Applicability Evaluation of Modified Epoxy Resin in the Repair and Reinforcement of Ancient Building Timber Members

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Modified Epoxy Resin System

2.3. Methods

2.3.1. Viscosity Test

2.3.2. Curing Rate Test

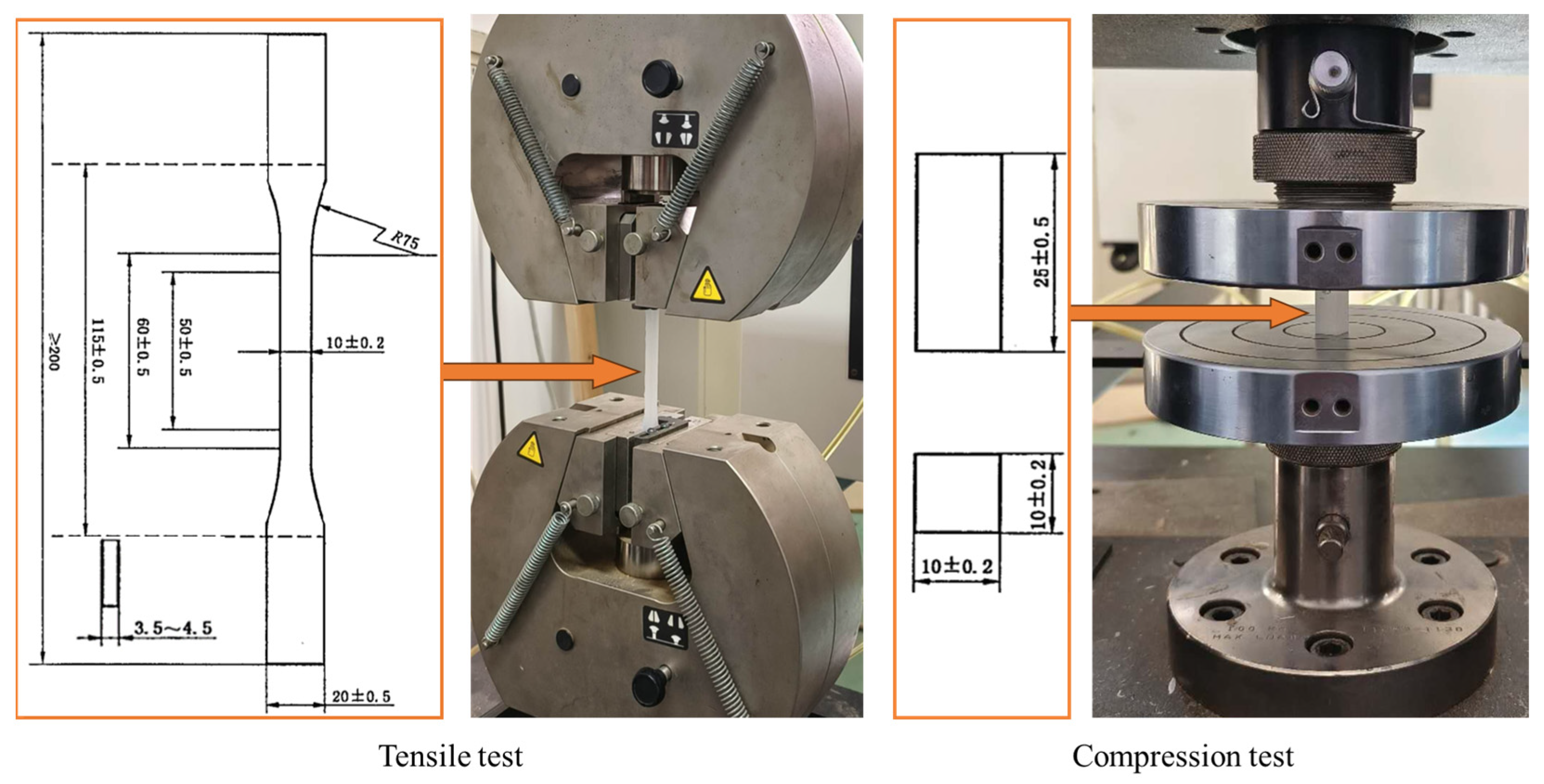

2.3.3. Mechanical Property Test

2.3.4. Hygrothermal Aging Resistance Test

2.3.5. Bonding Ability Test

2.3.6. Other Characterizations

3. Results

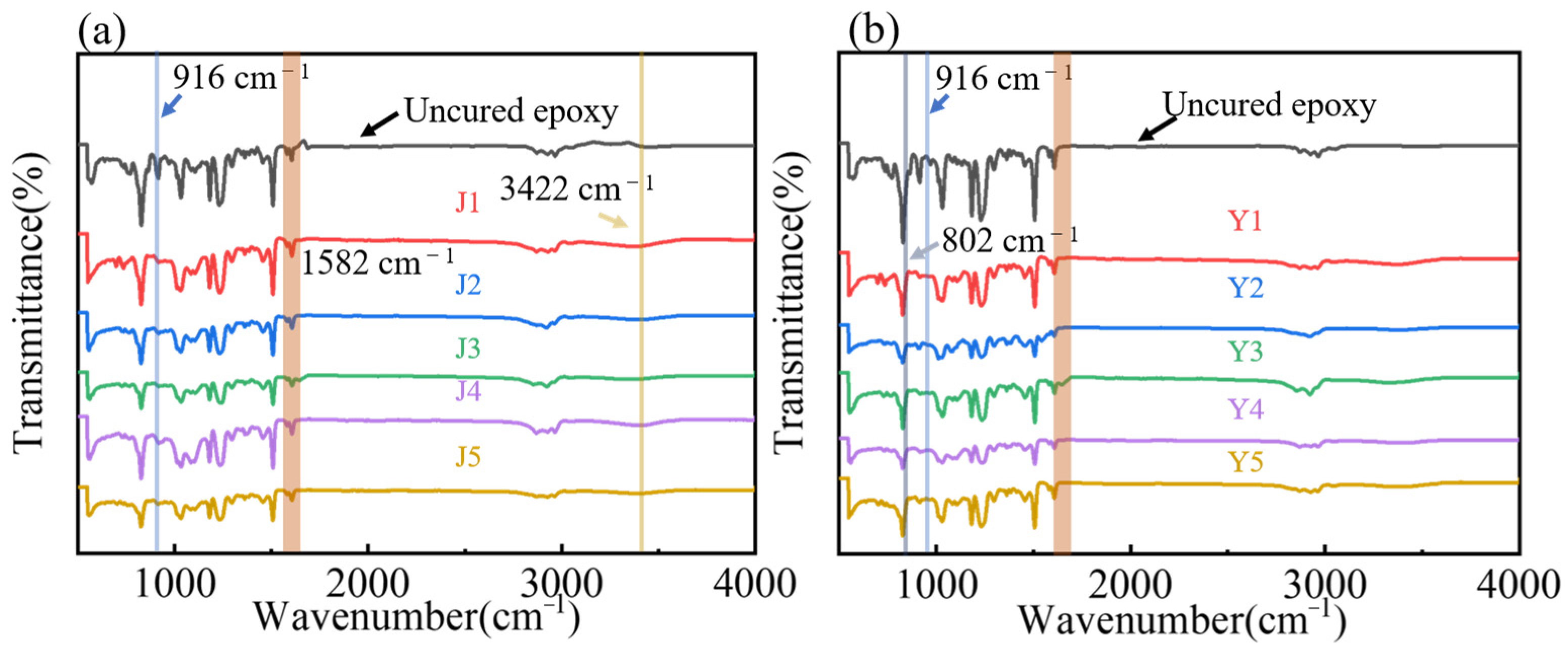

3.1. FTIR Analysis of Modified Epoxy Resin

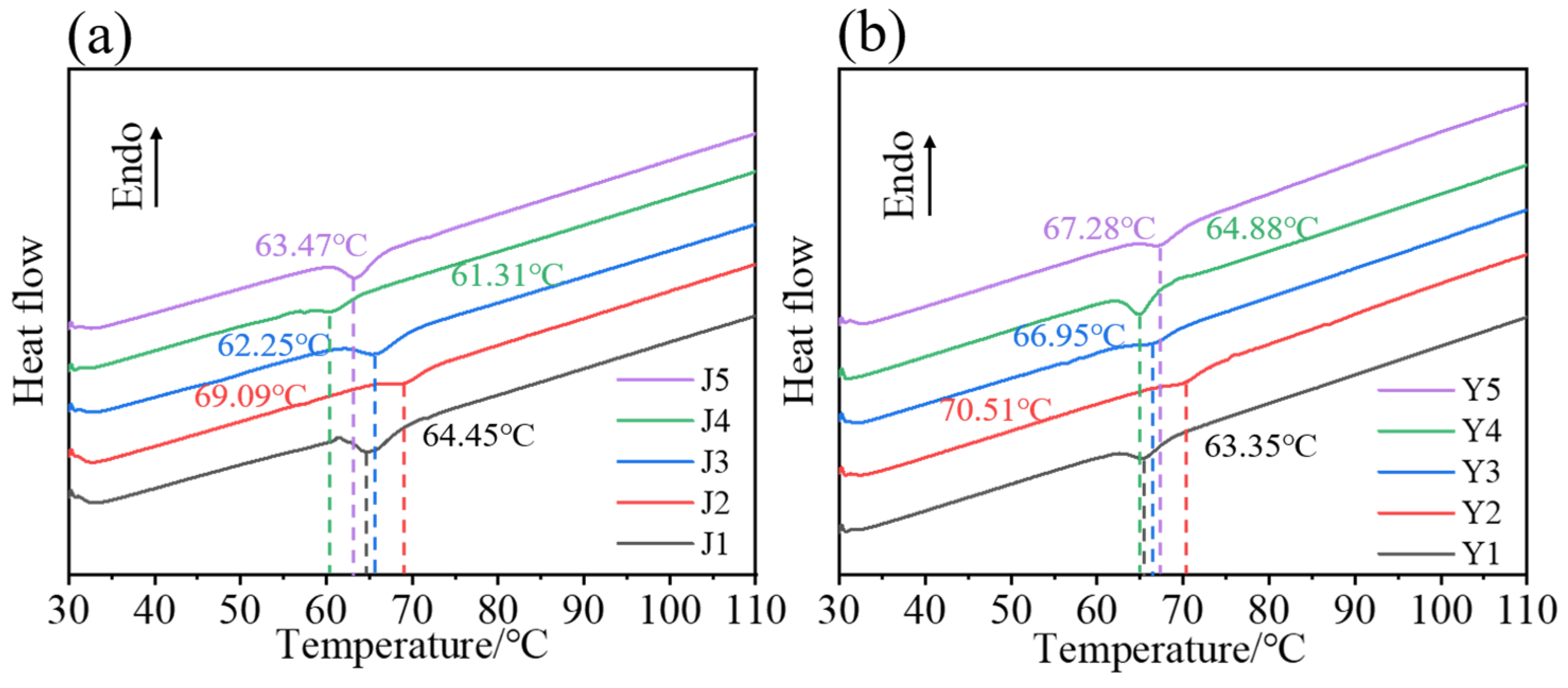

3.2. Glass Transition Temperature of Modified Epoxy Systems

3.3. Viscosity of Modified Epoxy Curing Systems

3.4. Curing Rate of Modified Epoxy Resin Mixtures

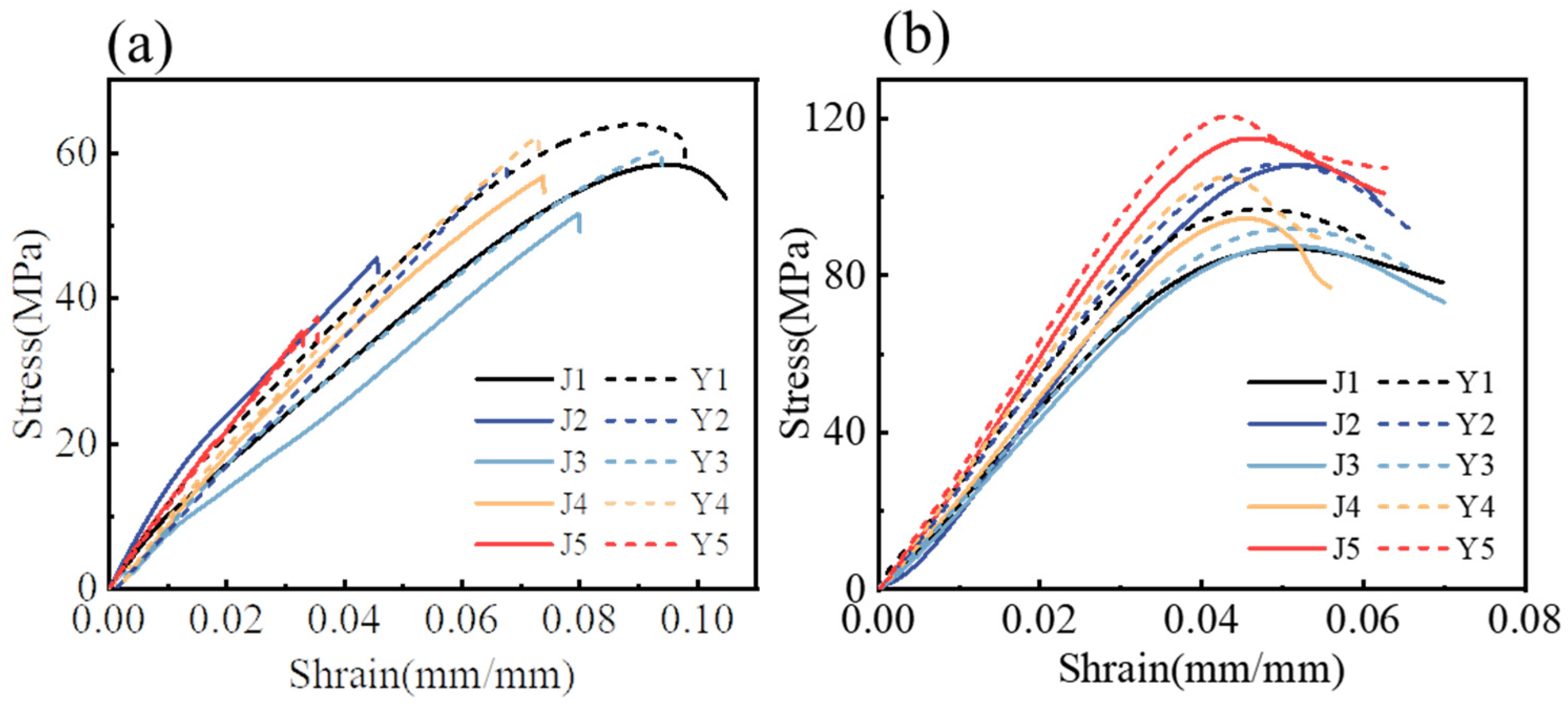

3.5. Mechanical Properties of Modified Epoxy Resins

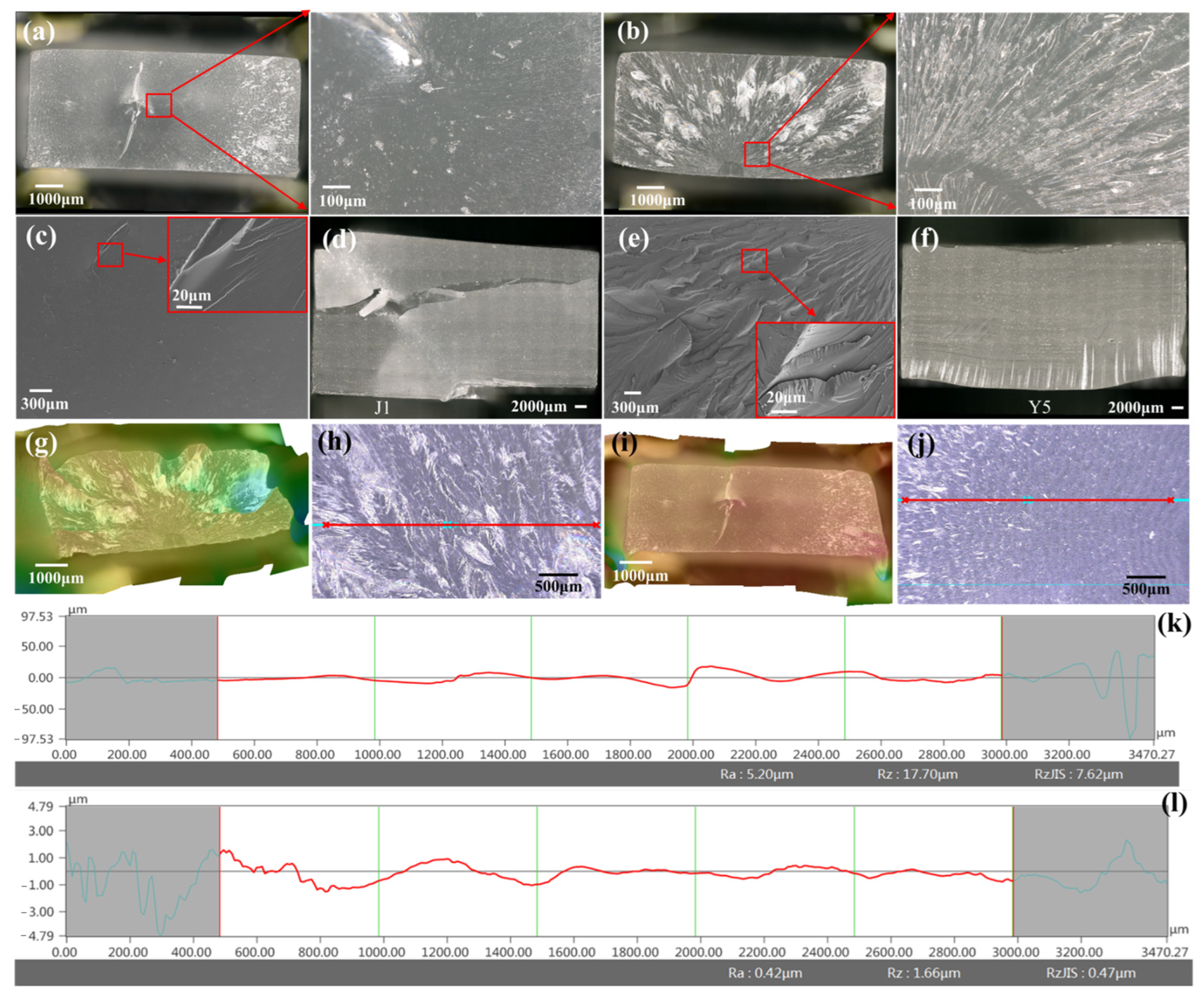

3.6. Failure Characteristics of Modified Epoxy Resin Cured Products

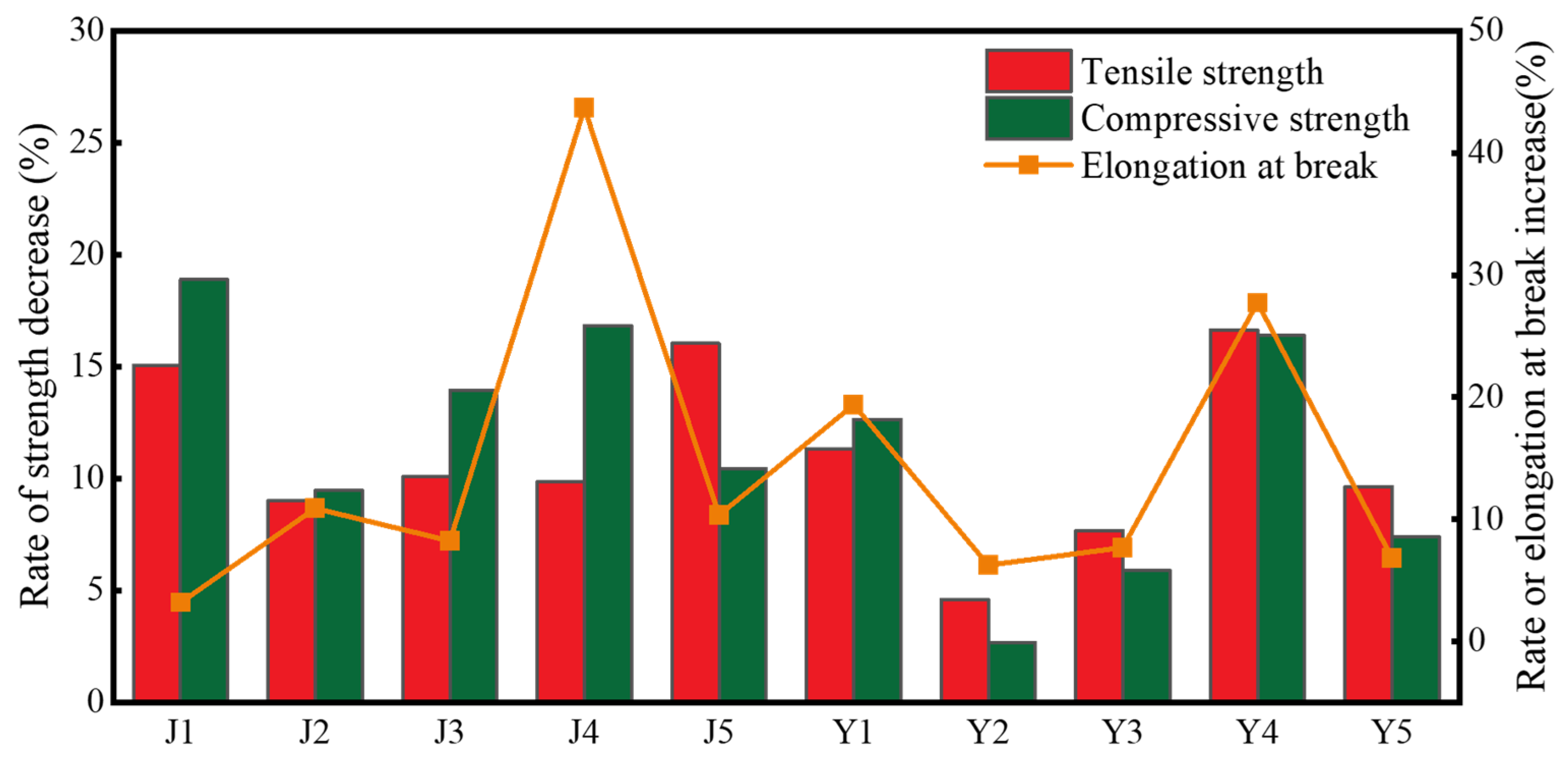

3.7. Hygrothermal Aging Property of Modified Epoxy Resin Systems

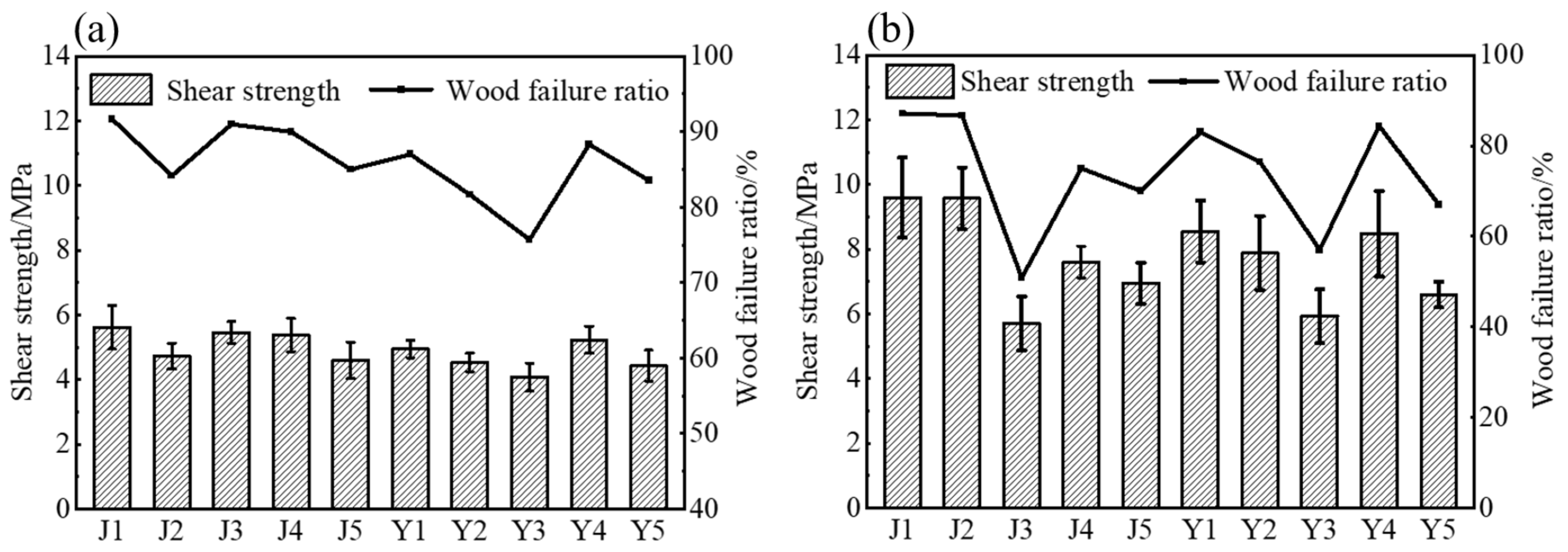

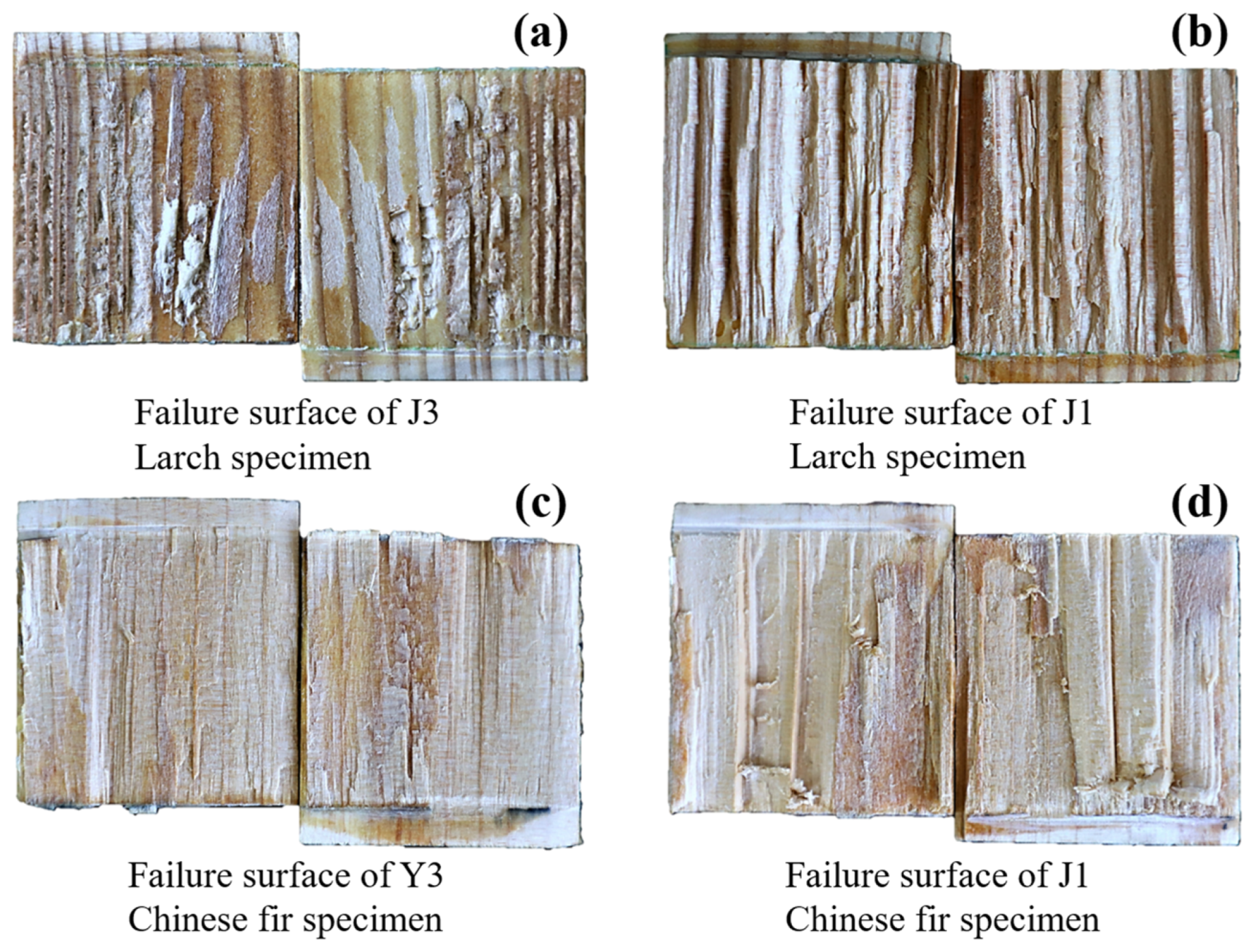

3.8. Bond Strength of Modified Epoxy Resin with Wood

4. Conclusions

- (1)

- The chemical structure of the two modified epoxy resins did not undergo any significant changes. They showed a higher degree of curing when cured with amine curing agents under room temperature conditions. The fluidity of the mixed epoxy resin increased with 593, 1,3-BAC, PA-D230, and MXDA, making the modified epoxy resin more appropriate as a grouting material for repairing and reinforcing timber members in ancient buildings. The curing rate of the two modified epoxy resins combined with amine curing agents still follows the curing rate law of bisphenol A epoxy resin.

- (2)

- The addition of polyurethane and silicone chains to the epoxy resin system effectively increased the toughness of the cured epoxy resin. The increase in toughness of the epoxy resin changed the tensile and compressive failure modes, with the tensile fracture surface exhibiting more complex crack patterns and increased roughness, and the compressive failure mode transitioning from brittle to plastic. The silicone-modified epoxy resin exhibits slightly higher mechanical properties than the polyurethane-modified epoxy resin.

- (3)

- The glass transition temperature of the two modified epoxy resins ranged from 61.31 °C to 70.51 °C. The introduction of silicone molecular chains increased the Tg of the curing system and improved the hygrothermal property of the epoxy resin.

- (4)

- The shear strength of the two types of epoxy resin for the larch shear samples after artificial aging was more than 5.9 MPa, which meets the standard requirements. The modified epoxy resin has a strong bonding capability to aged wood, making it suitable for bonding repairs and reinforcement of ancient building timber members.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, C.; Kuang, Y.; Zhu, S.; Burgert, I.; Keplinger, T.; Gong, A.; Li, T.; Berglund, L.; Eichhorn, S.J.; Hu, L. Structure–property–function relationships of natural and engineered wood. Nat. Rev. Mater. 2020, 5, 642–666. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Chang, L.-H.; Chang, X.-H.; Chang, H.; Qian, W.; Cheng, L.-T. The predictive research of ancient wooden building internal defects compressive bearing capacity based on nondestructive testing methods. Mech. Adv. Mater. Struct. 2021, 28, 252–259. [Google Scholar] [CrossRef]

- Han, L.; Wang, K.; Wang, W.; Guo, J.; Zhou, H. Nanomechanical and Topochemical Changes in Elm Wood from Ancient Timber Constructions in Relation to Natural Aging. Materials 2019, 12, 786. [Google Scholar] [CrossRef]

- Blanchette, R.A.; Held, B.W.; Jurgens, J.A.; Haight, J.E. Wood deterioration in Chacoan great houses of the southwestern United States. Conserv. Manag. Archaeol. Sites 2004, 6, 203–212. [Google Scholar] [CrossRef]

- Walsh-Korb, Z.; Avérous, L. Recent developments in the conservation of materials properties of historical wood. Prog. Mater. Sci. 2019, 102, 167–221. [Google Scholar] [CrossRef]

- Meng, H.; Yang, W.; Yang, X. Real-Time Monitoring of Timber-Surface Crack Repair Using Piezoelectric Ceramics. J. Sens. 2021, 2021, 8201780. [Google Scholar] [CrossRef]

- Klapwijk, D. Restoration and preservation of decayed timber structures and constructions with epoxies. Stud. Conserv. 1978, 23, 75–76. [Google Scholar] [CrossRef]

- Cruz, H.; Custódio, J. Adhesives for On-Site Rehabilitation of Timber Structures. J. Adhes. Sci. Technol. 2010, 24, 1473–1499. [Google Scholar] [CrossRef]

- Custódio, J.; Broughton, J.; Cruz, H. Rehabilitation of timber structures: Novel test method to assess the durability of bonded-in rod connections. Mater. Struct. 2012, 45, 199–221. [Google Scholar] [CrossRef]

- Li, H.; Qiu, H.; Zhao, Z.; Lu, Y. Axial compression behaviour of retrofitted long timber columns. Adv. Struct. Eng. 2017, 21, 445–459. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, X.; Chen, H.; Li, J.; Wang, X.; Zhu, J. Application of epoxy resin in cultural relics protection. Chin. Chem. Lett. 2023, 109194. [Google Scholar] [CrossRef]

- Bertolini Cestari, C.; Marzi, T. Conservation of historic timber roof structures of Italian architectural heritage: Diagnosis, assessment, and intervention. Int. J. Archit. Herit. 2018, 12, 632–665. [Google Scholar] [CrossRef]

- Zhang, C.-H.; Wei, H.-G.; Liu, Y.-Y.; Tan, H.-F.; Guo, Z. Enhanced toughness and shape memory behaviors of toughed epoxy resin. High Perform. Polym. 2012, 24, 702–709. [Google Scholar] [CrossRef]

- Awad, S.A.; Fellows, C.M.; Saeed Mahini, S. A comparative study of accelerated weathering of epoxy resins based on DGEBA and HDGEBA. J. Polym. Res. 2018, 25, 103. [Google Scholar] [CrossRef]

- Chen, C.-H.; Sun, Y.-Y. Mechanical properties of blocked polyurethane/epoxy interpenetrating polymer networks. J. Appl. Polym. Sci. 2006, 101, 1826–1832. [Google Scholar] [CrossRef]

- Xin, X.; Yu, R.; Su, L.; Qiu, Z.; Yang, C.; Liang, M.; Ji, P.; Zhong, G.; Yao, Z. Dynamic mechanical and chemorheology analysis for the blended epoxy system with polyurethane modified resin. J. Renew. Mater. 2022, 10, 1081. [Google Scholar] [CrossRef]

- Unnikrishnan, K.P.; Thachil, E.T. Toughening of epoxy resins. Des. Monomers Polym. 2006, 9, 129–152. [Google Scholar] [CrossRef]

- Zhang, K.; Huang, J.; Wang, Y.; Li, W.; Nie, X. Eco-Friendly Epoxy-Terminated Polyurethane-Modified Epoxy Resin with Efficient Enhancement in Toughness. Polymers 2023, 15, 2803. [Google Scholar] [CrossRef]

- Jin, F.L.; Li, X.; Park, S.J. Synthesis and application of epoxy resins: A review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Minty, R.F.; Yang, L.; Thomason, J.L. The influence of hardener-to-epoxy ratio on the interfacial strength in glass fibre reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 2018, 112, 64–70. [Google Scholar] [CrossRef]

- GB/T 13477.5; Test Method for the Surface Drying Time of Building Sealants—Part 5: Determination of the Tack-Free Time. Standardization Administration of China: Beijing, China, 2002.

- GB/T 2567; Test Methods for Properties of Resin Casting Body. Standardization Administration of China: Beijing, China, 2021.

- GB/T 50329; Standard for Test Methods of Timber Structures. Standardization Administration of China: Beijing, China, 2012.

- Li, L.; Chen, D.; Long, Y.; Wang, F.; Kang, Z. Silane modification of semi-curing epoxy surface: High interfacial adhesion for conductive coatings. Prog. Org. Coat. 2023, 174, 107228. [Google Scholar] [CrossRef]

- Triwulandari, E.; Fatriasari, W.; Iswanto, A.H.; Septiyanti, M.; Umam, E.F.; Ghozali, M. Effect of reaction time on the molecular weight distribution of polyurethane modified epoxy and its properties. J. Mater. Res. Technol. 2022, 19, 2204–2214. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, Z.; Gao, M.; Huang, Z. Hygrothermal Aging Characteristics of Silicone-Modified Aging-Resistant Epoxy Resin Insulating Material. Polymers 2021, 13, 2145. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Siow, K.S. Measurement of Tg in epoxy resins by DSC—Effects of residual stress. Polym. Eng. Sci. 1999, 39, 422–429. [Google Scholar] [CrossRef]

- Li, R.; Zhou, C.; Chen, Y.; Zou, H.; Liang, M.; Li, Y. Preparation, characterization, and properties of organic silicone intermediate-modified epoxy resin copolymers. High Perform. Polym. 2016, 29, 36–45. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, W.; Zhang, J.; Zhou, J. Epoxy-based grouting materials with super-low viscosities and improved toughness. Constr. Build. Mater. 2021, 267, 121104. [Google Scholar] [CrossRef]

- Wang, C.; Xiao, X.; Lu, Y.; Shu, C.; Guo, J. Utilization and properties of modified epoxy resin for colorful anti-slip pavements. Constr. Build. Mater. 2019, 227, 116801. [Google Scholar] [CrossRef]

- Aziz, T.; Haq, F.; Farid, A.; Cheng, L.; Chuah, L.F.; Bokhari, A.; Mubashir, M.; Tang, D.Y.Y.; Show, P.L. The epoxy resin system: Function and role of curing agents. In Carbon Letters; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar] [CrossRef]

- Chen, T.; Ma, Q.; Li, Y.; Li, G. Preparation and Characterization of Wood Composites for Wood Restoration. Forests 2023, 14, 1743. [Google Scholar] [CrossRef]

- Ignatenko, V.Y.; Ilyin, S.O.; Kostyuk, A.V.; Bondarenko, G.N.; Antonov, S.V. Acceleration of epoxy resin curing by using a combination of aliphatic and aromatic amines. Polym. Bull. 2020, 77, 1519–1540. [Google Scholar] [CrossRef]

- GB/T50165; Technical Standard for Maintenance and Strengthening of Historic Timber Buildings. Standardization Administration of China: Beijing, China, 2020.

- Kajorncheappunngam, S.; Gupta Rakesh, K.; GangaRao, H.V.S. Effect of Aging Environment on Degradation of Glass-Reinforced Epoxy. J. Compos. Constr. 2002, 6, 61–69. [Google Scholar] [CrossRef]

- Ohki, Y.; Hirai, N. Thermal ageing of soft and hard epoxy resins. High Volt. 2023, 8, 12–20. [Google Scholar] [CrossRef]

- Le Guen-Geffroy, A.; Le Gac, P.Y.; Habert, B.; Davies, P. Physical ageing of epoxy in a wet environment: Coupling between plasticization and physical ageing. Polym. Degrad. Stab. 2019, 168, 108947. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, Z.; Huang, Z.; Shang, J. Preparation and characteristics of silicone-modified aging-resistant epoxy resin insulation material. J. Mater. Sci. 2022, 57, 3295–3308. [Google Scholar] [CrossRef]

- Frihart, C.R.; Brandon, R.; Ibach, R.E.; Hunt, C.G.; Gindl-Altmutter, W. Comparative Adhesive Bonding of Wood Chemically Modified with Either Acetic Anhydride or Butylene Oxide. Forests 2021, 12, 546. [Google Scholar] [CrossRef]

| Epoxy Type | Type of Modified Epoxy Resin | Curing Agent | Mass Ratio of Epoxy Resin | Mass Ratio of Curing Agent | Mass Ratio of Defoamer |

|---|---|---|---|---|---|

| J1 | Polyurethane-modified epoxy resin | 593 | 79.84% | 19.96% | 0.2% |

| J2 | Polyurethane-modified epoxy resin | 1,3-BAC | 83.87% | 15.93% | 0.2% |

| J3 | Polyurethane-modified epoxy resin | PA-651 | 66.98% | 32.82% | 0.2% |

| J4 | Polyurethane-modified epoxy resin | PEA-D230 | 75.61% | 24.19% | 0.2% |

| J5 | Polyurethane-modified epoxy resin | MXDA | 84.58% | 15.22% | 0.2% |

| Y1 | Silicone-modified epoxy resin | 593 | 79.84% | 19.96% | 0.2% |

| Y2 | Silicone-modified epoxy resin | 1,3-BAC | 83.87% | 15.93% | 0.2% |

| Y3 | Silicone-modified epoxy resin | PA-651 | 66.98% | 32.82% | 0.2% |

| Y4 | Silicone-modified epoxy resin | PEA-D230 | 75.61% | 24.19% | 0.2% |

| Y5 | Silicone-modified epoxy resin | MXDA | 84.58% | 15.22% | 0.2% |

| Type of Epoxy | Viscosity (mPa·s) | Curing Agent | Viscosity (mPa·s) | Mixed Liquid Viscosity (mPa·s) |

|---|---|---|---|---|

| Polyurethane-modified epoxy resin | 6540 | 593 | 100 | 1450 |

| 1,3-BAC | 25 | 870 | ||

| PA-651 | 8030 | 6970 | ||

| PEA-D230 | 15 | 670 | ||

| MXDA | 20 | 710 | ||

| Silicone-modified epoxy resin | 6010 | 593 | 100 | 1230 |

| 1,3-BAC | 25 | 780 | ||

| PA-651 | 8030 | 6550 | ||

| PEA-D230 | 15 | 610 | ||

| MXDA | 20 | 640 |

| Type of Epoxy Resin | J1 | J2 | J3 | J4 | J5 | Y1 | Y2 | Y3 | Y4 | Y5 |

|---|---|---|---|---|---|---|---|---|---|---|

| Tack-free time (min) | 30 | 65 | 90 | 720 | 140 | 25 | 40 | 55 | 585 | 110 |

| Type of Epoxy Resin | J1 | J2 | J3 | J4 | J5 | Y1 | Y2 | Y3 | Y4 | Y5 |

|---|---|---|---|---|---|---|---|---|---|---|

| Tensile strength (MPa) | 57.44 | 50.08 | 51.17 | 56.39 | 35.26 | 63.54 | 58.64 | 59.91 | 62.03 | 37.09 |

| Elongation at break (%) | 10.35 | 5.04 | 7.30 | 6.89 | 3.48 | 9.40 | 6.48 | 9.26 | 6.84 | 3.54 |

| Compressive strength (MPa) | 86.49 | 108.29 | 86.53 | 94.60 | 114.93 | 96.92 | 112.86 | 91.12 | 104.21 | 122.20 |

| Conspicuousness significance | ** | ** | ** | ** | ** | ** | ** | ** | ** | ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, X.; Wang, S.; Huang, L.; Zhou, H. Applicability Evaluation of Modified Epoxy Resin in the Repair and Reinforcement of Ancient Building Timber Members. Forests 2024, 15, 933. https://doi.org/10.3390/f15060933

Han X, Wang S, Huang L, Zhou H. Applicability Evaluation of Modified Epoxy Resin in the Repair and Reinforcement of Ancient Building Timber Members. Forests. 2024; 15(6):933. https://doi.org/10.3390/f15060933

Chicago/Turabian StyleHan, Xu, Shuangyong Wang, Lei Huang, and Haibin Zhou. 2024. "Applicability Evaluation of Modified Epoxy Resin in the Repair and Reinforcement of Ancient Building Timber Members" Forests 15, no. 6: 933. https://doi.org/10.3390/f15060933