A Multi-Criterion Evaluation Process for Determining Cost-Effective Harvesting Systems in Fragmented Boreal Forests

Abstract

1. Introduction

2. Material and Methods

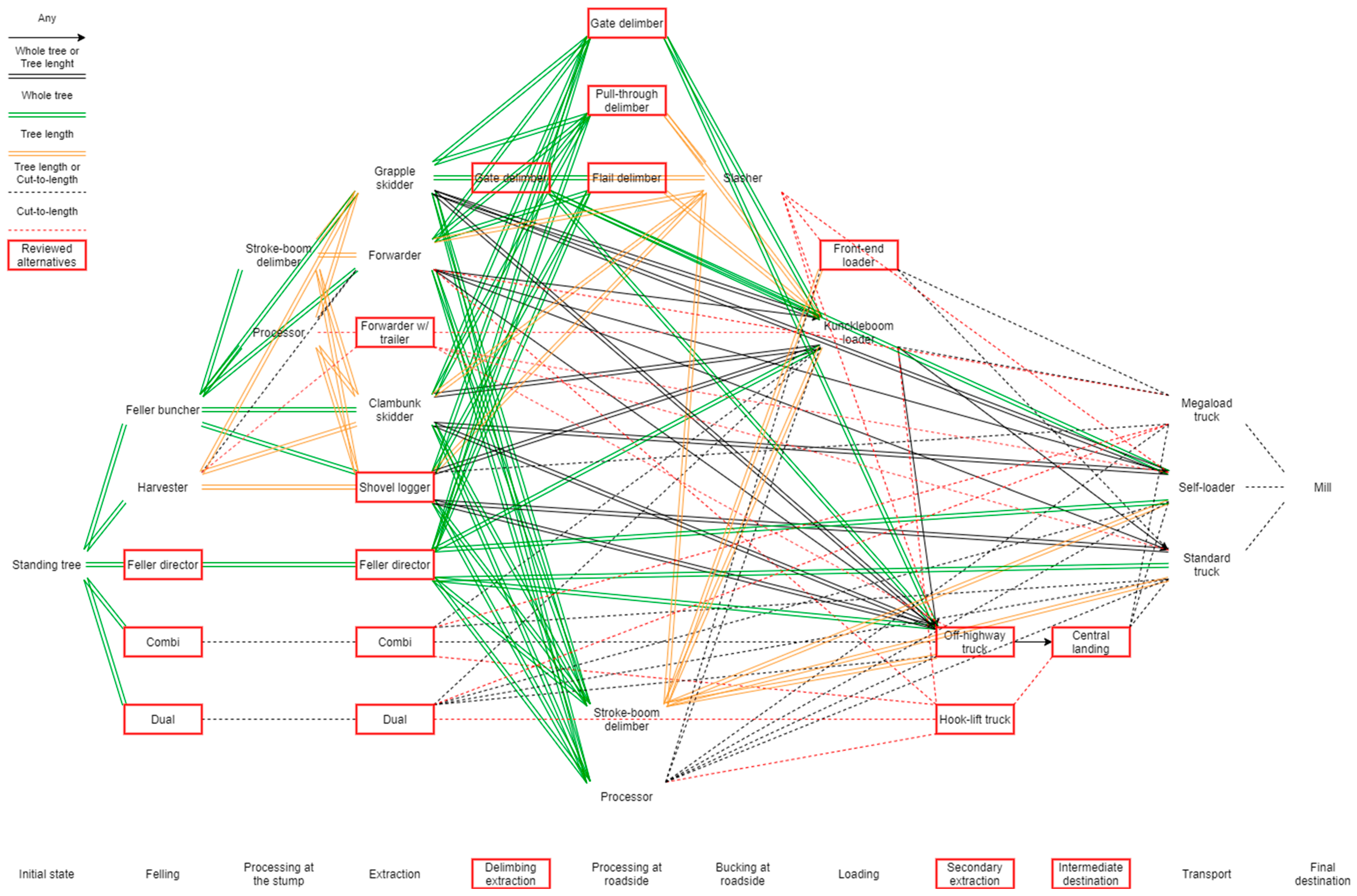

2.1. Review of Existing Systems

2.2. Systems Evaluation

2.2.1. Evaluation Criteria

2.2.2. Alternatives

2.2.3. Performance Evaluation

- (a)

- Road investments—Extraction distance (m)

- (b)

- Mobility—number of machines

- (c)

- Productivity—System productivity (m3/PMH)

- (d)

- Machinery operating costs—Unit cost (USD/m3)

- (e)

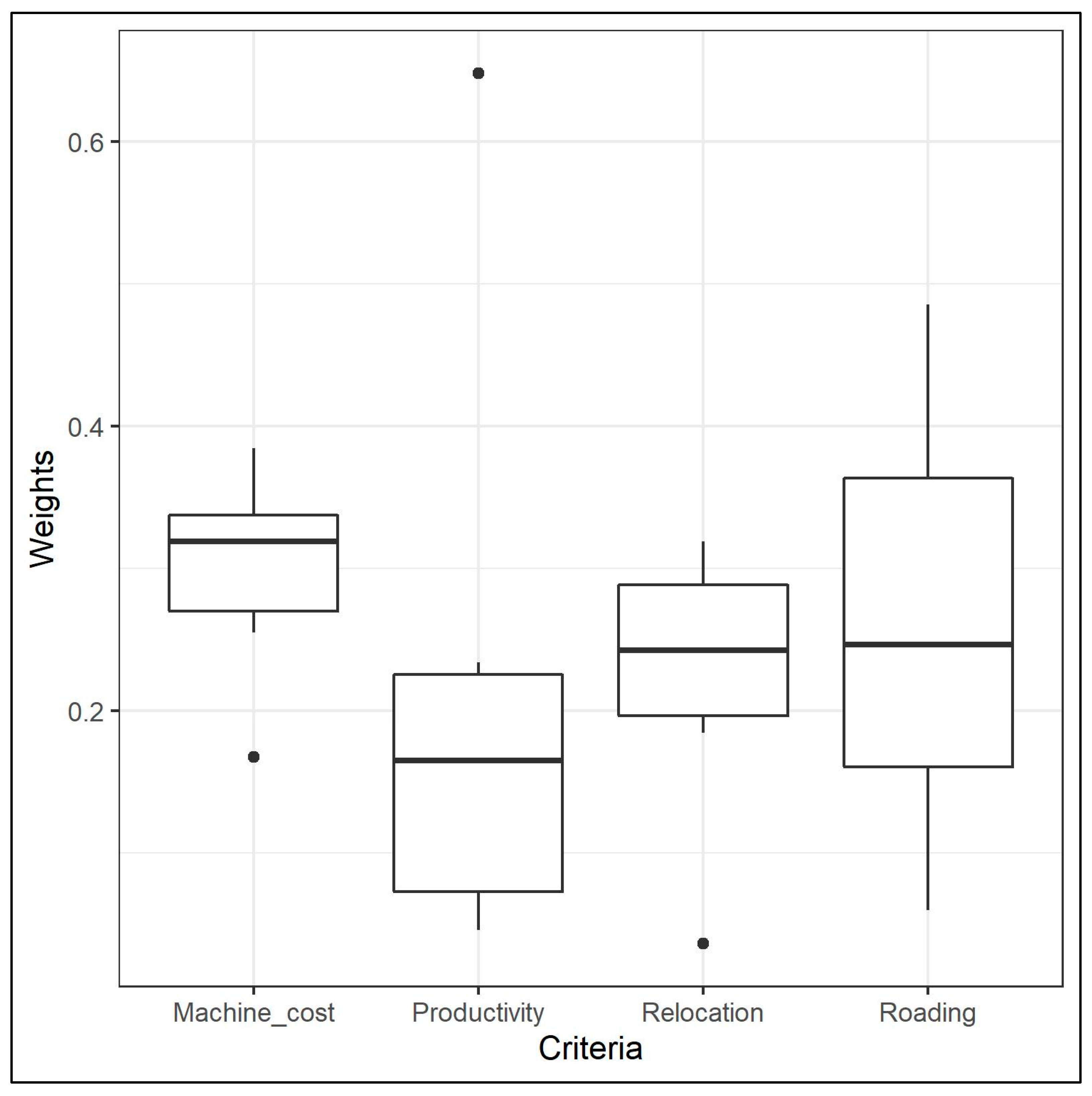

- Weighting and ranking

3. Results

3.1. Review of Existing Systems

3.1.1. Felling

3.1.2. Extraction

3.1.3. Processing

3.1.4. Loading

3.1.5. Transport

3.1.6. Complete Harvesting Systems

3.2. Systems Evaluation

3.2.1. Evaluation Criteria

3.2.2. Alternatives and Performance Evaluation

3.2.3. Weighting and Ranking

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Belleau, A.; Bergeron, Y.; Leduc, A.; Gauthier, S.; Fall, A. Using spatially explicit simulations to explore size distribution and spacing of regenerating areas produced by wildfires: Recommendations for designing harvest agglomerations for the Canadian boreal forest. For. Chron. 2007, 83, 72–83. [Google Scholar] [CrossRef]

- Dhital, N.; Raulier, F.; Asselin, H.; Imbeau, L.; Valeria, O.; Bergeron, Y. Emulating boreal forest disturbance dynamics: Can we maintain timber supply, aboriginal land use, and woodland caribou habitat? For. Chron. 2013, 89, 54–65. [Google Scholar] [CrossRef]

- Ketcheson, D.E. A Study of the Cost of Strip Cutting Black Spruce Stands in Northern Ontario; Canadian Forest Service, Great Lakes Forest Research Centre: Sault Ste. Marie, ON, Canada, 1979; 29p. [Google Scholar]

- Cubbage, F.W. Economies of Forest Tract Size in Southern Pine Harvesting; United States Department of Agriculture: New Orleans, LA, USA, 1982; 27p. [Google Scholar]

- Greene, W.D.; Harris, T.G.; DeForest, C.E.; Wang, J. Harvesting Cost Implications of Changes in the Size of Timber Sales in Georgia. South. J. Appl. For. 1997, 21, 193–198. [Google Scholar] [CrossRef]

- Favreau, J.; Gingras, J.-F. Facteurs Susceptibles D’influencer le Coût de Récolte par Coupe Mosaïque; FERIC: Pointe-Claire, QC, Canada, 2000; 5p. [Google Scholar]

- Eliasson, L.; Grönlud, Ö.; Lundström, H.; Sonesson, J. Harvester and Forwarder productivity and net revenues in patch cutting. Int. J. For. Eng. 2021, 32, 3–10. [Google Scholar] [CrossRef]

- Sundberg, U.; Silversides, C.R. Operational Efficiency in Forestry: Vol. 1: Analysis; Springer: Dordrecht, The Netherlands, 1988; 221p. [Google Scholar]

- Öhman, K.; Eriksson, L. Aggregating harvest activities in long term forest planning by minimizing harvest area perimeters. Silva Fenn. 2010, 44, 77–89. [Google Scholar] [CrossRef]

- Smaltschinski, T.; Seeling, U.; Becker, G. Clustering forest harvest stands on spatial networks for optimised harvest scheduling. Ann. For. Sci. 2012, 69, 651–657. [Google Scholar] [CrossRef]

- Heinonen, T.; Mäkinen, A.; Rasinmäki, J.; Pukkala, T. Aggregating microsegments into harvest blocks by using spatial optimization and proximity objectives. Can. J. For. Res. 2018, 48, 1184–1193. [Google Scholar] [CrossRef]

- Mobtaker, A.; Montecinos, J.; Ouhimmou, M.; Rönnqvist, M.; Paquet, M. Minimizing spatial dispersion of forest harvest areas using spectral clustering and set covering modelling. Can. J. For. Res. 2018, 48, 1563–1576. [Google Scholar] [CrossRef]

- Naderializadeh, N.; Crowe, K.; Rouhafza, M. Solving the integrated forest harvest scheduling model using metaheuristic algorithms. Oper. Res. 2022, 22, 2437–2463. [Google Scholar] [CrossRef]

- Fortin, Y. Procédés de Récolte des Bois Utilisés Dans les Forêts du Domaine de l’État—Rapport Annuel 2004–2005; Gouvernement du Québec: Quebec City, QC, Canada, 2006; 40p. [Google Scholar]

- Audy, J.-F.; Pinotti Moreira, M.; Westlund, K.; D’Amours, S.; LeBel, L.; Rönnqvist, M. Alternative Logistics Concepts Fitting Different Wood Supply Situations and Markets; CIRRELT Report; CIRRELT: Montréal, QC, Canada, 2012; 347p. [Google Scholar]

- Decoster, A. The Boom in Forest Owners—A Bust for Forestry? J. For. 1998, 96, 25–28. [Google Scholar] [CrossRef]

- Hatcher, J.; Straka, T.; Greene, J. The Size of Forest Holding/Parcelization Problem in Forestry: A Literature Review. Resources 2013, 2, 39–57. [Google Scholar] [CrossRef]

- Conrad, J.L. Adapting to a Changing Landscape: How Wisconsin Loggers Persist in an Era of Parcelization. For. Prod. J. 2014, 64, 273–280. [Google Scholar] [CrossRef]

- Cubbage, F.W.; Granskog, J.E. Harvesting systems and costs for southern pine in the 1980s. For. Prod. J. 1982, 32, 37–43. [Google Scholar]

- DeLasaux, M.J.; Hartsough, B.R.; Spinelli, R.; Magagnotti, N. Small Parcel Fuel Reduction with a Low-Investment, High-Mobility Operation. West. J. Appl. For. 2009, 24, 205–213. [Google Scholar] [CrossRef][Green Version]

- Abbas, D.; Di Fulvio, F.; Marchi, E. A Proposal for an Integrated Methodological and Scientific Approach to Cost Used Forestry Machines. Crojfe J. For. Eng. 2021, 42, 63–75. [Google Scholar] [CrossRef]

- Moldenhauer, M.C.; Bolding, C. Parcelization of South Carolina’s private forestland: Loggers’ reactions to a growing threat. For. Prod. J. 2009, 59, 37–43. [Google Scholar]

- Han-Sup, H.; Lee, H.; Johnson, L. Economic feasibility of an integrated harvesting system for small-diameter trees in southwest Idaho. For. Prod. J. 2004, 54, 21–27. [Google Scholar]

- Rawlings, C.; Seeley, C.; Thomas, C.E.; Morrison, D.; Han, H.-S.; Levi Cheff Atkins, D.; Graham, D.; Windell, K. A Study of How to Decrease the Costs of Collecting, Processing and Transporting Slash; Montana Community Development Corporation: Missoula, MT, USA, 2005; 21p. [Google Scholar]

- Bisson, J.A.; Han, S.-K.; Han, H.-S. Evaluating the System Logistics of a Centralized Biomass Recovery Operation in Northern California. For. Prod. J. 2016, 66, 88–96. [Google Scholar] [CrossRef]

- Sessions, J.; Wimer, J.; Costales, F.; Wing, M.G. Engineering Considerations in Road Assessment for Biomass Operations in Steep Terrain. West. J. Appl. For. 2010, 25, 144–153. [Google Scholar] [CrossRef][Green Version]

- Daugherty, B.; Sessions, J.; Zamora-Cristales, R.; Wing, M.G. Improving large trailer access for biomass recovery in steep terrain. For. Sci. 2018, 64, 429–441. [Google Scholar] [CrossRef]

- Zamora-Cristales, R.; Sessions, J.; Boston, K.D.; Murphy, G. Economic Optimization of Forest Biomass Processing and Transport in the Pacific Northwest USA. For. Sci. 2015, 61, 220–234. [Google Scholar] [CrossRef]

- Han, H.-S.; Halbrook, J.; Pan, F.; Salazar, L. Economic evaluation of a roll-off trucking system removing forest biomass resulting from shaded fuelbreak treatments. Biomass Bioenergy 2010, 34, 1006–1016. [Google Scholar] [CrossRef]

- Harrill, H.; Han, H.-S. Application of hook-lift trucks in centralized logging slash grinding operations. Biofuels 2010, 1, 399–408. [Google Scholar] [CrossRef]

- Hall, P. Two-Staging to Super-Skids with Bell Off-Higway Trucks; Liro: Rotorua, New Zealand, 1998; Volume 23, pp. 1–8. [Google Scholar]

- Rendell, T. A Case Study of Two-Stage Operations in the Kenderdine Forest and Survey Assessment of Current Two-Stage Operations in Industry; University of Canterburry: Christchurch, New Zealand, 2019; 22p. [Google Scholar]

- Sirén, M.; Aaltio, H. Productivity and Costs of Thinning Harvesters and Harvester-Forwarders. Int. J. For. Eng. 2003, 14, 39–48. [Google Scholar] [CrossRef]

- Affenzeller, G.; Stampfer, K. Comparison of integrated with conventional harvester-forwarder-concepts in thinning operations. In Proceedings of the International Mountain Logging and 13th Pacific Northwest Skyline Symposium, Corvallis, OR, USA, 1–6 April 2007; Sessions, J., Havill, Y., Eds.; International Union of Forest Research Organizations: Corvallis, OR, USA, 2007; pp. 32–38. [Google Scholar]

- Talbot, B.; Nordfjell, T.; Suadicani, K. Assessing the Utility of Two Integrated Harvester-Forwarder Machine Concepts Through Stand-Level Simulation. Int. J. For. Eng. 2003, 14, 31–43. [Google Scholar] [CrossRef]

- Asikainen, A. Integration of Work Tasks and Supply Chains in Wood Harvesting—Cost Savings or Complex Solutions? Int. J. For. Eng. 2004, 15, 11–17. [Google Scholar] [CrossRef]

- Väätäinen, K.; Liiri, H.; Röser, D. Cost-Competitiveness of Harwarders in CTL-Logging Conditions in Finland—A Discrete-Event Simulation Study at the Contractor Level. In Proceedings of the International Precision Forestry Symposium, Stellenbosch, South Africa, 5–10 March 2006; pp. 451–463. [Google Scholar]

- Wester, F.; Eliasson, L. Productivity in Final Felling and Thinning for a Combined Harvester-Forwarder (Harwarder). Int. J. For. Eng. 2003, 14, 45–51. [Google Scholar] [CrossRef]

- Jonsson, R.; Rönnqvist, M.; Flisberg, P.; Jönsson, P.; Lindroos, O. Comparison of modelling approaches for evaluation of machine fleets in central Sweden forest operations. Int. J. For. Eng. 2023, 34, 42–53. [Google Scholar]

- MFFP. Ressources et Industries Forestières du Québec: Portrait Statistique (Forest Resources and Industry of Quebec: Statistics), 2017 ed.; MFFP: Quebec City, QC, Canada, 2018. [Google Scholar]

- Gouvernement du Québec. Budget 2016–2017: Compétitivité de L’industrie Forestière au Québec; Gouvernement du Québec: Quebec City, QC, Canada, 2016.

- Groupe DDM. Enquête sur les Couts D’opération Forestière dans les Forêts du Domaine de L’État Ainsi que sur les Couts et Revenus de L’industrie du Sciage du Québec 2019; Report; Groupe DDM: Quebec City, QC, Canada, 2020; 23p. [Google Scholar]

- Diniz, F.; Sessions, J. ESPDS: A Support Tool to Assist Forest Equipment Purchase Decisions. Croat. J. For. Eng. 2022, 43, 99–108. [Google Scholar] [CrossRef]

- Jonsson, R.; Rönnqvist, M.; Flisberg, P.; Jönsson, P.; Lindroos, O. Country-Wide analysis of the potential use of harwarders for final felling in Sweden. Scand. J. For. Res. 2023, 38, 105–120. [Google Scholar] [CrossRef]

- Yoshimura, T.; Suzuki, Y.; Sato, N. Assessing the productivity of Forest Harvesting Systems Using a Combination of Forestry Machines in Steep Terrain. Forests 2023, 14, 1430–1446. [Google Scholar] [CrossRef]

- Kellogg, L.; Bettinger, P.; Robe, S.; Steffert, A. Mechanized Harvesting: A Compendium of Research; Forest Research Laboratory, College of Forestry, Oregon State University: Corvallis, OR, USA, 1992; 401p. [Google Scholar]

- Dempster, P.; Gallo, N.; Hartsough, B.; Jenkins, B.; Tittmann, P. Sponsorship-Equipment Review Agreement Number 8CA05704—Final Report to State of California Department of Forestry and Fire Protection; University of California: Davis, CA, USA, 2008. [Google Scholar]

- Ringdahl, O.; Hellström, T.; Lindroos, O. Potentials of possible machine systems for directly loading logs in cut-to-length harvesting. Can. J. For. Res. 2012, 42, 970–985. [Google Scholar] [CrossRef]

- Lindroos, O. Evaluation of Technical and Organizational Approaches for Directly Loading Logs in Mechanized Cut-to-Length Harvesting. For. Sci. 2012, 58, 326–341. [Google Scholar] [CrossRef]

- Lundbäck, M.; Hägstrom, C.; Fjeld, D.; Lindroos, O.; Nordjfell, T. The Economic Potential of semi-automated tele-extraction of roundwood in Sweden. Int. J. For. Eng. 2022, 33, 271–288. [Google Scholar] [CrossRef]

- Wästerlund, I.; Hassan, A.E. Forest Harvesting Systems Friendly to the Environment. In Proceedings of the ASME Winter Annual Meeting, Atlanta, GA, USA, 13–16 December 1994. 30p. [Google Scholar]

- Dimou, V.; Malivitsi, Z. Strategic decision model for the evaluation of timber harvesting systems. Int. J. For. Eng. 2015, 26, 146–157. [Google Scholar] [CrossRef]

- Kühmaier, M.; Stampfer, K. Development of a Multi-Attribute Spatial Decision Support System in Selecting Timber Harvesting Systems. Croat. J. For. Eng. 2010, 31, 75–88. [Google Scholar]

- Martínez-Mesa, J.; González-Chica, D.A.; Duquia, R.P.; Bonamigo, R.R.; Bastos, J.L. Sampling: How to select participants in my research study? An. Bras. Dermatol. 2016, 91, 326–330. [Google Scholar] [CrossRef] [PubMed]

- Matthews, D.M. (Ed.) Cost Control in the Logging Industry; McGraw-Hill: New York, NY, USA, 1942; 374p. [Google Scholar]

- Thompson, M.A. Considering overhead costs in road and landing spacing models. J. For. Eng. 1992, 3, 13–19. [Google Scholar] [CrossRef]

- Plamondon, J.A. Établir la Distance de Débardage Optimale en Fonction du Coût des Chemins; FERIC Report; FERIC: Pointe-Claire, QC, Canada, 1994; 8p. [Google Scholar]

- Macdonald, A.J. Harvesting Systems and Equipment in British Columbia; Ministry of Forests: Vancouver, BC, Canada, 1999; 56p. [Google Scholar]

- Ackerman, P.; Belbo, H.; Eliasson, L.; de Jong, A.; Lazdins, A.; Lyons, J. The COST model for calculation of forest operations costs. Int. J. For. Eng. 2014, 25, 75–81. [Google Scholar] [CrossRef]

- The World Bank. International Financial Statistics, Official Exchange Rate (LCU per US$, Period Average). 2020. Available online: http://data.worldbank.org/ (accessed on 29 May 2020).

- BLS. United States Department of Labour Statistics, Bureau of Labour Statistics. 2020. Available online: http://www.bls.gov/ (accessed on 29 May 2020).

- Di Fulvio, F.; Abbas, D.; Spinelli, R.; Acuna, M.; Ackerman, P.; Lindroos, O. Benchmarking technical and cost factors in forest felling and processing operations in different global regions during the period 2013–2014. Int. J. For. Eng. 2017, 28, 94–105. [Google Scholar] [CrossRef]

- Hansen, P.; Ombler, F. A new method for scoring additive multi-attribute value models using pairwise rankings of alternatives. J. Multi-Criteria Decis. Anal. 2008, 15, 87–107. [Google Scholar] [CrossRef]

- Legendre, P. Species associations: The Kendall coefficient of concordance revisited. J. Agric. Biol. Environ. Stat. 2005, 10, 226–245. [Google Scholar] [CrossRef]

- Lilleberg, R. Harvester-Forwarder for Logging in First-Thinning Stands; Metsäteho Report 28; Metsäteho Oy: Helsinki, Finland, 1997; 24p. [Google Scholar]

- Manner, J.; Jonsson, R.; Jönsson, P.; Björheden, R.; Lundström, H. Productivity and Logging Costs of the Harwarder Prototype Komatsu X19 and a Conventional CTL System; Skogforsk: Uppsala, Sweden, 2016; 40p. [Google Scholar]

- Kärhä, K. Whole-tree harvesting in young stands in Finland. For. Stud. Metsanduslikud Uurim. 2006, 45, 118–134. [Google Scholar]

- Laitila, J. Harvesting technology and the cost of fuel chips from early thinnings. Silva Fenn. 2008, 42, 267–283. [Google Scholar] [CrossRef]

- Bergkvist, I.; Hallonbord, U.; Nordén, B. Valmet 801 Combi with Rotating Load Space in Thinnings and Final Cuttings; Skogforsk: Uppsala, Sweden, 2003. [Google Scholar]

- Väätäinen, K.; Asikainen, A.; Sikanen, L.; Ala-Fossi, A. The cost effect of forest machine relocations on logging costs in Finland. For. Stud. Metsanduslikud Uurim. 2006, 45, 135–141. [Google Scholar]

- Kärhä, K.; Poikela, A.; Palander, T. Productivity and Costs of Harwarder Systems in Industrial Roundwood Thinning. Croat. J. For. Eng. 2018, 39, 23–33. [Google Scholar]

- Plamondon, J.A. Use of Convertible Machines “Combo” and “Dual” in Cut-to-Lenght Harvest; FPInnovations: Pointe-Claire, QC, Canada, 2009. [Google Scholar]

- Di Fulvio, F.; Bergström, D. Analyses of a single-machine system for harvesting pulpwood and/or energy-wood in early thinnings. Int. J. For. Eng. 2013, 24, 2–15. [Google Scholar] [CrossRef]

- Fisher, J. Shovel logging: Cost-effective systems gains ground. In Proceedings of the International Mountain Logging 10th Pacific Northwest Skyline Symposium, Corvalis, OR, Cananda, 28 March–1 April 1999; pp. 61–67. [Google Scholar]

- Sessions, J.; Boston, K. Optimization of Road Spacing for Log Length Shovel Logging on Gentle Terrain. Int. J. For. Eng. 2006, 17, 67–75. [Google Scholar] [CrossRef]

- Floch, R.F. Shovel Logging and Soil Compaction: A Case Study; Oregon State University: Benton County, OR, USA, 1988; 75p. [Google Scholar]

- McNeel, J.F.; Andersson, B. Shovel Logging with Different Retrieval Patterns in Second-Growth Timber. In Proceedings of the COFE 16th Annual Meeting, Savannah, GA, USA, 8–11 August 1993; pp. 109–122. [Google Scholar]

- Egan, A.; Hicks, R.; Waldron, K.; Skousen, J. Effects of Shovel Logging and Rubber-tired Skidding on Surface Soil Attributes in a Selectively Harvested Central Hardwood Stand. Int. J. For. Eng. 2002, 13, 27–32. [Google Scholar] [CrossRef]

- Eriksson, P. Påhängsvagn för Skotare (Semi-Trailers for Forwarders); SkogForsk Arbetsrapport Nr 404:14; SkogForsk: Uppsala, Sweden, 1998; 21p. [Google Scholar]

- Lindroos, O.; Wästerlund, I. Utvärdering av Skotning med Påhängsvagn (Evaluation of Forwarding with a Trailer); Swedish University of Agricultural Sciences: Umeå, Sweden, 2014; 48p. [Google Scholar]

- Miller, C.F.; Greene, W.D. Delimbing southern pines: Gate versus the CTR Model 314 De-Limber. For. Prod. J. 1992, 42, 11–16. [Google Scholar]

- Cutting Systems Inc. FDT-6000-COMBO Flail/Pull-Thru Delimber. Union Grove (NC). Available online: http://www.cuttingsys.com/ (accessed on 12 February 2020).

- Klepac, J.; Rummer, B. Productivity and Cost Comparison, of Two Different-Sized Skidders. In Proceedings of the 2000 ASAE Annual International Meeting, Milwaukee, WI, USA, 9–12 July 2000; pp. 1–10. [Google Scholar]

- Cass, R.D.; Baker, S.A.; Greene, W.D. Cost and Productivity Impacts of Product Sorting on Conventional Ground-Based Timber Harvesting Operations. For. Prod. J. 2009, 59, 108–114. [Google Scholar] [CrossRef]

- Hill, S.; Evanson, T. The Trinder Static Delimber in a Ground-Bsed Clearfell Operation; Report 20; Liro: Rotorua, New Zealand, 1995; 6p. [Google Scholar]

- Visser, R.; Stampfer, K. Tree-Length System Evaluation of Second Thinning in a Loblolly Pine Plantation. South. J. Appl. For. 2003, 27, 77–82. [Google Scholar] [CrossRef][Green Version]

- Fogdestam, N.; Lundström, H. Studier av Offset Crane Concept, OCC hos Kjellbergs Logistik & Teknik i Hällefors (Studies of Offset Crane Concept, OCC at Kjellbergs Logistik & Teknik in Hällefors); Skogforsk: Uppsala, Sweden, 2011. [Google Scholar]

- Jakobsson, M.; Nilsson, N. Faktorer som Påverkar Valet av Kranavställning vid Rundvirkestransporter hos Holmen Skog AB (Factors Affecting the Removal of the Self-Loader Crane during Roundwood-Transports for Holmen Skog AB); Sveriges Lantbruksuniversitet: Uppsala, Sweden, 2015. [Google Scholar]

- Erlandsson, E. Framgångsfaktorer för Rundvirkesåkerier i Mellansverige (Success Factors for Roundwood Truck Transport Companies in Mid-Sweden); Sveriges Lantbruksuniversitet: Uppsala, Sweden, 2008. [Google Scholar]

- Andersson, E. Kartläggning av Typfordon för Rundvirkestransport vid Holmen Skogs Regioner (A Mapping of Timber Truck Types on Holmen Skog’s Regions); Sveriges Lantbruksuniversitet: Uppsala, Sweden, 2014; 44p. [Google Scholar]

- Spinelli, R.; Hartsough, B.R. Harvesting SRF popular for pulpwood: Experience in the Pacific Northwest. Biomass Bioenergy 2006, 30, 439–445. [Google Scholar] [CrossRef]

- Mousavi, R.; Naghdi, R. Time consumption and productivity analysis of timber trucking using two kinds of trucks in northern Iran. J. For. Sci. 2013, 59, 211–221. [Google Scholar] [CrossRef]

- Kellogg, L. Small Landing Operation: A Study with A Mobile Hauler & Hydraulic Knuckle Boom Loader; Liro: Rotorua, New Zealand, 1987. [Google Scholar]

- Visser, R.; Spinelli, R.; Magagnotti, N. Landing Characteristics for Harvesting Operations in New Zealand. Int. J. For. Eng. 2011, 22, 23–27. [Google Scholar] [CrossRef]

- Lanford, B.L.; Stokes, B.J. Comparison of Two Thinning Systems. Part 2. Productivity and Costs. For. Prod. J. 1996, 46, 47–53. [Google Scholar]

- Akay, A.E.; Oǧuz, H.; Karas, I.R.; Aruga, K. Using LiDAR technology in forestry activities. Environ. Monit. Assess. 2009, 151, 117–125. [Google Scholar] [CrossRef] [PubMed]

- Adebayo, A.B.; Han, H.-S.; Johnson, L.R. Productivity and cost of cut-to-length and whole tree harvesting in a mixed-conifer stand. For. Prod. J. 2007, 57, 59–69. [Google Scholar]

- Baek, K. Productivity and Cost of a Cut-to-Length Commercial Thinning Operation in a Northern California Redwood Forest. Master’s Thesis, Humbolt State University, Arcata, CA, USA, 2018; 41p. [Google Scholar]

- Scheve, G. Stroker Loading a Log Truck. Youtube Video. 2012. Available online: https://youtu.be/rZrPwD_1Xsw (accessed on 15 June 2020).

- Shukla, M. Pierce GP—Grapple Processor HD. Youtube Video. 2014. Available online: https://youtu.be/2eA1BKEwQCU (accessed on 15 June 2020).

- Pierce Pacific. Pierce Grapple Processor. 8. Available online: https://piercepacific.com/docs/catalogs/pdf/forestry-gp/pierce-forestry-gp.pdf (accessed on 31 March 2020).

- Stokes, B.J.; Schilling, A. Improved harvesting systems for wet sites. For. Ecol. Manag. 1997, 90, 155–160. [Google Scholar] [CrossRef]

- McKerchar, A.; Twaddle, A. Central Log Yards—An Option to Consider; LIRA Technical Release: Rotorua, New Zealand, 1987; 8p. [Google Scholar]

- Atkins, D.; Rummer, B.; Dodson, B.; Thomas, C.E.; Horcher, A.; Messerlie, E.; Rawlings, C.; Haston, D. A Report on Conceptual Advances in Roll On/Off Technology in Forestry; USDA Forest Service: Washington, DC, USA, 2007. [Google Scholar]

- Kash, A.; Dodson, E. Production of a Roll-off Equipped Harwarder for Forest Biomass Utilization. Int. J. For. Eng. 2010, 21, 48–56. [Google Scholar] [CrossRef]

- Granskog, J.E. Harvesting Costs for Mechanized Thinning Systems in Slash Pine Plantations; Res paper. SO-141; U.S. Department of Agriculture, Forest Service: New Orleans, LA, USA, 1978. [Google Scholar]

- Akay, A.E.; Erdas, O.; Sessions, J. Determining Productivity of Mechanized Harvesting Machines. J. Appl. Sci. 2004, 4, 100–105. [Google Scholar] [CrossRef]

- Jernigan, P.; Gallagher, T.; Aulakh, J.; Tufts, R.; McDonald, T. Implementing residue chippers on harvesting operations in the southeastern US for biomass recovery. Int. J. For. Eng. 2013, 24, 129–136. [Google Scholar] [CrossRef]

- Brinker, R.W.; Kinard, J.; Rummer, B.; Lanford, B. Machine Rates for Selected Forest Harvesting Machines; Circular 296; Alabama Agriculture Experiment Station: Auburn, AL, USA, 2002; 32p. [Google Scholar]

- Väätäinen, K.; Laitila, J.; Anttila, P.; Kilpeläinen, A.; Asikainen, A. The influence of gross vehicle weight (GVW) and transport distance on timber trucking performance indicators—Discrete event simulation case study in Central Finland. Int. J. For. Eng. 2020, 31, 156–170. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Salvage value | % of purchase price | 10 |

| Expected economic life | Years | 5 |

| Interest rate | % | 10 |

| Insurance | % of the purchase price | 2.2 |

| Fuel cost | USD/l | 1.00 |

| Operator wage with benefits | USD/SMH | 30 |

| Scheduled days per year | days/y | 168.75 |

| Scheduled shifts per day | shifts/day | 2 |

| Scheduled hours per shift | SMH/shift | 12 |

| Profit margin | % gross cost and overhead | 10 |

| Criteria | Productivity | Mobility | Road Investment | Machinery Operating Cost | |

|---|---|---|---|---|---|

| Indicator | System Productivity | Nb of Machines | Maximum Extraction Distance | Unit Cost | |

| Unit | m3/PMH | Nb | m | $/m3 | |

| Levels | 1 | <10 | ≥5 | <225 | ≥30 |

| 2 | 10–20 | 3–5 | 225–500 | 28–30 | |

| 3 | 20–30 | 2–3 | 500–1000 | 26–28 | |

| 4 | ≥30 | <2 | ≥1000 | <26 |

| Felling | Extraction | Processing | Loading | Transport |

|---|---|---|---|---|

| Combi | Shovel logger | Gate delimber | Removable crane truck | Secondary extraction |

| Dual | Forwarder trailer | Pull-through delimber | Front-end loader | Super forwarder |

| Feller director | Flail delimber | Extraction machine | Set-out trailers | |

| Processing machine | Hook-lift |

| Expert (#) | 1 | 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|---|---|

| Context of operations | Approximate harvested volume (m3/y) | 500,000 | 1,000,000 | 400,000 | 200,000 | 200,000 | 1,000,000 |

| Harvest system | CTL | CTL | CTL | CTL | WT and CTL | WT and CTL | |

| Productivity of contractors | High | High | High | Low | High | High | |

| Work schedule | Day and night | Day and night | Day and night | Day only | Day only | Day and night | |

| Main transport type | Megaload | Megaload | Standard | Standard/self-loader | Standard | Standard/Megaload | |

| Fragmentation | Perceived proportion of annual volume | 10% | 10% | 50% | 100% | 50% | 33% |

| Solutions | Prioritized during winter | x | x | x | x | ||

| Longer extraction distances | x | x | x | x | x | x | |

| Prioritization of smaller teams | x | x | x | x | x | x |

| Parameter | Purchase Price | Fuel | Oil and Lubricants | Maintenance and Repair | Utilization | Hourly Cost | Productivity | Unit Cost | |

|---|---|---|---|---|---|---|---|---|---|

| Machine | Reference (Purchase Price and Fuel Consumption) | $ | l/PMH | % Fuel Cost | % Purchase Price | % PMH/ SMH | $/ PMH | m3/PMH | $/m3 |

| Harvester | FPInnovations | 650,000 | 30 | 15 | 115 | 75 | 198.70 | 12.8 | 15.52 |

| Feller buncher | FPInnovations | 550,000 | 45 | 15 | 100 | 80 | 185.19 | 30.8 | 6.01 |

| Feller director | Estimated equal to feller buncher | 550,000 | 45 | 15 | 100 | 80 | 185.19 | 23.3 | 7.95 |

| Combi | [66] | 750,000 | 20 | 15 | 115 | 80 | 192.85 | 7.7 | 25.05 |

| Dual | [73] | 550,000 | 20 | 15 | 115 | 75 | 168.09 | 7.7 | 21.83 |

| Combi hook lift | [66,104] | 800,000 | 20 | 15 | 115 | 80 | 201.27 | 7.7 | 26.14 |

| Dual hook lift | [73,104] | 600,000 | 20 | 15 | 115 | 75 | 177.07 | 7.7 | 23.00 |

| Forwarder | FPInnovations | 450,000 | 30 | 10 | 100 | 80 | 148.74 | 19 | 7.83 |

| Clambunk skidder | Tanguay, personal communications 22 July 2019 | 900,000 | 30 | 15 | 100 | 80 | 219.94 | 25.6 | 8.59 |

| Grapple skidder | FPInnovations | 350,000 | 40 | 10 | 100 | 80 | 145.12 | 16 | 9.07 |

| Shovel logger | [109] | 450,000 | 40 | 10 | 100 | 80 | 160.84 | 16.5 | 9.75 |

| Trailer for forwarder | [80] | 35,000 | 2 | 10 | 100 | 50 | 11.28 | 14.2 | 0.79 |

| Hook-lift forwarder | FPInnovations; [104] | 500,000 | 30 | 10 | 100 | 80 | 156.65 | 19 | 8.24 |

| Gate delimber for skidder | [4] | 4000 | 0 | 10 | 65 | 80 | 0.54 | 13.8 | 0.04 |

| Stroke boom delimber | FPInnovations | 430,000 | 25 | 10 | 100 | 80 | 139.53 | 16 | 8.72 |

| Processor | FPInnovations | 600,000 | 30 | 15 | 110 | 80 | 178.20 | 17.4 | 10.24 |

| Trailer loader/Pull-through delimber | Pro Pac personal communications | 300,000 | 35 | 10 | 100 | 80 | 131.06 | 12.2 | 10.74 |

| Loader | FPInnovations | 410,000 | 35 | 10 | 100 | 75 | 155.54 | 78.2 | 1.99 |

| Hook-lift truck | [30] | 180,000 | 26 | 0 | 100 | 90 | 91.81 | 13.5 | 6.80 |

| Self-loading crane | [110] | 82,000 | 35 | 10 | 100 | 21 | 248.92 | 78.2 | 3.18 |

| Criteria | Productivity | Mobility | Road Investments | Machinery Operating Costs |

|---|---|---|---|---|

| CTL Base case | 2 | 2 | 3 | 4 |

| CTL Harwarder felling/extraction | 1 | 3 | 2 | 3 |

| CTL Forwarder w\trailer extraction | 2 | 3 | 4 | 3 |

| CTL Self-loader removable crane transport | 2 | 3 | 3 | 3 |

| CTL TL harvester, shovel logger extraction/loading | 2 | 3 | 1 | 3 |

| CTL Forwarder extraction/loading | 2 | 3 | 2 | 4 |

| CTL Forwarder loading set-out trailers | 2 | 3 | 2 | 3 |

| CTL Articulated self-loader secondary extraction | 2 | 3 | 4 | 1 |

| CTL Hook-lift forwarder and trucks secondary extraction | 2 | 3 | 4 | 1 |

| CTL Harwarder felling/extraction, self-loader removable crane transport | 1 | 4 | 2 | 1 |

| CTL Harwarder felling/extraction/loading | 1 | 4 | 1 | 3 |

| CTL Harwarder felling/extraction/loading set-out trailers | 1 | 4 | 1 | 3 |

| CTL Harwarder felling/extraction, articulated self-loader secondary extraction | 1 | 4 | 3 | 1 |

| CTL Hook-lift harwarder felling/extraction, hook-lift trucks secondary extraction | 1 | 4 | 3 | 1 |

| WT Base case | 4 | 1 | 2 | 4 |

| WT Clambunk extraction | 3 | 1 | 3 | 4 |

| WT 2 forwarders extraction | 4 | 1 | 3 | 4 |

| WT Gate delimber skidders, 2 loaders/pull-through delimber processing/loading | 3 | 1 | 1 | 3 |

| WT Self-loader removable crane transport | 4 | 1 | 2 | 3 |

| WT 2 processors processing/loading | 3 | 1 | 2 | 3 |

| WT Articulated self-loader secondary extraction, centralized processing | 4 | 2 | 3 | 1 |

| WT Clambunk extraction, 2 processors processing/loading | 3 | 2 | 3 | 3 |

| WT 2 forwarders extraction, 2 processors processing/loading | 3 | 1 | 3 | 3 |

| WT Clambunk extraction, articulated self-loader secondary extraction, centralized processing | 3 | 2 | 4 | 1 |

| WT 2 forwarders extraction, articulated self-loader secondary extraction, centralized processing | 4 | 2 | 4 | 1 |

| WT Shovel logger extraction/processing with pull-through delimber/loading | 1 | 3 | 1 | 2 |

| WT Feller director felling/extraction/processing with pull-through delimber/loading | 1 | 4 | 1 | 1 |

| WT Feller director felling/extraction, articulated self-loader secondary extraction, centralized processing | 1 | 3 | 2 | 1 |

| # | Candidate Harvest Systems | Median | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | CTL Forwarder w\trailer extraction | 1.5 | 3 | 2 | 1 | |||||||||||||||||||||||||

| 2 | WT 2 forwarders extraction | 2.5 | 1 | 2 | 1 | 1 | 1 | |||||||||||||||||||||||

| 3 | CTL Self-loader removable crane transport | 3.0 | 1 | 3 | 1 | 1 | ||||||||||||||||||||||||

| 4 | CTL Base case | 4.0 | 2 | 1 | 1 | 1 | 1 | |||||||||||||||||||||||

| 5 | WT Clambunk extraction, 2 processors processing/loading | 5.0 | 2 | 2 | 1 | 1 | ||||||||||||||||||||||||

| 6 | CTL Forwarder extraction/loading | 6.0 | 2 | 1 | 1 | 1 | 1 | |||||||||||||||||||||||

| 7 | WT Clambunk extraction | 6.5 | 1 | 1 | 1 | 2 | 1 | |||||||||||||||||||||||

| 8 | WT 2 forwarders extraction, 2 processors processing/loading | 8.5 | 1 | 2 | 1 | 1 | 1 | |||||||||||||||||||||||

| 8 | WT Base case | 8.5 | 1 | 1 | 1 | 1 | 1 | 1 | ||||||||||||||||||||||

| 10 | CTL Forwarder loading set-out trailers | 9.0 | 1 | 3 | 2 | |||||||||||||||||||||||||

| 11 | WT 2 forwarders extraction, articulated self-loader secondary extraction, centralized processing | 12.5 | 1 | 1 | 1 | 1 | 1 | 1 | ||||||||||||||||||||||

| 12 | WT Clambunk extraction, articulated self-loader secondary extraction, centralized processing | 15.0 | 2 | 2 | 1 | 1 | ||||||||||||||||||||||||

| 13 | CTL Articulated self-loader secondary extraction | 15.5 | 1 | 1 | 1 | 2 | 1 | |||||||||||||||||||||||

| 13 | CTL Hook-lift forwarder and trucks secondary extraction | 15.5 | 1 | 1 | 1 | 2 | 1 | |||||||||||||||||||||||

| 15 | WT Articulated self-loader secondary extraction, centralized processing | 16.0 | 2 | 1 | 1 | 1 | 1 | |||||||||||||||||||||||

| 16 | CTL Harwarder felling/extraction | 16.5 | 1 | 1 | 1 | 2 | 1 | |||||||||||||||||||||||

| 17 | CTL Harwarder felling/extraction, articulated self-loader secondary extraction | 17.0 | 1 | 1 | 2 | 1 | 1 | |||||||||||||||||||||||

| 17 | CTL Hook-lift harwarder felling/extraction, hook-lift trucks secondary extraction | 17.0 | 1 | 1 | 2 | 1 | 1 | |||||||||||||||||||||||

| 17 | WT Self-loader removable crane transport | 17.0 | 1 | 1 | 1 | 2 | 1 | |||||||||||||||||||||||

| 20 | CTL TL harvester, shovel logger extraction/loading | 18.5 | 1 | 1 | 1 | 1 | 1 | 1 | ||||||||||||||||||||||

| 21 | CTL Harwarder felling/extraction/loading | 20.5 | 1 | 1 | 1 | 2 | 1 | |||||||||||||||||||||||

| 21 | CTL Harwarder felling/extraction/loading set-out trailers | 20.5 | 1 | 1 | 1 | 2 | 1 | |||||||||||||||||||||||

| 21 | WT 2 processors processing/loading | 20.5 | 1 | 1 | 1 | 1 | 1 | 1 | ||||||||||||||||||||||

| 24 | CTL Harwarder felling/extraction, self-loader removable crane transport | 24.0 | 1 | 3 | 2 | |||||||||||||||||||||||||

| 25 | WT Gate delimber skidders, 2 loaders/pull-through delimber processing/loading | 25.0 | 1 | 1 | 2 | 1 | 1 | |||||||||||||||||||||||

| 26 | WT Shovel logger extraction/processing with pull-through delimber/loading | 26.0 | 1 | 1 | 1 | 3 | ||||||||||||||||||||||||

| 27 | WT Feller director felling/extraction, articulated self-loader secondary extraction | 27.0 | 1 | 1 | 1 | 3 | ||||||||||||||||||||||||

| 27 | WT Feller director felling/extraction/processing with pull-through delimber/loading | 27.0 | 1 | 3 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Painchaud, L.; LeBel, L. A Multi-Criterion Evaluation Process for Determining Cost-Effective Harvesting Systems in Fragmented Boreal Forests. Forests 2024, 15, 1046. https://doi.org/10.3390/f15061046

Painchaud L, LeBel L. A Multi-Criterion Evaluation Process for Determining Cost-Effective Harvesting Systems in Fragmented Boreal Forests. Forests. 2024; 15(6):1046. https://doi.org/10.3390/f15061046

Chicago/Turabian StylePainchaud, Léo, and Luc LeBel. 2024. "A Multi-Criterion Evaluation Process for Determining Cost-Effective Harvesting Systems in Fragmented Boreal Forests" Forests 15, no. 6: 1046. https://doi.org/10.3390/f15061046

APA StylePainchaud, L., & LeBel, L. (2024). A Multi-Criterion Evaluation Process for Determining Cost-Effective Harvesting Systems in Fragmented Boreal Forests. Forests, 15(6), 1046. https://doi.org/10.3390/f15061046