Timber Extraction by Farm Tractors in Low-Removal-Intensity Continuous Cover Forestry: A Simulation of Operational Performance and Fuel Consumption

Abstract

1. Introduction

2. Materials and Methods

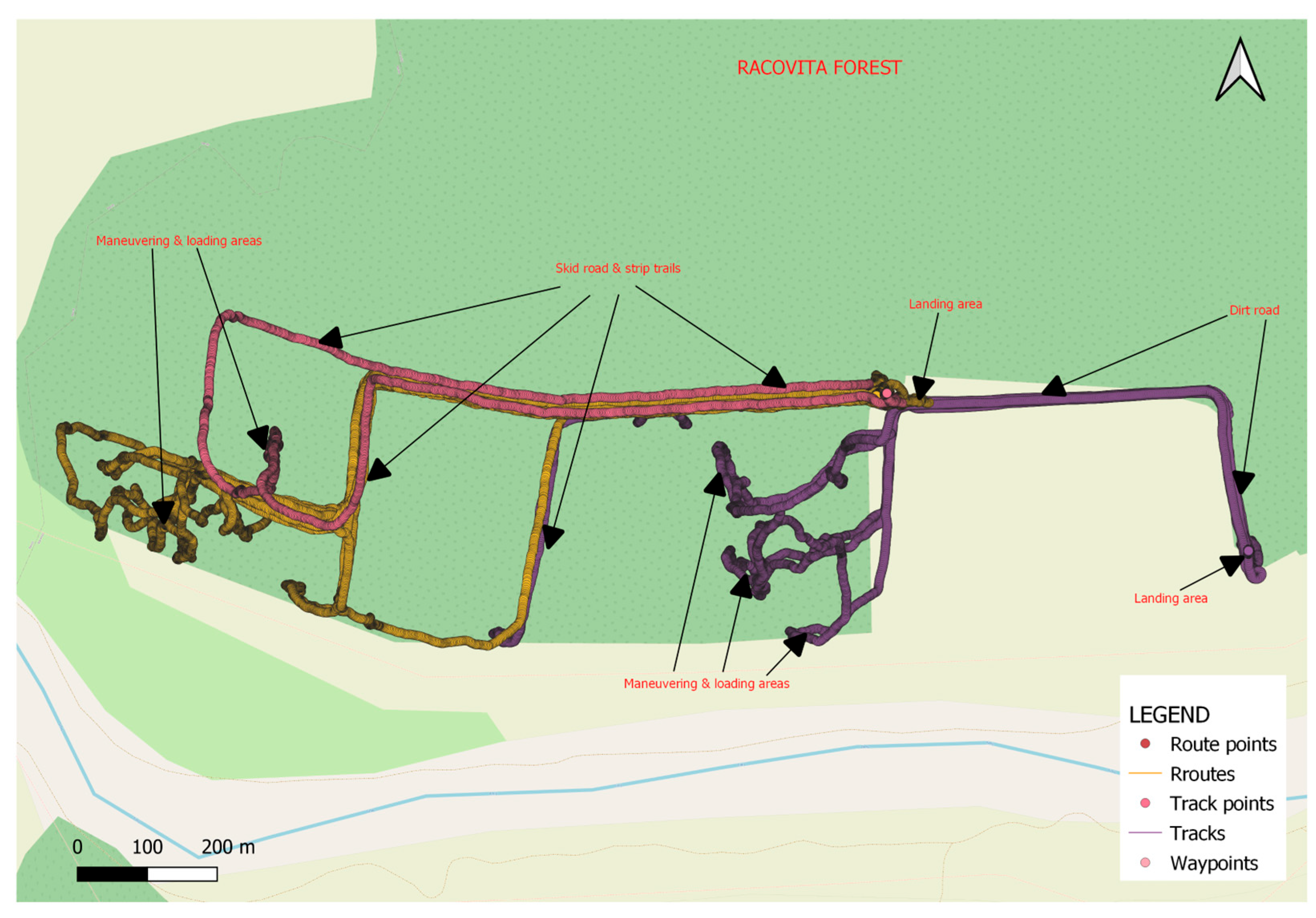

2.1. Study Area

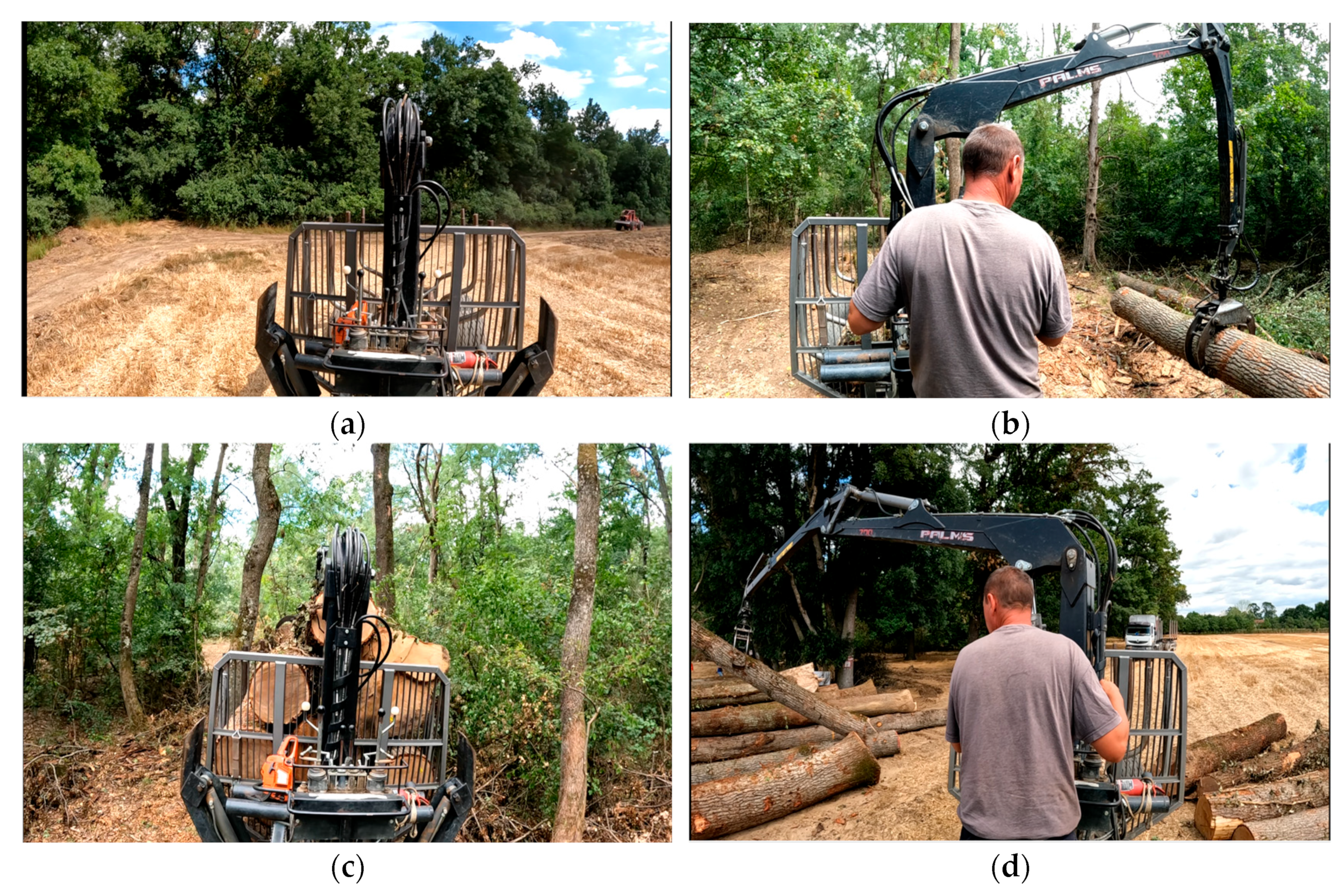

2.2. Description of the Equipment

2.3. Work Structure and Data Collection

2.4. Data Processing and Statistical Analysis

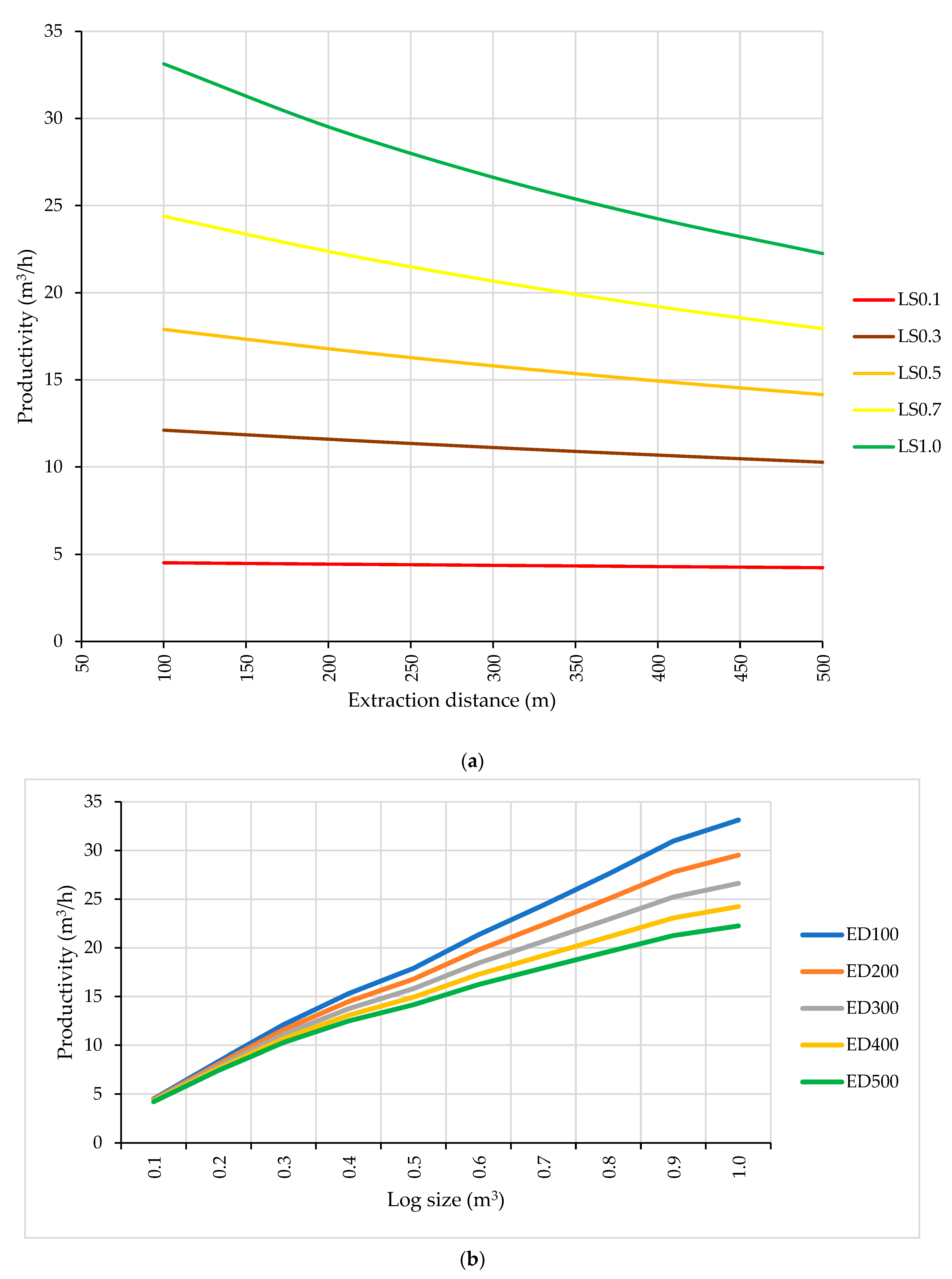

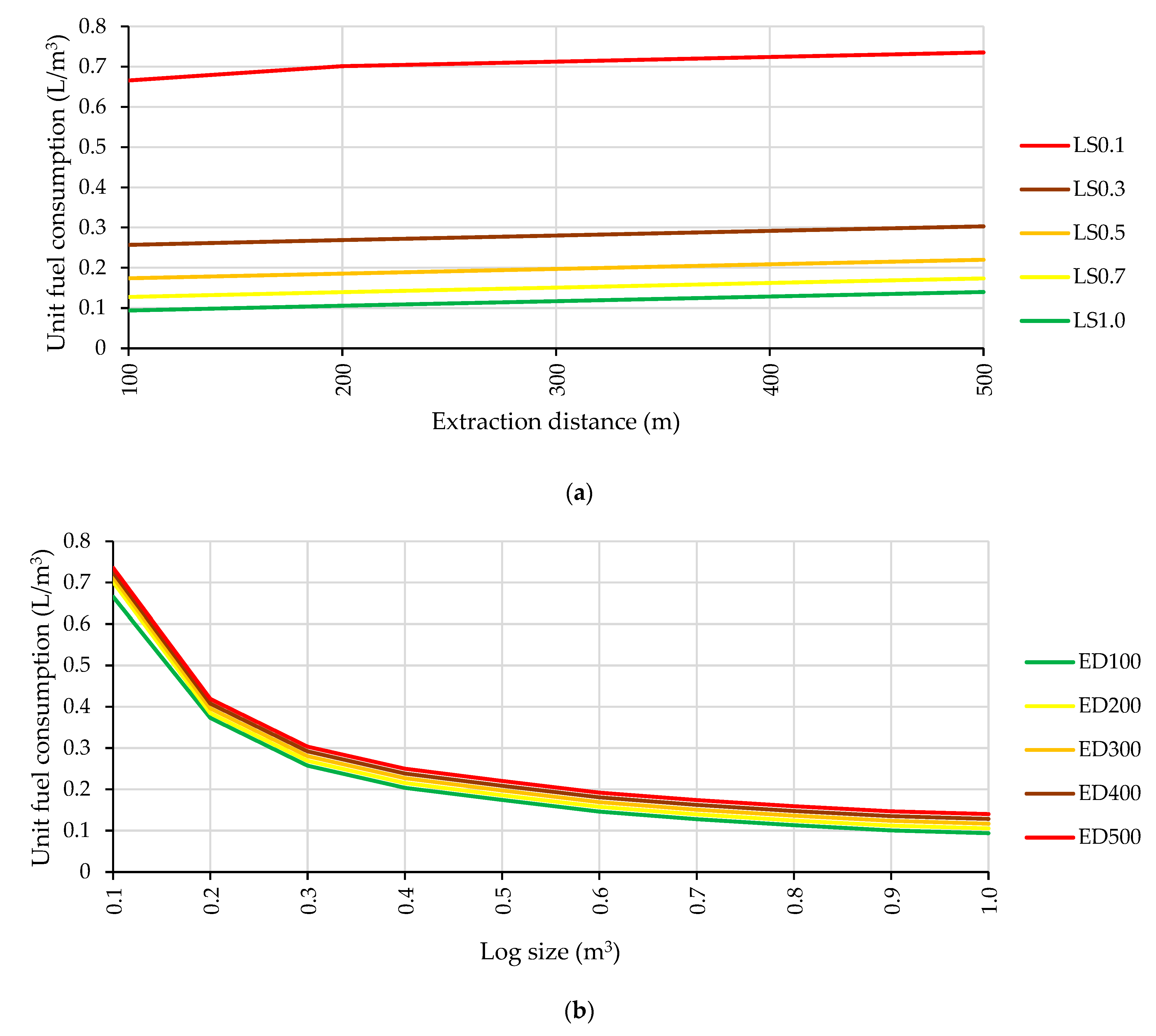

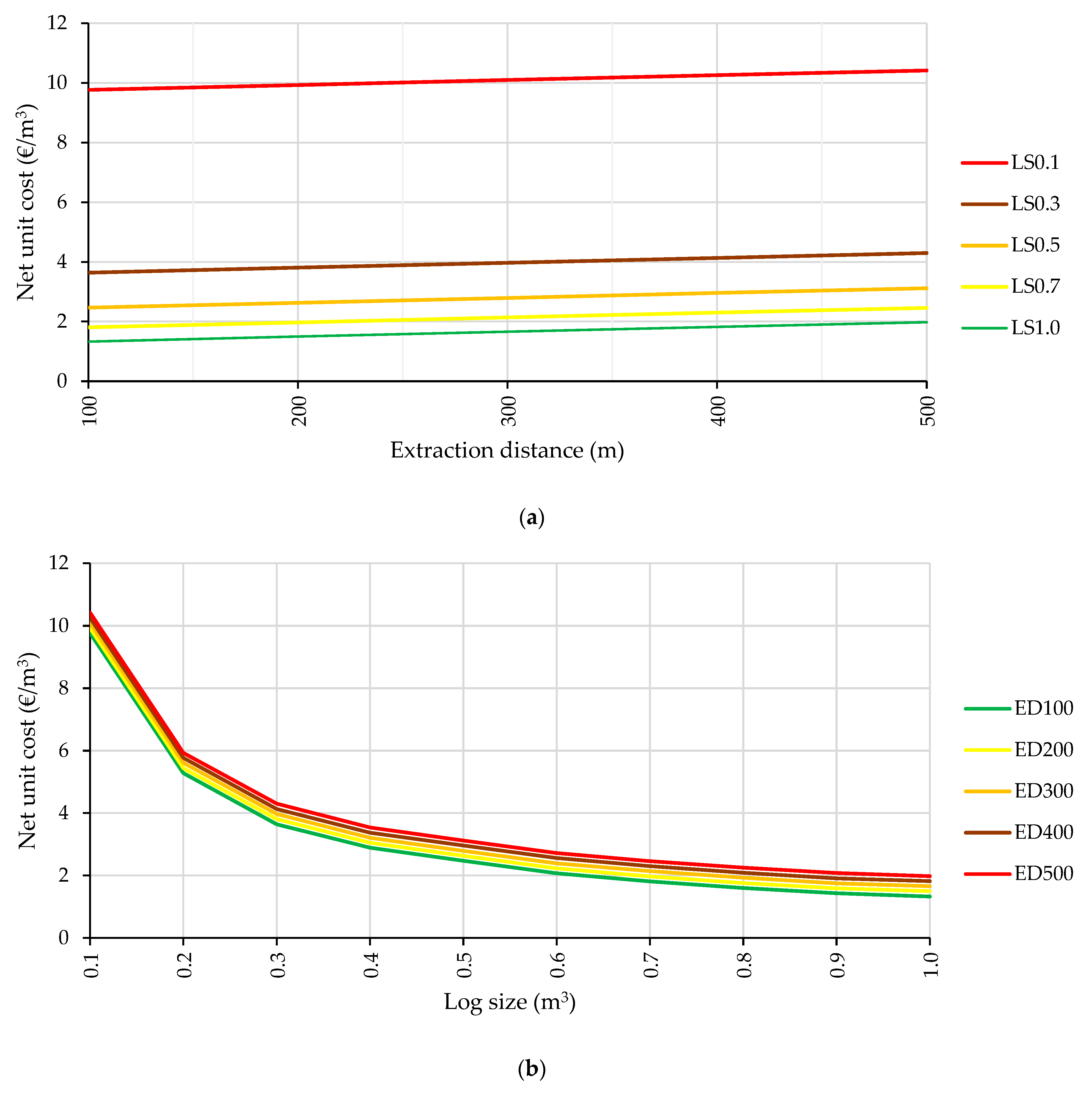

2.5. Simulation of Time Consumption, Productivity, and Fuel Use

2.6. Development of Performance Simulation Models

3. Results

3.1. Descriptive Statistics of the Operational Variables and Time Consumption

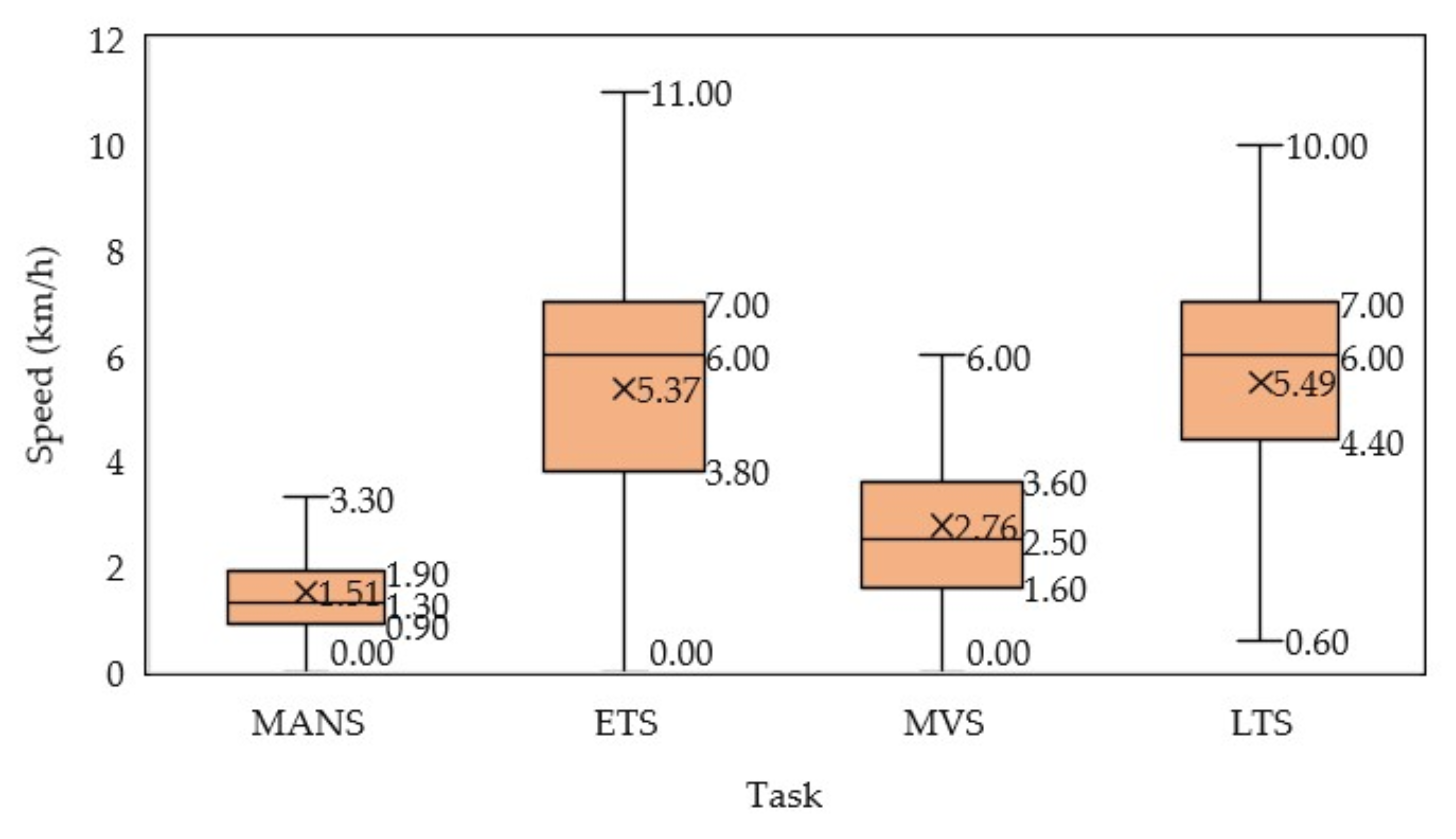

3.2. Descriptive Statistics of the Operational Speed

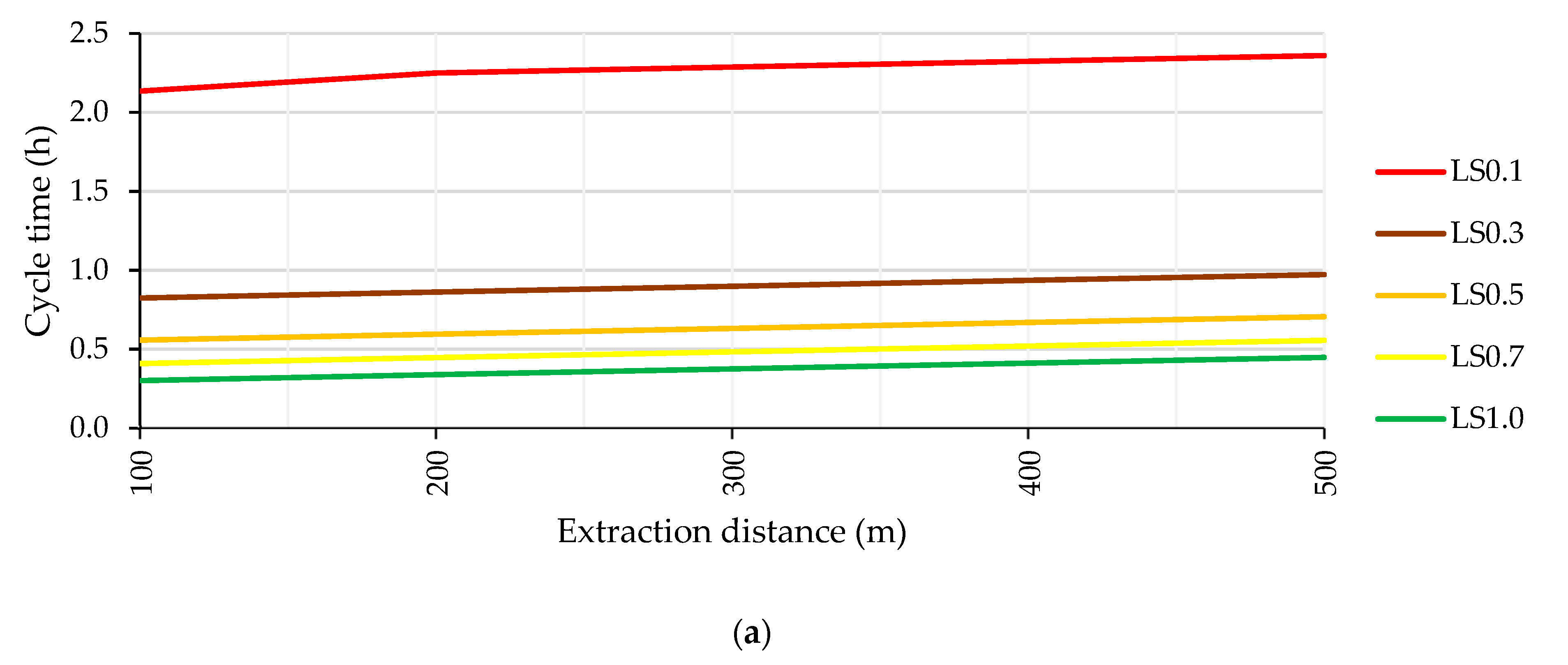

3.3. Models of Time Consumption, Productivity, Fuel Use, and Unit Cost

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Michelsen, O.; Solli, C.; Strømman, A.H. Environmental impact and added value in forestry operations in Norway. J. Ind. Ecol. 2008, 12, 69–81. [Google Scholar] [CrossRef]

- Arce, J.J.C. Forests, inclusive and sustainable economic growth and employment. In Background Study Prepared for the Fourteenth Session of the United Nations Forum on Forest (UNFF); Forests and SDG8; United Nations: New York, NY, USA, 2019; Available online: https://www.un.org/esa/forests/wp-content/uploads/2019/04/UNFF14-BkgdStudy-SDG8-March2019.pdf (accessed on 20 May 2024).

- Ezquerro, M.; Pardos, M.; Diaz-Balteiro, L. Operational research techniques used for addressing biodiversity objectives into forest management: An overview. Forests 2016, 7, 229. [Google Scholar] [CrossRef]

- Picchio, R.; Mercurio, R.; Venanzi, R.; Gratani, L.; Giallonardo, T.; Lo Monaco, A.; Frattaroli, A.R. Strip clear-cutting application and logging typologies for renaturalization of pine afforestation—A case study. Forests 2018, 9, 366. [Google Scholar] [CrossRef]

- FAO. Global Forest Resources Assessment 2020—Main Report; FAO: Rome, Italy, 2020; p. 184. ISBN 978-92-5-132974-0. [Google Scholar] [CrossRef]

- FAO. The State of the World’s Forests 2022: Forest Pathways for Green Recovery and Building Inclusive, Resilient and Sustainable Economies; FAO: Rome, Italy, 2022; Available online: https://www.fao.org/3/cb9360en/online/cb9360en.html (accessed on 10 April 2024).

- Forestry Commission. The UK Forestry Standard; Forestry Commission: Edinburgh, UK, 1998; p. 105. Available online: https://forestry.gov.scot/publications/105-the-uk-forestry-standard (accessed on 27 May 2024).

- Mason, W.L.; Kerr, G.; Simpson, J. What is Continuous Cover Forestry? Forestry Commission: Edinburgh, UK, 1999; p. 8. Available online: https://www.researchgate.net/publication/238711245 (accessed on 20 May 2024).

- Mason, W.L.; Diaci, J.; Carvalho, J.; Valkonen, S. Continuous cover forestry in Europe: Usage and the knowledge gaps and challenges to wider adoption. Int. J. For. Res. 2022, 95, 1–12. [Google Scholar] [CrossRef]

- Lundmark, T.; Bergh, J.; Nordin, A.; Fahlvik, N.; Poudel, B.C. Comparison of carbon balances between continuous-cover and clear-cut forestry in Sweden. Ambio 2016, 45, 203–213. [Google Scholar] [CrossRef] [PubMed]

- Kiisel, M.; Remm, L. Continuous cover forestry practitioners in a clear-cutting-oriented system: Assessing the potential to foster the practice. Small-Scale For. 2022, 21, 325–348. [Google Scholar] [CrossRef]

- Pommerening, A.; Murphy, S.T. A review of the history, definitions and methods of continuous cover forestry with special attention to afforestation and restocking. Forestry 2004, 77, 27–44. [Google Scholar] [CrossRef]

- Ashton, M.S.; Kelty, M.J. The practice of silviculture: Applied forest ecology. For. Perspect. 2019, 76, 101–104. [Google Scholar]

- Vitkova, L.; Dhubháin, Á.N. Transformation to continuous cover forestry—A review. Ir. For. 2013, 70, 119–140. [Google Scholar]

- Vanclay, J.K. Modelling continuous cover forests. In Continuous Cover Forestry; Springer: Dordrecht, The Netherland, 2012; pp. 229–241. [Google Scholar] [CrossRef]

- Dudáková, Z.; Allman, M.; Merganič, J.; Merganičová, K. Machinery-induced damage to soil and remaining forest stands—Case study from Slovakia. Forests 2020, 11, 1289. [Google Scholar] [CrossRef]

- Picchio, R.; Mederski, P.S.; Tavankar, F. How and how much, do harvesting activities affect forest soil, regeneration and stands? Curr. For. Rep. 2020, 6, 115–128. [Google Scholar] [CrossRef]

- Puche, C.; Erber, G.; Hasenauer, H. Europe’s potential wood supply by harvesting system. Forests 2023, 14, 398. [Google Scholar] [CrossRef]

- Tavankar, F.; Bonyad, A.E.; Nikooy, M.; Picchio, R.; Venanzi, R.; Calienno, L. Damages to soil and tree species by cable-skidding in Caspian forests of Iran. For. Syst. 2017, 26, e009. [Google Scholar] [CrossRef]

- Tepp, J.S. Assessing Visual Soil Disturbance on Eight Commercially Thinned Sites in Northeastern Washington; USDA Forest Service Report 14; Pacific Northwest Research Station: Corvallis, OR, USA, 2002. Available online: https://www.fs.usda.gov/research/treesearch/download/5055.pdf (accessed on 8 July 2024).

- Lindroos, O.; Wasterlund, I. Larger loads and decreased damage—The potential of a new forwarding concept. In Proceedings of the FORMEC 2011, Graz, Austria, 9–13 October 2011; p. 166. Available online: https://www.formec.org/images/proceedings/2011/formec2011_paper_lindroos_waesterlund.pdf (accessed on 12 June 2024).

- Cambi, M.; Giannetti, F.; Bottalico, F.; Travaglini, D.; Nordfjell, T.; Chirici, G.; Marchi, E. Estimating machine impact on strip roads via close-range photogrammetry and soil parameters: A case study in central Italy. iForest—Biogeosc. For. 2018, 11, 148. [Google Scholar] [CrossRef]

- Labelle, E.R.; Lemmer, K.J. Selected environmental impacts of forest harvesting operations with varying degree of mechanization. Croat. J. For. Eng. 2019, 40, 239–257. [Google Scholar] [CrossRef]

- Lindroos, O.; La Hera, P.; Häggström, C. Drivers of advances in mechanized timber harvesting—A selective review of technological innovation. Croat. J. For. Eng. 2017, 38, 243–258. [Google Scholar]

- Borz, S.A.; Marcu, M.V.; Cataldo, M.F. Evaluation of an HSM 208F 14tone HVT-R2 forwarder prototype under conditions of steep-terrain low-access forests. Croat. J. For. Eng. 2021, 42, 185–200. [Google Scholar] [CrossRef]

- Proto, A.R.; Macriì, G.; Visser, R.; Harrill, H.; Russo, D.; Zimbalatti, G. Factors affecting forwarder productivity. Eur. J. For. Res. 2018, 137, 143–151. [Google Scholar] [CrossRef]

- Borz, S.A.; Rommel, D.; Ziesak, M.; Vasiliauskas, G. Operational requirements and preferences towards forwarder technology. In Bulletin of the Transilvania University of Brasov. Series II: Forestry• Wood Industry• Agricultural Food Engineering; Transilvania University Press: Brasov, Romania, 2019; pp. 1–12. [Google Scholar] [CrossRef]

- Naghdi, R.; Lotfalian, M.; Bagheri, I.; Jalali, A.M. Damages of skidder and animal logging to forest soils and natural regeneration. Croat. J. For. Eng. 2009, 30, 141–149. [Google Scholar]

- Nichols, M.T.; Lemin, R.C., Jr.; Ostrofsky, W.D. The impact of two harvesting systems on residual stems in a partially cut stand of northern hardwoods. Can. J. For. Res. 1994, 24, 350–357. [Google Scholar] [CrossRef]

- Savelli, S.; Cavalli, R.; Baldini, S.; Picchio, R. Small scale mechanization of thinning in artificial coniferous plantation. Croat. J. For. Eng. 2010, 31, 11–21. [Google Scholar]

- Spinelli, R.; Magagnotti, N.; Facchinetti, D. Logging companies in the European mountains: An example from the Italian Alps. Int. J. For. Eng. 2013, 24, 109–120. [Google Scholar] [CrossRef]

- Ünver-Okan, S. Modelling of work efficiency in cable traction with tractor implementing the least-squares methods and robust regression. Croat. J. For. Eng. 2020, 41, 109–117. [Google Scholar] [CrossRef]

- Ghaffariyan, M.R. An overview of work productivity evaluation of farm tractors in timber skidding operations. Silva Balcan. 2022, 23, 21–36. [Google Scholar] [CrossRef]

- Kulak, D.; Szewczyk, G.; Stańczykiewicz, A. Productivity and working time structure of timber forwarding in flatland thinned pine stand with the use of farm tractors. Croat. J. For. Eng. 2023, 44, 57–67. [Google Scholar] [CrossRef]

- Stoilov, S.; Proto, A.R.; Oslekov, D.; Angelov, G.; Papandrea, S.F. Forest operations using a combi–forwarder in deciduous forests. Small-Scale For. 2024, 23, 25–40. [Google Scholar] [CrossRef]

- Akay, A.E. Using farm tractors in small-scale forest harvesting operations. J. Appl. Sci. Res. 2005, 1, 196–199. [Google Scholar]

- Gülci, S.; Büyüksakalli, H.H.; İnanç, T.A.Ş.; Akay, A.E. Productivity analysis of timber skidding operation with farm tractor. Eur. J. For. Eng. 2018, 4, 26–32. [Google Scholar] [CrossRef][Green Version]

- Shaffer, R.M. Farm Tractor Logging for Woodlot Owners; Publication 420-090; Virginia Cooperative Extension (VCE): Blacksburg, VA, USA, 2005; Available online: https://vtechworks.lib.vt.edu/bitstream/handle/10919/54926/420-090.pdf (accessed on 23 June 2024).

- Gülci, S. Productivity of a farm tractor with single drum winch during whole-tree timber extraction. J. For. Soc. Croat./Sumarski List Hrvatskoga Sumarskoga Drustva 2020, 144, 35. [Google Scholar] [CrossRef]

- Leszczyński, K.; Stańczykiewicz, A.; Kulak, D.; Szewczyk, G.; Tylek, P. Estimation of productivity and costs of using a track mini-harvester with a stroke head for the first commercial thinning of a Scots pine stand. Forests 2021, 12, 870. [Google Scholar] [CrossRef]

- Dudek, T.; Janas, D. The productivity and the costs forwarding wood of a farm tractor with a trailer in late thinning and cutting in gaps of forests. Forests 2022, 13, 1309. [Google Scholar] [CrossRef]

- Borz, S.A.; Mariş, A.C.; Kaakkurivaara, N. Performance of skidding operations in low-access and low-intensity timber removals: A simulation of productivity and fuel consumption in mature forests. Forests 2023, 14, 265. [Google Scholar] [CrossRef]

- Mousavi, R.; Naghdi, R. Comparison of productivity and cost of timber extraction by farm tractor, skidding vs. forwarding in Northern Iran. HortFlora Res. Spectr. 2014, 3, 201–210. [Google Scholar]

- Dong, X.; Mendoza-Trejo, O.; Morales, D.O.; Lindroos, O.; La Hera, P. Simulation-based comparison between two crane-bunk systems for loading work when considering energy-optimal motion planning. Int. J. For. Eng. 2020, 31, 70–77. [Google Scholar] [CrossRef]

- Gilanipoor, N.; Najafi, A.; Heshmat Alvaezin, S.M. Productivity and cost of farm tractor skidding. J. For. Sci. 2012, 58, 21–26. [Google Scholar] [CrossRef]

- Häggström, C.; Lindroos, O. Human, technology, organization and environment–a human factors perspective on performance in forest harvesting. Int. J. For. Eng. 2016, 27, 67–78. [Google Scholar] [CrossRef]

- Vusić, D.; Šušnjar, M.; Marchi, E.; Spina, R.; Zečić, Ž.; Picchio, R. Skidding operations in thinning and shelterwood cut of mixed stands–Work productivity, energy inputs and emissions. Ecol. Eng. 2013, 61, 216–223. [Google Scholar] [CrossRef]

- Kühmaier, M.; Kral, I.; Kanzian, C. Greenhouse gas emissions of the forest supply chain in Austria in the year 2018. Sustainability 2022, 14, 792. [Google Scholar] [CrossRef]

- Magagnotti, N.; Mihelic, M.; Perazzolo, A.; Spinelli, R. Seventeen years of forest restoration with small-scale technologies: Time and fuel consumption for alternative operations and techniques. Small-Scale For. 2023, 22, 557–581. [Google Scholar] [CrossRef]

- Hejazian, M.; Lotfalian, M.; Lindroos, O.; Mohammadi Limaei, S. Wood transportation machine replacement using goal programming. Scand. J. For. Res. 2019, 34, 635–642. [Google Scholar] [CrossRef]

- Naskrent, B.; Polowy, K.; Grzywinski, W.; Sobczak, A. Timber extraction in thinned stands using agricultural tractor coupled with a trailer with a hydraulic crane. Sylwan 2019, 163, 121–129. [Google Scholar]

- Spinelli, R.; Owende, P.M.; Ward, S.M.; Tornero, M. Comparison of short-wood forwarding systems used in Iberia. Silva Fenn. 2004, 38, 85–94. [Google Scholar] [CrossRef]

- Ackerman, P.; Belbo, H.; Eliasson, L.; de Jong, A.; Lazdins, A.; Lyons, J. The COST model for calculation of forest operations costs. Int. J. For. Eng. 2014, 25, 75–81. [Google Scholar] [CrossRef]

- Kaakkurivaara, N.; Kaakkurivaara, T. Productivity and cost analysis of three timber extraction methods on steep terrain in Thailand. Croat. J. For. Eng. 2018, 39, 213–221. [Google Scholar]

- Mousavi, S.R.; Nikooy, M. Evaluation of tree forwarding by farm tractor in patch cutting of poplar plantations in Northern Iran. Small-Scale For. 2014, 13, 527–540. [Google Scholar] [CrossRef]

- Banks, J.; Carson, J.S.; Nelson, B.L.; Nicol, D.M. Discrete-Event System Simulation, 5th ed.; Prentice-Hall: Hoboken, NJ, USA, 2010; 622p. [Google Scholar]

- Cutini, M.; Brambilla, M.; Pochi, D.; Fanigliulo, R.; Bisaglia, C. A simplified approach to the evaluation of the influences of key factors on agricultural tractor fuel consumption during heavy drawbar tasks under field conditions. Agronomy 2022, 12, 1017. [Google Scholar] [CrossRef]

- Visser, R.J.; McDonagh, K.D.; Meller, R.D.; McDonald, T.P. Harvesting system simulation using a systems dynamic model. South. J. Appl. For. 2004, 28, 91–99. [Google Scholar] [CrossRef]

- Wang, J.; LeDoux, C.B. Estimating and validating ground-based timber harvesting production through computer simulation. For. Sci. 2003, 49, 64–76. [Google Scholar] [CrossRef]

- McDonagh, K.D. Systems Dynamics Simulation to Improve Timber Harvesting System Management. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 2002. [Google Scholar]

- Claar, P.W. Simulation Modelling of Agricultural Tractor Performance and Mobility; SAE Technical Paper 872015; SAE International: Warrendale, PA, USA, 1987; 20p. [Google Scholar] [CrossRef]

- Gibson, H.G.; Ki, N.; Queiroz, D.M.; Parsons, N.J. Dynamic simulation techniques for steering of tracked agricultural and forestry vehicles. SAE Trans. 1999, 108, 87–92. [Google Scholar] [CrossRef]

- Ziesak, M.; Bruchner, A.K.; Hemm, M. Simulation technique for modelling the production chain in forestry. Eur. J. For. Res. 2004, 123, 239–244. [Google Scholar] [CrossRef]

- Goulet, D.V.; Iff, R.H.; Sirois, D.L. Analysis of five forest harvesting simulation models. II. Paths, pitfalls, and other considerations. For. Prod. J. 1980, 30, 18–22. [Google Scholar]

- Spinelli, R.; Magagnotti, N. Wood extraction with farm tractor and sulky: Estimating productivity, cost and energy consumption. Small-Scale For. 2012, 11, 73–85. [Google Scholar] [CrossRef]

- AGRIster. Deutz-Fahr Agrofarm 430 Tractor Specification: Deutz-Fahr Agrofarm 430 Tractor Specs, Dimensions, Fuel Consumption, Transmission, Drive, Equipment. 2023. Available online: https://www.agrister.com/tractors/deutz-fahr-agrofarm-430 (accessed on 10 June 2024).

- Palmse Mehaanikakoda OÜ. Trailers. Palms. 2024. Available online: https://www.palms.eu/forest-trailers (accessed on 13 June 2024).

- Deutz-Fahr. Deutz Fahr Agrofarm 430. 2017. Available online: https://www.deutz-fahr.com/en-nd/search?q=430 (accessed on 8 June 2024).

- Galli, L.E.; Facchinetti, D.; Gibin, M.; Pessina, D. Environmental impact of real gaseous pollutants emission of agricultural tractors. In Conference of the Italian Society of Agricultural Engineering; Springer International Publishing: Cham, Switzerland, 2022; pp. 555–563. [Google Scholar] [CrossRef]

- AgroDane. Deutz Fahr Agrofarm 85/100/410/420/430 Technical Data. 2023. Available online: https://www.agrodane.pl/ciagniki-rolnicze/deutz-fahr/agrofarm-85-100-410-420-430-dane-techniczne/ (accessed on 31 May 2024).

- Lectura. DEUTZ-FAHR Agrofarm 430 DT 4WD Farm Tractor Specifications & Technical Data (2015–2017). 2023. Available online: https://www.lectura-specs.com/en/model/agricultural-machinery/4wd-tractors-deutz-fahr/agrofarm-430-dt-1163451 (accessed on 10 June 2024).

- Deutz-Fahr. Agrofarm 430 Series. 2022. Available online: https://www.deutz-fahr.com/en-INT/products/models/tractors/agrofarm/agrofarm430/ (accessed on 7 June 2024).

- Editorial Team. Tractorinfo.com. DEUTZ-FAHR Agrofarm 430 Specs, Price, Review & Features. 2023. Available online: https://www.deutz-fahr.com/en-eu/tractors/agrofarm-g-410-430-series (accessed on 12 June 2024).

- Acuna, M.; Bigot, M.; Guerra, S.; Hartsough, B.; Kanzian, C.; Kärhä, K.; Lindroos, O.; Magagnotti, N.; Roux, S.; Spinelli, R.; et al. Good Practice Guidelines for Biomass Production Studies. CNR-IVALSA. 2012. Available online: https://pub.epsilon.slu.se/id/document/8261535 (accessed on 25 May 2024).

- Björheden, R.; Apel, K.; Shiba, M.; Thompson, M.A. IUFRO Forest Work Study Nomenclature; Swedish University of Agricultural Science: Grapenberg, Sweden, 1995; p. 16. [Google Scholar]

- Ignea, G.; Ghaffaryian, M.R.; Borz, S.A. Impact of operational factors on fossil energy inputs in motor-manual tree felling and processing: Results of two case studies. Ann. For. Res. 2017, 60, 161–172. [Google Scholar] [CrossRef]

- Borz, S.A.; Mititelu, V.B. Productivity and fuel consumption in skidding roundwood on flat terrains by a Zetor farm tractor in group shelterwood cutting of mixed oak forests. Forests 2022, 13, 1294. [Google Scholar] [CrossRef]

- Hemm, M.; Ziesak, M.; Warkotsch, W. Simulating harvesting procedures to evaluate different working systems based on discrete single tree events. In Proceedings of the International Precision Forestry Symposium, Stellenbosch, South Africa, 5–10 March 2006; p. 26. Available online: https://tinyurl.com/ycywdmcc (accessed on 15 July 2024).

- Sängstuvall, L.; Bergström, D.; Lämås, T.; Nordfjell, T. Simulation of harvester productivity in selective and boom-corridor thinning of young forests. Scand. J. For. Res. 2012, 27, 56–73. [Google Scholar] [CrossRef]

- Wang, J.; LeDoux, C.B.; Li, Y. Simulating cut-to-length harvesting operations in Appalachian hardwoods. Int. J. For. Eng. 2005, 16, 11–27. [Google Scholar] [CrossRef]

- Nurminen, T.; Korpunen, H.; Uusitalo, J. Time consumption analysis of the mechanized cut-to-length harvesting system. Silva Fenn. 2006, 40, 335–363. [Google Scholar] [CrossRef]

- Proto, A.R.; Macrì, G.; Visser, R.; Russo, D.; Zimbalatti, G. Comparison of timber extraction productivity between winch and grapple skidding: A Case study in Southern Italian Forests. Forests 2018, 9, 61. [Google Scholar] [CrossRef]

- She, J.; Chung, W.; Kim, D. Discrete-event simulation of ground-based timber harvesting operations. Forests 2018, 9, 683. [Google Scholar] [CrossRef]

- Lee, E.; Han, S.K.; Im, S. Performance analysis of log extraction by a small shovel operation in steep forests of South Korea. Forests 2019, 10, 585. [Google Scholar] [CrossRef]

- Visser, R.; Stampfer, K. Expanding ground-based harvesting onto steep terrain: A review. Croat. J. For. Eng. 2015, 36, 321–331. [Google Scholar]

- Zychowicz, W.I.; Kasprzyk, K.A. Effectiveness of agricultural tractor utilization in the wood skidding and forwarding. Ann. Warsaw Univ. Life Sci.-SGGW. Agric. 2014, 63, 113–123. [Google Scholar]

- Danilović, M.; Stojnić, D.; Karić, S.; Sućević, M. Transport of technical roundwood by forwarder and tractor assembly from poplar plantation. Nova Mech. Šumarstva 2014, 35, 11–21. [Google Scholar]

- Spinelli, R.; Kováč, B.; Heger, P.; Heilig, D.; Heil, B.; Kovács, G.; Magagnotti, N. The effect of target log length on log recovery and harvesting cost: The example of short-rotation poplar plantations. Forests 2022, 13, 669. [Google Scholar] [CrossRef]

- Sundberg, B.; Silversides, C.R. Operational Efficiency in Forestry: Vol. 1: Analysis; Springer Science & Business Media: Dordrecht, The Netherland, 1988; p. 29. ISBN 9024736838. [Google Scholar] [CrossRef]

- Samset, I. Some Observations on Time and Performance Studies in Forestry; Norsk Institutt for Skogforskning: Trondheim, Norway, 1990; p. 43. ISSN 0332-5709. Available online: https://nibio.brage.unit.no/nibio-xmlui/bitstream/handle/11250/2979624/Norsk-institutt-for-skogforskning-Meddelelser-1990-43.5.pdf?sequence=1&isAllowed=y (accessed on 12 May 2024).

- Sängstuvall, L. Improved Harvesting Technology for Thinning of Small Diameter Stands; Department of Forest Resource Management, Swedish University of Agricultural Sciences: Umeå, Sweden, 2018; Volume 66, ISSN 1652-6880. Available online: https://pub.epsilon.slu.se/15761/1/sangstuvall_l_181123.pdf (accessed on 28 April 2024).

- Poudyal, B.H.; Maraseni, T.N.; Cockfield, G. Implications of selective harvesting of natural forests for forest product recovery and forest carbon emissions: Cases from Tarai Nepal and Queensland Australia. Forests 2019, 10, 693. [Google Scholar] [CrossRef]

- Kaakkurivaara, N.; Kaakkurivaara, T.; Ketkaew, C.; Sakulya, T.; Borz, S.A. Modelling productivity in extraction operations by simulations based on GNSS documented data: An example from skidding teak wood in Thailand. In Bulletin of the Transilvania University of Brasov. Series II: Forestry• Wood Industry• Agricultural Food Engineering; Transilvania University Press: Brasov, Romania, 2022; pp. 13–32. [Google Scholar] [CrossRef]

- Hota, S.; Tewari, V.K.; Chandel, A.K. Workload assessment of tractor operations with ergonomic transducers and machine learning techniques. Sensors 2023, 23, 1408. [Google Scholar] [CrossRef] [PubMed]

- Proto, A.R.; Bernardini, V.; Cataldo, M.F.; Zimbalatti, G. Whole tree system evaluation of thinning a pine plantation in southern Italy. Ann. Silv. Res. 2020, 45, 44–52. [Google Scholar] [CrossRef]

- Manner, J.; Nordfjell, T.; Lindroos, O. Effects of the number of assortments and log concentration on time consumption for forwarding. Silva Fenn. 2013, 47, 1030. [Google Scholar] [CrossRef]

| Machine Specifications | |||||

|---|---|---|---|---|---|

| Deutz Fahr Agrofarm 430 | Forest Trailer PALMS 15U | Forest Crane PALMS 7.94 | |||

| Cylinders | 4 | Loading area cross section, m2 | 3.2 | Max outreach, m | 9.4 |

| Engine power (kW) | 80 | Loading area length, mm | 4175 | Lifting capacity at full reach, kg | 540 |

| Weight (kg) | 4100 | Frame extension length, m | 1.085 | Lifting capacity at 4 m, kg | 1410 |

| Engine type | Diesel engine | Gross weight, kg | 19,000 | Brutto lifting torque 215 Bar, kN m | 83 |

| Engine capacity (L) | 4.038 | ||||

| Wheelbase (mm) | 23,400 | ||||

| Travel speed (km/h) | 40 | Total length, mm | 6415 | Telescopic boom stroke length, m | 3.8 |

| Transmission | 30/30 | Width with standard wheels | 2450 | Slewing torque, kN m | 21 |

| Length (mm) | 3990 | Frame | Unibody | Working pressure, bar | 215 |

| Height (m) | 2810 | Max crane size by lifting torque, kN m | 120 | Rotator maximum load, kN | 60 |

| Width (mm) | 2458 | ||||

| Three-point hitch performance | 56 L/min | Standard wheel size | 500/50-22.5 | Crane weight without support leg and valve block, kg | 1310 |

| Maximum torque (N m/rmp) | 400 N m/rmp | Pillar slewing angle, degrees | 380 | ||

| Code | Time Component | Description |

|---|---|---|

| SDs | tSD | Study delay: delays resulting from human, mechanical, or operational factors that prevent the tractor from doing its usual tasks. |

| ET | tET | Empty turn (traveling unloaded): starts when the tractor departs from the landing location and ends when it stops to start loading or to perform another activity. |

| PL | tPL | Prepare for loading: starts when the operator gets out of the cabin, climbs the trailer, and begins to adjust the crane/boom from its stationary position to reach the logs for loading. |

| LD | tLD | Loading: starts when the tractor begins to load logs including adjusting the logs in the bunk and finishes when the boom is rested in a stationary position, prepared for a machine movement. |

| MV | tMV | Moving between bunches: starts when the crane or boom is positioned on the bunk and ends after the tractor has stopped moving after reaching another bunch of logs. |

| LT | tLT | Loaded turn (traveling loaded): begins when the crane/boom is rested stationary on the bunk, and ends when the tractor stops at the landing area. |

| PU | tPU | Prepare for unloading: starts when the operator exits the cabin, ascends to the space between the trailer and cabin, and starts to operate the crane or boom from its still position to reach the logs for unloading. |

| UL | tUL | Unloading: starts with the crane moving near the tractor’s bunk with an empty grapple and ends when the tractor starts another element or with the boom being rested immobile on the bunk for a trip back to the forest or other tasks. It incorporates adjustments to the log stack. |

| MAN | tMAN | Maneuvering: maneuvers taken to enter or exit the strip road once arrived or leaving a given bunch of logs. |

| Parameter | Description |

|---|---|

| Machine type | Deutz Fahr Agrofarm 430 |

| Currency | € |

| Unit of costing | m3 |

| Machine fixed cost inputs | |

| Purchase price (base machine/attachment) | 33,000.00/23,000.00 |

| Salvage price (base machine/attachment) | 10% of purchase price |

| Expected economic life (base machine/attachment) | 15,000.00/15,000.000 per PMH |

| Interest rate | 10% |

| Machine tax/registration (base machine/attachment) | 50.00 |

| Machine insurance (base machine/attachment) | 250.00 |

| Machine transfers | 2000.00 per annum |

| Garaging for machine | 0.00 per annum |

| Machine variable cost inputs | |

| Fuel cost (€/L) | 1.50 |

| Fuel consumption (L/PMH) | 3.12 |

| Oil and lubricant cost | 10% of fuel cost per PMH of base machine |

| Maintenance and repair cost (base machine/attachment) | (80%/100%) of purchase price |

| Tire cost per set of 4 | 2000.00 |

| Operator costs | |

| Number of operators/shift | 1 |

| Average net wage | 10 per hour |

| Social charges | 48% of operator wages |

| PPE (cost per annum) | 100.00 |

| Productivity and operations (general inputs) | |

| Number of working days per year | 210.00 |

| Scheduled hours per shift | 8.00 |

| Scheduled hours per annum | 1680 |

| Production (unit/PMH) | variable |

| Productive hours per annum | 1176 |

| Productivity: m3/PMH | variable |

| Machine utilization: MU (%) = PMH/SMH | 0.70 |

| Overhead costs as absolute value (costs per annum) | 12,000.00 |

| Variable (Description and Code) | Descriptive Statistics | |||||

|---|---|---|---|---|---|---|

| No. of Observations | Minimum Value | Maximum Value | Mean Value | Median Value | Standard Deviation | |

| Distance (m) | ||||||

| Empty turn distance, dET | 19 | 176 | 2128 | 1152.37 | 1195 | 398.91 |

| Distance covered when moving between locations, dMV | 19 | 93 | 988 | 392.84 | 334 | 266.73 |

| Loaded turn distance, dLT | 19 | 626 | 1428 | 1099.32 | 1199 | 231.76 |

| Maneuvering distance, dMAN | 19 | 4 | 109 | 46.16 | 33 | 28.54 |

| Time (s) | ||||||

| Study delay, tSD | 19 | 173 | 4005 | 1623.95 | 1428 | 1100.73 |

| Empty turn time, tET | 19 | 221 | 1207 | 775.26 | 771 | 248.96 |

| Time spent when preparing for loading, tPL | 19 | 44 | 302 | 162.37 | 165 | 64.67 |

| Loading time, tLD | 19 | 292 | 1819 | 695.84 | 537 | 441.79 |

| Time spent when moving between locations, tMV | 19 | 184 | 1351 | 510.63 | 438 | 285.02 |

| Loaded turn time, tLT | 19 | 378 | 973 | 720.32 | 748 | 176.56 |

| Time spent when preparing for unloading, tPU | 19 | 18 | 64 | 32.68 | 30 | 11.78 |

| Unloading time, tUL | 19 | 155 | 722 | 354.37 | 341 | 126.54 |

| Maneuvering time, tMAN | 19 | 15 | 311 | 104.05 | 77 | 85.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Forkuo, G.O.; Marcu, M.V.; Iordache, E.; Borz, S.A. Timber Extraction by Farm Tractors in Low-Removal-Intensity Continuous Cover Forestry: A Simulation of Operational Performance and Fuel Consumption. Forests 2024, 15, 1422. https://doi.org/10.3390/f15081422

Forkuo GO, Marcu MV, Iordache E, Borz SA. Timber Extraction by Farm Tractors in Low-Removal-Intensity Continuous Cover Forestry: A Simulation of Operational Performance and Fuel Consumption. Forests. 2024; 15(8):1422. https://doi.org/10.3390/f15081422

Chicago/Turabian StyleForkuo, Gabriel Osei, Marina Viorela Marcu, Eugen Iordache, and Stelian Alexandru Borz. 2024. "Timber Extraction by Farm Tractors in Low-Removal-Intensity Continuous Cover Forestry: A Simulation of Operational Performance and Fuel Consumption" Forests 15, no. 8: 1422. https://doi.org/10.3390/f15081422

APA StyleForkuo, G. O., Marcu, M. V., Iordache, E., & Borz, S. A. (2024). Timber Extraction by Farm Tractors in Low-Removal-Intensity Continuous Cover Forestry: A Simulation of Operational Performance and Fuel Consumption. Forests, 15(8), 1422. https://doi.org/10.3390/f15081422