USA, 1992; pp. 270–310. [Google Scholar] [CrossRef]

- Zhu, Z.L.; Buck, D.; Guo, X.L.; Xiong, X.Q.; Xu, W.; Cao, P.X. Energy Efficiency Optimization for Machining of Wood Plastic Composite. Machines 2022, 10, 104. [Google Scholar] [CrossRef]

- Li, R.; Yang, F.; Wang, X. Modeling and Predicting the Machined Surface Roughness and Milling Power in Scot’s Pine Helical Milling Process. Machines 2022, 10, 331. [Google Scholar] [CrossRef]

- Li, R.; Yao, Q.; Xu, W.; Li, J.; Wang, X. Study of cutting power and power efficiency during straight-tooth cylindrical milling process of particle boards. Materials 2022, 15, 879. [Google Scholar] [CrossRef]

- Wei, H.; Guo, X.; Zhu, Z.; Cao, P.; Wang, B.; Ekevad, M. Analysis of Cutting Performance in High Density Fiberboard Milling by Ceramic Cutting Tools. Wood Res. 2018, 63, 455–466. [Google Scholar]

- Hu, W.; Wan, H.; Guan, H. Size Effect on the Elastic Mechanical Properties of Beech and Its Application in Finite Element Analysis of Wood Structures. Forests 2019, 10, 783. [Google Scholar] [CrossRef]

- Nalbant, M.; Altin, A.; Gökkaya, H. The effect of cutting speed and cutting tool geometry on machinability properties of nickel-base Inconel 718 super alloys. Mater. Des. 2007, 28, 1334–1338. [Google Scholar] [CrossRef]

- Thasthakeer, A.T.; Farid, A.A.; Seng, C.T.; Namazi, H. Analysis of the Correlation between Fractal Structure of Cutting Force Signal and Surface Roughness of Machined Workpiece in End Milling Operation. Fractals 2019, 27, 1950013. [Google Scholar] [CrossRef]

- Shi, W.; Ma, Y.; Yang, C.; Jiang, B.; Li, Z. Evaluation of a regression prediction model for surface roughness of wood–polyethylene composite (WPC). Surf. Rev. Lett. 2017, 24, 1850033. [Google Scholar] [CrossRef]

- Kayahan, E.; Oktem, H.; Hacizade, F.; Nasibov, H.; Gundogdu, O. Measurement of surface roughness of metals using binary speckle image analysis. Tribol. Int. 2010, 43, 307–311. [Google Scholar] [CrossRef]

| Workpiece | Density (g/cm3) | Moisture Content (%) |

|---|---|---|

| Paulownia | 0.285 | 11.91 |

| No. | Rake Angle γ (°) | Rotation Frequency n (r/min) | Milling Depth h (mm) |

|---|---|---|---|

| 1 | 2 | 6000 | 0.5 |

| 2 | 6 | 8000 | 1.0 |

| 3 | 10 | 10,000 | 1.5 |

| Ex. No. | γ (°) | n (r/min) | h (mm) | Fx | Std. | Fy | Std. | Fz | Std. | Ra | Std. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 6000 | 0.5 | 96.41 | 4.98 | 177.60 | 2.15 | 46.81 | 7.56 | 5.53 | 1.65 |

| 2 | 2 | 8000 | 0.5 | 82.53 | 6.73 | 148.10 | 3.79 | 58.20 | 5.16 | 5.46 | 1.26 |

| 3 | 2 | 10,000 | 0.5 | 75.26 | 8.46 | 122.80 | 6.80 | 62.38 | 1.26 | 3.95 | 0.27 |

| 4 | 2 | 6000 | 1.0 | 106.20 | 5.65 | 196.30 | 3.52 | 53.91 | 8.57 | 5.65 | 1.17 |

| 5 | 2 | 8000 | 1.0 | 100.90 | 7.27 | 168.90 | 5.16 | 64.29 | 6.57 | 5.08 | 2.28 |

| 6 | 2 | 10,000 | 1.0 | 90.97 | 8.36 | 136.30 | 9.68 | 71.20 | 2.99 | 4.99 | 0.26 |

| 7 | 2 | 6000 | 1.5 | 110.70 | 5.09 | 210.20 | 1.15 | 70.05 | 9.57 | 7.65 | 1.84 |

| 8 | 2 | 8000 | 1.5 | 103.40 | 6.49 | 184.70 | 6.17 | 84.55 | 8.56 | 6.59 | 0.68 |

| 9 | 2 | 10,000 | 1.5 | 98.63 | 8.96 | 158.00 | 8.65 | 96.57 | 7.68 | 6.32 | 1.63 |

| 10 | 6 | 6000 | 0.5 | 91.32 | 4.98 | 149.00 | 4.68 | 32.55 | 5.26 | 5.33 | 1.27 |

| 11 | 6 | 8000 | 0.5 | 73.23 | 5.27 | 132.40 | 6.17 | 39.26 | 7.59 | 4.86 | 0.27 |

| 12 | 6 | 10,000 | 0.5 | 64.18 | 8.61 | 98.60 | 7.61 | 42.28 | 3.40 | 4.46 | 1.13 |

| 13 | 6 | 6000 | 1.0 | 101.50 | 6.90 | 167.00 | 3.68 | 48.66 | 8.56 | 5.39 | 1.27 |

| 14 | 6 | 8000 | 1.0 | 88.21 | 7.53 | 155.30 | 3.94 | 58.43 | 1.27 | 5.21 | 5.25 |

| 15 | 6 | 10,000 | 1.0 | 83.37 | 9.41 | 127.00 | 4.90 | 64.58 | 4.60 | 4.72 | 1.61 |

| 16 | 6 | 6000 | 1.5 | 114.90 | 3.53 | 172.00 | 2.11 | 58.53 | 3.95 | 5.98 | 0.40 |

| 17 | 6 | 8000 | 1.5 | 94.89 | 5.44 | 158.70 | 5.17 | 64.88 | 5.30 | 5.56 | 1.29 |

| 18 | 6 | 10,000 | 1.5 | 81.15 | 7.18 | 146.60 | 8.29 | 70.08 | 8.60 | 5.32 | 2.38 |

| 19 | 10 | 6000 | 0.5 | 80.58 | 4.89 | 138.60 | 4.17 | 29.48 | 9.27 | 5.21 | 0.59 |

| 20 | 10 | 8000 | 0.5 | 72.80 | 6.62 | 122.50 | 4.99 | 38.85 | 2.98 | 4.69 | 1.23 |

| 21 | 10 | 10,000 | 0.5 | 67.06 | 8.48 | 93.20 | 6.17 | 49.58 | 5.27 | 4.48 | 0.67 |

| 22 | 10 | 6000 | 1.0 | 86.32 | 2.49 | 118.20 | 1.18 | 43.67 | 4.30 | 5.38 | 1.00 |

| 23 | 10 | 8000 | 1.0 | 73.61 | 4.19 | 107.50 | 5.29 | 48.21 | 7.86 | 4.95 | 1.27 |

| 24 | 10 | 10,000 | 1.0 | 61.87 | 7.14 | 103.90 | 8.27 | 55.94 | 7.68 | 4.72 | 0.21 |

| 25 | 10 | 6000 | 1.5 | 95.15 | 5.47 | 132.70 | 4.12 | 46.48 | 1.38 | 5.90 | 2.24 |

| 26 | 10 | 8000 | 1.5 | 85.42 | 8.18 | 118.20 | 5.99 | 61.48 | 5.29 | 5.23 | 1.68 |

| 27 | 10 | 10,000 | 1.5 | 68.74 | 8.84 | 102.70 | 8.84 | 71.01 | 2.68 | 4.98 | 0.68 |

| Fx | Fy | Fz | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Level | γ (°) | n (r/min) | h (mm) | γ (°) | n (r/min) | h (mm) | γ (°) | n (r/min) | h (mm) |

| 1 | 96.11 | 98.12 | 78.15 | 167 | 162.4 | 131.4 | 67.55 | 47.79 | 44.38 |

| 2 | 88.08 | 86.11 | 88.11 | 145.2 | 144 | 142.3 | 53.25 | 57.57 | 56.54 |

| 3 | 76.84 | 76.8 | 94.78 | 115.3 | 121 | 153.8 | 49.41 | 64.85 | 69.29 |

| Delta | 19.27 | 21.32 | 16.62 | 51.7 | 41.4 | 22.3 | 18.14 | 17.05 | 24.92 |

| Rank | 2 | 1 | 3 | 1 | 2 | 3 | 2 | 3 | 1 |

| No. | γ (°) | h (mm) | n (r/min) | aav (mm) | Ra (μm) | Chips Morphology |

|---|---|---|---|---|---|---|

| 1 | 2 | 1.5 | 6000 | 0.2406 | 7.65 |  |

| 2 | 2 | 1.5 | 8000 | 0.1804 | 6.59 |  |

| 3 | 2 | 1.0 | 8000 | 0.1473 | 5.08 |  |

| 4 | 2 | 0.5 | 6000 | 0.1389 | 5.53 |  |

| 5 | 2 | 1.0 | 10,000 | 0.1178 | 4.99 |  |

| Model | Standard Deviation | Mean | C.V.% | R2 | Adeq Precision |

|---|---|---|---|---|---|

| Ra | 0.2205 | 5.29 | 4.17 | 0.9117 | 11.2577 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Wu, Z.; Zhang, F.; Song, C.; Hu, W.; Zhu, Z.; Guo, X.; Cao, P. Research on the End-Milling Surface Quality of Paulownia Based on Response Surface Model in Terms of Force and Chip Morphology. Forests 2024, 15, 325. https://doi.org/10.3390/f15020325

Wang J, Wu Z, Zhang F, Song C, Hu W, Zhu Z, Guo X, Cao P. Research on the End-Milling Surface Quality of Paulownia Based on Response Surface Model in Terms of Force and Chip Morphology. Forests. 2024; 15(2):325. https://doi.org/10.3390/f15020325

Chicago/Turabian StyleWang, Jinxin, Zhanwen Wu, Feng Zhang, Chaojun Song, Wei Hu, Zhaolong Zhu, Xiaolei Guo, and Pingxiang Cao. 2024. "Research on the End-Milling Surface Quality of Paulownia Based on Response Surface Model in Terms of Force and Chip Morphology" Forests 15, no. 2: 325. https://doi.org/10.3390/f15020325

APA StyleWang, J., Wu, Z., Zhang, F., Song, C., Hu, W., Zhu, Z., Guo, X., & Cao, P. (2024). Research on the End-Milling Surface Quality of Paulownia Based on Response Surface Model in Terms of Force and Chip Morphology. Forests, 15(2), 325. https://doi.org/10.3390/f15020325